Page 1

N8004 and N8006

OPERATOR MANUAL

Page 2

CONTENTS

GENERAL INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CALIBRATION, CERTIFICATION AND SERVICE ..........8

1. DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.1 Accessories Available. .....................10

2. OVERVIEW OF DISPLAY SYMBOLS ............11

3. OPERATING INSTRUCTIONS. . . . . . . . . . . . . . . . . . 12

3.1 Switch On. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 %RH/DP ...............................13

3.3 °C/°F ..................................13

3.4 Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.5 Max/Min . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.6 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.7 Auto-Switch Off ..........................14

4. MEASUREMENT. ............................14

5. PRECAUTIONS IN USE. . . . . . . . . . . . . . . . . . . . . . . 15

6. MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1 Sensor Cleaning .........................15

7. CALIBRATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8. PRECAUTIONS IN MEASUREMENT . . . . . . . . . . . . 16

9. DEFINITION OF TERMS . . . . . . . . . . . . . . . . . . . . . . 17

10. CHANGING THE BATTERIES ..................17

SPECIFICATION ...................................67

1

Page 3

TABLE DES METIÈRES

GENERALITES ....................................18

ETALONNAGE, CERTIFICATION ET

ENTRETIEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1. DESCRIPTION ..............................22

1.1 Accessoires disponibles ....................22

2. VUE D’ENSEMBLE DES SYMBOLES

D’AFFICHAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3. MODE D’EMPLOI ............................24

3.1 Mise en marche ..........................24

3.2 %RH/DP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.3 °C/°F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.4 Maintien (HOLD) . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.5 Maxi/Mini . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.6 Remise à zero (RESET) . . . . . . . . . . . . . . . . . . . 26

3.7 Arret Automatique . . . . . . . . . . . . . . . . . . . . . . . . 26

4. MESURAGE ................................26

5. PRECAUTIONS D’EMPLOI ....................27

6. MAINTENANCE .............................27

6.1 Nettoyage du capteur . . . . . . . . . . . . . . . . . . . . . 27

7. ETALONNAGE ..............................27

8. PRECAUTIONS DE MESURAGE HR . . . . . . . . . . . . 28

9. DEFINITIONS ...............................29

10. REMPLACEMENT DES PILES . . . . . . . . . . . . . . . . . 29

SPECIFICATIONS ..................................67

2

Page 4

INHALT

INFORMATIONEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

KALIBRIERUNG, ZERTIFIZIERUNG UND

SERVICE .........................................32

1 BESCHREIBUNG ............................34

1.1 Erhältliches Zubehör .......................34

2 ÜBERSICHT DER DISPLAYSYMBOLE . . . . . . . . . . 35

3 BETRIEBSANLEITUNG .......................36

3.1 Einschalten ..............................36

3.2 %RH/DP ................................37

3.3 °C/°F ...................................37

3.4 Halten (HOLD) . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.5 Max/Min . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.6 Zurücksetzen (RESET) .....................38

3.7 Automatikabschaltung ......................38

4 MESSEN ...................................39

5 VORSICHTSMASSNAHMEN BEIM

GEBRAUCH ................................39

6 WARTUNG .................................39

6.1 Sensorreinigung . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7 KALIBRIERUNG . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8 WAS BEI DER LUFTFEUCHTIGKEITSMESSUNG

ZU BERÜCKSICHTIGEN IST . . . . . . . . . . . . . . . . . . 40

9 BEGRIFFSDEFINITIONEN . . . . . . . . . . . . . . . . . . . . 41

10 BATTERIEWECHSEL . . . . . . . . . . . . . . . . . . . . . . . . 42

SPEZIFIKATION ...................................67

3

Page 5

INDICE

INFORMAZIONE GENERALE . . . . . . . . . . . . . . . . . . . . . . . . 43

CALIBRAZIONE, CERTIFAZIONE ED

ASSISTENZA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

1. DESCRIZIONE ..............................47

1.1 Accessori disponibili . . . . . . . . . . . . . . . . . . . . . . . 47

2. SPIEGAZIONE DEI SIMBOLI SUL DISPLAY . . . . . . 48

3. ISTRUZIONI DI FUNZIONAMENTO . . . . . . . . . . . . . 49

3.1 Accensione ..............................49

3.2 % U.R./DP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.3 °C /°F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.4 Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.5 Max/Min . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.6 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.7 Auto-Spegnimento . . . . . . . . . . . . . . . . . . . . . . . . 51

4. MISURAZIONE ..............................51

5. PRECAUZIONI D’USO ........................52

6. MANUTENZIONE ............................52

6.1 Pulizia del sensore . . . . . . . . . . . . . . . . . . . . . . . . 52

7. CALIBRAZIONE .............................52

8. PRECAUZIONE DI MISURA . . . . . . . . . . . . . . . . . . . 53

9. DEFINIZIONE DEI TERMINI . . . . . . . . . . . . . . . . . . . 54

10. SOSTITUZIONE DELLE BATTERIE .............54

CARATTERISTICHE ................................67

4

Page 6

CONTIENDOS

INFORMACION ....................................55

GENERALCALIBRACION,CERTIFICACION Y

SERVICIO ........................................57

1. DESCRIPCION ..............................59

1.1 Accesorios Disponibles . . . . . . . . . . . . . . . . . . . . 59

2. VISION GENERAL DE LOS SIMBOLOS EN LA

PANTALLA DE VISUALIZACION . . . . . . . . . . . . . . . 60

3. INSTRUCCIONES DE OPERACION .............61

3.1 Encendido . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

3.2 % Humedad/Punto de rocio .................62

3.3 °C/°F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

3.4 Boton de parada (HOLD) ...................63

3.5 Max/Min ................................63

3.6 Reinicializar (RESET) . . . . . . . . . . . . . . . . . . . . . 63

3.7 Apagado Automatico . . . . . . . . . . . . . . . . . . . . . . 63

4. MEDICION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5. PRECAUCIONES EN EL USO . . . . . . . . . . . . . . . . . 64

6. MANTENIMIENTO ...........................64

6.1 Limpiado del Sensor . . . . . . . . . . . . . . . . . . . . . . 64

7. CALIBRACION ..............................65

8. PRECAUCIONES EN LA MEDICION . . . . . . . . . . . . 65

9. DEFINICION DE LOS TERMINOS ...............66

10. CAMBIAR DE LAS PILAS .....................66

ESPECIFICACION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5

Page 7

ENGLISH

COMARK N8004/N8006

OPERATING INSTRUCTIONS

1. GENERAL INFORMATION

It is recommended that you read the safety and operating instructions

before using this instrument.

Notes:

N8006 is a RH/temperature handheld instrument using an integral sensor; N8004 uses a separate RH/temperature probe (N81).

WARNING

TO AVOID ELECTRIC SHOCK DO NOT ALLOW ANY PROBE OR

SENSOR TO COME INTO CONTACT WITH LIVE ELECTRICAL

POWER CONDUCTORS WITH VOLTAGES IN EXCESS OF 30V AC

RMS OR 60V DC.

TO AVOID DAMAGE OR BURNS, DO NOT MAKE TEMPERATURE

MEASUREMENTS IN MICROWAVE OVENS.

DO NOT PLACE THE THERMOMETER IN A DISHWASHER AS IT IS

NOT DISHWASHER SAFE.

THE SYMBOL ON THE INSTRUMENT INDICATES THAT THE OPERATOR MUST REFER TO THE WARNINGS GIVEN HERE.

CAUTION

Temperature Measurement Probes

This precision instrument has been designed for use with the

extensive range of Comark temperature probes. The use of

other probes may impair the performance and accuracy of the

instrument. Full details of Comark probes and sensors can be

obtained from Comark Customer Support department or your local

distributor. Repeated sharp exing can break thermocouple probe

leads. To prolong lead life, avoid sharp bends or kinks in the leads,

especially near the connector.

6

Page 8

This instrument is manufactured in accordance with the

Company’s ISO 9001 Quality Approved System.

ISO 9001

FM 29700

This instrument complies with the Electromagnetic

Compatibility Directive EN61326-1

Declarations of Conformity available. Contact Comark

Customer Support or your local Distributor.

In line with its policy of continuous development, Comark Instruments

reserves the right to alter the instrument specication without prior

notice. Further information is available from Comark Instruments or

your distributor.

7

Page 9

CALIBRATION, CERTIFICATION AND SERVICE

Certication

No. 0451

Comark can provide certicates of calibration for its whole product

range, to suit ISO 9000 and other quality assurance procedures, food

hygiene regulations, HACCPs and environmental regulations. Comark

certicates are produced by independent quality controlled processes

which compare product performance against agreed National Standards. For peace of mind and best practice Comark recommend annual

certication/recalibration.

Two levels of certication are available for infra-red temperature and

non temperature instruments, excluding humidity:- UKAS certicates via

an external accredited laboratory and NPL traceable certicates from

the Comark calibration laboratory.

Three levels of certication are available for contact temperature and

humidity products and these are detailed here:

a) UKAS Temperature Certication

The Comark UKAS (United Kingdom Accreditation Service)

accredited temperature calibration laboratory is one of the nest in the UK. Comark UKAS certicates can offer the lowest

uncertainty of 0.01°C and provide independent proof of correct

calibration using equipment and procedures audited by UKAS

inspectors. The equipment used is fully traceable to the National Physical Laboratory.

b) UKAS Humidity Certication

In addition to the Comark temperature laboratory, the humidity

laboratory continues the tradition of high accuracy certication

and a wide range (25% to 90%RH) with uncertainties of 2.8% of

reading. This range also includes Dew point measurements.

c) NPL Traceable Certication

Comark NPL certicates are traceable to the National Physical

Laboratory and can offer uncertainty as low as 0.3°C.

Conformance

Certicates of conformance can be supplied for new, serviced and

recalibrated instruments. These conrm that instruments are within their

original manufactured specication.

8

Page 10

Service/Repairs

Regular servicing and any required repairs, under warranty or after, are

available from the Comark Service Department.

For more information on all Comark certication, calibration and service

facilities please call Comark Customer Support or contact your local

distributor.

9

Page 11

1. DESCRIPTION

The N8000 range of handheld hygrometers incorporates high level accuracy (both temperature and humidity) with class leading features.

The N8006 has an integral sensor head, while the N8004 has the RH

sensor and its associated electronics, contained in a hand held probe

(N81) connected to the instrument by a cable. This probe is also tted

with a thermistor for high accuracy air temperature measurement. The

N8004 is also capable of independent temperature measurement via

a special adaptor enabling the use of wide range of Comark thermistor

probes.

Both units use a large LCD allowing both humidity and temperature to

be displayed simultaneously.

There are two basic operation modes for these instruments:

1. Measurement of Relative Humidity.

2. Calculation of Dew point.

1.1 ACCESSORIES AVAILABLE

Each hygrometer can be supplied with a rubber boot for those

demanding applications requiring additional protection for the

instrument. Each rubber boot comes complete with a built in

wrist strap for added security. (Part No: CRS/4)

N8004

The N8004 can measure temperature independently of the

N81 using an adaptor (KX7538) that allows the use of any of

Comark’s standard 6-way Lumberg thermistor probes.

10

Page 12

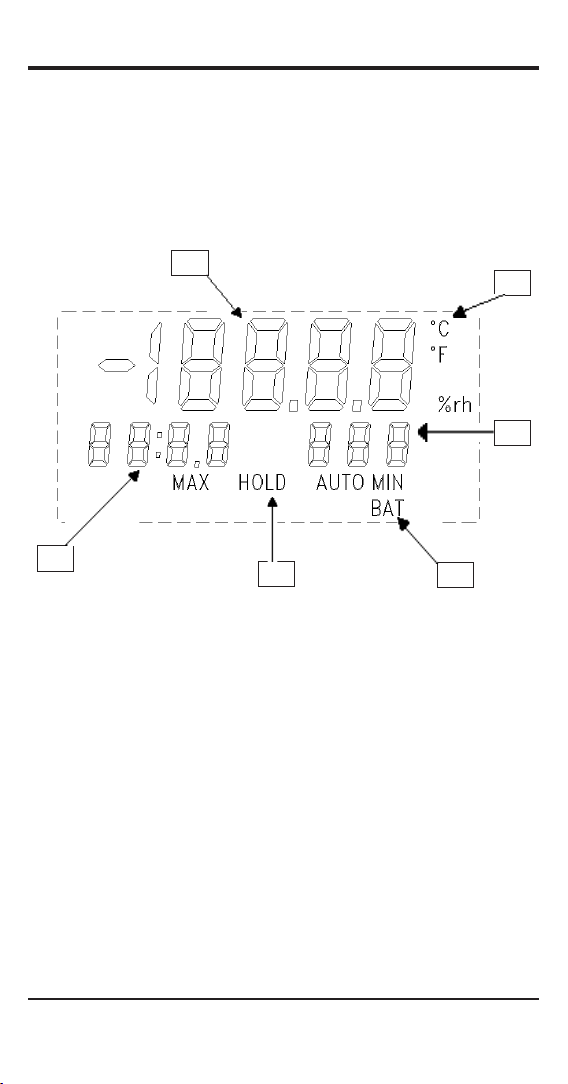

2. OVERVIEW OF DISPLAY SYMBOLS

The Display is split into three main areas. The rst line displays either

Relative Humidity or Dew Point. The second line is split into two areas;

the area to the left is used to display ambient temperature, whereas the

area to the right is used to indicate the temperature scale in use and

Dew point mode.

A

B

C

F

A. Main RH/Dewpoint display.

B. Used to indicate temperature scale in use when in

Dewpoint mode. %rh indicates that the instrument is in

Relative Humidity mode.

C. Displays the current temperature scale in use in RH mode or

indicates Dewpoint mode.

D. Indicates AUTO power off enabled/MINimum and Low BATtery.

E. Indicates MAXimum and HOLD mode.

F. Used to indicate ambient temperature.

E

FIG. 1

D

11

Page 13

3. OPERATING INSTRUCTIONS

A full description of the operation of the modes of the Hygrometers

is given below. Please read it carefully and if you have any further

queries contact the Comark Sales Ofce.

3.1 SWITCH ON

ON

OFF

Press to turn ON.

NOTE: The instrument performs a self-test for up to 1

second when switched on.

Press this button again to turn the instrument OFF.

N8004

A probe must be inserted before the instrument can be operated. If a probe is not inserted the display appears as follows:

FIG.2

This is the normal indication for an open circuit, broken probe or

out of range indication.

N8006

If your N8006 displays the above diagram it is faulty and should

be returned to Comark Service Department.

12

Page 14

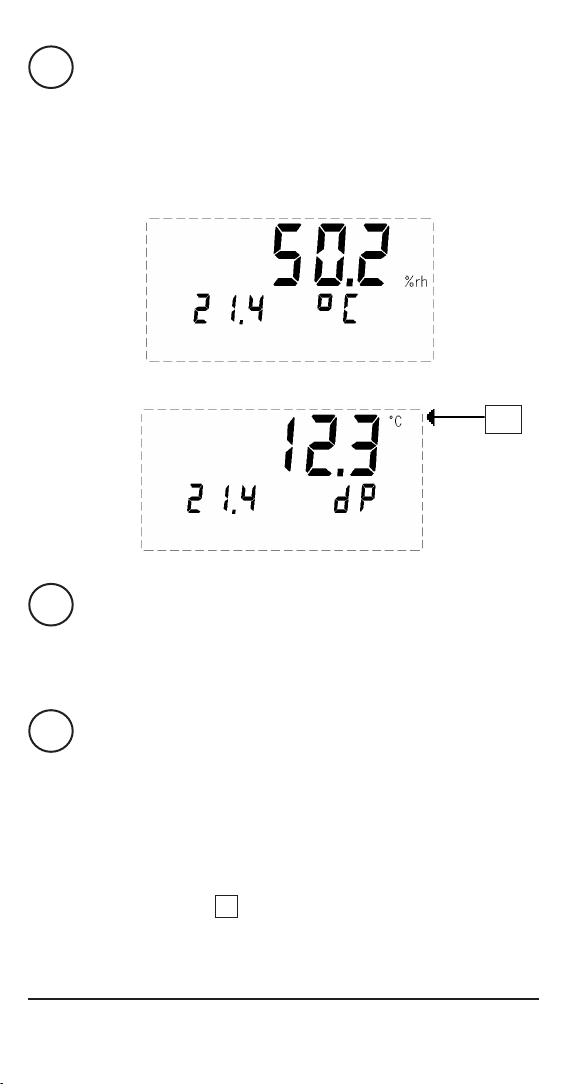

3.2 %RH/DP

%RH

DP

Selects direct relative humidity measurement or dewpoint

calculation mode and will be displayed in the main numeric area

of the display.

Relative Humidity Mode:

Dewpoint Mode:

FIG.3

FIG.4

3.3 °C/°F

°C

/°F

This selects the temperature scale used. This applies to both

ambient temperature and dewpoint temperature depending on

the mode of operation.

3.4 HOLD

HOLD

Freezes the display with the last measured value. ‘HOLD’ is

shown on the display. Press the button again to release this

function.

NOTE: Having selected HOLD, it is still possible to scroll the

held values of MAX, MIN and CURRENT temperatures and

to redisplay the temperature scale for any of these. It is also

possible to change to dewpoint mode or RH. Note that the

scale indicated by A in Fig. 4, either °C/°F, has now become

the scale indicator for both the dewpoint temperature and the

ambient air temperature.

A

13

Page 15

3.5 MAX/MIN

MAX

MIN

This button scrolls through the display of the Maximum, Minimum and current humidity and temperature. It also cycles

through the Maximum and Minimum values in dewpoint and

hold modes.

3.6 RESET

RESET

Resets Maximum and Minimum to Current value. This function

occurs automatically at switch-on.

The reset button copies the current value into the Maximum and

Minimum stores, but it does not alter the selection for display.

3.7 AUTO-SWITCH OFF

The N8000 series can be congured either to switch off

automatically ve minutes after the last button operation or to

remain permanently on until manually switched off.

This mode is indicated on the display by the AUTO symbol.

When this is visible the instrument will auto power down.

To change from one mode option to the other, switch the instrument OFF, then with the °C/°F button depressed switch the

instrument ON again.

4. MEASUREMENT

Although the humidity sensor is virtually insensitive to temperature over

the normal operating range, temperature itself affects Relative Humidity.

This and other factors are discussed at a later point. This dependence

(typically 0.5%RH for 0.1°C (0.2°F) temperature change) means that

when taking a cold probe into a warmer atmosphere, RH readings will

initially be high and conversely when a warm probe is taken into a cold

atmosphere, readings will initially be low.

To ensure accurate readings the user should wait until the display is

stable.

14

Page 16

5. PRECAUTIONS IN USE

Care should be taken where organic solvents are being used. Occasional exposure to hazardous environments is to be expected for a portable instrument but for more prolonged use (e.g. monitoring), Comark

should be contacted for advice.

Care must also be taken to protect all sensors against physical damage.

6. MAINTENANCE

6.1 SENSOR CLEANING

In the event of accidental pollution, the following steps may be

taken, though success cannot be guaranteed.

NOTE: On no account touch the humidity sensor (glass) with

even the softest material.

DUST – use a gentle air stream, e.g. from squeeze-bulb used

for cleaning camera lenses. If not successful, use a stream of

distilled water from a wash bottle, holding the probe downwards, so that water drips clear from the sensor. Dry in a

dust-free environment, using a hair-dryer to speed the drying

process, if required.

OILY POLLUTION – use a stream of perchlorethylene to remove contamination.

7. CALIBRATION

This can only be performed by Comark Ltd.

15

Page 17

8. PRECAUTIONS IN RH MEASUREMENT

Apart from the need to take reasonable care when using the N8004/6

as described already, there are precautions to be taken in measuring

humidity, regardless of the instrument being used.

AIR CIRCULATION

Without air circulation there will be humidity differentials across the

room or chamber.

TEMPERATURE

The temperature differences that exist across a room or chamber,

though small, will have a large effect on Relative Humidity. In a typical

case 0.5%RH for a temperature difference of 0.1°C (0.2°F).

AIR VELOCITY

Some air velocity is necessary to ensure accurate results and fast

response time.

ATMOSPHERIC PRESSURE EFFECTS

These are often neglected, but can be signicant. As an example, for

the same temperature, air measured at 1050mB (millibars) may give an

RH of 70%RH, whereas the same air at 950mB will read 77%RH.

CONDENSATION

This can occur at high RH when the probe is below the ambient dewpoint. Though the N8004/6 humidity sensor will recover from this, it

should be avoided if possible.

16

Page 18

9. DEFINITION OF TERMS

RELATIVE HUMIDITY – is a measure of the amount of water vapour

in the air as a percentage of the maximum water vapour the same air

could carry. In scientic terms, it is the partial pressure of water vapour

divided by the saturation pressure of water vapour at that temperature.

DEWPOINT – is the temperature at which dew would form if the air

were to be cooled. As the air cools, so it can carry less water vapour;

the point at which dew forms is the saturation temperature at that pressure.

SPECIFIC HUMIDITY – is the weight of water per weight of dry air and

is usually expressed in PPM (parts per million) which is milligrams per

kilogram

10. CHANGING THE BATTERIES

When the BAT symbol appears the batteries should be changed immediately. If this is not done the instrument will continue to work, but the

calibration of the unit can not be guaranteed.

To replace the batteries: Make sure the instrument is off, unscrew the

screw retaining the battery cover on the rear of the instrument using the

correct size at-blade screwdriver. Remove the two cells and replace

with new alkaline cells to ensure long life. Be careful to observe the cor-

rect polarity. Take care not to over-tighten the screw when re-tting the

cover, and not to lose the rubber sealing washer.

Note: NiCd or NiMh cells can be used but will result in reduced operating time. Do not attempt to recharge the cells in the instrument.

17

Page 19

FRANÇAIS

COMARK N8004/N8006

INSTRUCTIONS D’EMPLOI

1. GENERALITES

On lui recommande que vous lisiez le saftey et les consignes

d'utilisation avant d'utiliser cet instrument.

Notes :

N8006 est un instrument tenu dans la main de RH/temperature à

l'aide d'un capteur intégral ; N8004 utilise une sonde séparée de RH/

temperature (N81).

ATTENTION

OUR EVITER LES CHOCS ELECTRIQUES VOUS NE DEVEZ PAS

METTRE EN CONTACT LES CAPTEURS OU LES SONDES AVEC DES

CONDUCTEURS ELECTRIQUES DENUDES SOUMIS A UNE TENSION

SUPERIEURE A 30V CA RMS A 60V DC.

NE PRENEZ PAS LA TEMPERATURE DANS LES FOURS A MICROONDES POUR NE PAS CAUSER D’ACCIDENTS OU DE BRULURES.

NE PAS PLACER L’INSTRUMENT DANS UN LAVE-VAISELLE UN

POUR AINSI DIRE PAS LAVE-VAISSELLE SÛR.

LE SYMBOLE SUR L’INSTRUMENT INDIQUE QUE L’OPÉRATEUR

DOIT SE RÉFÉRER AUX EXPLICATIONS CI-DESSUS.

ATTENTION !

Sondes de mesure de la température

Cet appareil de précision a été conçu pour être utilisé avec les sondes de

température Comark dont un choix étendu vous est proposé. L’utilisation

d’autres sondes risque de nuire à la performance et à la précision de

l’appareil. Pour toutes informations sur les capteurs et les sondes Comark,

contactez le service client Comark ou votre distributeur local.

18

Page 20

Cet appareil est fabriqué conformément au

système d’homologation de la qualité ISO 9001

de la société.

Cet appareil est en conformité avec la Directive

sur la Compatibilité Electro-magnétique,

EN61326-1.

La Déclaration de Conformité est disponible

auprès du service commercial de Comark ou bien

auprès du distributeur local.

Conformément à sa politique de développement permanent,

Comark Instruments se réserve le droit de modier sa spécication

sans avis préalable. Pour toutes autres informations, contactez

Comark Instruments ou votre distributeur.

19

Page 21

ETALONNAGE, HOMOLOGATION, ET ENTRETIEN

Homologation

No. 0451

Le laboratoire Comark fournit des certicats d'étalonnage pour

l'ensemble de sa gamme de produits, en vue de satisfaire à la

norme ISO 9000, à d'autres procédures d'assurance qualité, aux

réglementations en matière d'hygiène alimentaire et d'environnement

ainsi qu'aux HACCP. Les certicats Comark sont délivrés à l'issue de

contrôles de la qualité indépendants qui comparent la performance d'un

produit envers celle d'une norme nationale convenue. Pour avoir l'esprit

tranquille et être dans les règles, Comark conseille de demander une

homologation / réétalonnage annuel(le).

Deux niveaux de certication sont disponsibles pour les thermomètres

à infra-rouge et les intraments ne mesurant pas la température (mesure

d’humidite exclue): certicat UKAS via un laboratoire accrédité

exterieur et certicate NPL du laboratoire d’étalonnage Comark.

Trois types d'homologation sont proposés pour les appareils de mesure

de la température et d'humidité par contact:

(a) Homologation UKAS

Le laboratoire Comark de calibration en température accrédité

UKAS (United Kingdom Accreditation Service) est un des meilleur

du Royaume-Uni. Les certicats UKAS de Comark peuvent offrir

une incertitude allant jusqu’à 0,01°C et fournissent les preuves

indépendantes d’une calibration correcte de part l’utilisation

d’équipements et de procédures audités par les inspecteurs UKAS.

La traçabilité de l’équipement est assurée par le Laboratoire

National de Physique anglais (NPL).

b) Certication UKAS pour l’humidite

En plus de la température, le laboratoire Comark est à present

accrédité pour delivrer des certicats UKAS pour l’humidite. Dans

une tradition de précision, ces certicats sont établis dans une

gamme allant de 25% à 90% RH avec une incertitude 2,8% de

la lecture. Bien entendu, le point de rosee peut également être

mesure.

c) Homologation identiable par rapport au NPL

Les certicats NPL de Comark offrent une incertitude de 0,3°C et

la traçabilité est assurée par le Laboratoire National de Physique

anglais (NPL).

20

Page 22

Conformité

Les certicats de conformité peuvent être fournis pour les instruments

neufs et ceux ayant subi une révision et un réétalonnage. Ils conrment

que l'instrument est conforme à sa spécication d'origine au moment de

sa fabrication.

Entretien/Réparations

Le Service d'entretien de Comark peut assurer des révisions régulières

et les réparations nécessaires des instruments sous garantie ou non.

Pour plus d'informations sur les homologations Comark, les services

d'étalonnage et de révision, appelez le service d'assistance Comark en

Grande-Bretagne ou votre distributeur local.

21

Page 23

1. DESCRIPTION

La gamme d’hygromètres portatifs N8000 allie un haut niveau de

précision (pour les relevés de température et d’humidité relative) à des

caractéristiques de référence.

Le modèle N8006 est muni d’une tête de capteur intégrée. Le capteur

d’humidité relative et les composants électroniques annexes du modèle

N8004 sont intégrés à une sonde portative (N81) relié à l’instrument par

un câble. Cette sonde est également munie d’une thermistance conçue

pour mesurer, avec précision, la température de l’air. Un adaptateur

de conception spéciale compatible avec les diverses sondes à

thermistance de la vaste gamme Comark permet également au modèle

N8004 de mesurer la température indépendamment.

Ces deux appareils ont été dotés d’un grand écran LCD capable

d’afcher simultanément le taux d’humidité relative et la température.

Ces instruments présentent deux modes d’utilisation de base :

1. Mesurage de l’Humidité Relative

2. Calcul du Point de rosée.

1.1 ACCESSOIRES DISPONIBLES

Chaque hygromètre peut être livré muni d’un soufet en

caoutchouc pour les cas où des applications particulièrement

éprouvantes obligent à prévoir une protection supplémentaire

de l’instrument. Chaque soufet en caoutchouc est livré comme

un ensemble complet muni d’une dragonne intégrée pour un

surcroît de sécurité (Réf . pièce No : CRS/4)

N8004

Un adaptateur (KX7538) permet au modèle N8004 de mesurer

la température indépendamment de l’hygromètre N81. Cet

adaptateur est compatible avec n’importe quelle sonde à

thermistance standard à six voies de type Lumberg proposée

par Comark.

22

Page 24

2. VUE D’ENSEMBLE DES SYMBOLES

D’AFFICHAGE

L’afchage est divisé en trois zones d’information principales. La

première ligne indique soit l’Humidité Relative, soit le Point de rosée. La

seconde ligne comporte deux zones. La température ambiante s’afche

à gauche et la zone de droite renseigne sur l’échelle de température

congurée et le mode Point de rosée.

A

B

C

F

E

D

FIG.1

A. Afchage principal de l’Humidité Relative et du Point de

rosée.

B. Indique l’échelle de température congurée en mode Point

de rosée. %rh indique que l’instrument est en mode Humidité

Relative.

C. Indique l’échelle de température actuellement congurée

(en mode RH) ou indique le mode Point de rosée.

D. Témoin de mode d’arrêt AUTO actif/MINimum et d’épuisement de la

pile (BAT).

E. Témoin de mode MAXimum et de maintien (HOLD).

F. Indique la température ambiante.

23

Page 25

3. MODE D’EMPLOI

Les pages suivantes vous expliquent, en détail, le fonctionnement des

Hygromètres. Nous vous invitons à les lire attentivement et à contacter

le Bureau des ventes Comark pour de plus amples informations.

3.1 MISE EN MARCHE

ON

OFF

Appuyer sur ce bouton pour mettre l’instrument sous tension

(ON).

NOTA : A la mise sous tension, l’instrument procède à une

vérication automatique d’une durée maximum de 1 seconde.

Appuyer de nouveau sur ce bouton pour le mettre hors tension

(OFF).

N8004

L’instrument ne fonctionne pas tant qu’une sonde n’a pas été

insérée. Si la sonde n’a pas été insérée, l’afchage renvoie

l’information suivante :

FIG.2

Cet afchage correspond à un circuit ouvert, à une sonde

cassée ou à une indication hors la plage.

N8006

Si le modèle N8006 afche le schéma ci-dessus, il est en panne

et doit être renvoyé au S.A.V. Comark.

l’air ambiant.

24

Page 26

3.2 %RH/DP

%RH

DP

Sélectionne le mesurage direct d’humidité relative ou le mode

de calcul du point de rosée et s’afche dans la zone numérique

principale de l’afchage.

Mode Humidité Relative :

FIG. 3

Mode Point de rosée :

FIG. 4

3.3 °C/°F

°C

/°F

Sélectionne l’échelle de température utilisée. Ceci est valable

pour la température ambiante comme pour la température du

point de rosée, selon le mode de fonctionnement sélectionné.

3.4 MAINTIEN (HOLD)

HOLD

Fige l’afchage sur le dernier relevé. Le mot 'HOLD' s’afche

sur l’écran. Appuyer de nouveau sur ce bouton pour désactiver

cette fonction.

NOTA : La sélection de la fonction de MAINTIEN n’empêche pas de

faire dérouler les valeurs maintenues des températures MAX, MIN

et ACTUELLE (CURRENT) et de réafcher l’échelle de température

de l’une ou de l’autre de ces valeurs. Il est également possible

de passer au mode Point de rosée ou HR. Noter que l’échelle de

température indiquée par un A dans la Fig. 4, soit °C ou °F,

devient l’indicateur d’échelle de température commun au point de

rosée et à l'air ambient.

25

Page 27

3.5 MAX/MIN

MAX

MIN

Ce bouton permet de parcourir les relevés Maximum, Minimum,

d’humidité actuelle et de température qui s’afchent à l’écran.

Il permet également de parcourir les valeurs Maximum et

Minimum des modes point de rosée (DP) et maintien (HOLD).

3.6 REMISE A ZERO (RESET)

RESET

Réinitialise la valeur actuelle des relevés Maximum et Minimum.

Cette fonction se déclenche automatiquement à la mise en

marche de l’appareil.

Le bouton de RESET copie la valeur actuelle dans les

mémoires Maximum et Minimum mais ne modie pas la

sélection à afcher.

3.7 ARRET AUTOMATIQUE

Les modèles de la série N8000 peuvent être congurés pour

s’arrêter automatiquement cinq minutes après la dernière

intervention de l’utilisateur sur les commandes ou pour rester

en marche en permanence, jusqu’à la mise à l’arrêt manuelle

par l’utilisateur.

Le symbole AUTO afché à l’écran se rapporte à ce mode. S’il

est visible, l’instrument s’arrête automatiquement.

Pour passer d’une option de mode à une autre, éteindre

l’instrument (OFF) et, tout en appuyant sur le bouton °C/°F,

remettre l’instrument en marche (ON).

4. MESURAGE

Bien que le capteur d’humidité soit pratiquement insensible à la

température dans les limites de la plage d’utilisation normale, la

température elle-même a une incidence sur l’Humidité Relative. Cet

aspect et d’autres facteurs feront l’objet d’une rubrique séparée. A

cause de cette dépendance (typiquement un taux HR de 0,5% HR pour

une différence de température de 0,1°C (0,2°F)), le relevé d’Humidité

Relative initial est élevé lorsqu’un détecteur froid est introduit dans un

milieu plus chaud. En revanche, le relevé d’Humidité Relative initial est

faible lorsqu’un détecteur chaud est introduit dans un milieu plus froid.

L’utilisateur devra attendre que l’afchage se stabilise pour pouvoir être

sûr de l’exactitude des relevés.

26

Page 28

5. PRECAUTIONS D’EMPLOI

L’utilisation de certains solvants organiques oblige à prendre certaines

précautions. Une exposition occasionnelle aux milieux dangereux est

inévitable avec ce type d’instrument portable. Ceci dit, on recommande

à l’utilisateur de se renseigner auprès de Comark avant une exposition

prolongée de l’instrument dans ces conditions (dans le cadre d’une

application de contrôle, par exemple).

Des précautions doivent également être prises pour protéger les

capteurs du risque de détérioration physique.

6. MAINTENANCE

6.1 NETTOYAGE DU CAPTEUR

Les mesures suivantes peuvent être prises en cas de pollution

accidentelle, mais sans garantie de résultat.

NOTA : Ne jamais toucher la surface du capteur d’humidité

(verre), même avec un tissu des plus doux.

POUSSIERES – utiliser de petits jets d’air, provenant d’une

buse caoutchouc utilisée pour dépoussiérer les lentilles

d’appareils photographiques, par exemple. Si cela ne fait pas

l’affaire, passer sous l’eau distillée d’un acon laveur en tenant

le capteur tête en bas pour permettre à l’eau de s’en écouler.

Sécher dans un milieu dépourvu de poussières à l’aide d’un

sèche-cheveux pour accélérer le séchage, si nécessaire.

POLLUTION HUILEUSE – Passer sous le perchloréthylène

pour éliminer le contaminant.

7. ETALONNAGE

Seule Comark Ltd. est habilitée à effectuer ce réglage.

27

Page 29

8. PRECAUTIONS DE MESURAGE HR

En plus des précautions d’utilisation des modèles N8004/6 déjà

décrites, certaines précautions sont à observer relativement au

mesurage de l’humidité, quel que soit l’instrument utilisé.

CIRCULATION D’AIR

Sans circulation d’air, des différences d’humidité sont relevées à

différents endroits de la salle ou de la chambre.

TEMPERATURE

Bien que peu importantes, les différences de température existant à

différents endroits d’une salle ou d’une chambre ont une incidence

manifeste sur l’Humidité Relative. On tiendra compte typiquement d’un

taux HR de 0,5 % pour une différence de température de 0,1°C (0,2°F).

VITESSE DE L’AIR

Des résultats exacts et un temps de réaction court dépendent d’une

certaine vitesse de l’air.

EFFETS DES PRESSIONS ATMOSPHERIQUES

Souvent négligés, ces effets peuvent jouer un rôle important. Par

exemple, compte tenu de la même température, l’air mesuré à 1050 mB

peut renvoyer une HR de 70% alors que, dans les mêmes conditions,

l’air mesuré à 950 mB renverra une HR de 77%.

CONDENSATION

Ce phénomène intervient en cas de taux HR élevé, si la sonde est audessous du point de rosée ambiant. Même si l’effet de ce phénomène

sur le capteur d’humidité des modèles N8004/6 n’est que passager, il

est préférable de l’éviter.

28

Page 30

9. DEFINITIONS

HUMIDITE RELATIVE – mesure correspondant à la quantité de vapeur

d’eau dans l’air indiquée par le pourcentage du maximum de vapeur

d’eau pouvant être présent dans le même air. En termes scientiques, il

s’agit de la pression partielle exercée par la vapeur d’eau, divisée par la

pression de saturation de la vapeur d’eau à la température de mesure.

POINT DE ROSEE – température à laquelle la rosée se forme si l’air

est refroidi. A mesure que l’air se refroidit, ses capacités de contenance

de vapeur d’eau diminuent. Le moment de la formation de rosée

correspond à la température de saturation à la pression de mesure.

HUMIDITE SPECIFIQUE – correspond au poids de l’eau par quantité

d’air sec normalement exprimé en p.p.m.(partie par million), soit

milligrammes par kilogramme.

10. REMPLACEMENT DES PILES

Remplacer les piles dès que le symbole BAT s’afche ou l’instrument

continue de fonctionner mais l’étalonnage correct de l’appareil n’est

plus garanti.

Pour remplacer les piles : vérier que l’instrument est bien hors

tension, dévisser la vis de retenue du cache de compartiment à piles

situé à l’arrière de l’instrument, à l’aide d’un tournevis plat de la taille

qui convient. Retirer les deux piles et les remplacer par de nouvelles

piles alcalines pour assurer une longue durée de fonctionnement de

l’instrument. Veiller à bien respecter la polarité, à ne pas trop resserrer

la vis en remettant le cache et à ne pas perdre la rondelle d’étanchéité

en caoutchouc.

Nota : Les piles rechargeables de type NiCd ou NiMH peuvent être

utilisées mais ne durent pas aussi longtemps. Ne pas essayer de

recharger les piles à l’intérieur de l’instrument.

29

Page 31

DEUTSCH

COMARK N8004/N8006

BEDIENUNGSANLEITUNGEN

1. INFORMATIONEN

Es wird empfohlen, daß Sie die Sicherheit und Bedienungsanleitung

lesen, bevor Sie dieses Instrument verwenden.

Anmerkungen:

N8006 ist ein RH/temperature Handinstrument mit einem integralen

Sensor; N8004 benutzt eine unterschiedliche RH/temperature

Prüfspitze (N81).

WARNUNG

BEI BERÜHRUNG EINES FÜHLERS MIT SPANNUNGSFÜHRENDEN

TEILEN ÜBER 30V WS BESTEHT FÜR DEN ANWENDER DIE GEFAHR

EINES ELEKTRISCHEN SCHLAGS.

U M B E S C H Ä D IG U N G O D E R VE R B R E N N U NG Z U

V E R H I N D E RN , KEINE T E M P E R ATUR - M E S S U NG EN I N

MIKROWELLENHERDEN DURCHFÜHREN.

DA ES NICHT SPÜLMASCHINENFEST IST, DARF DAS INSTRUMENT NICHT IN EINER GESCHIRRSPÜL-MASCHINE VERWENDET

WERDEN.

DAS SYMBOL LÄßT ERKENNEN, DAß DER BEDIENER SICH AUF

DIE O.A. ERKLÄRUNGEN BEZIEHEN MUß.

Temperaturfühler

Dieses Präzisionsgerät wurde für die Verwendung mit der ausgedehnten Reihe von Comark-Temperaturfühlern konstruiert.

Die Verwendung von anderen Fühlern könnte die Leistung und

Genauigkeit des Geräts beeinträchtigen. Sämtliche Einzelheiten

über Comark-Fühler und -Sensoren sind erhältlich von der ComarkKundendienstabteilung oder Ihren lokalen Händler.

30

VORSICHT

Page 32

Die Fertigung des Geräts erfolgt

in Übereinstimmung mit den

Qualitätssicherungsnachweisforderungen von

ISO 9001.

Das Gerät entspricht den Richtlinien für

elektromagnetische Verträglichkeit

EN61326-1.

EC Konformitätsbescheinigungen sind erhältlich

und anzufordern vom Comark Kundenservice

oder vom lokalen Vertriebspartner.

Entsprechend dem Geschäftsgrundsatz einer dauernden Weiterentwicklung

behält sich Comark Instruments das Recht vor, die technischen Daten des

Geräts ohne vorherige Notiz zu ändern. Weitere Informationen stehen von

Comark Instruments oder Ihrem Händler zur Verfügung.

31

Page 33

KALIBRIERUNG, ZERTIFIZIERUNG UND

SERVICE

Zertizierung

No.0451

Comark kann Kalibrierzertikate für die gesamte Produktpalette

bereitstellen, die für ISO 9000 und andere Qualitätssicherungsverfahren

sowie für Lebensmittelhygieneverordnungen, HACCPs und

Umweltverordnungen gültig sind. Zertikate von Comark werden

in unabhängigen, qualitätskontrollierten Verfahren erstellt, die

die Produkteigenschaften mit den jeweiligen nationalen Normen

vergleichen. Um den sorgenfreien Betrieb sicherzustellen und die

Vorschriften zu beachten, empehlt Comark eine jährliche Zertizierung

und Neukalibrierung.

Zwei Zertikat-Klassen sind für Infrarot-Temperaturmessgeräte und

Nicht-Temperaturmessgeräte sowie Feuchtemeggeräte lieferbar:

UKAS-Zertikate über ein externes akkreditiertes Labor und NPL

rückführbare Zertikate durch das Comark Kalibrierlabor.

Für Kontakttemperaturmessprodukte und Feuchtigkeit Produkte gibt es

die drei folgenden Zertizierungsniveaus:

a) UKAS-Zertizierung

Das von UKAS (United Kingdom Accreditation Service) akkreditierte

Comark-Temperaturkalibrierungslabor gehört zu den besten

in Großbritannien. Comark können UKAS Bescheinigungen

die niedrigste Ungewißheit von 0.01°C anbieten und können

unabhängigem Beweis Gebrauch Geräte richtiger Kalibrierung und

Verfahren versorgen, die von UKAS Inspektoren revidiert werden.

b) UKAS Zertikate für rel. Feuchte

Zusätzlich zur Comark-Temperatur ist unser Labor für Feuchtigkeit

jetzt in der Lage Kalibrierzerticake für rel. Feuchte zu erstellen.

Die Tradition für Zertikate mit hoher Genauigkeit und einen weiten

Messbereich wird fotgesetzt. Wir kalibrieren Feuchte von 25% bis

90% rF mit einer Abweichung von 2,8% des gelesenen Wertes.

c) Zertizierung nach NPL-Standards

Comark sind NPL Bescheinigungen auffundbar zum Nationalen

Physischen Labor und können Ungewißheit so niedrig wie 0.3°C

anbieten.

32

Page 34

Konformität

Konformitätszertikate können für neue, gewartete und neu kalibrierte

Instrumente vorgelegt werden. Diese Zertikate bestätigen, dass die

Geräte ihren ursprünglichen Herstellerspezikationen entsprechen.

Service/Reparaturen

Die Kundendienstabteilung von Comark bietet regelmäßige Wartung

und alle erforderlichen Reparaturen, auch nach Ablauf der Garantiezeit.

Weitere Informationen über alle Comark-Zertizierungen, Kalibrierungen

und Kundendiensteinrichtungen erhalten Sie entweder bei Comark

direkt oder bei Ihrem Händler.

33

Page 35

1. BESCHREIBUNG

Die Baureihe tragbarer Hygrometer N8000 zeichnet sich durch höchste

Genauigkeit (für Lufttemperatur und Luftfeuchtigkeit) aus und weist

Funktionsmerkmale auf, die in ihrer Klasse führend sind.

Das N8006 besitzt einen integrierten Sensorkopf, während beim

N8004 der RH-Sensor und die zugehörige Elektronik in einem

Handmessfühler (N81) untergebracht sind, der mittels Kabel an

das Instrument angeschlossen wird. Dieser Messfühler ist weiterhin

mit einem Thermistor für akkurate Lufttemperaturmessungen

ausgestattet. Das N8004 eignet sich außerdem für unabhängige

Temperaturmessungen mittels eines speziellen Adapters, der die

Anwendung des breiten Sortiments von Comark Thermistorfühlern

ermöglicht.

Beide Geräte besitzen ein großes LCD-Display, das die gleichzeitige

Anzeige von Luftfeuchtigkeit und Lufttemperatur gewährleistet.

Es gibt zwei Grundbetriebsmodi für diese Instrumente:

1. Messen der relativen Luftfeuchtigkeit

2. Taupunktberechnung.

1.1 ERHÄLTLICHES ZUBEHÖR

Für anspruchsvolle Anwendungen kann jedes Hygrometer

mit einer Gummischutzmanschette geliefert werden, um den

zusätzlichen Schutz des Instrumentes zu gewährleisten.

Für Extrasicherheit ist jede Gummischutzmanschette mit

Handgelenkband ausgestattet. (Artikel-Nr. CRS/4)

N8004

Mit einem Adapter (KX7538) kann das N8004 unabhängig vom

N81 Temperaturen messen, indem ein beliebiger 6-poliger

Lumberg-Thermistorfühler der Comark Standardbaureihe

angeschlossen wird.

34

Page 36

2. ÜBERSICHT DER DISPLAYSYMBOLE

Das Display ist in drei Hauptbereiche unterteilt. In der ersten Zeile

wird die relative Luftfeuchtigkeit oder der Taupunkt angezeigt. Die

zweite Zeile ist in zwei Bereiche unterteilt; der linke Bereich dient zur

Anzeige der Umgebungstemperatur, wogegen im rechten Bereich

die verwendete Temperaturskala und der Taupunktmodus angezeigt

werden.

A

B

C

F

E

D

ABB. 1

A. Hauptanzeige Luftfeuchtigkeit/Taupunkt

B. Im Taupunktmodus zur Anzeige der verwendeten

Temperaturskala genutzt. %rh weist darauf hin, dass sich

das Instrument im Modus Relative Luftfeuchtigkeit bendet.

C. Anzeige der aktuelle verwendeten Temperaturskala im

RH-Modus an oder zeigt Taupunktmodus an.

D. Anzeige von AUTO-Abschaltung Freigabe/MINimum und

niedrige BATterieladung.

E. Anzeige von MAXimum und HOLD-Modus (HALTEN).

F. Wird zur Anzeige der Umgebungstemperatur verwendet.

35

Page 37

3. BETRIEBSANLEITUNG

In diesem Abschnitt werden die Modusfunktionen der Hygrometer

umfassend beschrieben. Lesen Sie den Abschnitt bitte sorgfältig durch. Bei

etwaigen Fragen wenden Sie sich bitte an das Comark Vertriebsbüro.

3.1 EINSCHALTEN

ON

OFF

Drücken, um das Instrument EIN-zuschalten (ON).

HINWEIS: Nach dem Einschalten führt das Instrument 1

Sekunde langeinen Selbsttest durch.

Zum AUS-Schalten (OFF) des Instruments diese Taste erneut

drücken.

N8004

Bevor das Instrument genutzt werden kann, muss ein Messfühler

angeschlossen werden. Wenn kein Messfühler eingesteckt ist, sieht

die Displayanzeige wie folgt aus:

ABB. 2

Das ist die normale Anzeige für einen offenen Kreis, einen defekten

Messfühler oder eine Messbereichsüberschreitung.

N8006

Wenn die oben stehende Anzeige an Ihrem N8006 erscheint, ist das

Gerät defekt und muss an die Comark Serviceabteilung geschickt.

36

Page 38

3.2 %RH/DP

%RH

DP

Direktwahl von Messung der relativen Luftfeuchtigkeit oder

des Taupunktberechnungsmodus und wird im numerischen

Hauptbereich am Display angezeigt.

Modus Relative Luftfeuchtigkeit:

ABB. 3

Taupunktmodus:

ABB. 4

3.3 °C/°F

°C

/°F

Wahl der zu verwendenden Temperaturskala. Das gilt je

nach Betriebsmodus für die Umgebungstemperatur oder die

Taupunkttemperatur.

3.4 HALTEN (HOLD)

HOLD

Displayanzeige bleibt beim letzten Messwert stehen. „HOLD“

wird am Display angezeigt. Die Taste erneut drücken, um die

Funktion zu deaktivieren.

HINWEIS: Bei aktiver HOLD-Funktion ist es immer noch

möglich, zwischen den MAX-, MIN- und AKTUELLEN

Temperaturwerten zu scrollen und die Temperaturskala für

diese Werte neu anzuzeigen. Außerdem kann der Taupunktoder RH-Modus gewechselt werden. Bitte beachten, dass die

37

Page 39

unter A angezeigte Skala in Abb. 4, entweder °C oder °F,

jetzt die Skalenanzeige für die Taupunkttemperatur und die

Umgebungslufttemperatur geworden ist.

3.5 MAX/MIN

MAX

MIN

Mit dieser Taste kann man zwischen den maximalen, minimalen

und aktuellen Feuchtigkeits- und Temperaturwerten scrollen.

Außerdem kann man die Maximum- und Minimumwerte im

Taupunktmodus (DP) und im Haltemodus (HOLD) zyklisch

durchlaufen.

3.6 ZURÜCKSETZEN (RESET)

RESET

Setzt die Maximum- und Minimumwerte auf den aktuellen

Wert. Diese Funktion wird beim Einschalten automatisch

durchgeführt.

Mit der Taste RESET wird der aktuelle Messwert in die

Maximum- und Minimumspeicher übernommen, und die Wahl

der Displayanzeige bleibt unverändert.

3.7 AUTOMATIKABSCHALTUNG

Geräte der N8000 Baureihe können so konguriert werden,

dass sie sich fünf Minuten nach dem letzten Tastendruck von

selber ausschalten oder so lange eingeschaltet bleiben, bis sie

manuell ausgeschaltet werden.

Dieser Modus wird am Display vom Symbol AUTO

repräsentiert. Wenn das Symbol zu sehen ist, wird das

Instrument automatisch ausgeschaltet.

Um von einer Modusoption zur anderen zu wechseln, ist das

Instrument AUS-zuschalten (OFF) und dann mit gedrückt

gehaltener Taste °C/°F wieder EIN-zuschalten (ON).

38

Page 40

4. MESSEN

Obwohl der Feuchtigkeitssensor gegenüber Temperaturen über dem

normalen Betriebsbereich nahezu unempndlich ist, hat die Temperatur

selbst Einuss auf die relative Luftfeuchtigkeit. Dieser und andere

Faktoren werden später behandelt. Diese Abhängigkeit (typischerweise

0,5 % rF bei 0,1 °C Temperaturunterschied) bedeutet, dass beim

Überführen eines kalten Messfühlers in eine wärmere Atmosphäre die

rF-Messwerte anfänglich hoch und beim Überführen eines warmen

Messfühlers in eine kalte Atmosphäre dementsprechend anfänglich

niedrig sind.

Um akkurate Messwerte sicherzustellen, sollte der Benutzer warten, bis

sich die Displayanzeige stabilisiert hat.

5. VORSICHTSMASSNAHMEN BEIM GEBRAUCH

Wenn organische Lösungsmittel verwendet werden, ist

Vorsicht angeraten. Ein tragbares Instrument kann gelegentlich

Gefahrenbereichen ausgesetzt werden, für länger dauernde

Einsatzzwecke (z. B. Überwachung) wenden Sie sich aber bitte an

Comark.

Darauf achten, dass alle Sensoren vor mechanischen Beschädigungen

geschützt werden.

6. WARTUNG

6.1 SENSORREINIGUNG

Im Falle einer versehentlichen Verunreinigung können folgende

Schritte ausgeführt werden, deren Erfolg aber nicht garantiert

ist.

HINWEIS: Der Feuchtigkeitssensor (Glas) darf auf keinen Fall

berührt werden, auch nicht mit dem weichsten Material.

STAUB – einen sanften Luftstrom verwenden, z. B. von einem

Quetschballon zur Kameraobjektivreinigung. Wenn nicht

zufriedenstellend, ist ein Strahl destillierten Wassers aus

39

Page 41

einer Waschasche zu verwenden, wobei der Messfühler nach

unten gehalten wird, damit dass Wasser vom Sensor ablaufen

kann. In einer staubfreien Umgebung trocknen, ggf. einen

Haartrockner benutzen, um die Trocknungszeit zu verkürzen.

ÖLVERUNREINIGUNGEN - einen Strahl Perchlorethylen

verwenden, um die Verunreinigung zu beseitigen.

7. KALIBRIERUNG

Die Kalibrierung kann nur von Comark Ltd. vorgenommen werden.

8. WAS BEI DER

LUFTFEUCHTIGKEITSMESSUNG ZU

BERÜCKSICHTIGEN IST

Abgesehen von der bereits beschriebenen allgemeinen Sorgfalt beim

Einsatz des N8004/6 sind unabhängig vom verwendeten Instrument

einige Einussfaktoren zu berücksichtigen.

LUFTZIRKULATION

Ohne Luftzirkulation treten Luftfeuchtigkeitsunterschiede in einem

Raum oder in einer Kammer auf.

TEMPERATUR

Die Temperaturunterschiede in einem Raum oder in einer Kammer

haben einen starken Einuss auf die relative Luftfeuchtigkeit, auch

wenn sie nur gering sind – in einem typischen Fall 0,5 % rF bei einem

Temperaturunterschied von 0,1 °C.

LUFTGESCHWINDIGKEIT

Eine gewisse Luftgeschwindigkeit ist erforderlich, um akkurate

Messergebnisse und schnelle Reaktionszeiten sicherzustellen.

AUSWIRKUNGEN DES ATMOSPHÄRISCHEN DRUCKS

40

Page 42

Die Auswirkungen werden oft außer Acht gelassen, können aber

signikant sein. Bei gleicher Temperatur wird zum Beispiel bei

1050 mbar eine Luftfeuchtigkeit von 70 % rF gemessen, wohingegen

bei 950 mbar 77 % rF gemessen werden.

KONDENSATION

Kondensation kann bei hoher Luftfeuchtigkeit auftreten, wenn die

Temperatur des Messfühlers unterhalb des Umgebungstaupunktes liegt.

Auch wenn sich der N8004/6 Feuchtigkeitssensor davon erholt, sollte

dies vermieden werden.

9. BEGRIFFSDEFINITIONEN

RELATIVE LUFTFEUCHTIGKEIT - ist ein Maß der Wasserdampfmenge

in der Luft als Prozentualwert des maximalen Wasserdampfgehalts, den

die Luft aufnehmen kann. Als wissenschaftlicher Begriff ist die relative

Luftfeuchtigkeit das Verhältnis des Wasserdampfpartialdrucks zum

Sättigungsdampfdruck

bei dieser Temperatur.

TAUPUNKT - ist die Temperatur bei der sich Tau bildete, wenn die Luft

gekühlt würde. Wenn Luft abkühlt, kann sie weniger Wasserdampf

tragen; der Punkt, an dem sich Tau bildet, ist die Sättigungstemperatur

bei diesem Druck.

SPEZIFISCHE LUFTFEUCHTIGKEIT - ist das Verhältnis des

Wassergewichts zum Trockenluftgewicht und wird normalerweise in

ppm (parts per million) angegeben, was gleichbedeutend mit mg/kg ist.

10. BATTERIEWECHSEL

Wenn das Symbol BAT am Display erscheint, sollten die Batterien sofort

ausgewechselt werden. Wenn das nicht geschieht, ist das Instrument

immer noch arbeitsfähig, aber die Kalibrierung des Geräts kann nicht

garantiert werden.

Auswechseln der Batterien: Sicherstellen, dass das Gerät ausgeschaltet

ist und mit einem passenden Flachschraubendreher die Schraube

41

Page 43

vom Batteriedeckel an der Rückseite des Instruments entfernen. Die

beiden Zellen herausnehmen und, um eine lange Batterielebensdauer

zu gewährleisten, durch neue Alkalizellen ersetzen. Beim Einlegen auf

die richtige Polarität achten. Wenn der Deckel wieder befestigt wird,

darauf achten, dass die Schraube nicht überdreht wird und dass die

Gummidichtscheibe nicht verloren geht.

Hinweis: NiCd- oder NiMh-Zellen können verwendet werden, führen

aber zu kürzeren Betriebszeiten. Nicht versuchen, die Zellen im

Instrument aufzuladen.

42

Page 44

ITALIANO

COMARK N8004/N8006

ISTRUZIONI PER L'USO

1. INFORMAZIONI GENERALI

È suggerito che leggete le istruzioni di funzionamento e di sicurezza

prima di per mezzo di questo strumento.

Note:

N8006 è uno strumento tenuto in mano di RH/temperature per mezzo

di un sensore integrale; N8004 usa una sonda separata di RH/temperature (N81).

ATTENZIONE

PER EVITARE SHOCK ELETTRICI, NON PERMETTERE AD ALCUNA

SONDA O SENSORE DI ENTRARE IN CONTATTO CON CONDUTTORI

DI POTENZA ELETTRICA A VOLTAGGI SUPERIORI DI 30V CA VQM

O 60V CC.

PER EVITARE DANNI O BRUCIATURE SI CONSIGLIA DI NON USARE

IL TERMOMETRO PER MISURARE LA TEMPERATURA ALL’INTERNO

DEI FORNI A MICROONDE.

NON METTERE LO STRUMENTO NELLE LAVAPIATTI SE NON IN

SICUREZZA.

IL SIMBOLO CHE APPARE SULLO STRUMENTO INDICA CHE

L’OPERATORE PUÒ CONSULTARE LE SPIEGAZIONI DI CUI SOPRA.

ATTENZIONE

Sonde di temperatura

Questo strumento di precisione è stato realizzato appositamente per

essere usato con le numerosissime sonde di temperatura della linea

Comark. L’impiego di altre sonde potrebbe ridurre sia la prestazione

che la precisione dello strumento. Per informazioni complete sulle sonde e

sui sensori Comark, rivolgersi all’ufcio di assistenza al cliente della Comark

o al distributore di zona.

43

Page 45

La fabbricazione di questo strumento è soggetta al

sistema di controllo qualità della Comark, certicato ai

sensi della norma ISO 9001.

Questo strumento è conforme alle Direttive di

Compatibilità Elettromagnetica EN 61326-1.

È possibile ottenere attraverso la Comark la

Dichiarazione di Conformità.

In applicazione della sua politica di sviluppo continuo dei prodotti, la

Comark Instruments si riserva il diritto di modicare la specica del

prodotto senza preavviso. Per maggiori informazioni, rivolgersi alla Comark

Instruments o al distributore di zona.

44

Page 46

TARATURA, CERTIFICAZIONE E MANUTENZIONE

Certicazione

No. 0451

La Comark può fornire, per tutta la sua gamma di prodotti, i certicati

di taratura conformi alle procedure di controllo della qualità ISO 9000

e altri, per le norme d'igiene alimentare, per sistemi HACCP e per le

norme ambientali. I certicati della Comark vengono rilasciati in base ai

risultati di controlli di massima qualità, che confrontano le prestazioni

del prodotto alle norme nazionali. Per garantire l'afdabilità dei prodotti

e il rispetto delle migliori procedure la Comark consiglia di far certicare/

ritarare i prodotti una volta all'anno.

Sono disponibili due livellidi certicazione per gli strumenti che rilevano

la temperatura a raggi infrarossi e non, escludendo l’umidità: UKAS

Certicazione effettuata da laboratorio esterno accreditato. NPL certicato riferibile da laboratorio di calibrazione Comark.

Per gli strumenti di misurazione a contatto della temperatura ed umidità

sono disponibili, inoltre, tre livelli di certicazione:

a) Certicazione di temperatura UKAS (equivalente SIT)

L’UKAS è il più alto livello di certicazione riconosciuto nel

Regno Unito.Questo offre la più bassa incertezza di misura

esistente (0,01°C) e fornisce un riscontro della corretta taratura,

usando strumenti e procedure approvate dagli ispettori UKAS.

Gli strumenti usati sono in piena rintracciabilità al Laboratorio di

Fisica Nazionale (NPL).

b) Certicazione UKAS (equivalent SIT) per umidità

Il laboratorio Comark, oltre alla temperatura, si avvale ora

anche dell’accreditamento per il parametro umidità, ad alta

precisione ed ampio campo di misura (25% - 90% U.R.) con

incertezza di 2,8% della lettura. La certicazione può includere

inoltre la misurazione del punto di rugiada (dew points).

c) Certicazione conforme alle norme NPL

Le Certicazioni NPL sono utilizzate dal Laboratorio di Fisica

Nazionale epossono offrire un’incertezza pari a 0,3°C.

45

Page 47

Conformità

La Comark rilascia certicati di conformità per strumenti nuovi, riparati

e ritarati. Questi certicati confermano che gli strumenti sono conformi

alle speciche originali del fabbricante

Manutenzione/Riparazione

Il reparto manutenzione della Comark offre un servizio di manutenzione

ed effettua tutte le riparazioni necessarie, anche tramite il proprio

distributore locale.Per maggiori informazioni sui servizi di certicazione,

taratura e manutenzione della Comark basta rivolgersi all'ufcio di

assistenza al cliente o al distributore di zona.

46

Page 48

1. DESCRIZIONE

La gamma di termo – igrometri della serie N8000 combina

un’elevata precisione con caratteristiche di assoluta qualita’.

Il modello N8006 è fornito con un sensore integrato, mentre

il N8004 possiede una sonda elettronica (N81) esterna che

include il sensore di umidita’ ed è connesso allo strumento

tramite un cavo, la sonda include inoltre un termistore per la

misura della temperatura ad alta precisione. Il N8004 è inoltre

in grado di rilevare la temperatura con altre sonde a termistore

della gamma COMARK tramite uno speciale adattatore.

Entrambi gli strumenti possiedono un ampio LCD che visualizza

simultaneamente sia umidità che temperatura.

I due strumenti forniscono due modi operativi di base:

1. Misura di umidita’ relativa (U.R).

2. Calcolo del punto di rugiada (D.P)

1.1 ACCESSORI DISPONIBILI

Ogni termoigrometro puo’ essere fornito di un guscio

in gomma per avere una maggiore protezione. Ogni

guscio in gomma è completo di un velcro per migliore

sicurezza (CRS/4).

N8004

Il N8004 può misurare indipendentemente la

temperatura usando un adattatore (KX 7538) che

permette di utilizzare qualsiasi sonda a termistore

LUMBERG a 6 vie della gamma COMARK.

47

Page 49

2. SPIEGAZIONE DEI SIMBOLI SUL DISPLY

Il display è suddiviso in tre principali aree. La prima linea mostra

l’umidità relativa ad il punto di rugiada. La seconda linea è

suddivisa in due zone.

La zona a sinistra è usata per mostrare la temperatura e la

modalità DP.

A

B

C

F

E

FIG. 1

A. Visualizzatore principale U.R./DP.

B. Usata per indicare la scala di temperatura in uso

nella modalità DP. % rh indica che lo strumento è

nella modalità UR.

C. Mostra la scala di temperatura corrente in modalità

RH o indica la modalità DP.

D. Indica auto–spegnimento attivato / il minimo e

batteria in scarica.

E. Indica maxima e modalità Hold di blocco misura.

F. Usata per indicare la temperatura ambiente.

48

D

Page 50

3. ISTRUZIONI DI FUNZIONAMENTO

Una completa descrizione delle operazioni di tutte le modalità dei

termoigrometri è sotto elencata. Leggere attentamente e se c’è

necessità di ulteriori chiarimenti contattare gli ufci ISOIL INDUSTRIA

SPA rappresentanti della COMARK in Italia.

3.1 Accensione

ON

OFF

Premere ON.

Nota: Lo strumento esegue un test automatico per 1

secondo durante l’accensione.

Premere nuovamente il tasto per spegnere lo strumento, OFF.

N8004

E’ necessario inserire una sonda per far funzionare lo

strumento. Se non è inserita alcuna sonda il display appare

come segue:

FIG. 2

Questa è l’indicazione del circuito aperto, della sonda rotta

oppure l’eccesso del campo di misura.

N8006

Se il N8006 mostra l’indicazione suddetta, lo strumento non è

funzionante e dovrebbe essere reso al servizio assistenza.

49

Page 51

3.2 %RH/DP

%RH

DP

Seleziona direttamente la misura dell’umidità relativa o la

modalità di calcolo del punto di rugiada mostrandoli nella parte

principale del display.

Modalità Umidità Relativa (RH):

FIG. 3

Modalità Punto di Rugiada (DP):

FIG. 4

A

3.3 °C/F

Seleziona la scala di temperatura utilizzata. Essa è applicata ad

entrambe le temperature sia ambiente che del punto di rugiada

in funzione della modalità operativa.

3.4 Hold

Blocca il display all’ultimo valore misurato. HOLD è mostrato sul

display. Premere il tasto nuovamente per abbandonare questa

funzione.

Nota: Avendo selezionato HOLD è ancora possibile

far scorrere i valori mantenuti di Max, Min e istantanei

delle temperature e visualizzare nuovamente la scala di

temperatura per ognuno di loro. E’ inoltre possibile passare

50

Page 52

dalla modalità DP a UR. Notare che la scala indicata da A in

g. 4, sia °C/°F, è ora diventata l’indicatore di scala sia per la

temperatura del punto di rugiada che ambiente.

3.5 Max/Min

MAX

MIN

Il tasto fa scorrere il display dal valore massimo, minimo ed

istantaneo dell’umidità e temperatura. Inoltre fa passare dai

valori massimi e minimi nelle modalità DP e HOLD.

3.6 Reset

RESET

Azzera il massimo ed il minimo al valore istantaneo. Questa

funzione si attiva automaticamente all’accensione.

Il tasto di reset copia il valore istantaneo nelle registrazioni di

massimo e minimo, ma non altera la selezione del display.

3.7 Auto-spegnimento

La serie N8000 può essere congurata per essere spenta

automaticamente cinque minuti dopo l’ultima operazione

effettuata, oppure rimanere permanentemente accesa sino allo

spegnimento manuale.

La funzione è indicata tramite simbolo Auto sul display. Quando

esso è visibile lo strumento si spegnerà automaticamente.

Per passare da una funzione all’altra, spegnere lo strumento

OFF, poi con il tasto °C/°F premuto, accenderelo strumento

nuovamente, ON.

4. MISURAZIONE

Sebbene il sensore di umidità è insensibile alla temperatura alle

normali condizioni di lavoro, la temperatura stessa inuisce l’umidità

relativa. Ciò ed altri punti saranno discussi piu’ avanti. Si intende che

questa inuenza (tipicamente) 0.5% UR per 0.1°C/0.2°F di variazione

termica) dipende dalle condizioni di sonda fredda in atmosfera piu’

calda, determinando nell’iniziale lettura di UR un innalzamento e

vicendevolmente una sonda calda in atmosfera piu’ fredda determina

inizialmente una lettura piu’ bassa.

Per assicurarsi letture corrette si consiglia di attendere che il display sia

stabile.

51

Page 53

5. PRECAUZIONI D’USO

Particolare attenzione deve essere fatta quando sono utilizzati solventi

organici. Occasionali esposizioni in ambienti pericolosi sono consentiti

per uno strumento portatile, ma per prolungati utilizzi (es. monitoraggio)

è consigliabile contattarci per ulteriori suggerimenti.

Massima attenzione deve essere fatta per proteggere tutti i sensori da

eventuali danneggiamenti sici.

6. MANUTENZIONE

6.1 Pulizia del sensore

Nell’eventualità di inquinamento accidentale, del sensore

devono essere intraprese le seguenti operazioni, assicurando

diversamente la buona riuscita della misura.

Note: Non intervenire sul sensore di umidità (vetro), neanche

con il materiale piu’ sofce.

POLVERE: usare l’aria con delicatezza come ad esempio

quella utilizzata per pulire le lenti di una fotocamera. Se non si

sono ottenuti risultati, utilizzare una minima quantità di acqua

distillata tenendo la sonda capovolta, in modo che scorra

naturalmente sul sensore. Lasciare asciugare in ambiente libero

da polvere, usando un asciugacapelli al minimo, se richiesto.

INQUINAMENTO OLFOSO: usare una quantità minima di

etilene perclorato.

7. CALIBRAZIONE

Questa puo’ unicamente essere effettuata dal nostro laboratorio

approvato.

52

Page 54

8. PRECAUZIONI DI MISURA

Oltre che le ragionevoli attenzioni che devono essere prestate all’uso

del N8004/6 già descritte, ci sono precauzioni che devono essere prese

nella misura dell’umidità, in funzione dello strumento che sarà utilizzato.

CIRCOLAZIONE D’ARIA

Senza circolazione d’aria ci saranno differenze di umidità all’interno

della stanza o camera.

TEMPERATURA

Le differenze di temperatura che esistono in una stanza o camera,

sebbene piccola, avranno un signicativo effetto sull’umidità relativa.

Tipicamente 0.5% UR per una differenza di temperatura di 0.1°C

(0.2°F).

VELOCITA’ DELL’ARIA

La velocità dell’aria è necessaria per assicurare risultati precisi e tempi

di risposta rapidi.

EFFETTI DELLA PRESSIONE ATMOSFERICA

Questi sono spesso trascurati, ma possono essere signicativi. Per

esempio, ad una stessa temperatura, con aria misurata a 1050 mbar si

può raggiungere il 70% UR, nei confronti della stessa aria a 950 mbar

che rileverà 77% UR.

CONDENSA

Ciò può incorrere ad alti valori di UR quando la sonda è sotto il punto

di rugiada ambiente. Sebbene il sensore dell’umidità del N8004/6 si

proteggerà da questo, si suggerisce di evitarlo, se possibile.

53

Page 55

9. DEFINIZIONE DEI TERMINI

UMIDITA’ RELATIVA - E’una misura della quantità del vapore acqueo

nell’aria, come percentuale del massimo vapore acqueo che la stessa

aria potrebbe portare. In termini specici, è la pressione parziale del

vapore acqueo diviso pressione di saturazione del vapore acqueo, a

quella temperatura.

PUNTO DI RUGIADA - E’ la temperatura alla quale la rugiada si

formerebbe se l’aria si raffreddasse. Con il raffreddamento dell’aria, che

così potrebbe portare meno vapore acqueo; il punto al quale la rugiada

si forma è la temperatura di saturazione a quella pressione.

UMIDITA’ ASSOLUTA O SPECIFICA - E’ il peso dell’acqua per peso

all’aria secca ed è solitamente espressa in PPM (parti per milione) che

corrisponde a milligrammi per Kg.

10. SOSTITUZIONE DELLE BATTERIE

Quando il simbolo BAT appare le batterie dovrebbero essere subito

sostituite. Se ciò non avviene lo strumento continuerà a rilevare, ma la

sua calibrazione non può essere garantita.

Per sostituire le batterie : assicurarsi che lo strumento sia spento,

svitare le viti di ssaggio nel retro del coperchio di chiusura dello

strumento utilizzando il cacciavite adatto. Togliere le due batterie e

sostituirle con nuove alcaline a lunga durata. Osservare la corretta

polarità. Prestare attenzione a non serrare eccessivamente le viti e di

non perdere le guarnizioni in gomma.

Notare: batterie al Nicd o Nimh possono essere utilizzate, ma risulterà

ridotto il tempo di lavoro. Non eseguire la ricarica delle batterie nello

strumento.

54

Page 56

ESPAÑOL

COMARK N8004/N8006

MANUAL DE OPERACION

1. INFORMACION GENERAL

Se recomienda que usted lea las instrucciones de seguridad y de

funcionamiento antes de usar este instrumento.

Notas:

N8006 es un instrumento portátilde RH/temperatura utilizando un

sensor integral; N8004 utiliza una punta de prueba separada de RH/

temperatura (N81).

ADVERTENCIA

PARA EVITAR UNA POSIBLE DESCARGA ELECTRICA NO PONER LA

SONDA EN CONTACTO CON CABLES ELECTRICOS CON TENSIONES

SUPERIORES A 30V CA RED RMS O 60V CC.

PARA EVITAR HERIR O QUEMARSE, NUNCA MEDIR LA TEMPERATURA

EN UN HORNO MICROONDAS.

NO COLOQUE IL INSTRUMENTO EN UN LAVAPLATOS PUES NO

ES CAJA FUERTE DEL LAVAPLATOS.

EL SÍMBOLO EN EL INSTRUMENTO INDICA QUE EL OPERADOR

DEBE REFERIR A LAS EXPLICACIÓNES ARRIBA.

ADVERTENCIA

Sondas para la medición de temperatura

Este instrumento de precisión ha sido diseñado para uso con la

gama extensa de sondas de temperatura Comark. El uso de otras

sondas puede perjudicar las prestaciones y exactitud del instrumento.

Se pueden obtener detalles completos de las sondas y sensores

Comark del departamento de Soporte de los Clientes Comark, o de su

distribuidor local.

55

Page 57

Este instrumento ha sido fabricado de acuerdo

con el Sistema de Calidad Aprobada ISO 9001.

Este instrumento cumple con la Directiva

EN61326-1 de Compatibilidad Electro-magnética.

Disponemos de las declaraciones de conformidad. Consultar con el Distribuidor de Comark.

De acuerdo con su política de desarrollo continuo, Comark Instruments

se reserva el derecho de modicar la especicación del instrumento sin

aviso previo. Se puede obtener información adicional de Comark Instru-

ments o de su distribuidor.

56

Page 58

CALIBRACION, CERTIFICACION Y SERVICIO

Certicación

No. 0451

Comark puede facilitar certicados de calibración para toda su gama

de productos, para adaptarse a la ISO 9000 y a otros procedimientos

de aseguramiento de la calidad, reglamentos de higiene alimentaria,

HACCPs y reglamentos medioambientales. Los certicados Comark

son creados por procesos sometidos a un control de calidad

independiente que comparan el rendimiento del producto frente a las

Normas Nacionales establecidas. Para una mayor tranquilidad y como

buena práctica, Comark recomienda una certicación / recalibración

anual.

Son disponsibles dos niveles de certicación para instrumentos que

miden la temperatura de forma infra roja y para los que no, exluyendo

humedad - Certicados UKAS efectuada por un laboratorio externo que

está acreditado para ello y certicados trazados a NPL del laboratorio

Comark.

Existen tres niveles de certicación para los productos de temperatura

por contacto y productos de humedad, son los que se detallan a

continuación:

a) Certicación UKAS

UKAS es el nivel más alto de certicatión reconocido en el

Reino Unido. Los certicados UKAS de Comark peuden

ofrecer una incertidumbre tan baja como de 0.01°C y puden

ofrecer preuba de correcta calibración utilizando instrumentos

y procedimientos auditados por los inspectores de UKAS.

Los instrumentos utilazados está completamente trazable al

Laboratorio de Fisica Nacional.

b) Certicación UKAS en Humedad

El laboratorio de Comark, además de temperatura, ahora

tambien de humedad continúa la tradición de una certicación

con gran precisión y un gran campo de medición (25% a 90%

RH) con incertidumbres del 2.8% de la lectura. Esta certicaión

tambien incluye la medida del punto de rocío.

c) Certicación de Trazabilidad NPL

Los certicados Comark NPL están trazables al Laboratorio

de Física Nacional y puden ofrecer una incertidumbre tan baja

como de 0,3 ºC.

57

Page 59

Conformidad

Pueden suministrarse Certicados de Conformidad para los

instrumentos nuevos, recalibrados y para los que se les ha efectuado

una puesta en servicio. Dichos certicados conrman que los

instrumentos se encuentran dentro de la especicación original que

corresponde a su fabricación.

Servicio / Reparaciones

Bajo el periodo de garantía o con posterioridad, el Departamento

de Servicio Comark llevará a cabo el servicio regular y cualquier

reparación necesaria.Para más información acerca de cualquier

certicación, calibración y servicios por parte de Comark, sírvanse

contactar con nuestro Servicio al Cliente o contacten con su distribuidor

local.

58

Page 60

1. DESCRIPCION

La gama de medidores portátiles de humedad relativa N8000 vienen

diseñados con un gran nivel de exactitud (para ambas mediciones de

temperatura y humedad) y se presentan con un diseño sensacional.

El N8006 tiene un sensor cabezal integrado, mientras que el N8004

tiene el sensor RH y sus asociados electrónicos contenidos en una

sonda portátil (N81) conectada al instrumento por medio de un cable.

Esta sonda también viene equipada con un termistor para una mayor

exactitud en la medición de temperatura ambiente. El N8004 también

es capaz de medir la temperatura independientemente por medio de un

adaptador que le permite el uso de una gran gama de sondas termistor

de Comark.

Ambos instrumentos tienen una gran pantalla de visualización LCD

la cual permite visualizar la temperatura y la humedad de forma

simultánea.

Para estos dos instrumentos hay dos modos de operación:

1. Medida de la Humedad Relativa

2. Cálculo del Punto de Rocío

1.1 ACCESORIOS DISPONIBLES

Cada medidor de humedad relativa se puede suministrar con

una funda protectora de goma para aquellas aplicaciones

donde el instrumento requiera una protección adicional.

Cada funda protectora viene completa con una correa para la

muñeca para una mayor seguridad (CRS/4)

N8004

El N8004 puede medir temperatura independientemente

del N81 por medio del uso de un adaptador (KX7538) que

le permite el uso de cualquiera de las sondas termistor con

Lumberg conector estándard de Comark.

59

Page 61

2 VISION GENERAL DE LOS SIMBOLOS DE

VISUALIZACION

La pantalla de visualización tiene tres zonas. La primera línea muestra la humedad relativa o el punto de rocío. La segunda línea está

dividida en dos zonas; la zona de la izquierda se utiliza para visualizar

la temperatura ambiente, y la zona de la derecha visualiza la escala de

temperatura que se esté usando bien sea °C o °F y el modo de Punto

de Rocío.

A

B

C

F

E

D

FIG. 1

A. Visualización RH/Punto de Rocío.

B. Indica la escala de temperatura que se está utilizando

cuando está en modo de Punto de Rocío. %RH indica que el

instrumento está en modo de humedad relativa.

C. Visualiza la escala de temperatura que se está utilizando

en modo RH o indica modo de Punto de Rocío.

D. Indica que el apagado automático está activado/Mínimo y

bajo de pilas.

E. Indica máximo y modo de parada.

F. Utilizado para indicar la temperatura ambiente.

60

Page 62

3 INSTRUCCIONES DE OPERACION

A continuación le damos una descripción general del modo de

operación para los medidores de humedad relativa. Por favor lea

estas instrucciones detenidamente y si tiene alguna duda póngase en

contacto con su distribuidor local o con el Departamento de Ventas

Internacionales de Comark.

3.1 ENCENDIDO

ON

OFF

Pulse éste botón para encender el aparato.

NOTA: Cuando el instrumento se pone en funcionamiento éste

realizará una autocomprobación que dura un segundo.

Pulse éste botón otra vez para apagar el instrumento .

N8004

Se debe de insertar una sonda antes de que el instrumento

pueda funcionar. Si no se inserta una sonda la pantalla de

visualización mostrará lo siguiente.

N8006

N8006

FIG. 2

Esta indicación es normal cuando existe un circuito abierto, la

sonda está rota o está fuera de especicaciones.

61

Page 63