Page 1

Installation

Manual

C3100 Speaker

Universal Mounting Bracket Kit

Sirens produce loud sounds that may damage hearing

• Wear hearing protection when testing

• Use siren only for emergency response

• Roll up windows when siren is operating

• Avoid exposure to the siren sound outside of vehicle

IMPORTANT:

WARNING

Read all instructions and warnings before

installing and using this equipment.

INSTALLER This manual must be

delivered to the end user of this equipment.

Page 2

!

WARNING!

SIREN PRODUCTS:

Sirens are an integral part of an effective audio/visual

emergency warning system. However, sirens are only short

range secondary warning devices. The use of a siren does

not insure that all drivers can or will observe or react to an

emergency warning signal, particularly at long distances or

when either vehicle is traveling at a high rate of speed. Sirens

should only be used in a combination with effective warning

lights and never relied upon as a sole warning signal. Never

take the right of way for granted. It is your responsibility to be

sure you can proceed safely before entering an intersection,

driving against traffic, or responding at a high rate of speed.

The effectiveness of this warning device is highly dependent

upon correct mounting and wiring. Read and follow the

manufacturer’s instructions before installing or using this

device. The vehicle operator should check the equipment

daily to insure that all features of the device operate correctly.

To be effective, sirens must produce high sound levels that

potentially can inflict hearing damage. Installers should be

warned to wear hearing protection, clear bystanders from the

area and not to operate the siren indoors during testing.

Vehicle operators and occupants should assess their

exposure to siren noise and determine what steps, such as

consultation with professionals or use of hearing protection

should be implemented to protect their hearing.

This equipment is intended for use by authorized personnel

only. It is the user’s responsibility to understand and obey all

laws regarding emergency warning devices. The user should

check all applicable city, state and federal laws and regulations.

Code 3, Inc., assumes no liability for any loss resulting from

the use of this warning device.

Proper installation is vital to the performance of the siren and

the safe operation of the emergency vehicle. It is important to

recognize that the operator of the emergency vehicle is under

psychological and physiological stress caused by the

emergency situation. The siren system should be installed in

such a manner as to: A) Not reduce the acoustical performance of the system, B) Limit as much as practical the noise

level in the passenger compartment of the vehicle, C) Place

the controls within convenient reach of the operator so that he

can operate the system without losing eye contact with the

roadway.

Emergency warning devices often require high electrical

voltages and/or currents. Properly protect and use caution

around live electrical connections. Grounding or shorting of

electrical connections can cause high current arcing, which

can cause personal injury and/or severe vehicle damage,

including fire.

PROPER INSTALLATION COMBINED WITH OPERATOR

TRAINING IN THE PROPER USE OF EMERGENCY

WARNING DEVICES IS ESSENTIAL TO INSURE THE

SAFETY OF EMERGENCY PERSONNEL AND THE PUBLIC.

Page 3

Selecting a Mounting

Location: The mounting

location should not only be

as flat as possible but also,

allow the siren to project its

tone parallel to the road.

For detailed information on

mounting locations for

certain specific vehicles,

see the following pages.

Installation: Position the

bracket onto the desired

mounting area and mark

the centers of the 4

mounting holes using the bracket as a template.

Now in the center of each of the 4 holes you marked, drill a 1/8-inch pilot

hole into the mounting surface for each of the 4 screws then enlarge the

pilot holes with a 9/32-inch drill. If you can get access to the other side of

the mounting area, and it is not too thick, you may want to substitute the 4

mounting screws with nuts, bolts and washers (customer supplied) of

comparable strength and size.

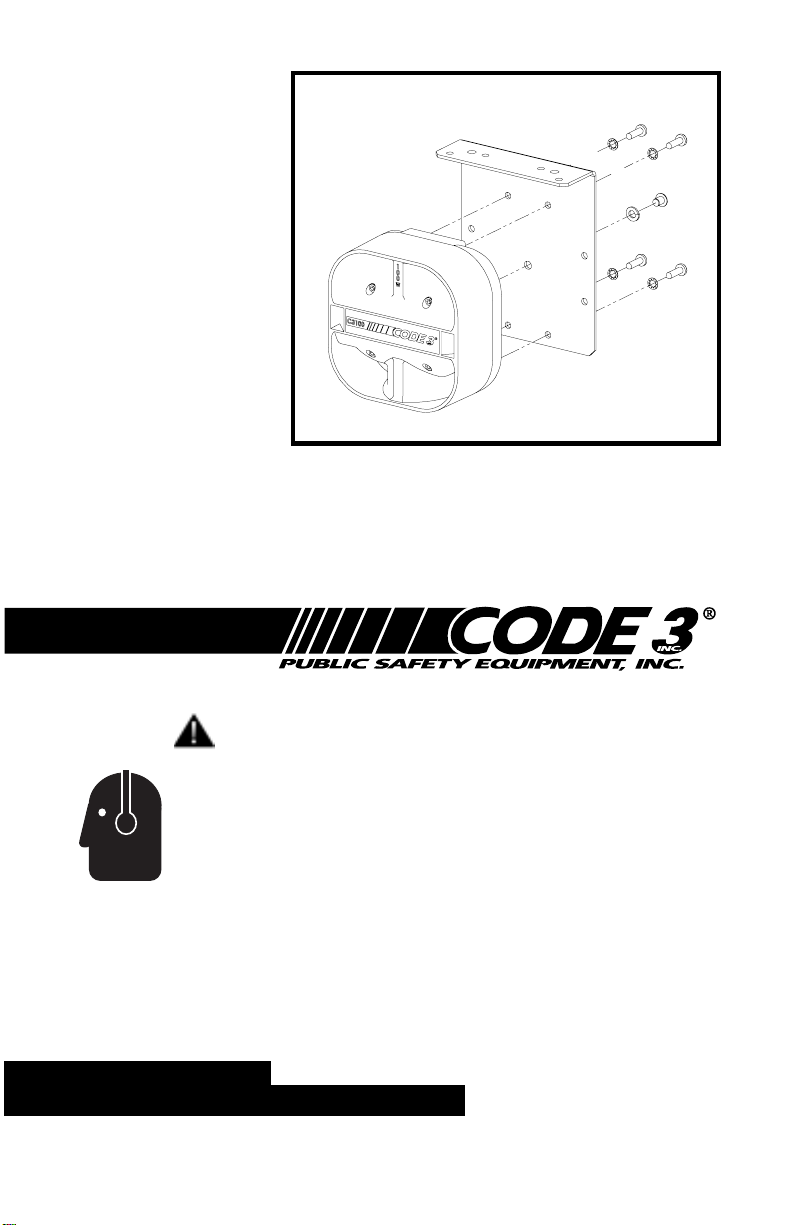

Fig 1

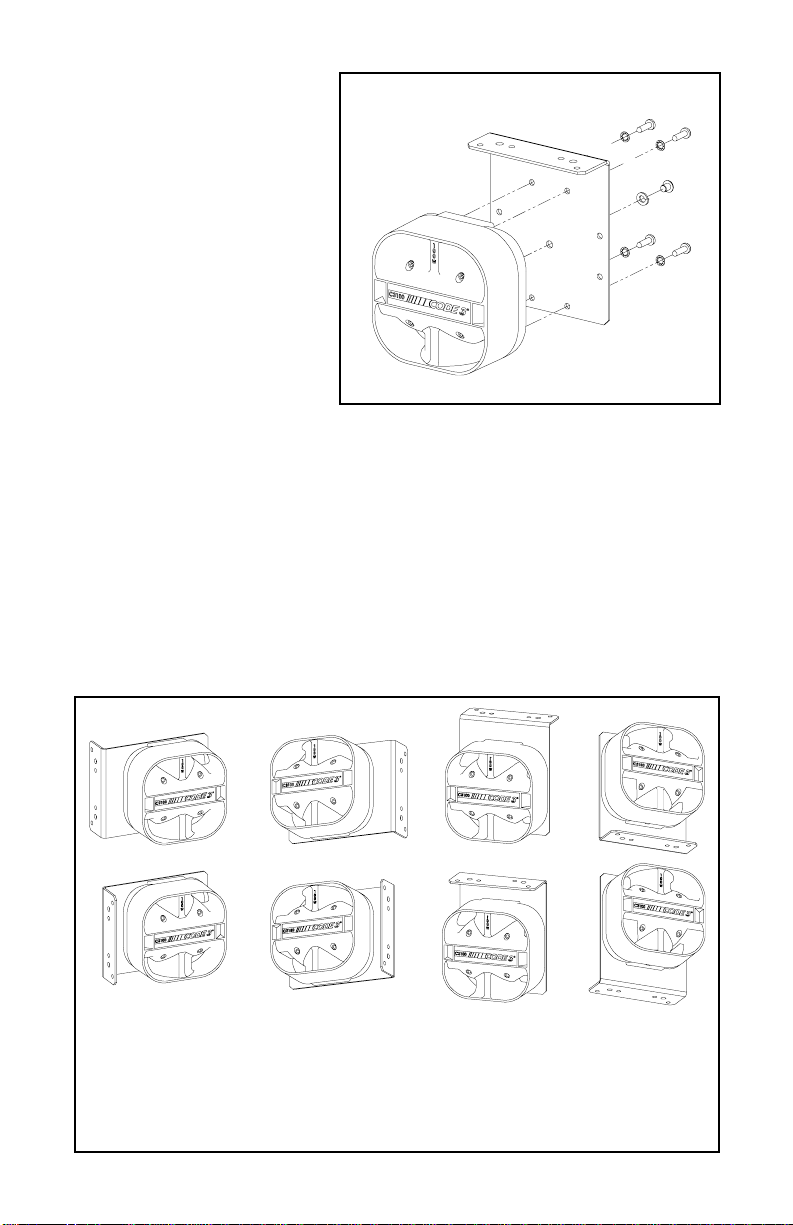

Fig 2, 8 possible mounting positions for the Universal bracket. It is

absolutely essential that the speaker be mounted so that the wires

exit at the the bottom (toward the ground). Improper mounting will

cause damage to your C3100 Speaker and void the warranty

Page 4

Secure the bracket to the mounting surface with the 4 supplied hex head

screws or the customer supplied fasteners of comparable strength and

size.

Note: Some kits are supplied with self-tapping screws. When

installing this type of screw you may need a socket and

electric drill to drive the screws.

Attach the siren to the bracket using the supplied screws and washers as

shown in Fig. 1. Note the center screw is a button head cap screw and

lock washer.

Extend the BLUE (Positive) and WHITE (Negative) speaker wires to your

siren amplifier and connect as shown in the amplifiers instructions.

Test the siren for proper operation.

Mounting The Speaker

Installation / 2002-2003 Ford Explorer:

The speaker will be mounted in front of the driver side front tire,

behind the bumper. You will use two existing nuts and their bolts

that are already on the vehicle. Always be sure that the sirens

wires exit the bottom of the siren after mounting for proper

drainage of the siren.

Attach the mounting bracket to the speaker as shown in figure 3.

Looking in through the drivers side wheel well, find the 2 existing bolts on

the vehicle that match up to the mounting holes on the bracket (Fig 4).

Fig 3,Attaching Mounting

Bracket

Fig 4

Fig 6, Use these holes for the 02-03

Ford Explorer

Fig 5

Page 5

Remove the 2 nuts from their bolts and mount the bracket ( with speaker

attached) securing it with the 2 nuts you removed (Figs. 2 & 3).

Extend the BLUE (Positive) and WHITE (Negative) speaker wires to your

siren amplifier and connect as shown in the amplifiers instructions.

Test the siren for proper operation.

Installation / 2001 Ford Taurus:

The speaker will mount in the area usually occupied by the Antilock Brake

System (ABS). If your vehicle is equipped with ABS you cannot mount the

speaker in this location.

Otherwise, the C3100 speaker will mount under the battery tray. First, you

will need to remove the battery tray, and the air filter and housing (Fig. 5).

The siren bracket will mount to the drivers side of the engine

compartment, on the side wall.

Disconnect the

ground terminal from

the negative post of

the battery, remove

the battery and tray

and then remove the

filter and housing.

Attach the bracket to

speaker as shown in

Fig. 6.

Position the bracket

and speaker onto the

mounting area. Try

not to position it too

far forward so the

siren is muffled. Be

sure the bracket

doesnt interfere with

any existing vehicle

components. Be sure

the bracket is not too

near any existing

holes on the mounting

Fig 5

Fig 6

Page 6

Fig 7

bracket and mount the bracket to the vehicle in the previously determined

location, using the self-tapping screws and washers supplied. You will

need to install these screws using a socket driver and electric drill.

Remount the speaker to the bracket making sure that the siren wires exit

the bottom of the speaker for proper drainage.

Extend the BLUE (Positive) and WHITE (Negative) speaker wires to your

siren amplifier and connect as shown in the amplifiers instructions.

Test the siren for proper operation.

Mark location of

the top edge of

the bracket

area, then

mark the

mounting

surface to

show the

location of

the top of

the bracket

(Fig. 7).

Now

remove the

speaker

from the

Page 7

NOTES

Page 8

WARRANTY

Code 3, Inc.'s emergency devices are tested and found to be

operational at the time of manufacture. Provided they are installed and

operated in accordance with manufacturer's recommendations, Code

3, Inc. guarantees all parts and components except the lamps to a

period of 1 year (unless otherwise expressed) from the date of

purchase or delivery, whichever is later. Units demonstrated to be

defective within the warranty period will be repaired or replaced at the

factory service center at no cost.

Use of lamp or other electrical load of a wattage higher than

installed or recommended by the factory, or use of inappropriate or

inadequate wiring or circuit protection causes this warranty to become

void. Failure or destruction of the product resulting from abuse or

unusual use and/or accidents is not covered by this warranty. Code

3, Inc. shall in no way be liable for other damages including consequential,

indirect or special damages whether loss is due to negligence or breach

of warranty.

CODE 3, INC. MAKES NO OTHER EXPRESS OR IMPLIED

WARRANTY INCLUDING, WITHOUT LIMITATION, WARRANTIES

OF FITNESS OR MERCHANTABILITY, WITH RESPECT TO THIS

PRODUCT.

PRODUCT RETURNS

If a product must be returned for repair or replacement*, please

contact our factory to obtain a Return Goods Authorization Number

(RGA number) before you ship the product to Code 3, Inc. Write the

RGA number clearly on the package near the mailing label. Be sure

you use sufficient packing materials to avoid damage to the product

being returned while in transit.

*Code 3, Inc. reserves the right to repair or replace at its discretion. Code 3, Inc. assumes no responsibility

or liability for expenses incurred for the removal and /or reinstallation of products requiring service and/or repair.; nor

for the packaging, handling, and shipping: nor for the handling of products return to sender after the service has been

rendered.

10986 N. Warson Road

©2005, CODE 3, Inc. Printed in USA

Code 3 is a registered trademark

of Public Safety Equipment, Inc.

St. Louis, Missouri 63114-2029—USA

Ph. (314) 426-2700 Fax (314) 426-1337

Revision 0, 02/05 - Instruction Book Part No. T11271

CODE 3, Inc.Ò

Loading...

Loading...