Page 1

Instruction Sheet

24290-A

ADCP-90-459

Issue 2, June 2016

FMT

Two Rack Unit (2RU)

Fiber Management Tray (FMT)

2RU FMT (Micro-VAM Configuration Shown)

Content Page

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1 PRODUCT INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.1 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2 Configurations and Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.2.1 Termination (Universal Entry) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.2 Termination (Left Entry for IFC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.3 Micro-VAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.4 48-Position Termination/Splice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.5 Bulk Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3 Attenuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2 DIMENSIONS AND SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3 UNPACKING THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4 MOUNTING THE 2RU FMT ON THE RACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5 INSTALLING MICRO-VAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

(continued)

300001717914 Rev B Page 1

www.commscope.com © 2016 CommScope. All Rights Reserved.

Page 2

ADCP-90-459 • Issue 2 • June 2016

Content Page

6 INSTALLING AND ROUTING CABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.1 General Cable Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.2 Internal Cable Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.1 Opening the Tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.2 Sliding Adapter Packs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.3 Micro-VAMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.4 Closing the Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8 TECHNICAL ASSISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2.1 Termination (Universal Entry). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.2.2 Termination (Left Entry for IFC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.2.3 Micro-VAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2.4 48-Position Termination/Splice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2.5 Bulk Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

INTRODUCTION

This manual describes the Two-Rack Unit (2RU) Fiber Management Tray (FMT) and provides

all information required to install and use this product.

Revision History

ISSUE DATE REASON FOR CHANGE

1 3/2011 Original

Trademark Information

CommScope (logo), CommScope, and ADC are trademarks, Scotchlok are registered trademarks of 3M

Company. FiberLok is a trademark of 3M Company. VELCRO is a registered trademark of Velcro

Industries, B.V.

Admonishments

Important safety admonishments are used throughout this manual to warn of possible hazards to

persons or equipment. An admonishment identifies a possible hazard and then explains what

may happen if the hazard is not avoided. The admonishments — in the form of Dangers,

Warnings, and Cautions — must be followed at all times. These warnings are flagged by use of

the triangular alert icon (seen below), and are listed in descending order of severity of injury or

damage and likelihood of occurrence.

Danger: Danger is used to indicate the presence of a hazard that will cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Page 2

© 2016 CommScope. All Rights Reserved.

Page 3

Warning: Warning is used to indicate the presence of a hazard that can cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that will or can cause minor

personal injury or property damage if the hazard is not avoided.

General Safety Precautions

Caution: Fiber optic cables may be da maged if be nt or curved to a radius that is le ss than the

recommended minimum bend radius. Always observe the recommended bend radius limit when

installing fiber optic cables and patch cords.

Danger: Exposure to laser radiation can seriously damage the retina of the eye. Do not look

into the ends of any optical fiber. Do not assume t he laser power is turned-off or that the fiber is

disconnected at the other end.

ADCP-90-459 • Issue 2 • June 2016

Caution:

Improper handling can damage fiber optic cables. Do not bend fiber optic cable more

sharply than the minimum recommen ded ben d radius spec ified by th e cable manufa cturer. D o not

apply more pulling force to the c ab le than spec ified . D o not co mpress th e fi ber or al low it to kink .

Caution: Placing a load in excess of 12 pounds (5.4 kg) onto an open tray will result in

misalignment or damage to the tray.

1 PRODUCT INTRODUCTION

This section introduces the Two-Rack Unit (2RU) Fiber Management Tray (FMT).

1.1 General Description

The Two-Rack Unit (2RU) Fiber Management Tray (FMT) is a rack-mount fiber optic panel

consisting of a basic chassis with a slide-out drawer and a drop-in plate (DIP) installed inside

the drawer to provide various functions such as cable termination. The basic chassis is the same

for all models of the 2RU FMT. The drop-in plate, which is installed in the factory, depends on

customer order. Figure 1 shows a 2RU FMT with a drop-in plate providing a micro-VAM

splitter function.

The 2RU FMT is available with the following rack-mount options:

• EIA or WECO, 19-inch (48.26 cm);

• EIA or WECO, 23-inch (58.42 cm);

• ETSI, 20.28 inch (51.51 cm);

• All rack-mount options (EIA, WECO, or ETSI) provide the following recess options: 2.2inch (5.59 cm), 5-inch (12.70 cm), 6-inch (15.24 cm), or 40 mm (1.6 inch).

© 2016 CommScope. All Rights Reserved.

Page 3

Page 4

ADCP-90-459 • Issue 2 • June 2016

24291A

DROP-IN

PLATE (DIP)

BASIC

CHASSIS

1.2 Configurations and Components

The 2RU FMT is currently available in a variety of DIP configurations, with more being

developed based on customer requests. The configurations available as of this printing of this

manual are:

• Termination (FMT-GRT, universal entry);

• Termination (FMT-GN7, left entry for Intrafacility Fiber Cable);

• Micro-VAMs (FMT-GVM, universal entry);

• 48-position termination/splice (FMT-GTL, left side splice, right side termination).

• Bulk storage (FMT-GBS, universal entry).

For multifiber cable assemblies, FMTs with termination for IFC (left entry) is your best choice. If

you are installing patch cords terminated with adapters, universal en try is your best ch oice.

1.2.1 Termination (Universal Entry)

Figure 2 shows the main external features of the 64-position termination model (available with

up to 72-terminations.

Figure 1. 2RU FMT (Micro-VAM Model Shown)

The features shown include the following (going from bottom left clockwise):

• Slide Latches (2)—Hold tray closed. Sliding latches inward releases tray to be opened.

Page 4

© 2016 CommScope. All Rights Reserved.

Page 5

ADCP-90-459 • Issue 2 • June 2016

• Radius Limiters (4)—Maintain a protective, minimum-bend radius for cables routed into

tray. There are two front and two rear radius limiters, as shown.

• Sliding Adapter 6-Packs (8)—Provide easy access for connecting cables and cleaning

connectors and adapters. A variety of singlemode and multimode connector types are

available from ADC. For details, refer to the product catalog.

• VELCRO Loop Tie-Down Points (Each Side)—Are used to secure cables to the side of

the tray using the velcro loops provided with the product.

• Wax Lacing Tie-Down Points (Each Side)—Are used to secure cables on the back of the

tray using wax lacing (not provided).

• Mounting Brackets (2)—Are used to fasten the tray to the rack.

• Sliding Radius Limiters (2)—Provide protected entry points for cables. The movement

of these radius limiters is controlled for optimum slack management.

• Keylock (Optional)—Provides a means to lock the tray when closed.

VELCRO LOOP

(PROVIDED)

TIE-DOWN POINTS

(EACH SIDE)

SLIDING

ADAPTER

6-PACKS

RADIUS

LIMITER

(2 PLACES)

RADIUS

LIMITER

(2 PLACES)

WAX LACING

TIE-DOWN POINTS

(2 EACH SIDE)

LOCK OPEN

LATCH

SLIDE

LATCH

(2 PLACES)

24300-A

MOUNTING

BRACKET

(2 PLACES)

SLIDING RADIUS

LIMITER (2 PLACES)

KEYLOCK

(OPTIONAL)

Figure 2. 64-Position Termination Only (Universal Entry) 2RU FMT

© 2016 CommScope. All Rights Reserved.

Page 5

Page 6

ADCP-90-459 • Issue 2 • June 2016

KEYLOCK

(OPTIONAL)

SLIDING

ADAPTER

6-PACKS

WAX LACING

TIE-DOWN POINTS

(EACH SIDE)

SLIDE LATCH

(2 PLACES)

SLIDING RADIUS

LIMITER (2 PLACES)

MOUNTING

BRACKET

(2 PLACES)

24292-A

VELCRO LOOP

(PROVIDED)

TIE-DOWN POINTS

(EACH SIDE)

1.2.2 Termination (Left Entry for IFC)

Figure 4 shows the external features of the 72-position left-entry model, intended for use with

IFC. Except for the left-side entry, the components are similar to the universal entry model. For

a definition of the callouts, refer to subsection 1.2.1.

Figure 3. 72-Position Termination (Left Entry for IFC) 2RU FMT

1.2.3 Micro-VAM

Figure 4 shows the 64-position micro-VAM model, which has micro-VAMs in place of adapter

6-paks. VAMs (Value Added Modules are housings for fiber optic splitters and Wave Division

Multiplexers (WDM).

Figure 5 shows an example of a dual-circuit micro-VAM with its schematic label.

Micro-VAMs can be either single circuit or dual circuit, and can be populated one at a time.

• Single circuit micro-VAMs have one input port and two output ports.

• Dual circuit micro-VAMs have two input ports and four output ports.

2RU FMT capacity is 12 inputs and 24 outputs for a tray loaded with single-circuit microVAMs, and 24 inputs and 48 outputs for a tray loaded with dual circuit micro-VAMs.

Page 6

© 2016 CommScope. All Rights Reserved.

Page 7

ADCP-90-459 • Issue 2 • June 2016

24293-A

SLIDE

LATCH

(2 PLACES)

RADIUS

LIMITER

(2 PLACES)

RADIUS

LIMITER

(2 PLACES)

SLIDING RADIUS

LIMITER (2 PLACES)

MOUNTING

BRACKET

(2 PLACES)

WAX LACING

TIE-DOWN POINTS

(EACH SIDE)

VELCRO LOOP

(PROVIDED)

TIE-DOWN POINTS

(EACH SIDE)

SLIDING

MICRO VAM

6-PACKS

KEYLOCK

(OPTIONAL)

18643-A

1 x N

SPLITTER

IN OUT

1 x N

SPLITTER

IN OUT

A1

A2

A

B1

B2

B

Figure 4. 64-Position Micro-VAM 2RU FMT

Figure 5. Sliding Micro-VAM With Dual-Circuit Schematic Label

1.2.4 48-Position Termination/Splice

Figure 6 shows the 48-Position Termination/Splice model. This panel has many of the same

features as the 72-position termination panel, plus a splice tray. Optical fibers brought into the

panel from an outside source are spliced in the splice tray to internal pigtails.

Page 7

© 2016 CommScope. All Rights Reserved.

Page 8

ADCP-90-459 • Issue 2 • June 2016

The pigtails are routed within the drawer to be terminated on the front side of the sliding adapter

packs. Optical circuits are completed by connecting connectorized fibers to the rear side of the

adapter packs.

This model provides splicing and termination for 48 optical fibers. It holds two splice trays,

each with the capacity for 24 splices. It has eight adapter six packs providing 48 connectorized

terminations.

VELCRO LOOP

(PROVIDED)

TIE-DOWN POINTS

(EACH SIDE)

WAX LACING

TIE-DOWN POINTS

(EACH SIDE)

SLIDE

LATCH

(2 PLACES)

SPLICE

TRAY

RADIUS

KEYLOCK

(OPTIONAL)

LIMITERS

SLIDING

ADAPTER

6-PACKS

RADIUS

LIMITER

(2 PLACES)

SLIDING RADIUS

LIMITER (2 PLACES)

Figure 6. 48-Position Termination/Splice 2RU FMT

24294-A

MOUNTING

BRACKET

(2 PLACES)

Page 8

© 2016 CommScope. All Rights Reserved.

Page 9

ADCP-90-459 • Issue 2 • June 2016

24296-A

SLIDE

LATCH

(2 PLACES)

RADIUS

LIMITERS

(2 PLACES)

SLIDING RADIUS

LIMITER (2 PLACES)

MOUNTING

BRACKET

(2 PLACES)

WAX LACING

TIE-DOWN POINTS

(EACH SIDE)

VELCRO LOOP

(PROVIDED)

TIE-DOWN POINTS

(EACH SIDE)

RADIUS LIMITERS FOR

STORAGE SPOOLS

1.2.5 Bulk Storage

Figure 7 shows the Bulkhead Storage model. This model stores 150 1.6mm patch cords (with

two meters stored per patch cord). Patch cords can enter from top or bottom, left or right side.

1.3 Attenuators

Attenuators (optional) decrease the optical power in a fiber by a specific or adjustable amount.

Once the desired level of attenuation is determined, fixed attenuators may be inserted in the

fiber optic line to deliver a precise output. In the 48-position termination/splice (FMT-GTL)

configuration and 72-position termination configuration (FMT-GN7), attenuators may be used

on either side of the sliding adapter packs. In the 72-position termination (FMT-GRT)

configuration, attenuators may only be used on the rear (back) side of sliding adapter packs.

2 DIMENSIONS AND SPECIFICATIONS

Figure 8 shows 2RU FMT dimensions for rack type, rack width, and recess options. Table 1 lists

specifications for the 2RU FMT.

Figure 7. Bulkhead Storage 2RU FMT

Page 9

© 2016 CommScope. All Rights Reserved.

Page 10

ADCP-90-459 • Issue 2 • June 2016

18547-B

3.46 IN.

(8.79 CM)

10.86 IN.

(27.58 CM)

17.27 IN.

(43.87 CM)

TOP VIEW

FRONT VIEW

RECESS OPTIONS

40 mm

2.2-INCH

5-INCH

6-INCH

6.5-INCH

1.535 IN.

2.25 IN.

5.0 IN.

6.0 IN.

6.5 IN.

3.9 CM

5.7 CM

12.7 CM

15.2 CM

16.5 CM

ETSI

19-INCH EIA/WECO

23-INCH EIA/WECO

20.28 IN.

18.31 IN.

22.32 IN

51.5 CM

46.5 CM

56.7 CM

RACK WIDTH OPTIONS

ETSI

WECO

EIA

0.98 IN.

1.0 IN.

1.25 IN

2.5 CM

2.5 CM

3.25 CM

RACK TYPE OPTIONS

Figure 8. 2RU FMT Dimensions

Page 10

© 2016 CommScope. All Rights Reserved.

Page 11

ADCP-90-459 • Issue 2 • June 2016

Table 1. 2RU FMT Specifications

ITEM DESCRIPTION

Dimensions (H W D) See Figure 8. Shipping dimensions 8 x 15.5 x 24 in. (20.3 x 39.4 x 61 cm)

Weight Approx. 10 lbs. (4.54 Kg) Shipping weight approx. 11 lbs. (5 Kg)

72-POSITION TERMINATION (UNIVERSAL OR LEFT ENTRY)

Capacity One tray holds up to 12 adapter 6-packs, providing a capacity of 72 front

terminations and 72 rear terminations per tray.

Connector Types A variety of connector types are available. Refer to the product catalog for a

current listing.

72-POSITION MICRO-VAM

Capacity With single circuit micro-VAMs: 12 inputs, 24 outputs

With dual circuit micro-VAMs: 24 inputs, 48 outputs

Connectors A variety of connector types are available. Refer to the product catalog for a

current listing.

Split Ratio Split ratios ranging from 98:2 to 50:50 are available. Refer to the product

catalog for a current listing.

48-POSITION TERMINATION/SPLICE

Capacity 48 splices; 48 terminations.

Connectors Same as above.

Splice tray capacity Four tray capacity each with two splice chips providing a total of 12 splices.

BULKHEAD STORAGE See Figure 23 on page 26.

Capacity 150 1.6mm patch cords.

115 1.7mm patch cords.

85 2.0mm patch cords.

50 3.0mm patch cords.

Storage per patch cord 2 meters (6.56 feet).

3 UNPACKING THE PRODUCT

Unpack and inspect the 2RU FMT as follows:

1. Inspect the exterior of the shipping container fo r evidence of rough h andling that may have

damaged the contents of the container.

2. Unpack the 2RU FMT and check for possible damage.

3. If damage is detected or if parts are missing, file a claim with the commercial carrier and

then notify ADC Customer Service. Save damaged carton for inspection by the carrier.

4. For repair, replacement, and warranty information, refer to Section 8 on the last page of

this manual.

5. Save the shipping container for use if equipment requires shipment at a future date.

© 2016 CommScope. All Rights Reserved.

Page 11

Page 12

ADCP-90-459 • Issue 2 • June 2016

18546-A

MOUNTING

HOLES

(TYPICAL)

NOTE:

USE TOP AND BOTTOM HOLES ON BOTH SIDES.

4 MOUNTING THE 2RU FMT ON THE RACK

For all mounting configurations, the 2RU FMT uses two mounting brackets, one on either side.

Each bracket has four mounting holes (see Figure 9), but only the top and bottom holes are

required. Install the tray using the following procedure:

Note: For mounting hole dimensions, see Figure 8.

1. Position the tray on the rack aligning the tray mounting holes with the corresponding holes

in the rack.

2. Using the fastening hardware provided, fasten the tray to the rack using four fasteners of

the required type. Use the top and bottom holes in each bracket. Leave the two middle

holes empty.

5 INSTALLING MICRO-VAMS

Micro-VAM trays are shipped empty. Micro-VAMs if ordered, are packaged separately. To

install a micro-VAM, position it as shown in Figure 10 and slide it down into the guide.

Figure 9. 2RU FMT Mounting Holes

Page 12

© 2016 CommScope. All Rights Reserved.

Page 13

ADCP-90-459 • Issue 2 • June 2016

18612-A

GUIDE

REAR RADIUS

LIMITER

Figure 10. Installing a Micro-VAM

© 2016 CommScope. All Rights Reserved.

Page 13

Page 14

ADCP-90-459 • Issue 2 • June 2016

6 INSTALLING AND ROUTING CABLES

6.1 General Cable Information

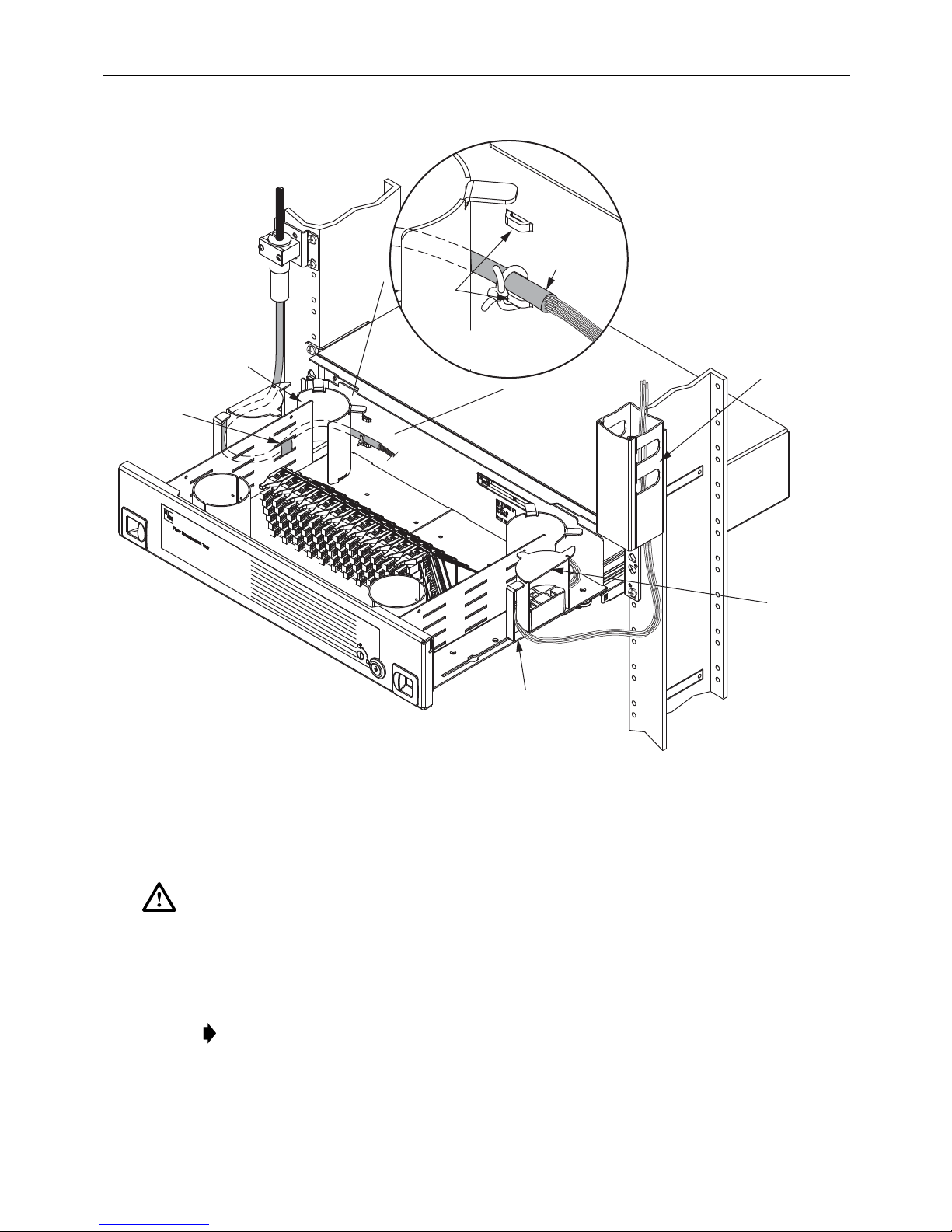

Incoming IFC or OSP must be secured with a cable clamp to the frame before entering the FMT, as

shown in

Refer to Figure 12 for appropriate cable length.

Caution: Do not route 900 micron fibers through sliding radius limiters. Fiber damage may

occur. Route only jacketed fibers through the sliding radius limiters.

Figure 11. FMTs may be ordered without

CABLE

CLAMP

SUBUNIT BREAKOUT POINT

FOR 6, 12, OR 24 FIBER SUBUNIT

OR INDIVIDUAL JACKET

OR 2 MM CABLES

IFC or OSP

cables installed at the factory.

FRAME

24295-A

SLIDING

RADIUS

LIMITER

Figure 11. Cable Clamping Point

Page 14

© 2016 CommScope. All Rights Reserved.

Page 15

ADCP-90-459 • Issue 2 • June 2016

OSP/IFC

CABLE

31.0 IN. (78.7 CM)

+0.0 IN./-6.0 IN.

(+0.0 CM/-15.2 CM)

65.0 IN. (165.1 CM)

+0.0 IN./-6.0 IN.

(+0.0 CM/-15.2 CM)

SUBUNIT

DESIGNATION

LABEL

CONNECTORS

CLAMP

20208-A

1.0 IN.

(2.54 CM)

6.2 Internal Cable Routing

Figure 12. Cable Assembly Breakout Detail

A separate procedure is provided here for each different DIP configuration.

6.2.1 Termination (Universal Entry)

Cables routed into the tray for termination are normally pre-terminated individual cables

(simplex or duplex patch cords). Refer to the following instructions.

1. Open tray fully and lock it using the lock open latch (see Subsection 7.1 Opening the Tray).

2. Route the cable along the rack to the 2RU FMT, as shown in Figure 13.

Note: The cable may be routed from either above or below the tray. It may be routed into

the 2RU FMT from either the left or right side.

3. Secure the cable to the rack using local practice.

4. Route the cable into the fully-open tray through the cable guide as shown.

Note: The sliding radius limiters must be in the position shown.

Note: Before tying off the cable as shown, proceed with the next step below.

Page 15

© 2016 CommScope. All Rights Reserved.

Page 16

ADCP-90-459 • Issue 2 • June 2016

ROUTE CABLE INTO

2RU THROUGH SLIDING

RADIUS LIMITER

18548-E

REQUIRED

POSITION

OF SLIDING

RADIUS

LIMITER

(2 PLACES)

TIE

LANCES

DETAIL OF

CABLE TIE-OFF

POINTS

VELCRO

TIE-OFF

POINT

ROUTE BEHIND

RADIUS LIMITER

900 MICRON

SUBUNIT

FANOUT

POINT

2 x 2

FiberGuide

Figure 13. Securing Cables Within 72-Position Termination Tray

5. Route the cable within the tray as shown in Figure 14. Note that there are different

routings for cables being terminated at the front and rear of the adapters packs.

Danger:

Infrared radiation is invisible and can seriously damage the retina of the eye. Do not

look into the ends of any optical fiber. Do not look directly into the optic al adapters of the adapter

packs. Exposure to invisible laser radiation may result. An optical power meter should be used to

verify active fibers. A protective cap or hood MUST be immediately placed over any radiating

adapter or optical fiber connector to avoid the potential of dangerous amounts of radiation

exposure. This practice also prevents dirt particles from entering the adapter or connector

.

Note: Always clean and inspect connectors and adapters before mating them. For

guidelines, refer to the connector cleaning instructions, ADCP-90-159.

6. Secure the cables on the side and rear of the tray as shown in Figure 13.

Page 16

© 2016 CommScope. All Rights Reserved.

Page 17

ADCP-90-459 • Issue 2 • June 2016

18550-C

Figure 14. Cable Routing for 72-Position Termination Tray

(Use Either This or Mirror Image)

7. To connect an individual cable connector to an adapter, lift up the release tab on top of the

adapter pack and slide up the adapter pack (see Figure 25 on page 2 8). Pull the dust cap

straight out from the adapter and connect the cable connector to the adapter.

6.2.2 Termination (Left Entry for IFC)

Cables routed into the tray for termination are normally pre-terminated individual cables

(simplex or duplex patch cords). Refer to the following instructions.

1. Open tray fully and lock it using the lock open latch (see Subsection 7.1 Opening the Tray).

2. Route the cable along the rack to the 2RU FMT, as shown in Figure 11 on page 14.

Note: The cable may be routed from either above or below the tray on the left side.

3. Secure the cable to the rack using local practice.

© 2016 CommScope. All Rights Reserved.

Page 17

Page 18

ADCP-90-459 • Issue 2 • June 2016

19994-C

LOOP FIBERS ONE

TIME AROUND

SPOOL AS SHOWN

SECURE

SUBUNIT TO

BRACKET

LIGHTLY SECURE

FIBER TO DRAWER

WITH VELCRO

USING SLOTS

IN DRAWER

RIBBON

CABLE

FANOUT

POINT

ADAPTER POSITION

67 THROUGH 72

(67 ON TOP, 72 ON BOTTOM)

ADAPTER POSITION

1 THROUGH 6

(1 ON TOP, 6 ON BOTTOM)

WAX LACING TIE POINT

FOR 900 MICRON SUBUNIT

4. Route the cable into the fully-open tray through the cable guide as shown.

Note: Before tying off the cable as shown, proceed with the next step below.

Figure 15. Cable Routing for 72-Position Termination Tray

(Left Entry Only)

5. Route the cable within the tray as shown in Figure 15. Note that there are different

routings for cables being terminated at the front and rear of the adapters packs.

Danger:

Infrared radiation is invisible and can seriously damage the retina of the eye. Do not

look into the ends of any optical fiber. Do not look directly into the optic al adapters of the adapter

packs. Exposure to invisible laser radiation may result. An optical power meter should be used to

verify active fibers. A protective cap or hood MUST be immediately placed over any radiating

adapter or optical fiber connector to avoid the potential of dangerous amounts of radiation

exposure. This practice also prevents dirt particles from entering the adapter or connector

.

Note: Always clean and inspect connectors and adapters before mating them. For

guidelines, refer to the connector cleaning instructions, ADCP-90-159.

6. Secure the cables on the side and rear of the tray as shown in Figure 15.

Page 18

© 2016 CommScope. All Rights Reserved.

Page 19

ADCP-90-459 • Issue 2 • June 2016

18549-E

REQUIRED

POSITION

OF SLIDING

RADIUS

LIMITER

(2 PLACES)

VELCRO

TIE-OFF

POINT

ROUTE BEHIND

RADIUS LIMITER

ROUTE CABLE INTO

2RU THROUGH SLIDING

RADIUS LIMITER

TIE

LANCES

DETAIL OF

CABLE TIE-OFF

POINTS

900 MICRON

SUBUNIT

FANOUT

POINT

2 x 2

FiberGuide

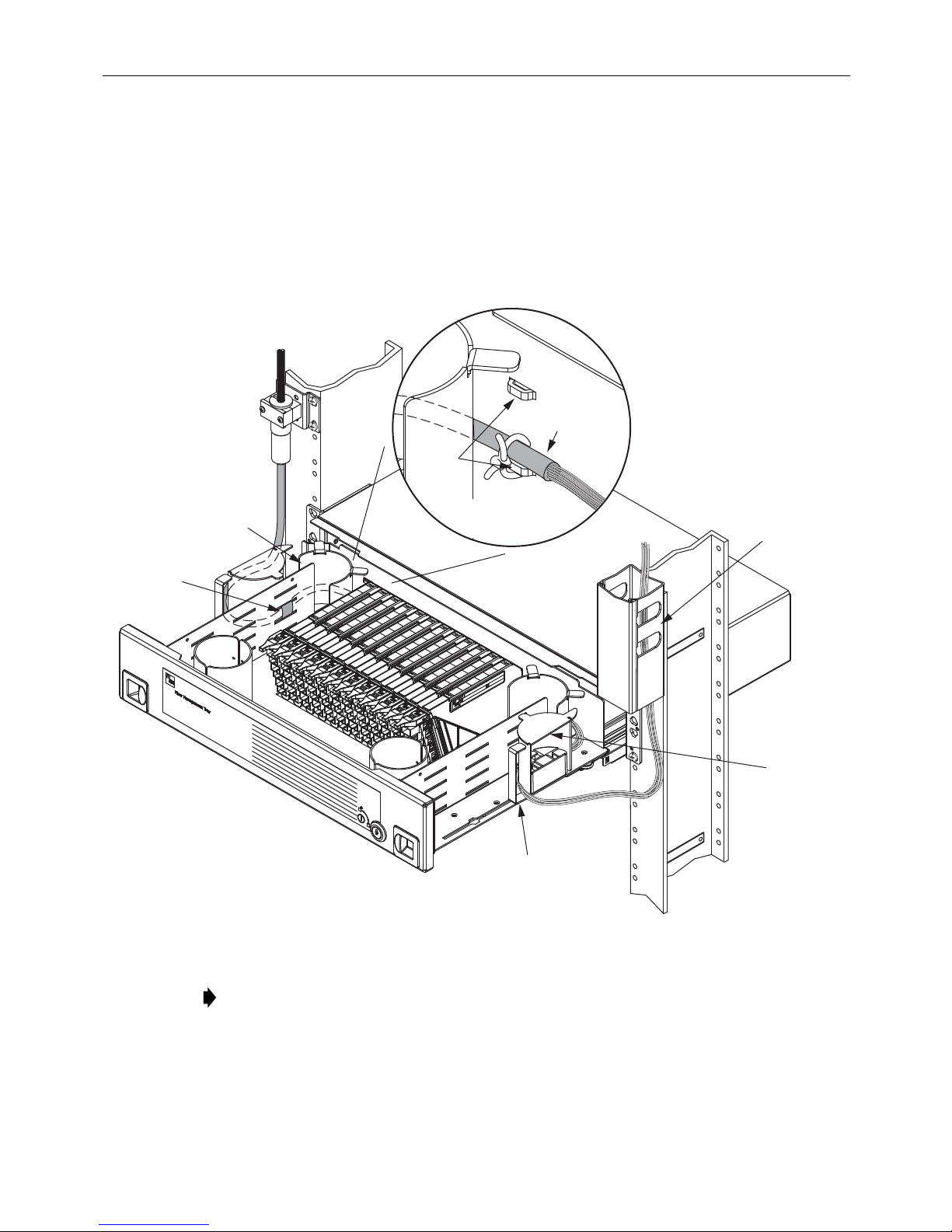

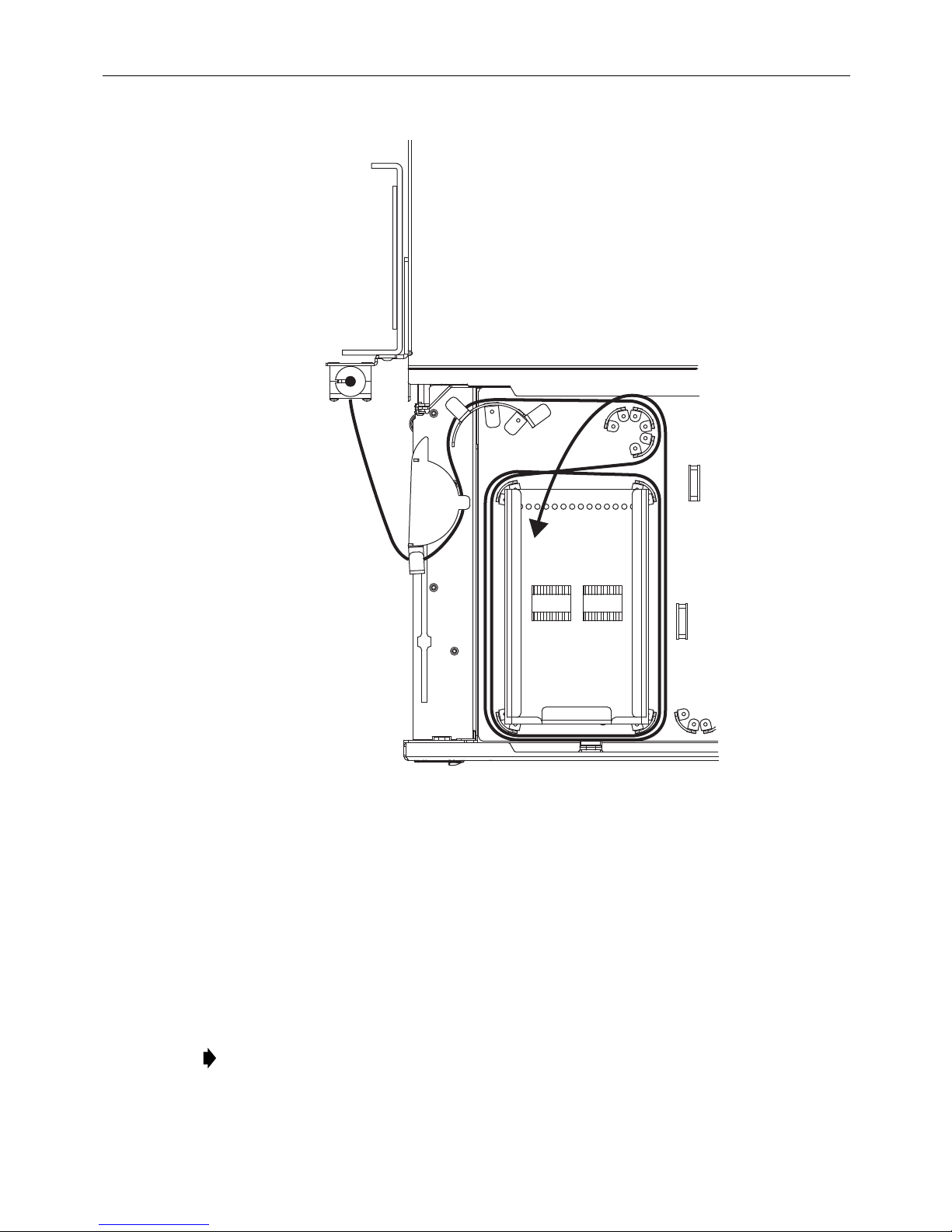

6.2.3 Micro-VAM

Cables routed into the micro-VAM tray are normally pre-terminated individual cables. Refer to

the following instructions.

1. Open the tray fully and lock it using the lock open latch (see

Tray

).

Subsection 7.1 Opening the

2. Route the cable along the rack to the tray as shown in Figure 16 on page 19.

Figure 16. Securing Cables Within 72-Position Micro-VAM Tray

Note: The cable may be routed from either above or below the tray. The cable may be

routed into the tray from either the left or right side or from both sides

3. Secure the cable to the rack using local practice.

4. Route the cable into the fully-open tray through the cable guide as shown.

© 2016 CommScope. All Rights Reserved.

Page 19

Page 20

ADCP-90-459 • Issue 2 • June 2016

18550-C

Note: The sliding radius limiters must be in the position shown.

Note: Before tying off the cable as shown, proceed with the next step below.

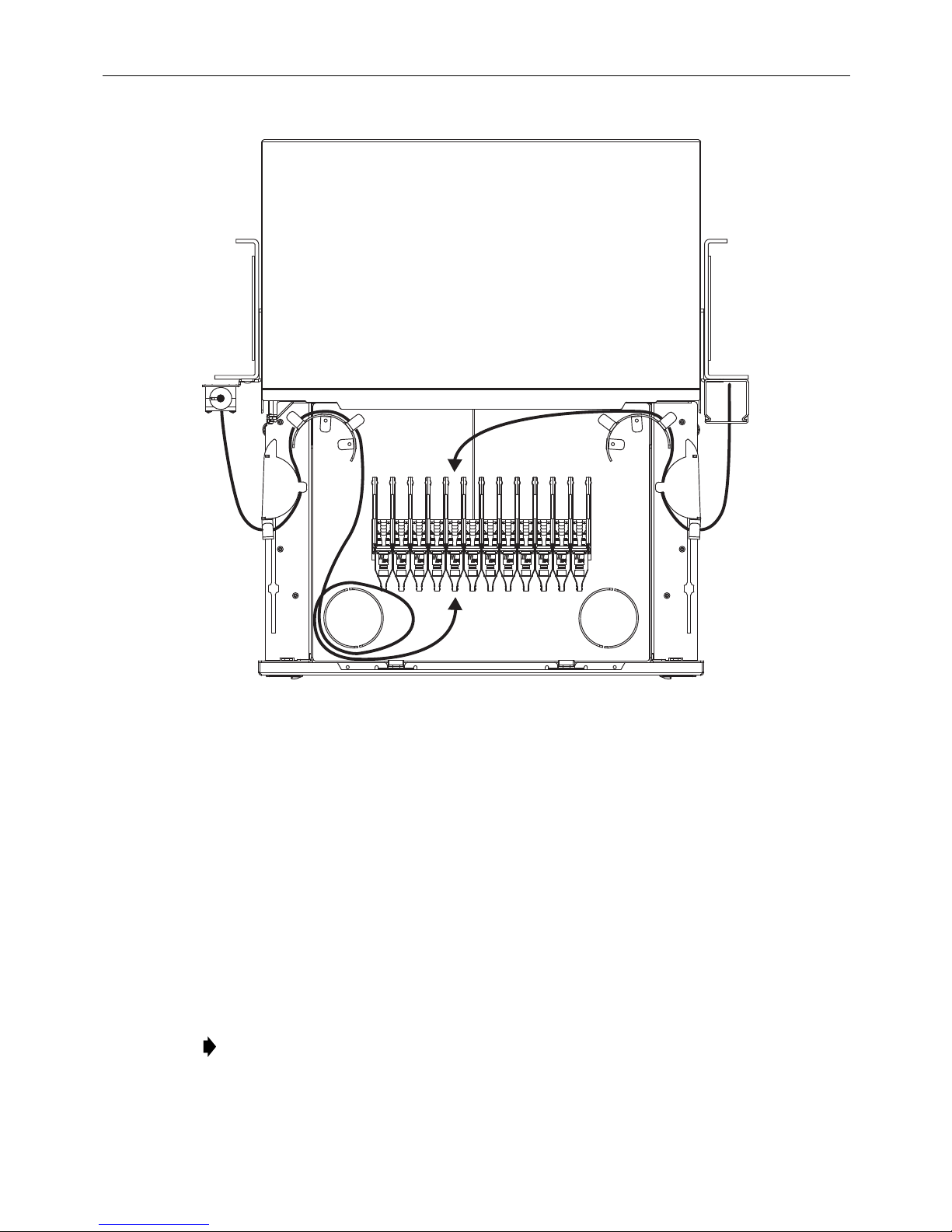

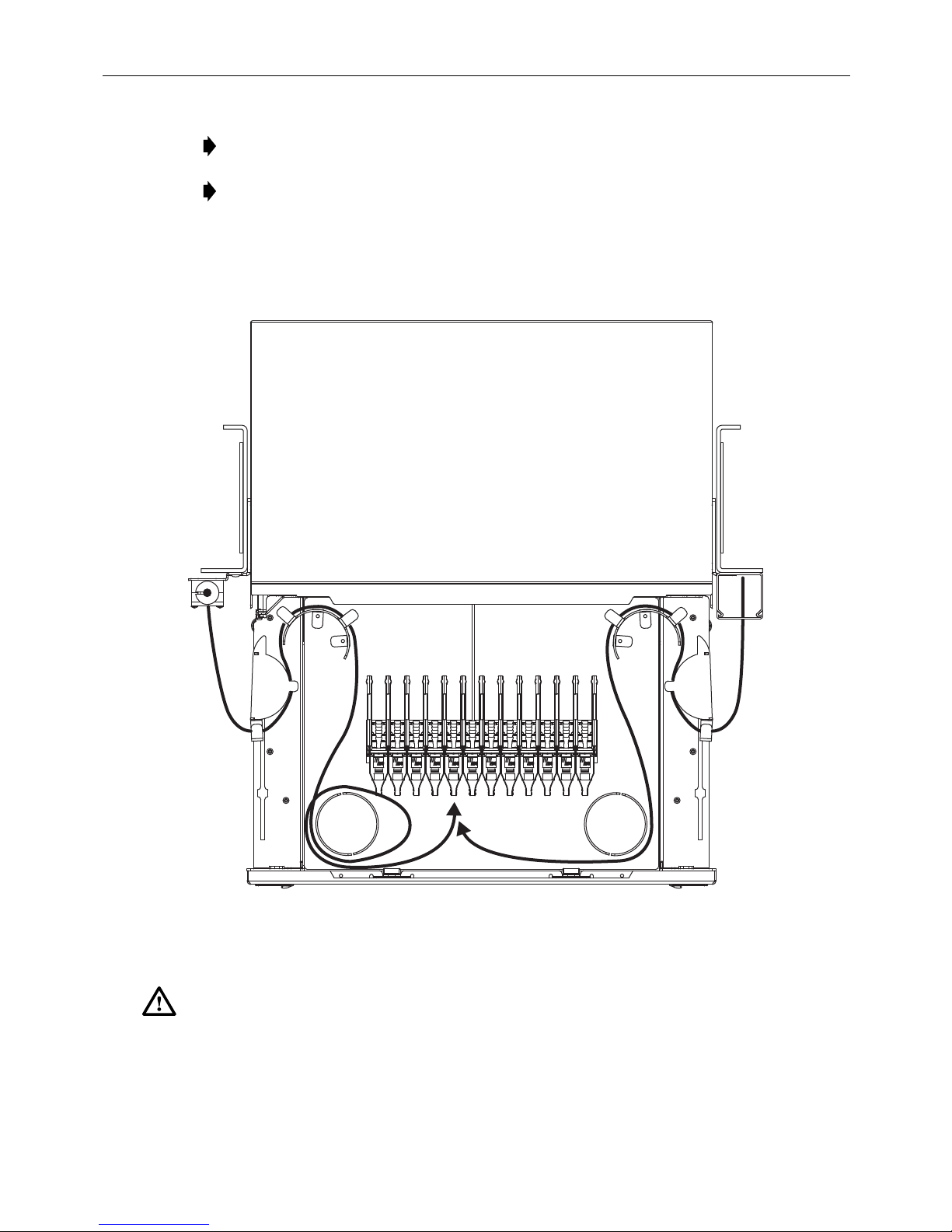

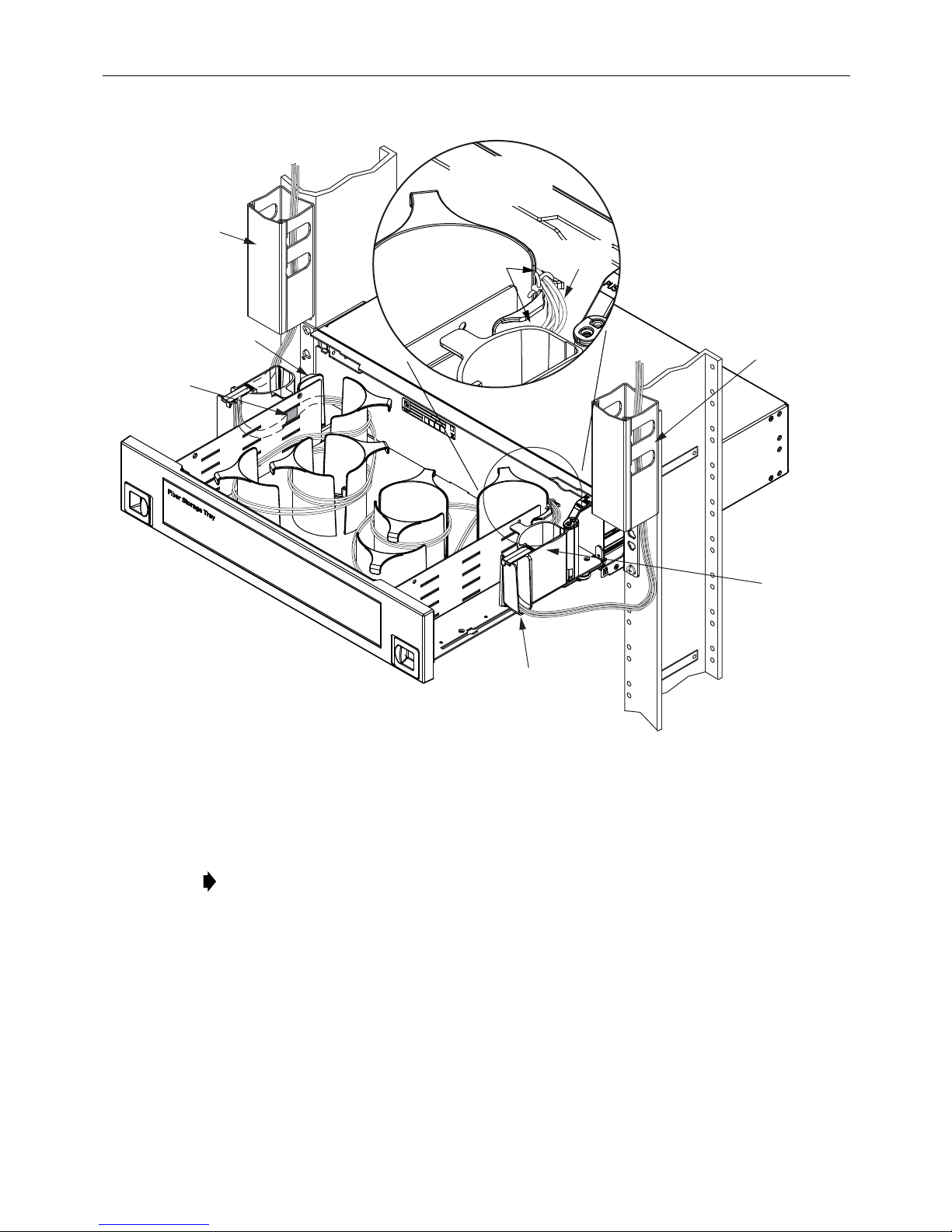

5. Route the cables within the tray as shown in Figure 17 for entry from both sides or as

shown in Figure 18 for entry from either left or right side. (Left side entry is shown.

Routing for right side entry is a mirror image of the routing shown.) All cable are

terminated on the front of the micro-VAMs.

Figure 17. Cable Routing for 72-Position Micro-VAM Tray (Enter From Both Sides)

Danger:

Infrared radiation is invisible and can seriously damage the retina of the eye. Do not

look into the ends of any optical fiber. Do not look directly into the optic al adapters of the adapter

packs. Exposure to invisible laser radiation may result. An optical power meter should be used to

verify active fibers. A protective cap or hood MUST be immediately placed over any radiating

adapter or optical fiber connector to avoid the potential of dangerous amounts of radiation

exposure. This practice also prevents dirt particles from entering the adapter or connector

Page 20

© 2016 CommScope. All Rights Reserved.

.

Page 21

ADCP-90-459 • Issue 2 • June 2016

18649-B

LEFT OR RIGHT

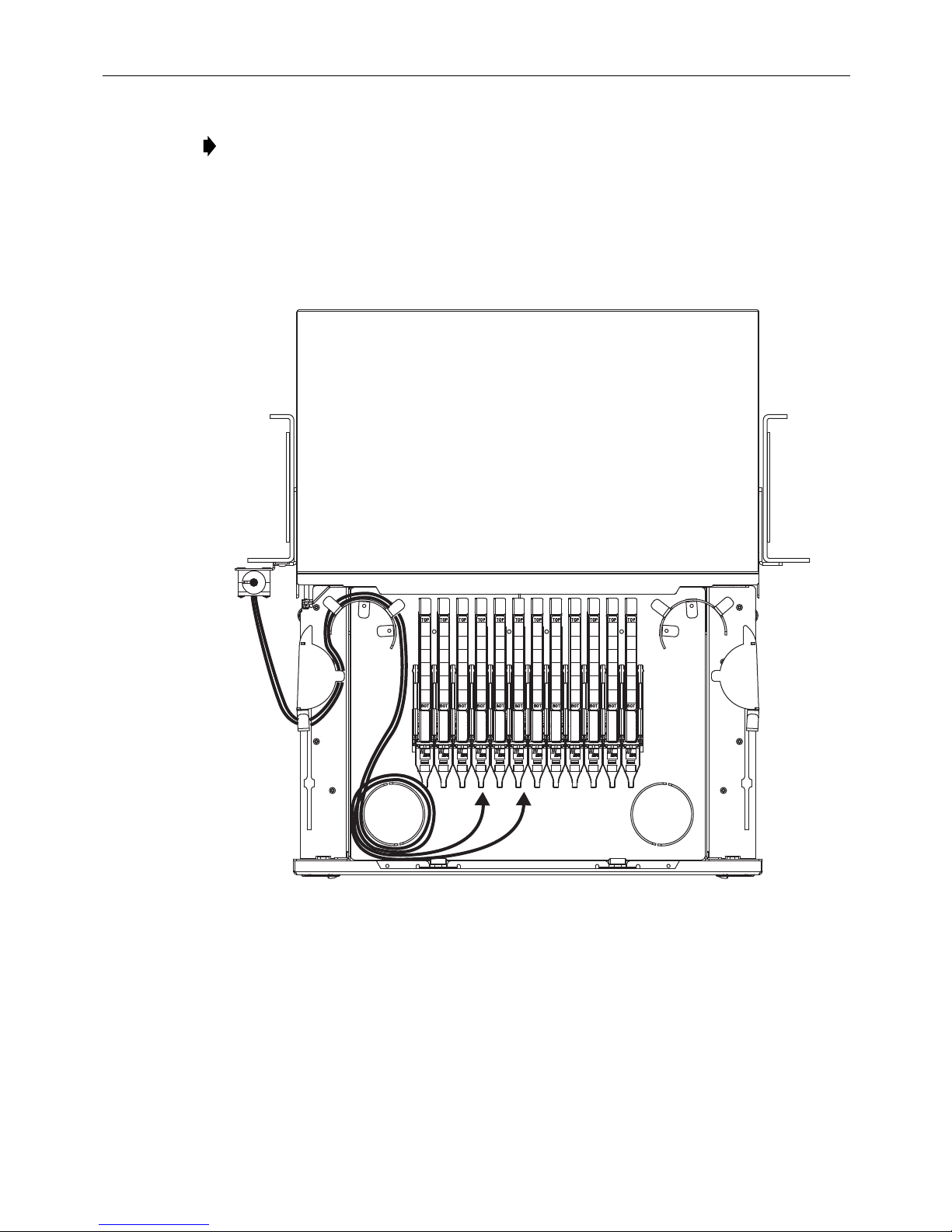

Note: Always clean and inspect connectors and adapters before mating them. For

guidelines, refer to ADCP-90-159.

6. To connect an individual cable connector to a micro-VAM, lift up the release tab on top of

the micro-VAM and slide the micro-VAM upward (see Figure 26 on page 28). Pull the

micro-VAM dust cap straight out and connect the connector to the micro-VAM port.

7. Secure the cables on the side and rear of the tray as shown in Figure 16 on page 19.

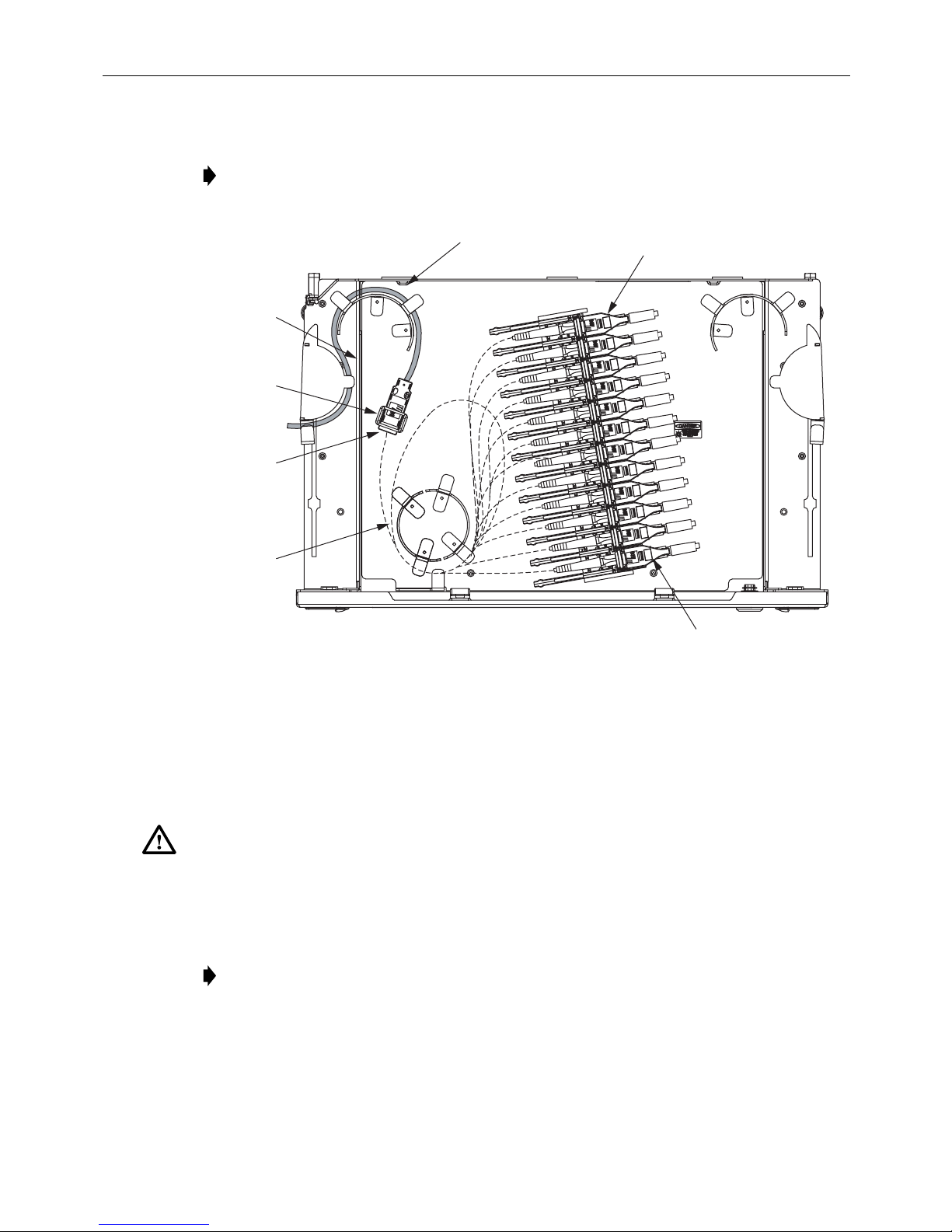

6.2.4 48-Position Termination/Splice

Cables routed into the tray for splicing or termination are normally multifiber cable assemblies.

Cables to be spliced will be bare-ended. Cables to be terminated will be pre-terminated. The

2RU FMT will also have factory-installed, internal pigtails between splice tray and connector

bulkhead. Refer to the following instructions.

Figure 18. Cable Routing for 72-Position Micro-VAM Tray

Left or Right Entry (Use Either This or Mirror Image)

Page 21

© 2016 CommScope. All Rights Reserved.

Page 22

ADCP-90-459 • Issue 2 • June 2016

ROUTE CABLE INTO

2RU FMT THROUGH

SLIDING RADIUS LIMITER

19393-C

REQUIRED

POSITION

OF SLIDING

RADIUS

LIMITER

(2 PLACES)

TIE

LANCES

DETAIL OF

CABLE TIE-OFF

POINTS

VELCRO

TIE-OFF

POINT

ROUTE BEHIND

RADIUS LIMITER

900 MICRON

SUBUNIT

FANOUT

POINT

2 x 2

FiberGuide

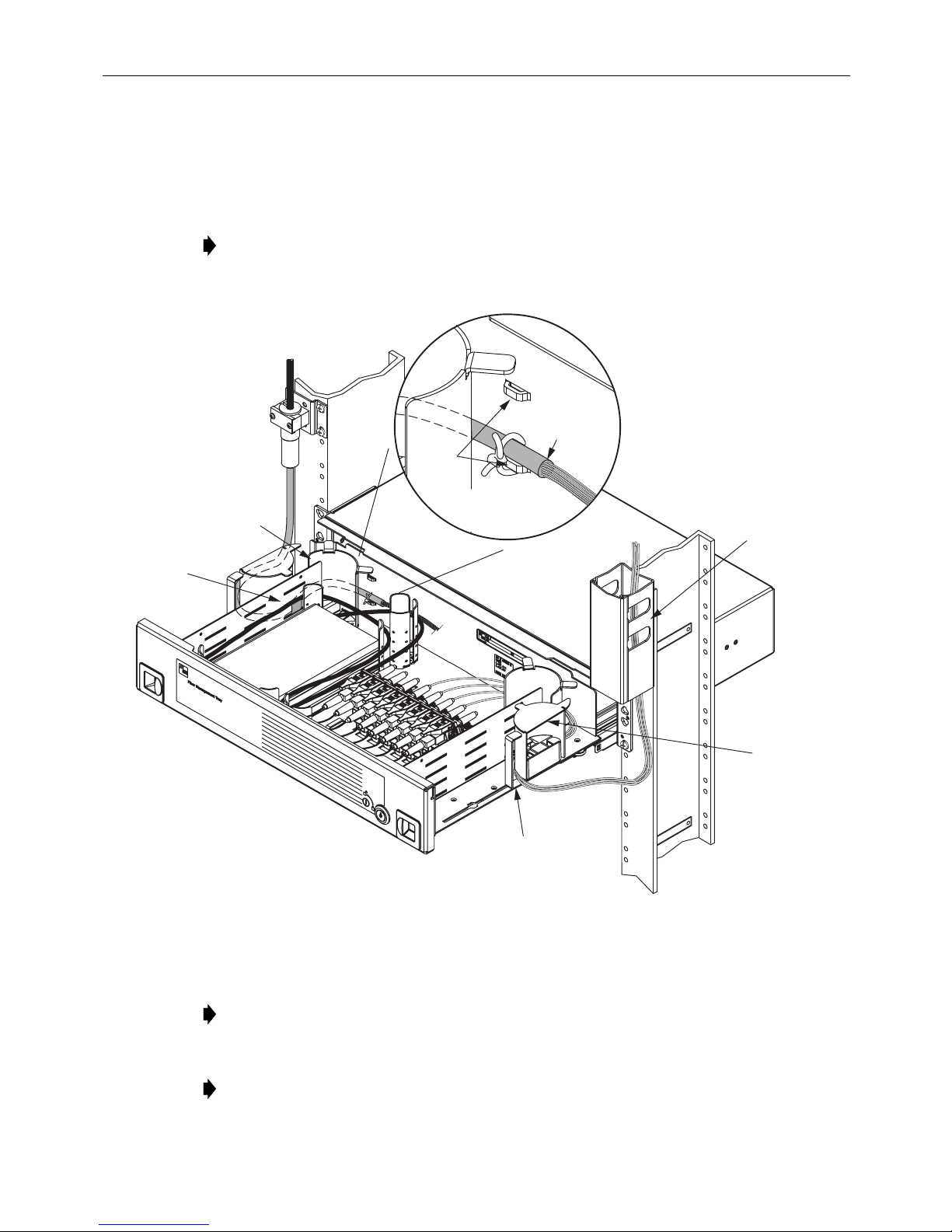

1. Open the tray fully and lock it using the lock open latch (see

Tray

).

2. Route cables along the rack to the 2RU FMT, as shown in

Subsection 7.1 Opening the

Figure 19

. Route cable to be

spliced on the left side of the rack . Rout e cable to be term inated on the righ t side o f the rack .

Note: The cables may be routed from either above or below the tray.

3. Secure the cables to the rack using local practice.

Figure 19. Securing Cables Within 48-Position Termination/Splice Tray

4. Route the cables into the fully-open tray through the cable guides as shown.

Note: The sliding radius limiters must be in the position shown.

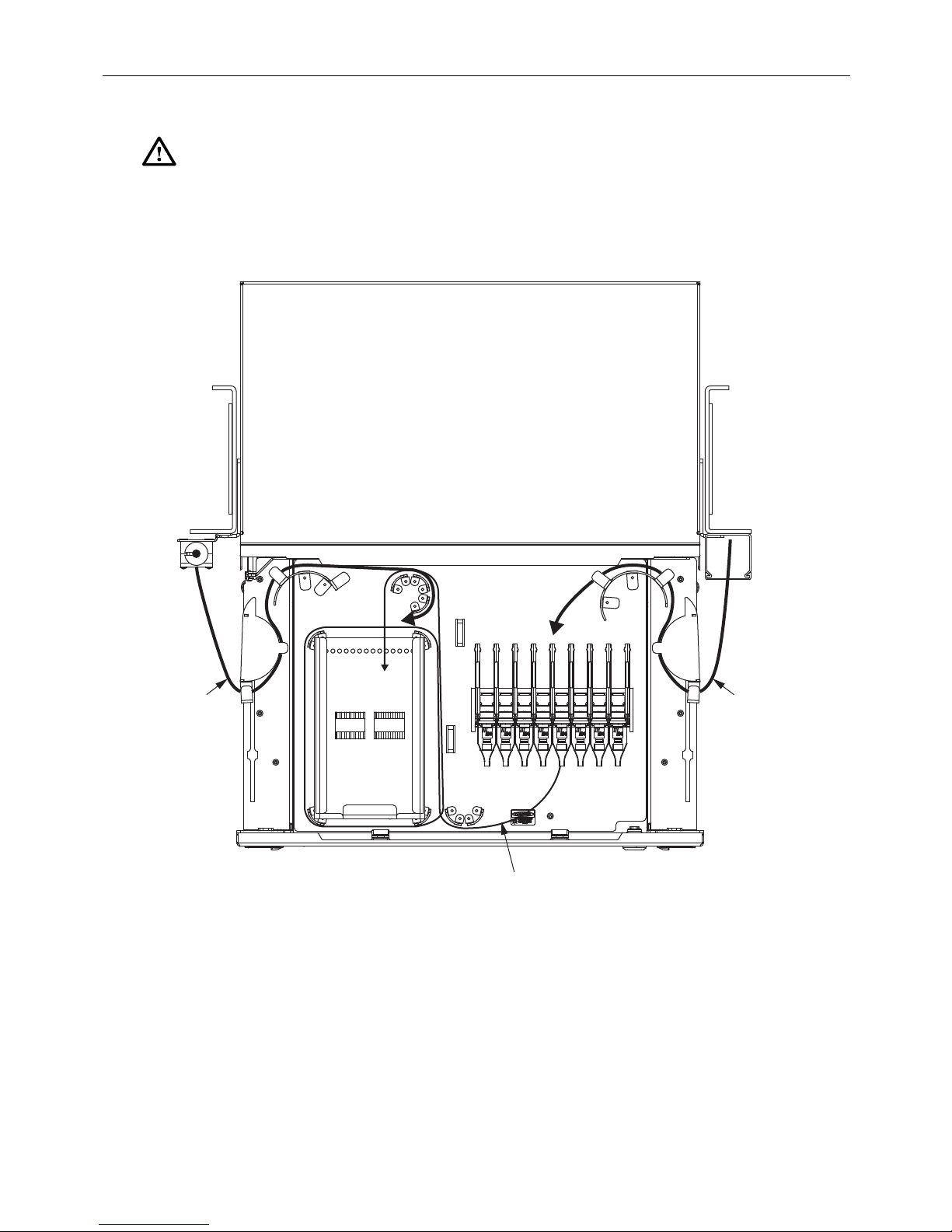

5. Route the cables within the tray as shown in Figure 20.

Note: Always clean and inspect connectors and adapters before mating them. For

guidelines, refer to the connector cleaning instructions, ADCP-90-159.

Page 22

© 2016 CommScope. All Rights Reserved.

Page 23

ADCP-90-459 • Issue 2 • June 2016

19394-C

PATCH CORDS

TO TERMINATION

POINT

IFC/OSP

CABLE TO

SPLICE TRAY

PIGTAILS FROM

BULKHEAD TO

SPLICE TRAY

Danger:

Infrared radiation is invisible and can seriously damage the retina of the eye. Do not

look into the ends of any optical fiber. Do not look directly into the optic al adapters of the adapter

packs. Exposure to invisible laser radiation may result. An optical power meter should be used to

verify active fibers. A protective cap or hood MUST be immediately placed over any radiating

adapter or optical fiber connector to avoid the potential of dangerous amounts of radiation

exposure. This practice also prevents dirt particles from entering the adapter or connector

.

Figure 20. Cable Routing for 48-Position Terminatio n/Splice Tray

6. Route the cables within the splice tray as shown in Figure 21.

7. Secure the cables on the side and rear of the tray as shown in Figure 19 on page 22.

8. To connect an individual cable connector to an adapter, lift up the release tab on top of the

adapter pack and slide up the adapter pack (see Figure 25 on page 28). Pull the dust cap

straight out from the adapter and connect the cable connector to the adapter.

Page 23

© 2016 CommScope. All Rights Reserved.

Page 24

ADCP-90-459 • Issue 2 • June 2016

19597-A

6.2.5 Bulk Storage

Cable routed into the tray are typically 1.66mm patch cords. To store the patch cords in a bulk

storage tray, refer to the following instructions.

1. Open the tray fully and lock it using the lock open latch (see

Tray

).

2. Route the patch cords along the rack to the 2RU FMT, as shown in

patch cords in from either side o f the tray.

Note: The cables may be routed from either above or below the tray.

Page 24

© 2016 CommScope. All Rights Reserved.

Figure 21. Routing Within Splice Tray

Subsection 7.1 Opening the

Figure 22

. Route the

Page 25

2 x 2

FiberGuide

DETAIL OF

CABLE TIE-OFF

POINTS

TIE

LANCE

LOCATIONS

ADCP-90-459 • Issue 2 • June 2016

2 MM

CABLES

ROUTE BEHIND

RADIUS LIMITER

VELCRO

TIE-OFF

POINT

ROUTE CABLE INTO

2RU FMT THROUGH

SLIDING RADIUS LIMITER

Figure 22. Routing Patch Cords into Bulkhead Storage Tray

2 x 2

FiberGuide

REQUIRED

POSITION

OF SLIDING

RADIUS

LIMITER

(2 PLACES)

24297-A

3. Secure the patch cords to the rack using local practice.

4. Route the patch cords into the fully-open tray through the cable guides as shown.

Note: The sliding radius limiters must be in the position shown.

5. Route the patch cords within the tray as shown in Figure 23.

© 2016 CommScope. All Rights Reserved.

Page 25

Page 26

ADCP-90-459 • Issue 2 • June 2016

24299-A

Figure 23. Cable Routing for Bulk Storage FMT Panel

6. Route the patch cords within the tray as shown in Figure 23.

Note: For maximum storage, balance the load between the two sides.

7 OPERATION

Operation consists of opening the tray, connecting patch cords to adapters or micro-VAMs, and

closing the tray. When routing patch cords, refer to the routing diagrams provided in Section 6.

Page 26

© 2016 CommScope. All Rights Reserved.

Page 27

ADCP-90-459 • Issue 2 • June 2016

24301-A

LOCK

OPEN

LATCH

PUSH DOWN

TO RELEASE

LOCK

Danger:

Infrared radiation is invisible and can seriously damage the retina of the eye. Do not

look into the ends of any optical fiber. Do not look directly into the optic al adapters of the adapter

packs. Exposure to invisible laser radiation may result. An optical power meter should be used to

verify active fibers. A protective cap or hood MUST be immediately placed over any radiating

adapter or optical fiber connector to avoid the potential of dangerous amounts of radiation

exposure. This practice also prevents dirt particles from entering the adapter or connector

7.1 Opening the Tray

To open the 2RU FMT tray, slide the release tabs inward with both hands and pull the drawer

straight out as far as it goes. While working in the tray, lock tray in position as shown in

Figure 24. Press latch down to unlock tray and push closed.

Caution: Placing a load in excess of 12 pounds (5.4 kg) onto an open tray will result in

misalignment or damage to the tray.

.

7.2 Sliding Adapter Packs

To access a sliding adapter pack (Figure 25):

1. Route the patch cord into the tray as shown in the appropriate diagram in Section 6.

Figure 24. Tray Locked in Open Position

© 2016 CommScope. All Rights Reserved.

Page 27

Page 28

ADCP-90-459 • Issue 2 • June 2016

18650-A

2. Lift up the release tab and slide up the adapter pack.

Note: Always clean and inspect connectors and adapters before mating them. For

guidelines, refer to ADCP-90-159.

3. Pull the dust cap straight out.

4. Connect the patch cord connector to the adapter and slide the adapter pack back down.

5. Close the tray as described in Subsection 7.4 Closing the Tray.

Figure 25. Removing Dust Cap From Standoff Style Adapter Pack

7.3 Micro-VAMs

To access a micro-VAM (Figure 26):

1. Route the patch cord into the tray as shown in the appropriate diagram in Section 6.

2. Lift up the release tab and slide up the micro-VAM.

Note: Always clean and inspect connectors and adapters before mating them. For

guidelines, refer to ADCP-90-159.

3. Pull the dust cap straight out.

4. Connect the patch cord connector to the desired adaptor.

5. Close the tray as described in Subsection 7.4 Closing the Tray.

Page 28

© 2016 CommScope. All Rights Reserved.

Page 29

ADCP-90-459 • Issue 2 • June 2016

18651-A

7.4 Closing the Tray

Close the tray using the following procedure:

1. Fully lower and seat all connector or micro-VAM 6-packs.

2. Assure that all cables and fibers are properly secured and located below the top surface of

the tray.

3. Release the lock open latch (“unlocked position” shown in Figure 24 on page 27).

4. Slowly close the tray, observing that no fiber kinks or macro bends occ ur as a result of

fiber routing.

5. Latch tray shut using the lock open latch (“locked position” shown in

Figure 26. Accessing a Micro-VAM

Figure 24 on page 27

).

© 2016 CommScope. All Rights Reserved.

Page 29

Page 30

ADCP-90-459 • Issue 2 • June 2016

8 TECHNICAL ASSISTANCE

Contact the Technical Assistance Center (TAC) for technical question. Call 800.830.5056 or

send an email to TAC.Americas@commscope.com.

Page 30

© 2016 CommScope. All Rights Reserved.

Loading...

Loading...