Coherent PowerMax-USB, PowerMax-RS User manual

User Manual

PowerMax™-USB/RS

Sensor System

User Manual

PowerMax-USB/RS

Sensor System

27650 SW 95th Ave.

Wilsonville, OR 97070

PowerMax-USB/RS User Manual

This document is copyrighted with all rights reserved. Under the copyright

laws, this document may not be copied in whole or in part or reproduced in

any other media without the express written permission of Coherent, Inc.

Permitted copies must carry the same proprietary and copyright notices as

were affixed to the original. This exception does not allow copies to be

made for others, whether or not sold, but all the material purchased may

be sold, given or loaned to another person. Under the law, copying

includes translation into another language.

Coherent and the Coherent Logo are registered trademarks of Coherent,

Inc. PowerMax is a trademark of Coherent, Inc. National Instruments and

LabVIEW are trademarks of National Instruments Corporation.

Every effort has been made to ensure that the data given in this document

is accurate. The information, figures, tables, specifications and schematics

contained herein are subject to change without notice. Coherent makes no

warranty or representation, either expressed or implied with respect to this

document. In no event will Coherent be liable for any direct, indirect,

special, incidental or consequential damages resulting from any defects in

its documentation.

Technical Support

In the U.S.:

Should you experience difficulties with your product, or need technical

information, please visit our website: www.Coherent.com

additional support by either telephoning our Technical Support Hotline at

1.800.343.4912, or e-mailing our Support Team at

support.instruments@Coherent.com. Telephone coverage is available

Monday through Friday (except U.S. holidays).

If you call outside our office hours, your call will be taken by our answering

system and will be returned when the office reopens.

If there are technical difficulties with your product that cannot be resolved

by support mechanisms outlined above, please e-mail or telephone

Coherent Technical Support with a description of the problem and the

corrective steps attempted. When communicating with our Technical

Support Department, via the web or telephone, the model and serial

number of the product will be required by the Support Engineer responding

to your request.

Outside the U.S.:

If you are located outside the U.S., visit our website for technical

assistance, or telephone our local Service Representative. Representative

phone numbers and addresses can be found on the Coherent website,

www.Coherent.com

.

. You can obtain

Coherent provides web and telephone technical assistance as a service to

its customers and assumes no liability thereby for any injury or damage

that may occur contemporaneous with such services. These support

services do not, under any circumstances, affect the terms of any warranty

agreement between Coherent and the buyer. Operating a Coherent

product with any of its interlocks defeated is always at the operator's risk.

ii

Table of Contents

TABLE OF CONTENTS

Preface ................................................................................................................................. vii

RoHS Compliance ............................................................................................................... vii

U.S. Export Control Laws Compliance ............................................................................... vii

Publication Updates .............................................................................................................vii

Symbols Used in This Document ........................................................................................ vii

Safety ...........................................................................................................................................1

Waste Electrical and Electronic Equipment (WEEE, 2002)...................................................1

Declaration of Conformity......................................................................................................2

Description ...............................................................................................................................3

Introduction.............................................................................................................................3

Product Overview ...................................................................................................................3

Product Features ............................................................................................................3

Software Features ..........................................................................................................4

Technical Description .............................................................................................................5

Thermopile Technology .................................................................................................5

Long-Pulse Energy Measurement With a Thermopile .........................................6

Semiconductor Technology ...........................................................................................7

Applying Wavelength Compensation Accuracy.....................................................................9

Operation................................................................................................................................11

LED Status Indicators...........................................................................................................11

PowerMax-USB LED Lights.......................................................................................11

PowerMax-RS LED Lights..........................................................................................12

Powering PowerMax-RS Sensors.........................................................................................12

Extending Cable Length .......................................................................................................12

How to Take a Power Measurement .....................................................................................13

Measuring Power With a PowerMax-USB Thermopile Sensor ..................................13

Measuring Power With a PowerMax-RS Thermopile Sensor .....................................16

Zeroing..................................................................................................................................18

Setting the Wavelength .........................................................................................................18

Using the Software................................................................................................................19

Front Panel...................................................................................................................19

Keyboard Shortcuts.............................................................................................19

Select Sensor.......................................................................................................20

Start/Stop Data Collection ..................................................................................21

Trending Chart....................................................................................................22

Histogram Chart..................................................................................................23

Tuning Chart .......................................................................................................24

Alignment Target Chart ......................................................................................25

Synchronized Trending Chart.............................................................................26

Reset Error ..........................................................................................................28

Graph Palette.......................................................................................................29

iii

PowerMax-USB/RS User Manual

Live Reading.......................................................................................................30

Wavelength .........................................................................................................30

Live Data Averaging ...........................................................................................31

Mean ...................................................................................................................31

Min......................................................................................................................32

Counts .................................................................................................................32

Std Dev................................................................................................................33

Max .....................................................................................................................34

Mode ...................................................................................................................34

Sample Collection...............................................................................................35

Sample Size.........................................................................................................35

Zero Sensor .........................................................................................................36

Reset Button........................................................................................................36

Gain Correction...................................................................................................37

Collection Mode .................................................................................................38

Collection Interval ..............................................................................................38

Log Data to File ..................................................................................................39

Log Data File ......................................................................................................39

Menus...........................................................................................................................40

File Menu............................................................................................................40

Settings Menu .....................................................................................................45

View Menu..........................................................................................................47

Window Menu.....................................................................................................49

Help Menu ..........................................................................................................49

Host Interface.......................................................................................................................51

Introduction...........................................................................................................................51

Message Terminators ............................................................................................................52

Messages Received by the Sensor ...............................................................................52

Messages Sent by the Sensor .......................................................................................52

Host Command Quick Reference .........................................................................................53

SCPI Interface Section..........................................................................................................55

Syntax and Notation Conventions ...............................................................................55

Commands and Queries ...............................................................................................56

SCPI Common Commands.................................................................................56

System Options ...................................................................................................56

Error Record Reporting and Collection ..............................................................58

Measurement Setup and Control.........................................................................60

Querying Measurement Data ..............................................................................62

Sensor Information .............................................................................................63

Legacy LaserPAD/SSIM Interface Section...........................................................................65

Commands and Queries ...............................................................................................65

LaserPAD/SSIM Streaming Data Record Format .......................................................69

Data Streaming Transmission Interface Section ...................................................................70

Streaming Measurement Data......................................................................................70

Commands and Queries ...............................................................................................70

Operational Parameters.........................................................................................................71

iv

Table of Contents

Calibration and Warranty ...........................................................................................73

Calibration ............................................................................................................................73

Coherent Calibration Facilities and Capabilities ..................................................................73

Limited Warranty ..................................................................................................................74

Extended Warranty................................................................................................................74

Warranty Limitations ............................................................................................................75

Obtaining Service .................................................................................................................75

Product Shipping Instructions...............................................................................................76

Appendix A: Specifications..........................................................................................77

Compatible Sensors ..............................................................................................................77

Appendix B: Troubleshooting and Error Messages.....................................79

Index ..........................................................................................................................................81

LIST OF TABLES

1. Wavelength Compensation Accuracy ................................................................................10

2. PowerMax-USB LED Light Conditions............................................................................11

3. PowerMax-RS LED Light Conditions...............................................................................12

4. Keyboard Shortcuts............................................................................................................19

5. Host Command Quick Reference ......................................................................................53

6. Status Condition Character Definitions .............................................................................56

7. Error Codes and Description Strings .................................................................................58

8. Measurement Data Record Formats ..................................................................................62

9. Flags Character Definitions ...............................................................................................63

10. Measurement Data Record Formats ..................................................................................69

11. Data Streaming Transmission Rates ..................................................................................71

12. Operational Parameters......................................................................................................71

13. Coherent Service Centers...................................................................................................76

14. Compatible Sensors ...........................................................................................................77

LIST OF FIGURES

1. Waste Electrical and Electronic Equipment Label...............................................................1

2. Saturation Power and Minimum Power for PowerMax-USB UV/VIS Quantum Sensor ...8

3. Photo Sensitivity Temperature Characteristics ....................................................................9

4. RV Spectral Correction for Thermal Sensors (Normalized to Calibration Wavelength)...10

5. Front Panel.........................................................................................................................19

6. Drop-Down Menus ............................................................................................................40

7. File Menu...........................................................................................................................40

8. Settings Menu ....................................................................................................................45

9. View Menu.........................................................................................................................47

10. Window Menu....................................................................................................................49

11. Help Menu .........................................................................................................................49

v

PowerMax-USB/RS User Manual

vi

Preface

Preface

RoHS Compliance

U.S. Export Control Laws Compliance

This manual contains user information for the Coherent

PowerMax™ meterless power sensors and the PowerMax PC software.

This Coherent product is RoHS compliant.

It is the policy of Coherent to comply strictly with U.S. export

control laws.

Export and re-export of lasers manufactured by Coherent are subject

to U.S. Export Administration Regulations, which are administered

by the Commerce Department. In addition, shipments of certain

components are regulated by the State Department under the International Traffic in Arms Regulations.

The applicable restrictions vary depending on the specific product

involved and its destination. In some cases, U.S. law requires that

U.S. Government approval be obtained prior to resale, export or

re-export of certain articles. When there is uncertainty about the

obligations imposed by U.S. law, clarification should be obtained

from Coherent or an appropriate U.S. Government agency.

Publication Updates

Symbols Used in This Document

To view information that may have been added or changed since this

publication went to print, connect to www.Coherent.com.

This symbol is intended to alert the operator to the presence of

dangerous voltages associated with the product that may be of

sufficient magnitude to constitute a risk of electrical shock.

This symbol is intended to alert the operator to the presence of

important operating and maintenance instructions.

vii

PowerMax-USB/RS User Manual

viii

Safety

SAFETY

Carefully review the following safety information to avoid personal

injury and to prevent damage to this product or any equipment

connected to it. There are no user-serviceable parts in Coherent

PowerMax meterless power sensors. For service information, refer

to “Obtaining Service” on page 75.

Do not operate the system if its panels are removed or any of the

interior circuitry is exposed.

Waste Electrical and Electronic Equipment (WEEE, 2002)

Do not operate the system in wet or damp conditions, or in an

explosive atmosphere.

Do not operate the system if there are suspected failures. Refer

damaged units to qualified Coherent service personnel.

The European Waste Electrical and Electronic Equipment (WEEE)

Directive (2002/96/EC) is represented by a crossed-out garbage

container label (Figure 1). The purpose of this directive is to minimize the disposal of WEEE as unsorted municipal waste and to facilitate its separate collection.

Figure 1. Waste Electrical and Electronic Equipment Label

1

PowerMax-USB/RS User Manual

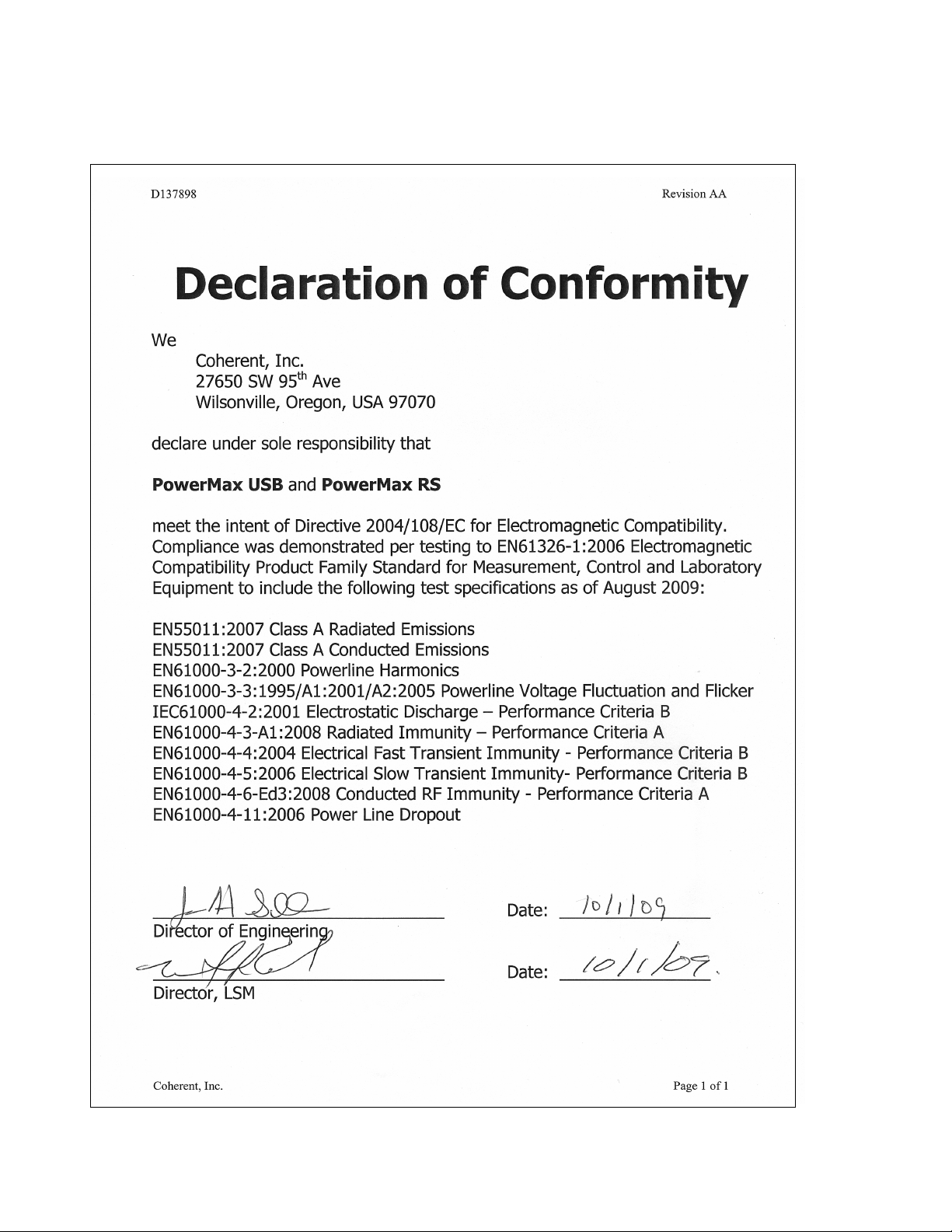

Declaration of Conformity

2

DESCRIPTION

Description

Introduction

Coherent PowerMax-USB and PowerMax-RS sensors are the

world’s first laser power sensors that utilizes state of the art microelectronics miniaturization techniques and integrate an entire instrument within a USB 2.0 or RS-232 cable connector. Specifically,

PowerMax-USB and PowerMax-RS sensors have all the signal

processing and power measurement electronics normally contained

in a LabMax meter and connect directly to a PC with plug-and-play

functionality. Ideally suited for low- and high-volume embedded

sensor applications, Coherent’s new family of sensors eliminates the

need for a separate meter box, thus delivering a significant savings

in cost and space, but with no reduction whatsoever in performance.

This measurement platform can also be used to measure the energy

in a long laser pulse—typically greater than 1 millisecond in pulse

width—by integrating the output of a thermopile sensor.

Coherent’s PowerMax PC application software provides a virtual

instrument interface for sensors that enable the operator to take laser

power readings, log data, and compute measurement statistics.

Users can also write their own software using host interface

commands that control all aspects of power meter operation.

For the first time, separate electronics are no longer required

between the sensor and a PC. For those customers who can use a PC

for monitoring laser power, these sensors offer significant cost

savings, space savings, and no reduction in performance.

Product Overview

Product Features

PowerMax-USB provides direct USB 2.0 connection to a PC.

•

Power is provided via USB connection.

• PowerMax-RS provides RS-232 connectivity. Power input is

provided by a +5VDC input (power supply is available as an

optional accessory).

• Instrumentation platform is compatible with thermopile and

optical sensors and can be adapted to most power sensors that

Coherent manufactures.

3

PowerMax-USB/RS User Manual

• Displays beam position with position-sensing quadrant ther-

• High resolution 24-bit A/D converter supports four digits of

• Sensors include spectral compensation for accurate use at

• Thermopile sensors include a speed-up algorithm that speeds

• LED status indicators inside USB and RS-232 connectors

• Thermopile sensors offer long-pulse joules capability.

mopiles (such as LM-model sensors like the LM-10).

resolution and measurement accuracy equivalent to that found

in Coherent's LabMax meters.

wavelengths that differ from the calibration wavelength. Each

sensor receives a unique spectral compensation curve specific

to the responsivity of its specific element, as well as transmission characterization of any associated optics.

up the natural response of the thermopile detector without

overshoot.

provide health-and-status information.

Software Features

Plug-and-play application software is supplied standard and

includes the following features:

• Trending

• Statistics (mean, minimum, maximum, and standard devia-

tion) and log batch to file.

• Tuning

• Display beam position on position-sensing thermopiles and

log results to file

• Histogram

• Simultaneously operate multiple sensors

4

Description

• Perform synchronized ratiometery (A/B analysis). Trend and

log results to file.

• For LaserPAD or SSIM customers, the host command set

includes drop-in compatibility.

For system integrators and for implementations involving

customer-written software, the sensors incorporate a comprehensive

command set that is easy to access:

• Utilized a Window USB driver and supports simple ASCII

host commands for remote interfacing using both

PowerMax-USB and PowerMax-RS sensors.

• Using customer-written software, the remote interfacing host

command set allows sensors to be remotely controlled.

• National Instruments

LabVIEW integration.

™

LabVIEW™ driver is supplied for easy

Technical Description

Thermopile Technology

Thermopile sensors are a great all-purpose technology suitable for

many lasers. They are used for measuring CW laser power, average

power in pulsed lasers, and are often used to integrate the energy of

long pulses. Thermopile sensors absorb incident laser radiation and

convert it into heat. This heat ultimately flows to a heat sink that is

held at ambient temperature by either convection-cooling or

water-cooling. The temperature difference between the absorber and

the heat sink is converted into an electrical signal by a thermocouple

junction.

Thermopiles operate across a wide range of input powers, and unlike

a photodiode-based sensor they will not saturate. The spectral range

is dependent upon the coating applied to absorb the laser power. The

coating used on many thermopiles is broadband in nature and is relatively flat from the ultraviolet through the infrared.

These sensors have natural response times on the order of several

seconds for a low power sensor and up to one minute for a kilowatt

sensor. The exponential nature of the natural thermopile output

allows one to electronically accelerate the voltage to its final value

ahead of the actual sensor signal using a software algorithm. We

typically call this capability a “speed-up” algorithm. When

combined with the PowerMax-USB and PowerMax-RS circuitry, a

5

PowerMax-USB/RS User Manual

speed-up algorithm can be applied to provide a much faster

response—on the order of seconds or less for most thermopile

sensors. This feature can be turned on and off in the software.

Coherent has two main types of thermopile sensors:

• The LM Model line utilizes a unique thermopile disk in which

• The PM Model line incorporates traditional thermopile disks

PowerMax-USB and PowerMax-RS sensors can use both types of

sensors.

Long-Pulse Energy Measurement With a Thermopile

the thermocouples are split into four quadrants, allowing the

sensors to provide beam position information in addition to

power measurement.

that provide power measurement without beam position information.

Thermopile sensors are most commonly used for average power

measurements on pulsed and CW lasers. A unique capability of thermopile sensors is the ability to integrate the power of a single “long”

laser pulse (long pulse refers to pulses roughly 1 millisecond up to

several seconds in pulse length). The instrumentation analyzes the

output of the thermopile and applies the integration through the use

of an algorithm that results in a Joules reading. This allows the thermopile to measure the energy of single pulses between 1 millisecond

and 10 seconds in length, and with energies from millijoules to

6

Description

hundreds of Joules. The measurement accuracy of this mode is typically better than ± 3% when performed with PowerMax-USB and

PowerMax-RS sensors.

This capability is very useful for what are commonly called

long-pulse medical or industrial type lasers. Common applications

for this type of measurement are in the medical field—especially

skin resurfacing and hair removal—and in material processing

applications, such as laser welding. These laser systems often utilize

high-energy lasers that have large beam sizes and relatively long

pulses.

This type of measurement requires careful selection of the appropriate power sensor, based upon the laser pulse being measured. A

good “rule of thumb” for using a thermopile for this type of

measurement is to compare the maximum pulse energy you need to

measure (in Joules) with the maximum power rating of a sensor (in

Watt s).

Often times a sensor like the PM150-50C is ideal for these measurements. It features a large 50 mm aperture size, can handle pulse energies up to 150J, and can be used air-cooled for single pulse energy

measurements. A PM150-50C normally needs to be water-cooled

for continuous power measurements. The PS19Q sensors, on the

other hand, allow long-pulse measurements down into the mJ level.

Semiconductor Technology

Thermopile joules mode specifications for several PowerMax-USB

and PowerMax-RS sensor can be found in Table 14 on page 77. For

an up-to-date list of all compatible sensors and their specifications,

visit out website: www.Coherent.com/LMC.

Semiconductor photodiode-based sensors convert incident photons

into current that can be measured by our instrumentation. We typically refer to these devices as optical sensors or quantum sensors.

The photodiodes used in these types of sensors offer high sensitivity

and low noise, enabling them to detect very low light levels. The

UV/VIS optical sensor in the PowerMax-USB line is designed to

measure power of CW sources, as well as the average power of

pulsed sources, as long as the repetition rate is above 100 pps. Photodiodes also have a fast response time, making this senor convenient

for tuning and peaking lasers.

These types of sensors have several orders of magnitude higher

sensitivity than thermopile sensors and are quite stable. They do,

however, suffer from photocurrent saturation. The UV/VIS sensor

incorporated into the PowerMax-USB product line includes an

attenuating filter that allows the sensor to be used into the hundreds

7

PowerMax-USB/RS User Manual

of milliwatt level without saturation. This ND filter, and the light

shield threaded onto the front of the sensor, also help to block stray

light, thereby resulting in a lower noise floor.

We incorporate spectral compensation in the PowerMax-USB and

PowerMax-RS UV/VIS sensor to provide accurate measurements

across the 325 to 1065 nm spectrum. Because the spectral response

of the ND filter and photodiode varies significantly across this

wavelength range, it is important to check the maximum measurable

power at the wavelength of use to make sure the sensor is not being

saturated. Figure 2, below, indicates the maximum and minimum

measurable power levels by wavelength.

The following curve plots the maximum measurable power—which

is the saturation level of the photodiode—as well as the minimum

recommended power level, by wavelength.

Figure 2. Saturation Power and Minimum Power for PowerMax-USB UV/VIS Quantum Sensor

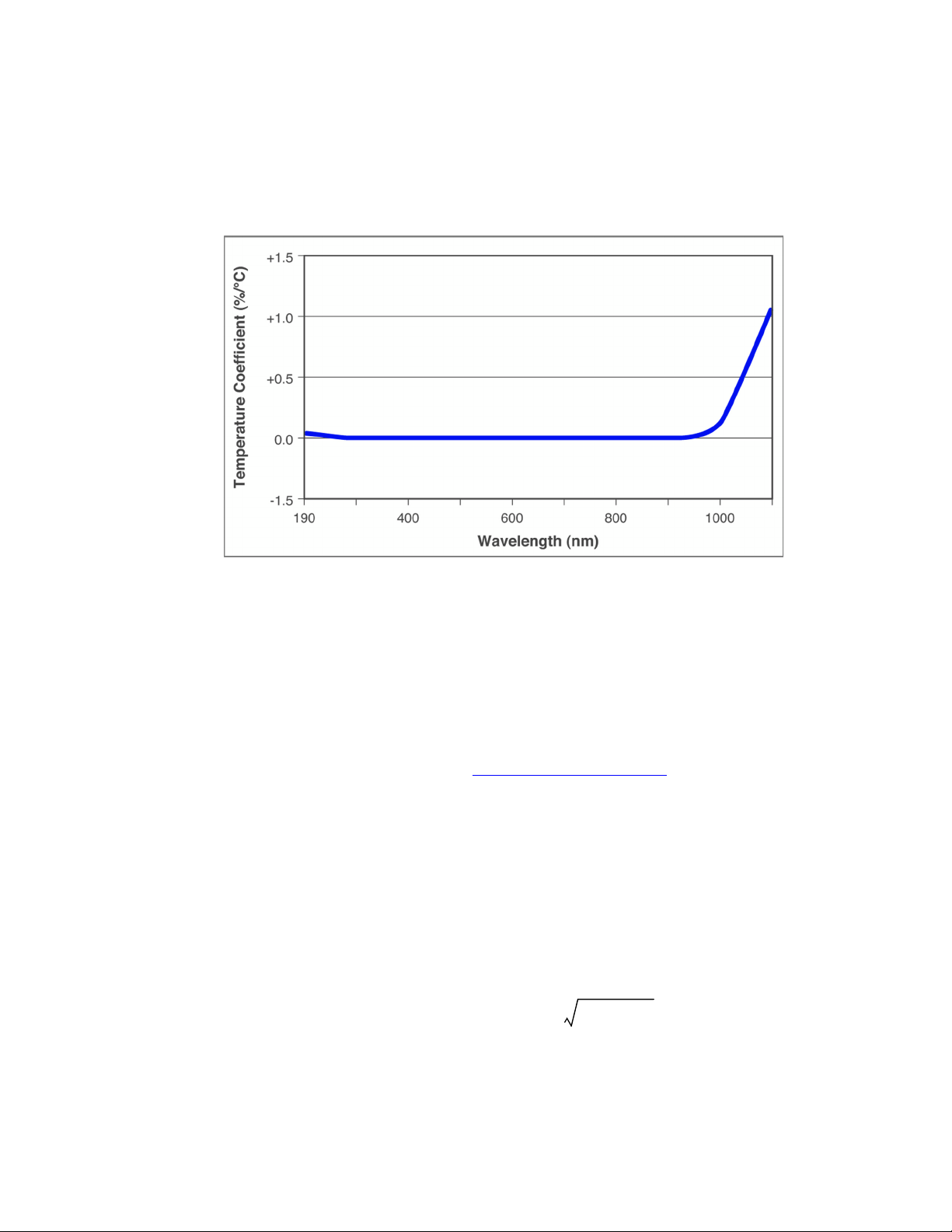

UV/VIS Temperature Linearity: Like all silicon photodiodes, the

UV/VIS Quantum sensor has temperature sensitivity in the infrared

region. At 1064 nm, for example, it has a 0.5%/ºC thermal coefficient. Due to the electronics inside the sensor, measurement error of

up to 2% is present at 1064 nm after a 10-minute warm-up time.

Additional error can be present if the ambient measurement environment differs from the calibration wavelength listed on the calibration

certificate.

8

Description

In practice, wavelengths shorter than 1000 nm have insignificant

effects due to temperature.

The following figure references the thermal coefficient at the wavelength of use.

Figure 3. Photo Sensitivity Temperature Characteristics

Applying Wavelength Compensation Accuracy

Overall measurement accuracy is a combination of:

• Calibration uncertainty. Note: Specifications for several

sensors are available in Table 14 on page 77. For an up-to-date

list of all compatible sensors and their specifications, visit out

website: www.Coherent.com/LMC.

• Wavelength compensation accuracy (refer to Table 1 on

page 10).

The combined accuracy is based upon practices outlined in the

National Institute of Standards Guidelines for Evaluating and

Expressing Uncertainty (NIST Technical Note 1297, 1994 Edition).

The combined accuracy of the measurement is calculated by using

the law of propagation of uncertainty using the

“root-sum-of-square” (square root of the sum of squares), sometimes described as “summing in quadrature” where:

Measurement Accuracy =

U

2

2

W

+

where:

U = Percent Calibration Uncertainty

W = Wavelength Accuracy

9

PowerMax-USB/RS User Manual

Example:

PowerMax-USB LM-10 used at 1064 nm

U = 2%

W = 1.5%

Measurement Accuracy = %

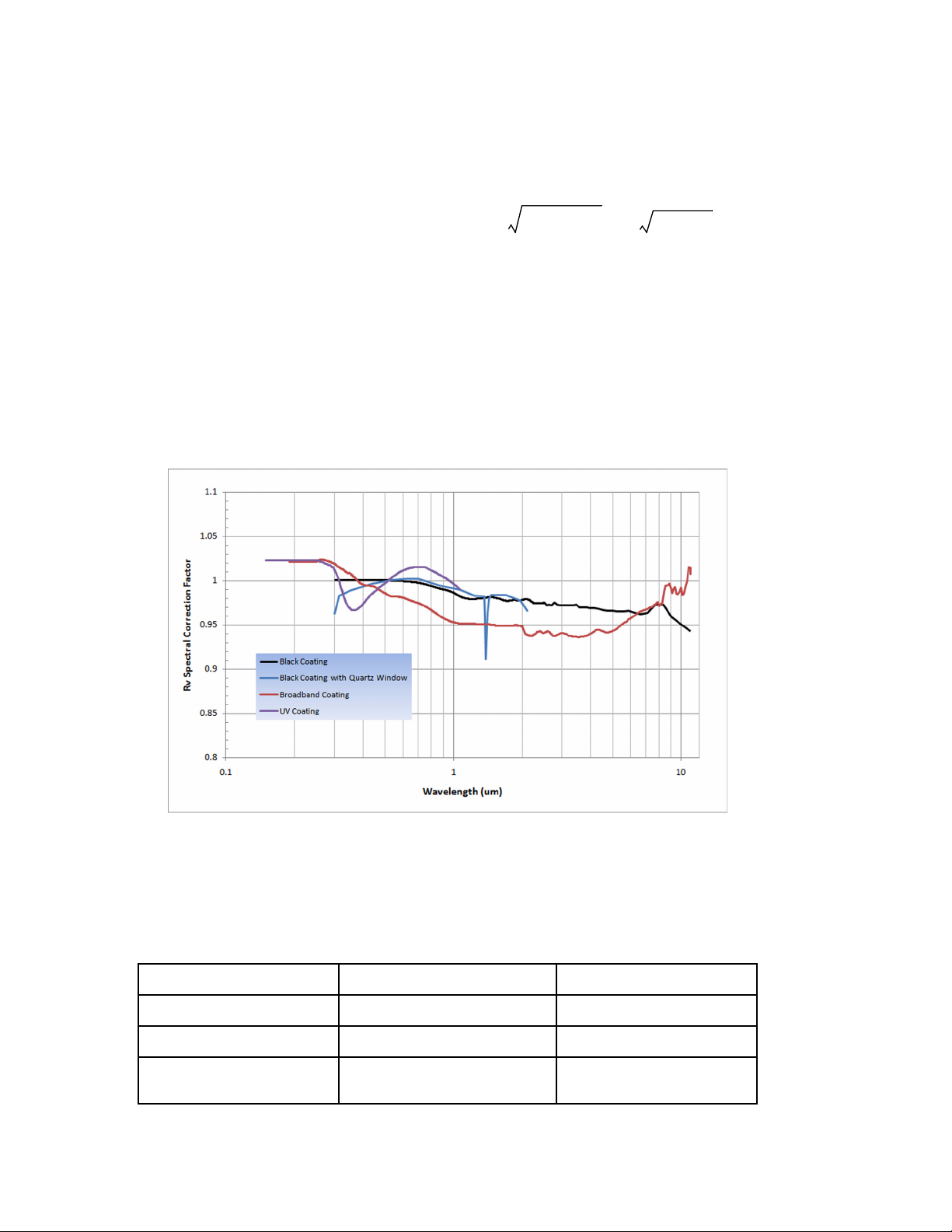

Coherent uses three primary coatings to capture the incident radiation on our thermal sensors. The specifications for each sensor list

which coating is used. Typical wavelength ranges and response

curves for these coatings are shown in Figure 4, below. Each sensor

contains a spectral curve generated from reflectance measurements

taken with spectrometers. The reflectance data are converted into a

wavelength compensation look-up table that is loaded into the

sensor. This data is accessed by selecting a wavelength of operation

in the software.

2

2

2

1.5

+ 42.3+ 2.5==

Figure 4.

All PM- and LM-model thermopiles ± 1.5% 10600

PS model ± 1.5% 514

UV/VIS optical model ± 4% (325 to 900 nm)

a. Refers to wavelengths other than the calibration wavelength.

RV Spectral Correction for Thermal Sensors (Normalized to Calibration Wavelength)

Table 1 lists the spectral compensation accuracy for each type of

sensor.

Table 1. Wavelength Compensation Accuracy

SENSOR

Wavelength Compensation Accuracy

± 5% (900 to 1065 nm)

10

a

CALIBRATION WAVELENGTH (nm)

514

OPERATION

In this section:

• LED status indicators (this page)

• Powering PowerMax-RS sensors (page 12)

• Extending cable length (page 12)

• How to take a power measurement (page 13)

• Zeroing (page 18)

• Setting the wavelength (page 18)

• Using the software (page 19)

Operation

LED Status Indicators

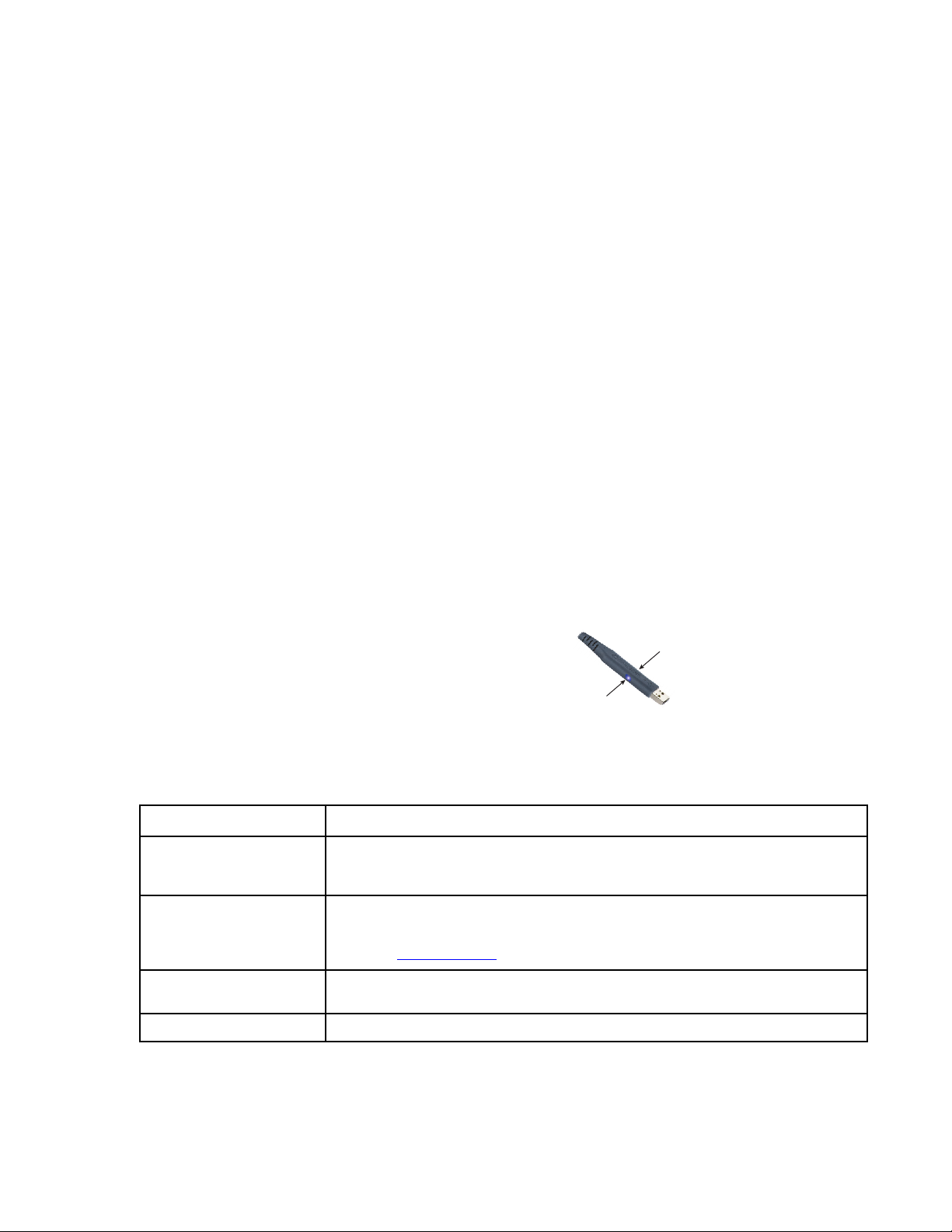

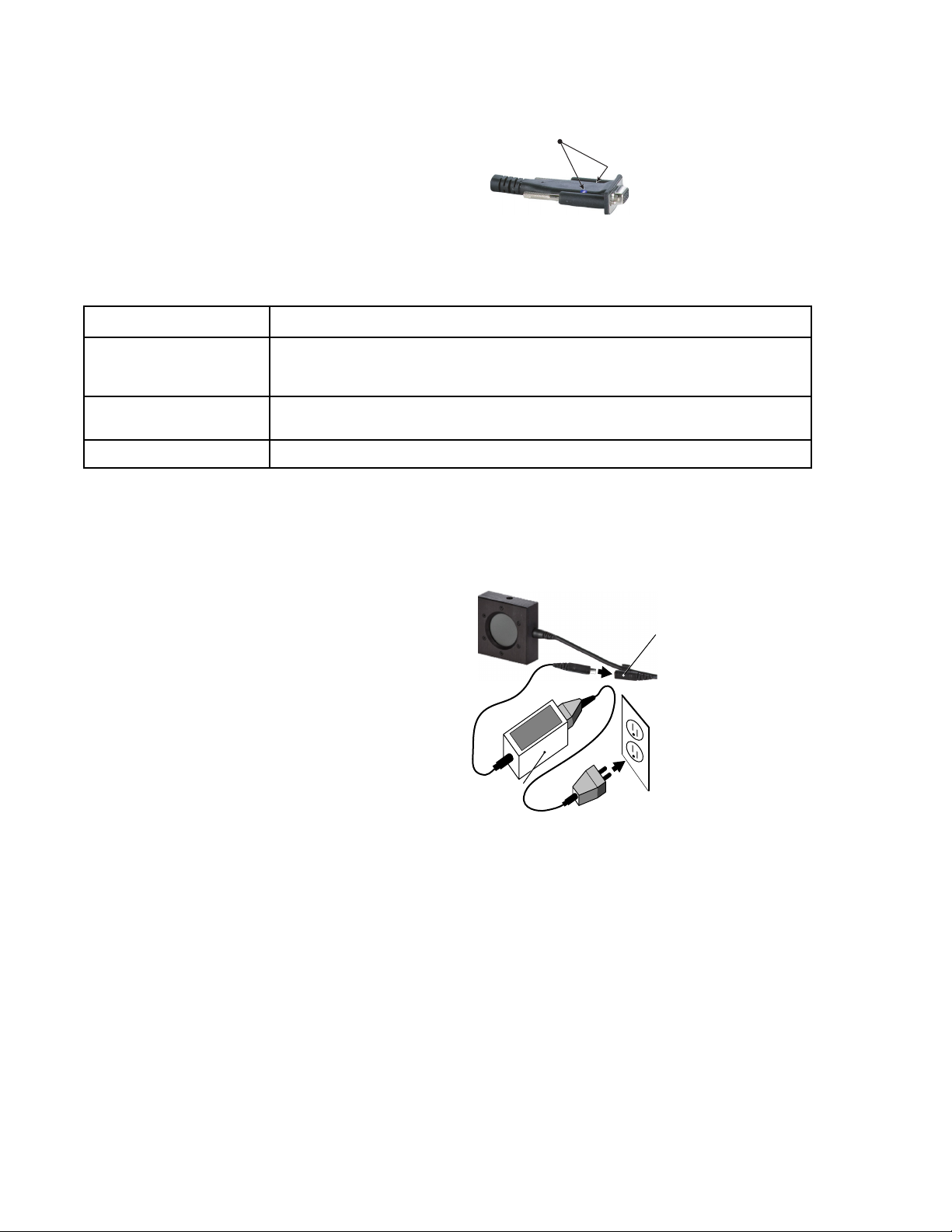

Blue LED lights are contained within the PowerMax-USB and

PowerMax-RS connectors to provide health-and-status information.

PowerMax-USB LED Lights

Blue LED

Table 2. PowerMax-USB LED Light Conditions

LED LIGHT CONDITION STATUS

No light visible If the PowerMax-USB sensor is connected to the PC but there are no visible lights, the sensor is not

powering up properly. Test the sensor on another USB port and if that does not solve the problem, contact

Coherent for service (refer to Table 13 on page 76 for contact information).

Lights flashing slowly (0.5 Hz) Sensor is functioning; however, the driver has not been properly loaded. First, make sure power is being

properly applied to the USB port. If that does not solve the problem, remove the sensor from the USB port

and reinstall the software from the CD that shipped with the product (or download the latest software from

our website: www.Coherent.com

).

Blue LED

Lights slowing ramping up and

down in intensity

Lights flashing fast (10 Hz) The sensor is taking power measurements and sending data over the host port.

Sensor is functioning and the driver has been properly loaded.

11

PowerMax-USB/RS User Manual

PowerMax-RS LED Lights

Table 3. PowerMax-RS LED Light Conditions

LED LIGHT CONDITION STATUS

No light visible If + 5VDC has been applied to the PowerMax-USB sensor but there are no visible lights in the connector,

the sensor is not powering up properly. Contact Coherent for service (refer to Table 13 on page 76 for

contact information).

Blue LEDs

Lights slowing ramping up and

down in intensity

Lights flashing fast (10 Hz) The sensor is taking power measurements and sending data over the host port.

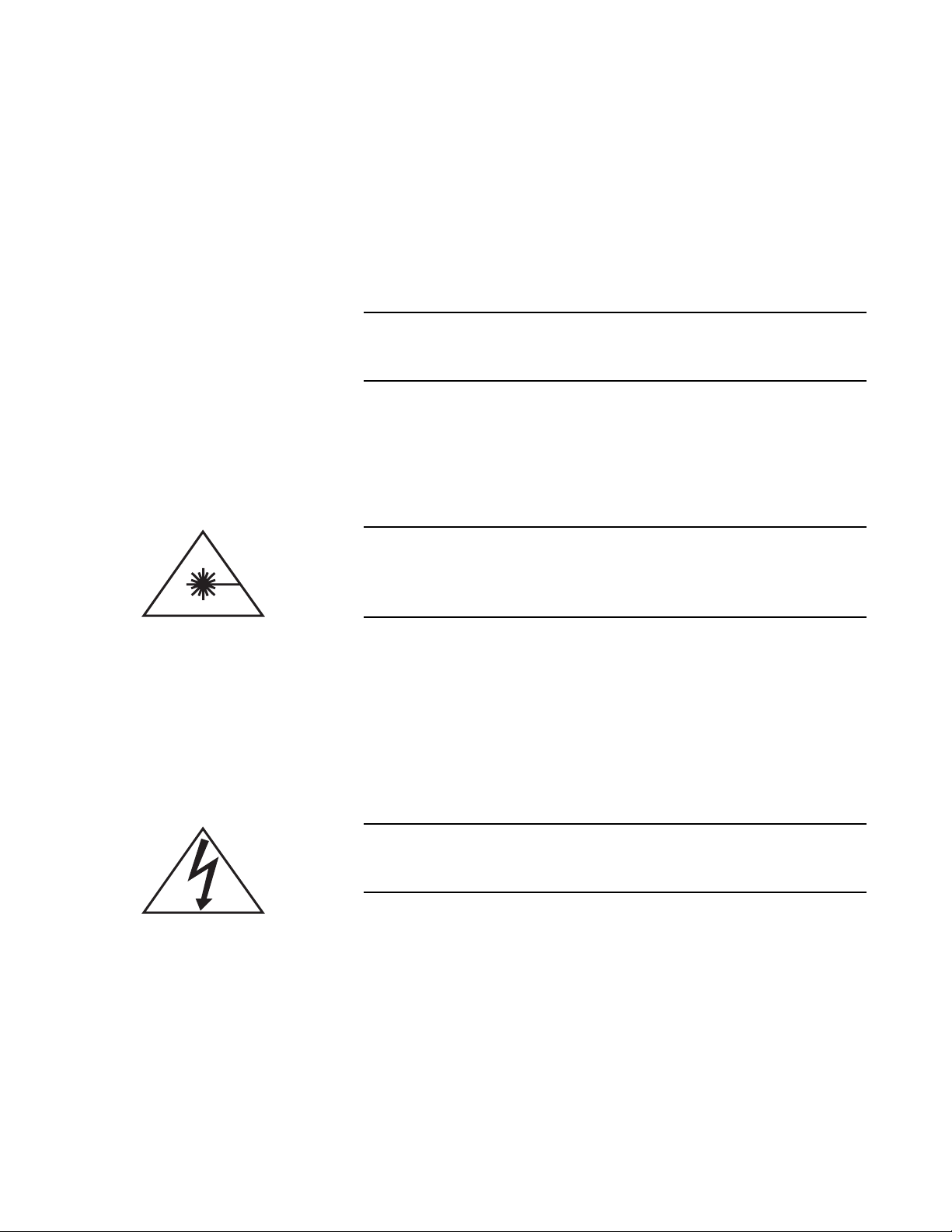

Powering

PowerMax-RS

Power has been applied to the sensor and it is functioning.

The PowerMax-RS sensor is powered via a +5 VDC power supply

input.

Sensors

Sensor power cable

Power supply

Extending Cable Length

USB sensors: The PowerMax-USB cable is 2.5 meters in length.

USB hubs can be employed to extend the length of the cable. The

USB standard allows for up to five hubs—connected in series with

5-meter cables connecting the hubs—thus providing a maximum

range of 27.5 meters.

There are also active 5-meter USB extension cables on the market

that perform as if they were a USB hub, but for just a single USB

sensor. (Feel free to contact Coherent for advice related to particular

hubs we have tested in-house.)

12

Operation

RS sensors: The RS cable is 300 mm in length. It is intended to be

used with a standard off-the-shelf RS-232 extension cable to extend

the length.

How to Take a Power Measurement

This section presents two “mini-tutorials” that explain how to

connect a PowerMax-USB or PowerMax-RS sensor to your PC and

begin taking measurements using the PowerMax PC software.

For instructions on communicating with the sensor directly via

host commands, refer to “Host Interface” on page 51.

Tutorials include:

• Measuring power with a PowerMax-USB thermopile sensor.

• Measuring power with a PowerMax-RS thermopile sensor.

Follow all laser safety procedures. The laser must be switched

OFF or shuttered before running the tutorials presented in this

section.

Measuring Power With a PowerMax-USB Thermopile Sensor

This tutorial describes how to take a power measurement using a

PowerMax-USB thermopile sensor.

Verify the laser is switched OFF or shuttered before starting this

tutorial.

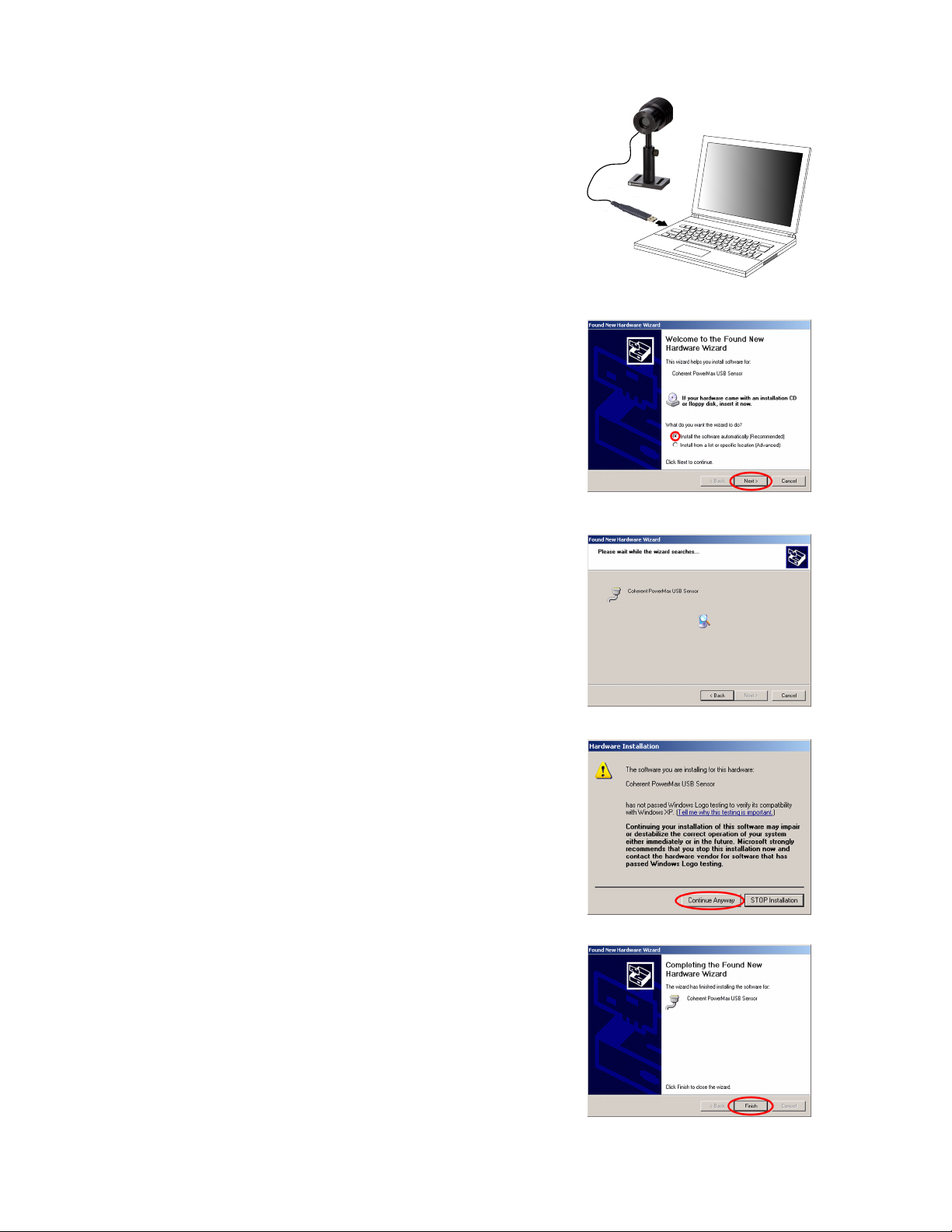

1. Install the PowerMax PC software (for detailed installation

instructions, refer to the PowerMax-USB/RS Software Instal-

lation and Quick Start Guide—part number 1169931—that

shipped with your system).

13

PowerMax-USB/RS User Manual

2. Plug in the PowerMax-USB

3. When the Found New

sensor.

Hardware Wizard screen

appears, click “Install the

software automatically

(Recommended)” and

then click the Next button

to continue.

This screen display while the

installation program searches for

the PowerMax-USB sensor.

4. Click the Continue Anyway

button to proceed with the

installation.

5. Click Finish to complete the

installation.

14

Operation

6. Confirm the blue LEDs on the USB

Blue LED

connector are lit and slowly ramping up

and down in intensity (which signifies

the sensor is working and the driver is

Blue LED

properly loaded).

7. Run the PowerMax PC software.

8. Select the sensor serial

number from the Select Sensor

dropdown menu. In the

example at right, the selected

sensor serial number is

0347E09.

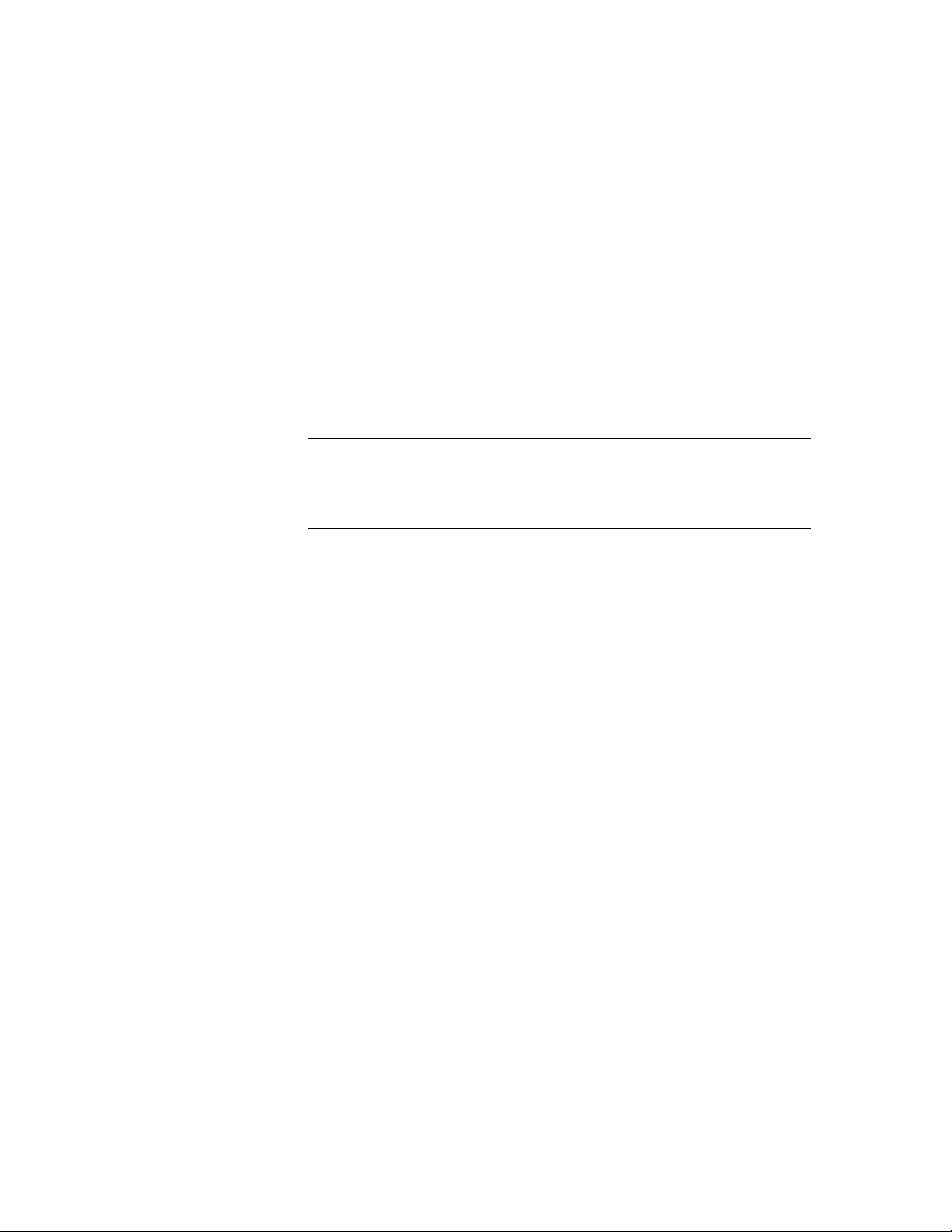

9. Press the Zero Sensor button to zero out any offset in the

sensor.

10. Press the Start Data Collec-

tion button and then turn ON

the laser to begin taking

power measurements.

15

PowerMax-USB/RS User Manual

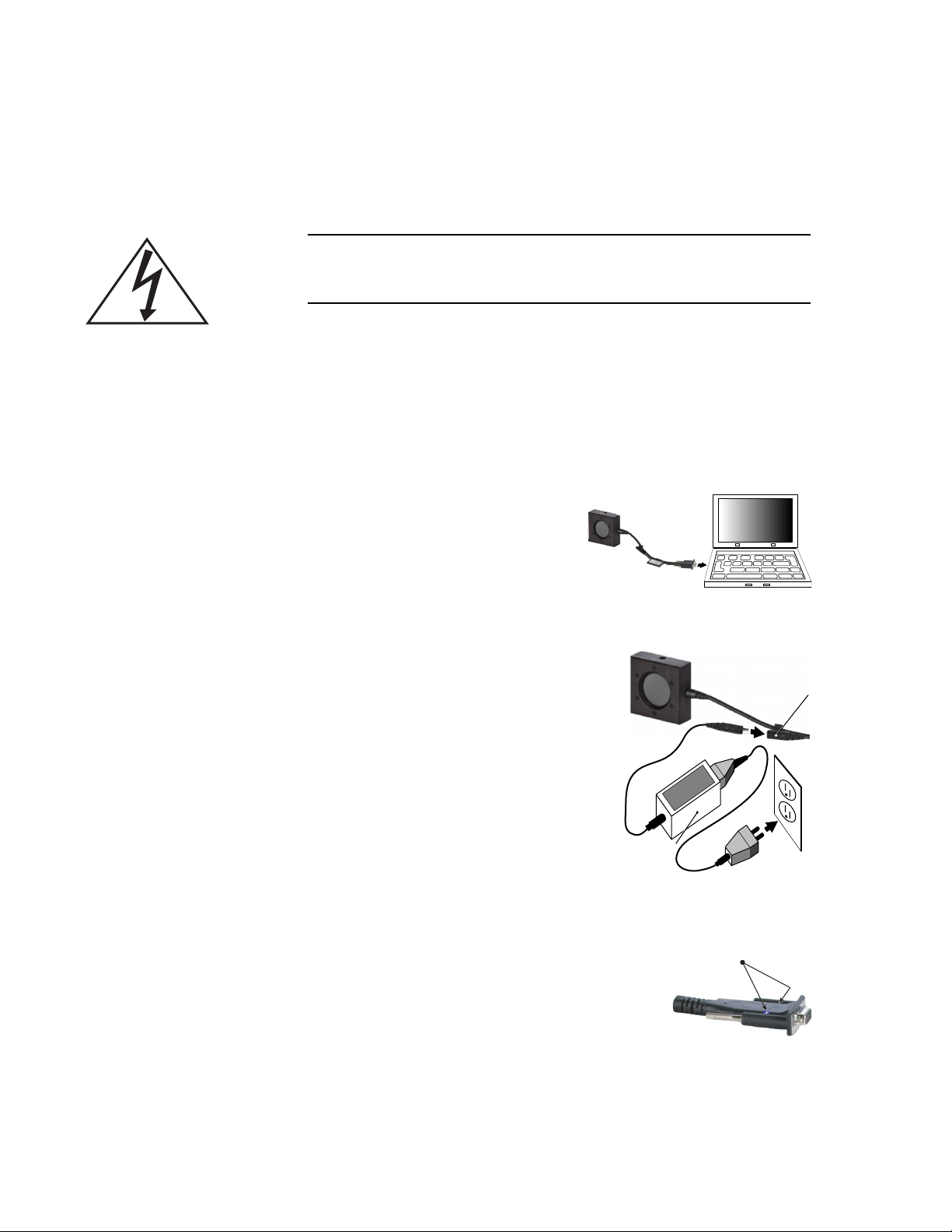

Measuring Power With a PowerMax-RS Thermopile Sensor

This tutorial explains how to take a power measurement using a

PowerMax-RS thermopile sensor.

Verify the laser is switched OFF or shuttered before starting this

tutorial.

1. Install the PowerMax PC software (for detailed installation

instructions, refer to the “Software Installation” section of the

PowerMax-USB/RS Software Installation and Quick Start

Guide—part number 1169931—that shipped with your

system).

2. Plug the PowerMax-RS

sensor into an available

RS-232 COM port on the

computer.

3. Plug the +5V DC power supply

cable into the sensor power cable

and the power supply into a wall

electrical outlet. (The power

supply is available from Coherent

as an optional accessory—part

number 1105557.)

Power supply

4. Confirm the blue LEDs on the RS

connector are lit and slowly ramping up

and down in intensity (which signifies the

sensor is working and the driver is properly loaded).

5. Run the PowerMax PC software.

Sensor power cable

Blue LEDs

16

Operation

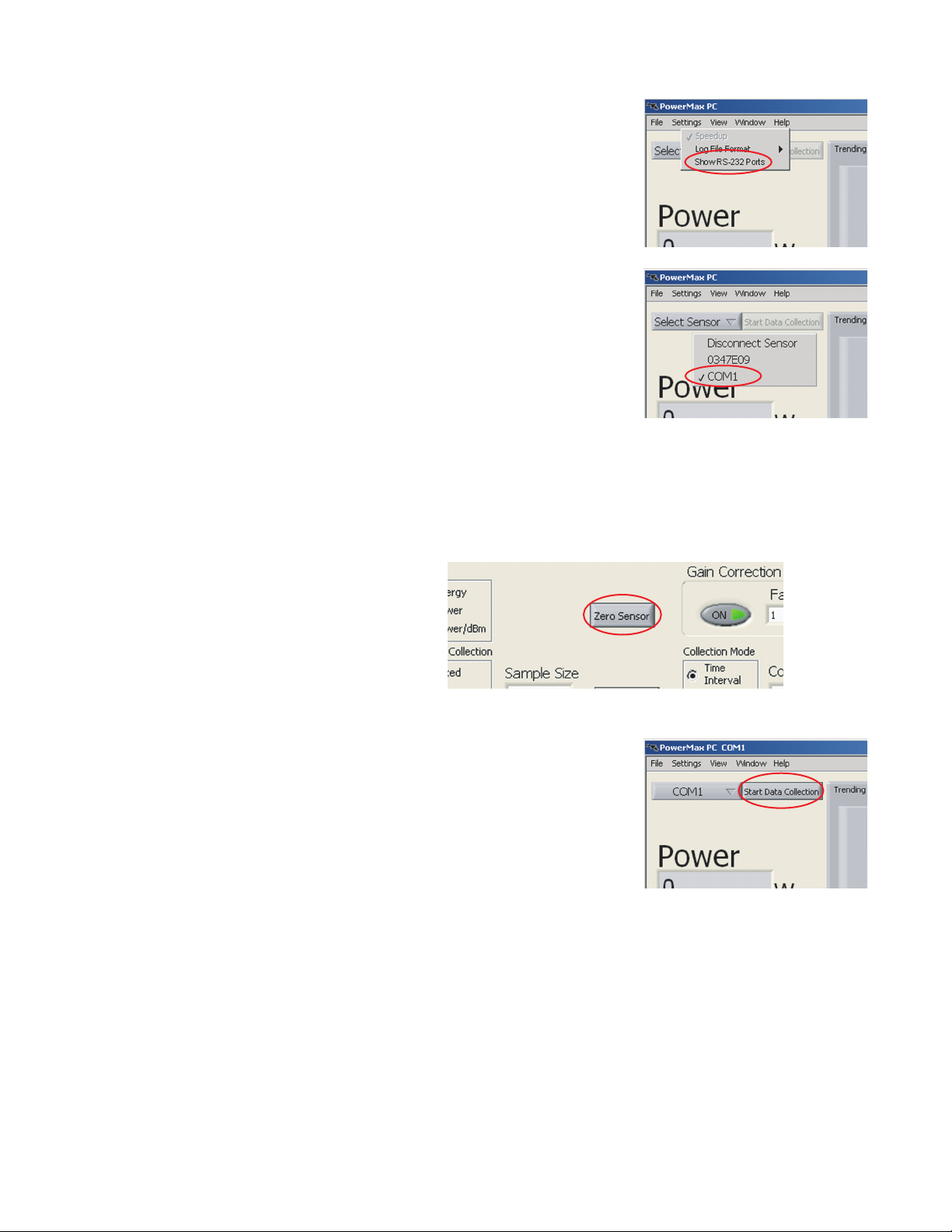

6. Click Show RS-232 Ports

from the Settings dropdown

menu. The software will scan

COM ports for PowerMax-RS

sensors.

7. Select the COM port to which

the PowerMax-RS sensor is

attached. In the example at

right, the selected COM port is

COM1.

8. Insert the sensor into the beam path, making sure the laser is

turned OFF or shuttered until the sensor is zeroed.

9. Press the Zero Sensor button to zero out any offset in the

sensor.

10. Press the Start Data

Collection button and then

turn ON the laser to begin

taking power measurements.

17

PowerMax-USB/RS User Manual

Zeroing

Pressing the Zero button implements the Zero function and sets the

current sensor input as the baseline for future measurements. It is

recommended that you zero the sensor after first turning it on and

before beginning any new set of power measurements.

When a zero procedure is in process, no other button events are

queued or activated until the procedure ends. The zero procedure

immediately terminates if the sensor is disconnected or if an error is

encountered.

Normally you should press the Zero button while the laser is turned

off, or while the laser beam is blocked. If a finite power level is

present at the sensor, the instrumentation will attempt to null it out.

The sensor can only zero a finite level of offset equivalent to approximately 10% of full scale range.

If zeroing is unsuccessful—which means that the power input is

too large to null—re-zero in a more stable environment or select

a different range.

Setting the Wavelength

The wavelength should always be set for accurate power measurements. This can be done either in the PowerMax PC application software or over the host port via a host command.

18

Using the Software

Operation

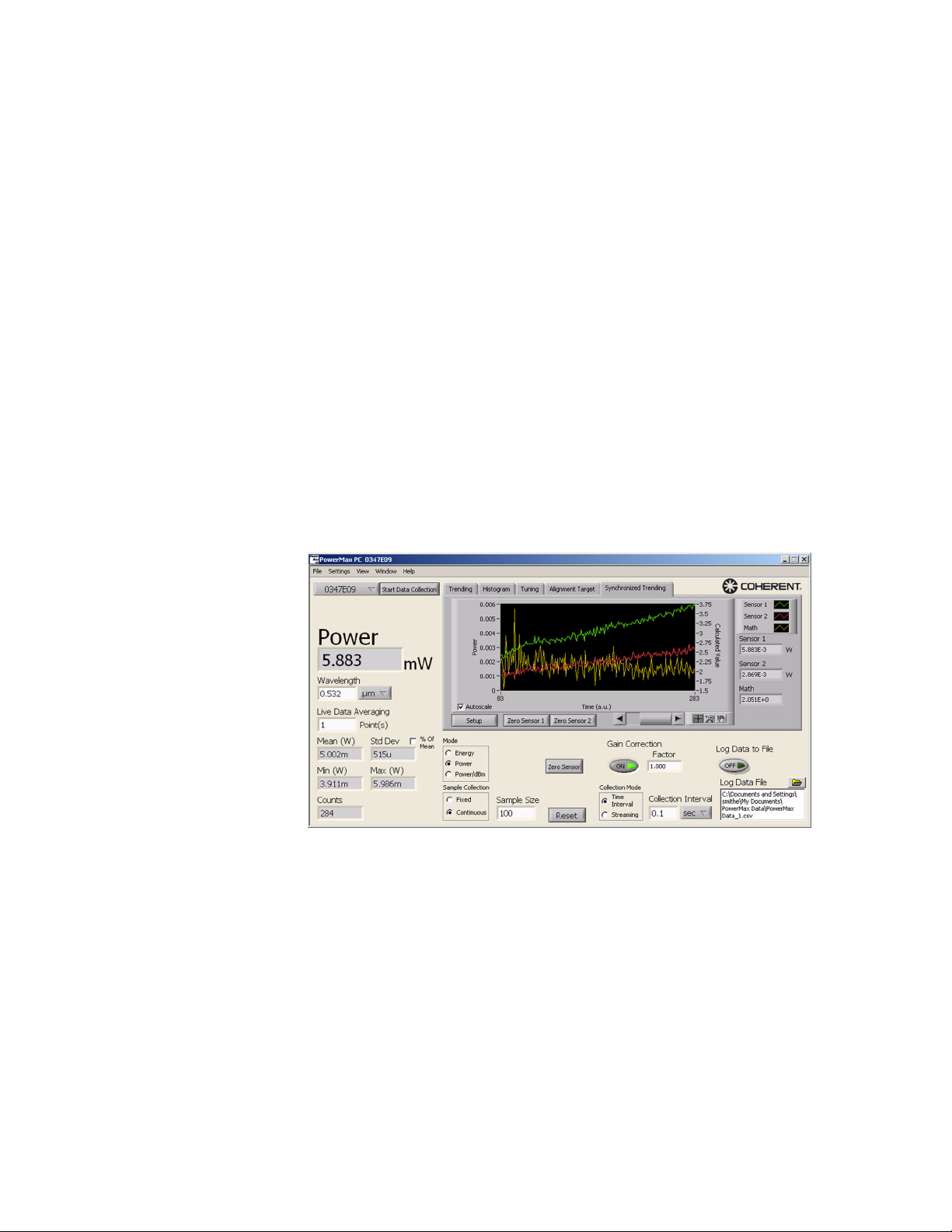

Front Panel

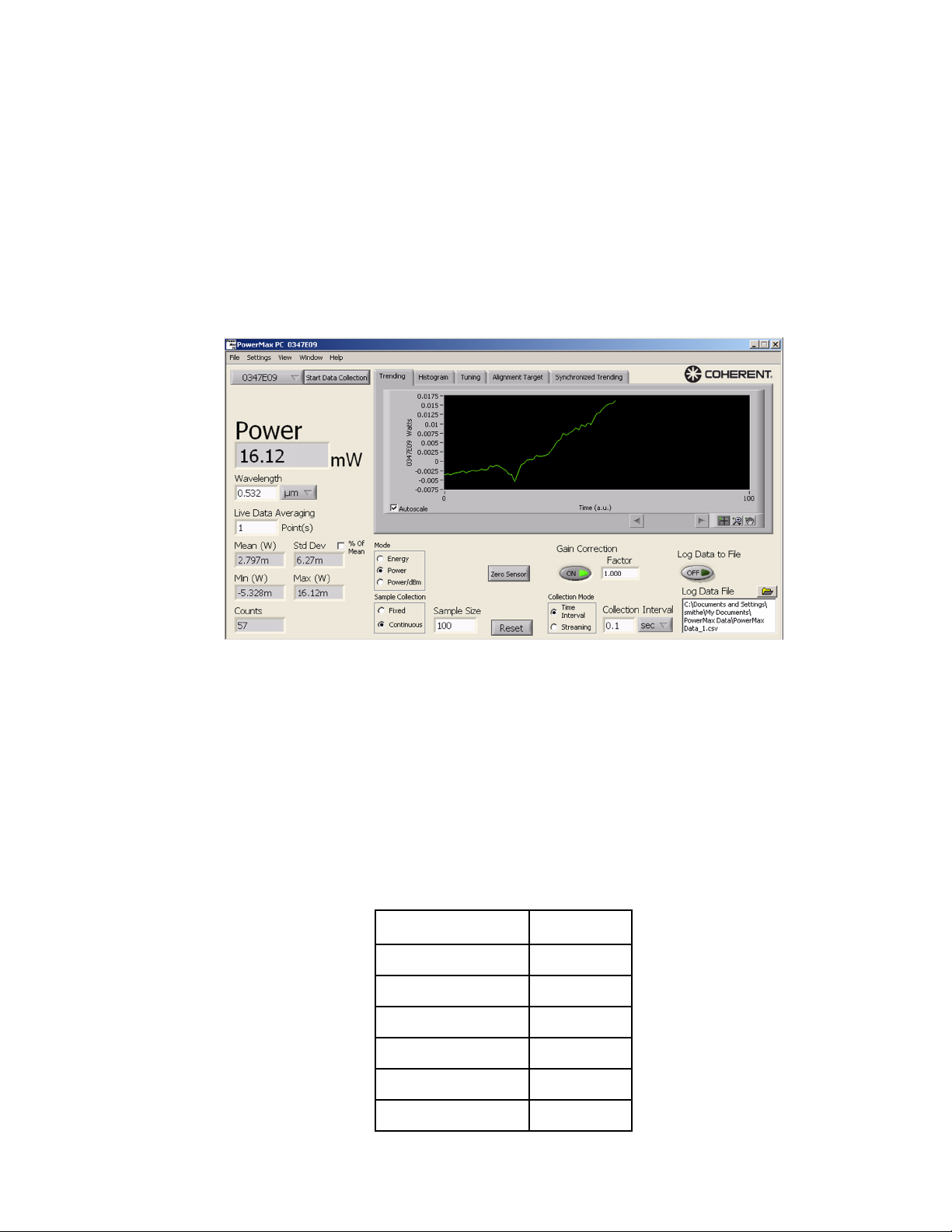

The Front panel (shown in Figure 5) is the first screen that appears

once the software is launched. From here you can enter parameters,

select modes, change ranges, start/stop data acquisition, and view

the output in a chart format.

Figure 5. Front Panel

Individual functions accessed through the Front panel are discussed,

starting next.

Keyboard Shortcuts The following table shows available shortcuts for several standard

functions:

Table 4. Keyboard Shortcuts

FUNCTION SHORTCUT

Exit program <Ctrl>+<Q>

Open new Front panel <Ctrl>+<N>

Print window <Ctrl>+<P>

Show context help <Ctrl>+<H>

View full application <Ctrl>+<F>

View saved data file <Ctrl>+<V>

19

Loading...

Loading...