Page 1

1601 J. P. Hennessy Drive, LaVergne, TN USA 37086-3565 615/641-7533 800/688-6359 Manual Part No.: 8107758 01

HENNESSY INDUSTRIES INC. Manufacturer of AMMCO

®

, COATS®and BADA®Automotive Service Equipment and Tools. Revision: 07/02

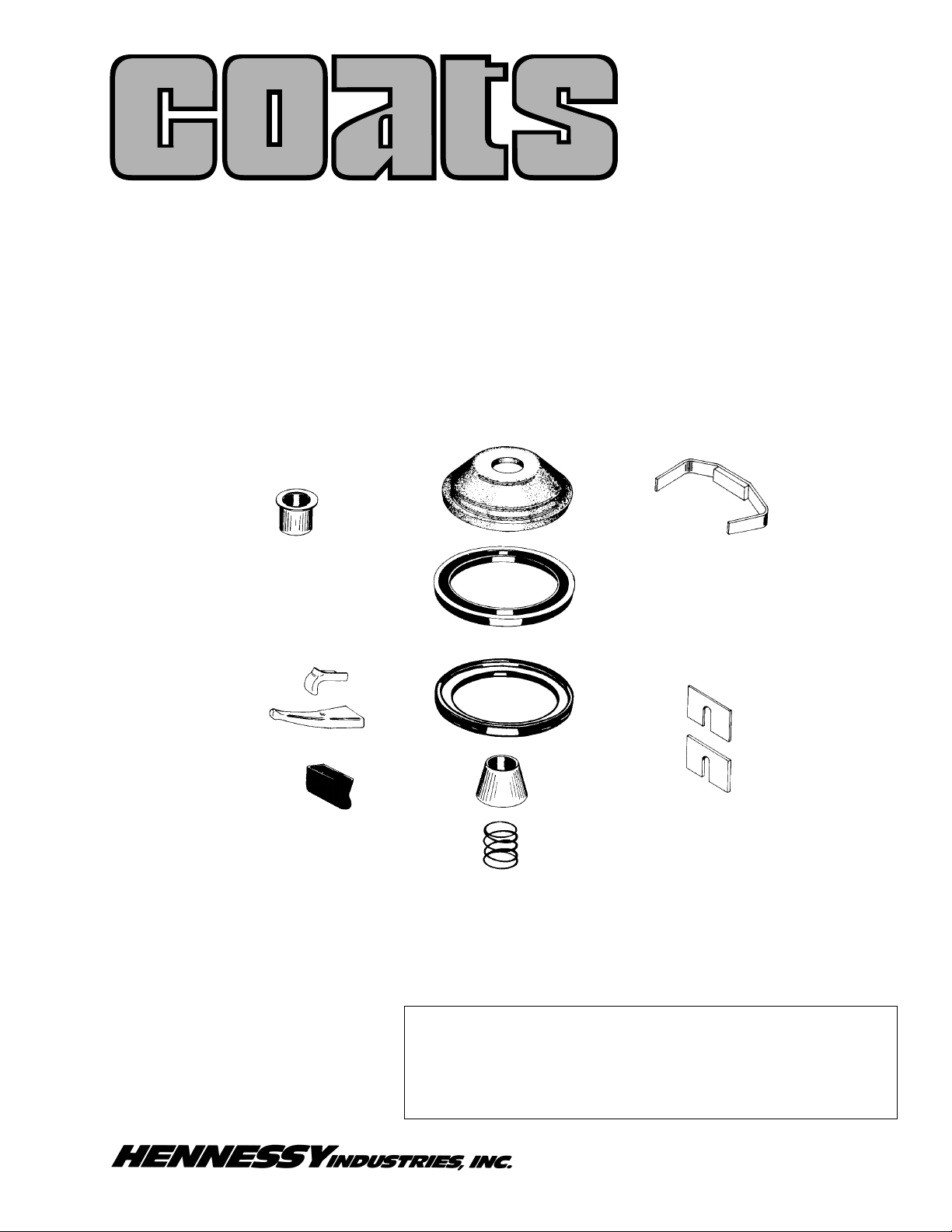

Speed-Mag Adapter

Set for Center Post

Tire Changers

®

Operating Instructions

with Parts Identification

READ these instructions before placing unit in

service KEEP these and other materials delivered

with the unit in a binder near the machine for

ease of reference by supervisors and operators.

Page 2

Model Usage

This adapter set is for use with 4040SA, 4040A,

3040A, 3030A, 2020, 2020A, 1010 (serial #153601 and

up), and 1010A (serial #12025 and up).

Before You Begin

When working on custom wheels, take your time and

use extreme care in all tire servicing operations to prevent damaging these costly wheels. Read and follow all

the instructions and acquaint yourself with this adapter

before use.

Adapter Usage Instructions

1. Before servicing aluminum or magnesium wheels

with a large rim flange, install the 3/16-inch shim to prevent the lower bead loosener from catching on, or damaging the wheel.

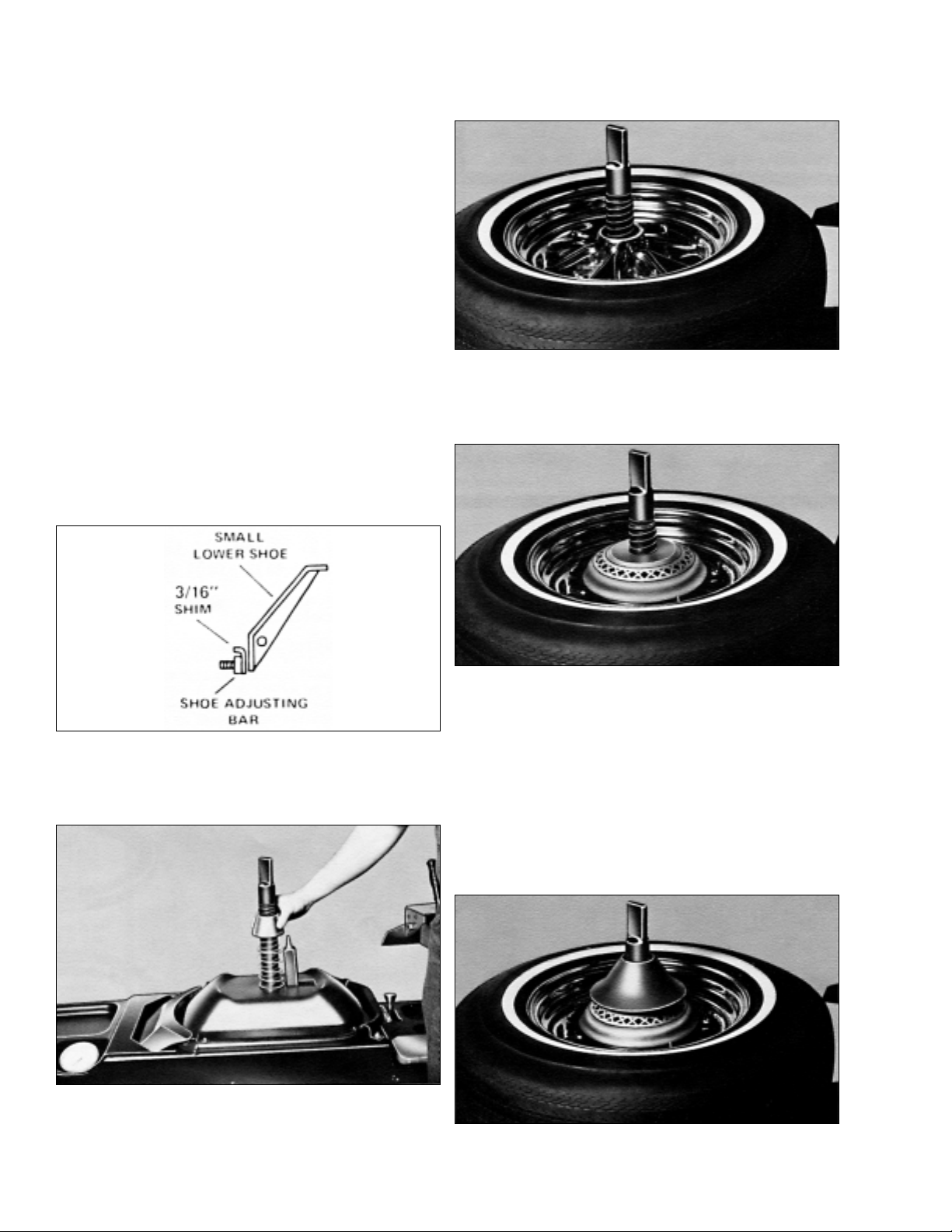

To install 3/16-inch Shim: Depress the foot pedal until

the cylinder reaches the top of its stroke. Lay the lower

bead loosener shoe back and place the shim between

the small lower shoe and the shoe adjusting bar (figure

1). When loosening beads on wide flanged rims, watch

the small lower shoe and make certain it clears the rim

flange. If it does not, use the 1/4-inch shim or combine

both shims. Do not use shims on steel wheels.

Figure 1 - Installation of Shim

2. Place the spring and positioning cone over the center post onto the table. The small end of the cone

points upward (figure 2).

Figure 2 - Place Spring and Positioning Cone on Post

3. Place the wheel over the center post onto the

table top, guiding the positioning pin into a lug hole. Be

sure the valve stem is in front of the operator.

Figure 3 - Place Wheel on Table Top

4. Place the adapter plate over the center post onto

the wheel with the large side (cushion side) down.

Figure 4 - Place Adapter Plate Over Wheel

Note: On some high center hub wheels where the

adapter assembly touches the hub of the wheel, the

spacer cushion must be used. Place the cushion on the

wheel, ledge side up, and place the adapter plate on top

of the cushion.

5. Turn the tire changer hold down cone over and

thread it onto the center post. Tighten it down securely

onto the adapter plate. Be sure the hold down cone is

tight.

Figure 5 - Thread Hold Down Cone Onto Post and Tighten

Page 3

6. On models 1010, 1010A, 2020, 2020A, 3030A and

3040A, install the black upper bead loosener protector

on the upper bead loosener nose to protect the wheel

from possible marring by the bead loosener guide.

Place the upper bead loosener shoe on the tire next to,

but not on, the rim. Be sure the top bead loosener

guide is engaged on the rim (figure 6). Depress the

foot pedal until both bead looseners complete their full

strokes. If the top bead is not completely loosened,

release the foot pedal until the machine completes the

full return cycle, then

depress the foot pedal

again. The ratchet effect of

the upper bead loosener will

deliver a deeper stroke.

Important: Use the second stroke only if the upper

bead is not completely loosened by the first stroke.

Figure 6 - Install Protector on Upper Bead Loosener

7. Check detent control knob for proper setting.

Forward is used for all tire and rim combinations

except 15-inch x 4-inch - 4-1/2-inch, 16-inch x 5-inch - 51/2-inch, and 17.5-inch x 5-1/2-inch - 6-1/2-inch.

Relocate detent knob by pushing it down and moving

forward or backward to the proper setting.

Figure 7 - Position Detent Knob

8. Install the combination tool end protectors.

Figure 8 - Install Tool Protectors

9. Demount the tire in the usual manner. Make certain the plastic protector is positioned to completely

cover the end of the tool. Always apply plenty of rubber lubricant to tire beads.

Figure 9 - Demount the Tire

10. Mount the tire in the usual manner. Make certain the plastic protector is positioned to completely

cover the end of the tool. Always apply plenty of rubber lubricant to tire beads.

Figure 10 - Mount the Tire

Styled Steel Wheels

1. Place wheel over center post onto table top.

Guide the positioning pin into a lug hole.

2. Slide styled steel wheel adapter tube over post

and into wheel center hole (flange up).

Figure 11 - Install Styled Steel Wheel Adpater Flange Up

3. Invert the hold down cone and tighten the assembly to the table top.

Figure 12 - Install Hold Down Cone

4. Mount and demount tire as usual.

Page 4

Small Lower Bead Loosener Shoe

Adjustment

Important: Before attempting to loosen beads, make

sure small lower bead loosener shoe is in adjustment.

1. Clamp a 13-inch, 14-inch, or 15-inch wheel, with-

out tire, on the table top.

2. Depress the foot pedal and cycle the bead

loosener shoe through to the top of its stroke. Watch

closely and inspect the shoe/wheel clearance.

Clearance between the shoe and the wheel rim flange

should be approximately 1/16-inch to 1/8-inch at all

points across the shoe edge. If the clearance is out of

range evenly across the shoe, it can be adjusted. If the

clearance is uneven across the shoe, it has been damaged and must be straightened or replaced.

3. Adjust shoe by loosening the 3/8-inch c 1-1/4-inch

self-tapping bolt located just below the shoes on the

end of the power arm (figure 13). Add or remove shims

turning the small lower shoe into adjustment. Addition

of shims will increase the clearance, and removal of

shims will decrease the clearance. Additional shims

are available.

4. Retighten the self tapping bolt and recheck shoe

adjustment.

Tire failure under pressure can be hazardous. Inspect the tire carefully for wear or

defects before seating or inflating. Never

use pressure beyond the tire industry recommendation of 40 PSI. Always lubricate

with approved lubricant and never damage

beads. Keep hands and entire body back

from inflating or inflated tire.

Special Safety Instructions

1. Never stand with any part of your body over the

tire during inflation process.

2. Before starting, release all air from the tire.

3. Place wheel on the table top with the narrow,

mounting side of the wheel up.

4. Position tire with valve stem directly in front of

operator.

5. Hand tighten hold down cone or adapter before

breaking beads, mounting, or demounting.

6. Use approved lubricant on all beads before seat-

ing, mounting, or demounting.

7. On units with Air-flate, depress inflation pedal only

when seating or inflating the tire.

8. Loosen hold down cone on full turn immediately

after obtaining initial bead seal and before attempting

further inflation.

9. To seat beads, use a small amount of air intermittently. Never exceed tire industry recommendation of

40PSI.

10. During inflation, observe pressure frequently

and avoid distraction to prevent over inflation.

11. When using a bead expander band, do not

exceed 5 PSI in the tire when the band is in place.

This instruction booklet is intended to supplement your tire changer operator’s manual. It is not intended to replace it. Always

follow the instructions and safety information provided with your machine to assure

safe operation and prevent accidents and

injuries.

8107758 01 07/02 © COPYRIGHT 1995 HENNESSY INDUSTRIES AND COATS ALL RIGHTS RESERVED PRINTED IN U.S.A.

Parts Identification

Item Part No. Description

1 8106568 Boot Kit, Set of 10 and 2

2 8106144 Adapter Tube, Styled Steel Wheel

3 8102803 Shim, 3/16", Black

4 8102927 Shim, 1/4", Red

5 8102789 Adapter, Eldorado/Toronado

6 8107641 Adapter Plate

7 8107634 Cushion

8 8107636 Positioning Cone

9 8107637 Spring

10 8107734 Spacer Cushion

11 8107689 Hold Down Assembly

12 8107760 Instructions Spacer

DANGER

CAUTION

Loading...

Loading...