Page 1

Vero Series™ Wheel Balancer

Calibration Instructions

COATS, Inc. • Hennessy Industries • 1601 J.P. Hennessy Drive, LaVergne, TN 37086

(800) 688-6359 • (615) 641-7533 • (615) 641-5104 FAX • www.ammcoats.com

Calibration Wheel Set Up

For best calibration results, use a 16-inch steel tire/

wheel assembly on the balancer. A balanced tire/wheel

assembly is required.

What is needed:

• 16-inch steel wheel in good condition

• 16-inch tire in good condition

• Tape Weights

Note: To make calibration easier, use tape weights

and place them at the Tape 1 (T1) and Tape 2 (T2)

positions on the steel wheel. This keeps the flange

positions free for placement of the 4-ounce calibration

weight.

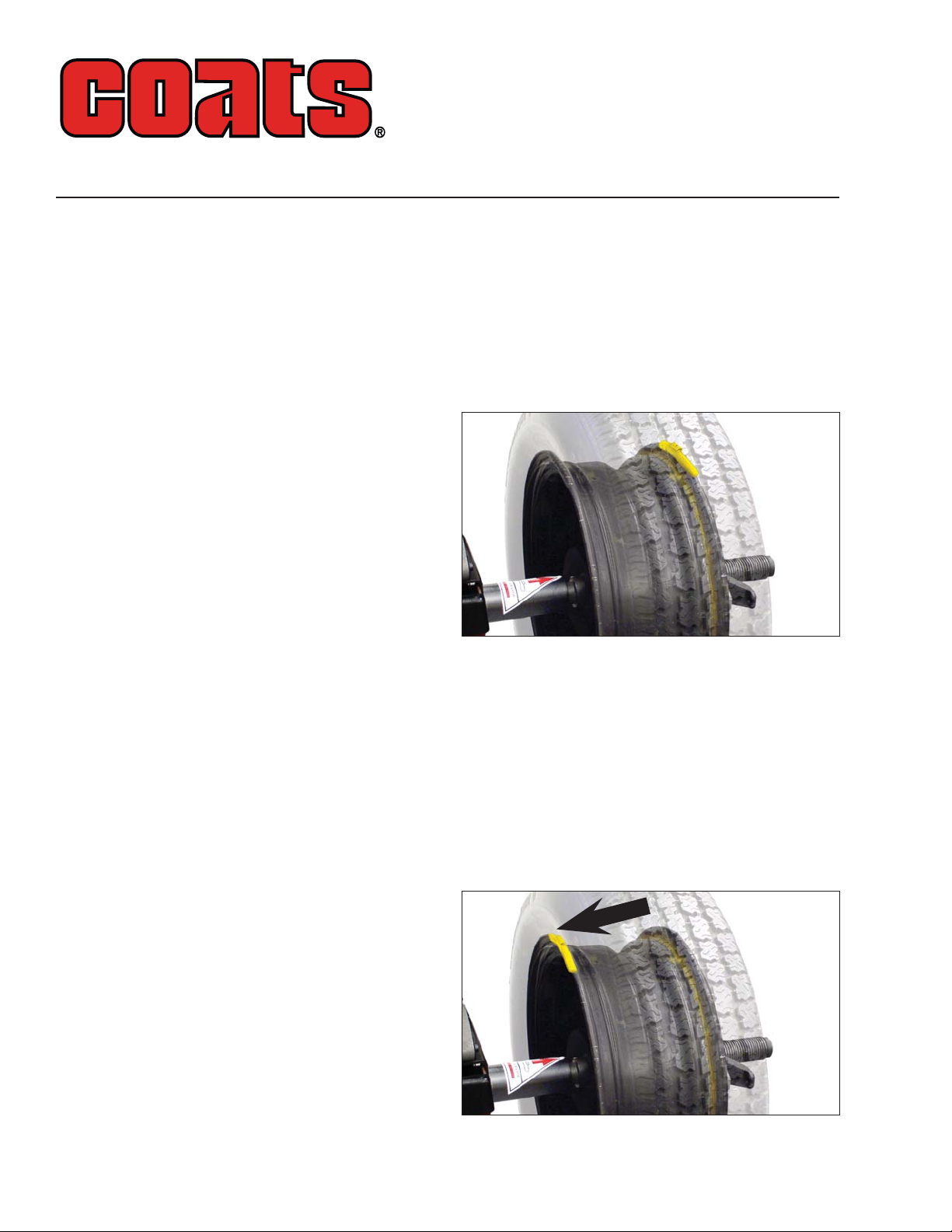

Helpful Hint: Take a paint pen and mark the tire as

shown in the provided photo. The mark should be as

accurate as possible — from Inboard to Outboard. Position on the wheel does not matter as long as the marks

match at the same location on each side of the wheel.

If you have marked the wheel (as noted above), follow

this procedure to make the 4-ounce calibration weight

placement easy and accurate.

1. Turn the machine OFF. Mount tire/wheel assembly

on the balancer and rotate the wheel so that the marks

you just added are at the 12 o’clock position. Hold the

wheel in this position and turn the balancer ON. The

balancer will be indexed to this wheel position for calibration and weight placement.

Machine Calibration

1. Press SETTINGS icon and then select MACHINE

CALIBRATION.

2. Press continue.

3. Enter the D dimension (include decimal point,

example: 16.0 for a 16-inch wheel). Press ENTER.

4. Lower the hood and press SPIN.

5. After spin, raise the hood. Attach 4-ounce calibra-

tion weight to the outside flange at top-dead-center.

Figure 1 - Calibration Weight On Outside Flange At Top-DeadCenter

6. Lower the hood and press SPIN

Important: It is critical that the inner weight be

placed accurately to achieve proper calibration. If the

calibration weight is not moved from the outside flange

directly across to the inside flange, an inner weight

placement error will occur. To correct, follow the balancer instructions.

7. After spin, raise the hood. Move the 4-ounce

calibration weight directly across and attach it on the

inside flange at top-dead-center.

Figure 2 - Calibration Weight Moved (Directly Across) To

Inside Flange

85609633 00 06/14 © COPYRIGHT 2014 ALL RIGHTS RESERVED PRINTED IN U.S.A.

Page 2

8. Lower the hood and press SPIN.

Note: Rotate laser dot toward inner flange

9. After spin, raise the hood. Rotate wheel to line up/

center of 4-ounce calibration weight with laser dot. Hold

position while pressing NEXT.

Note: If desired, rotate laser dot toward inner flange.

10. Press NEXT; then press EXIT.

11. Bring the tip edge of the arm precisely to the

outer edge of the faceplate and hold it there (through

step 12) while pressing the NEXT. (If necessary to reach

the faceplate accurately, loosen the calibration wheel

temporarily.)

12. With arm still at the edge of the faceplate, enter

the A dimension (include decimal point) read off the arm

gauge; see figure 3. Press ENTER.

Hold Arm

Tip Edge

At Edge Of

Faceplate

Enter A

Value

Shown On

Arm Gauge

Figure 3 - While Holding Arm at Faceplate Edge, Enter A

13. Move arm to its home position and press NEXT.

14. Move arm to clip-on weight location on rim

flange and hold it there (through step 16). Wait for voltage reading to stabilize, then press NEXT.

15. With arm still at clip-on weight location, enter

the D dimension (16.0 for a 16-inch wheel) that is the

diameter of the tire. Press EXIT.

16. While still holding the arm at the wheel’s clip-on

weight location, enter the A dimension (include decimal

point) read off the arm gauge. Press ENTER

17. Return the arm to home position; calibration is

complete. Press EXIT. Press STOP & EXIT to go back to

the main screen.

85609633 00 06/14 2 of 2 © COPYRIGHT 2014 ALL RIGHTS RESERVED PRINTED IN U.S.A.

Loading...

Loading...