Page 1

User Manual

ADCP-90-545

Issue 4, July 2016

Rack-Mount Panel and Wall-Mount Box

Content Page

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1 UNPACKING AND INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 RACK-MOUNT PANEL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 WALL-MOUNT BOX INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 TECHNICAL ASSISTANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FL1000

. . . . . . . . . . .2

. . . . . . . . .3

2.1 Installing a Rack-Mount Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 19-Inch Rack, 5-Inch Recess (as Shipped). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.2 19-Inch Rack, Flush; 23-Inch Rack, 5-Inch Recess; 23-Inch Rack, Flush. . . . . . . . . . . . . . . . . . . . . 4

2.2 Installing 6pak Adapter Plates and Pigtails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Adapter Plates Without Pigtails (Blank or 6Pak) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2.2 Adapter Plates With Pigtails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Installing Cables and Routing Fibers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 12-Fiber Termination Rack Mount Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.2 24-Fiber Termination Rack Mount Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3.3 24-Fiber Termination/Splicing Rack-Mount Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4 Splicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Installing the Wall-Mount Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Installing 6pak Adapter Plates and Pigtails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Installing Cables and Routing Fibers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 12-Fiber Termination/Splicing Wall-Mount Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.3.2 24-Fiber Termination/Splicing Wall-Mount Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.3.3 48-Fiber Splicing Wall-Mount Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Splicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Installing Patch Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Cleaning Adapters and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .14

. . . . . . . .14

. . . . . . . . . . . . .32

. . . . . . . . . . . . . . .33

. . . . . . . . . .33

. . . . . . . . . . .34

. . . . . . . .3

. . . . . .5

6

. . . . . . . .8

. . . . . . .14

. . . . .17

. . . . . . .19

29

. . . . . . .33

INTRODUCTION

FL1000 products provide solutions for terminating and splicing fibers in small fiber networks. The

product line consists of three rack-mount panels and three wall-mount boxes. The rack-mount panels

include a 12-fiber termination panel, a 24-fiber termination panel, and a 24-fiber termination/splicing

panel. The wall-mount boxes include a 12-fiber termination/splicing box, a 24-fiber termination/

splicing box, and a 48-fiber splicing box. Options include 6pak adapter plates, with or without

pigtails, splice trays, and cable kits.

300001735123 Rev C Page 1

www.commscope.com © 2016 CommScope. All Rights Reserved.

Page 2

ADCP-90-545 • Issue 4 • July 2016

This manual contains all procedures required to install and operate any FL1000 product or product

option. The procedures are presented in the order in which they would normally be done, with

separate installation sections for rack-mount and wall-mount units. Select from the procedures based

on your specific installation.

Revision History

ISSUE DATE REASON FOR CHANGE

Issue 1 09/1998 Original.

Issue 2 04/2001 Non-technical update.

Issue 3 08/2011 Revised for new two-door design for wallbox.

Issue 4 July 2016 Reformatted for CommScope.

Trademark Information

FL1000

is a registered trademark of CommScope . In c.

ST is a registered trademark of AT&T Technologies, Inc.

Admonishments

Important safety admonishments are used throughout this manual to warn of possible hazards to

persons or equipment. The admonishments — in the form o f Dangers, Warnings, and Caution s

— must be followed at all times.

Danger: Danger is used to indicate the presence of a hazard that will cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Warning: Warning is used to indicate the presence of a hazard that can cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that will or can cause minor

personal injury or property damage if the hazard is not avoided.

1 UNPACKING AND INSPECTION

Unpack and inspect the various components as follows:

1. Inspect the exterior of the shipping container(s) for evidence of rough handling that may

ha

ve damaged the components in the container.

2. Unpack each container while carefully checking the conte

3. File a claim with the commercial carrier and notify BCG Technical Assistance Center, if

damage is detected

4. Save all shipping containers for use if the equipment requires

Page 2

© 2016 CommScope. All Rights Reserved.

nts for damage.

or if parts are missing. Save damaged cartons for inspection by the carrier.

shipment at a future date.

Page 3

2 RACK-MOUNT PANEL INSTALLATION

11247-C

DANGER

INVISIBLE LASER RADIATION

AVOID DIRECT EXPOSURE TO BEAM

CAT #

S/N

DATE

CODE

MADE

IN USA

‚

MOUNTING

BRACKET

POSITIONED

FOR 5-INCH

RECESS

MOVE MOUNTING

BRACKETS TO THIS

POSITION FOR

FLUSH MOUNT

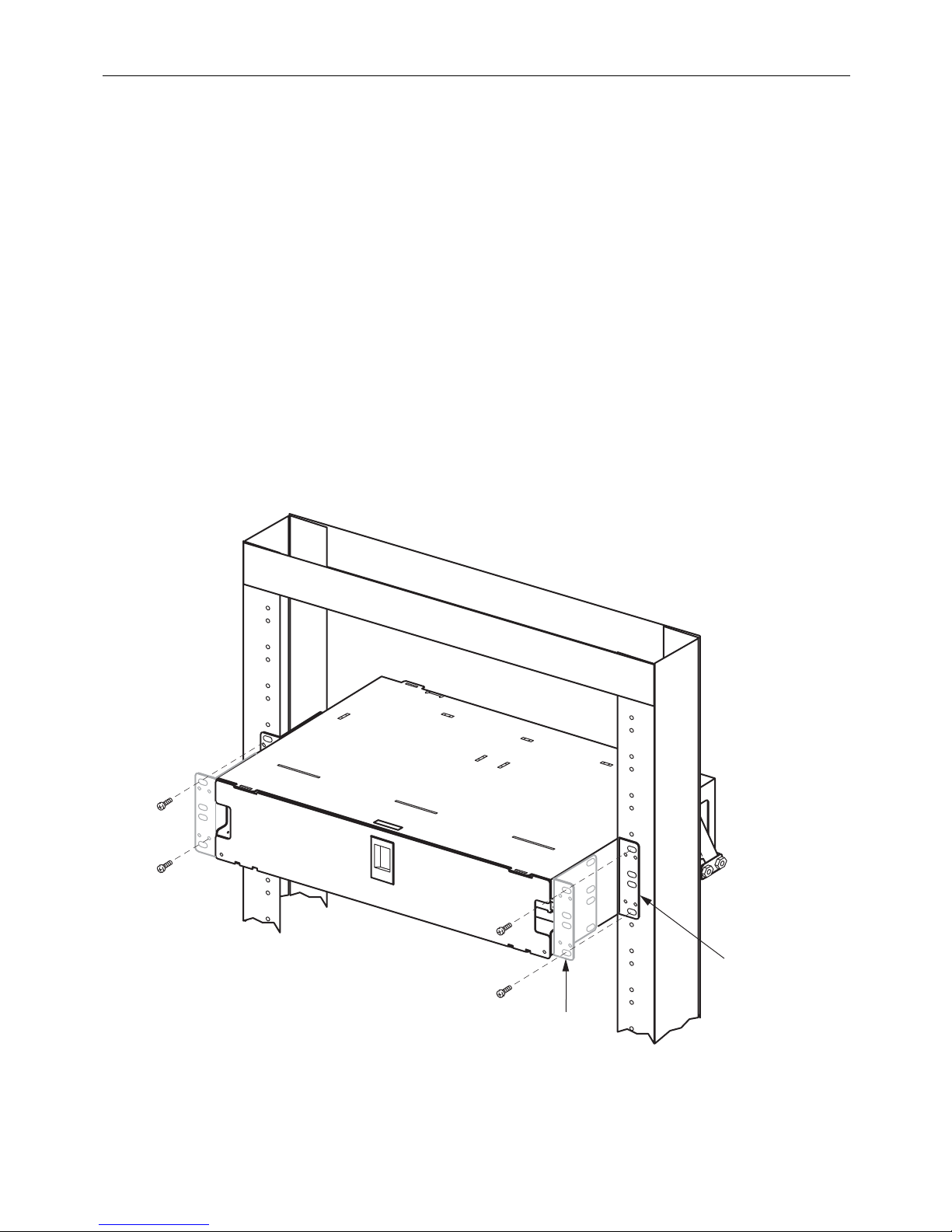

2.1 Installing a Rack-Mount Chassis

The FL1000 rack-mount panel can be installed on either a 19-inch (48.26 cm) or 23-inch (58.42 cm)

rack. It is designed for mounting in an EIA style rack, but a WECO style rack can also be used. It can

be mounted flush on the rack or with a 5-inch (12.7 cm) recess. The panel is shipped ready to be

installed with a 5-inch recess on a 19-inch rack. For other mounting positions, the mounting brackets

must be removed and remounted in a different orientation. Select from the procedures below based

on your specific installation.

ADCP-90-545 • Issue 4 • July 2016

2.1.1 19-Inch Rack, 5-Inch

Recess (as Shipped)

See Figure 1. Use the following procedure.

1. Position the chassis on the rack.

2. Attach the mounting brackets to the rack

using the #12-24 screws supplied.

Figure 1. Installing a Chassis on a 19-Inch Rack

© 2016 CommScope. All Rights Reserved.

Page 3

Page 4

ADCP-90-545 • Issue 4 • July 2016

11248-C

DANGER

INVISIBLE LASER RADIATION

AVOID DIRECT EXPOSURE TO BEAM

CAT #

S/N

DATE

CODE

MADE

IN USA

‚

MOUNTING

BRACKET

POSITIONED

FOR 5-INCH

RECESS

MOVE MOUNTING

BRACKETS TO THIS

POSITION FOR

FLUSH MOUNT

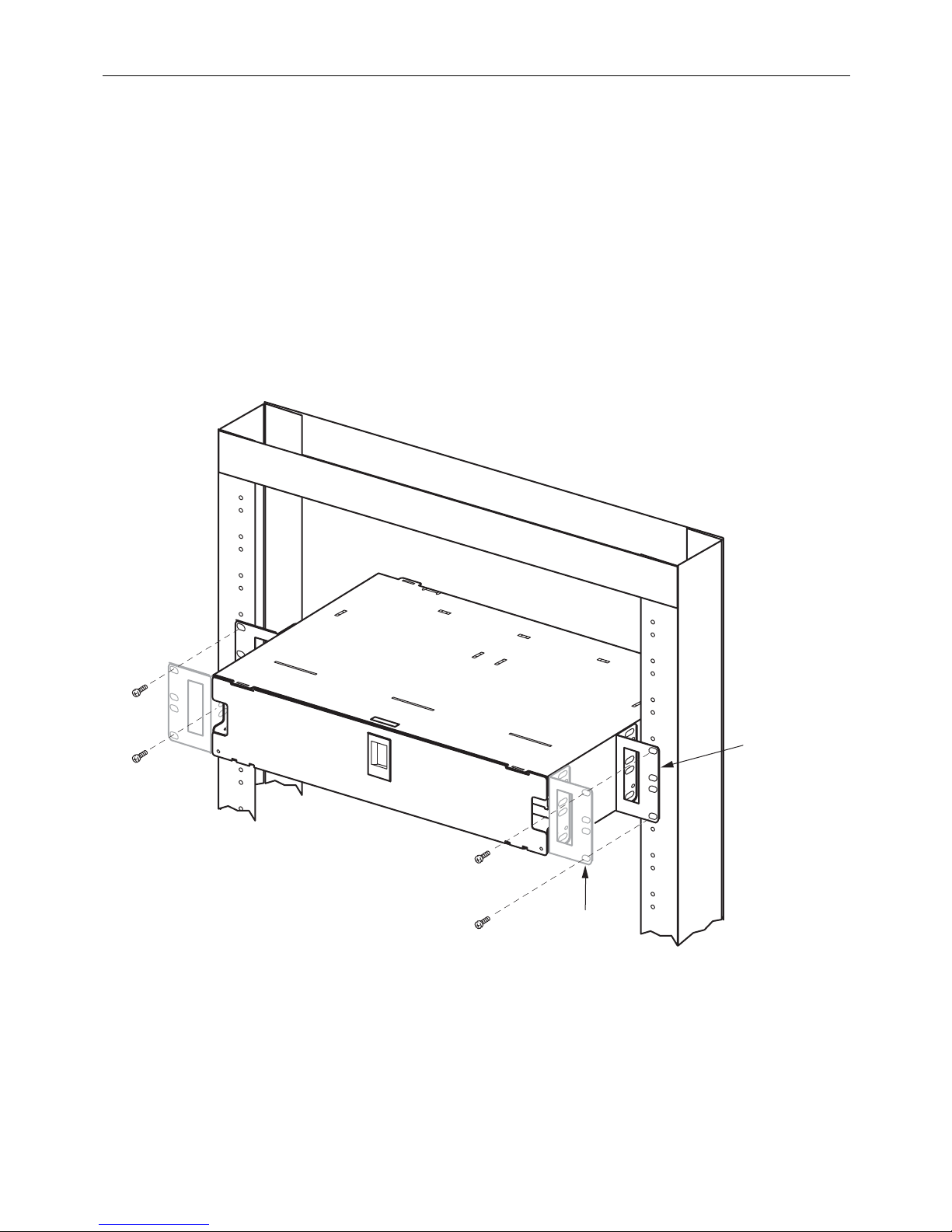

2.1.2 19-Inch Rack, Flush; 23-Inch Rack, 5-Inch Recess; 23-Inch Rack, Flush

For these positions, the mounting brackets must be removed and remounted

orientation. Use the following procedure.

1. Remove the mounting brackets.

2. Remount the mounting brackets

in the position shown:

a. For 19-inch rack, flush mount, use Figure 1 forward position;

b. For 23-inch rack, 5-inch

recess mount, use Figure 2 back position;

c. For 23-inch rack, flush mount, use Figure 2 forward position.

3. Attach the mounting brackets to the rack

using the #12-24 screws supplied.

in a different

Page 4

© 2016 CommScope. All Rights Reserved.

Figure 2. Installing a Chassis on a 23-Inch Rack

Page 5

2.2 Installing 6pak Adapter Plates and Pigtails

The 6pak adapter plates may be any of several types including:

• Simplex or duplex with adapters only

• Blank plates for filling in unused slots

ADCP-90-545 • Issue 4 • July 2016

• Simplex or duplex with adapters and attached pi

gtails

To install adapter plates without pigtails, refer to the first procedure below. To install adapter

plates with pigtails, refer to the second procedure. Adapter plat

es with pigtails are used in the

24-fiber termination/splicing panel only.

2.2.1 Adapter Plates Without Pigtails (Blank or 6Pak)

Use the following procedure to install blanks

or 6pak plates without pigtails:

1. Remove the front cover.

2. Align the adapter plate tabs with

3. Slide the 6pak or blank up into the slot until

the notches in the mounting slot as shown in Figure 3.

it snaps in place.

SLOT

SPLICE

DECK

END

TAB

6 PAK PLATE

(LOADED)

Figure 3. Installing 6pak Plates

11418-B

Page 5

© 2016 CommScope. All Rights Reserved.

Page 6

ADCP-90-545 • Issue 4 • July 2016

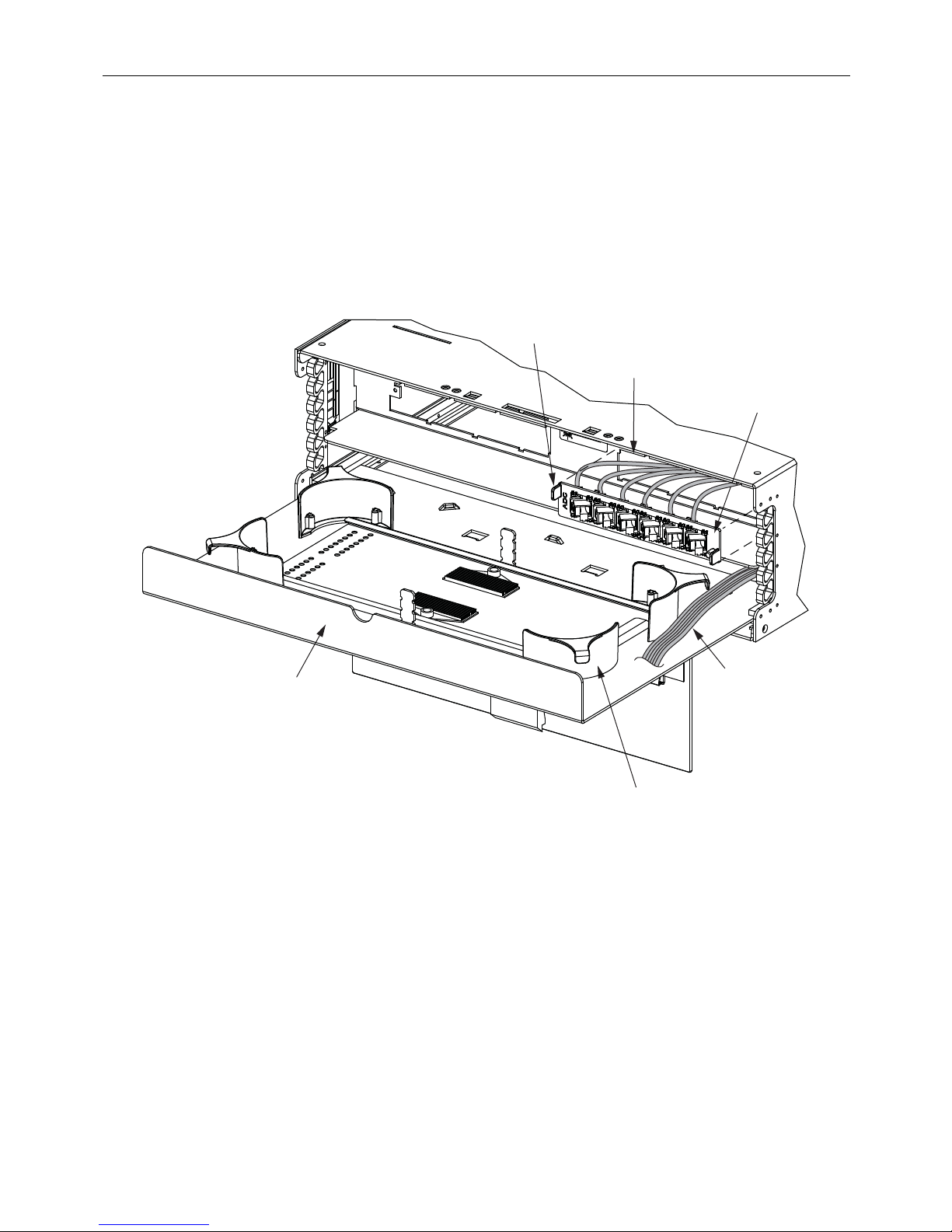

2.2.2 Adapter Plates With Pigtails

Use the following procedure to install 6pak plates wit

h pigtails in the 24-fiber termination/splicing

panel.

1. Remove the front cover and slide out the splice deck.

2. Thread the pigtails through the empty mounting slot and loop the pigtails around the

radius limiters i

n the chassis as shown in Figure 4.

END

TAB

SLOT

6 PAK PLATE

(LOADED)

11367-C

SPLICE

DECK

RADIUS LIMITER

(4 PLACES)

PIGTAILS

Figure 4. Installing 6pak Plates with Pigtails

3. Align the adapter plate tabs with the notches in the mounting slot as shown in Figure 4.

4. Slide the 6pak plate into the

5. Fan out the fibers and tie them

slot until it snaps in place.

to the radius limiter on the right rear side of the splice deck

as shown in Figure 5. To tie the fibers, use cord lacing.

6. Route the fibers to the splice tray. For an

illustration of correct routing, refer to

subsection 3.4, Splicing, below.

Page 6

© 2016 CommScope. All Rights Reserved.

Page 7

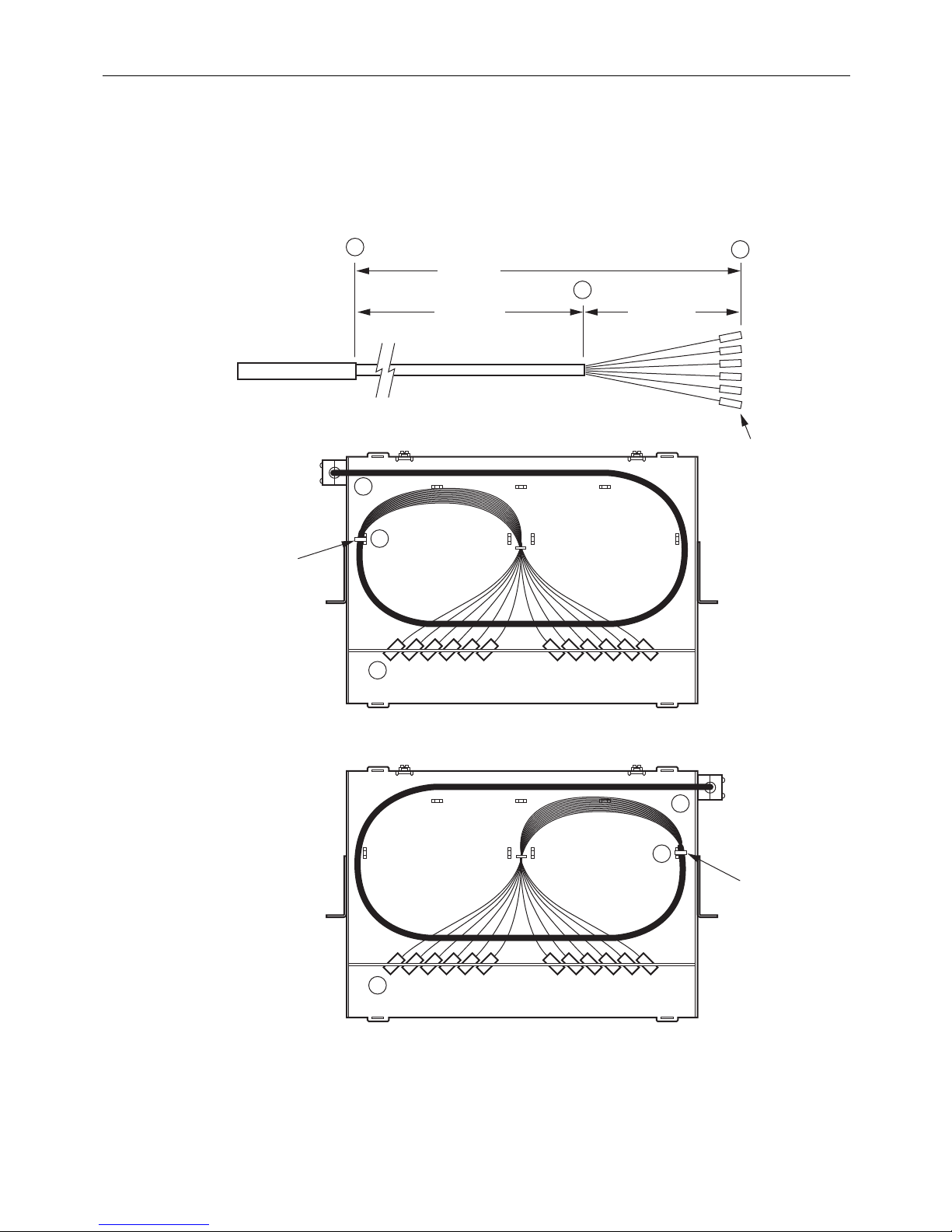

TOP VIEW WITH SPLICE DRAWER CLOSED

TOP VIEW WITH SPLICE DRAWER OPEN

TIE DOWN

USING CORD

LACING

TIE DOWN

USING CORD

LACING

11434-B

PROPER BEND RADIUS

MUST BE MAINTAINED

ADCP-90-545 • Issue 4 • July 2016

Figure 5. Correct Pigtail Routing within 24-Fiber Termination/Splicing Module

© 2016 CommScope. All Rights Reserved.

Page 7

Page 8

ADCP-90-545 • Issue 4 • July 2016

2.3 Installing Cables and Routing Fibers

The rack-mount panel can accommodate either IFC or OSP cable. The procedures used to

install the cable differ slightly for the three chassis types (12-fiber termination panel, 24-fiber

termination panel, and 24-fiber termination/splicing panel). Refer to the appropriate topic below

for the type being installed.

2.3.1 12-Fiber Termination Rack Mount Panel

Figure 6 shows cable routing options and breakout dimensions for the 12-fiber termin ation rack-

mount panel. The cable can enter from above or below

Use the following procedure to install the cable.

the chassis and from the left or right side.

1. Route the cable to the chassis and break out the ca

ble corresponding to Figure 6.

2. Secure the cable as follows:

a. Fasten the tie-down bracket to the panel at t

he cable point of entry using the screws

provided.

b. Position the cable on the tie down bracket with the ca

ble sheath extending about 0.75 inch

(1.9 cm) beyond the bracket into the chassis.

c. Tie down the cable using cord lacing.

d. Secure the cable in a second location on the

rack or wall using a user-provided clamp

per local practice.

3. Remove the front access door and s

4. Route the buffers within the chassis from the cable point of entry to the opposite

lide out the bulkhead deck.

side of

the bulkhead deck, as shown in Figure 6.

5. Tie down the buffers in the location shown in Figure 6 using cord lacing secured to the lan ce.

6. At the buffer breakout point, fan out the fibers

from the buffers and secure them using a

curly lock at the location shown in Figure 6.

Danger: Infrared radiation is invisible and can seriously damage the retina of the eye. Do not

look into the optical bulkhead of an operational transmitter, or into the launching (output) end

of an active fiber. A clean, protective cap or hood MUST be immediately placed over any

radiating bulkhead receptacle or optical fiber connector to avoid exposure to potentially

dangerous amounts of radiation. This practice also helps prevent contamination of connectors

and adapters.

7. Connect the fiber connectors to the adapters on the rear of the 6pak adapter plate.

8. Slide in the bulkhead deck

9. Replace the front access cover.

Page 8

© 2016 CommScope. All Rights Reserved.

to its closed position.

Page 9

ADCP-90-545 • Issue 4 • July 2016

IFC OR OSP

CABLE

SHEATH

CABLE ENTRY

FROM LEFT

TIE OFF USING

TIE-DOWN BRACKET

SUPPLIED WITH PANEL

A

18.0 IN.

(47.72 CM)

SUB-UNITS

A

(220.98 CM)

B

C

87.0 IN.

(134.62 CM)

53.0 IN.

D

C

16.0 IN.

(40.64 CM)

FIBERS

B

TIE DOWN ON OPPOSITE

SIDE FROM ENTRY USING

CORD LACING SECURED

CONNECTORS

ON LANCE

ATTACH USING

CURLY LOCK

SUPPLIED WITH

PANEL

TIE DOWN ON OPPOSITE

SIDE FROM ENTRY USING

CORD LACING SECURED

ON LANCE

D

A

B

C

D

Figure 6. Cable Breakout for 12-Fiber Panel

CABLE ENTRY

FROM RIGHT

TIE OFF USING

TIE-DOWN BRACKET

SUPPLIED WITH PANEL

11246-D

© 2016 CommScope. All Rights Reserved.

Page 9

Page 10

ADCP-90-545 • Issue 4 • July 2016

2.3.2 24-Fiber Termination Rack Mount Panel

Figure 7 shows cable routing options and breakout dimensions for the 24-fiber termin ation rack-

mount panel. The cable can enter from above or below

the chassis and from the left or right side.

IFC OR OSP

CABLE

SHEATH

CABLE ENTRY

FROM LEFT

TIE DOWN

USING CORD

LACING

A

57.0 IN.

(144.78 CM)

41.0 IN.

(104.14 CM)

SUB-UNITS

A

B

C

B

16.0 IN.

(40.64 CM)

FIBERS

C

CONNECTORS

Use the following procedure to install a cable in the 24-fiber termination rack-mount panel.

Page 10

© 2016 CommScope. All Rights Reserved.

C

Figure 7. Cable Breakout for 24-Fiber Panel

A

CABLE ENTRY

FROM RIGHT

B

TIE DOWN

USING CORD

LACING

11245-E

Page 11

ADCP-90-545 • Issue 4 • July 2016

CLAMP

BRACKET

11363-B

CLAMP

YOKES (2)

RUBBER

GROMMET

USE EITHER COVER

OR PLATE IN THIS

POSITION

COVER

NUTS (2)

PLATE

1. Route the cable to the chassis and break out the cable corresponding to Figure 7.

2. Secure the cable as follows (see Figure 8):

a. Install the clamp bracket at the chosen clamp lo

cation by inserting the two integral

bolts from inside the chassis.

b. Sort through the rubber grommets in the kit and find the

one that best fits the cable. If

the cable is too small to fit snugly in the smallest grommet, build up the cable with

tape of a suitable material per local standards.

c. Assemble the cable clamp components on the bracket studs in the order shown in the

figu

re and secure with the two nuts provided.

Figure 8. Installing a Cable Clamp on a Rack-Mount Panel (Select from Four Mounting Locations)

3. If the cable being installed is an OSP cable with a metallic strength member, bond the

cable to ground following the instructions for the bonding/grounding kit.

4. Remove the rear door, if not already removed.

5. Route the fibers within the chas

position shown.

sis as shown in Figure 7 and tie down the fibers in the B

Page 11

© 2016 CommScope. All Rights Reserved.

Page 12

ADCP-90-545 • Issue 4 • July 2016

Danger: Infrared radiation is invisible and can seriously damage the retina of the eye. Do not

look into the optical bulkhead of an operational transmitter, or into the launching (output) end

of an active fiber. A clean, protective cap or hood MUST be immediately placed over any

radiating bulkhead receptacle or optical fiber connector to avoid exposure to potentially

dangerous amounts of radiation. This practice also helps prevent contamination of connectors

and adapters.

6. Connect the fiber connectors to the adaptors on the rear of the 6pak adapter plate.

7. Replace the rear door.

2.3.3 24-Fiber Termination/Splicing Rack-Mount Panel

Figure 9 shows cable routing options and breakout dimensions for the 24-fiber termin ation rack-

mount panel. The cable can enter from above or below

the chassis and from the left or right side.

Use the following procedure to install a cable in the 24-

fiber termination/splicing rack-mount panel.

1. Route the cable to the chassis.

2. Pull out the splice drawer and thread the cable stub through the chassis

onto the splice tray

in the approximate position shown in Figure 9. Based on the figure, determine how much

length of cable will be required for the B to C double loop section shown.

3. Break out the cable, leaving 36 inches (91.

4. Secure the cable with a cable clamp in the position shown,

44 cm) of bare fiber for a splicing loop.

about 0.75 inches (1.91 cm)

before the breakout point. For instructions refer to Figure 8 in the previous procedure.

5. Tie the fibers down with cord lacing

6. If the cable being installed is an OSP cable

in the B position shown in Figure 9.

with a metallic strength member, bond the

cable to ground following the instructions for the bonding/grounding kit.

Page 12

© 2016 CommScope. All Rights Reserved.

Page 13

ADCP-90-545 • Issue 4 • July 2016

IFC OR OSP

CABLE

SHEATH

A

A

18.0 IN.

(20.32 CM)

B DC

TWO FULL

LOOPS

SUB-UNITS

D

36.0 IN.

(91.4 CM)

FIBERS

TIE DOWN CABLE

ON OPPOSITE

SIDE FROM ENTRY

B

C

PREFERRED

TO USE PANEL AS SHIPPED

WITH PIGTAILS LOADED, ROUTE

CABLE IN FROM REAR LEFT

AND ROUTE CLOCKWISE

TO BRING CABLE IN FROM

RIGHT REAR, ROUTE CABLE

COUNTER-CLOCKWISE.

ALSO, REMOVE AND REROUTE

PIGTAILS COUNTER-CLOCKWISE

TIE DOWN CABLE

ON OPPOSITE

SIDE FROM ENTRY

Figure 9. Fiber Routing in 24-Fiber Termination/Splicing Panel

© 2016 CommScope. All Rights Reserved.

11232-D

Page 13

Page 14

ADCP-90-545 • Issue 4 • July 2016

2.4 Splicing

Use the following procedure for splicing.

1. Place a splice tray in the splice drawer (if not already there).

2. Route the fiber into the splice tray on the same side as the

pigtail fiber that it is going to be

spliced to, as shown in Figure 10. Loop the fiber around twice in the splice tray.

3. Splice per local practice.

4. Tie down the fibers with cord lacing in

the C position shown in Figure 10. Refer also to

Figure 9 for correct routing.

C

LEFT

C

3 WALL-MOUNT BOX INSTALLATION

3.1 Installing the Wall-Mount Chassis

Note: If using a cable clamp (as opposed to a compression fitting), install the cable clamp

prior to mounting the box on the wall.

FL1000 wall-mount boxes can be mounted directly to any wall, but CommScope recommends that

they be mounted, using the #12 woodscrews supplied with the unit, on a 3/4-inch thick plywood

panel that is attached to the wall in accordance with local fire code.

Page 14

© 2016 CommScope. All Rights Reserved.

11419-A

RIGHT

Figure 10. Routing Fibers on a Splice Tray

Page 15

ADCP-90-545 • Issue 4 • July 2016

3.55 IN.

(9.0 CM)

10.07 IN.

(25.6 CM)

MOUNTING

HOLE

(4 PLACES)

12.80 IN.

(32.5 CM)

3.55 IN.

(9.0 CM)

4.22 IN.

(10.7 CM)

8.23 IN.

(20.9 CM)

14.00 IN.

(35.6 CM)

11.23 IN.

(28.5 CM)

TOP VIEW

FRONT VIEW

24562-A

Use the following procedure.

1. Make sure the location provides room for the door to swing out. See Figure 11 and Figure 12.

2. Position the box in its assigned

location and mark the mounting hole locations.

3. Fasten using the four #10-1.25 inch wood screws provided. See Figure 11 and Figure 12

for mounting hole location.

Figure 11. 12-Fiber Wall-Mount Box Dimensions

© 2016 CommScope. All Rights Reserved.

Page 15

Page 16

3.55 IN.

(9.0 CM)

10.07 IN.

(25.6 CM)

MOUNTING

HOLE

(4 PLACES)

12.80 IN.

(32.5 CM)

3.55 IN.

(9.0 CM)

4.22 IN.

(10.7 CM)

12.00 IN.

(30.5 CM)

14.00 IN.

(35.6 CM)

15.00 IN.

(38.1 CM)

TOP VIEW

FRONT VIEW

24563-A

ADCP-90-545 • Issue 4 • July 2016

Figure 12. 24/48 Wall-Mount Box Dimensions

Page 16

© 2016 CommScope. All Rights Reserved.

Page 17

3.2 Installing 6pak Adapter Plates and Pigtails

PIGTAILS

SLOT

END TAB

END TAB

6 PAK PLATE

(LOADED)

24565-A

Wall-mount boxes with a termination function have mounting slots for 6pak adapter plates. The

6pak adapter plates may be any of several types including:

• Simplex or duplex with adapters only

• Blank plates for filling in unused slots

ADCP-90-545 • Issue 4 • July 2016

• Simplex or duplex with adapters and attached pi

Use the following procedure to install

adapter plates.

1. If the 6pak plate has attached pigtails, thread

gtails

the pigtails through the empty mounting slot

and loop the pigtails around the radius limiters in the chassis, as shown in Figure 13 belo w.

Figure 13. Installing a 6Pak Plate with Pigtails in a Wall-Mount Box

Page 17

© 2016 CommScope. All Rights Reserved.

Page 18

ADCP-90-545 • Issue 4 • July 2016

24569-A

24568-A

2. Align the tabs on the 6pak plate with the notches in the mounting slot.

3. Slide the 6pak or blank up into the slot until

4. If installing pigtails, route the fibers within

it snaps in place.

the chassis corresponding to Figure 14 and

Figure 15 for the 12-fiber and 24-fiber termination/splicing panel, respecti

Figure 14. Pigtail Routing in 12-Fiber Termination/Splicing Panel

vely.

Figure 15. Pigtail Routing in 24-Fiber Termination/Splicing Panel

Page 18

© 2016 CommScope. All Rights Reserved.

Page 19

3.3 Installing Cables and Routing Fibers

IFC OR OSP

CABLE

A

B

C

SHEATH

45.0 IN.

(114.3 CM)

64.0 IN.

(162.6 CM)

19.0 IN.

(48.3 CM)

SUB-UNITS

FIBERS

CONNECTORS

24570-A

ROUTED

FROM TOP

C

B

A

RADIUS

LIMITERS

The cable must be routed within the chassis in an orderly way that provides maximum

protection for the fibers and ease in future maintenance. For details refer to the following topics

for the three different types of wall-mount boxes. When routing and terminating fibers, observe

the following precaution to avoid potential eye damage.

Danger: Infrared radiation is invisible and can seriously damage the retina of the eye. Do not

look into the optical bulkhead of an operational transmitter, or into the launching (output) end

of an active fiber. A clean, protective cap or hood MUST be immediately placed over any

radiating bulkhead receptacle or optical fiber connector to avoid exposure to potentially

dangerous amounts of radiation. This practice also helps prevent contamination of connectors

and adapters.

3.3.1 12-Fiber Termination/Splicing Wall-Mount Box

ADCP-90-545 • Issue 4 • July 2016

This unit can be used for either fiel

correct breakout for field termination. Figure 18 shows the correct breakout for

d termination or splicing. Figure 16 and Figure 17 show the

splicing.

Figure 16. Field Termination Breakout and Routing, 12-Fiber Wall-Mount Box (Top Entry)

Page 19

© 2016 CommScope. All Rights Reserved.

Page 20

IFC OR OSP

CABLE

A

B

B

C

C

SHEATH

45.0 IN.

(114.3 CM)

64.0 IN.

(162.6 CM)

19.0 IN.

(48.3 CM)

SUB-UNITS

FIBERS

CONNECTORS

24573-A

ROUTED

FROM BOTTOM

A

RADIUS

LIMITERS

ADCP-90-545 • Issue 4 • July 2016

Figure 17. Field Termination Breakout and Routing, 12-Fiber Wall-Mount Box (Bottom Entry)

Page 20

© 2016 CommScope. All Rights Reserved.

Page 21

ADCP-90-545 • Issue 4 • July 2016

IFC OR OSP

CABLE

SHEATH

A

ROUTED FROM TOP

63 - 69 IN.

(160 - 175 CM)

SUB-UNITS

B C

36 IN. MIN.

(91.44 CM)

FIBERS

RADIUS

LIMITER

PLACE GROMMETS

ON EACH RADIUS

LIMITER BEHIND

AND IN FRONT OF

SPLICE TRA Y

CORNER OF

SPLICE TRA Y

24578-A

ROUTED FROM BOTTOM

Figure 18. Splicing Breakout and Routing, 12-Fiber Wall-Mount Box

© 2016 CommScope. All Rights Reserved.

Page 21

Page 22

ADCP-90-545 • Issue 4 • July 2016

CLAMP

BRACKET

INTEGRAL

BOLTS

CLAMP

YOKES (2)

RUBBER

GROMMET

PLATE

NUTS (2)

24566-A

Use the following procedure to prepare and install the cable.

1. Determine whether a cable clamp or compression

fitting will be used to hold the cable. In

general, a cable clamp is intended for a larger diameter cable, but either method can be

used for securing the cable.

2. Strip the outer sheath of the cable to expose the inner fiber bundles. Figure 16 and

Figure 17 show the correct breakout for

for splicing. The cable sheath sho

termination. Figure 18 shows the correct breakout

uld extend about 0.75 inch (1.9 cm) beyond the cable

clamp or compression fitting.

3. If using a cable clamp (Figure 19):

a. Before mounting the wall-mount chassis to the

wall, determine which of the four

available mounting locations will be used and install the clamp bracket by inserting the

two integral bolts from the rear, as shown. If the cable is routed to the wall box from

above, install the cable clamp bracket in the upper part of the box. If the cable is routed

to the wall box from below, install the cable clamp bracket in the lower part of the box.

b. Sort through the rubber grommets in the kit and find the

one that best fits the cable. If

the cable is too small to fit snugly in the smallest grommet, build up the cable with

tape of a suitable material per local standards.

c. Assemble the cable clamp components on the integral bolts in the order shown in the

re and secure with the two nuts provided.

figu

Figure 19. Cable Clamp Assembly (Select from Four Mounting Locations)

Page 22

© 2016 CommScope. All Rights Reserved.

Page 23

4. If using a compression fitting (Figure 20):

a. Thread the cable through the cap and housing.

b. Determine which of the eight available mounting slots wi

housing into the slot.

c. Fasten to box using lock nut provided.

d. Turn cap clockwise until tight on cable.

ADCP-90-545 • Issue 4 • July 2016

ll be used and insert the

CAP

GASKET

WASHER

TPE

BUSHING

HOUSING

COMPRESSION

FITTING BRACKET

SLOT

GROMMIT

LOCK

NUT

Figure 20. Compression Fitting (Select from Eight Mounting Locations)

24567-A

5. If the cable being installed is an OSP cable with a metallic strength member, bond the

cable to ground following the instructions for the bonding/grounding kit.

© 2016 CommScope. All Rights Reserved.

Page 23

Page 24

ADCP-90-545 • Issue 4 • July 2016

6. Route the fibers within the wall-mount box as shown in Figure 16, Figure 17, and

Figure 18. Tie the fibers down in the loc

Danger: Infrared radiation is invisible and can seriously damage the retina of the eye. Do not

look into the optical bulkhead of an operational transmitter, or into the launching (output) end

of an active fiber. A clean, protective cap or hood MUST be immediately placed over any

radiating bulkhead receptacle or optical fiber connector to avoid exposure to potentially

dangerous amounts of radiation. This practice also helps prevent contamination of connectors

and adapters.

7. Refer to subsection 3.4, Splicing for splicing instructions.

3.3.2 24-Fiber Termination/Splicing Wall-Mount Box

ation shown using cord lacing.

This unit can be used for either fiel

correct breakout for field termination when the

d termination or splicing. Figure 21 and Figure 22 show the

cable is routed in from the top. Figure 23 and

Figure 24 show the correct breakout for field termination when the cable is routed

bottom. Figure 25 shows the correct breakout for splicing.

C

CONNECTORS

IFC OR OSP

CABLE

SHEATH

A

86.0 IN.

(218.4 CM)

67.0 IN.

(170.2 CM)

SUB-UNITS

RADIUS

LIMITERS

A

C

B

19.0 IN.

(48.3 CM)

FIBERS

ROUTE TOP

THREE FIBERS

AROUND BOTH

RADIUS LIMITERS

in from the

Figure 21. Field Termination Breakout and Routing, 24-Fiber Wall-M ount Box (Top Entry, Top 6paks)

Page 24

© 2016 CommScope. All Rights Reserved.

B

TOP 6 PAKS

(ROUTED FROM TOP)

ROUTE BOTTOM

THREE FIBERS

AROUND LEFT

RADIUS LIMITER

ONLY

24574-A

Page 25

ADCP-90-545 • Issue 4 • July 2016

IFC OR OSP

CABLE

SHEATH

A

92.0 IN.

(233.7 CM)

67.0 IN.

(170.2 CM)

SUB-UNITS

RADIUS

LIMITERS

A

B

C

B

25.0 IN.

(63.5 CM)

FIBERS

BOTTOM FIBERS

AROUND LEFT

RADIUS LIMITER

C

CONNECTORS

ROUTE

ONLY

BOTTOM 6 PAKS

(ROUTED FROM TOP)

24576-A

Figure 22. Field Termination Breakout and Routing, 24-Fiber Wall-Mount Box (Top Entry, Bottom 6paks)

© 2016 CommScope. All Rights Reserved.

Page 25

Page 26

ADCP-90-545 • Issue 4 • July 2016

IFC OR OSP

CABLE

SHEATH

A

100.0 IN.

(254.0 CM)

81.0 IN.

(205.7 CM)

SUB-UNITS

RADIUS

LIMITERS

C

B

B

19.0 IN.

(48.3 CM)

FIBERS

ROUTE TOP

THREE FIBERS

AROUND BOTH

RADIUS LIMITERS

ROUTE BOTTOM

THREE FIBERS

AROUND LEFT

RADIUS LIMITER

C

CONNECTORS

ONLY

A

TOP 6 PAKS

(ROUTED FROM BOTTOM)

24575-A

Figure 23. Field Termination Breakout and Routing, 24-Fiber Wall-Mount Box (Bottom Entry, Top 6paks)

Page 26

© 2016 CommScope. All Rights Reserved.

Page 27

ADCP-90-545 • Issue 4 • July 2016

IFC OR OSP

CABLE

SHEATH

A

106.0 IN.

(269.2 CM)

81.0 IN.

(205.7 CM)

SUB-UNITS

RADIUS

LIMITERS

B

C

B

25.0 IN.

(63.5 CM)

FIBERS

BOTTOM FIBERS

AROUND LEFT

RADIUS LIMITER

C

CONNECTORS

ROUTE

ONLY

A

BOTTOM 6 PAKS

(ROUTED FROM BOTTOM)

24577-A

Figure 24. Field Termination Breakout and Routing, 24-Fiber Wall-Mount Box (Bottom Entry, Bottom 6paks)

© 2016 CommScope. All Rights Reserved.

Page 27

Page 28

ADCP-90-545 • Issue 4 • July 2016

IFC OR OSP

CABLE

SHEATH

A

ROUTED FROM TOP

104 - 110 IN.

(264 - 279 CM)

SUB-UNITS

B C

36 IN. MIN.

(91.44 CM)

FIBERS

RADIUS

LIMITER

CORNER OF

SPLICE TRA Y

24578-A

ROUTED FROM BOTTOM

Figure 25. Splicing Breakout and Routing 24-Fiber Wall-Mount Box

PLACE GROMMETS

ON EACH RADIUS

LIMITER BEHIND

AND IN FRONT OF

SPLICE TRA Y

Use the following procedure to prepare and install the cable.

Page 28

© 2016 CommScope. All Rights Reserved.

Page 29

ADCP-90-545 • Issue 4 • July 2016

1. Determine whether a cable clamp or compression fitting will be used to hold the cable. In

general, a cable clamp is intended for a larger diameter cable, but either method can be

used for securing the cable.

2. Strip the outer sheath of the cable to

Figure 23, and Figure 24 show the correct breakout for terminat

correct breakout for splicing. The cable sheath sh

expose the inner fiber bundles. Figure 21, Figure 22,

ion. Figure 25 shows the

ould extend about 0.75 inch (1.9 cm)

beyond the cable clamp or compression fitting.

3. If using a cable clamp, refer to Figure 19 and associated text in the procedure

above for the

12-fiber wall-mount box.

4. If using a compression fitting, refer to Figure 20 and associated text in the procedure

above for the 12-fiber wall-mount box.

5. If the cable being installed is an OSP cable

with a metallic strength member, bond the

cable to ground following the instructions for the bonding/grounding kit.

6. Route the fibers within the wall-mount box as shown in Figure 21, Figure 22, Figure 23,

Figure 24, or Figure 25. Tie the fibers down in the location shown using cord lacing.

Danger: Infrared radiation is invisible and can seriously damage the retina of the eye. Do not

look into the optical bulkhead of an operational transmitter, or into the launching (output) end

of an active fiber. A clean, protective cap or hood MUST be immediately placed over any

radiating bulkhead receptacle or optical fiber connector to avoid exposure to potentially

dangerous amounts of radiation. This practice also helps prevent contamination of connectors

and adapters.

7. Refer to subsection 3.4, Splicing, below, for splicing instructions.

3.3.3 48-Fiber Splicing Wall-Mount Box

Figure 26 shows the three routing options within the

mount box. At least two cables are always inv

olved. They may both enter from the top, both

chassis for the 48-fiber splicing wall-

enter from the bottom, or enter from both top and bottom, on the left side. If from top and

bottom, then an “S” curve, under the splice tray, must be used to reverse the direction of one

cable so that they may both enter the splice tray from the bottom.

© 2016 CommScope. All Rights Reserved.

Page 29

Page 30

24581-A

IFC OR OSP

CABLE

A

B C

SHEATH

36.0 IN.

(91.44 CM)

110 - 116 IN.

(279 - 295 CM)

SUB-UNITS

FIBERS

BOTH BUNDLES

ROUTED FROM TOP

IFC OSP

IFC OSP

BOTH BUNDLES

ROUTED FROM BOTTOM

ROUTED FROM BOTTOM

OSP

ROUTED FROM TOP

IFC

RADIUS

LIMITER

PLACE GROMMETS

ON EACH RADIUS

LIMITER BEHIND

AND IN FRONT OF

SPLICE TRA YS

CORNER OF

SPLICE TRA YS

ADCP-90-545 • Issue 4 • July 2016

Page 30

© 2016 CommScope. All Rights Reserved.

Figure 26. Routing within 48-Fiber Splicing Wall-Mount Box

Page 31

Use the following procedure to route the cable.

ADCP-90-545 • Issue 4 • July 2016

1. Determine whether a cable clamp

or compression fitting will be used to hold the cables. In

general, a cable clamp is intended for a larger diameter cable, but either method can be

used for securing the cable.

2. Strip the outer sheath of the cables to expose the inner fiber bundles as shown in Figure 26

above. The cable sheath should extend about 0.75 inch (1.9 c

m) beyond the cable clamp or

compression fitting.

3. If using a cable clamp, refer to Figure 19 and associated text in the procedure

above for the

12-fiber wall-mount box.

4. If using a compression fitting, refer to Figure 20 and associated text in the procedure

above for the 12-fiber wall-mount box.

5. If either cable being installed is an OSP cable

with a metallic strength member, bond the

cable to ground following the instructions for the bonding/grounding kit.

6. Route the fibers within the wa

in the location shown

using cord lacing.

ll-mount box as shown in Figure 26 and tie the fibers down

Danger: Infrared radiation is invisible and can seriously damage the retina of the eye. Do not

look into the optical bulkhead of an operational transmitter, or into the launching (output) end

of an active fiber. A clean, protective cap or hood MUST be immediately placed over any

radiating bulkhead receptacle or optical fiber connector to avoid exposure to potentially

dangerous amounts of radiation. This practice also helps prevent contamination of connectors

and adapters.

7. Refer to subsection 3.4, Splicing, below, for splicing instructions.

© 2016 CommScope. All Rights Reserved.

Page 31

Page 32

ADCP-90-545 • Issue 4 • July 2016

3.4 Splicing

Use the following procedure to install a splice tray and set up a splice.

1. If there is an “S” fiber curve within the cha

ssis and crossing through the area where the

splice tray will be installed, place grommets on the radius limiters to hold the splice tray

above the “S” curve. (Refer to previous topic for an illustration of the grommets).

2. Place the splice tray within the radius limiters

in the desired orientation based on the

routing diagrams presented in the foregoing topics.

3. Route all fibers to the open end of the splice tray (witho

ut foldover tab), divided into left and

right groups corresponding to which splice chip they are going to be splice at. Figure 27

shows the recommended route within the splice tray using this

method. Tie down the fibers

with cord lacing using the tie-down holes (shown below) on the open side of the splice tray.

4. Remove the splice tray to a

working surface and complete the splice per local practice.

5. Repeat steps 2 to 4 above for any additional splice tray.

6. Place the splice trays back in the splice dec

k and place grommets on the radius limiters

above the splice trays to hold it in place within the splice deck (see Figure 26 insert).

Page 32

© 2016 CommScope. All Rights Reserved.

Figure 27. Routing Fibers on a Splice Tray

Page 33

4 OPERATION

In all operation procedures, observe the following precaution.

Danger: Infrared radiation is invisible and can seriously damage the retina of the eye. Do not

look into the optical bulkhead of an operational transmitter, or into the launching (output) end

of an active fiber. A clean, protective cap or hood MUST be immediately placed over any

radiating bulkhead receptacle or optical fiber connector to avoid exposure to potentially

dangerous amounts of radiation. This practice also helps prevent contamination of connectors

and adapters.

4.1 Installing Patch Cords

Use the following procedure to install patch cords.

1. Clean all connectors according to local practice.

ADCP-90-545 • Issue 4 • July 2016

2. Open the front cover and connect patch cords at

panel.

3. Route the patch cords in the dire

unit and then to office equipment (interconnect) or another FL1000 unit (cross-connect).

4. Record the cable fiber identification on th

4.2 Cleaning Adapters and Connectors

Dust and other contaminants on fiber optic connectors and adapters can seriously degrade

circuit performance.

To prevent contamination, each unused connec

cap. Routine termination activity can also introduce contaminants; therefore, it is essential that

connectors and adapters be cleaned before making connections.

The cleaning kit available from CommScope (catalog number FPC-CLNKIT) can be used to

n any style connector, or any adapters that are accessible from both sides (such as those on

clea

the 6pak).

the applicable receptacles on the bulkhead

ction of the angled adaptor toward the side of the FL1000

e designation label on the front cover.

tor or adapter must be protected with a clean dust

© 2016 CommScope. All Rights Reserved.

Page 33

Page 34

ADCP-90-545 • Issue 4 • July 2016

5 TECHNICAL ASSISTANCE

Contact the Technical Assistance Center (TAC) for technical question. Call 800.830.5056 or

send an email to TAC.Americas@commscope.com.

Page 34

© 2016 CommScope. All Rights Reserved.

Loading...

Loading...