DISCLAIMER OF WARRANTY

This motorcycle is sold “as is” with all faults, obvious or not. There are no warranties

expressed or implied, including any warranty of merchantability and warranty of fitness

for any particular purpose.

“WARNING”

THE COBRA CX65 IS A COMPETITION MODEL ONLY AND IS NOT

MANUFACTURED FOR, NOR SHOULD IT BE USED ON PUBLIC STREETS, ROADS

OR HIGHWAYS.

THE USE OF THIS BIKE SHOULD BE LIMITED TO PARTICIPATION IN

SANCTIONED COMPETITION EVENTS UPON A CLOSED COURSE BY A

SUFFICIENTLY SKILLED RIDER AND SHOULD NOT BE USED FOR GENERAL

OFF-ROAD RECREATIONAL RIDING.

IMPROPER USE OF THIS MOTORCYCLE CAN CAUSE INJURY OR DEATH.

THIS BIKE IS INTENDED FOR EXPERIENCED RACERS ONLY AND NOT FOR

BEGINNERS.

IT IS YOUR RESPONSIBILITY AS THE OWNER OF THIS COBRA MOTORCYCLE

OR AS THE PARENT, OR LEGAL GUARDIAN OF THE OPERATOR, TO KEEP THIS

COBRA MOTORCYCLE IN PROPER OPERATING CONDITION.

THIS BIKE WAS DESIGNED FOR RIDERS THAT WEIGH LESS THAN 110 LBS WITH

FULL RIDING GEAR AND SHOULD NOT BE OPERATED BY RIDERS THAT WEIGH

MORE THAN THAT.

BE SURE THAT THE RIDER ALWAYS WEARS ADEQUATE SAFETY GEAR

EVERYTIME HE OR SHE RIDES THEIR COBRA MOTORCYCLE.

IMPORTANT SAFETY NOTICE

Failure to follow WARNING instructions could result in severe injury or death to

the machine operator, a bystander, or a person inspecting or repairing the

machine.

CAUTION:

A CAUTION indicates special precautions that must be taken to avoid damage to

the machine.

NOTE:

A NOTE provides key information to make procedures easier or clearer.

MCC62014.V1

1

2

Table of Contents

GENERAL INFORMATION .......................................................................................... 4

SPECIFICATIONS - GENERAL ............................................................................................. 4

OPTIONAL COMPONENTS ................................................................................................. 5

SPECIFICATIONS - TORQUE VALUES ................................................................................. 5

BREAK-IN PROCEDURE .................................................................................................... 6

STARTING PROCEDURE .................................................................................................... 6

MAINTENANCE ........................................................................................................... 7

TIPS ................................................................................................................................. 7

SCHEDULE........................................................................................................................ 8

REPLACING TRANSMISSION / CLUTCH LUBRICANT .......................................................... 9

CHAIN ADJUSTMENT ...................................................................................................... 10

AIR FILTER CLEANING ................................................................................................... 11

FORK MAINTENANCE ..................................................................................................... 11

Fork Air Bleeding ..................................................................................................... 12

Fork Oil Replacement ............................................................................................... 12

IGNITION TIMING ........................................................................................................... 14

CABLE TIES .................................................................................................................... 14

PARTS ........................................................................................................................ 16

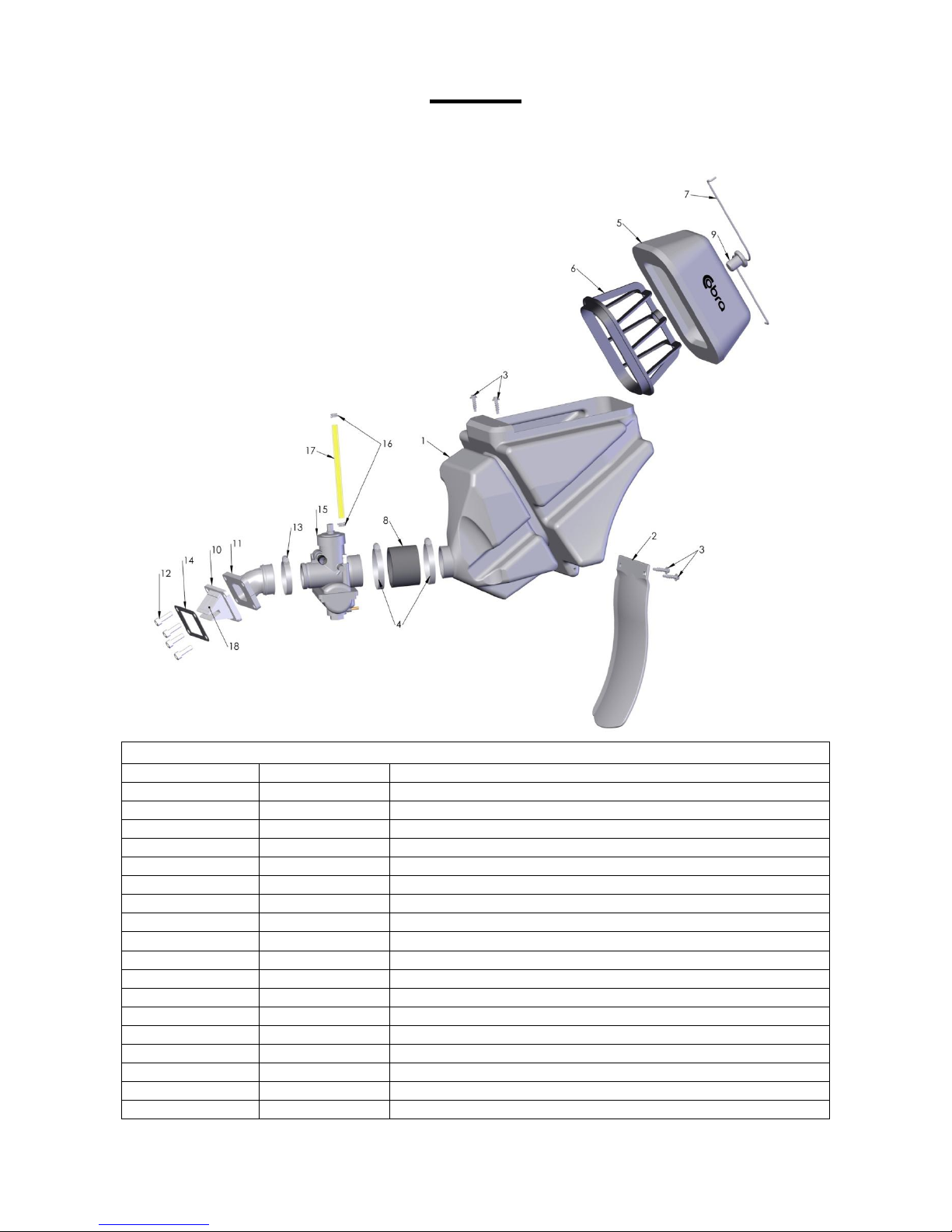

PARTS – AIRBOX & INLET SYSTEM ................................................................................ 16

PARTS – BARS AND CONTROLS ...................................................................................... 17

PARTS - CARBURETOR ................................................................................................... 18

PARTS – CLUTCH – MASTER CYLINDER ......................................................................... 19

PARTS – COOLANT SYSTEM ........................................................................................... 20

PARTS – ELECTRICAL SYSTEM ....................................................................................... 21

PARTS – ENGINE CLUTCH .............................................................................................. 22

PARTS – ENGINE – CLUTCH / KICK COVER .................................................................... 23

PARTS – ENGINE – IGNITION SIDE .................................................................................. 24

PARTS – ENGINE – KICK MECHANISM............................................................................ 25

PARTS – ENGINE – SHIFT MECHANISM ........................................................................... 26

PARTS – ENGINE – TOP END .......................................................................................... 27

PARTS – ENGINE – POWER VALVE ................................................................................. 28

PARTS – ENGINE – TRANSMISSION ................................................................................. 29

PARTS – EXHAUST SYSTEM ............................................................................................ 30

PARTS – FORKS & TRIPLE CLAMPS ................................................................................ 31

PARTS – FORK – LEG ASSEMBLY – BRAKE SIDE ............................................................ 32

PARTS – FORK – LEG ASSEMBLY – NON-BRAKE SIDE ................................................... 33

3

PARTS – FRAME ............................................................................................................. 34

PARTS – FRONT WHEEL ................................................................................................. 35

PARTS – FRONT BRAKES – MASTER CYLINDER ............................................................. 36

PARTS – FRONT BRAKES – CALIPER ............................................................................... 37

PARTS – BODYWORK ..................................................................................................... 38

PARTS – REAR BRAKE.................................................................................................... 39

PARTS – REAR WHEEL ................................................................................................... 40

PARTS – SHOCK EXTERNAL ........................................................................................... 41

PARTS – SHOCK – INTERNAL .......................................................................................... 42

PARTS – SWINGARM ASSEMBLY .................................................................................... 43

SERVICE .................................................................................................................... 44

ENGINE SERVICE ............................................................................................................ 44

Base Gasket Selection ............................................................................................... 45

Power Valve .............................................................................................................. 47

EXHAUST ....................................................................................................................... 48

FUEL & AIR SYSTEM ...................................................................................................... 48

CARBURETOR: ................................................................................................................ 48

REAR SHOCK.................................................................................................................. 50

BRAKES ......................................................................................................................... 50

Rear Brakes ............................................................................................................... 50

Front Brakes ............................................................................................................. 51

FRONT WHEEL ............................................................................................................... 52

Assembly ................................................................................................................... 52

TUNING ...................................................................................................................... 53

GEARING ........................................................................................................................ 53

SUSPENSION ................................................................................................................... 54

Adjustment: ............................................................................................................... 54

Front Fork Operation ............................................................................................... 54

Fork Damping Adjustments ...................................................................................... 55

Rear Shock Adjustments. ........................................................................................... 56

CARBURETOR ................................................................................................................. 57

TROUBLESHOOTING ............................................................................................... 60

INDEX ......................................................................................................................... 62

4

General Information

Items

CX65

Dimensions

Wheelbase

40.9” (1040mm)

Wheel size

12” (305mm) rear, 14” (356mm) front

Seat height

29.9” (760mm)

Engine

Type

2-stroke, single cylinder, reed valve

Cooling system

Liquid-cooled

Coolant

50/50 antifreeze-coolant / distilled water

Displacement

64.9 cc

Bore and stroke

44.5 mm x 41.7 mm

Ignition system

Electronic, digital advance

Spark plug

Autolite 4063 or XS4063

Gap

0.024” – 0.026” (0.60 – 0.65 mm)

Ignition timing

Digital advance (set at “0” timing mark)

Fuel type

High octane pump gasoline

Premix Oil type

Bel-Ray H1-R

Premix oil ratio after break-in

40:1 – 50:1

Carburetion

26 mm VM Mikuni

Main Jet / Slow (Pilot) Jet

280 / 42.5

Needle

5I 14 - 4

Float Height

21.1 ± 1.0

Transmission

6 speed

Final drive ratio

14/45

Chain

116 links 420

Transmission / clutch oil type

Quality gear lubricant, or Cobra clutch milk

Do Not Run Automotive Motor Oil

Quantity

530 ml (18.0oz)

Chassis

Front tire

60/100 – 14

Rear tire

80/100 – 12

Front fork

CARD 37mm USD, Fully adjustable

Fork oil type

SAE 2.5 WT

Fork oil amount

250 ml (8.5oz)

Adjustments (turns out)

Compression 5/8, Rebound 2 1/2, Bottoming 2 3/4

Rear shock (clicks out)

Compression Low 9, High 8, Rebound 26

Race sag 87mm

Specifications - General

5

Optional Components

Weight of Rider (lb)

Fork Spring

Shock Spring

less than 70 lb

0.24 kg/mm

KCC63724

42 N/MM (240 lb/in)

SCC60240P (white)

75-85 lb

0.26 kg/mm

KCC63726

45 N/MM (260 lb/in)

SCC60260PY stock (yellow)

85-100 lb

0.28 kg/mm

KCC63728

49 N/MM (280 lb/in)

SCC60280PG (gold)

Greater than 100

53 N/MM (300 lb/in)

SCEX1300 (red)

Fastener

Torque Value

Size & Remarks

ft-lb

in-lb

Nm

Cylinder head nuts

9

110

12

M6 x 1.0

Cylinder nuts

22

265

30

M8 x 1.25**

Crankcase bolts

9

110

12

M6 x 1.0

PV Jam Nut

6

72 8 M6 x 1.0**

PV Cap Screws

3

35 4 M5 x 0.8

Exhaust Flange

5

60 6 M6 x 1.0

Spark plug

(SP)

(SP)

(SP)

M14 x 1.25

Stator bolts

2.1

25

2.8

M5 X 0.8

Stator cover bolts

1.7

20

2.3

M4 X 0.75

Clutch cover bolts

5.8

70

7.9

M6 X 1.0

Clutch nut

40

480

54

M10 x 1.25

Front axle bolt

33

400

45

M20 x 1.0

Front axle pinch bolt

8.8

106

12

M6 X 1.0

Front brake rotor

7.4

88.5

10

M6 x 1.0

Engine mount bolts

22

265

30

M8 X 1.25

Swingarm pivot

21

250

28

M12 X 1.5

Intake manifold bolts

4.6

55

6.2

M6 X 1.0

Rear axle

25

300

34

M14 X 1. 5

Rear sprocket

20

240

27

M8 X 1.25

Rear brake rotor

7.4

88.5

10

M6 x 1.0

Triple clamp (top)

9

108

12

M6 x 1.0

Triple clamp (bottom)

6

72 8 M6 x 1.0

Fork cap

15

177

20 Fork Damper Nut

11

133

15 Ignition rotor nut

33

400

45

M10 x 1.25*

Specifications - Torque Values

* Apply high strength thread locking agent when installing

** Use a ‘crows foot’ attachment oriented 90° to the torque wrench

(SP) To apply the proper torque to the spark plug when inserting, one must first

screw the spark plug in until the metal gasket ring causes resistance and then

turn another 1/8 to ¼ turn.

6

Break-In Procedure

Your Cobra CX65 is a close-tolerance high performance machine and break-in

time is very important for maximum life and performance. The CX65 can be

ridden hard after the first ½ hour break-in time.

Cobra recommends Bel-Ray H1-R premix oil with high octane pump gas mixed

at 40:1.

CAUTION:

Failure to use proper fuel, oil, or fuel/oil mixture may result in premature engine

wear or damage to the machine.

Adhering to the following break-in schedule will result in long lasting high

performance machine.

Start bike on stand

First 5 minute period, operate the bike on the stand with a combination of idle

and high RPM operation. (avoid prolonged high RPM but spin the rear

wheel good at least once or twice per minute)

Allow bike to cool

Ride for 15 minutes maximum (avoid prolonged high RPM operation and

avoid abusing the clutch).

Cool and inspect bike for loose fasteners.

Check & retighten wheel spokes

Next ½ hour of operation, avoid prolonged operation at Wide Open Throttle.

After 1 hour of operation

o Check for loose bolts and nuts on the bike and retighten as necessary

(proper toque values are listed under Specifications).

o Clean the carburetor bowl.

o Change the transmission / clutch lubricant.

After 8 hours of operation

o Change the fork oil.

o Have a Certified Cobra Mechanic change the shock oil.

Your bike is now ready for the highest level of competition!

Starting Procedure

Before starting the machine inspect the following:

Check for proper tire pressure in both tires.

Observe the chain tension and adjust if necessary.

Observe the coolant level and fill if necessary.

Verify that the chain rollers and sliders do not have improper wear.

Verify that the handlebars are tight.

Check the throttle for smooth operation and sound closing.

Check for loose bolts and nuts, and re-torque as necessary.

Verify that the air filter is clean and properly saturated with oil.

7

Insure that the fuel tank contains an adequate volume of fuel / oil mixture to

complete the distance required.

Turn the fuel on by rotating the fuel petcock lever to the vertically downward

position.

CAUTION:

For best results from your Cobra Motorcycle use only the recommended fuels.

‘Race’ fuels can be used, however, they are not required with the stock engine,

and the engine will require addition attention to maintain proper jetting as

weather condition change throughout the day.

Always wear a helmet and other protective riding gear.

When your pre-ride inspection is complete the bike may be started. For a cold

engine follow this procedure.

1. Place the motorcycle on a stand of sufficient strength that positions the

motorcycle in a level upright position with the rear wheel off the ground.

2. Engage the choke by pulling out on the choke button until it stops.

3. Kick start the engine.

4. Rev the engine in short spurts, turning the throttle no more than 1/4 open

until the engine will run without the choke.

5. Verify a functional engine shut-off switch by shutting off the engine.

6. Restart the engine and proceed with riding when the engine is sufficiently

warm (i.e. the side of the cylinder is warm to touch).

CAUTION:

Never rev an engine full throttle when it's cold or slightly warmed up. This may

lead to premature wear of engine components or complete cold seizure of the

engine.

CAUTION:

Cobra recommends that you tell your child to take it easy the first couple of

minutes in practice until the engine comes up to full operating temperature.

It is important that you adhere to this maintenance schedule so as to promote the

longevity of your Cobra Motorcycle.

Tips

1. Cobra lubricants:

a. Use only high quality transmission oil designed specifically for two-

stroke racing engines.

b. Bel-Ray H1-R oil is the recommended premix oil:

Maintenance

8

2. Fill your transmission only with the recommended amount of oil. Overfilling

may lead to premature seal failure.

3. The cylinder base gasket has been ‘fitted’ for your engine. See the service

section of this manual for instructions how to properly size a base gasket

during an engine rebuild.

4. Evaluate the bikes jetting only after it has been warmed up to race

temperatures.

5. A properly maintained machine is safer, faster, and more fun to ride.

6. New chains will stretch on first use. Never install a new chain prior to a

race. Always ‘break’ them in during practice.

7. Your Cobra Motorcycle has a 10 digit VIN (Vehicle Identification Number).

The first two digits indicate the model and the seventh indicates the model

year (MY).

a. Example, CXxxxx7xxx is a 2007 MY CX65.

Schedule

Prior to each ride

o Check the air filter (clean and re-oil as necessary).

o Insure the smooth operation of the throttle cable (throttle soundly

‘clacks’ shut).

o Check for frayed strands of the throttle cable inside the throttle housing

and replace if necessary.

o Check for adequate tire pressures and adjust if necessary.

o Check all nuts and bolts for proper torque and re-torque if necessary.

o Check drive chain for

Proper tension and adjust if necessary.

Adequate lubrication and lubricate if necessary.

o Insure that the ignition stator and rotor are clean and dry.

o Check the frame for cracks in the metal or cracks in the paint that

might indicate that the metal has been stressed beyond its safe limits.

Replace or get properly re-welded as necessary.

o Check the spokes for tightness and adjust if necessary.

o Check the rims and hubs for signs of stress, like cracks around the rim,

spokes and hub.

o Equalize the pressure in the forks with atmosphere.

o Check for adequate brake operation and pad thickness

Every 2 hours of operation

o Replace the transmission oil.

o Check spoke tension

Every 10 hours of operation

o Replace the fork oil.

o Have the shock oil replaced by a Certified Cobra Mechanic.

Every 15 hours

o Replace piston rings

Inspect piston for wear and cracks.

o Clean the power valve (no adjustment necessary)

o Inspect the power valve cable.

9

CAUTION:

Figure 1

If you ever need to weld anything on the bike, disconnect the spark plug cap,

unplug the ignition, disconnect the kill switch, scrape the paint bare near the area

to be welded and put the ground clamp as close to the area to be welded as

possible.

Be sure the fuel tank and carburetor have been removed and safely located

away from the welding process.

The frame is a combination of HSLA steel and 4130 Chrome Moly and it is

important to weld it with the proper rod and heat settings set as light as possible.

Cobra recommends replacing the frame with a new one if the old one becomes

damaged. Use ER70S6 filler if welding on the frame.

Replacing Transmission / Clutch Lubricant

Tools needed:

18 oz, of high quality transmission oil, or Cobra clutch milk

8 mm Allen wrench

CAUTION:

General automotive motor oil has frictional modifiers which will cause premature

wear and failure of the clutch.

Procedure:

1. Begin this procedure with a bike that has been ridden more than 5 minutes

but less than 10 minutes. It is desired to have the engine warm enough so

that the oil is ‘runny’ but not so hot that there is risk of being burned by the

engine or the oil.

Hot oil and hot components on the

motorcycle may cause burns.

2. Lean the bike against something or

set on stand with oil drain hole.

3. Using a 8mm Allen wrench, remove

the oil drain bolt located on the

right side of the engine, on the

clutch cover, near the brake lever

(See Figure 1).

NOTE: You may need to adjust the

brake pedal (up or down) to gain

access to the drain bolt.

10

4. After it has drained, reinstall the bolt being sure that the rubber gasket is in

Figure 2

Figure 3

place. Torque to 11 Nm (8 ft-lb).

5. Remove oil fill plug with an 8mm Allen wrench.

6. Carefully pour 16 oz (470 ml) of transmission oil into the oil fill opening.

7. Reinstall the oil fill plug making sure the rubber gasket is in place.

NOTE: Filling after an engine rebuild required additional transmission fluid. If the

engine is completely flushed of oil, refill with 18 oz (530ml).

Always capture and dispose of used oil properly (all auto parts stores accept

used oil). Dumping oil on the ground is illegal, inconsiderate, and can get you

disqualified from a race weekend quicker than cutting the track.

Chain adjustment

Tools required for chain adjustment

22 mm wrench or socket

2 - 11 mm open-end wrenches

1. Make sure that the rear wheel is aligned

properly.

2. For proper adjustment, the chain should

have 35 mm free movement just behind

the chain block with no load on the bike

(Figure 2)

CAUTION:

Sit on the bike and verify that the chain has a minimum of 12mm (1/2”) free

movement when the chain is at its tightest point.

3. If the chain requires adjusting, loosen the axle

with a 22mm wrench, and loosen the jam nut with

an 11mm wrench. Tighten the chain by rotating

the adjustor bolts clockwise (CW) or loosen the

chain by rotating the adjustor bolts (CCW).

4. Put a rag between the sprocket and chain, and

roll the wheel backward to pull the chain adjustor

blocks tightly against the adjustor bolts (Figure

3).

5. Retighten the axle bolt to 25 ft-lb (34 Nm).

6. Retighten the adjustor jam nuts.

CAUTION:

Always check rear brake adjustment and free-play after adjusting the chain.

11

Air Filter Cleaning

Figure 5

Figure 4

Tools recommended for air filter maintenance:

5 mm hex key (Allen)

Foam filter oil

1. Removed seat with the 5mm hex key.

2. Unhook the air filter wire from its perch

3. Carefully remove the air filter and frame out the top

of the airbox making sure not to dislodge any dirt

into the intake tract.

4. Clean the filter in a nonflammable solvent to

remove the filter oil.

Do not clean the air filter with gasoline or other highly

volatile petroleum product. Diesel fuel, mineral spirits,

or kerosene would be preferred but caution should still

be taken.

5. Clean the filter in hot soapy water to remove all dirt

particles.

6. Allow it to dry thoroughly.

7. Saturate with filter oil and remove excess.

NOTE: It is very important to keep the air filter clean

and properly oiled with high quality water-resistant

foam filter oil. Apply oil consistently because varied

amounts of oil will affect carburetor jetting.

8. Reinstall the filter assembly by pushing it down and forward into the airbox

making sure the lip of the filter cage is properly seated into its receptacle

(figure 5). Reinstall the air filter cap and holding wire.

CAUTION:

Double check to insure that the filter is pushed in tight at the bottom

NOTE: Make sure you change or clean your filter after each moto. We

recommend carrying multiple filters in your toolbox, one for each practice session

and moto.

Fork Maintenance

Cobra strongly recommends that a professional service technician conduct all

internal maintenance other than changing springs and oil. This will help to ensure

safe and consistent operation.

12

For routine maintenance, the chart below provides suggested service intervals

Each Ride

10 hours

20 hours

As Needed

Bleed excess air

X Change Oil

X

Change

Seal/Swiper

X

Change Bushings

X

for common procedures:

Fork Air Bleeding

Tools required

3mm hex key (Allen wrench)

During normal operation, both fork legs will build up air pressure. This pressure

acts as an additional spring so it must be bled on a regular basis to maintain

consistent suspension operation. Before each ride, loosen the socket head cap

screw located at the front of each fork cap far enough so that any excess

pressure in the leg is relieved. After excess air is bled off, retighten the screw to 5

in-lb. Be careful not to lose or damage the sealing ring that is located under the

head of each bleed screw.

Fork Oil Replacement

Tools required

37mm Fork Cap Tool (MCMUTL37)

22mm closed-end wrench or socket

14mm open-end wrench

Drift punch (12mm OD x 300mm long (1/2” x 12”))

5 & 6 mm hex key (Allen wrench)

Mallet

2.5 wt. Bel-Ray fork oil

Disassembly procedure

1. Remove the front wheel.

a. Loosen the brake-side axle pinch bolts (5mm hex key)

b. Carefully remove the brake side axle cap using a closed-end wrench to

protect the cap from damage. (22mm wrench)

c. Loosen the non-brake side axle pinch bolts (5mm hex key)

d. Using the drift punch (a long 3/8 socket extension will also work),

remove the axle from the fork lugs by placing the punch inside the

hollow axle and tapping lightly on the exposed end with the mallet.

13

e. Carefully slide with wheel downward out of the brake caliper.

2. Remove the brake caliper from the fork leg (6mm hex key).

3. Loosen the fork caps (Cobra 37mm Fork Cap Tool).

4. Remove the fork legs from the triple clamps (5mm hex key).

5. One leg at a time:

a. Remove the fork cap from the fork tube.

b. Lower the fork tube to expose the fork spring.

c. Pull the fork spring down from the fork cap to expose the damper rod

lock nut. Secure this nut using a 14mm wrench.

d. With the 14mm wrench on the damper rod nut, use the 37mm fork cap

wrench to free the fork cap from the damper rod.

e. Remove the 14mm wrench and allow the damper rod to fall into the

cartridge tube.

f. Remove the fork spring.

g. Invert the fork to allow the oil to drain. Pump the damper rod assembly

several times to help any excess oil trapped in the cartridge to drain.

Assembly procedure

1. Completely collapse the outer fork tube onto the stanchion tube. Add enough

2.5 wt. Bel-Ray fork oil to fill the cartridge tube. Pump the damper rod up and

down slowly to help the assembly fill with oil.

2. Once the cartridge assembly is bled, continue to fill the fork with oil until it is

120mm +/- 2.5mm from the top of the fork.

3. Install the fork spring.

4. Use a flexible retrieving tool to pull the damper rod up through the fork spring

and thread the damper rod into the fork cap.

CAUTION:

Ensure that the fork cap is completely threaded onto the damper rod before it

makes contact with the lock nut.

5. Pull the fork spring down from the cap and torque the damper rod lock nut to

15 N-m (11ft-lb) with a 14mm wrench.

CAUTION:

The damper rod is hollow and will break if the nut is over tightened.

6. Ensure that the fork cap o-ring is in good condition, Use the 37mm fork cap

wrench to secure the fork cap to the fork outer tube. Torque the fork cap to 20

Nm (15 ft-lb).

7. Pump the fork leg several times to verify that it operates smoothly.

8. Install each leg back into the triple clamp. Torque each pinch bolt to 11N-m (8

ft-lb) making sure both legs are set to the same height in the clamps.

9. Reinstall the brake caliper.

10. Reinstall the front wheel.

1. Install axle through non-brake side fork lug and wheel hub

14

2. Slide wheel spacer over axle taking care to ensure that the internal

o-ring is in place.

3. Continue sliding axle through brake-side lug and reinstall axle cap

(6 ft-lb, 8 Nm)

4. Lightly torque all four axle pinch bolts

5. Drop the bike onto the ground, engage the front brake, and push up

and down on the handlebars several times to ensure that the front

forks and the front wheel are properly aligned with each other.

6. Apply final torque to all four axle pinch bolts (7.4 ft-lb, 10 Nm)

Ignition Timing

The ignition timing value for the CX65 is 0° retarded from the standard base

reference (0°). This can be verified by removing the ignition cover and looking as

shown in the figure below.

The center mark on the cases is the standard base reference timing mark (0°),

and the other two large marks are 5° advanced and retarded. The small timing

marks between 0 & 5° is 2.5°.

To change the timing, one must remove the flywheel with Cobra 65 flywheel

puller # MCMUTL05. After the flywheel has been removed, the timing can be

adjusted by loosening the stator bolts and rotating the stator to the desired

position.

Cable Ties

There are two locations where we have used reusable frame mount cable ties

this year on the 2013 CX65.

15

To disconnect these cable ties, use a screw driver as shown and push down on

the short tab. The tab will be hidden from view by the cable tie strap.

16

Parts

Air Box & Inlet

REF #

PART #

DESCRIPTION

1

RCC60007

AIRBOX

2

TCC60008

MUD FLAP

3

HCSP0003

SCREW - PLASCREW

4

MCKGHO03

CLAMP, AIR BOOT TO AIR BOX

5

RCC60002

AIR FILTER

6

RCC60003

AIR FILTER CAGE

7

RCC60004

AIR FILTER WIRE

8

RCC60014

AIR BOOT, CARB TO AIRBOX

9

RCC60006

AIR FILTER CAP

10

ECC60006

REED ASSEMBLY

11

ECC60007

INLET MANIFOLD

12

HCBC0625

M6x25mm SOCKET HEAD CAP SCREW

13

MCC60003

CLAMP, MANIFOLD TO CARB

14

ZCC60021

GASKET REED

15

RCR60026

CARBURETOR 26mm MIKUNI

16

MCMUCL04

HOSE CLAMP 8mm

17

FCMU0026

FUEL LINE

18

ECC60014

REED PETALS - REPLACEMENT

Parts – Air Box & Inlet System

17

Parts – Bars and Controls

Bars and Controls

REF #

PART #

DESCRIPTION

1

FAMU0011

HANDLEBAR – ALUMINUM

2

TCMU0008

GRIPS (SET OF TWO)

3

FCMU0066

THROTTLE ASSEMBLY

4

FCPW0004

CABLE COVER

5

FCMU0021

THROTTLE COVER

6

RAC60001

THROTTLE CABLE

7

CAC60003

MASTER CYLINDER W/LEVER - CLUTCH

8

FCMU0033

KILL SWITCH ASSEMBLY

9

TKMU0404

BAR MOUNT KIT, SHORT (1 REQ’D) STANDARD

9A

TKMU0403

BAR MOUNT KIT, TALL (1 REQ’D)

10

HCBC1002

M10X50mm SOCKET HEAD CAP SCREW (2 REQ’D)

11

HCNL1001

M10 LOCK NUT

12

HCBH0820

M8 X 20 HEX HEAD BOLT (4 REQ’D)

13

BCC60057

BRAKE LEVER

14

BAC60008

BRAKE ASSY COMPLETE – FRONT CX65 ZL150

ACCESSORY

BKC60004

BRAKE - MASTER CYLINDER - REBUILD KIT - ZL150

ACCESSORY

CKC60001

CLUTCH - MASTER CYLINDER - REBUILD KIT

18

Parts - Carburetor

PILOT JET

MAIN JET

30

RCEX0030

190

RCMU0190

32.5

RCEX0032

195

RCMU0195

35

RCEX0035

200

RCMU0200

37.5

RCEX0037

205

RCMU0205

40

RCEX0040

210

RCMU0210

42.5

RCEX0042

215

RCMU0215

45

RCEX0045

220

RCMU0220

47.5

RCEX0047

225

RCMU0225

50

RCEX0050

230

RCMU0230

52.5

RCEX0052

235

RCMU0235

55

RCEX0055

240

RCMU0240

57.5

RCEX0057

250

RCMU1250

60

RCEX0060

260

RCMU1260

270

RCMU1270

280

RCMU1280

290

RCMU1290

300

RCMU1300

310

RCMU1310

Carburetor

REF. #

PART #

DESCRIPTION

1

RCR60026

CARBURETOR 26MM MIKUNI

2

RCC60017

FLOAT BOWL CHAMBER

4

RCMU0271

NEEDLE VALVE & SEAT ASSY

6

SEE BELOW

MAIN JET

9

RCEX0026

NEEDLE JET STOCK 5L14

10

SEE BELOW

PILOT JET

11

RCC60013

GASKET, FLOAT BOWL

15

RCEX0016

SPRING IDLE ADJUST SCREW

16

RCEX0015

IDLE ADJUST SCREW

17

ZCDCOR01

O’RING BOWL PLUG

18

RCEX0012

FLOAT BOWL SCREW

20

RCC60025

SLIDE

21

RCC60016

SLIDE STUFFER

22

RCMU0277

CLIP - NEEDLE

24

RCEX0005

ADJUSTER

25

RCEX0006

LOCK NUT

27

RCC60026

CHOKE ASSY

33

RCEX0013

AIR ADJUSTING SCREW

34

RCEX0014

SPRING – AIR ADJUST SCREW

NOT

SHOWN

RCMU0415

CABLE ADJUSTER CAP (RUBBER)

RCC60021

AIR SCREW O-RING

RCC60020

AIR SCREW WASHER

19

Parts – Clutch – Master Cylinder

Clutch – Master Cylinder

REF#

PART #

DESCRIPTION

1

CAC60003

ASSEMBLY - CLUTCH MASTER CYLINDER (M/C) CX65

2

BKC60008

CAP & BLADDER KIT ZL150

CAP

BLADDER

M3-0.5 X 6mm LONG PHILLIPS SCREW (2)

3

BCC60058

CLAMP ZL150

4

HCBC0601

M6-1.0 X 25mm LONG SOCKET HEAD CAP SCREW

5

BKC60007

PIVOT BOLT KIT ZL150

BOLT – PIVOT ZL150

CLIP – PIVOT BOLTZL150

6

BCC60055

BOOT MASTER CYLINDER

7

CKC60001

REBUILD KIT - MASTER CYLINDER

PISTON

SEAL FRONT

SEAL REAR

SPRING

CLIP

SPACER

8

BCC60057

LEVER ZL150

9

BKC60005

KIT – LEVER FREEPLAY ADJUSTMENT

SPRING - BALL DETENT

BALL - DETENT

DIAL - ADJUSTMENT

SCREW – SET

PLUNGER - BALL END - ADJUSTABLE

10

BKC60006

KIT - LEVER RETURN STOP POSITION - BOLT & SPRING KIT

11

BCMU0017

FERRULE – COMPRESSION FITTING

12

BCMU0020

FITTING – THREADED CLUTCH LINE END

13

CCC60010

LINE – CLUTCH - REPLACEMENT KIT CX65

FERRULE – COMPRESSION FITTING (2 INCLUDED)

CLUTCH - LINE

NOT SHOWN

BCC60017

BOOT – CLUTCH MASTER CYLINDER PISTON COVER

Loading...

Loading...