Page 1

Page 1 of 29

© 2017 CommScope, Inc. All Rights Reserved

Installation Instructions

660001737

Rev. C

FIBER INDEXING TERMINAL

TC-96202-IP

Rev C, Aug 2018

www.commscope.com

1. About this installation instruction

This installation instruction describes the installation of the ber indexing terminal of both housings, the DLX connector

housing and the full size hardened connector housing, and their different applications: the standard indexing terminal

with splitter (1:4 or 1:8), the indexing only terminal, the branch terminal and the multi-use terminal.

The instruction will explain how to handle the stubbed cable, how to mount the terminal in different situations (hand

hole, pedestal, pole and aerial), how to connect and maintain the different connector types (DLX, full size hardened

connector and HMFOC) and how to test the installed chain of terminals.

Page 2

Page 2 of 29

© 2017 CommScope, Inc. All Rights Reserved

2. General safety precautions

2.1. Fiber optic cables may be damaged if bent or

curved to a radius that is less than the recommended

minimum bend radius. Always observe the recommended

bend radius limit when installing ber optic cables and

patch cords.

2.2. Exposure to laser radiation can seriously

damage the retina of the eye. Do not look into the ends of

any optical ber. Do not assume the laser power is turned

off or that the ber is disconnected at the other end.

3. List of acronyms and

abbreviations

MST Multiport Service Terminal

FTTX Fiber To The X

DLX Dual Locking Connector

HMFOC Hardened Multiber Optical Connector

MPO Multi-ber Push On

FDH Fiber Distribution Hub

UMB Universal Mounting Bracket

VAM Value Added Module

CO Central Ofce

VFL Visual Fault Locator

Lead a single chain of terminals

Upstream a position closer to the CO or head end

Downstream to a position closer to the end of a lead

1. About this installation instruction .......................................1

2. General safety precautions ..................................................2

3. List of acronyms and abbreviations ....................................2

4. Fiber indexing ........................................................................3

4.1. Fiber indexing building blocks .................................................3

4.2. Reverse feed ...........................................................................3

4.3. Fiber indexing technology .......................................................3

5. Fiber indexing terminal .........................................................4

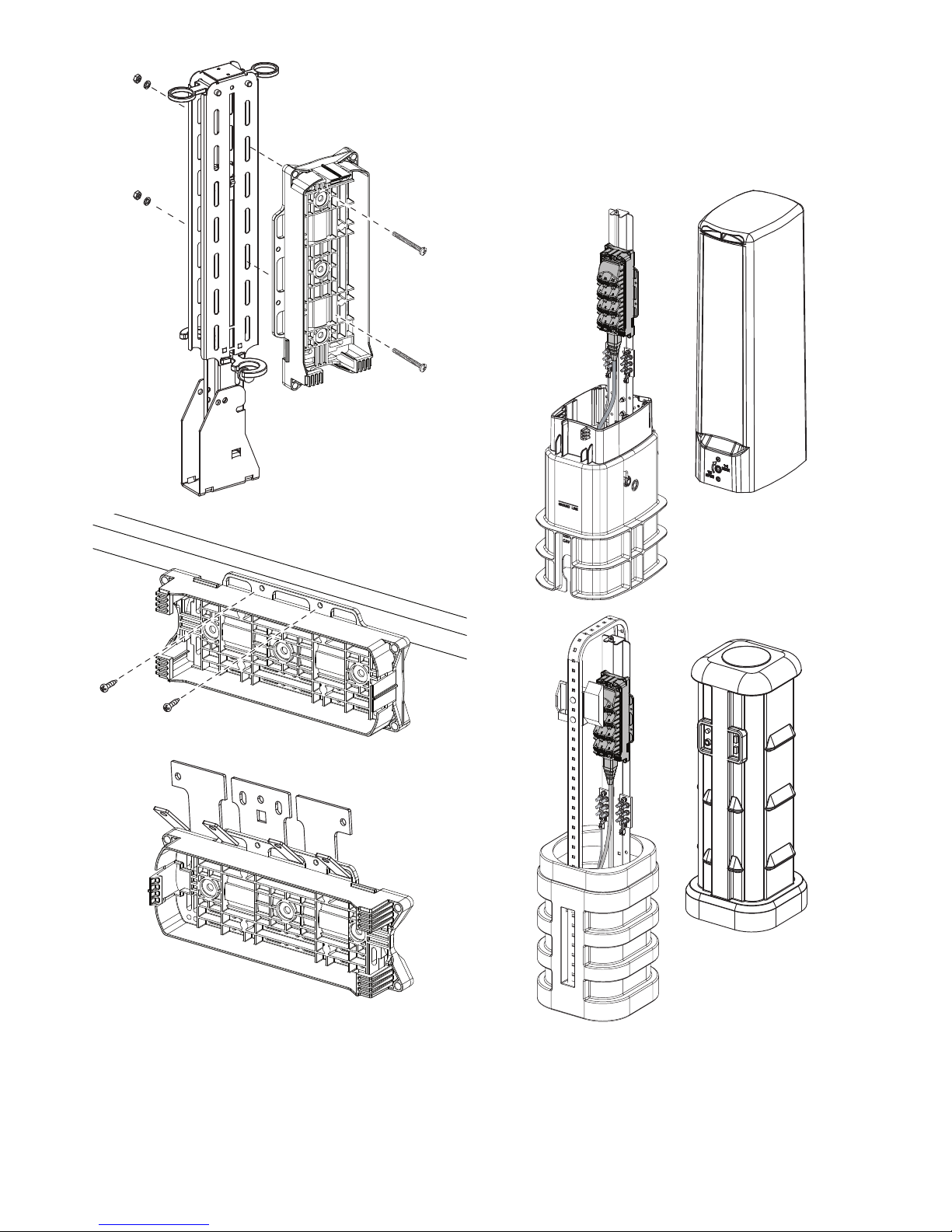

5.1. Housings .................................................................................4

5.2. Congurations .........................................................................5

5.3. Cable stub ...............................................................................8

5.4. Universal Mounting bracket .....................................................9

5.5. Accessories .............................................................................9

6. Network design with the indexing terminals ......................9

7. Installation .............................................................................9

7.1. Tools and materials required ...................................................9

7.2. Installation overview ..............................................................10

7.3. Unpacking and inspection .....................................................10

8. Cable handling recommendations .....................................11

9. Mounting the terminal .........................................................12

9.1. Disconnect the terminal from its UMB ...................................12

9.2. Hand-Hole mounting .............................................................12

9.3. Pedestal mounting.................................................................13

9.4. Pole-mounting .......................................................................14

9.5. Strand-mounting ....................................................................15

9.6. Installing the terminal in its UMB ...........................................15

10. Link installation (HMFOC) ..................................................16

10.1. Connector components .........................................................16

10.2. Adapter components .............................................................16

10.3. HMFOC specications ...........................................................16

10.4. Connecting the HMFOC (making the link installation)...........16

10.5. Disconnecting the HMFOC ...................................................17

11. DLX connector installation .................................................18

11.1. Connector components .........................................................18

11.2. Adapter components ............................................................18

11.3. DLX specications .................................................................19

11.4. Connecting the drop cable to the indexing terminal

(DLX connector housing) adapter port ..................................19

11.5. Disconnecting the drop cable from the indexing terminal

(DLX connector housing) adapter port ..................................20

12. Full size hardened connector installation .........................21

12.1. Connector components .........................................................21

12.2. Adapter components .............................................................21

12.3. Full size hardened connector specications ........................21

12.4. Connecting the drop cable to the indexing terminal (full size

hardened connector housing) adapter port ..........................22

12.5. Disconnecting the drop cable from the indexing terminal

(full size hardened connector housing) adapter port .............23

12.6. Applying O-ring lubricant .......................................................23

13. Testing ..................................................................................23

13.1. Conformance Testing ............................................................23

13.2. Bench Testing ........................................................................25

13.3. Trouble Shooting ...................................................................25

13.4. Restoral .................................................................................26

13.5. Appendix ...............................................................................26

14. Maintenance .........................................................................27

14.1. HMFOC cleaning ...................................................................27

14.2. Cleaning DLX connector and adapter ...................................27

14.3. Cleaning full size hardened connector and adapter ..............28

15. Trademarks ..........................................................................29

16. Contact information ............................................................29

Contents

Page 3

Page 3 of 29

© 2017 CommScope, Inc. All Rights Reserved

4. Fiber indexing

4.1. Fiber indexing building blocks

CommScope’s ber indexing system consists of terminals

and connectorized 12 strand ber cables using hardened

connectivity. It allows to build the FTTX network in the

outside plant environment faster, with plug and play

installation.

The exact same components (ber indexing terminal

and the corresponding drops to the homes) are installed

between a ber distribution hub (FDH) and subscribers

(homes) in a daisy chain architecture. Several daisy

chains are connected to the hub. Each chain consist of

up to 12 ber indexing terminals and d istributes services

to up to 96 subscribers (homes). Drop cable assemblies

transport the optical signal from the ber indexing

terminal to the home.

4.2. Reverse feed

When a second cable is connected from the hub (FDH) to

the last terminal , the signal runs “backwards” toward the

rst terminal. This makes additional bers available that

can be used to add subscribers or roll out new services.

More information on how to make this installation, can be

obtained in section 7.2.5.

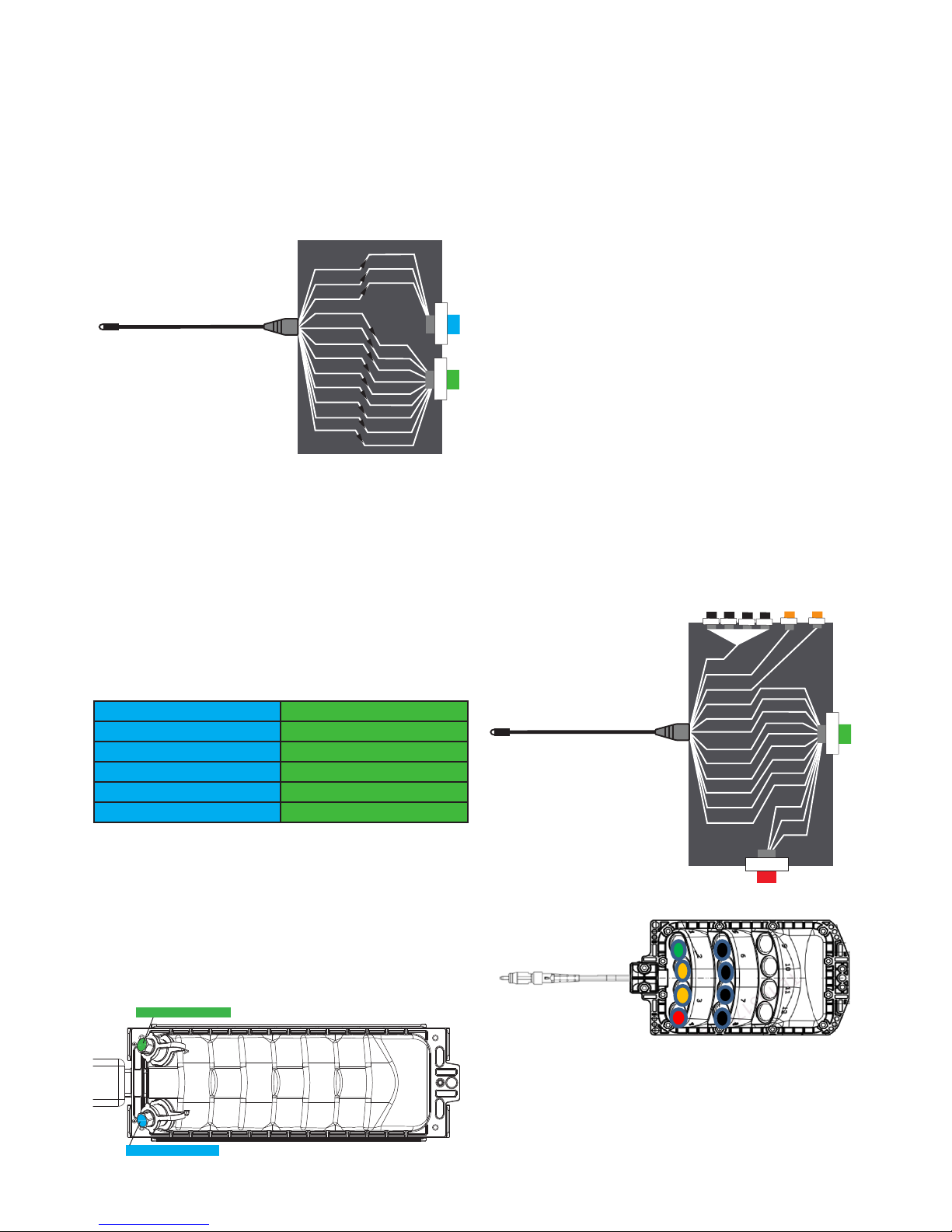

4.3. Fiber indexing technology

Indexing refers to the shifting of a ber’s position - from

one multi-ber connector to the other - within each

terminal.

• The process begins with a 12 ber cable from the

ber distribution hub (FDH) entering the rst ber

indexing terminal.

• Inside the terminal, the bers divide and the signal on

the ber on the rst position is routed to a splitter (1:4

or 1:8) for servicing local customers.

• All other bers are indexed - advanced one position

in the order - so that the number 2 ber shifts to

the number 1 position, ready to be routed to the

subscribers at the next terminal.

• The bers are re-combined using a 12 ber HMFOC.

The last ber position of the 12 ber HMFOC

becomes accessible via the reverse path optical port.

DROP

DROP

DROP

DROP

HMFOC

DROP

Fiber 1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

REVERSE FEED

DROP

DROP

DROP

DROP

DROP

Fiber 1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

DROP

DROP

DROP

DROP

DROP

Fiber 1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

DROP

DROP

DROP

DROP

HMFOC

DROP

Fiber 1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

HMFOC

HMFOC

Fiber

Distribution

Hub

Indexing terminal Indexing terminal Indexing terminal

Hardened Multi Fiber

Connector (HMFOC)

12 fiber cable

basic building block:

connectorized cable and terminal

repeat repeat

HUB

6

8

5

4

3

2

1

9

10

11

7

12

Reverse feed

Page 4

Page 4 of 29

© 2017 CommScope, Inc. All Rights Reserved

5.1.2. DLX connector housing

This housing contains DLX adapters. (See chapter 11

for installation guidelines) for the single-ber drops and

an HMFOC adapter (male) to connect the terminal to the

next terminal. (See chapter 10 for installation guidelines).

The input for these adapters is a 12 ber cable that

enters the terminal through a sealed opening located at

the bottom of the terminal. The stub cable is terminated

with an HMFOC connector (female). The terminal ships

with its UMB.

This housing is also used for the branch terminal

conguration that doesn’t contain single-ber drops. Only

2 HMFOC ports are available in this model (see section

5.2.4)

5. Fiber indexing terminal

All indexing terminals have a hardened, weather

resistant plastic housing. The housing type depends on

the adapter type of the single-ber drop port, either full

size hardened or DLX. Both housing types use HMFOC

adapter(s) for the multi-ber connection.

5.1. Housings

5.1.1. Full size hardened connector housing

This housing contains full size hardened adapters (see

chapter 12 for installation guidelines) for the single-

ber drops and an HMFOC adapter (male) to connect

the terminal to the next terminal. (See chapter 10 for

installation guidelines). The input for these adapters is a

12 ber cable that enters the terminal through a sealed

opening located at the bottom of the terminal. The stub

cable is terminated with an HMFOC connector (female).

The terminal ships with its UMB.

[3,69 IN]

9,38 CM

[7,4 IN]

18,8 CM

[11,26 IN]

28,6 CM

[11,69 IN]

29,69 CM

[5,13 IN]

13,03 CM

[3,91 IN]

9,92 CM

Page 5

Page 5 of 29

© 2017 CommScope, Inc. All Rights Reserved

5.2.2. Standard indexing terminal 1:4 splitter with

reverse port

In this conguration, the terminal will drop the rst ber

from the incoming 12 ber strand. This ber will be

routed to an integrated 1:4 splitter. The outputs of this

splitter are DLX adapters or full size hardened adapters

(depending on the housing type). The others 11 bers

from the incoming 12 ber strand cable will proceed

unsplit and be terminated on a HMFOC adapter port,

together with the ber coming from the reverse port.

The ber coming from the reverse port will take # 12 of

the outgoing 12 ber HMFOC, the incoming ber # 2 will

take # 1 of this outgoing 12 ber HMFOC.

The HMFOC adapter port is colored green and indicated

with an ‘A’ on the terminal. The reverse port is colored red

and indicated with a ‘R’ and the terminal.

Image below shows the schematics inside the terminal.

The 12 ber strand cable terminated on a female HMFOC

of this terminal is connected to the green HMFOC

adapter port of its up-stream terminal (to the FDH in case

of the rst terminal of the chain), a forward feed path is

created. 4 subscribers (homes) can be fed around this

indexed terminal by connecting a connectorized drop

cable (DLX or full size hardened) to one of the 4 black

dust cap adapter ports.

Up to 12 indexed terminals can be connected one after

the other (link installation).

Image below shows the available ports and color code of

the adapters of this terminal conguration:

DROP

DROP

DROP

DROP

HMFOC

DROP

Fiber 1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

HMFOC Adapter port Drop port

Reverse port

5.1.3. Specications

PARAMETER SPECIFICATION US SPECIFICATION IEC

Environmental GR-771-CORE,

and GR-3120-CORE

(HMFOC)

IEC 61753-1 Ed2

CAT A&G

Operation

Temperature

–40ºF (± 3.6º) to 150ºF

(± 3.6º)

–40ºC (± 2º) to 65ºC

(± 2º)

Installation

temperature

23°F to 113°F - 5°C to 45°C

Humidity 0% to 100%RH

Water resistance NEMA 6

(10-foot water head for

7 days without leakage)

IEC 60529-IP 68 (till 3

meters for 7 days)

Flammability UL94-5VA

Color Black

Both housings are designed to meet aerial and pedestal

conditions. For hand-hole application, the housings are

designed to meet the conditions for hand-holes located

up to 3 meters (10 feet) under ground.

5.2. Congurations

To build the network, each housing type is available in 4

congurations:

• Standard indexing terminal with 1:4 splitter

• Standard indexing terminal with 1:8 splitter

• Indexing only

• Branch terminal

5.2.1. Color code (ports)

To ensure correct installation, the terminal ports are colorcoded:

BLACK forward feed

DLX or full size hardened connector

single-ber drop (split signal)

ORANGE forward feed

DLX or full size hardened connector

single-ber drop (unsplit signal)

RED reverse feed

DLX or full size hardened connector

single-ber drop or HMFOC

GREEN HMFOC

12 ber cable output to the next terminal

BLUE HMFOC-branching only

12 ber cable output that route a portion

of the 12 input bers to another terminal

Page 6

Page 6 of 29

© 2017 CommScope, Inc. All Rights Reserved

5.2.4. Indexing only terminal with reverse port

The indexing terminal is also available without an

integrated splitter. In this case the unsplit signal of the

rst ber of the incoming chain, goes to a single drop

(black dust cap). This single drop can be connected to a

more peripheral terminal where splicing and or splitting

is performed. This topology enables a greater spatial

coverage though the possible number of drops remains

the same for each chain.

Images below shows the schematics inside the terminal

and the color code of the adapters of this terminal.

HMFOC

DROP

Fiber 1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

DROP

5.2.3. Standard indexing terminal 1:8 splitter with

reverse port

If there are more subscribers (homes) around the

indexing terminal to feed, the terminal can have a 1:8

splitter instead of a 1:4 as described in section 5.2.2.

8 homes can be fed (passed) from this terminal.

Images below shows the schematics inside the terminal

and the color code of the adapters of this terminal.

Image below illustrates the positions of the different

terminal congurations in the network:

DROP

DROP

DROP

DROP

DROP

DROP

DROP

DROP

HMFOC

DROP

Fiber 1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

HMFOC Adapter port Drop port

Reverse port

HMFOC Adapter port

Drop port

Reverse port

HUB

A

B

1

8

2

3

4

5

6

9

10

11

7

12

INDEXING BRANCH

INDEXING 1:4

INDEXING 1:8

INDEXING ONLY

SPLITTER ONLY

Page 7

Page 7 of 29

© 2017 CommScope, Inc. All Rights Reserved

The daisy chaining installation can continue from each

HMFOC adapter port, but with a reduced chain in either

direction as dened by the ber branch quantity.

Although this terminal has no reverse feed adapter port,

the reverse feed functionality is still available in the

reduced chains.

5.2.6. Multi-use

5.2.6.1. Internal splitter with pass-thru bers

Multi-use ber terminals are designed to deliver splitter

based services and/or traditional “unsplit” services. The

splitter (if present) is always connected to the rst ber of

the incoming 12 ber stand. The outputs of the splitter are

indicated with a black dust cap. Adapters with an orange

dust cap indicate a straight pass-thru ber. It is a ber

dropped of from the incoming 12 ber chain, but unsplit

(it is a regular ber coming from the hub).

Example below shows the rst ber dropped of routed

to an integrated 1:4 splitter and the second and the third

ber dropped of directly routed to the adapter port.

The other 9 bers from the incoming 12 ber strand

continue via the green HMFOC adapter port where ber

4 of the incoming strand will take in position 1 in the

adapter port. 3 bers from the red reverse port will take in

positions 10,11 and 12 in the green HMFOC port. In this

case the reverse port is also an HMFOC adapter port.

In this example, link installation decreases to 4 terminals

in a chain.

DROP

DROP

DROP

DROP

Fiber 1

1

2

2

3

1

4

3

5

4

6

6

5

7

7

8

8

9

9

10

10

11

11

12

12

DROP

DROP

HMFOC

HMFOC

5.2.5. Indexing branch terminal

The indexing branch terminal enables dividing the

incoming 12 bers into 2 HMFOC adapter ports. This

conguration provides more exibility in the distribution

network as greater spatial coverage area can be

achieved. Neither the reverse feed port nor the single

drop ports are included on an indexing branch terminal.

The image below shows the schematic inside the

terminal:

The rst bers from the incoming 12 ber tail are always

routed to the blue HMFOC connector, indicated with

letter B, the other bers are routed to the green HMFOC,

indicated with letter A.

The bers always take in the rst ber positions in the

multi ber connector. Image above illustrates the rst 3

bers from the incoming 12 ber tail (input) routed to the

rst 3 positions in the blue HMFOC connector, the last

9 bers from the incoming 12 ber tail routed to the rst

positions in the green HMFOC connector. The remaining

positions of the green and blue HMFOC are unused.

The Indexing branch terminal can be delivered with

following division of the incoming 12 bers.

B (blue) A (green)

1,2 3 to 12

1 to 3 4 to 12

1 to 4 5 to 12

1 to 5 6 to 12

1 to 6 7 to 12

The model number (catalogue number) indicates the

quantity of bers going to the blue HMFOC:

For example NDX-B3 indicates that the rst 3 bers

of the incoming 12 ber strand are routed to the blue

HMFOC and the last 9 bers are routed to the green

HMFOC taking in the rst positions (position 1-9) in the

connector.

The image below shows the color code and the letter

code of the 2 HMFOC adapter ports.

HMFOC

1

2

3

4

5

6

7

1

2

3

1

3

2

4

8

5

9

6

10

7

11

12

8

9

B

HMFOC

A

HMFOC Adapter port A

HMFOC Adapter port B

Page 8

Page 8 of 29

© 2017 CommScope, Inc. All Rights Reserved

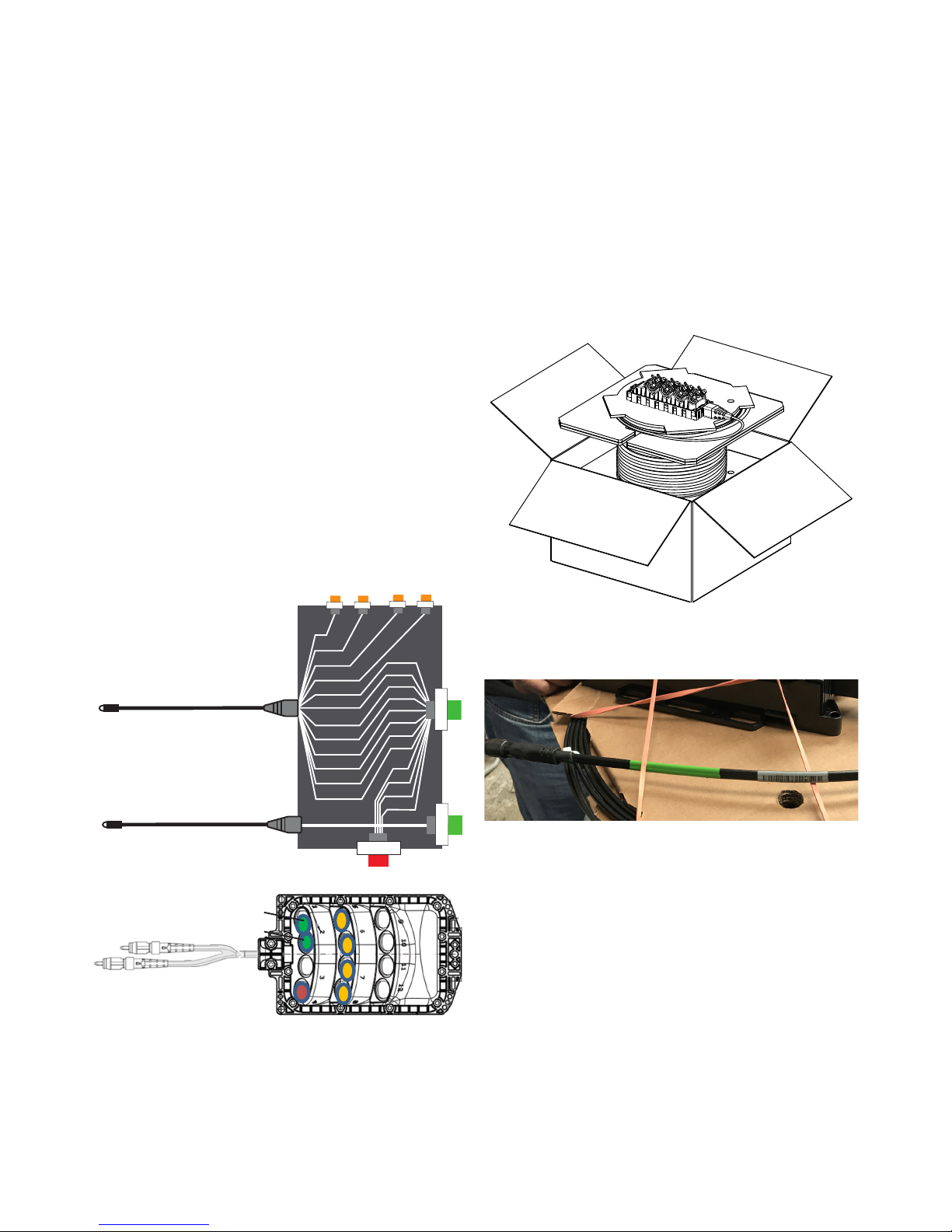

5.3. Cable stub

5.3.1. Cable type and length

The cable stub on the terminal is an all-dielectric at drop

cable terminated with a female (non-pinned) HMFOC.

The cable outer dimensions are 8 x4.3 mm (0.31x0.17

inch).

Cable length that can be ordered, range from 3 to 609 m

(10 to 2000 feet). See ordering guide for details.

Terminals with cable stub lengths less than 30.5 m (100

feet) are shipped coiled. When the cable stub is 30.5 m

(100 feet) or longer, the terminal is shipped on a spool,

with the terminal secured on the spool ange as shown in

the image below:

A serial number label is applied on the cable

approximately 0.2 m (8 inch) from the connector body.

See image below.

5.2.6.2. 24 ber Indexing terminals

Twenty-four ber Indexing terminals are designed to

deliver bulk ber into a distribution area where split and

unsplit services are needed. On board splitters have been

removed in favor of external splitters. Fibers are allocated

into two groups. Fibers 1-12 are congured to the

standard indexing model. Fibers 13-24 are congured as

pure pass-thru without indexing. This segregation allows

for the express delivery of bers independent of indexing

architectures when necessary and replenishment of ber

when the indexing string becomes exhausted.

Example below shows the rst 4 bers dropped of. The

signal is unsplit. The ber in each of these drop off port is

a straight pass-thru ber. The dust cap is orange.

Fiber 5 of the incoming 12F strand takes in position 1 of

the outgoing HMFOC adapter port (A1). 4 bers of the

reverse port take in position 8,9,10, 11 and 12 in that

adapter port.

Indexing terminals exhaust themselves once 12 bers

have been allocated. This may happen in as few as three

links or as many as 12 links dependent on how the bers

are distributed along the way. Twenty-four ber terminals

have the capacity to replenish an indexing string by

harnessing the express group on the “A2” port. This is

achieved by attaching the next indexing terminal to the

“A2” port. If the next terminal is a twenty-four ber

terminal then the tail connectors will be swapped (e.g.

“a1” tail connector to “A2” port and “a2” tail connector to

“A1” port).

A1

A2

Fiber 1

1

2

2

3

1

4

3

5

4

6

6

5

7

7

8

8

9

9

10

10

11

11

12

12

DROP

DROP

DROP

DROP

HMFOC

12F

HMFOC

A2

HMFOC

A1

a1, Fiber 1-12

a2, Fiber 13-24

Page 9

Page 9 of 29

© 2017 CommScope, Inc. All Rights Reserved

5.5.5. Cleaning kit HMFOC

To clean the HMFOC adapter and connector, a US

Conec HMFOC connector cleaning tool (PN 15639)

can be ordered at US Conec.

6. Network design with the

indexing terminals

The different congurations of the indexing terminals

can be combined to provide all the necessary exibility

and maximize the capacity of the distribution network.

First splitting level occurs typically in a Mini-FDH 3000

with 96 ports or an OSP closure (FOSC/FIST/TENIO)

with additional HMFOC connectors. The second splitting

level occurs within the indexing terminals, the different

congurations are explained in section 5.2.

Indexing chains always start with terminal one and build

outward in procession to a value no greater than twelve.

Indexing chains always provide the next ber to the

next terminal (i.e. Terminal 1 will use ber 1 within the

“chained” assembly).

In order to build an optimized network utilizing indexing

terminals, the following items should be considered prior

to beginning the network design:

• Locate and identify all Customers to have an

overview of all area to be covered/deployed.

• Clear up all drawing nomenclature: hand holes,

poles, ducts, terminals, etc.

• Identify feeder ber cables availability. If available,

dene the ber count & type of cables.

• Locate nearest CO, Node or HUB to determine the

maximum distance allowed within the optical budget

• Take into consideration, drop cable distances/routes

• Identify any network deployment restriction: Poles,

aerial capacity, underground ducts

• Discuss the best location for Indexing Terminals

(aerial, pole, wall, manhole)

• Consider the maximum number of services per

indexing terminal

• Split ratio: Specied by project

7. Installation

7.1. Tools and materials required

The following basic tools, auxiliary equipment, and

materials are required for the installation of the indexing

terminals:

• Vertical roller reel (if the terminal is mounted on a

cable spool)

• 216B key tool (used to open optical port dust cap)

• Hardened connector/adapter cleaning kit

(FHD-ACC-CLNKIT1)

• US Conec HMFOC connector cleaning tool (PN

15639)

• Utility knife

• Cable pulling equipment

• Appropriate fasteners to mount the UMB and tools to

install the fasteners

• “P” clamps for self supporting aerial installations.

Cable routing rings or fasteners (see local practices).

Cable can be lashed for messenger applications.

5.4. Universal Mounting bracket

Each terminal is supplied with the Universal Mounting

Bracket (UMB) which is used for mounting the ber

indexing terminal. The UMB may be attached to various

mounting surfaces using a variety of fasteners as will be

explained in section 9.

The UMB is housing specic and exist for the full size

hardened housing as well as for the DLX housing.

5.5. Accessories

5.5.1. Strand mounting kit

To secure the terminal to a strand, a strand-mount

bracket kit is available and must be ordered separately.

Refer to Universal Mounting bracket Strand-Mount

Installation InstructionADCP-96-124 for the installation

procedure. Section 9.5 provides some info about how to

use this strand mounting kit.

5.5.2. NDX-POLE-BRKT

To store excess cable in aerial applications, an NDXPOLE-BRKT kit is available and must be ordered

separately. If using the full size hardened connector

housing, an adapter bracket must also be ordered when

using the excess cable storage bracket (part number

NDX-4X3-ADPT-BRKT).

The bracket is secured with 1/4 inch thread size hardware

to a pole. Excess cable can be looped around the

bracket. When all excess cable is stored, the terminal

with its UMB can be slided in an upward direction into the

NDX-pole bracket.

5.5.3. 216B key tool

The opening to each optical port is sealed with a

threaded dust cap that prevents the entry of dirt and

moisture. A standard 216B security tool can be ordered to

remove the dust cap.

5.5.4. Cleaning kit FHD-ACC-CLNKIT1

To clean the drop ports adapters and connectors (both full

size hardened and DLX), a cleaning kit can be ordered.

How to use this is explained in chapter 14 maintenance.

Page 10

Page 10 of 29

© 2017 CommScope, Inc. All Rights Reserved

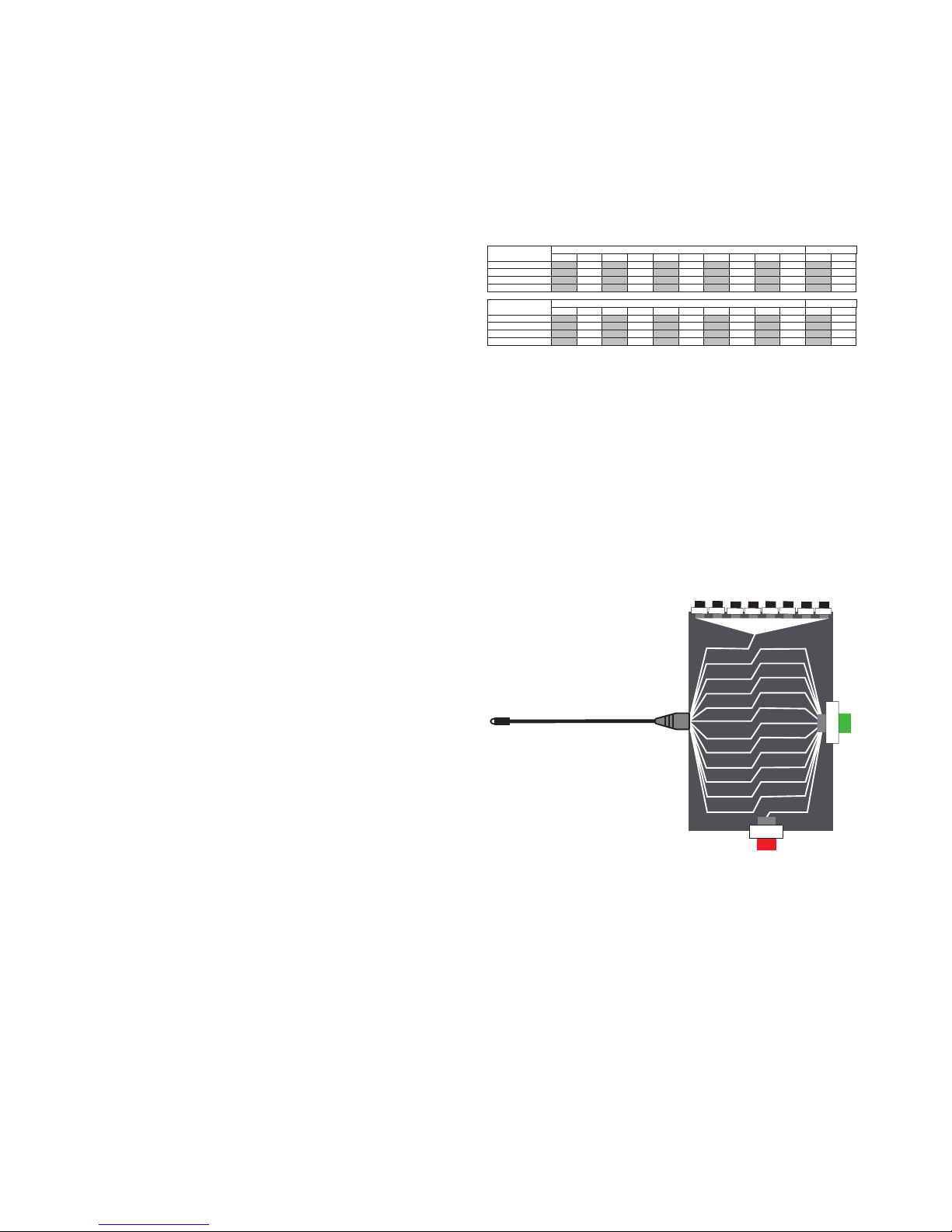

7.3. Unpacking and inspection

Open the shipping carton(s) and carefully inspect the

terminal and the attached cable. If there are damages,

contact CommScope product support at:

http://www.commscope.com/SupportCenter.

With each terminal a test report (VAM/Splitter Module

Assembly Performance Sheet) of the optical ports is

delivered:

Insertion Loss (IL) as well as Return Loss (RL) are tested

on 2 different wavelengths before shipment. IL is the

insertion loss between the female (non-pinned) HMFOC

on the tail and the output ports. RL is the return loss on

the output ports itself.

For an indexing terminal with a 1:8 splitter, port 1 to 8 are

the results for the forward feed adapters (ports with black

dust cap indicated respectively with number 1 to 8). Port

9 to 19 are the results for the rst 11 individual bers in

the HMFOC adapter (green dust cap, indicated with A).

Port 20 is the test result for the reverse feed adapter (red

dust cap). Image below illustrates the port numbering in

case of a 1:8 splitter.

For an indexing terminal with a 1:4 splitter, port 1 to 4 are

the results for the forward feed adapters (ports with black

dust cap indicated respectively with number 1 to 4). Port

5 to 15 are the results for the rst 11 individual bers in

the HMFOC adapter (green dust cap, indicated with A).

Port 16 is the test result for the reverse feed adapter (red

dust cap).

VAM/Splitter Module Assembly Performance Sheet

Catalog Number: NDX-10BTM0U-A0010F

Serial Number: 71171926081

Test Port Summary

12345678910MaxMin

IL @ 1310nm 9.905 9.849 9.863 9.509 9.571 9.629 9.575 9.496 0.207 0.204 9.905 0.204

RL @ 1310nm > 65 > 65 > 65 > 65 > 65 > 65 > 65 > 65 > 65 > 65 > 65 > 65

IL @ 1550nm 9.858 9.758 9.715 9.47 9.515 9.603 9.529 9.645 0.128 0.196 9.858 0.128

RL @ 1550nm > 65 > 65 > 65 > 65 > 65 > 65 > 65 > 65 > 65 > 65 > 65 > 65

Test Port Summary

11 12 13 14 15 16 17 18 19 20 Max Min

IL @ 1310nm 0.367 0.285 0.131 0.113 0.233 0.038 0.31 0.10 0.254 0.632 0.632 0.038

RL @ 1310nm > 65 > 65 > 65 > 65 > 65 > 65 > 65 > 65 > 65 > 65 > 65 > 65

IL @ 1550nm 0.354 0.222 0.091 0.092 0.154 0.025 0.253 0.089 0.209 0.481 0.481 0.025

RL @ 1550nm > 65 > 65 > 65 > 65 > 65 > 65 > 65 > 65 > 65 > 65 > 65 > 65

DROP

DROP

DROP

DROP

DROP

DROP

DROP

DROP

HMFOC

DROP

spliced

9

1

8

10

11

12

13

14

15

16

17

18

19

20

12F

Note: If using an enclosure such as a hand-hole or

pedestal, refer to the instructions provided with the

enclosure for any additional tools or equipment required.

7.2. Installation overview

To install the indexing terminals in the network and to

build the indexing network, following main tasks must be

perfomed:

1. Mounting the terminal (refer to section 9)

The terminal must be mounted on or within a suitable

support base or enclosure. The UMB allows the

terminal to be mounted in a variety of applications

including the following:

• Hand-Hole (below ground)

• Pole-Mount (aerial)

• Strand-Mount (aerial)

• Pedestal (at nal grade)

2. Link installation (installing the HMFOC)

The terminals connect to one another via a Hardened

Multi-Fiber Optic Connector (HMFOC). The nonpinned tail connector (HMFOC) is routed to the up-

stream component like an FDH or a previous terminal

for termination. The “green” capped MPO (pinned,

male) in the body of the terminal housing receives the

downstream tail connector (non-pinned,female).

For the indexing branch terminal, the blue adapter

port is a capped MPO (pinned) which can receive the

downstream tail from another chain.

Refer to section 8 for cable handling recommen-

dations and refer to section 10 for making the

HMFOC connection.

3. Testing the indexing chain (refer to section 13)

After installing the indexing chain, the signal on the

drops should be tested to ensure a correct installation

of the chain.

4. Drop cable installation and connection

After the indexing chain is set up, the single drop

connection can be made. Follow local practice

for pulling and installing drop cables. Refer to the

instructions provided with the mounting system for

drop cable entry and routing. Service is enabled by

connecting the drop cable connectors to the black

dust cap adapter ports on the terminal (see section

11 and 12).

In the Indexing Only conguration, a splitter only

terminal can be installed to the single black dust cap

adapter port. The subscribers will be connected to

this splitter only terminal.

5. Reverse feed installation

If all indexing terminals are installed, a FO cable with

HMFOC connectors at both ends can be connected

to the green dust cap adapter port of the last terminal

and to a 2nd HMFOC connector of the FDH. Now,

all RED ports from all Indexing terminals can be

connected to subscribers. The red adapter port is a

DLX or full size hardened connector, depending on

the housing. For installation, refer to section 11 or

12).

6. Maintenance

Maintenance for the indexing terminal is limited

to cleaning the hardened adapters as needed to

maintain optimal performance. Refer to section14.

Page 11

Page 11 of 29

© 2017 CommScope, Inc. All Rights Reserved

To relieve strain on the HMFOC connection,

CommScope recommends component coupling.

Component coupling in optical cables is important

to harmonizing the movement of the various cable

components created by stresses during installation,

through thermal cycling and environmental loading.

Input: Loop the cable tail before entering the upstream

terminal. Make 5 loops with a diameter of 152.4 mm (6

inch).

Output: Also on the output component coupling is

recommended, looping the cable 5 ½ loops (with

diameter 152.4 mm (6 inch)) adequately enhances the

coupling to prevent buffer tube movement.

Note: For applications where the cable is pulled, remove

the coupling coils and reinstall when cable pull is

completed.

Overlength:

Always store overlength near the terminal where the

cable leaves the terminal. For pole mounting the NDX-

pole-BRT bracket can be used.

Cable pay off:

1. Determine the terminal’s nal location. Mount the spool

on a vertical arbor on that location and pull the tail to the

upstream network element (hub or terminal). Maximum

pulling force 444.8 N (100 lbs).

2. Secure the cable at the location of the upstream

network element (for example with a P-clamp attached to

a D-ring in aerial application).

The cable length from this securing point to the connector

should be long enough to make the HMFOC link

installation with correct cable bend and 5 loops to relieve

strain on the connection.

3. Make the link installation (chapter 10) to the upstream

network element and go back to the terminal.

4. Mount the UMB or NDX-pole-BRKT and secure the

cable (for example with a P-clamp attached to a D-ring in

aerial applications).

Input

5 loops

Output

5

1/2

loops

8. Cable handling

recommendations

Each terminal is equipped with an optical cable.

Depending on the length of the cable, the dielectric cable

may be coiled up and placed in a box or it may be coiled

on a spool.

Coiled Cable Handling: Leave the terminal on top and in

the center of the coil. Locate the free end of the cable and

then carefully uncoil the cable from around the terminal.

Spooled Cable Handling: If the dielectric cable is coiled

on a spool, remove the spool from the box. Leave the

terminal on top of the spool and place the spool on a

vertical arbor. Locate the free end of the cable. Carefully

pull the cable away from the spool allowing the spool

assembly to rotate about the vertical arbor.

Cable Bend Radius Limits: Take care to observe the

recommended minimum bend radius limits for the cable.

Always maintain a minimum bend radius of 76.2 mm (3

inch).

Pulling the cable: When pulling the cable into place,

do not exceed a pulling force of 444.8 N (100 lbs) on

the optical cable. Pulling on the cable should be done

through the pulling cap, see picture below:

When connector is mated – in service, pulling force is

max 111.2 N (25 lbs).

Span rating: the recommended span width is as

followed:

m ft

NESC Light load Destrict 122 400

NESC Medium load Destrict 76 250

NESC Heavy load Destrict 46 150

Page 12

Page 12 of 29

© 2017 CommScope, Inc. All Rights Reserved

9.2. Hand-Hole mounting

Hand-Hole Mounting (below ground) – A hand-hole

enclosure (examples shown in Figure below) is an OSP

below-ground mounting system that may be used for any

indexing terminal or other similar products. When

installed, the top of the hand-hole enclosure is ush with

the top of the ground. Hand-hole enclosures consist of a

base unit and a top cover. The base unit mounts in the

ground. Cables and conduit enter the base unit from the

bottom.

CARSON

INDUSTRIES

®

CHANNELL

®

5. Store overlength near the terminal where the cable

leaves the terminal. For pole mounting the NDX bracket

can be used.

Note: The reverse option (cable spooled in opposite

way to pay off the cable in the reverse direction - from

upstream component to terminals nal position) is

available.

9. Mounting the terminal

9.1. Disconnect the terminal from its

UMB

To install the terminal in several situations, the terminal is

supplied with its UMB (universal mounting bracket). The

UMB can be attached to various mounting surfaces using

a variety of fasteners. Multiple holes and slots are

provided in the UMB to accommodate these variety of

fasteners. To reach these holes and slots, the terminal

should be disconnected from its UMB. This can be done

by lifting the snap t.

Release the terminal and move it slightly upwards. Now

the cable end can be taken out of the bracket:

Page 13

Page 13 of 29

© 2017 CommScope, Inc. All Rights Reserved

9.3. Pedestal mounting

Pedestal Mounting (at nal grade) – Pedestal enclosures

(examples shown below) may be used for mounting the

indexing terminal at ground level. Pedestal enclosures

consist of a base assembly and a top cover. The base

assembly mounts partly in the ground. Cables and

conduit enter the base assembly from the bottom.

7-INCH PROFORM

®

6- OR 8-INCH

CHANNELL

®

HAND-HOLE SWING

ARM MOUNT

#10 X 2 INCH

SCREWS,

WASHERS,

NUTS

HAND-HOLE

LEDGE MOUNT

#10 X 1 INCH

SELF TAPPING

SCREWS

HAND-HOLE

HANGER MOUNT

Page 14

Page 14 of 29

© 2017 CommScope, Inc. All Rights Reserved

An example to attach the UMB to the pedestal

infrastructure is shown below. Use local practice to mount

he UMB to the pedestal infrastructure.

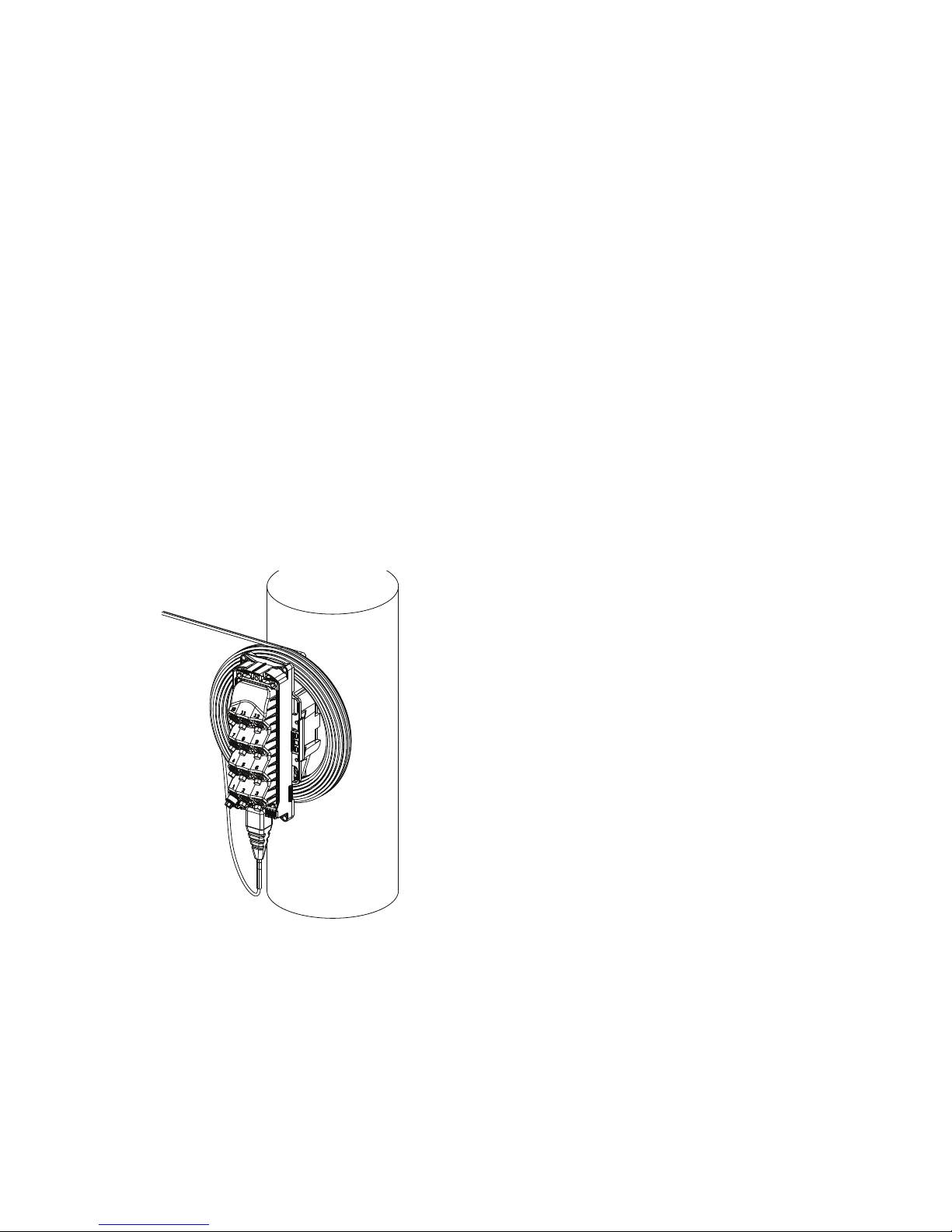

9.4. Pole-mounting

Pole-Mounting (aerial) – The indexing terminal may be

mounted on a utility pole. The UMB may be attached to

the pole with lag screws or construction screws.

Also metal straps can be used to mount the UMB to a

pole, for instance in case of a metal pole.

FLAT BRACKET MOUNT

#8-16 X 1/2 INCH

THREAD ROLLING

SCREWS FOR PLASTIC

CAPPED HOLES

METAL STRAPS

USE CENTER HOLES

WHEN SECURING UMB

WITH LAG SCREWS

1/4 X 1-1/2 INCH

LAG SCREWS

USE SIDE HOLES

WHEN SECURING

UMB WITH

CONSTRUCTION

SCREWS

#10 X 1 INCH SELF

TAPPING SCREWS

Page 15

Page 15 of 29

© 2017 CommScope, Inc. All Rights Reserved

Or alternatively, cable straps can be used to mount the

UMB to a strand

9.6. Installing the terminal in its UMB

After the UMB is mounted, install the indexing terminal in

the UMB as shown in Figure 11. Insert the cable end of

the terminal into the UMB rst and then push the front of

the terminal into the UMB until the latch snaps closed.

1

2

2. PUSH ON FRONT OF MST

UNTIL LATCH SNAPS SHUT

1. INSERT CABLE END OF

MST INTO THE UMB

9.5. Strand-mounting

Strand-mounting (aerial) – A strand-mount bracket kit is

available for aerial mounting the indexing terminal from

an overhead strand as shown. The brackets mount on the

UMB and are then clamped to the strand.

Refer to Universal Mounting bracket Strand-Mount

Installation Instruction ADCP-96-124 for the installation

procedure.

.

1/4-20

NYLON NUT

(2 PLACES)

10-24

NYLON NUT

(4 PLACES)

1/4-20 x 1-1/4 IN.

CARRIAGE BOLT

(2 PLACES)

10-24 x 1 IN.

CARRIAGE BOLT

(4 PLACES)

STRAND-MOUNTING THE UMB

USING Deltec® CABLE STRAPS

Page 16

Page 16 of 29

© 2017 CommScope, Inc. All Rights Reserved

10.3. HMFOC specications

HMFOC Intermateability:

Compatible with Corning Optitip®

HMFOC:

Per GR 3120 and

IEC 61753-1 Ed2 CAT G (hardened connector)

10.4. Connecting the HMFOC (making the

link installation)

Danger: Exposure to laser radiation can seriously

damage the retina of the eye. Do not look into the ends

of any optical ber. Do not assume the laser power is

turned-off or that the ber is disconnected at the other

end.

10.4.1. Remove dust caps

10.4.1.1. Field personnel must take care when proceed

to remove dust caps at the HFMOC at the adapter plugs

or cables, to prevent contaminant particles entering to the

adapters or connector end-face.

10.4.1.2. Before removing dust cap, be sure to turn the

terminal to a position where adapters are protected (i.e.

for aerial application, adapters will face down), helping

to prevent any particle/ dust to fall down and contaminate the adapter. Before removing the terminals optical

port dust cap, clean any debris from around the indexing

terminal optical ports, preferably using compressed air,

to minimize the risk of introducing contaminants into the

optical port.

10.4.1.3. Use the 216B key tool (accessory) to unscrew

the dust cap from the indexing terminal optical port. This

is the green port, indicated with a letter A or the blue port,

indicated with letter B.

10.4.1.4. For the cables, before taking out the dust cap,

take in consideration all possible precaution to prevent

any particle to contact the end-face connector and, keep

the terminal with the adapters facing down to insert and

tight the drop cable. Before removing the cable’s con-

nector dust cap, clean any debris from around the cable

connector housing, preferably using compressed air, to

minimize the risk of introducing contaminants onto the

ferrule.

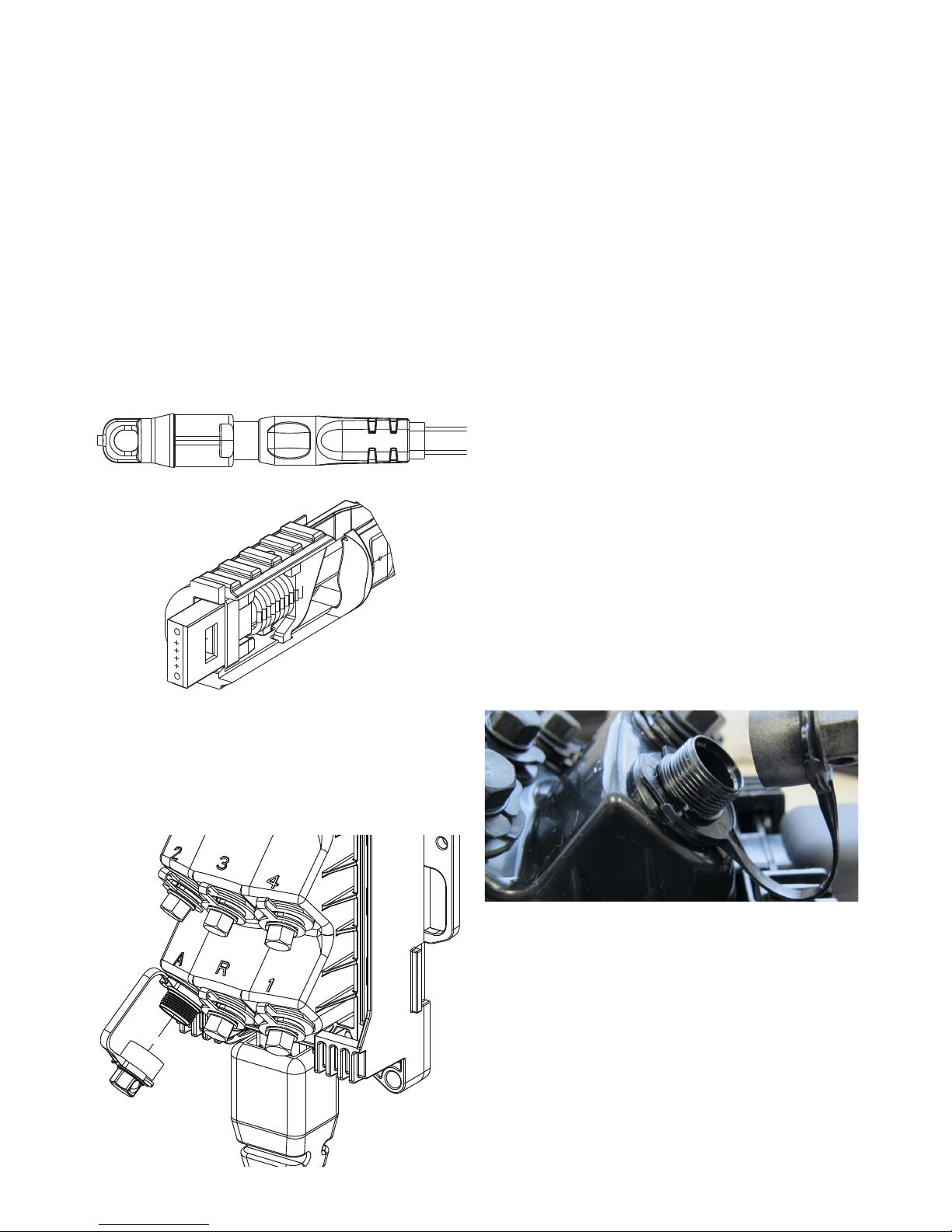

10. Link installation (HMFOC)

10.1. Connector components

The HMFOC connector at the end of the terminal’s tail

is a hardened 12 ber connector that can be used for

many applications. The primary application is to connect

indexing terminals in cascade or to connect an indexing

terminal to the Fiber Distribution Hub (FDH) or Closure, to

extend the distribution network.

The connector on the tail is the non-pinned female type.

The connector is protected by a dust cap. The O-ring on

the connector body provide a water tight seal when the

dust cap is in place. A pulling eye is provided in the end of

the dust cap for pulling the drop cable.

Do not exceed a pulling force of 444.8N (100 lbs) and

when connected, don’t exceed cable pull of 111.2 N

(25 lbs).

10.2. Adapter components

On the indexing terminal up to 2 ports are HMFOC

adapter ports, the green present on all the terminals and

the blue only present on the indexing branch terminal.

The connector inside the adapter is the pinned, male

type. It is a captured Multi-ber Push On (MPO)

connector.

Page 17

Page 17 of 29

© 2017 CommScope, Inc. All Rights Reserved

10.4.3.3. Thread the optical port dust cap into the drop

cable dust cap and tighten both dust caps nger tight.

This ensures that both dust caps will stay clean when not

in use.

10.5. Disconnecting the HMFOC

Danger: Exposure to laser radiation can seriously

damage the retina of the eye. Do not look into the ends

of any optical ber. Do not assume the laser power is

turned-off or that the ber is disconnected at the other

end.

10.5.1. Before removing the connector dust cap, clean

any debris from around the dust cap, preferably using

compressed air, to minimize the risk of contaminants be-

ing introduced onto the ferrule. Unscrew the optical port

dust cap from the drop cable dust cap.

10.5.2. Before removing the drop cable connector,

clean any debris from around the connector housing and

the terminal optical port, preferably using compressed air

to minimize contaminants from being introduce onto the

connector ferrule or into the optical port.

10.5.3. Unscrew the drop cable connector coupling nut

until the thread of the adapter port is completely free.

10.5.4. Grasp the connector and pull it straight out of

the adapter. The pull out force to remove the connector

should be minimum once the coupling nut is fully disengaged.

10.5.5. Uncouple the two dust caps.

10.5.6. Thread the optical port dust cap into the optical

port and tighten until nger tight.

10.5.7. Thread the drop cable connector coupling nut

into the drop cable dust cap and tighten until nger tight.

10.4.1.5. Unscrew the coupling nut from the cable

connector dust cap in the direction of the arrow.

10.4.2. HMFOC cleaning

Note: The connector and adapter come clean from the

factory and should not require additional cleaning before

the rst connection.

If cleaning is required before installing the connector,

follow procedure as described in section 14.1.

10.4.3. Install the connector

10.4.3.1. Find the alignment keys on the adapter port

(square notch in the thread area) and on the connector

(groove). And push the plug connector in the jack of the

adapter port until it seats.

10.4.3.2. Thread the cable connector’s coupling nut onto

the thread of the adapter port until it is nger tight.

Alignment indicator

(groove) on plug

Page 18

Page 18 of 29

© 2017 CommScope, Inc. All Rights Reserved

a standard SC connector using the DLX adapter (which

is the case in the indexing terminal drop adapter ports).

The connector design is based on standard SC single

mode ferrule and spring assembly in a miniature rugged

body. The connector is designed with a dual-locking

feature that includes a push-pull detent engagement and

twist-lock secure retention. The connector has a keying

feature to allow it to be fully seated in the adapter in only

one orientation, therefore, ensuring proper alignment and

mating of 8-degree APC ferrules.

The basic components of the drop cable connector

are shown in gure below. The connector coupling nut

threads onto the dust cap. The O-ring on the connector

body provide a water tight seal when the dust cap is in

place. A pulling eye is provided in the end of the dust cap

for pulling the drop cable.

Do not exceed a pulling force of 444.8N (100 lbs) and

when connected, don’t exceed cable pull of 111.2 N

(25 lbs).

DUST CAP

O-RING

COUPLING NUT

CONNECTOR

BODY

11. DLX connector installation

Indexing terminals with the DLX connector housing use

DLX technology to connect a subscriber to the drop

adapter ports (black dust cap) and to connect the reverse

feed (red dust cap).

CommScope DLX hardened connectors and adapters

provide sealed environmental protection for the

subscriber drop cable connector, SC connector, and

adapter mounted within the indexing terminal optical

port. The following sections provide a description of

the connector and adapter components and provide

instructions for connecting or disconnecting the drop

cable to/from the optical ports. Also a section describing

the cleaning procedures for both connector and adapter

is integrated.

11.1. Connector components

The DLX connector can be mated with any SC adapter

to provide a low loss optical connection. It can also mate

11.2. Adapter components

The DLX adapter on the DLX connector housing

(black and red port) is a heavy duty plastic case

environmentally sealed for extreme weather conditions.

One side of the adapter receives the hardened DLX

connector and the other side is designed to receive a

standard SC connector plug. The SC side of the adapter

provides a rugged stationary SC receptacle per standard

industry specications. The DLX adapter has an opening

designed specically to receive the DLX connector and

to provide a sealing surface for the connector O-ring.

The adapter’s inner body holds two retainers and a split

sleeve using snap latches and provides the plug with both

push-pull and twist-lock engagement. The inner body also

contains detent latch and alignment features that guide

and hold the DLX connector inside the adapter.

The basic components of a typical indexing terminal

optical port hardened adapter are shown in Figure below.

The dust cap threads into the adapter housing. An O-ring

on the dust cap provides a water tight seal when the dust

cap is in place. The 216B key tool is required to remove

the dust cap.

OPTICAL

ADAPTER PORT

DUST CAP

Page 19

Page 19 of 29

© 2017 CommScope, Inc. All Rights Reserved

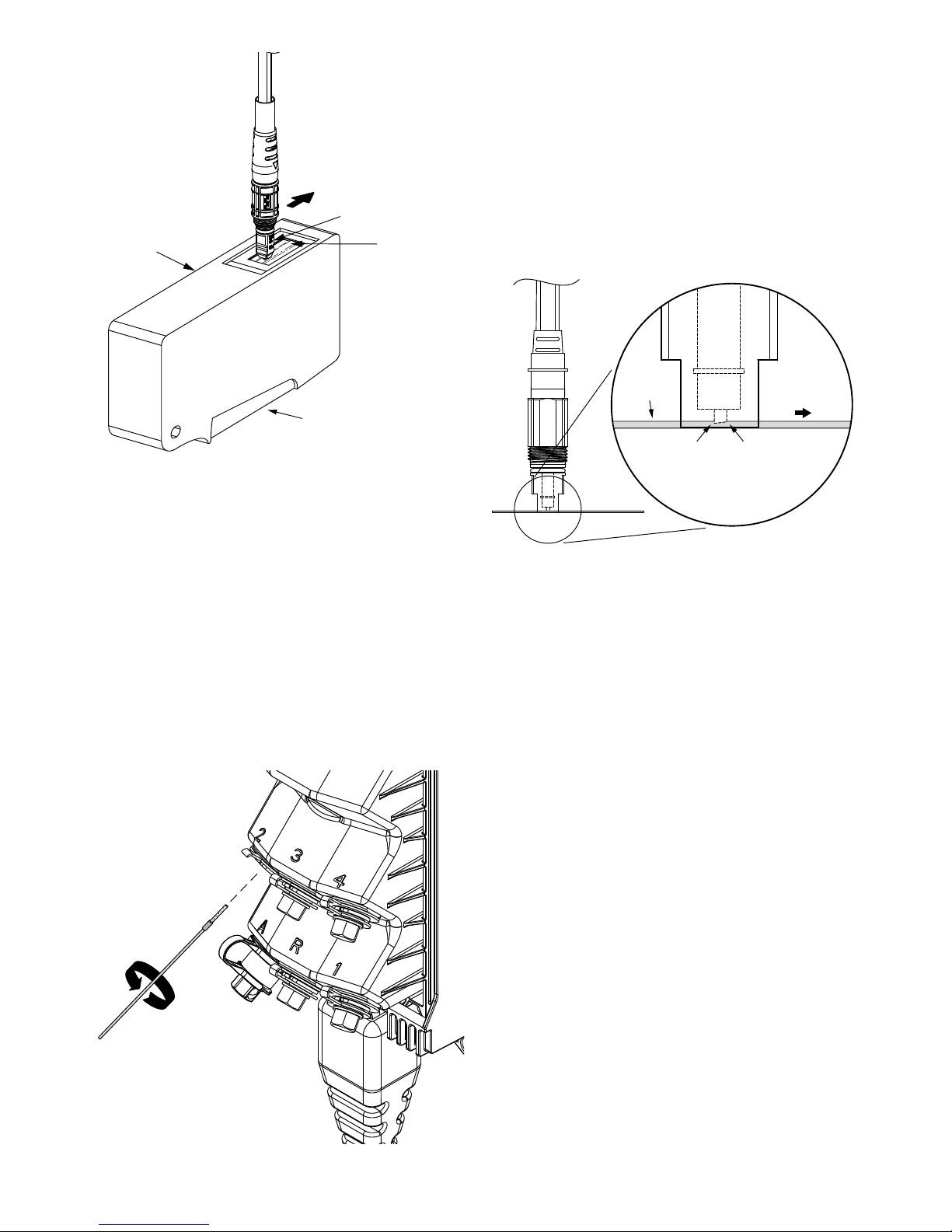

11.4. Connecting the drop cable to the

indexing terminal (DLX connector

housing) adapter port

Danger: Exposure to laser radiation can seriously

damage the retina of the eye. Do not look into the ends

of any optical ber. Do not assume the laser power is

turned-off or that the ber is disconnected at the other

end.

11.4.1. Remove dust cap

11.4.1.1. Field personnel must take care when proceed

to remove dust caps at the DLX at the adapter plugs or

cables, to prevent contaminant particles entering to the

adapters or connector end-face.

11.4.1.2. Before removing dust cap, be sure to turn the

terminal to a position where adapters are protected (i.e.

for aerial application, adapters will face down), helping

to prevent any particle/ dust to fall down and contaminate the adapter. Before removing the terminals optical

port dust cap, clean any debris from around the indexing

terminal optical ports, preferably using compressed air,

to minimize the risk of introducing contaminants into the

optical port.

11.4.1.3. Use the 216B key tool (accessory) to unscrew

the dust cap from the indexing terminal drop port: one of

the black ports with number 1 to 8 or the red port (reverse

feed).

11.4.1.4. For the cables, before taking out the dust cap,

take in consideration all possible precaution to prevent

any particle to contact the end-face connector and, keep

the terminal with the adapters facing down to insert and

tight the drop cable. Before removing the cable’s con-

nector dust cap, clean any debris from around the cable

connector housing, preferably using compressed air, to

minimize the risk of introducing contaminants onto the

ferrule.

11.4.1.5. Unscrew the coupling nut from the drop cable

connector dust cap. (See gure on pg 18).

11.3. DLX specications

Designed to GR-326 generic requirements for SM optical

connector.

Designed to GR-3120 / IEC 61753-1 Ed2 Category G

generic performance requirements for hardened ber

connector.

TIA EIA 604-3a / IEC 61754-4 and IEC 61755-3-2 optic

connector intermateability standard type SC.

GR-20 / IEC 60794-3-10 generic requirements for single

mode ber optic cables.

Minimum Hole Size for Connector: 15.88 mm (0.625 inch)

Latching: Keyed alignment dual latching, push-pull

detent, twist-lock secure long term connection.

Physical Contact: Angled Polished Contact (APC),

standard 8-degree angle

Retention Force: 444.8 N (100 lbs)

Cable pull when connected: 111.2N (25 lbs)

Page 20

Page 20 of 29

© 2017 CommScope, Inc. All Rights Reserved

11.5. Disconnecting the drop cable from

the indexing terminal (DLX connector

housing) adapter port

Danger: Exposure to laser radiation can seriously

damage the retina of the eye. Do not look into the ends

of any optical ber. Do not assume the laser power is

turned-off or that the ber is disconnected at the other

end.

11.5.1. Before removing the connector dust cap, clean

any debris from around the dust cap, preferably using

compressed air, to minimize contaminants from being

introduced onto the ferrule. Unscrew the optical port dust

cap from the drop cable dust cap.

11.5.2. Before removing the drop cable connector,

clean any debris from around the connector housing and

the terminal optical port, preferably using compressed air

to minimize contaminants from being introduce onto the

connector ferrule or into the optical port.

11.5.3. Unscrew the drop cable connector coupling nut

until the thread of the adapter port is completely free.

11.5.4. Grasp the connector and pull it straight out of

the adapter. 5 Lbs. of force or less is required to extract

the connector.

11.5.5. Uncouple the two dust caps. Thread the optical

port dust cap into the optical port and tighten until nger

tight. Thread the drop cable connector coupling nut into

the drop cable dust cap and tighten until nger tight.

11.4.2. DLX cleaning

Note: The connector and adapter come clean from the

factory and should not require additional cleaning before

the rst connection.

If cleaning is required before installing the connector,

follow procedure as described in section 14.2.

11.4.3. Install the connector

11.4.3.1. Align the drop cable connector with the optical

port as shown in Figure below. The protrusions on the

drop cable connector should line up with the arrow on the

optical port.

11.4.3.2. Insert the drop cable connector into the optical

port until it slides freely into place and latches.

11.4.3.3. Thread the drop cable connector coupling nut

into the optical port and tighten coupling nut until nger

tight.

11.4.3.4. Thread the optical port dust cap into the drop

cable dust cap as shown below and then tighten both

dust caps nger tight. This ensures that both dust caps

will stay clean when not in use.

OPTICAL PORT

DUST CAP

DROP CABLE

DUST CAP

COUPLING

NUT

NOTE: ORIENT CONNECTOR

SO ARROW IS ALIGNED

WITH PROTRUSIONS.

ARROW

PROTRUSIONS

Page 21

Page 21 of 29

© 2017 CommScope, Inc. All Rights Reserved

12.1. Connector components

The basic components of the drop cable connector are

shown in Figure below. The dust cap threads onto the

connector coupling nut. A pair of O-rings on the connector

body provide a tight seal when the dust cap is in place.

A pulling eye is provided in the end of the dust cap for

pulling the drop cable through conduit.

Do not exceed a pulling force of 444.8N (100 lbs) and

when connected, don’t exceed cable pull of 111.2 N

(25 lbs).

DUST CAP

O-RINGS

COUPLING NUT

CONNECTOR

BODY

12. Full size hardened connector

installation

Indexing terminals with the full size hardened connector

housing use full size hardened connector technology to

connect a subscriber to the drop adapter ports (black dust

cap) and to connect the reverse feed (red dust cap).

CommScope full size hardened connectors and

adapters provide sealed environmental protection for

the subscriber drop cable connector and the SC adapter

mounted within the full size hardened connector housing

optical adapter port. The following sections provide a

description of the connector and adapter components

and provide instructions for connecting or disconnecting

the drop cable to/from the optical ports. Also a section

describing the cleaning procedures for both connector

and adapter is integrated.

12.2. Adapter components

The basic components of the optical port hardened

adapter (black and red dust cap) on the full size hardened

connector housing are shown in the Figure to the right.

The dust cap threads into the adapter housing. An O-ring

on the dust cap provides a tight seal when the dust cap is

in place. The 216B key tool is required to remove the dust

cap.

12.3. Full size hardened connector

specications

Designed to GR-3120 / IEC 61753-1 Ed2 Category G

generic performance requirements for hardened ber

connector.

GR-20 / IEC 60794-3-10 generic requirements for single

mode ber optic cables.

Latching: Twist-lock secure long term connection.

Physical Contact: Angled Polished Contact (APC),

standard 8-degree angle

Retention Force: 444.8 N (100 lbs)

Cable pull when connected: 111.2N (25 lbs)

Page 22

Page 22 of 29

© 2017 CommScope, Inc. All Rights Reserved

12.4. Connecting the drop cable to the

indexing terminal (full size

hardened connector housing)

adapter port

Danger: Exposure to laser radiation can seriously

damage the retina of the eye. Do not look into the ends

of any optical ber. Do not assume the laser power is

turned-off or that the ber is disconnected at the other

end.

12.4.1. Remove dust cap

12.4.1.1. Field personnel must take care when proceed

to remove dust caps at the Full size hardened connector

at the adapter plugs or cables, to prevent contaminant

particles entering to the adapters or connector end-face.

12.4.1.2. Before removing dust cap, be sure to turn the

terminal to a position where adapters are protected (i.e.

for aerial application, adapters will face down), helping to

prevent any particle/ dust to fall down and contaminate

the adapter. Before removing the connector dust cap,

clean any debris from around the drop cable connector

housing, preferably using compressed air, to minimize

contaminants from being introduced onto the ferrule.

12.4.1.3. Use the 216B key tool (accessory) to unscrew

the dust cap from the indexing terminal drop port: one of

the black ports with number 1 to 8 or the red port (reverse

feed).

12.4.1.4. For the cables, before taking out the dust cap,

take in consideration all possible precaution to prevent

any particle to contact the end-face connector and, keep

the terminal with the adapters facing down to insert and

tight the drop cable. Before removing the cable’s con-

nector dust cap, clean any debris from around the cable

connector housing, preferably using compressed air, to

minimize the risk of introducing contaminants onto the

ferrule.

12.4.1.5. Unscrew the coupling nut from the drop cable

connector dust cap.

12.4.2. Full size hardened connector cleaning

Note: The connector and adapter come clean from the

factory and should not require additional cleaning before

the rst connection.

If cleaning is required before installing the connector,

follow procedure as described in section 14.3.

12.4.3. Install the connector

12.4.3.1. Inspect the optical port dust cap O-ring and

the drop cable connector O-rings for dryness and apply

O-ring lubricant (MST-ACC-LUBE1) to the O-ring if dry.

Refer to Section 12.6 for the procedure.

Note: The optical port dust cap O-ring and the connec-

tor O-ring is pre-lubricated by the factory and should not

require additional lubrication for the initial assembly.

12.4.3.2. Align the drop cable connector with the optical

port. The pointer on the drop cable connector should line

up with the notch on the optical port.

12.4.3.3. Insert the drop cable connector into the optical

port. If the drop cable connector does not insert all the

way to the bottom of the port, rotate drop cable connector

slightly to either side until it slides freely into place.

12.4.3.4. Thread the drop cable connector coupling nut

into the optical port and tighten coupling nut until nger

tight.

ORIENT CONNECTOR

SO ARROW IS ALIGNED

WITH NOTCH

COUPLING

NUT

Page 23

Page 23 of 29

© 2017 CommScope, Inc. All Rights Reserved

13. Testing

Testing ber indexing terminals is dependent on many

factors including the architecture of its end user. This

chapter will address a variety of methods suitable to test

a lead prior to and after it is in service.

The reader should consider some terminology within like;

“Lead” refers to a single chain of terminals.

“Upstream” refers to a position closer to the CO or head

end or the direction light would be owing from a piece of

equipment.

“Downstream” refers to a position closer to the end of a

lead or the direction light would be owing from a piece of

test equipment.

Indexing chains always start with terminal one and build

outward in procession to a value no greater than twelve.

Indexing chains always provide the next ber to the

next terminal (i.e. Terminal 1 will use ber 1 within the

“chained” assembly ).

Note: Branching terminals can offset a sequence but do

not interfere with the indexing process in given “chains”.

13.1. Conformance Testing

13.1.1. Testing with VFL – (Recommended)

Testing with “light” owing down stream is the simplest

way to verify lead continuity as it only requires a dust cap

removal on the far end to verify all links are connected.

SAFETY NOTE: Laser driven VFL’s are powerful and

should not be looked a directly to evaluate beam. Use

caution when searching for light with you naked eye and

maintain a safe distance. Refer to VFL documentation for

safe defused viewing distance.

13.1.1.1. Lead Continuity

• From an upstream position like an FDH, place your

VFL on the 12th ber* of the lead you are testing.

• At the last terminal in the lead, remove the green

HMFOC dust cap and look for red light. If no light,

remove any black dust cap and look for red light**. If

no light still, the chain is “open”.

* 12th ber continuity testing relies on all bers being spliced or

connected prior to the rst terminal.

** Applies to twelfth link in chain

12.4.3.5. Thread the optical port dust cap into the drop

cable dust cap as shown below and then tighten both

dust caps nger tight. This ensures that both dust caps

will stay clean when not in use.

12.5. Disconnecting the drop cable from

the indexing terminal (full size

hardened connector housing)

adapter port

Danger: Exposure to laser radiation can seriously

damage the retina of the eye. Do not look into the ends

of any optical ber. Do not assume the laser power is

turned-off or that the ber is disconnected at the other

end.

12.5.1. Unscrew the optical port dust cap from the drop

cable dust cap.

12.5.2. Unscrew the drop cable connector coupling nut

from the optical port and pull the connector straight out

the adapter.

12.5.3. Inspect the optical port dust cap O-ring for

dryness and apply O-ring lubricant (MST-ACC-LUBE1)

to the O-ring if dry. Refer to Section 12.6 for the required

procedure.

12.5.4. Thread the optical port dust cap into the optical

port and tighten using the 216B key tool.

12.5.5. Inspect the drop cable connector O-rings for

dryness and apply O-ring lubricant (MST-ACC-LUBE1) to

each O-ring if dry. Refer to Section 12.6 for the required

procedure.

12.5.6. Thread the drop cable dust cap onto the drop

cable connector coupling nut and tighten until nger tight.

12.6. Applying O-ring lubricant

The O-rings used on the hardened connector and on

the optical port dust cap are lubricated when shipped

from the factory to prevent damage during installation.

If the O-rings become excessively dry, they may require

additional lubrication to prevent damage. Remove the

O-rings from the connector or dust cap and apply a small

amount of lubricant directly to each ring. Then reinstall

the O-rings on the connector or dust cap. Apply only the

recommended O-ring lubricant (MST-ACC-LUBE1).

Note: Excessive lubricant on the o-ring may cause

contamination of ber endface.

DROP CABLE

DUST CAP

OPTICAL PORT

DUST CAP

Page 24

Page 24 of 29

© 2017 CommScope, Inc. All Rights Reserved

13.1.2.3. Terminal Performance

• From an upstream position like an FDH or CO, attach

one of the test units to the ber associated with the

terminal you are testing.

• At the target terminal, connect the other test unit

to each black dust cap port and take readings.

Readings across all ports should be similar.

13.1.3. Testing with an OTDR

13.1.3.1. Lead continuity

From an upstream position like a CO or FDH, attach the

OTDR test lead to a ber associated with the last terminal

in the lead you are wanting to test. Ideally this would

be a ber without a splitter. Attach a reective device

like a hybrid patch cord to the same ber at the far end.

Conrm reection, move to next lead.

13.1.3.2. Terminal continuity

From an upstream position like a CO or FDH, attach the

OTDR test lead to a ber associated with the terminal

in the lead you are wanting to test. Ideally this would

be a ber without a splitter. Attach a reective device

like a hybrid patch cord to the same ber at the far end.

Conrm reection, move to next lead.

13.1.3.3. Terminal performance

At the terminal location test all single ber connectors,

record trace(s). Caps sharing same color code should

share same characteristics. QR code can be used to

access terminal data.

13.1.3.4. Upstream Testing with IOLM

OTDR’s must look upstream to see beyond splitters

properly. They must have a dynamic range sufcient to

register multiple cascading events. OTDR’s with IOLM

software are specialized to distinguish splitter type,

mechanical connections, and fusion splices. Use a

known reective event like that of a hybrid SC/APC to

SC/UPC launch box to conrm the end-of ber/far end

test point.

• Connect a qualied OTDR to any port on the target

terminal.

• Connect a reective event upstream to the ber

associated with the targeted terminal record test

readings.

If the rst terminal or “chain” link is known to be good

you can use the reverse port on the rst terminal to test

continuity for the remainder of the lead as follows:

• Connect VFL to reverse port on rst terminal

• At the last terminal in the chain, remove the green

HMFOC dust cap and look for red light. If no light, the

chain is “open”.

13.1.1.2. Terminal Continuity

Terminal continuity is ber specic.

• Attach VFL on target ber.

• Look for red light at work order dened end point.

Black dust cap adapters on a given terminal associate to

the same single ber up stream.

13.1.2. Testing with a power meter

As with the VFL continuity test, Power Meters (master/

satellite) can be attached in a similar way depending on

the architecture of the deployment. Generally this means

connecting one test unit at an upstream location like a

hub or CO and the other test unit to the last terminal in

the lead being tested. Power Meter testing will require

FDH compatible test cords, DLX test cord or Full size

TEST CORD, and possibly an HMFOC test cord or other

assembly (FST) if testing via the “multi-ber ports”.

13.1.2.1. Lead Continuity

• From an upstream position like an FDH or CO,

attach one of the test units to the target ber in the

lead you are testing. The target ber should be the

ber assigned to the last terminal in the lead you are

testing.

• At the last terminal in the lead, connect the other test

unit to any black dust cap DLX/full size hardened port

and take readings.

13.1.2.2. Terminal Continuity

• From an upstream position like an FDH or CO, attach

one of the test units to the ber associated with the

terminal you are wanting to test.

• At the target terminal, connect the other test unit to

any black dust cap and take readings. If any ports

show light, continuity is conrmed.

Page 25

Page 25 of 29

© 2017 CommScope, Inc. All Rights Reserved

13.2.4. Cable testing

Injecting red light into the black capped port(s) when the

terminal tail HMFOC connector is plugged back into itself

via the green capped HMFOC on the body, will allow red

light to travel through all ber in the assembly to the red

capped reverse port.

Using an OTDR in this fashion will allow the technician to

see through all ber and connections of the cable

assembly in one trace (best results when connected to

the reverse port).

13.2.5. Splitter Performance

Splitter performance can only be tested as part of the

terminal assembly. It will be a combination of splitter loss,

connector losses (2), and an integral splice. All black

dust cap ports on a terminal* shall have similar readings

in relation to their shared input ber. See loss tables.

* Index only terminals are excluded as they do not have built in splitters.

13.3. Trouble Shooting

13.3.1. Decision making

• Start at the ONT and work upstream.

• Conrm adjacent ports on terminals are experiencing

same trouble.

• Determine status of adjacent terminals

• Understand the cable leads and their counts.

• Do not disconnect multi ber connectors until you can

physically see its other end or damage.

13.2. Bench Testing

13.2.1. Primary port verication

Injecting red light into black dust cap service ports will

disperse red light in the female (non-pinned) HMFOC

connector on the tail of the terminals.

13.2.2. Reverse port verication

Injecting red light into red cap reverse ports will disperse

red light in the male (pinned) HMFOC connector on the

body of the terminal body.

13.2.3. Branching port verication

Injecting red light into the blue cap HMFOC port will

disperse red light in the female (non-pinned) HMFOC

connector on the terminal tail.

Page 26

Page 26 of 29

© 2017 CommScope, Inc. All Rights Reserved

13.5.3. Indexing terminal Insertion loss

13.5.3.1. Optical Performance

Splitter Congurations 1x4 1x8

Max Loss*: 7.2 dB 10.2 dB

Typical Loss*: 6.6 dB 9.7 dB

Uniformity: 0.8 dB 1.0 dB

Return Loss: ≥55 dB ≥55 dB

Directivity: ≥60 dB ≥60 dB

PDL: 0.2 dB 0.2 dB

Wavelength Range: 1260-1635 nm 1260-1635 nm

* Includes PDL and WDL. Does not include connector loss

13.5.3.2. Connector

Insertion Loss: < 0.4 dB

13.5.3.3. Cable

Attenuation: 1310 nm = 0.40 dB/km max

1550 nm = 0.30 dB/km max

Compliance: Meets GR-771 generic requirements for

Fiber Splice Closures

13.3.2. Loss expectations

Insertion loss and ORL values are recorded and included

with each indexing terminal. Refer to these for “chain”

performance expectation.

13.3.3. Cleaning

Refer to section 14.1 HMFOC cleaning

13.4. Restoral

13.4.1. Spare parts

Areas deploying ber indexing terminals should consider

stocking a couple spare terminals for tear downs and digups. All four port indexing terminals are interchangeable

so stock a length that will cover your needs. Likewise, all

eight port indexing terminals are interchangeable. Index

only terminals are ber specic but interchangeable in

relation to ber count. As an example, if you have a 2f

indexing terminal it will interchange with all 2f terminals.

13.4.2. Splicing

Indexing terminals use 12f stranded at drop. No special

splicing requirements. Suggest using GATOR splice

closure, FDSC-GATOR-12F-T.

13.5. Appendix

13.5.1. HMFOC Fiber map

ABS (n-13)= position of rst reverse ber in HMFOC

n=terminal position in the chain

13.5.2. Loss Table - MONTE-CARLO

Page 27

Page 27 of 29

© 2017 CommScope, Inc. All Rights Reserved

14.2. Cleaning DLX connector and adapter

14.2.1. DLX connector cleaning

14.2.1.1. Clean both the optical port adapter and the

drop cable connector (requires accessory kit FHD-ACCCLNKIT1) as specied in ADCP-96-163.

14.2.1.2. Examine the end of the drop cable connector,

note the position of the protrusions on the connector.

14.2.1.3. Locate the cleaning tape cassette that is

provided with the cleaning kit.

14.2.1.4. Open the tape shutter by squeezing the lever

on the underside of the cassette and then keep the shutter open by continuing to squeeze the lever.

14.2.1.5. Hold connector facing you with the protrusions

perpendicular to the length of the cleaning cassette, tilt

the connector to the right (no more than 8-degrees) this

places the connector in the correct position for cleaning.

Note: The drop cable connector uses angled SC type

connectors. Make sure the connector end-face is point-

ing in the correct direction before starting the cleaning

motion.

14.2.1.6. With light pressure, slide the connector end-