Page 1

22673-A

Fiber Distribution Hub

FDH 3000

288 Cabinet With Splicing

User Manual

ADCP-96-139

Rev B, July 2017

www.commscope.com

ADC-96-139 Rev B

Page 2

ADCP-96-139 • Rev B • July 2017 • Preface

COPYRIGHT

© 2017, CommScope Inc.

All Rights Reserved

REVISION HISTORY

ISSUE DATE REASON FOR CHANGE

1 3/2008 Original.

B July 2017 Updated to CommScope format.

TRADEMARK INFORMATION

CommScope, CommScope(logo), and NG4access are registered trademarks of CommScope, Inc.

ADC and ADC Telecommunications are registered trademarks of CommScope, Inc.

Telcordia is a registered trademark of Telcordia Technologies, Inc.

GORE is a registered trademark of W. L. Gore & Associates, Inc.

DISCLAIMER OF LIABILITY

Contents herein are current as of the date of publication. CommScope reserves the right to change the contents without prior notice.

In no event shall CommScope Inc. be liable for any damages resulting from loss of data, loss of use, or loss of profits and

CommScope Inc. further disclaims any and all liability for indirect, incidental, special, consequential or other similar

damages. This disclaimer of liability applies to all products, publications and services during and after the warranty period.

This publication may be verified at any ti me by con tacting CommSc ope’s Technical Assistance Center at 1.800.830.5056, or by email to TAC.Americas@commscope.com.

Page ii

Page 3

ABOUT THIS MANUAL

This publication describes the OmniReach FDH 3000 288 cabinet with splicing. Also included

are procedures for mounting the cabinet, installing and splicing feeder and distribution cables,

installing additional splitter modules, installing additional distribution panels, storing the

splitter output fibers, connecting the splitter output fibers to the distribution fibers, and

replacing damaged components.

RELATED PUBLICATIONS

Listed below are related manuals and their publication numbers. Copies of these publications

can be ordered on the CommScope website at the following URL:

http://www.commscope.com/SupportCenter

Title ADCP Number

Optical Fiber Connector Wet and Dry Cleaning Instructions 90-159

Plug And Play Splitter Installation Guide 96-087

ADCP-96-139 • Rev B • July 2017 • Preface

Round Splice Tray Cable Routing Instructions 90-321

Breakout and Moisture Blocking Kit for Dielectric Uni-Tube Cable Instructions 93-064

Breakout and Moisture Blocking Kit for Armored Uni-Tube Cable Instructions 93-039

ADMONISHMENTS

Important safety admonishments are used throughout this manual to warn of possible hazards to

persons or equipment. An admonishment identifies a possible hazard and then explains what

may happen if the hazard is not avoided. The admonishments — in the form of Dangers,

Warnings, and Cautions — must be followed at all times. These warnings are flagged by use of

the triangular alert icon (seen below) and are listed in descending order of severity of injury or

damage and likelihood of occurrence.

Danger: Danger is used to indicate the presence of a hazard that will cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Warning: Warning is used to indicate the presence of a hazard that can cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that will or can cause minor

personal injury or property damage if the hazard is not avoided.

© 2017, ADC Telecommunications, Inc.

Page iii

Page 4

ADCP-96-139 • Issue A • June 2001 • Preface

GENERAL SAFETY PRECAUTIONS

Warning: Wet conditions increase the potential for receiving an electrical shock when

installing or using electrically-powered equipment. To prevent electrical shock, never install or

use electrical equipment in a wet location or during a lightning storm.

Danger: Do not look into the ends of any optical fiber. Exposure to laser radiation may result.

Do not assume the laser power is turned-off or that the fiber is disconnected at the other end.

Danger: Use adequate lifting equipment when moving or installing Fiber Distribution Hub

cabinets. Verify that the maximum lift weight rating of the equipment is sufficient to handle the

weight of the cabinet.

Danger: Do not stand under a Fiber Distribution Hub cabinet as it is being hoisted into

position for mounting. A failure of the lifting equipment or apparatus could result in serious

personal injury and cause significant damage to the cabinet.

Warning: Before digging, check with all local utilities for the presence of buried cables or

pipes. Contact with underground cables or pipes, especially electric power cables and gas

service lines, could interrupt local utility service and cause serious personal injury and

extensive property damage.

STANDARDS CERTIFICATION

Telcordia: This equipment complies with the applicable sections of GR-3125-CORE

LIST OF ACRONYMS AND ABBREVIATIONS

The acronyms and abbreviations used in this manual are detailed in the following list:

AWG American Wire Gauge

C Centigrade

F Fahrenheit

FDH Fiber Distribution Hub

FMS Mounting Sleeve

FTTP Fiber To The Premises

OSP Outside Plant

PMF Pad Mount Frame

PNP Plug and Play

Page iv

© 2017, ADC Telecommunications, Inc.

Page 5

TABLE OF CONTENTS

Content Page

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Admonishments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

General Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

Standards Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

List of Acronyms and Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

1 DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 General Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Main Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Specifications and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 BEFORE STARTING THE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Unpacking and Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Cabinet Installation Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 OSP Cable and Cabinet Grounding Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5 Tools and Materials Required for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.6 Cabinet Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 MOUNTING THE CABINET ON A MOUNTING SLEEVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Installation Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Excavation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Placement of the FMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Cable Conduit Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.5 Grounding System Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.6 Back Fill. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.7 Mounting the Cabinet on the FMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.8 Grounding Wire Connection To Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 MOUNTING THE CABINET ON A CONCRETE PAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1 Installation Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2 Base Construction and Conduit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3 Concrete Pad Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.4 Grounding System Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.5 Mounting the Cabinet on the Concrete Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.6 Grounding Wire Connection To Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5 FEEDER CABLE INSTALLATION AND SPLICING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.1 Cable Bracket Cover Removal/Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2 Feeder Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3 Grounding the Feeder Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.4 Splicing the Feeder Cable Fibers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6 DISTRIBUTION CABLE INSTALLATION AND SPLICING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1 Distribution Cable Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2 Grounding the Distribution Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

ADCP-96-139 • Rev B • July 2017 • Preface

© 2017, ADC Telecommunications, Inc.

Page v

Page 6

ADCP-96-139 • Rev B • July 2017 • Preface

TABLE OF CONTENTS

Content Page

6.3 Splicing the Distribution Cable Fibers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7 PLUG AND PLAYER SPLITTER MODULE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8 ROUTING AND CONNECTING THE SPLITTER OUTPUT FIBERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.1 Storing The Splitter Output Fibers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.2 Enabling Service To a Subscriber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9 PASS-THROUGH ROUTING PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.1 Sliding Adapter Pack Pass-Through Routing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.2 Splitter Compartment Pass-Through Routing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

10 MAINTENANCE AND REPAIR PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.1 Painting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.2 Distribution Panel Adapter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.3 Splitter Compartment Adapter Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

10.4 Replacing a Damaged Fiber or Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

10.4.1 Splitter Output Fiber Connector Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

10.5 Door Gasket Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

10.6 Door Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

10.7 Grounding System Terminal Access Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

11 CUSTOMER INFORMATION AND ASSISTANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Page vi

© 2017, ADC Telecommunications, Inc.

Page 7

1 DESCRIPTION

22673-A

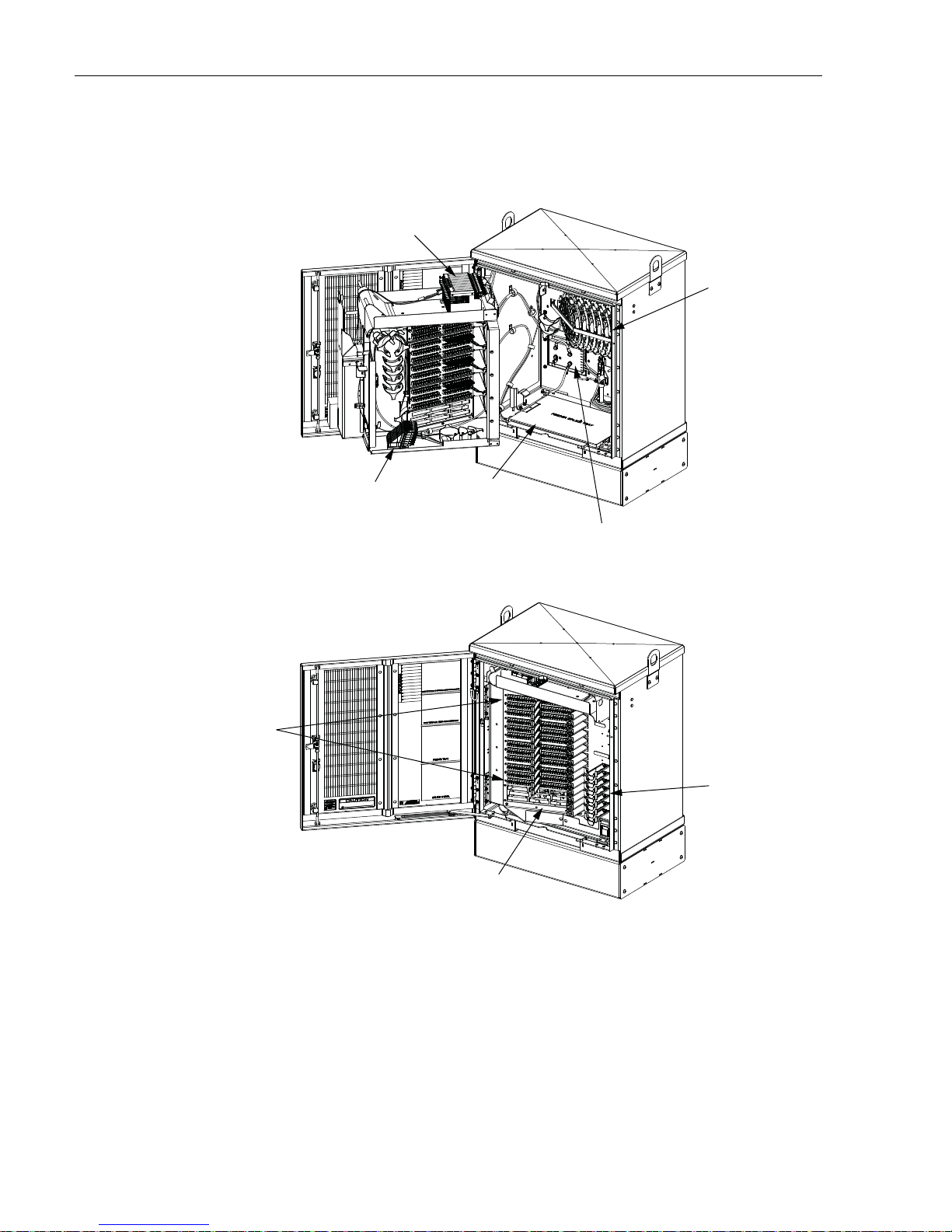

1.1 General Description

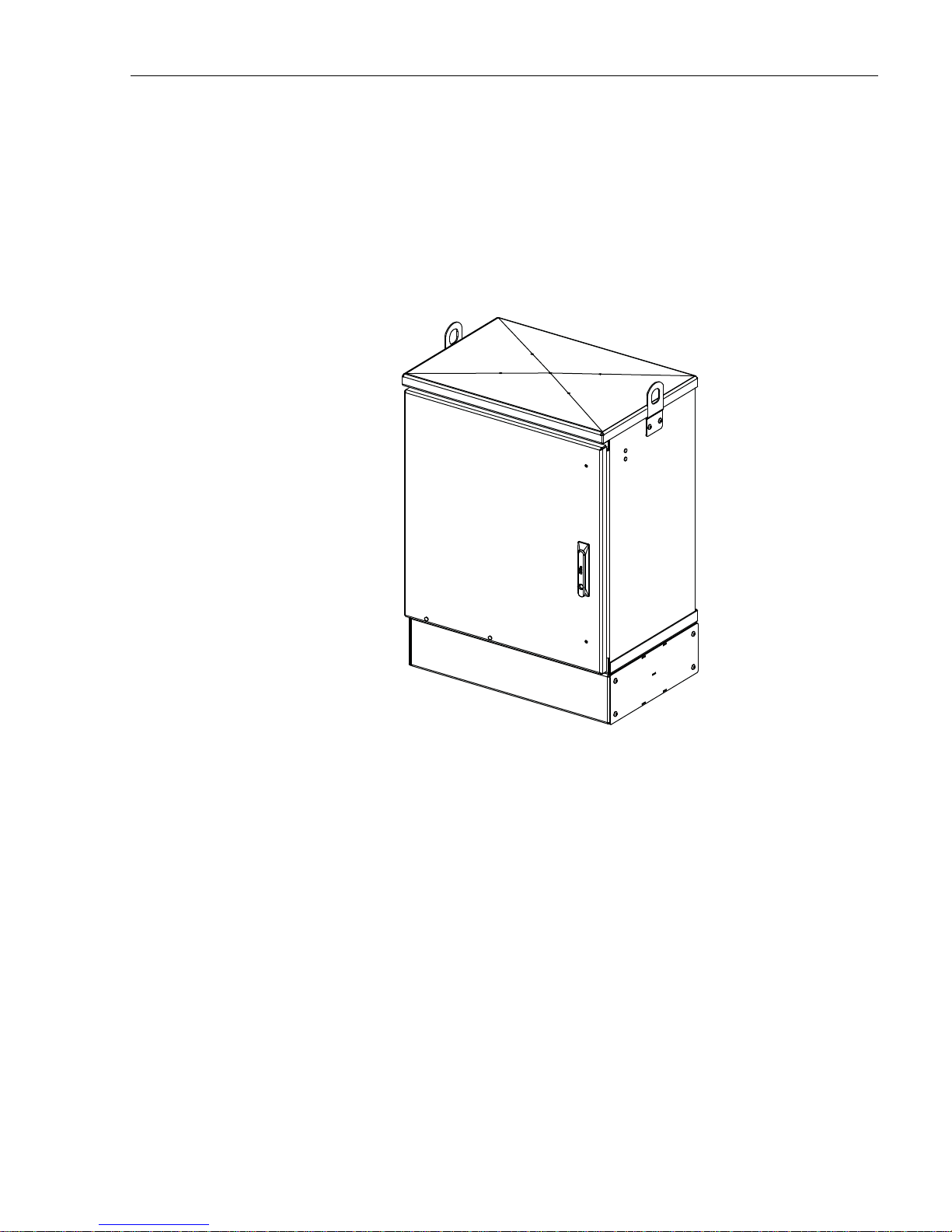

The 288 cabinet with splicing is a secure, above-ground, outdoor fiber optic distribution cabinet

that is designed to hold the various optical components required for Fiber To The Premises

(FTTP) distribution network applications. The cabinet is designed for pedestal-mount

applications. Figure 1 shows a typical cabinet.

ADCP-96-139 • Rev B • July 2017

Figure 1. Typical Cabinet

The cabinet may be mounted on a concrete pad or on a mounting sleeve. Mounting kits

(accessories) are available for each mounting option. The feeder and distribution cables

(stranded cable only) enter/exit the cabinet from the bottom.

Clamps are provided for securing the cables to the inside of the cabinet. The bottom of the

cabinet is enclosed with a moisture barrier. The cable entry/exit hole is fitted with a flexible

membrane to resist the entry of dust, moisture, and insects. GORE membrane vents are

provided to release any moisture that may accumulate within the cabinet.

The exterior shell of the cabinet is constructed of heavy gauge aluminum and is coated with an

almond-colored finish. Each cabinet is equipped with a single front door equipped with a

tamper-resistant latch, padlock hasp, stainless steel hinges, and door catches that prevent

accidental closing. Access to the cabinet requires a

216B key tool (accessory) to release the latch

handle. Lifting eyes are provided for hoisting the cabinet into position for mounting. Each

cabinet is equipped with a 6-inch ground spacer/riser for extra ground clearance. An additional

spacer/riser (accessory item) can be installed if even more ground clearance is required.

© 2017, ADC Telecommunications, Inc.

Page 1

Page 8

ADCP-96-139 • Rev B • July 2017

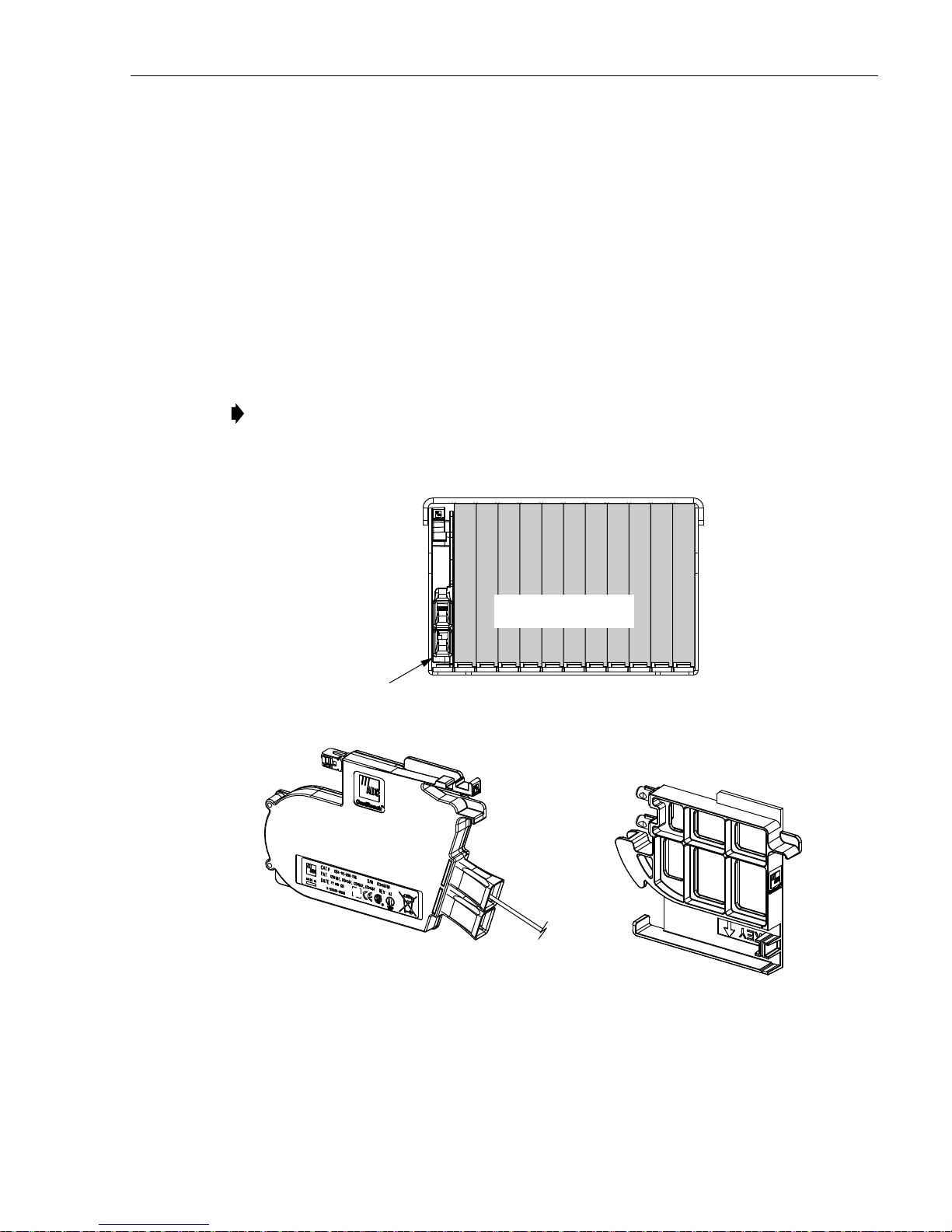

1.2 Main Components

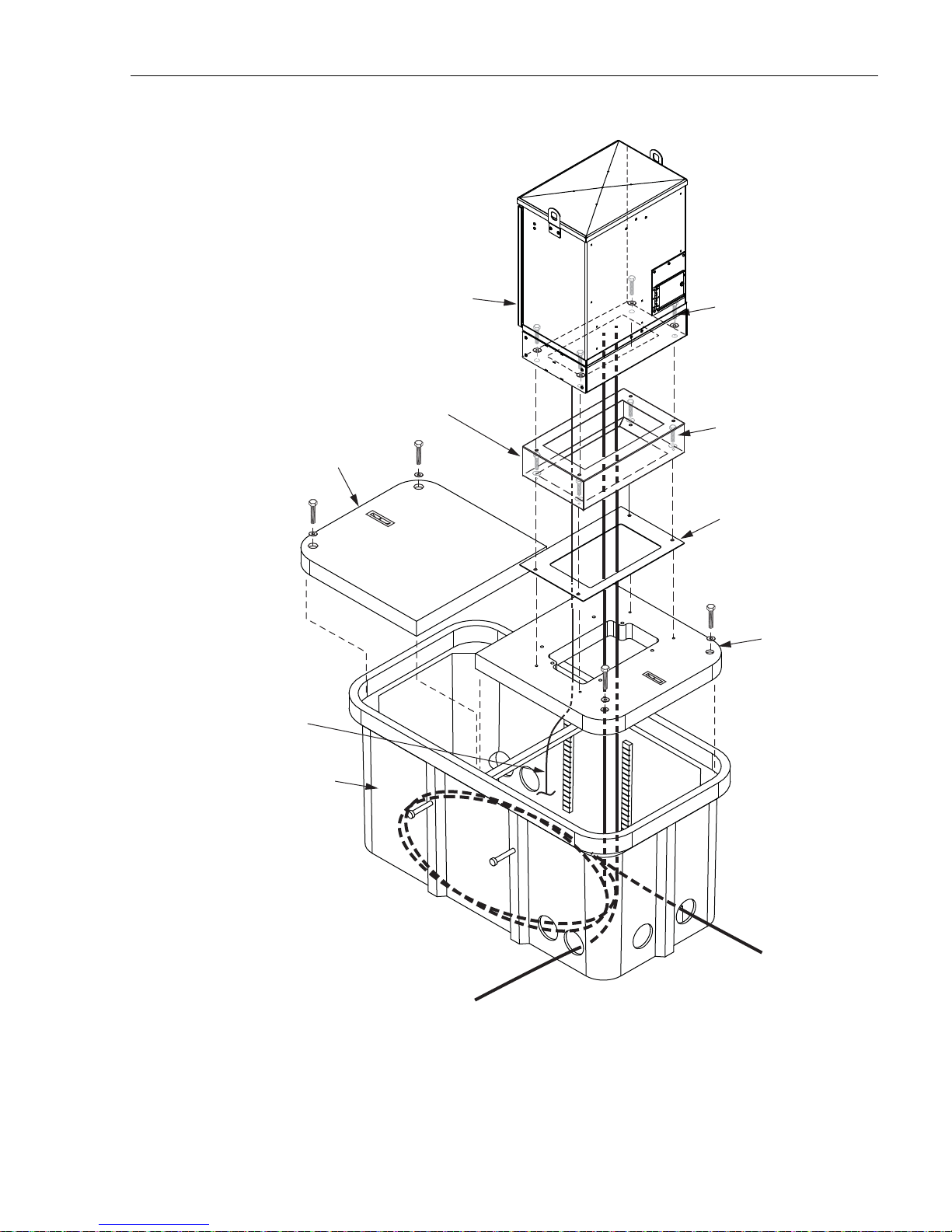

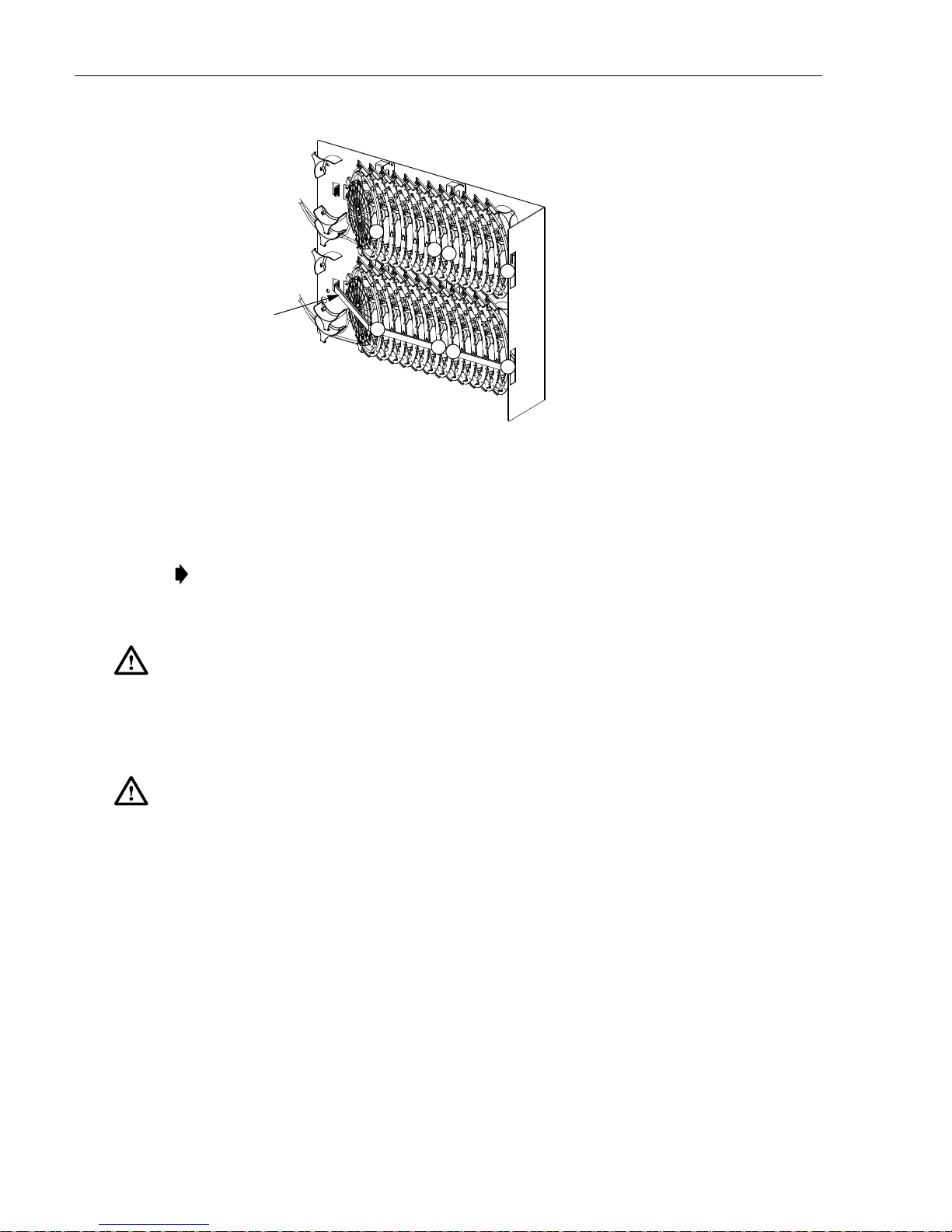

Figure 2 shows the main components of a typical 288 cabinet with splicing. Included are:

SPLITTER

COMPARTMENT

DISTRIBUTION

SPLICE WHEEL

STORAGE

DISTRIBUTION

PANELS

SLIDING

ADAPTER

PAC K

FEEDER

SPLICE TRAY

STORAGE

STORAGE

PA NE L

GROUNDING

BLOCK

RADIUS

LIMIITERS

22674-A

Figure 2. Main Components of a Typical 288 Cabinet With Splici ng

• Distribution Panels: Provide a point for connecting the splitter output fibers with the

terminated distribution cable fibers. Each panel provides mounting spaces for 72 bulkhead

adapters. The cabinet may be ordered with one to six distribution panels installed.

Additional panels may be ordered and installed as needed. UPC/SC or APC/SC style

connectors are available.

Page 2

© 2017, ADC Telecommunications, Inc.

Page 9

ADCP-96-139 • Rev B • July 2017

• Storage Panel: Provides a temporary “parking lot” for unused splitter output fibers. Each

splitter module comes with a connector pack that mounts in the storage panel. Up to nine

8-position connector packs (72 fibers total) can be mounted in the storage panel.

• Radius Limiters: Provide a place for storing excess slack from the splitter output fibers.

• Splitter Compartment: Provides a place for mounting the splitters. Will support up to 12

splitters. Unused splitter slots can be used for pass-though fibers. The splitters specified

for use with the FDH 3000 cabinet are equipped with bend-optimized fibers.

• Sliding Adapter Pack (Input panel): Provides a place for terminating spare feeder cable

fibers. Will support up to 36 adapters. Spare feeder cable fibers are typically used for

signal pass-through functions.

• Grounding Block: Provides a point for grounding the cabinet and OSP cables.

• Feeder Cable Splice Tray Storage: Provides storage for one or two 5 x 11.75 inch

rectangular splice trays which are used for splicing the feeder cable fibers to the splitter

input pigtails. Each stranded cable splice tray provides storage for up to 36 splices.

• Distribution Cable Splice Tray Storage: Provides storage for up to thirty-six round

splice trays which are used for splicing the distribution cable fibers to the distribution

panel pigtails. Each stranded cable splice tray provides storage for up to twelve splices.

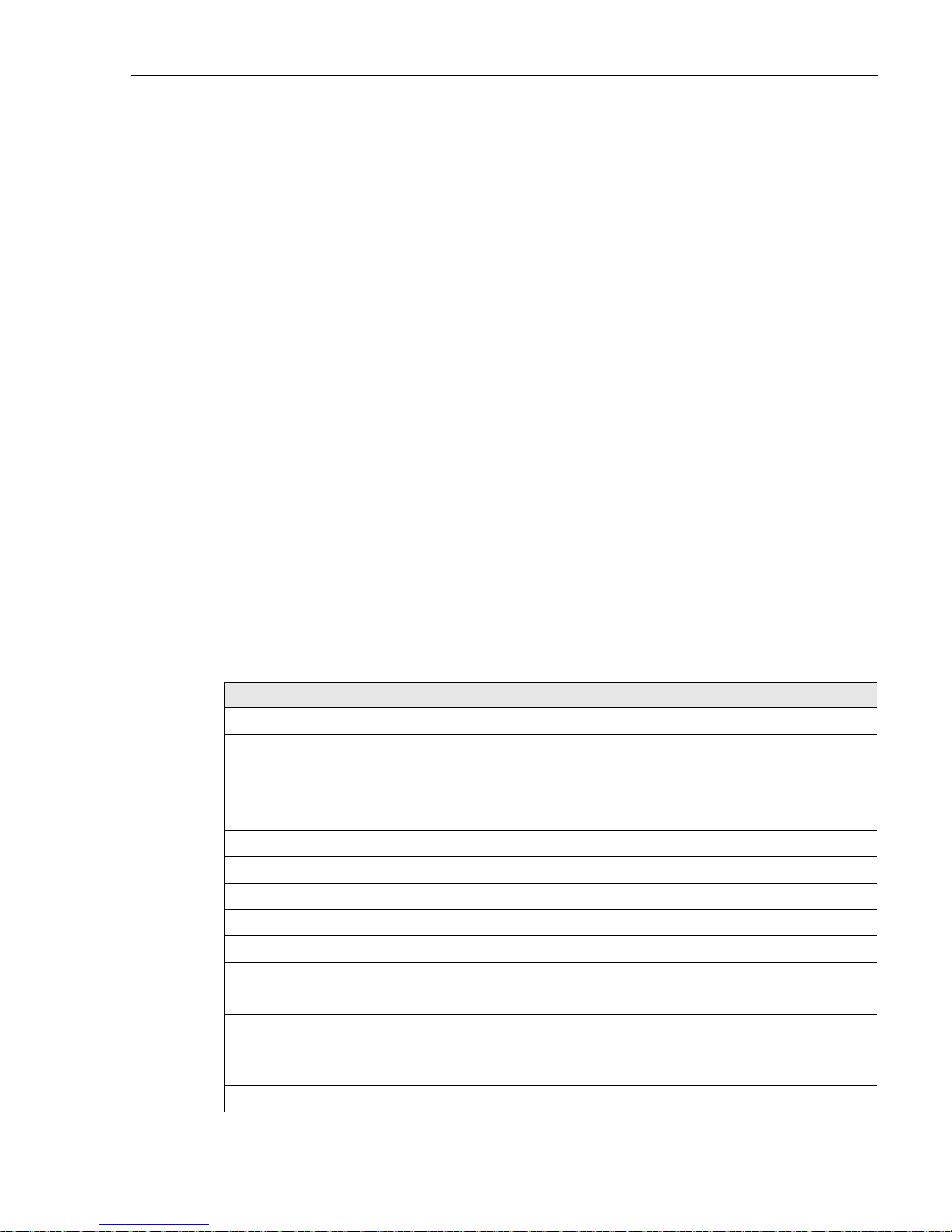

1.3 Specifications and Dimensions

Table 1 lists the specifications for the FDH 3000 288 cabinet. Figure 3 shows dimensions.

Table 1. 288 Cabinet With Splicing Specifications

PARAMETER SPECIFICATION

Cabinet

Dimensions (H x W x D)

Pedestal-Mount (See Figure 3) 36.0 x 26.8 x 18.2 inches (91.3 x 68.1 x 46.2 cm)

Weight (fully loaded) 208 lbs (94.3kg)

Certification (pending) GR-3125-CORE

Distribution panels (maximum) 4

Distribution ports Up to 288 with four 72-port distribution panels.

Distribution port adapters/connectors UPC/SC or APC/SC,

Splitter compartment splitter capacity 12 splitters

Splitter compartment adapter capacity 24 adapters

Storage panel capacity 72 connectors

Sliding adapter pack capacity 36 adapters

Splitter Modules

Splitter module input and output pigtails Bend-optimized fiber terminated with UPC/SC or APC/

Test bandpass 1260–1360 nm, 1480–1500 nm, 1550–1560 nm

SC connectors

© 2017, ADC Telecommunications, Inc.

Page 3

Page 10

ADCP-96-139 • Rev B • July 2017

PARAMETER SPECIFICATION

Overall bandpass 1260–1625 nm

Return loss at test bandpass >

Maximum insertion loss at test bandpass

1 x 2

1 x 4

1 x 8

1 x 16

1 x 32

1 x 64

2 x 16

2 x 32

Table 1. 288 Cabinet With Splicing Specifications, continued

55 dB

Note: Includes loss from input and output connectors

4.1 dB with UPC, 4.3 with APC

7.6 dB with UPC, 7.8 dB with APC

10.7 dB with UPC, 10.9 dB with APC

13.9 dB with UPC, 14.1 dB with APC

17.1 dB with UPC, 17.3 dB with APC

20.8 dB with UPS, 21 dB with APC

14.5 dB with UPC, 14.7 dB with APC

17.8 dB with UPC, 18 with APC

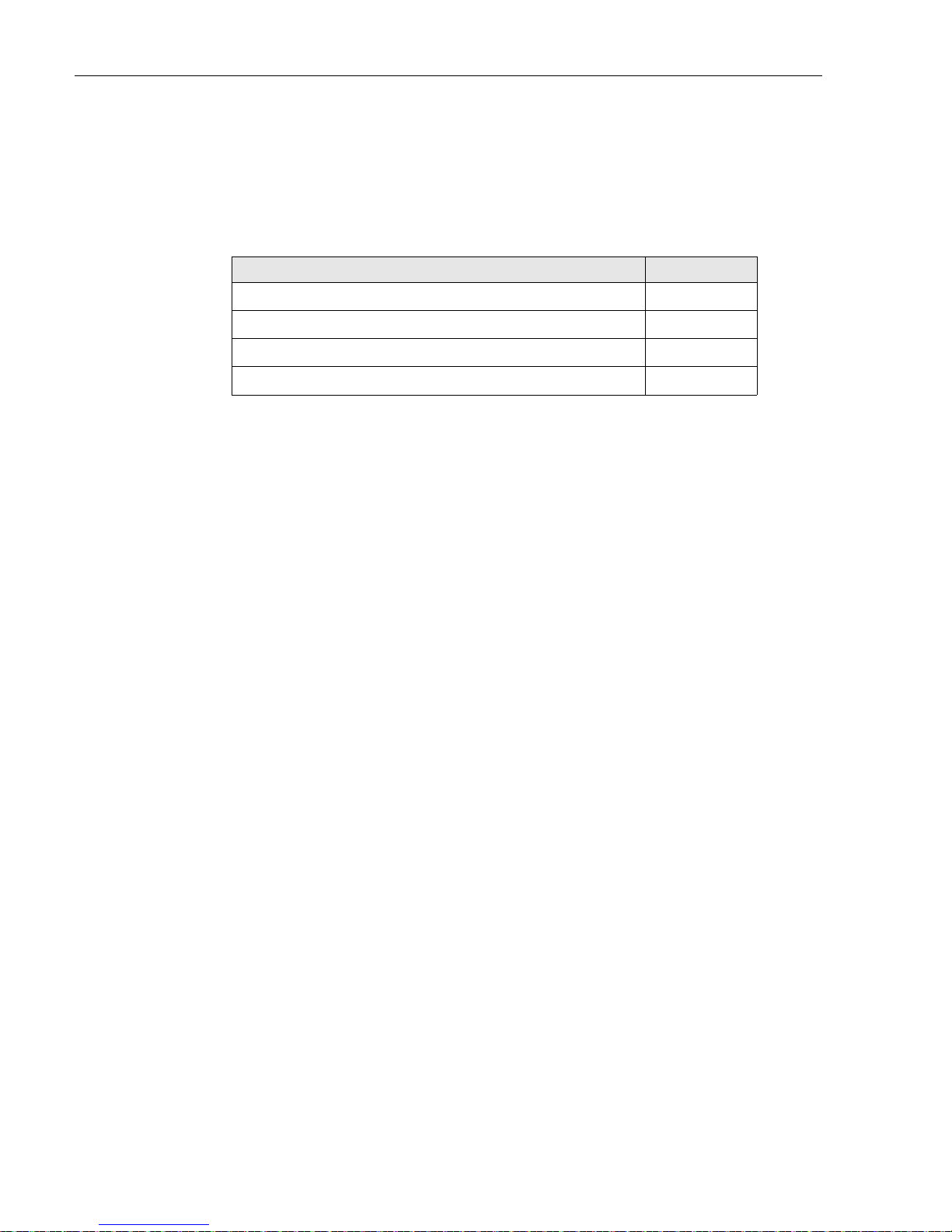

35.96 INCHES

(91.3 CM)

26.8 INCHES

(68.1 CM)

18.2 INCHES

(46.2 CM)

22675-A

Page 4

© 2017, ADC Telecommunications, Inc.

Figure 3. Typical 288 Cabinet With Splicing

Page 11

2 BEFORE STARTING THE INSTALLATION

2.1 Installation Overview

Installation of the 288 cabinet with splicing involves the following main tasks:

Mounting the Cabinet – The cabinet must be mounted on a support base. The following two

mounting options are available:

• Mounting Sleeve (FMS) – The FMS is a polymer concrete sleeve that mounts in the

ground. The FMS provides a stable mounting platform plus storage space under the

cabinet for OSP cable slack. The FMS may also be used as a splicing vault for OSP cables.

• Poured Concrete Pad – Concrete base with Pad Mounting Frame (PMF). The PMF is a

stainless-steel frame that is embedded in the concrete during installation of the pad. The

cabinet attaches to the PMF which holds it securely to the pad.

Splitter Installation – The cabinet may be ordered with one or two splitters. If additional

splitters are required, they must be ordered separately. All splitter modules that are ordered

separately must be installed in the splitter compartment.

ADCP-96-139 • Rev B • July 2017

Feeder Cable Installation – The feeder cable must be routed to the cabinet and spliced to the

splitter input fibers.

Distribution Cable Installation - The distribution cables must be routed to the cabinet and

spliced to the distribution panel pigtails.

Splitter Output Fiber Connections – Service is enabled by connecting the splitter output fiber

connectors to the subscriber distribution ports. Unused output fibers are temporarily “parked” in

the storage panel until they are needed for service.

2.2 Unpacking and Inspection

Use the following procedure to unpack and inspect the cabinet and all accessories:

1. Inspect the exterior of the shipping container(s) for evidence of rough handling that may

have damaged the components in the container.

2. Unpack each container while carefully checking the contents for damage a nd verify with

the packing slip.

3. If damage is found or parts are missing, file a cla im with th e comm ercial c arrier an d notify

ADC Customer Service. Save the damaged cartons for inspection by the carrier.

4. Refer to Section 11 of this manual if you need to contact ADC.

5. Save all shipping containers for use if the equipment requires shipment at a future date.

© 2017, ADC Telecommunications, Inc.

Page 5

Page 12

ADCP-96-139 • Rev B • July 2017

2.3 Cabinet Installation Hardware

The cabinet is shipped with various parts (see Table 2) for securing the cabinet to the FMS or

PMF. Verify that the specified cabinet installation hardware is received.

Table 2. Cabinet Installation Hardware

ITEM QUANTITY

3/8 x 1-inch hex head capscrews 4

3/8-inch flat washers 4

3/8-inch lock washers 4

Isolation gasket 1

2.4 OSP Cable and Cabinet Grounding Cables

The cabinet is equipped with a common grounding block that is used to tie together all the

components of the cabinet that must be grounded. The cabinet itself and any OSP cables with

metallic strength members must be connected to an earth ground source. Information on

grounding is provided in the sections that cover cabinet mounting.

2.5 Tools and Materials Required for Installation

The following tools and materials are required for all cabinet installation:

All Cabinet Installations

•Hammer

• Wire cutter

• Utility knife

• Screwdriver (flat blade)

• Torque wrench (with 7/16-inch socket and standard screwdriver socket)

• Tape measure

• Pen or marker

• 9/16-inch wrench

• 216B key tool (accessory - required to open cabinet door)

• 3/16-inch hex-key (required to open riser panels or remove lifting eyes)

• Level

• Padlock (optional)

• Grounding system, copper wire, and grounding clamp (per local requirements)

• Splicing equipment for splicing OSP feeder and distribution cables

Page 6

© 2017, ADC Telecommunications, Inc.

Page 13

ADCP-96-139 • Rev B • July 2017

• Tamping equipment

• Excavation and earth moving equipment

• Lifting equipment for hoisting the cabinet into position for mounting

• Landscaping equipment and site restoration supplies

Mounting Sleeve Installation

The following additional materials are required for mounting the cabinet on a mounting sleeve:

• Mounting Sleeve kit (FMS-ACE100-KIT-A)

• Stone aggregate

• Hole saw and drill (use to cut holes for cable conduit if pre-drilled holes are not usable)

Concrete Pad Installation

The following additional materials are required for mounting the cabinet on a concrete pad:

• Pad Mount Frame kit for FDH 3000 cabinet (FD3-PMFE06)

• Concrete finishing equipment

• Approximately 11.5 cu. ft. concrete

• Sand or gravel

• 2 x 6 inch framing lumber

• 1 x 4 inch wooden stakes (4)

• Nails and construction screws

• Utility wire (to secure PMF during installation)

•Saw

• Drill with screwdriver bits

•Square

2.6 Cabinet Mounting

The next two sections provide installation instructions for the various cabinet mounting systems.

Use whichever procedure is appropriate for the installation.

3 MOUNTING THE CABINET ON A MOUNTING SLEEVE

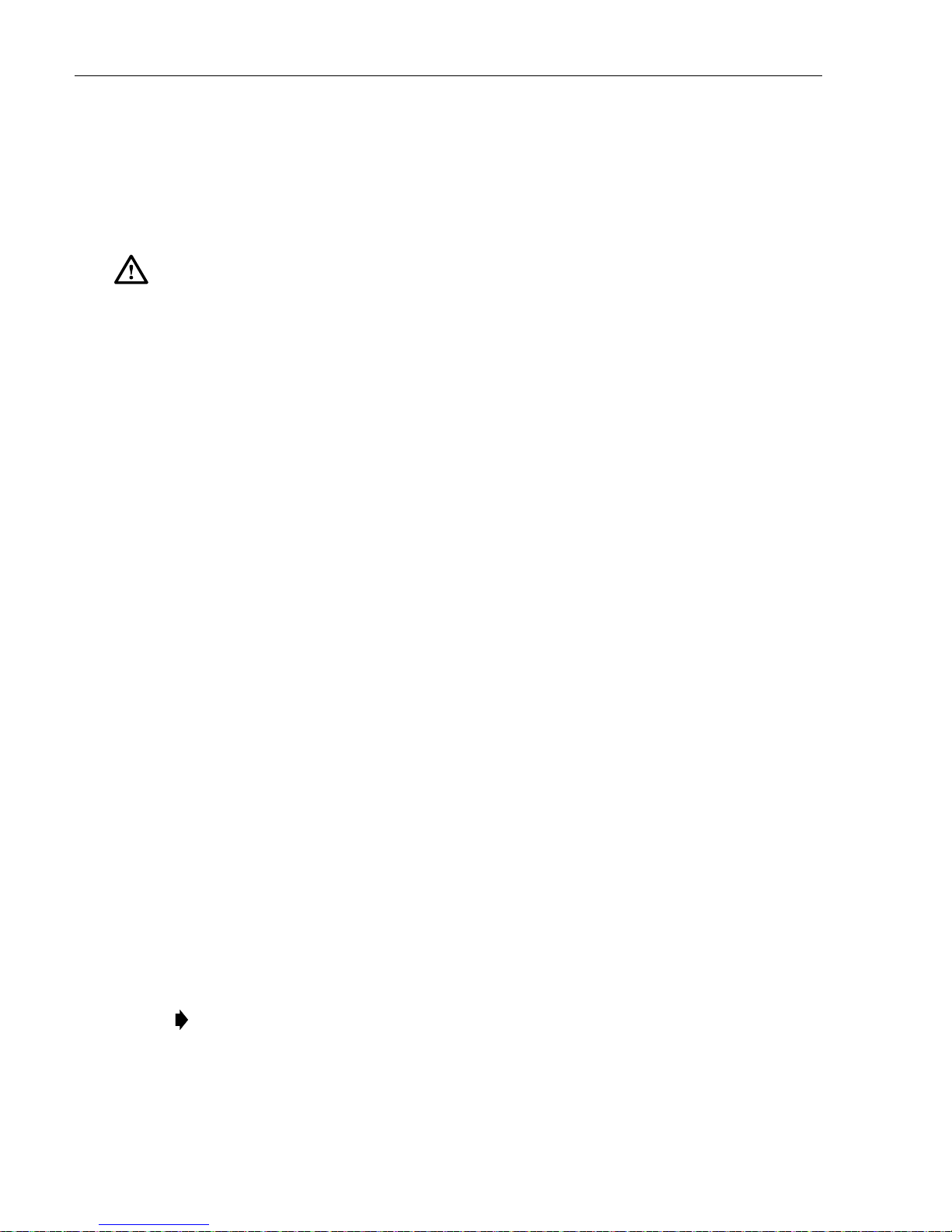

The FMS, shown in Figure 4, is a polymer concrete sleeve that may be used to support the

cabinet at ground level. The FMS may also be used as a splicing vault. Four vertical racks are

molded into the sides of the FMS to accommodate removable rungs (not provided ). The rungs

provide support for splice cases or OSP cable storage.

© 2017, ADC Telecommunications, Inc.

Page 7

Page 14

ADCP-96-139 • Rev B • July 2017

3.1 Installation Recommendations

The site chosen for the installation must conform to all local codes and any permits required

must be obtained prior to the start of installation. The location must be accessible and provide

adequate parking for worker and vehicle safety. Situate the FMS close to the trench that was

used for routing the OSP fiber cables for the network distribution system.

The installed cabinet must not create a visual or physical obstruction to vehicular or pedestrian

traffic. Ensure that there is sufficient space on all sides to facilitate cabinet installation.

Depending on the landscaping requirements, the top surface of the mounting sleeve may be

located from 0 to 4 inches (10.2 cm) above the surrounding grade.

30.13 IN.

FMS COVER

FMS ADAPTER

COVER

3.2 Excavation

The excavation must be large enough to provide a fill base that will maintain stability for the

FMS and the cabinet mounted on it. There must be room for 12 inches (30.5 cm) of fill belo w

and on each side of the FMS. The excavation dimensions for the FMS are shown in Figure 5.

Excavate a rectangular hole for the FMS.

29.69 IN.

MOUNTING

SLEEVE (FMS)

30.0 IN.

59.5 IN.

30.0 IN.

21510-D

Figure 4. Mounting Sleeve (FMS-ACE100-KIT-A)

Page 8

© 2017, ADC Telecommunications, Inc.

Page 15

ADCP-96-139 • Rev B • July 2017

21511-A

84 IN (213 CM)

54 IN (137 CM)

TOPSOIL OR

DECORATIVE ROCK

STONE

AGGREGATE FILL

STONE

AGGREGATE FILL

42 IN

(106.7 CM)

12 IN

(30.5 CM)

12 IN

(30.5 CM)

CONDUIT

ENTRANCE

HOLES

COMPACTED SOIL

COMPACTED SOIL

TAMP AGGREGATE AS

HOLE IS FILLED

GRADE

SIDE

VIEW

END

VIEW

CONDUIT

ENTRANCE

HOLES

VERTICAL RACKS

FOR MANHOLE

CABLE SUPPORT BARS

3.3 Placement of the FMS

Danger: Use adequate lifting equipment when installing the FMS. Do not stand in the hole while

placing the FMS in position. An unexpected shift of the FMS could result in personal injury.

Use the following procedures to place the FMS into the excavation.

1. Fill the bottom of the ho le with stone aggregate, tamping it as it is filled to build a 12 inch

(30.5 cm) layer with a level surface. The stone aggregate will provide a stable base to

support the FMS.

Note: Use crushed rock 3/8-inch or less in size mixed with stone dust (per local practice)

to fill the hole. The name of the material may differ in different geographical areas.

Possible names are Class 5, stone dust, aughts (0s) and ones (1s), or stone aggregate

Figure 5. Excavation Recommendations for FMS-ACE100-KIT-A

© 2017, ADC Telecommunications, Inc.

Page 9

Page 16

ADCP-96-139 • Rev B • July 2017

2. Use appropriate lifting equipment to place the FMS into the center of the hole. Lifting

loops are provided on either side of the FMS for attaching a sling or chain.

3. Use a carpenter’s level to verify that the FMS is level. If it is necessary to add or remove

fill for leveling, tamp any added fill to maintain the base stability.

3.4 Cable Conduit Installation

Select the conduit entrance holes (see Figure 5) for the OSP feeder and distribution cables. If

necessary, additional conduit entrance holes may be cut using a power drill and hole saw. Place

and route the conduit into the entrance hole(s). If preferred, the FMS may be installed without

conduit. OSP cables may be routed into the FMS at any point that is convenient. Cut the cable

entrance hole to match the size of the cable.

3.5 Grounding System Installation

Install a grounding system (not provided) that meets all local electrical codes. Check local codes

for grounding system installation, use of clamps, wire size, and any other grounding

requirements. Typically, #6 AWG copper wire is used for the grounding wire. Install the

grounding system inside the FMS where it will not interfere with the conduit or cables. Leave

sufficient slack in the grounding wire to allow it to be routed into the cabinet after the cabinet is

mounted on the sleeve.

3.6 Back Fill

If installing conduit, hand shovel stone aggregate under the conduit to avoid damage from the

power tamper. Complete the back fill as follows:

1. Add stone aggregate evenly around the FMS and tamp. Fill to approximately 6 inches

(15.2 cm) from the top of the excavation.

2. Complete the back-fill with crushed rock or topsoil depending on the landscaping

requirements. The top surface of the mounting sleeve may be located from 0 to 4 inches

(10.2 cm) above the surrounding grade (see Figure 5).

3.7 Mounting the Cabinet on the FMS

Use the 216B key tool to un-latch and latch the cabinet door as needed during th e mounting

process. Refer to Figure 6 as necessary when mounting the cabinet.

Warning: Use appropriate lifting equipment when moving or installing the cabinet. Do not

stand under a cabinet as it is being hoisted into position for mounting. A failure of the lifting

equipment could result in serious personal injury.

Page 10

© 2017, ADC Telecommunications, Inc.

Page 17

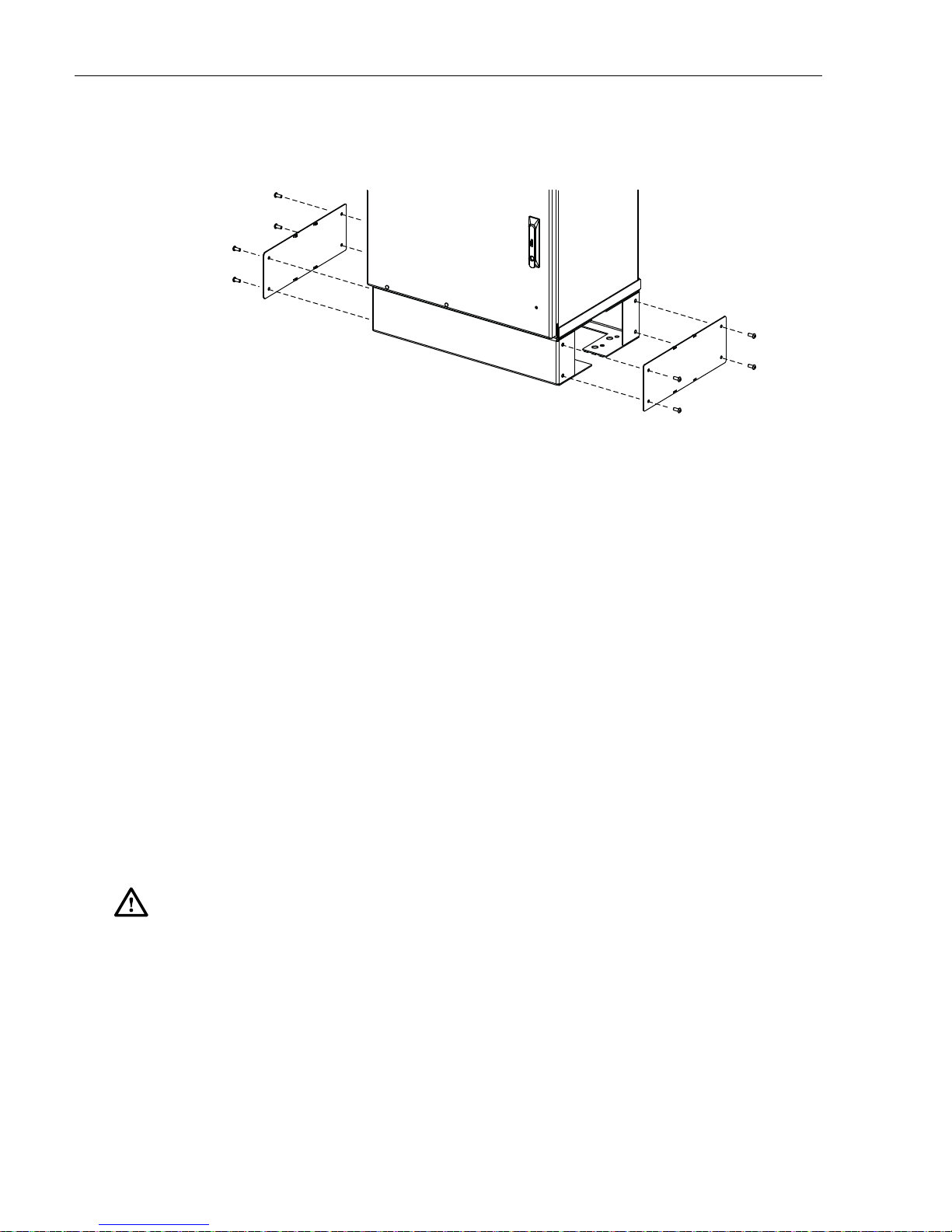

288 TERMINATION

FDH 3000 CABINET

(FRONT)

ADCP-96-139 • Rev B • July 2017

CAPSCREWS (4), LOCK

WASHERS (4), AND FLAT

WASHERS (4)

FMS COVER

GROUNDING

WIRE

GROUND SPACER

(OPTIONAL ACCESSORY)

FMS

CAPSCREWS (4), LOCK

WASHERS (4), AND FLAT

WASHERS (4)

CABINET FRONT

ISOLATION GASKET

FMS ADAPTER

COVER

Figure 6. Mounting the 288 Termination Cabinet With Splicing on the FMS

Use the following procedure to mount the cabinet on the FMS:

22677-A

Page 11

© 2017, ADC Telecommunications, Inc.

Page 18

ADCP-96-139 • Rev B • July 2017

22678-A

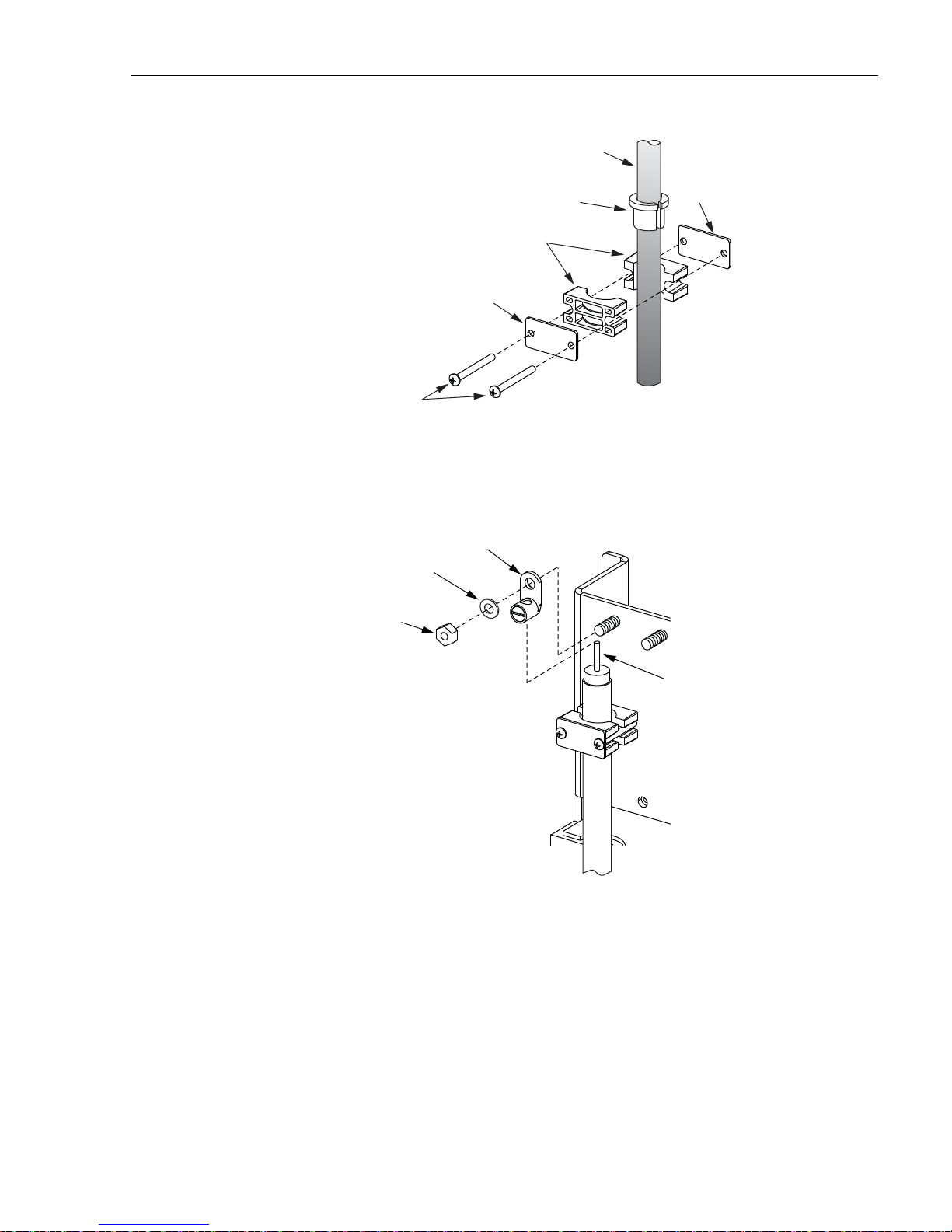

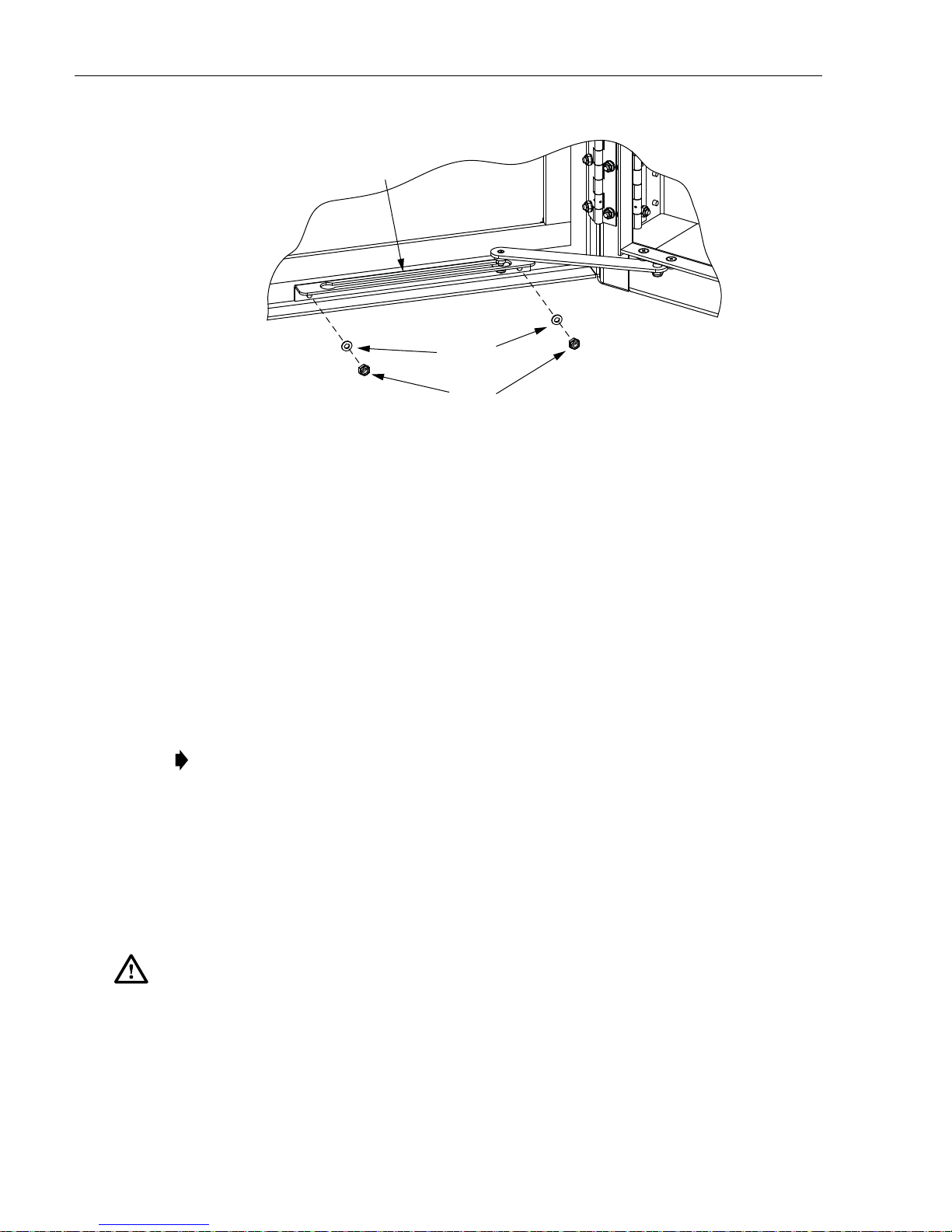

1. Use a 3/16-inch hex-key to remove the screws that secure the access covers to the left and

right sides of the cabinet ground spacer/riser as shown in Figure 7.

2. Remove the access covers from the ground spacer/riser and set aside both the covers and

the screws for reuse.

Figure 7. Removing Side Access Covers From Ground Spacer/Riser

3. Mount the FMS adapter cover on the FMS and secure using the two capscrews and flat

washers provided. Tighten each capscrew securely.

4. Place the isolation gasket (provided with cabinet) on the adapter cover and align the holes

in the gasket with the holes in the adapter cover. Make sure the wide side of the gasket is

on the side of the adapter cover that corresponds to the front side of the cabinet.

5. If a ground spacer/riser (optional accessory) will be installed, place the spacer in position

for mounting on the adapter cover. The isolation gasket installed in step 4 should remain in

place between the adapter cover and ground spacer. If a ground spacer will not be

installed, proceed to step 8.

6. Align the mounting holes in the spacer/riser with the mounting holes in the adapter cover.

7. Secure the spacer/riser to the adapter cover using the four capscrews, four lock washers,

and four flat washers provided with the spacer. Tighten all capscrews securely.

8. Using appropriate lifting equipment, hoist the cabinet into position for mounting on the

spacer/riser or adapter cover.

Danger: Do not stand directly under the cabinet as it is being hoisted into position for cable

installation. A failure of the lifting equipment could result in serious personal injury.

9. Lower the cabinet onto the ground spacer/riser or adapter cover and align the mounting

holes in the cabinet base with the threaded holes in the spacer/riser or adapter cover. If a

spacer/riser was not installed, leave the isolation gasket (installed in step 4) in place on the

adapter cover.

10. Secure the cabinet to the spacer/riser or adapter cover using the four capscrews, lock

washers, and flat washers provided with the cabinet Tighten all four capscrews securely.

11. Install the FMS sleeve cover on the FMS and secure using the two capscrews and washers

provided. Tighten both capscrews securely.

Page 12

© 2017, ADC Telecommunications, Inc.

Page 19

Note: The FMS sleeve cover may be installed at a later time so the interior of the FMS

22681-A

TIGHTEN GROUNDING LUG SET SCREW

TO 30 TO 35 LBS FORCE - INCHES

(3.4 TO 4.0 Nm) OF TORQUE

GROUNDING WIRE

ENTRY POINT

GROUNDING

LUG

GROUNDING

CABLE

sleeve to be accessed for cable installation, ground wire installation, or splicing.

12. The lifting eyes may be left in place or removed from the cabinet. To remove the lifting

eyes, use the 3/16 hex-key to remove the lifting eye screws. Store the lifting eyes inside the

cabinet and then re-install the lifting eye screws in the cabinet.

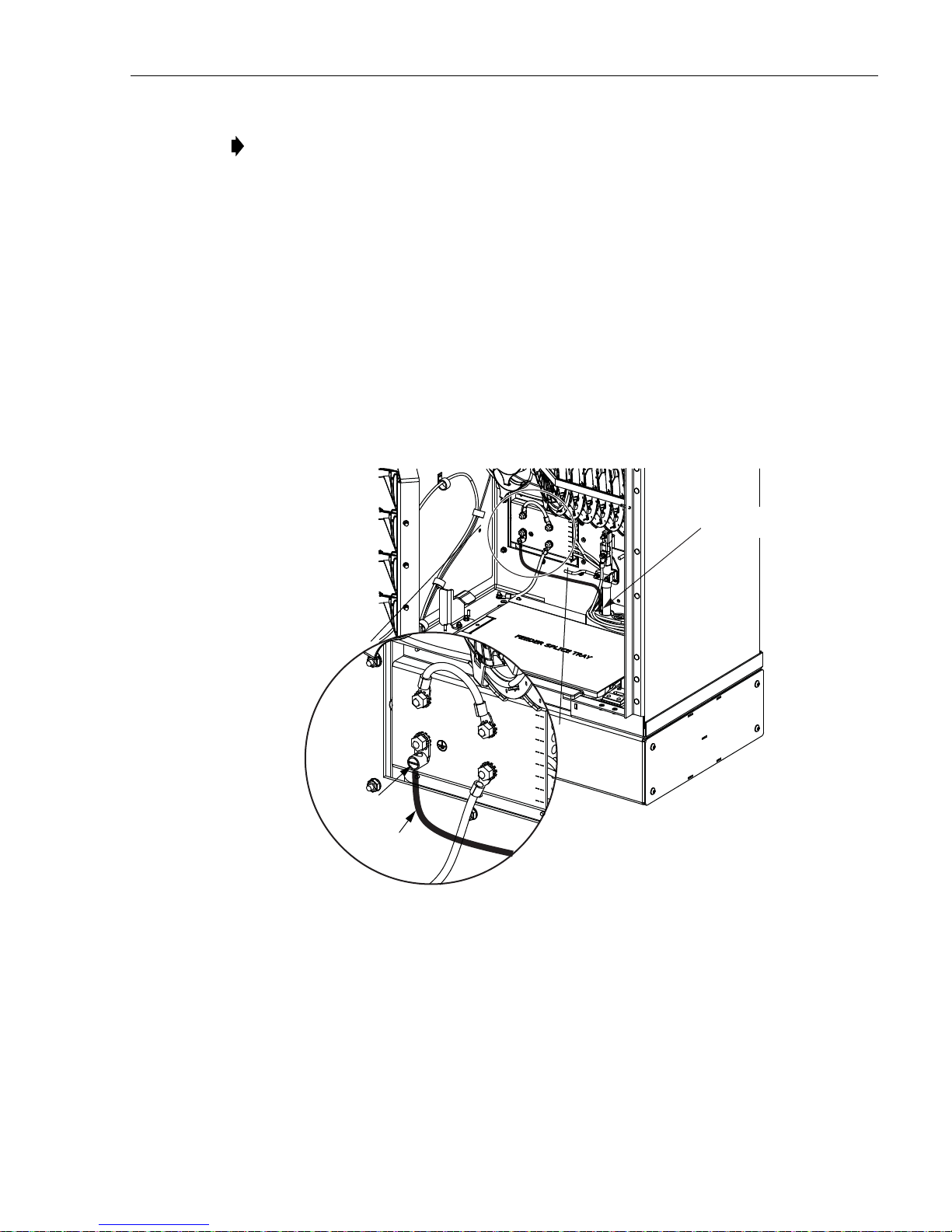

3.8 Grounding Wire Connection To Cabinet

Prior to mounting the cabinet, a grounding system and grounding wire should have been

installed (see Section 3.5) in the space below the cabinet. Use the following procedure to

connect the grounding wire to the cabinet:

1. Locate the grounding wire that was installed inside the FMS prior to mounting the cabinet.

2. Working from the bottom side of the cabinet, insert the grounding wire through the

flexible membrane at the point indicated in Figure 8.

ADCP-96-139 • Rev B • July 2017

3. Attach the grounding wire to the cabinet grounding lug. The grounding lug can be used for

#6 to #14 AWG wire.

4. Tighten the grounding lug set screw to 30 to 35 lbs force-inches (3.4 to 4.0 Nm) of torque.

5. Reinstall the left and right access covers that were removed in step 1 of Section 3.7. Use

the 3/16-inch hex-key to tighten the screws that secure the access covers to the sides of the

cabinet ground spacer/riser.

Figure 8. Grounding Wire Connection To Cabinet

Page 13

© 2017, ADC Telecommunications, Inc.

Page 20

ADCP-96-139 • Rev B • July 2017

21400-B

28.35 IN.

(72.0 CM)

18.35 IN.

(46.6 CM)

5.5 IN.

(14.0 CM)

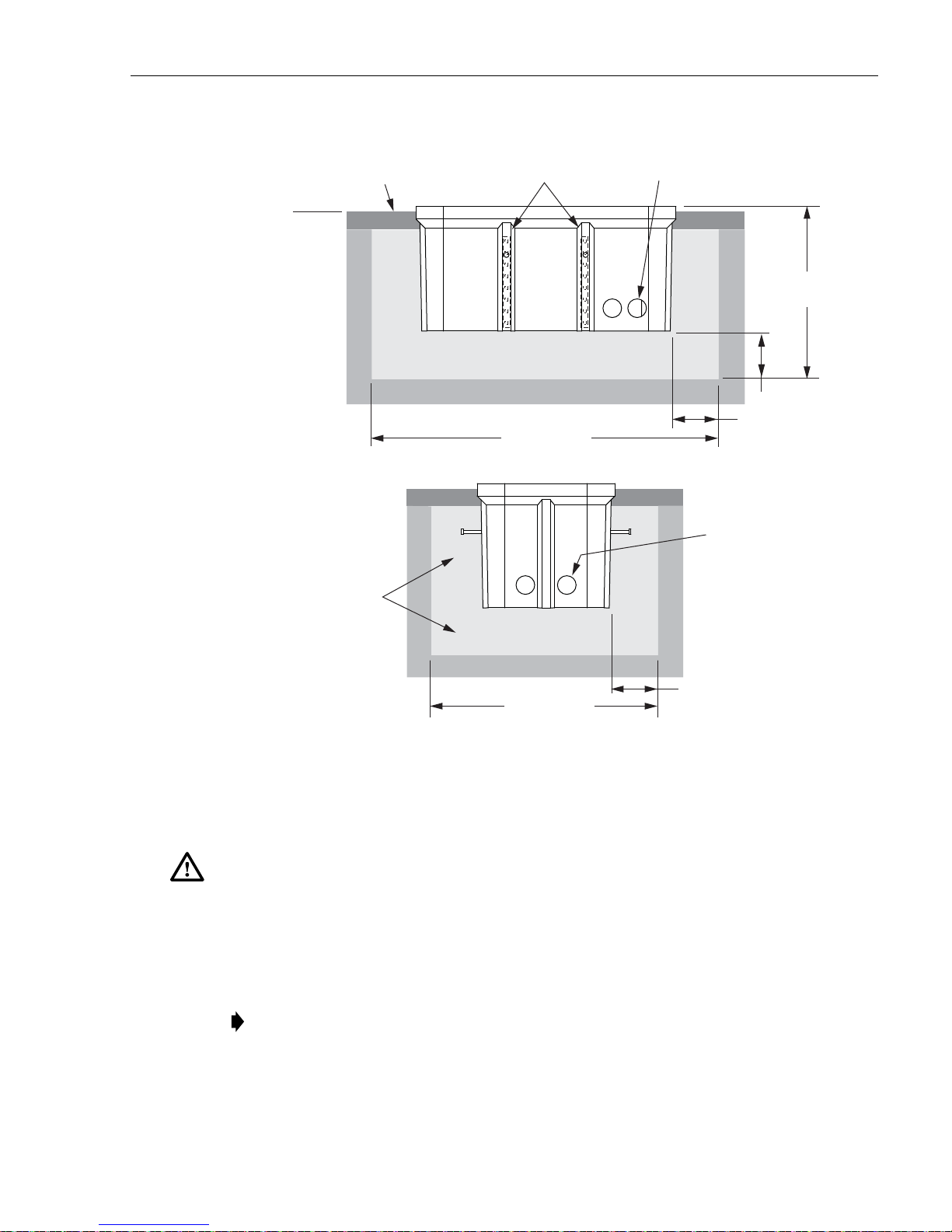

4 MOUNTING THE CABINET ON A CONCRETE PAD

The Pad Mount Frame (PMF), shown in Figure 9, is a stainless steel frame that provides a

mounting base for the cabinet when embedded in a concrete foundation.

Caution: Mounting the cabinet directly on a concrete pad may cause chemical corrosive action

to the cabinet. Use only the Pad Mount Frame (PMF) as a mounting base for the cabinet. Do

not use caulking compounds as a sealer between the cabinet and the PMF.

Figure 9. Pad Mount Frame Dimensions

4.1 Installation Recommendations

The site chosen for the installation must conform to all local codes and any permits required

must be obtained prior to the start of installation. The location must be accessible and provide

adequate parking for worker and vehicle safety. Situate the concrete pad close to the trench that

was used for routing the OSP fiber cables for the network distribution system.

The installed cabinet must not create a visual or physical obstruction to vehicular or pedestrian

traffic. Ensure that there is sufficient space on all sides to facilitate cabinet installation.

Depending on the landscaping requirements, the top surface of the concrete pad may be located

from 0 to 3 inches (7.6 cm) above the surrounding grade.

4.2 Base Construction and Conduit Installation

Prepare a base for the concrete pad that meets all local code requirements. The base must have a

footing of 4 to 6 inches (10.2 to 15.2 cm) of sand or gravel (per local practice) on firmly

compacted soil. Refer to the construction diagram in Figure 10 for details.

Install the cable conduit from below and position it so that the top of each upward bend will be

located within the PMF opening at the indicated point. When installed, the top of the conduit

should be located 1 to 2 inches (2.54 to 5.08 cm) below the top of the finished concrete pad.

Install the conduit before pouring the pad.

Page 14

© 2017, ADC Telecommunications, Inc.

Page 21

44.5 IN.

(113.0 CM)

4 IN. DUCT FOR

FEEDER CABLE

(LOCATE 1 - 2 INCHES

BELOW TOP OF PAD)

ADCP-96-139 • Rev B • July 2017

20.25 IN.

(51.4 CM)

15.25 IN

(38.7 CM)

8.0 IN.

(20.3 CM)

GROUND ROD

(LOCATE 1 - 2 INCHES

BELOW TOP OF PAD)

PAD MOUNT FRAME

CAST IN PLACE

REINFORCED

CONCRETE PAD

6.0 IN.

(15.2 CM)

TOPSOIL OR

DECORATIVE ROCK

DO NOT POUR

CONCRETE

INSIDE PAD

MOUNT FRAME

CABINET FRONT

FLUSH WITH TOP OF CONCRETE

8.0 IN.

(20.3 CM)

11.75 IN.

(29.8 CM)

4 IN. DUCT FOR

DISTRIBUTION CABLE

(LOCATE 1 - 2 INCHES

BELOW TOP OF PAD)

44.5 IN.

(113.0 CM)

18.0 IN.

(45.7 CM)

TOP OF PMF SHOULD BE

GRADE

4.0 IN. MIN.

(10.2 CM)

COMPACTED SOIL

Figure 10. Constructing the Concrete Pad for the 288 Termination Cabinet With Splicing

A template is provided with the cabinet isolation gasket. The template may be used to determine

the cable conduit locations. Place the template over the top of the PMF and align the top right

corner of the template with the top right corner of the PMF as shown in Figure 11. The holes

punched in the template show the locations for the conduit within the PMF.

SAND OR GRAVEL

90 BEND

IN DUCT

21359-C

Page 15

© 2017, ADC Telecommunications, Inc.

Page 22

ADCP-96-139 • Rev B • July 2017

ALIGN EDGES OF

TEMPLATE WITH

EDGES OF PMF

CUT-OUT INDICATES

LOCATION OF FEEDER

CABLE CONDUIT

CUT-OUT INDICATES

LOCATION OF

DISTRIBUTION

CABLE CONDUIT

PLACE CARDBOARD

TEMPLATE OVER

TOP OF PMF

21405-A

FRONT OF

CABINET

Figure 11. Using the Template To Determine Duct Location Within the PMF

4.3 Concrete Pad Construction

Use the following procedure to construct the concrete pad:

1. Build a wood form for the concrete pad using 2 x 6 framing lumber as shown in Figure 12.

2. Locate the PMF as shown in the construction diagram (see Figure 10). When installed, the

top surface of the PMF must be flush and level with the top of the concrete pad.

Note: Use temporary top framing to keep the top surface of the PMF flush and level with

the top of the concrete pad (see Figure 12).

3. Place reinforcing material inside the form but outside of the PMF.

4. Verify that the PMF and form are level. Depending on the landscaping requirements, the

top surface of the concrete pad may be 0 to 3 inches (0 to 7.6 cm) above the final grade. The

weld nuts are covered with plugs which must be left in place until the enclosure is mounted.

5. Pour the concrete to form the pad but do not pour concrete into the center area of the PMF.

Note: Allow some concrete to flow under the flanges on the bottom of the PMF so the

PMF will be locked in place when the concrete hardens. However, do not allow concrete to

fill the center of the PMF. If necessary, partially fill the center of the PMF with sand or

gravel to prevent an inflow of concrete.

Page 16

© 2017, ADC Telecommunications, Inc.

Page 23

ADCP-96-139 • Rev B • July 2017

44.5 IN.

(113.0 CM)

44.5 IN.

(113.0 CM)

LEVELING

STAKES

(4 PLACES)

21343-B

TEMPORARY

SUPPORT WIRES

(4 PLACES)

2 x 6 FRAMING

FOR FORM

DIMENSIONS SHOW FINISHED

SIZE OF CONCRETE PAD

PAD MOUNT

FRAME (PMF)

FRONT

4.4 Grounding System Installation

4.5 Mounting the Cabinet on the Concrete Pad

Figure 12. Concrete Pad Framing

6. Remove the top framing and the temporary support wires when the concrete is ready to be

finished.

7. Allow concrete to cure before proceeding with the installation.

Install a grounding system (not provided) that meets all local electrical codes. Check local codes

for grounding system installation, use of clamps, wire size, and any other grounding

requirements. Typically, #6 AWG copper wire is used for the ground wire. If the grounding

system includes a ground rod, install the rod (see Figure 10) within the PMF opening at the

indicated point. When installed, the top of the rod should be located 1 to 2 inches (2.54 to 5.08

cm) below the top of the finished concrete pad. Leave sufficient slack in the grounding wire to

allow it to be routed into the cabinet after the cabinet is mounted on the pad.

Use the 216B key tool to un-latch and latch the cabinet doors as needed during the mounting

process. Refer to Figure 13 as necessary when mounting the cabinet.

Warning: Use appropriate lifting equipment when moving or installing the cabinet. Do not

stand under the cabinet as it is being hoisted into position for installation. A failure of the lifting

equipment could result in serious personal injury.

Use the following procedures to mount the cabinet on the concrete pad.

Page 17

© 2017, ADC Telecommunications, Inc.

Page 24

ADCP-96-139 • Rev B • July 2017

1. Use a 3/16-inch hex-k ey to remove the screws that secure the access covers to the left and

right sides of the cabinet ground spacer/riser as shown in Figure 14.

288 TERMINATION

FDH 3000 CABINET

CAPSCREWS (4), LOCK

WASHERS (4), AND FLAT

WASHERS (4)

(FRONT)

CAPSCREWS (4), LOCK

WASHERS (4), AND FLAT

WASHERS (4)

ISOLATION GASKET

GROUNDING

WIRE

CONCRETE

PAD

FEEDER

CABLE CONDUIT

GROUND SPACER

(OPTIONAL ACCESSORY)

CABINET FRONT

DISTRIBUTION

CABLE CONDUIT

22682-A

PAD MOUNT

FRAME (PMF)

Figure 13. Mounting the 288 Termination Cabinet with Splicing on the Concrete Pad

Page 18

© 2017, ADC Telecommunications, Inc.

Page 25

ADCP-96-139 • Rev B • July 2017

22678-A

Figure 14. Removing Side Access Covers From Ground Spacer/Riser

2. Remove the plastic plugs that are installed in the threaded corner holes of the PMF and

clean off any concrete that may have adhered to the top of the PMF.

Note: Make sure all remnants of concrete are removed from the PMF prior to mounting

the cabinet. It is not necessary to use shims to level or align the cabinet as long as the top

surface of the PMF is clean and free of any installation debris.

3. Place the isolation gasket (provided with cabinet) on the PMF and align the holes in the

gasket with the holes in the PMF. Make sure the wide side of the gasket is on the side of

the PMF that corresponds to the front side of the cabinet.

4. If a ground spacer/riser (accessory) will be installed, place the spacer/riser in position for

mounting on the PMF. The isolation gasket installed in step 3 should remain in place

between the PMF and spacer/riser. If a spacer/riser will not be installed, proceed to step 7.

5. Align the mounting holes in the spacer/riser with the mounting holes in the PMF.

6. Secure the spacer/riser to the PMF using the four capscrews, four lock washers, and four

flat washers provided. Tighten all capscrews securely.

7. Using appropriate lifting equipment, hoist the cabinet into position for mounting on the

spacer/riser or PMF.

Danger: Do not stand directly under the cabinet as it is being hoisted into position for cable

installation. A failure of the lifting equipment could result in serious personal injury.

8. Lower the cabinet onto the ground spacer/riser or PMF and align the mounting holes in the

cabinet base with the threaded holes in the spacer/riser or PMF. If a spacer/riser was not

installed, leave the isolation gasket (installed in step 3) in place on the PMF.

9. Secure the cabinet to the spacer/riser or PMF using the four capscrews, four lock washers,

and four flat washers provided with the cabinet. Tighten all four capscrews securely.

10. The lifting eyes may be left in place or removed from the cabinet. To remove the lifting

eyes, use the 3/16 hex-key (accessory) to remove the lifting eye screws. Store the lifting

eyes inside the cabinet and then re-install the lifting eye screws in the cabinet.

© 2017, ADC Telecommunications, Inc.

Page 19

Page 26

ADCP-96-139 • Rev B • July 2017

22681-A

TIGHTEN GROUNDING LUG SET SCREW

TO 30 TO 35 LBS FORCE - INCHES

(3.4 TO 4.0 Nm) OF TORQUE

GROUNDING WIRE

ENTRY POINT

GROUNDING

LUG

GROUNDING

CABLE

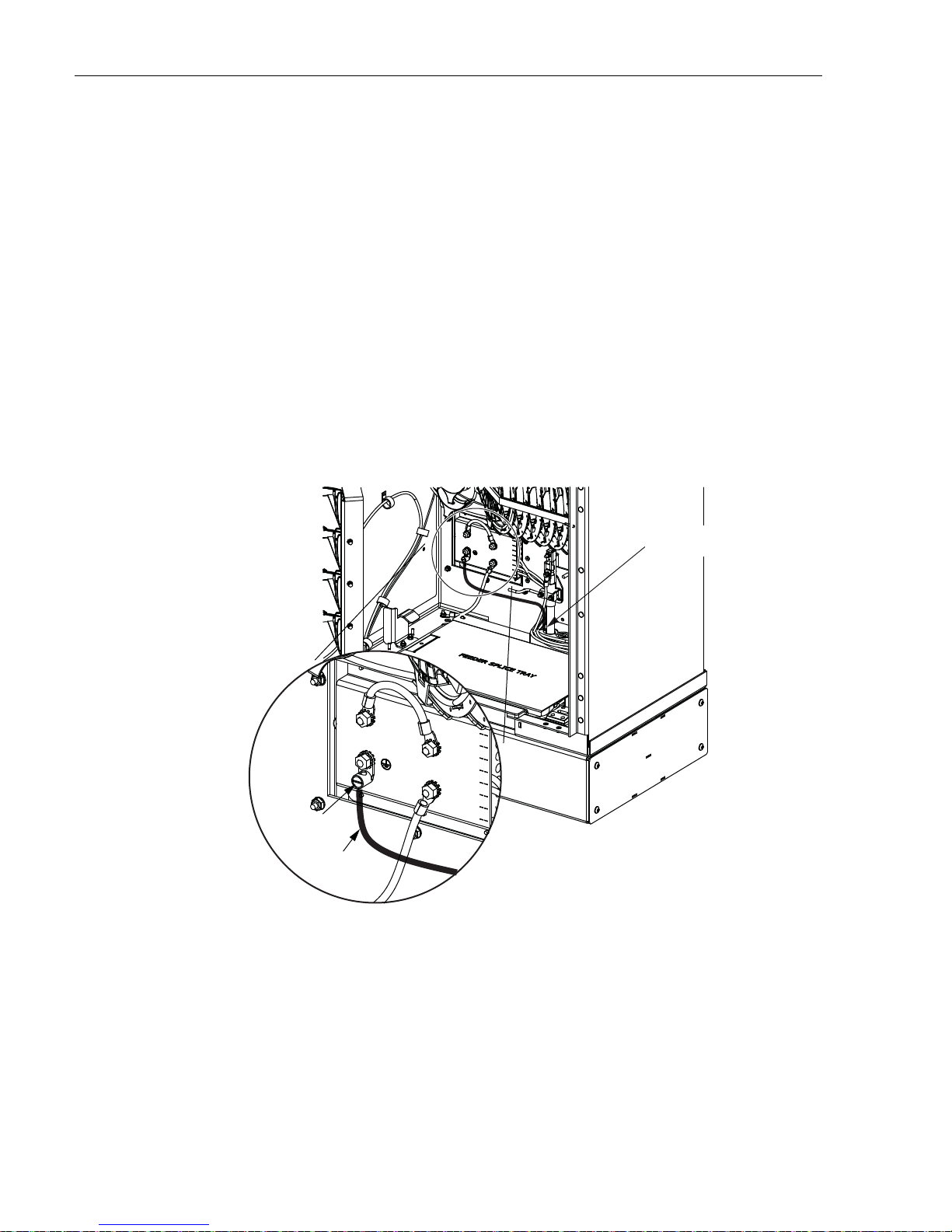

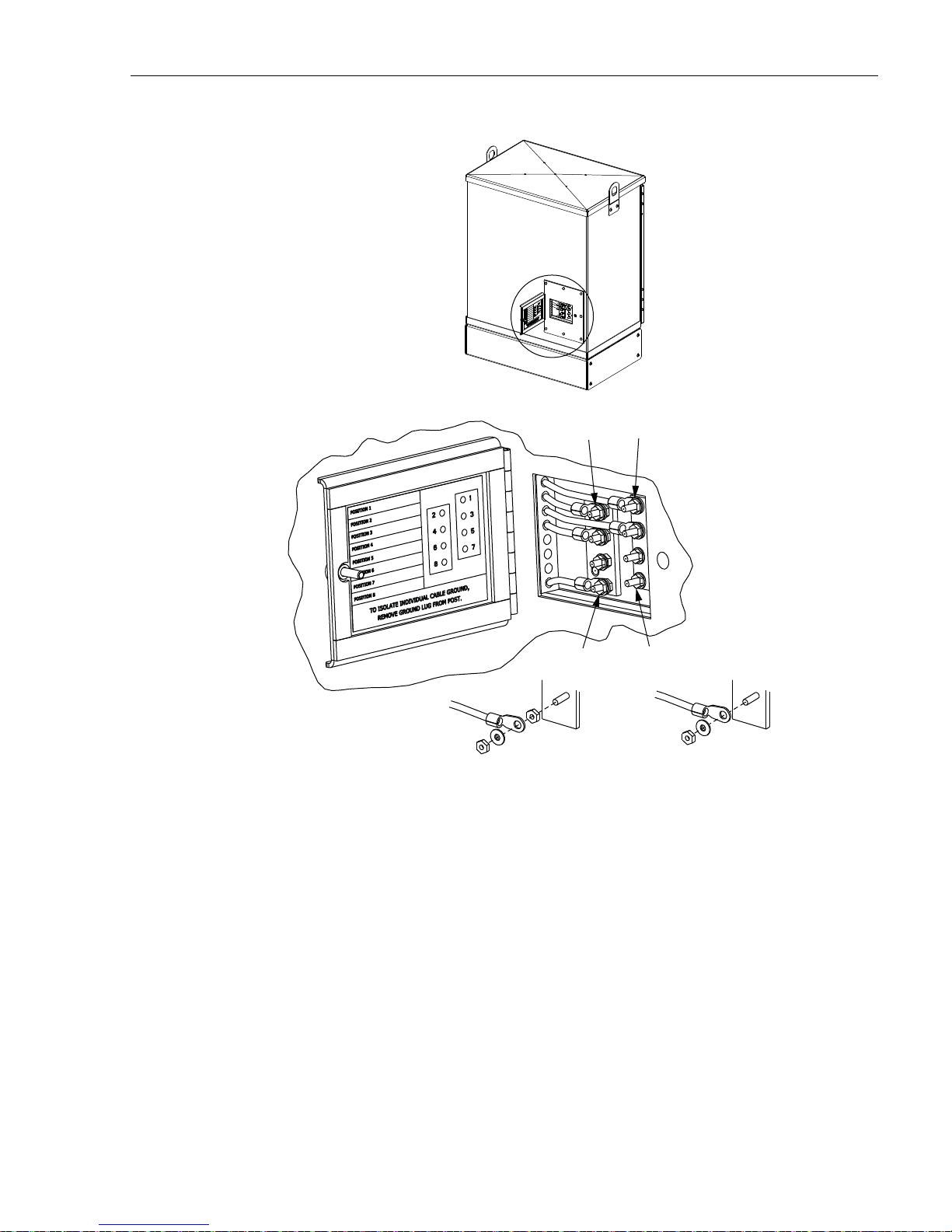

4.6 Grounding Wire Connection To Cabinet

Prior to mounting the cabinet, a grounding system and grounding wire should have been

installed (see Section 4.4) in the space below the cabinet. Use the following procedure to

connect the grounding wire to the cabinet:

1. Locate the grounding wire that was installed prior to mounting the cabinet on the pad.

2. Working through the access openings in the base of the cabinet, insert the grounding wire

through the flexible membrane at the point indicated in Figure 15.

3. Attach the grounding wire to the cabinet grounding lug. The grounding lug can be used for

#6 – #14 AWG wire.

4. Tighten the grounding lug set screw 30 to 35 lbs force-inches (3.4 to 4.0 Nm) of torque.

5. Reinstall the left and right access covers that were removed in step 1 of Section 4.5. Use

the 3/16-inch hex-key to tighten the four screws that sec ure ea ch acce ss cove r to the side s of

the cabinet ground spacer/riser.

5 FEEDER CABLE INSTALLATION AND SPLICING

This section describes how to install the OSP feeder cable and how to splice the feeder cable

fibers to the splitter input fibers.

Page 20

© 2017, ADC Telecommunications, Inc.

Figure 15. Grounding Wire Connection To Cabinet

Page 27

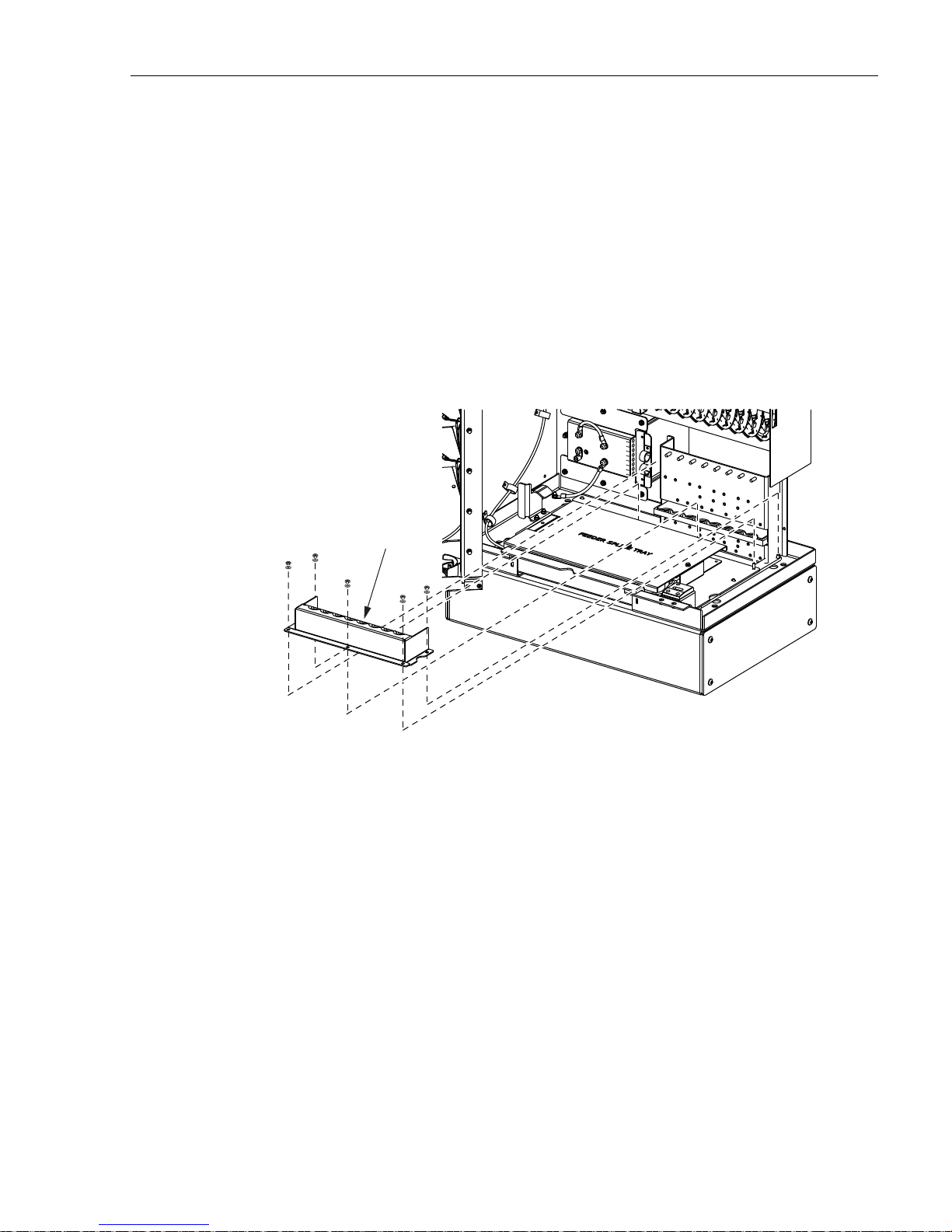

5.1 Cable Bracket Cover Removal/Installation

The cabinet is equipped with a cable bracket cover that prevents dirt, moisture, and insects from

entering the cabinet through the cable entry/exit holes. The cable bracket cover must be

removed to allow installation of the OSP cables and then reinstalled when the cables are in

place. Use the following procedure to remove/install the cable bracket cover:

1. Remove the five nuts and flat washers that secure the cable bracket cover to the bottom of

the cabinet as shown in Figure 16. Save all nuts and washers for later re-installation.

2. Lift the cable bracket cover upward until it is free of the mounting studs and then set it

aside for later re-installation.

3. Reinstall cover when installation of the feeder and distribution cables is complete.

CABLE

BRACKET

COVER

ADCP-96-139 • Rev B • July 2017

5.2 Feeder Cable Installation

The OSP feeder cable enters/exits the cabinet from the bottom. At the entry/exit point to t he

cabinet, the feeder cable is secured with two clamps. Beyond the clamps, the outer sheath of the

cable is removed to expose the optical fibers. The feeder cable is typically a 12-, 24-, or 48-fiber

cable with stranded fiber construction. Blocking and/or grounding kits should be installed (per

local practice) to protect the exposed optical fibers. From the clamping point, the optical fibers

are routed to splice trays for splicing to the splitter input fibers. A lug for securing cable strength

members is provided with the cabinet.

Use the following procedure to install the feeder cable:

1. Remove the cable bracket cover (if not already removed) from the cabinet as described in

Section 5.2 to allow installation of the OSP cables. Then return to step 2 of this procedure

to complete installation of the feeder cable.

22373-A

SHOWN WITH EXTERIOR CABINET

SHELL REMOVED TO ALLOW VIEWING

OF THE CABLE BRACKET COVER

Figure 16. Cable Bracket Cover Removal/Installation

© 2017, ADC Telecommunications, Inc.

Page 21

Page 28

ADCP-96-139 • Rev B • July 2017

2. Route the feeder cable into the cabinet from the bottom. If the cabinet is mounted on a

concrete pad, use the duct on the left side.

3. Pull the cable up through the cabinet and strip off 17.5 feet (5.4 m) of the outside cable

sheath to expose the fiber subunits.

4. Install breakout/blocking and grounding kits as required by local practice. Follow the

installation instructions provided with each kit.

Note: If a grounding kit is required, strip the cable sheath to the recommended length and

install the grounding clamp prior to securing the cable to the cabinet.

5. Locate the cable clamping position specified for securing the feeder cable to the cable

bracket as shown in Figure 17.

FEEDER CABLE

POSITION (8)

8

7

6

REMOVE CUTOUT

TO FIT CABLE

5

DISTRIBUTION

CABLES POSITONS

(1 - 7)

4

3

2

1

22384-A

Figure 17. Secure Feeder Cable to Cable Bracket

6. Locate the clamps, grommets, cover plates, and screws that are provided for securing the

cable to the cabinet.

Note: Two small cable clamps are provided for securing the feeder cable to the cabinet.

7. Assemble each pair of clamps (and grommet if required) on the cable as shown in

Figure 18 and secure the cable to the cabinet at the feeder cable clamping position.

Note: Rubber plugs are inserted into the cable bracket holes to prevent insects from

entering the cabinet. Remove only those rubber plugs necessary to allow installation of the

feeder cable clamps. All other plugs should be left in place.

8. If the cable has a central strength member, locate the lug that is provided for clamping the

strength member to the cable bracket. If the cable does not have a central strength mem ber,

proceed to step 11.

Page 22

© 2017, ADC Telecommunications, Inc.

Page 29

CABLE

ADCP-96-139 • Rev B • July 2017

USE GROMMET

FOR SMALLER

DIAMETER CABLES

CLAMPS

COVER

PLATE

SCREWS

SPACER

21636-B

Figure 18. Cable Clamp Assembly

9. Insert the central strength member into the lug as shown in Figure 19 and then install the

lug on the cable bracket.

LUG

FLAT

WASHER

NUT

CABLE

STRENGTH

MEMBER

22387-B

Figure 19. Strength Member Lug Installation

10. Trim the central strength member to length and tighten the lug set screw.

11. If a grounding kit was installed on the cable, refer to Section 5.3 for the cable grounding

procedure. If a grounding kit was not installed on the cable, refer to Section 5.4 for the

feeder cable splicing procedure.

© 2017, ADC Telecommunications, Inc.

Page 23

Page 30

ADCP-96-139 • Rev B • July 2017

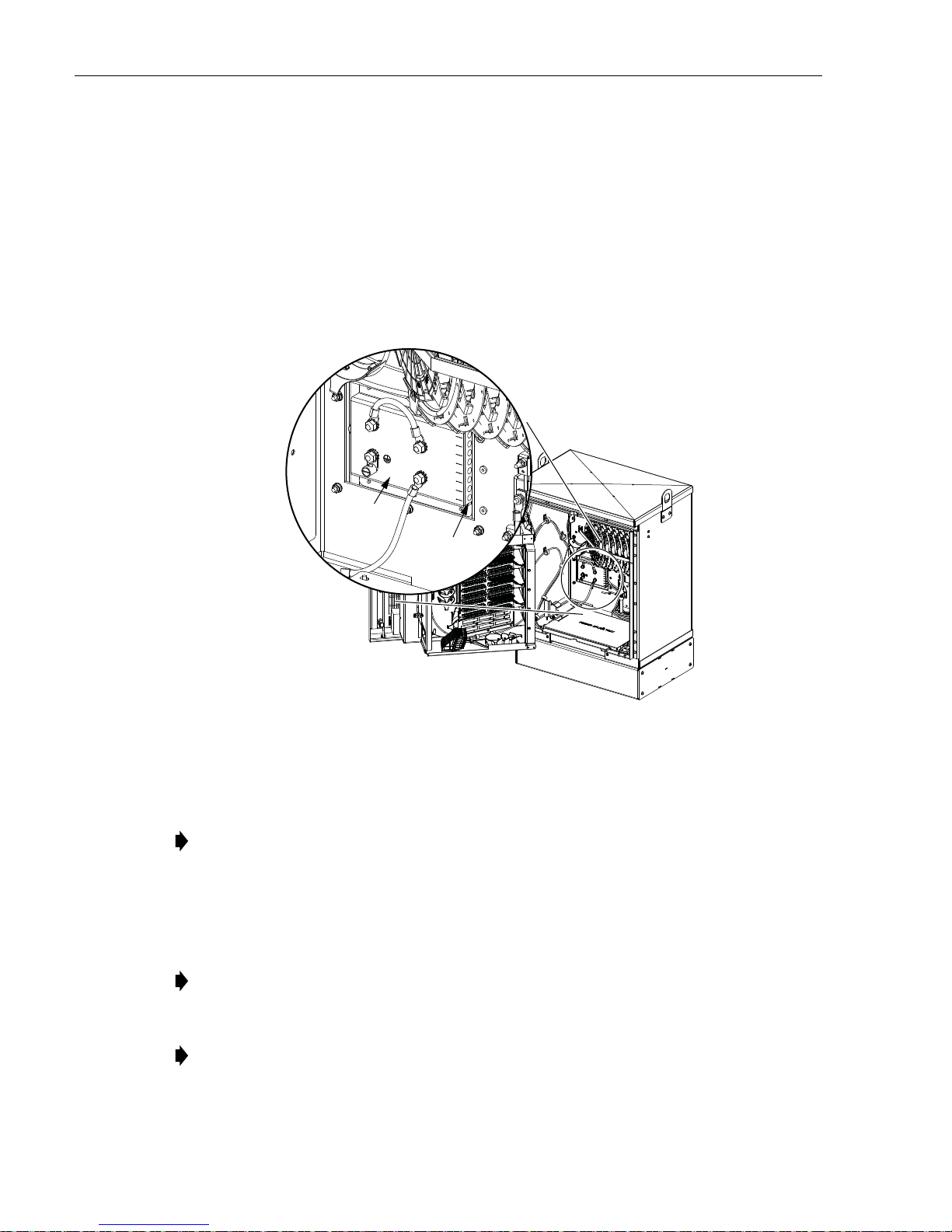

5.3 Grounding the Feeder Cable

If the feeder cable is constructed with a metallic shield or other metallic components, a

grounding kit must be installed on the cable. Use the following procedure for grounding a

feeder cable that has been fitted with a grounding kit:

1. Connect a #6 AWG stranded copper jumper wire (terminated with ring terminals) to the

feeder cable grounding stud.

2. Locate the weather-seal strip attached to the right side of the cabinet grounding system as

shown in Figure 20.

CABINET

GROUNDING

SYSTEM

WEATHER-

SEAL STRIP

22685-A

Figure 20. Cable Grounding System - Interior View

3. Route the feeder cable jumper wire to the weather-seal strip as shown in Figure 21 and

push the free end of the wire through the hole that corresponds to cable 8.

Note: The fiber optic cables are numbered 1 – 8 starting with the first cable on the right

side of the cable bracket. The holes for the grounding cables are numbered 1 – 8 starting

with the top opening in the weather-seal strip.

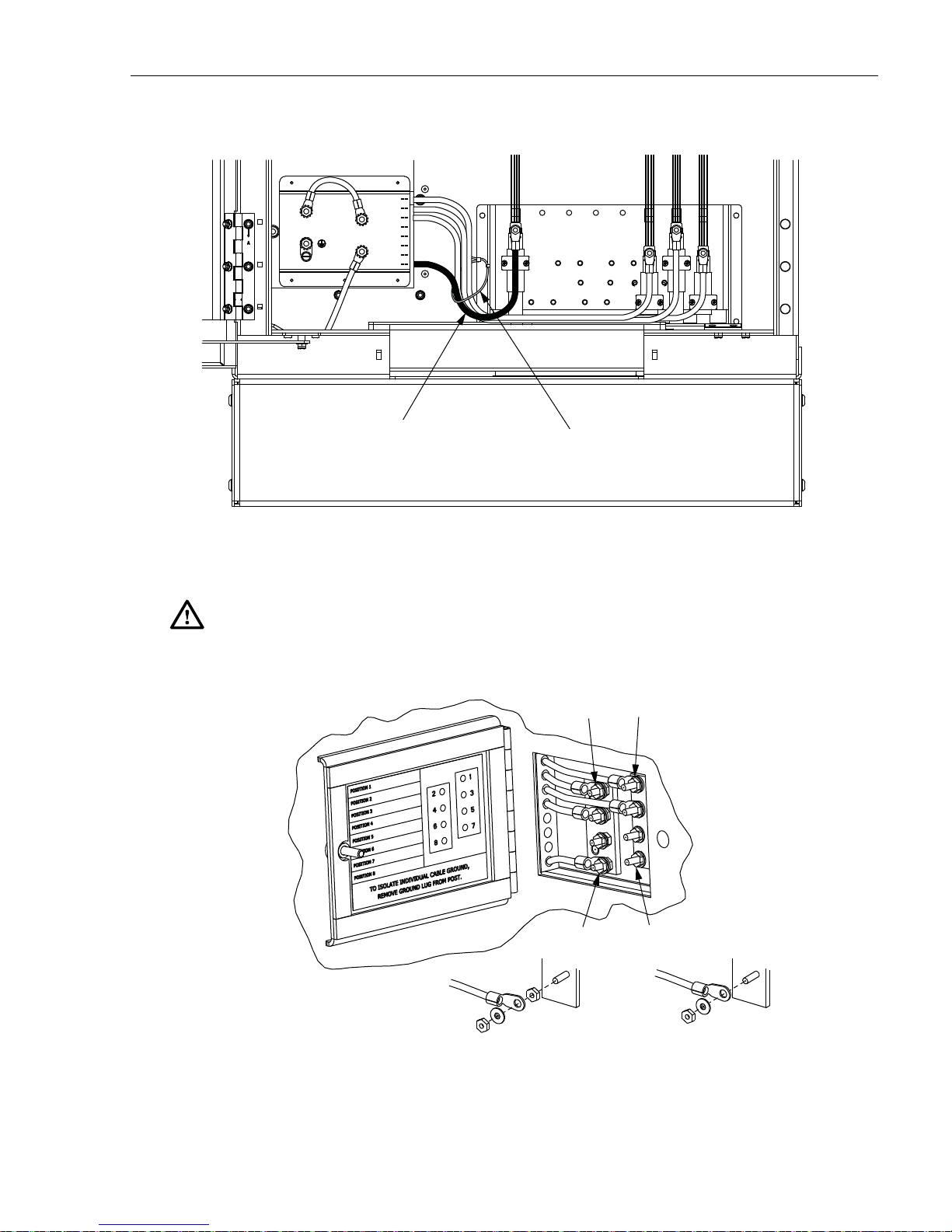

4. Open the grounding system access cover located on rear of cabinet (Figure 22).

5. Identify the grounding stud for cable #8.

Note: A label on the back of the access cover indicates the grounding stud numbers.

6. Connect the grounding jumper wire to grounding stud #8.

Note: Each grounding stud on the left bus bar is equipped with two nuts. When connecting

a jumper wire to the left bus bar, place the cable terminal between the two nuts.

7. Tighten the grounding stud nut to 30 to 35 lbs force-inches. (3.4 to 4.0 Nm) of torque.

Page 24

© 2017, ADC Telecommunications, Inc.

Page 31

ADCP-96-139 • Rev B • July 2017

1

2

3

4

5

6

7

8

12345678

GROUNDING WIRE

FOR FEEDER CABLE

22694-B

SECURE GROUNDING WIRES TO

CABLE BRACKET WITH CABLE TIE

Figure 21. Route Grounding Cable to Grounding System

Warning: The grounding cables ar e connected to cabinet ground through the copp er grounding

blocks. Failure to properly tighten the nut on each individual cable grounding stud could result

in improper grounding of the cable and result in performance or safety issues.

CABLE 1CABLE 2

TIGHTEN TO 30 TO 35

LBS FORCE - INCHES

(3.4 TO 4.0 Nm) OF TORQUE

LEFT BUS BAR

CABLE ASSEMBLY

CABLE 7CABLE 8

21687-A

RIGHT BUS BAR

CABLE ASSEMBLY

Figure 22. Cable Grounding System - Exterior View

Page 25

© 2017, ADC Telecommunications, Inc.

Page 32

ADCP-96-139 • Rev B • July 2017

8. Close the cable grounding system access door and secure using the 216B tool.

5.4 Splicing the Feeder Cable Fibers

Depending on the option ordered, the cabinet may be equipped with either one or two splice

trays for feeder cable splicing. Use the following procedure to route the feeder cable fibers to

the splice trays and to splice the feeder cable fibers to the splitter input fibers:

1. Locate the feeder splice tray which is mounted at the bottom of the cabinet, as shown in

Figure 23, and locate the splitter input fibers which are routed to the feeder splice tray.

SPLITTER

FIBERS

COMMON

TIE POINT

FEEDER CABLE

FIBERS

FEEDER SPLICE

TRAY ASSEMBLY

NOTE: SHOWN WITH CABINET REMOVED

TO ALLOW VIEWING OF FIBER ROUTING

22692-A

Figure 23. Feeder Splice Tray and Feeder/Splitter Fiber Routing

2. Lift the sheet metal cover away from the splice tray holder as shown in Figure 24.

3. Unfasten the hook and pile strips that secure the tray in place and unwind the attached

splitter fibers from around the splice tray assembly.

4. Beginning at the feeder cable subunit breakout point shown in Figure 25, route the feeder

cable fibers to the intersect point with the splitter fibers.

Caution: Always allow sufficient fiber length to permit routing without severe bends. Non bendoptimized fibers may be permanently damaged if bent/curved to a radius of less than 1.5 inches

(3.81 cm).

Page 26

© 2017, ADC Telecommunications, Inc.

Page 33

ADCP-96-139 • Rev B • July 2017

22404-A

SHEET METAL

COVER

SPLICE TRAY

HOLDER

SPLITTER FIBERS

(PRE-INSTALLED)

SPLICE

TRAY

FEEDER CABLE

SUBUNIT BREAKOUT

NOTE: SHOWN WITH CABINET AND SWING

FRAME REMOVED TO ALLOW VIEWING OF

FIBER ROUTING

22693-A

SPLITTER

SUBUNIT

ROUTING

FEEDER

SUBUNIT

ROUTING

SPLICE

TRAY

COVER

COMMON

TIE POINT

Figure 24. Feeder Splice Tray Assembly

Figure 25. Feeder Fiber Routing To Splice Tray

© 2017, ADC Telecommunications, Inc.

Page 27

Page 34

ADCP-96-139 • Rev B • July 2017

5. Create a common tie point by securing the feeder cable subunits (use lacing or cable ties)

to the splitter subunits at the intersect point.

6. Route the feeder cable subunits to the splice tray and then remove the clear plastic cover

from the splice tray.

7. Use lacing or cable ties to secure the feeder cable subunits to the splice tray and verify that

the feeder subunits are the same length as the attached splitter subunits. Adjust as needed

to make the lengths equal.

Caution: Improper handling can damage fiber optic cables. Do not over tighten cable ties or

lacing as this can cause damage or attenuation. Do not compress the fibers or allow them to kink.

8. From the tie point on the splice tray, trim the feeder cable fibers to a cut length of 28

inches (71 cm) and the splitter fibers to a cut length of 36 inches (92 cm).

9. Within the splice tray, remove the subunit tubes from the feeder cable fibers to expose the

bare individual optical fibers.

10. Splice the feeder cable fibers to the appropriate splitter fibers as specified by local policies

and procedures. Adjust and route the fibers within the splice tray as shown in Figure 26.

Refer to Table 3 for the splitter fiber designations.

11. After splicing is completed, re-install the clear plastic cover on the splice tray.

FEEDER CABLE

TIE POINT

SPLITTER

FIBERS

TIE POINT

12. To replace the splice tray, route the attached subunits (there should be two service loops)

FIBER

BREAKOUT

POINT

NOTE: USE LACING

TO SECURE FIBER

SUBUNITS TO TRAY

SPLITTER FIBERS

(36 INCHES / 92 CM)

FEEDER CABLE FIBERS

(28 INCHES / 71 CM)

22447-A

Figure 26. Stranded Fiber Splice Tray - Feeder Cable Splicing

around the splice tray holder radius limiters as shown in Figure 27 Avoid twisting or

kinking the fiber subunit tubes. Maintain a 1.5-inch (3.81 cm) minimum bend radius for all

non bend-optimized fiber.

13. Secure the splice tray to the splice tray holder using the hook and pile strips.

14. Re-install the sheet metal cover on the splice tray holder.

Page 28

© 2017, ADC Telecommunications, Inc.

Page 35

ADCP-96-139 • Rev B • July 2017

Table 3. Splitter and Spare Fiber Port Designations for 12-, 24-, and 48-Fiber Feeder Cables

SUBUNIT FIBER

1 (Blue) 1 –

2 (Orange) 2 – 2 (Orange) – 26

3 (Green) 3 – 3 (Green) – 27

4 (Brown) 4 – 4 (Brown) – 28

5 (Slate) 5 – 5 (Slate) – 29

6 (White) 6 – 6 (White) – 30

1

7 (Red) 7 – 7 (Red) – 31

(12-, 24-,

or 48-

fiber

cable)

8 (Black) 8 – 8 (Black) – 32

9 (Yellow) 9 – 9 (Yellow) – 33

10 (Violet) 10 – 10 (Viol et) – 34

11 (Rose) 11 – 11 (Rose) – 35

12 (Aqua) 12 – 12 (Aqua) – 36

1 (Blue) 13 –

2 (Orange) 14 – 2 (Orange) – 38

3 (Green) 15 – 3 (Green) – 39

4 (Brown) 16 – 4 (Brown) – 40

5 (Slate) 17 – 5 (Slate) – 41

6 (White) 18 – 6 (White) – 42

2

7 (Red) 19 – 7 (Red) – 43

(24- or

48-fiber

cable)

8 (Black) 20 – 8 (Black) – 44

9 (Yellow) 21 – 9 (Yellow) – 45

10 (Violet) 22 – 10 (Viol et) – 46

11 (Rose) – 23 11 (Rose) – 47

12 (Aqua) – 24 12 (Aqua) – 48

SPLITTER

PORT

SPARE

PORT SUBUNIT FIBER

1 (Blue) – 25

3

(48-fiber

cable)

1 (Blue) – 37

4

(48-fiber

cable)

SPLITTER

PORT

SPARE

PORT

COIL ONE SERVICE

LOOP AROUND

RADIUS LIMITERS

START ROUTING

AT THIS POINT

HOOK AND PILE

STRAPS

22412-A

Figure 27. Feeder Splice Tray Replacement

Page 29

© 2017, ADC Telecommunications, Inc.

Page 36

ADCP-96-139 • Rev B • July 2017

6 DISTRIBUTION CABLE INSTALLATION AND SPLICING

This section describes how to install the OSP distribution cables and how to splice the

distribution cable fibers to the distribution panel pigtails.

6.1 Distribution Cable Installation

The OSP distribution cables enter/exit the cabinet from the bottom. At the entry/exit point to the

cabinet, the each cable is secured with two clamps. Beyond the clamps, the outer sheath of the

cable is removed to expose the optical fibers. Distribution cables are typically 72- or 144-fiber

cable with stranded construction. Blocking and/or grounding kits should be installed (per local

practice) to protect the exposed optical fibers. From the clamping point, the optical fibers are

routed to the splice trays for splicing to the distribution panel pigtails. A lug for securing cable

strength members is provided with the cabinet

Use the following procedure to install each distribution cable:

1. Remove the cable bracket cover (if not already removed) from the cabinet as described in

Section 5.2 to allow installation of the OSP cables. Then return to step 2 of this procedure

to complete installation of the distribution cable.

2. Route the distribution cable into the cabinet from the bottom. If the cabinet is mounted on

a concrete pad, use the duct on the right side.

3. Pull the cable up through the cabinet and strip off 17 feet (6.1 m) of the outside cable

sheath to expose the fiber subunits.

4. Install breakout/blocking and grounding kits as required by local practice. Follow the

installation instructions provided with each kit.

Note: If a grounding kit is required, strip the cable sheath to the recommended length and

install the grounding clamp prior to securing the cable to the cabinet.

5. Locate the cable clamping positions specified for securing the distribution cables to the

cable bracket as shown in Figure 28.

Note: Use cable positions 3 and 5 for distribution ca bles that are greater than 0.8 inches in

diameter that require large size cable clamps.

6. Locate the clamps, grommets, cover plates, and screws that are provided for securing the

cable to the cabinet.

Note: Two large cable clamps (for cables 0.8 inches or more in diameter) are provided for

securing the distribution cable to the cabinet. Additional cable clamps must be ordered

separately if more than one distribution cable will be installed or if small cable clamps (for

cables smaller than 0.8 inches in diameter) are required. If additional large cable clamps

are required, order kit FD3-ACCLGCLMP. If small cable clamps are required, order kit

FD3-ACCSMCLMP.

7. Assemble each pair of clamps (and grommet if required) on the cable as shown in

Figure 29 and secure the cable to the cabinet at the selected cable clamping position.

Page 30

© 2017, ADC Telecommunications, Inc.

Page 37

ADCP-96-139 • Rev B • July 2017

1

2

3

4

5

6

7

FEEDER CABLE

POSITION (8)

DISTRIBUTION

CABLES POSITONS

(1 - 7)

22415-A

REMOVE CUTOUT

TO FIT CABLE

123

4

56

78

HOLES FOR

POSITION 5

LARGE CLAMP

HOLES FOR

POSITION 3

LARGE CLAMP

FRONT VIEW OF CABLE BRACKET

USE THE LARGE CABLE CLAMP

FOR CABLES THAT ARE GREATER

THAN 0.8 INCHES IN DIAMETER

Figure 28. Secure Distribution Cable to Cable Bracket

Note: Rubber plugs are inserted into the cable bracket holes to prevent insects from

entering the cabinet. Remove only those rubber plugs necessary to allow installation of the

distribution cable clamps. All other plugs should be left in place.

CABLE

USE GROMMET

FOR SMALLER

DIAMETER CABLES

CLAMPS

SCREWS

COVER

PLATE

Figure 29. Cable Clamp Assembly

SPACER

21636-B

© 2017, ADC Telecommunications, Inc.

Page 31

Page 38

ADCP-96-139 • Rev B • July 2017

NUT

FLAT

WASHER

LUG

CABLE

STRENGTH

MEMBER

22417-A

8. If the cable has a central strength member, locate the lug that is provided for clamping the

strength member to the cable bracket. If the cable does not have a central strength mem ber,

proceed to step 11.

9. Insert the central strength member into the lug as shown in Figure 19 and then install the

lug on the cable bracket.

Figure 30. Strength Member Lug Installation

10. Trim the central strength member to length and tighten the lug set screw.

11. If a grounding kit was installed on the cable, refer to Section 6.2 for the cable grounding

procedure. If a grounding kit was not installed on the cable, refer to Section 6.3 for the

feeder cable splicing procedure.

6.2 Grounding the Distribution Cables

If a distribution cable is constructed with a metallic shield or other metallic components, then a

grounding kit must be installed on the cable. The grounding kit should provide a stud for

attaching a #6 AWG copper jumper wire to the distribution cable. Use the following procedure

for grounding a distribution cable that has been fitted with a grounding kit:

1. Connect a #6 AWG stranded copper jumper wire (terminated with ring terminals) to the

distribution cable grounding stud.

2. Locate the weather-seal strip attached to the right side of the cabinet grounding system as

shown in Figure 31.

3. Route the distribution cable jumper wire to the weather-seal strip as shown in Figure 31

and push the free end of the wire through the hole that corresponds to the cable mounting

position.

Page 32

© 2017, ADC Telecommunications, Inc.

Page 39

ADCP-96-139 • Rev B • July 2017

1

2

3

4

5

6

7

8

12345678

GROUNDING WIRE

FOR DISTRIBUTION

CABLE #1

22695-B

SECURE GROUNDING WIRES TO

CABLE BRACKET WITH CABLE TIE

Note: The fiber optic cables are numbered 1 – 8 starting with the first cable on the right

side of the cable bracket. The holes for the grounding cables are numbered 1 – 8 starting

with the top opening in the weather-seal strip.

CABINET

GROUNDING

SYSTEM

WEATHER-

SEAL STRIP

22685-A

4. Open the grounding system access cover located at the rear side of the cabinet as shown in

Figure 32.

Figure 31. Route Grounding Cable to Grounding System

© 2017, ADC Telecommunications, Inc.

Page 33

Page 40

ADCP-96-139 • Rev B • July 2017

5. Identify the grounding stud that corresponds to the cable mounting position.

Note: A label on the back of the access cover indicates the grounding stud numbers.

CABLE 1CABLE 2

CABLE 7CABLE 8

TIGHTEN TO 30 TO 35

LBS FORCE - INCHES

(3.4 TO 4.0 Nm) OF TORQUE

LEFT BUS BAR

CABLE ASSEMBLY

RIGHT BUS BAR

CABLE ASSEMBLY

21687-A

Figure 32. Cable Grounding System - Exterior View

6. Connect the grounding jumper wire to the appropriate cable grounding stud.

Note: Each grounding stud on the left bus bar is equipped with two nuts. When connecting

a jumper wire to the left bus bar, place the cable terminal between the two nuts.

7. Tighten the grounding stud nut to 30 to 35 lbs force-inches. (3.4 to 4.0 Nm) of torque.

Warning: The grounding ca bles are connected to cabinet ground th rough the copper grounding

blocks. Failure to properly tighten the nut on each individual cable grounding stud could result

in improper grounding of the cable and result in performance or safety issues.

8. Close the cable grounding system access door and secure using the 216B tool.

Page 34

© 2017, ADC Telecommunications, Inc.

Page 41

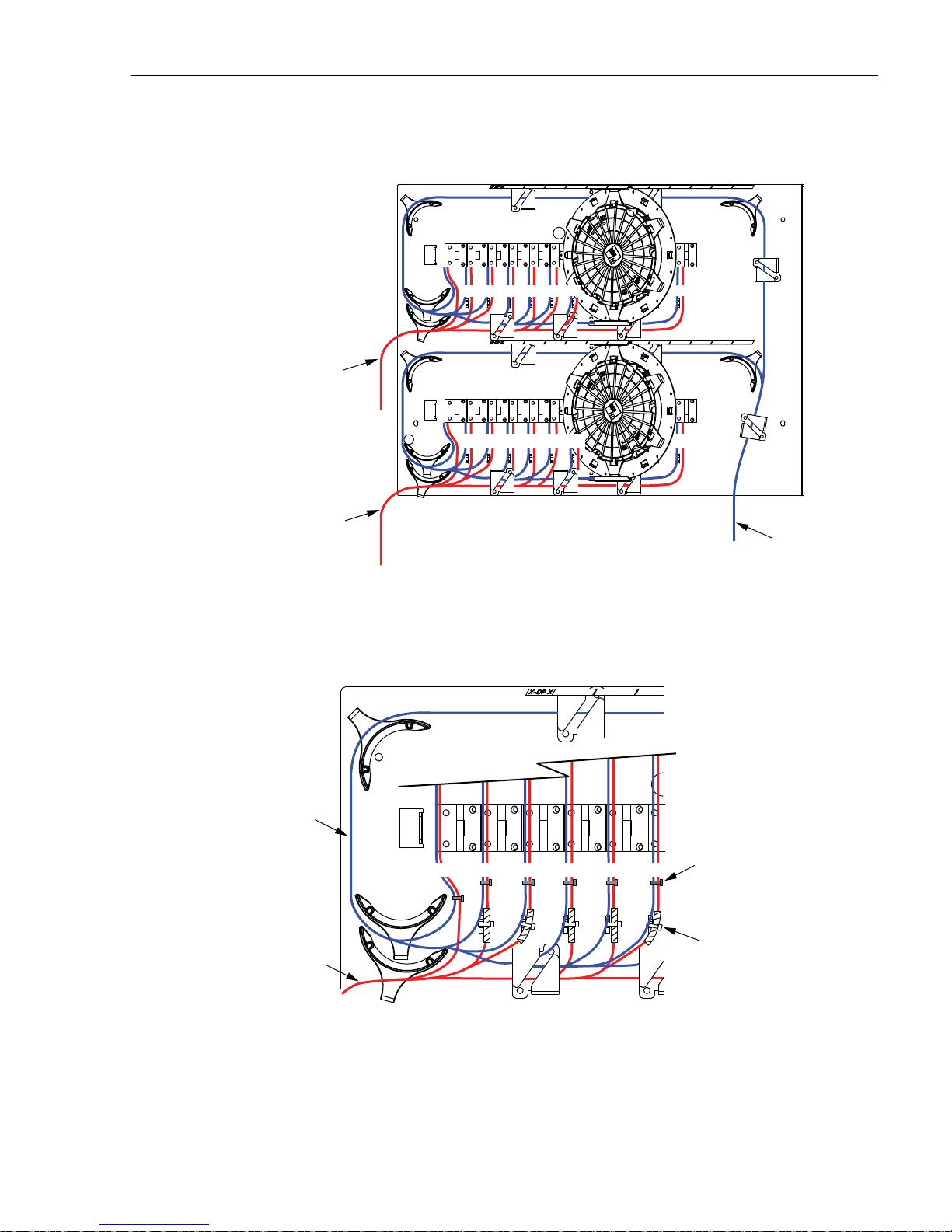

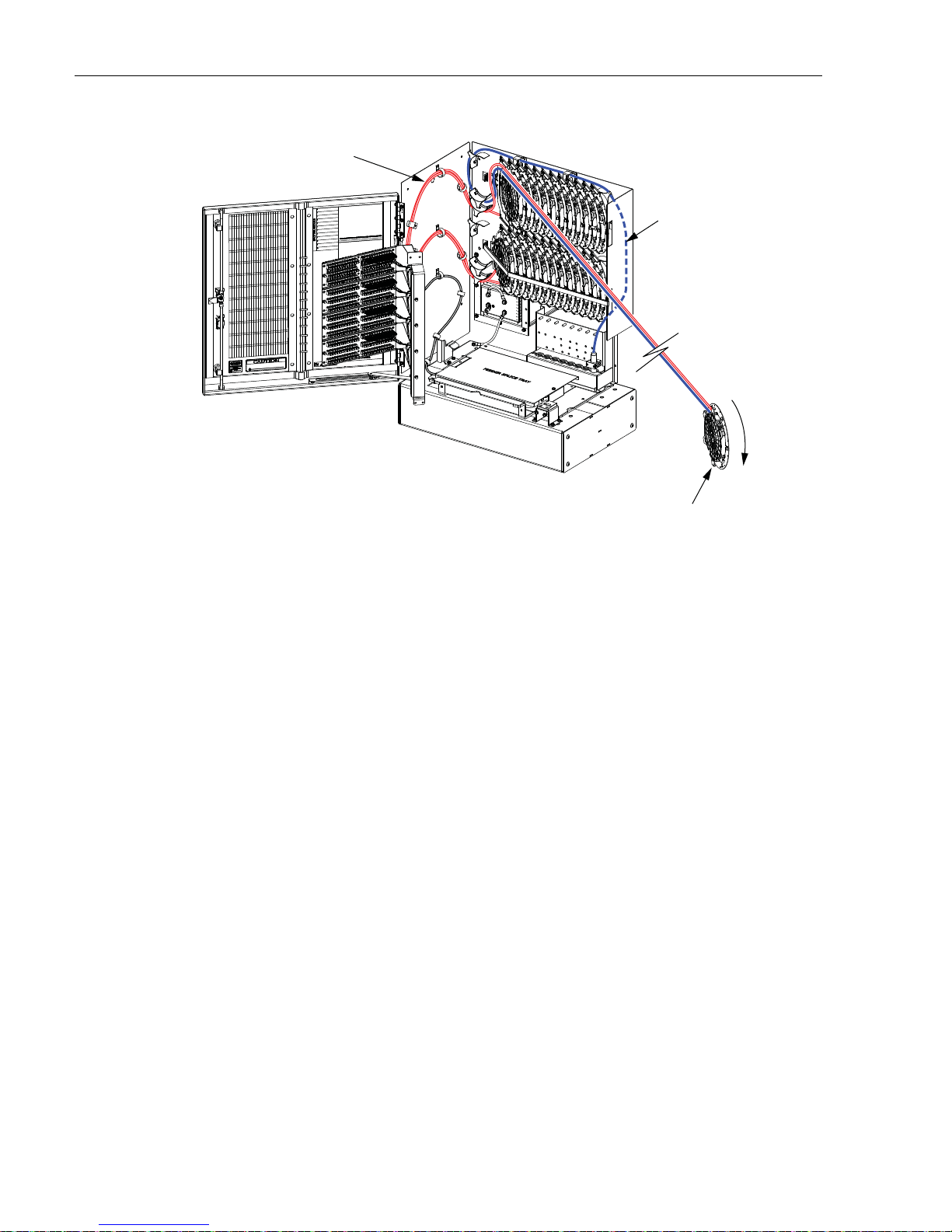

6.3 Splicing the Distribution Cable Fibers

DISTRIBUTION

SPLICE WHEEL

ASSEMBLY

NOTE: SHOWN WITH CABINET REMOVED

TO ALLOW VIEWING OF FIBER ROUTING

22696-A

DISTRIBUTION CABLE

SUBUNITS ROUTED

TO SPLICE WHEELS

DISTRIBUTION PANEL

SUBUNITS ROUTED

TO SPLICE WHEELS

Depending on the option ordered, the cabinet may be equipped with up to 24 splice wheels for

distribution cable splicing. Use the following procedure to route the distribution cable fibers to

the splice trays and to splice the distribution cable fibers to the distribution panel pigtails:

1. Identify and locate the distribution panel subunits that are routed from the back of each

panel to the splice wheels as shown in Figure 33.

2. Unfasten the hook and pile strip that secures the top row of splice wheels to the back of the

cabinet. Rotate the splice wheels outward so the distribution panel fibers and cable rings

are visible.

3. Refer to Figure 34 to identify and locate the splice wheels for distribution panel #1.

Note: The pigtails from each distribution panel are grouped into six 12-fiber subunits and

each subunit is routed to a splice wheel. The subunits are numbered from 1 – 24 and the

individual fibers are numbered from 1 – 288. The splice wheels are arranged from left to

right starting at the top and are labeled with the individual fiber/port numbers.

ADCP-96-139 • Rev B • July 2017

Figure 33. Distribution Splice Wheels and Distribution Panel Subunit Routing

Page 35

© 2017, ADC Telecommunications, Inc.

Page 42

ADCP-96-139 • Rev B • July 2017

1

7

6

12

13

18

19

24

HOOK AND

PILE STRIP

SUBUNITS PANEL FIBERS

1 - 6 1 1 - 72

7 - 12 2 73 - 144

SUBUNITS PANEL FIBERS

13 - 18 3 145 - 216

19 - 24 4 217 - 288

22697-A

Figure 34. Distribution Splice Wheel Assembly

4. Beginning at the distribution cable fiber breakout point, route each distribution cable

subunit to the tie point below the appropriate splice wheel as shown in Figure 35.

Note: Each distribution panel subunit is secured to the cabinet at a point just below a

splice wheel. Spiral wrap is placed over the subunit at the tie point to prevent the cable tie

from compressing the fiber within the subunit.

Caution: Always allow sufficient fiber length to permit routing without severe bends. Non bendoptimized fibers may be permanently damaged if bent/curved to a radius of less than 1.5 inches

(3.81 cm).

5. Use cable ties or lacing to loosely secure each distribution fiber subunit to the appropriate

distribution panel subunit at a point just above the spiral wrap as shown in Figure 36.

Caution: Improper handling can damage fiber optic cables. Do not over tighten cable ties or

lacing as this can cause damage or attenuation. Do not compress the fibers or allow them to kink.

Page 36

© 2017, ADC Telecommunications, Inc.

Page 43

ADCP-96-139 • Rev B • July 2017

NOTE: SHOWN WITH MOST OF THE SPLICE WHEELS

REMOVED TO ALLOW VIEWING OF SUBUNIT ROUTING

DISTRIBUTION

PANEL 1 AND 2

SUBUNITS 1 - 12

FIBERS 1 - 144

DISTRIBUTION

PANEL 3 AND 4

SUBUNITS 13 - 24

FIBERS 145 - 288

1

13

141516 17 18

762345 12

19

24

Figure 35. Distribution Cable Subunit Routing to Splice Wheel s

NOTE: SHOWN WITH SPLICE WHEELS REMOVED

TO ALLOW VIEWING OF SUBUNIT TIE POINTS

22698-A

DISTRIBUTION

CABLE

SUBUNITS

DISTRIBUTION

CABLE SUBUNITS

DISTRIBUTION

PANEL SUBUNITS

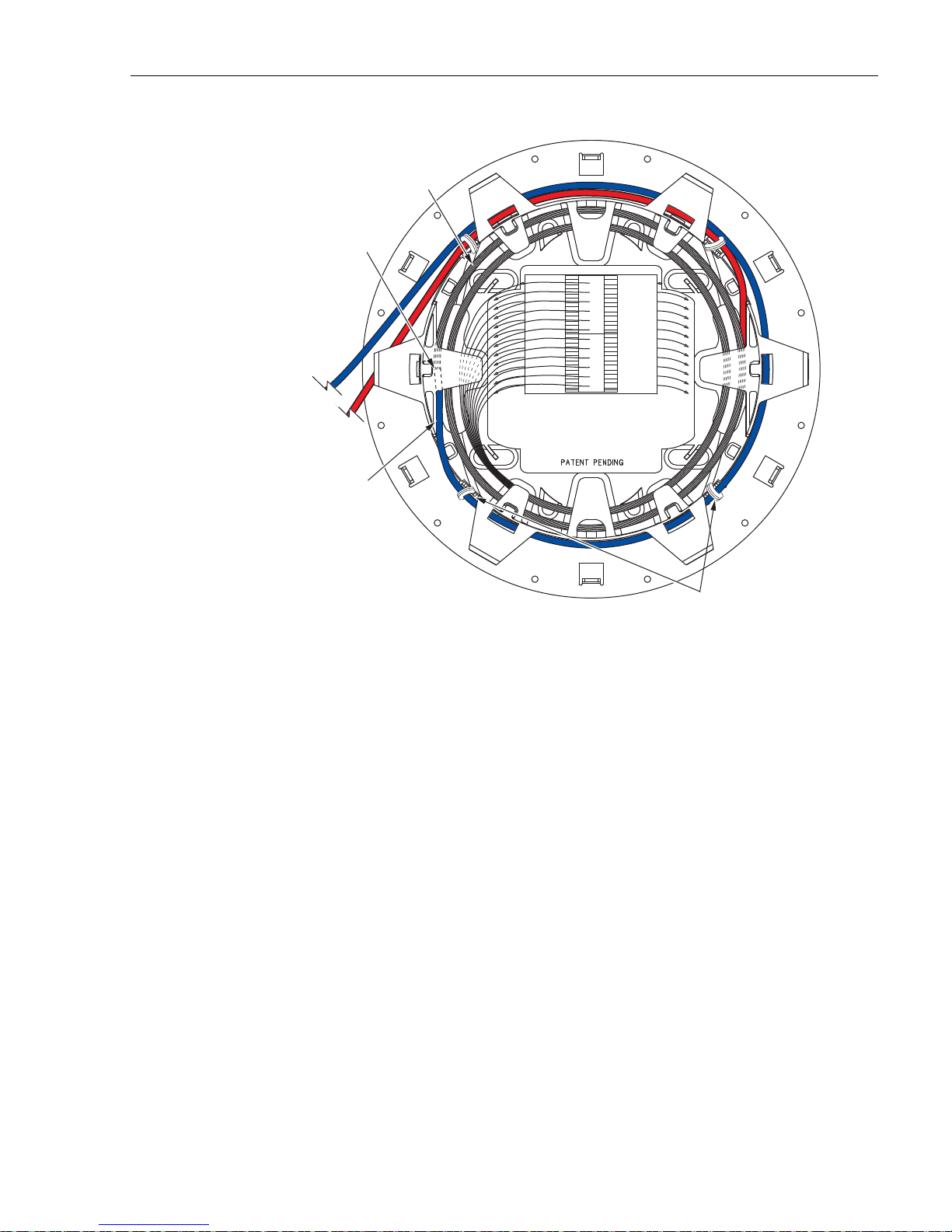

6. Remove the splice wheel for fibers/ports 1-12 from the cabinet and carefully unwind the

the distribution panel subunit (uncoil to full length) that is coiled around the wheel.

LOOSELY SECURE DISTRIBUTION

CABLE AND DISTRIBUTION PANEL

SUBUNITS TOGETHER AT A POINT

JUST ABOVE THE SPIRAL WRAP

1

45

623

FACTORY INSTALLED

CABLE TIES OVER

SPIRAL WRAP

22449-A

Figure 36. Securing the Distribution Cable Subunits

© 2017, ADC Telecommunications, Inc.

Page 37

Page 44

ADCP-96-139 • Rev B • July 2017

7. Starting at the common tie point below the splice wheel, route the distribution cable

subunit to the splice wheel. Make sure the distribution cable subunit and distribution panel

subunit are same length as shown in Figure 37.

Figure 37. Equalize the Distribution Panel and Distribut ion Cable Subunit Lengths

8. Coil the distribution subunit once around th e splice wheel and then mark the fiber breakout

point (see Figure 37) on the outside of the subunit protective jacket.

9. From the point marked in step 8, trim the distribution cable breakout fibers to a breakout

length of 37 inches (94 cm).

10. Starting at the breakout mark, remove the protective jacket to expose the distribution cable

subunit fibers.

11. Remove the top cover from the splice wheel.

12. Secure the distribution cable subunit to the splice wheel at the points specified in

Figure 38.

13. Adjust the distribution cable subunit so the fiber breakout is positioned at the specified

point (see Figure 38).

Page 38

© 2017, ADC Telecommunications, Inc.

Page 45

ADCP-96-139 • Rev B • July 2017

TOP SIDE

FIBER BREAKOUT

POINT

MAKE LOOP AS

LARGE AS POSSIBLE TO

ENSURE MAXIMUM

FIBER STORAGE

DISTRIBUTION

CABLE

SUBUNIT

DISTRIBUTION

PANEL

SUBUNIT

ROUTE TO

INSIDE OF TRAY

DISTRIBUTION CABLE

SUBUNIT TIE POINTS

22429-A

ROUTE FIBERS 2 TIMES

AROUND INSIDE OF TRAY

Figure 38. Installing Distribution Cable Subunit In Splice Wheel

14. Route the breakout fibers at least two times around the inside of the wheel making the loop

as large as possible to ensure maximum fiber storage.

15. Splice the distribution panel fibers to the distribution cable fibers in accordance with local

policies and procedures.

16. Replace the splice wheel top cover and then turn the splice wheel in a clockwise direction

to roll up the excess slack as shown in Figure 39

© 2017, ADC Telecommunications, Inc.

Page 39

Page 46