Page 1

INSTALLATION &

OPERATION

MANUAL

IMPORTANT:

ARCH™ Beacon

Contents:

Introduction................................................................................2

Features and Specications.....................................................2

Flash Patterns.........................................................................3-4

Dimensions.......................................................................5

Installation & Mounting.......................................................5-7

Wiring..............................................................................8

Operation.........................................................................8

Maintenance&Troubleshooting............................................9

Notes ...............................................................................10-11

Warranty........................................................................12

Read all instructions and warnings before installing and using.

INSTALLER: This manual must be delivered to the end user of this equipment.

1

Page 2

Introduction

The ARCH™ Beacon is a weatherproof LED based warning light that contains 36 state-of-the-art high intensity

LEDs in three stacked rows. The unique design efciently captures light from the LEDs with individual optics

that diffuse the light in an effective warning pattern.

This Product contains high intensity LED devices. To prevent eye damage, DO NOT stare

WARNING!

WARNING!

The use of this or any warning device does not insure that all drivers can or will observe or react to an emergency

warning signal. Never take the right-of-way for granted. It is your responsibility to be sure you can proceed

safely before entering an intersection, driving against trafc, responding at a high rate of speed, or walking on

or around trafc lanes.

The effectiveness of this warning device is highly dependent upon correct mounting and wiring. Read and follow

the manufacturer’s instructions before installing or using this device. The vehicle operator should insure daily that

all features of the device operate correctly. In use, the vehicle operator should insure the projection of the warning

signal is not blocked by vehicle components (i.e.: open trunks or compartment doors), people, vehicles, or other

obstructions. This equipment is intended for use by authorized personnel only. It is the user’s responsibility to

understand and obey all laws regarding emergency warning devices. The user should check all applicable city,

state and federal laws and regulations.

Code 3 , Inc., assumes no liability for any loss resulting from the use of this warning device.

Proper installation is vital to the performance of this warning device and the safe operation of the emergency

vehicle. It is important to recognize that the operator of the emergency vehicle is under psychological and physiological stress caused by the emergency situation. The warning device should be installed in such a manner as

to: A) Not reduce the output performance of the system, B) Place the controls within convenient reach of the

operator so that he can operate the system without losing eye contact with the roadway.

Emergency warning devices often require high electrical voltages and/or currents. Properly protect and use caution around live electrical connections. Grounding or shorting of electrical connections can cause high current

arcing, which can cause personal injury and/or severe vehicle damage, including re.

PROPER INSTALLATION COMBINED WITH OPERATOR TRAINING IN THE PROPER USE OF EMERGENCY

WARNING DEVICES IS ESSENTIAL TO INSURE THE SAFETY OF EMERGENCY PERSONNEL AND THE

PUBLIC.

into light beam at close range.

Features and Specications:

Operating Voltage: DC11V-16V, Reverse Polarity Protected

Operating Current: Avg 3.75 amps, Max 7.5 amps

Weight: 4.5 lb

Flash Modes Description:

1. Cycle-Flash: Cycles through Quad, Double, Triple, and Single modes.

2. Quad-Flash: Four consecutive pulses per ash.

3. Triple-Flash: Three consecutive pulses per ash.

4. Double-Flash: Two consecutive pulses per ash.

5. Single-Flash: Single pulse per ash.

6. Variable Single-Flash Single pulse per ash with varying ash rate.

Please note that a beacon set with a PHASE 0 ash pattern will alternate with beacons set with a PHASE 1 pattern

and ash simultaneously with beacons set with a PHASE 0 ash pattern.

2

Page 3

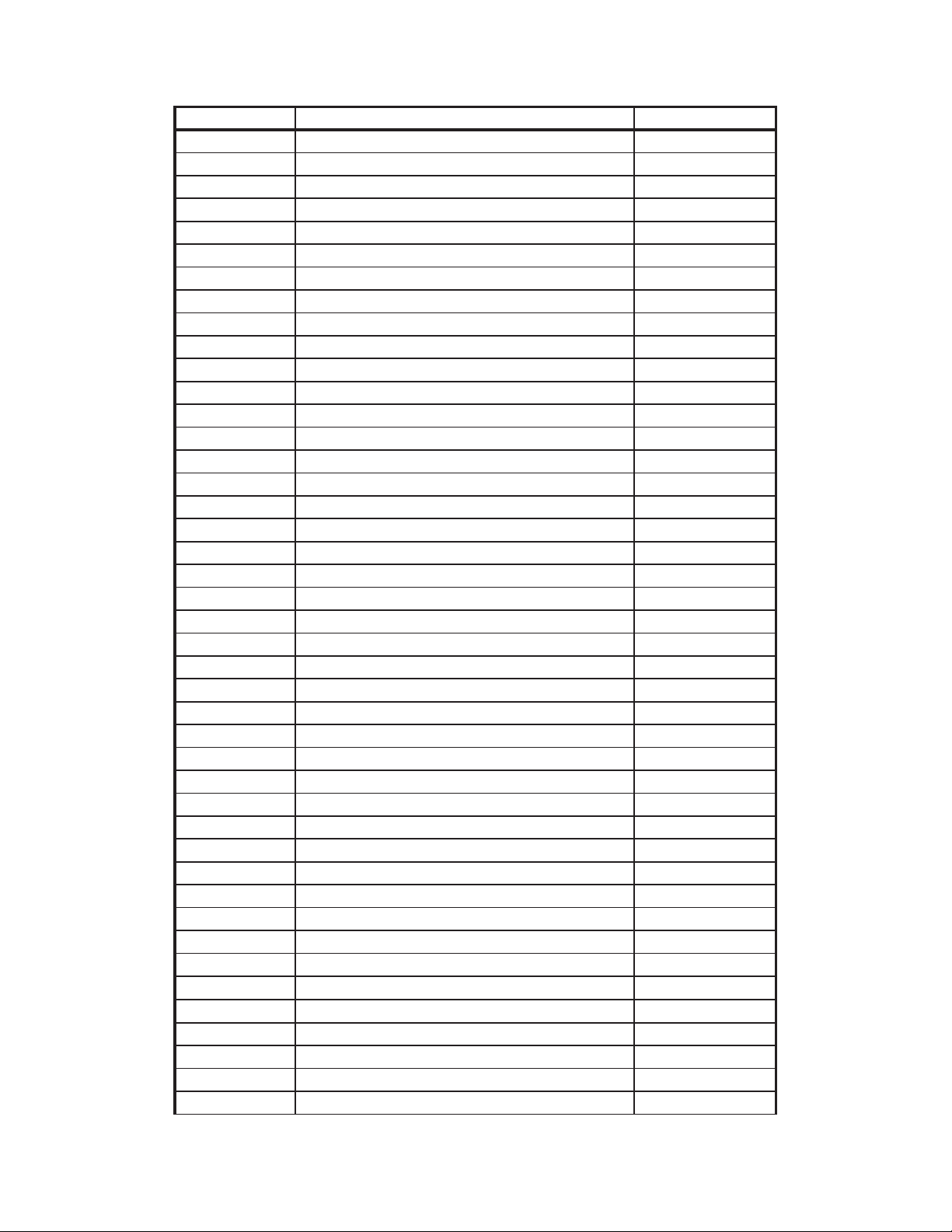

Flash Patterns (including for those with scene lights):

PATTERN NO. PATTERNS SYNCHRONIZE

1 NFPA Quad Phase 0 YES

2 Cycle Flash 75fpm Phase 0 YES

3 Quad 75fpm Phase 0 YES

4 Triple 75fpm Phase 0 YES

5 Double 75fpm Phase 0 YES

6 Single 75fpm Phase 0 YES

7

8 Rotate 75rpm Simultaneous Only

9 NFPA Quad Phase 1 YES

10 Cycle Flash 75fpm Phase 1 YES

11 Quad 75fpm Phase 1 YES

12 Triple 75fpm Phase 1 YES

13 Double 75fpm Phase 1 YES

14 Single 75fpm Phase 1 YES

15 Variable Single Flash Phase 1 YES

16 Cycle Flash 150fpm Phase 0 YES

17 Quad 150fpm Phase 0 YES

18 Triple 150fpm Phase 0 YES

19 Double 150fpm Phase 0 YES

20 Single 150fpm Phase 0 YES

21 Single 250fpm Phase 0 YES

22 Single 375fpm Phase 0 YES

23 Rotate 150rpm Simultaneous Only

24 Cycle Flash 150fpm Phase 1 YES

25 Quad 150fpm Phase 1 YES

26 Triple 150fpm Phase 1 YES

27 Double 150fpm Phase 1 YES

28 Single 150fpm Phase 1 YES

29 Single 250fpm Phase 1 YES

30 Single 375fpm Phase 1 YES

31 NFPA Quad Alternating Simultaneous Only

32 Cycle Flash 75fpm Alternating Simultaneous Only

33 Quad 75fpm Alternating Simultaneous Only

34 Triple 75fpm Alternating Simultaneous Only

35 Double 75fpm Alternating Simultaneous Only

26 Single 75fpm Alternating Simultaneous Only

37 Cycle Flash 150fpm Alternating Simultaneous Only

38 Quad 150fpm Alternating Simultaneous Only

39 Triple 150fpm Alternating Simultaneous Only

40 Double 150fpm Alternating Simultaneous Only

41 Single 150fpm Alternating Simultaneous Only

42 Single 250fpm Alternating Simultaneous Only

43 Single 375fpm Alternating Simultaneous Only

Variable Single Flash Phase 0

YES

3

Page 4

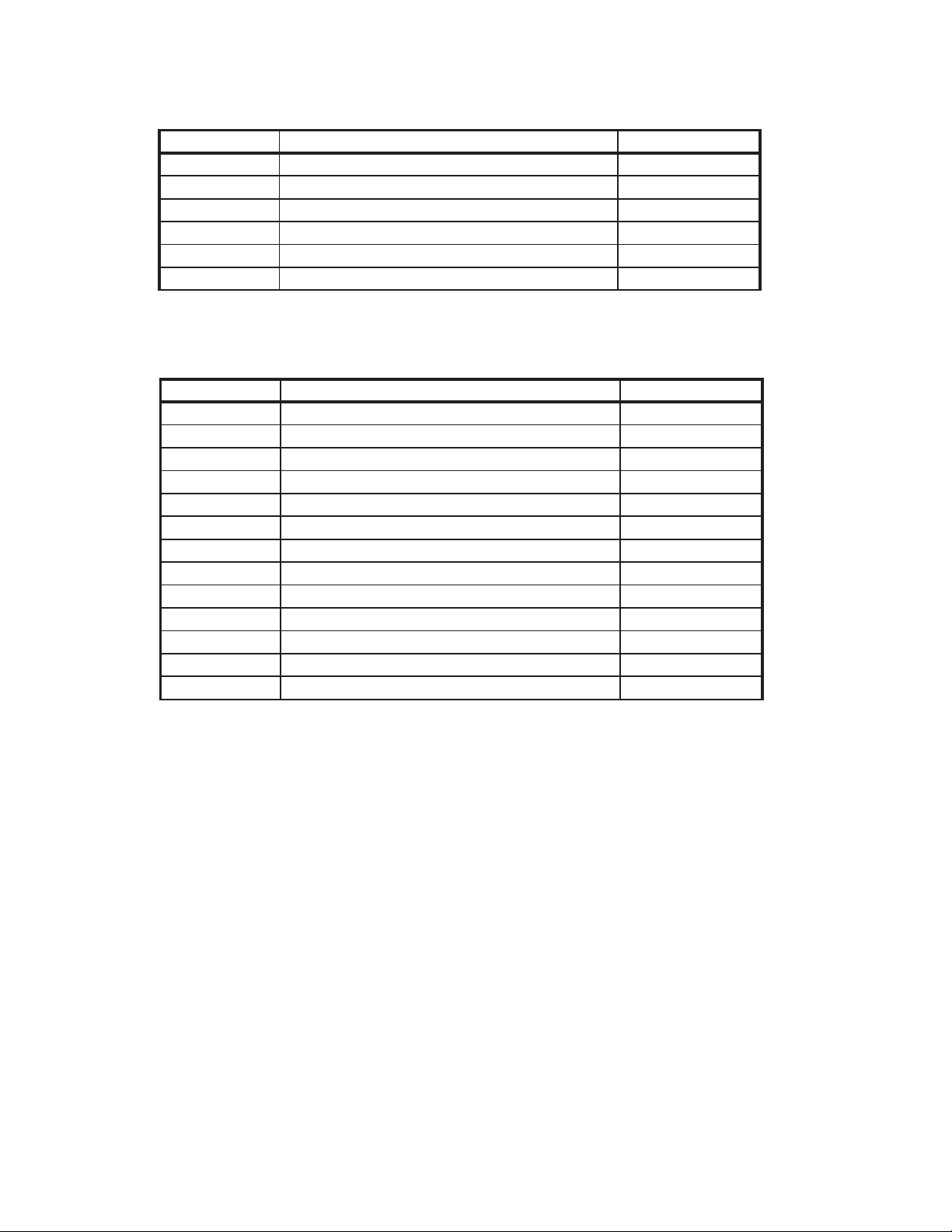

Flash Patterns for ECE-65 compliant beacons:

PATTERN NO. PATTERNS SYNCHRONIZE

1 Single Flash 120fpm Simultaneous Only

2 Double Flash 120fpm Simultaneous Only

3 Triple Flash 120fpm Simultaneous Only

4 Quad Flash 120fpm Simultaneous Only

5 Quintuple Flash 120fpm Simultaneous Only

6 Rotate 120rpm Simultaneous Only

Flash Patterns for multi-color beacons:

PATTERN NO. PATTERNS SYNCHRONIZE

1 NFPA Quad Simultaneous Only

2 Cycle Flash 75fpm Simultaneous Only

3 Quad 75fpm Simultaneous Only

4 Triple 75fpm Simultaneous Only

5 Double 75fpm Simultaneous Only

6 Single 75fpm Simultaneous Only

7 Cycle Flash 150fpm Simultaneous Only

8 Quad 150fpm Simultaneous Only

9 Triple 150fpm Simultaneous Only

10 Double 150fpm Simultaneous Only

11 Single 150fpm Simultaneous Only

12 Single 250fpm Simultaneous Only

13 Single 375fpm Simultaneous Only

4

Page 5

Dimensions:

(Basic dimensions are as shown)

Standard Mounting Procedure:

1. Remove beacon outer lens.

Note: Two hole patterns are provided for the user. The stan

dard 6 inch dia pattern and optional 5.7 inch

dia pattern. Only three #10 fasteners are

required to securely mount the beacon assembly.

2. Choose hole pattern (6" dia or 5.7" dia). Identify the 3 holes

chosen as indicated on the base's label and punch out with a sharp

object.

3. Use the beacon base to locate holes on mounting surface. Holes

should accomodate a #10 fastener. A hole should be provided for

wiring access at the center of the mounting area. The hole should

be grommeted and sealed with RTV around the wiring.

4. Align the gasket and and perimeter of the beacon base and

punch out the 3 chosen mounting holes with a sharp object. Place

gasket and beacon assembly on mounting surface being careful

to align the mounting holes. Care should be taken to not pinch the

wiring when placing the beacon assembly.

5. Install three #10 fasteners, at washers with neoprene backing,

and lock nuts (included) as shown to attach the assembly. Apply

RTV to the fastener holes during the installation.

6. Reinstall beacon outer lens.

5

Page 6

Optional 1in NPT

Pipe Mount Assembly:

1. Remove beacon outer lens.

2. Choose the 6" dia hole pattern. Identify the 3 holes

chosen as indicated on the base's label and punch out

with a sharp object.

3. Align the base gasket and and perimeter of the beacon base and punch out the 3 chosen mounting holes

with a sharp object. Place base gasket, adapter plate,

pipe mount gasket, and pipe mount ange against base

of beacon assembly.

4. Install three machine screws #10-24x1.5, at washers with neoprene backing, and lock nuts (included) as

shown to attach gasket and pipe mounting

plate to beacon base.

5. Reinstall beacon outer lens.

6. Caution: do not thread pipe past depth of threads

Optional Branch

Guard Assembly:

1. Remove beacon outer lens.

2. Choose the 6" dia hole pattern. Identify the 3 holes

chosen as indicated on the base's label and punch out

with a sharp object.

3. Use the branch guard base to locate holes on

mounting surface. Holes should accomodate a #10

fastener. A hole should be provided for wiring access

at the center of the mounting area. The hole should be

grommeted and sealed with RTV around the wiring.

4. Align the base gaskets and and perimeter of the

beacon base and punch out the 3 chosen mounting

holes with a sharp object. Place base gasket, branch

guard base, second base gasket, and beacon assembly on mounting surface being careful to align the

mounting holes. Care should be taken to not pinch the

wiring when placing the beacon assembly.

5. Install three #10 fasteners, at washers with neoprene backing, and lock nuts (included) as shown to

attach the assembly. Apply RTV to the fastener holes

during the installation.

6

Page 7

Mounting Instructions for NFPA Compliance:

Multiple beacons may be mounted at the corners of a vehicle as shown below. Some special service

beacons are built where the warning signal is limited to half the circumference of the beacon. These beacons

must be arranged so the warning signal faces at 45° to the longitudinal axis of the vehicle in order to comply

with NFPA standards.

When the beacon's lens is removed for installation, the warning signal producing optic-LED assemblies can

be identied by inspecting the label on the beacon base or noting the silver stars on the controller board.

7

Page 8

Wiring Instructions:

The beacon is terminated with a 12" long 6-wire cable harness that may be connected as follows:

COLOR FUNCTION CONNECT TO

Red Power +VDC

Black Ground Chassis ground

White Pattern switching Chassis ground to activate

Yellow

Green

Violet

Synchronization

Failure mode detect

Dim

See synchronization below

See failure mode detect below

+VDC to activate

Operation:

Synchronization:

To synchronize multiple beacons, congure as noted below. A maximum of 8 lights may be synchronized.

- To congure the beacons to ash their patterns simultaneously, advance the pattern for each beacon to Phase

0 mode of the chosen pattern. Connect the YELLOW wires from each beacon together. When the beacons are

activated, their patterns will ash together.

- To congure the beacons to alternate their patterns, advance the pattern of either beacon (but not both) to the

Phase 1 mode of the chosen pattern.

Failure Mode Detect:

This feature activates when +VDC is connected to the beacon. The following conditions are checked:

- Input voltage is at an adequate level to fully operate the beacon.

- The beacon's micro-processor is operating.

When the above are satised, the green wire is switched to ground and will support a current load up to 250

milli-amps. The green wire may serve to control an Indicator Light connected to +VDC that activates when the

beacon is ON and is functioning. The indicator light is not provided with the beacon.

Setting the Flash Pattern:

Momentarily connect the WHITE wire to chassis ground as follows:

- For the NEXT pattern; release contact when beacon ashes ON (less than 2 seconds)

- For the PREVIOUS pattern; release contact when beacon ashes ON then OFF (2 to 4 seconds)

- For the DEFAULT pattern; release contact when beacon ashes ON then OFF then ON again (greater

than 4 seconds)

8

Page 9

Maintenance:

The beacons are designed to be maintenance free. Refer to the guide below for help with troubleshooting.

Should the unit be diagnosed as malfunctioning, remove unit and replace with a new beacon.

LED beacon housings may become hot with extended use. Allow beacons to cool completely

WARNING!

Problem Probable Cause Remedy

Beacon does not activate a. No power to unit a. Check wire for loose connection

Beacon is constantly ON a. Control wire permanently

before attempting to remove.

TROUBLESHOOTING

b. Power input wire reversed b. Reverse power wires

c. Damaged or shortaged cabling c. Check cables for damage

d. Defective beacon d. Replace beacon module

a. Avoid permanent grounding of

grounded or shorted to GND

control wire

9

Page 10

Notes:

10

Page 11

Notes:

11

Page 12

WARRANTY

Code 3, Inc.'s L.E.D. emergency devices are tested and found to be operational at the time of manufacture.

Provided they are installed and operated in accordance with manufacturer's recommendations, Code 3, Inc. guarantees

all parts and components except the lamps to a period of 1 year, LED Lighthead modules to a period of 5 years (unless

otherwise expressed) from the date of purchase or delivery, whichever is later. Units demonstrated to be defective

within the warranty period will be repaired or replaced at the factory service center at no cost.

Use of lamp or other electrical load of a wattage higher than installed or recommended by the factory, or use

of inappropriate or inadequate wiring or circuit protection causes this warranty to become void. Failure or destruction

of the product resulting from abuse or unusual use and/or accidents is not covered by this warranty. Code 3, Inc.

shall in no way be liable for other damages including consequential, indirect or special damages whether loss is due

to negligence or breach of warranty.

CODE 3, INC. MAKES NO OTHER EXPRESS OR IMPLIED WARRANTY INCLUDING, WITHOUT LIMITATION, WARRANTIES OF FITNESS OR MERCHANTABILITY, WITH RESPECT TO THIS PRODUCT.

PRODUCT RETURNS

If a product must be returned for repair or replacement*, please contact our factory to obtain a Return

Goods Authorization Number (RGA number) before you ship the product to Code 3, Inc. Write the RGA number

clearly on the package near the mailing label. Be sure you use sufcient packing materials to avoid damage to

the product being returned while in transit.

*Code 3, Inc. reserves the right to repair or replace at its discretion. Code 3, Inc. assumes no responsibility or liability for expenses incurred for the removal and /or

reinstallation of products requiring service and/or repair.; nor for the packaging, handling, and shipping: nor for the handling of products return to sender after the service has been

rendered.

PROBLEMS OR QUESTIONS? CALL OUR TECHNICAL ASSISTANCE HOTLINE (314) 996-2800

or visit WWW.CODE3PSE.COM, select C3 FORUM and put your question on the forum

St. Louis, Missouri 63114-2029—USA

Ph. (314) 426-2700 Fax (314) 426-1337

10986 N. Warson Road

www.code3pse.com

Code 3, Inc.

Code 3® is a registered trademark of Code 3, Inc., a subsidiary of Public Safety Equipment, Inc.

12

Revision 1, 08/12 - Instruction Book Part No. T51315

©2012 Public Safety Equipment, Inc. Printed in USA

Loading...

Loading...