Page 1

N9002 THERMOMETER

OPERATING INSTRUCTIONS

Page 2

CONTENTS

GENERAL INFORMATION ......................................................... 2

CALIBRATION, CERTIFICATION AND SERVICE ...................... 3

1. N9002 DESCRIPTION ................................................................ 4

2. N9002 WITH BIOCOTE® PROTECTION ................................... 4

3. OVERVIEW OF DISPLAY SYMBOLS ........................................ 5

4. THERMOMETER SETUP ........................................................... 6

5. SWITCHING ON AND OFF ......................................................... 8

6. N9002 OPERATION .................................................................... 8

7. CONNECTING PROBES ............................................................. 9

8. CARE OF THE THERMOMETER ................................................ 9

9. CHANGING THE BATTERIES .................................................... 10

10. N9002 SPECIFICATION .............................................................. 11

PAGE

1

Page 3

GENERAL INFORMATION

It is recommended that you read the safety and operation instructions

before using this instrument.

TO AVOID ELECTRIC SHOCK DO NOT ALLOW ANY PROBE OR

WARNING

SENSOR TO COME INTO CONTACT WITH LIVE ELECTRICAL

POWER CONDUCTORS WITH VOLTAGES IN EXCESS OF 30V AC

RMS OR 60V DC.

CAUTION

Temperature Measurement Probes

This precision instrument has been designed for use with the extensive

range of Comark temperature probes. The use of other probes may

impair the performance and accuracy of the instrument. Full details of

Comark probes and sensors can be obtained from Comark Customer

Support department or your local distributor.

Repeated sharp exing can break thermocouple probe leads. To

prolong lead life, avoid sharp bends or kinks in the leads, especially

near the connector.

This instrument is manufactured in accordance with

the Company’s ISO 9001 Quality Approved

System.

ISO 9001

FM 29700

This instrument complies with the Electromagnetic

Compatibility Directive EN 61326-1.

Declarations of Conformity available. Contact

Comark Customer Support or your local Distributor.

In line with its policy of continuous development, Comark Instruments

reserves the right to alter the instrument specication without prior

notice. Further information is available from Comark Instruments or your

distributor.

2

Page 4

CALIBRATION, CERTIFICATION AND SERVICE

Certication

Comark can provide certicates of calibration for its whole product range, to suit

ISO 9000 and other quality assurance procedures, food hygiene regulations,

HACCPs and environmental regulations. Comark certicates are produced by

independent quality controlled processes which compare product performance

against agreed National Standards. For peace of mind and best practice Comark

recommend annual certication/recalibration.

Two levels of certication are available for infra-red temperature and non

temperature instruments, excluding humidity:- UKAS certicates via an external

accredited laboratory and NPL traceable certicates from the Comark calibration

laboratory.

Three levels of certication are available for contact temperature and humidity

products and these are detailed here:

a) UKAS Temperature Certication

The Comark UKAS (United Kingdom Accreditation Service) accredited

temperature calibration laboratory is one of the nest in the UK. Comark

UKAS certicates can offer the lowest uncertainty of 0.01°C and

provide independent proof of correct calibration using equipment and

procedures audited by UKAS inspectors. The equipment used is fully

traceable to the National Physical Laboratory.

b) UKAS Humidity Certication

In addition to the Comark temperature laboratory, the humidity laboratory

continues the tradition of high accuracy certication and a wide range

(25% to 90%RH) with uncertainties of 2.8% of reading. This range also

includes Dew point measurements.

c) NPL Traceable Certication

Comark NPL certicates are traceable to the National Physical

Laboratory and can offer uncertainty as low as 0.3°C.

No. 0451

Conformance

Certicates of conformance can be supplied for new, serviced and recalibrated

instruments. These conrm that instruments are within their original manufactured

specication.

Service/Repairs

Regular servicing and any required repairs, under warranty or after, are available

from the Comark Service Department.

For more information on all Comark certication, calibration and service facilities

please call Comark Customer Support or contact your local distributor.

3

Page 5

1. N9002 DESCRIPTION

The N9002 is a high performance handheld industrial

thermometer housed in the proven 'N' series case for ultimate

strength and durability. It has IP67 certication against water

and dust penetration. The case is easy to clean and the sealed

soft-touch keypad provides smooth operation. The N9002

features a clock, selectable thermocouple type, single and dual

differential mode, auto-off and data

The N9002 has a two year warranty, a free certicate of

conformity and full compatibility with the existing Comark probe

range. A slip on boot is available for added protection.

2. N9002 THERMOMETER WITH BIOCOTE

PROTECTION

®

BioCote

impregnated into the instrument case during moulding.

BioCote® effectively inhibits the function, growth and

reproduction of a wide range of micro-organisms and its

protection is increasingly accepted as part of HACCP, due

diligence and health and safety procedures to reduce cross

contamination. BioCote

instrument because the agent is present throughout the case

plastic and cannot rub off or be washed or leached out.

BioCote® active ingredients are registered with the US

Environmental Protection Agency (EPA).

is a silver based antimicrobial agent that is

®

protection lasts for the life of the

®

Although BioCote® inhibits the growth of micro-organisms on

the instrument case, it does not protect individuals against such

harmful organisms or remove the need to maintain the highest

standards of personal and product hygiene and cleanliness.

4

Page 6

3. OVERVIEW OF DISPLAY SYMBOLS

A – Activated during DIFFerential mode with both T1 and T2 enabled.

B – Main Temperature display. T1 is displayed here when enabled. Will

display DIFFerential temperature in two-channel DIFF mode.

C – Displays current scale in use.

D – CAL is displayed to indicate that the annual instrument

re-calibration is due.

E – Nominally used for displaying time, but will display temperature

in DIFFerential mode, and MAX/MIN mode. M indicates display of

the stored reading in single channel DIFFerential mode.

F – Displays the current sensor type.

G – Indicates MAXimum/HOLD/ and SETUP mode. PRINTing not

applicable to N9002.

H – Indicates AUTO power off enabled/MINimum/ and Low BATtery.

LOGging not applicable to N9002.

I – Alarms not applicable to N9002.

J – This is the third numeric display, and will nominally display

channel T2. Delta T is indication of channel DIFF mode.

5

Page 7

4. THERMOMETER SETUP

Pressing SETUP will enter the setup menu for the thermometer.

The following stages are included in the SETUP menu and are

accessed sequentially, i.e. each stage must be access in turn to

reach the one required. Pressing ENTER will accept the setting

and step on to the next function. The setup menu can be exited

using the CLEAR key. Settings changed in previous steps will

however be retained.

4.1 Auto-Power-OFF Enable / Disable

Press SETUP

Toggle AUTO Power ON/OFF with the UP/DOWN arrow

keys.

Press ENTER/HOLD to continue.

4.2 Channel Enable / Disable

N.B. At least one channel must be selected.

Toggle T1 ON/OFF with the UP/DOWN arrow keys

Press ENTER/HOLD

Toggle T2 ON/OFF with the UP/DOWN arrow keys

Press ENTER/HOLD to continue.

4.3 Thermocouple Type Setup

Select the thermocouple type with the UP/DOWN arrow

keys.

Press ENTER/HOLD to continue.

4.4 Scale Setup

Select the scale required with the UP/DOWN arrow keys.

°C, °F and Kelvin scales are available.

Press ENTER/HOLD to continue.

6

Page 8

4.5 Date and Time Setup

Use the UP/DOWN arrow keys to select the minutes.

Press ENTER/HOLD

Use the UP/DOWN arrow keys to select the required hours

in 24 Hr Format.

Press ENTER/HOLD.

Use the UP/DOWN arrow keys to select the century.

Press ENTER/HOLD.

Select the year using the UP/DOWN arrow keys.

Press ENTER/HOLD.

Use the UP/DOWN arrow keys to select the month.

Press ENTER/HOLD.

Use the UP/DOWN arrow keys to select the day.

Press ENTER/HOLD to continue.

4.6 Display contrast adjustment

Use the arrow keys to select high or low display contrast.

Use high for extended operation in ambient temperatures

below –10°C.

Use low for higher ambient temperatures.

4.7 Mains supply rejection frequency

To change this setting, when entering the setup menu, hold

the setup key down for longer than 5 seconds.

Toggle the Mains Supply rejection frequency using the UP/

DOWN arrow keys.

In the UK use the 50 setting for 50Hz, in the USA use the 60

setting for 60Hz.

7

Page 9

If the correct setting is not known, contact Comark or your

Distributor for details.

Press ENTER/HOLD to nish and exit from SETUP.

5.0 SWITCHING ON AND OFF

5.1 Display Test

The ‘ON/OFF’ button on the keypad switches on the

instrument. When the instrument is rst switched on the unit

performs a self-test and the whole display will be energised.

After a short pause the display will revert to normal

temperature display. The current time is also displayed.

5.2 Auto Power off (APO)/Power Saving

The N9002 can be set to auto-power-off three minutes after

the last button operation or to remain permanently on until

manually switched off. This mode is indicated on the LCD in

the lower portion of the display by the word AUTO. Enabling

or disabling auto-power-off (APO) is available from the

keypad in SETUP.

6.0 N9002 OPERATION

6.1 Display Hold

Pressing ENTER/HOLD will prevent display updates for

actual temperature displays and suppresses update of max

and min values. HOLD will appear on the display to indicate

this mode. Pressing ENTER/HOLD again will cancel display

hold.

6.2 Maximum & Minimum Mode

The N9002 instrument automatically updates the maximum

and minimum readings as soon as the instrument is

switched on. These can be displayed by pressing the MAX

or MIN buttons. If both channels, T1 and T2, are enabled,

MAX or MIN is displayed for both channels. If T1 or T2 only

is enabled both MAX and MIN are displayed together for

the enabled channel. MAX and MIN readings can be reset

individually at any time for all channels by pressing CLEAR

followed by either MAX or MIN.

8

Page 10

6.3 Differential Mode (DIFF)

There are two DIFF modes available for the N9002, single

channel and twin channel. If only one channel (T1 or T2)

is enabled the instrument will memorise the temperature

at the moment the DIFF button is pressed and displays

this temperature on the lower left area of the LCD. It also

displays the difference between the current temperature and

the memorized temperature on the lower right area of the

LCD. The main display area shows the current temperature.

If both channels (T1 and T2) are enabled the instrument

will display the difference between T1 and T2 on the main

display and T1 and T2 actual temperatures on the lower left

and lower right areas respectively.

6.4 Clear MAX, Clear MIN

To clear MAX or MIN from the memory press CLEAR

followed by MAX or CLEAR followed by MIN.

N.B. The N9002 thermometer clears MAX and MIN

individually.

7.0 CONNECTING PROBES

The N9002 thermometer is a two-channel instrument using

sub-miniature connectors. When connecting probes to the

N9002 always remember to check the polarity of the plug before

tting. In order to get correct results make sure that you have

selected the correct thermocouple type for the probe that you

have connected.

Note: It is recommended that insulated thermocouples be used.

8.0 CARE OF THE THERMOMETER

The N9002 thermometer is dust and waterproof as stated in

the specications and will withstand harsh environments. Use

a damp cloth or warm soapy water to remove deposits and

prevent them from hardening or becoming sticky. Do not use

solvent-based cleaners or methylated spirit, etc.

Caution: Do not place the N9002 thermometer in a dishwasher.

If the instrument is to be stored for an extended period (for

example as a spare unit) remove the battery to eliminate the

risk of leakage.

9

Page 11

9.0 CHANGING THE BATTERIES

The symbol BAT ashes on the display as soon as the battery

voltage drops to an initial warning level. During this rst level

of low battery the instrument can be operated normally, but it is

recommended that the battery be replaced as soon as possible.

If the battery is allowed to discharge further there is a second

level of low battery, which is indicated by the symbol remaining

on and not ashing. Replace the battery straight away after

seeing this symbol.

To replace the battery: Make sure the instrument is off,

unscrew the screw retaining the battery cover on the rear of

the instrument using the correct size at-blade screwdriver.

Remove the two cells and replace with new alkaline cells to

ensure long life. Be careful to observe the correct polarity. Take

care not to over-tighten the screw when re-tting the cover, and

not to lose the rubber-sealing washer.

Note: The N9002 thermometer will continue to keep correct

date & time for at least 30 seconds after removal of cells. If this

time is exceeded setup may be necessary.

Note: NiCd or NiMh cells can be used but will result in reduced

operating time. Do not attempt to recharge the cells in the

instrument.

10

Page 12

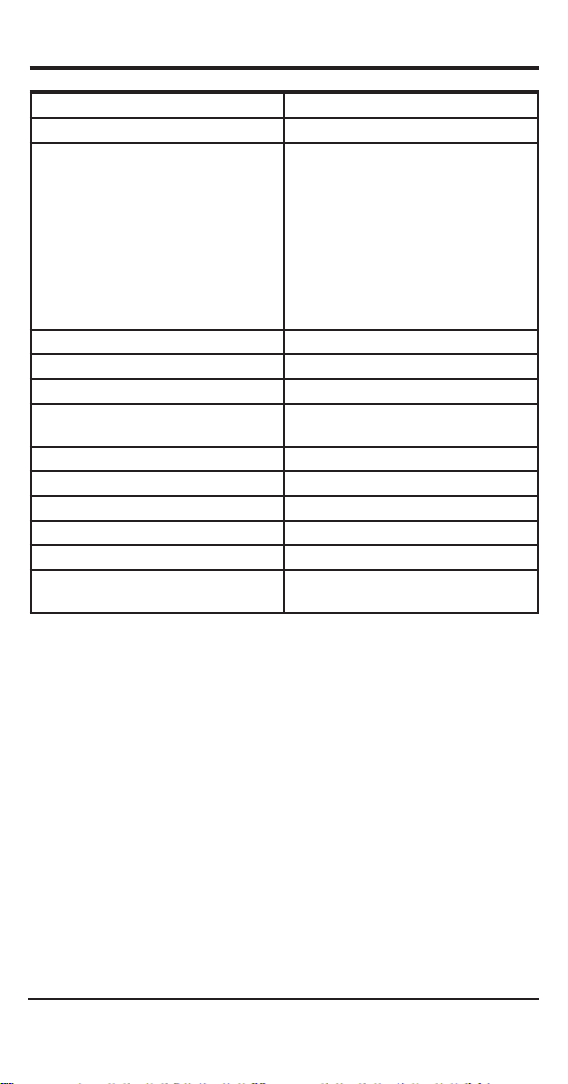

10. N9002 THERMOMETER SPECIFICATIONS

Measurement Thermocouple types K, N, T, J, R, S, E, B

Connector 2-pin sub-min connector

Measurement Range (°C)

Type K

Type N

Type T

Type J

Type R

Type S

Type E

Type B

Scales °C, °F and Kelvin

Resolution 0.1°

Instrument Accuracy at +23°C Better than ± 0.1 % of reading ± 0.2°C

Temperature Coefcient Less than ± 0.01 % of reading

Ambient Operating Temperature Range -25°C to +50°C

Response Time 1 second to full accuracy

Battery Two Type I.E.C. LR6 Size AA

Battery Life (continuous) Greater than 300 hours (Alkaline)

Environmental Protection I.P.67 BS60529 IEC 529

EMC Tested to EN 61326-1

From (°C) To (°C)

-200 +1372

-200 +1300

-200 +400

-200 +1200

-50 +1767

-50 +1767

-200 +1000

+100 +1820

±0.02 °C per °C change from +23°C

Criteria B Performance

Due to our policy of continual product improvement specications are

subject to change without prior notice.

11

Page 13

12

Page 14

Comark Instruments

52 Hurricane Way,

Norwich, Norfolk, NR6 6JB United Kingdom

Tel: +44 844 815 6599

Fax: +44 844 815 6598

Email: sales@comarkinstruments.com

Website: www.comarkinstruments.com

Comark Instruments

PO Box 500, Beaverton

OR 97077 USA

Tel: 503 643 5204

Fax: 503 644 5859

Email: sales@comarkusa.com

Website: www.comarkusa.com

© Comark Instruments Stock No. 18489 Issue 5 (11/12)

Loading...

Loading...