Page 1

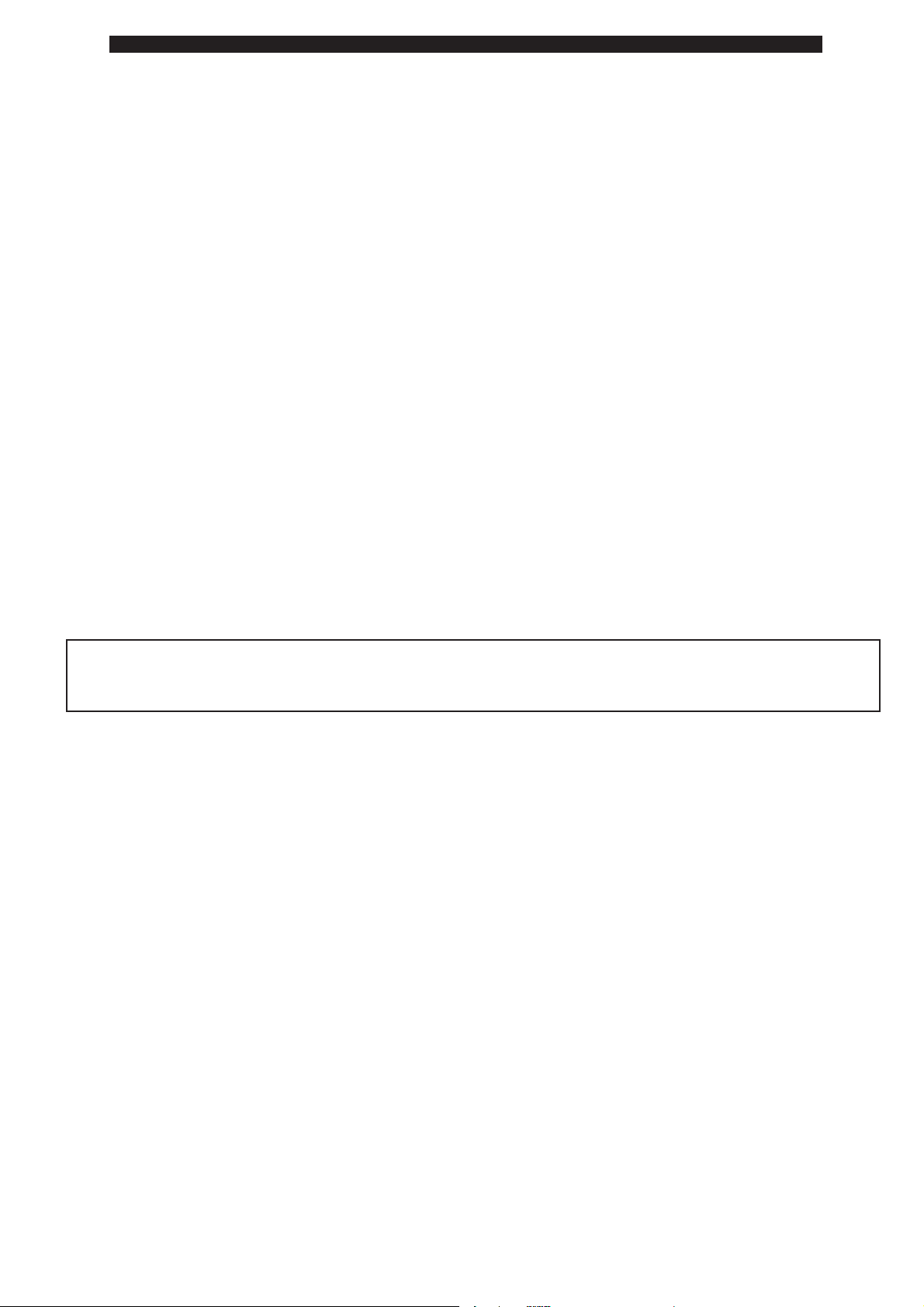

For servicing single piece automotive and

most light truck tire/wheel assemblies.

Safety Instructions

Set-up Instructions

Operation Instructions

Maintenance Instructions

READ these instructions before placing unit in

service. KEEP these and other materials delivered

with the unit in a binder near the machine for ease

of reference by supervisors and operators.

1601 J. P. Hennessy Drive, LaVergne, TN USA 37086-3565 615/641-7533 800/688/6359 www.ammcoats.com Manual Part No.: 85606719 02

HENNESSY INDUSTRIES INC. Manufacturer of AMMCO

®

, COATS® and BADA® Automotive Service Equipment and Tools. Revision: 11/13

Page 2

Operation Manual - COATS PRO GUARD PLUS - 2

Page 3

INDEX

INTRODUCTION.....................................................................................................................................................5

DETAILS OF THE TIRE CHANGER.......................................................................................................................5

1 .0_General information.......................................................................................................................................6

2.0_General safety instructions............................................................................................................................6

2.1_Safety instructions................................................................................................................................7

3.0_Safety devices.................................................................................................................................................8

4.0_Safety notices and decals..............................................................................................................................8

4.1_Safety decals (p/n 82031373)..............................................................................................................9

5.0_Remember R.I.M............................................................................................................................................10

6.0_Principle operating parts.............................................................................................................................11

7.0_Description of the machine’s controls........................................................................................................12

7.1_Control overview.................................................................................................................................13

8.0_Transport.......................................................................................................................................................15

9.0_Unpacking......................................................................................................................................................15

10.0_Installation...................................................................................................................................................16

10.1_Space required to position the machine..........................................................................................16

10.2_Positioning.......................................................................................................................................16

10.3_Commissioning................................................................................................................................17

11.0_Operational test...........................................................................................................................................18

12.0_Identifying and checking the rim and tire.................................................................................................19

13.0_Positioning the valve..................................................................................................................................20

14.0_Tire classifi cation.......................................................................................................................................20

15.0_Tire lift.........................................................................................................................................................21

16.0_Wheel clamping..........................................................................................................................................22

16.1_Wheel locking..................................................................................................................................22

16.2_Pneumatic locking system (optional)...............................................................................................22

17.0_Bead loosening...........................................................................................................................................23

17.1_Upper bead loosening......................................................................................................................23

17.2_Lower bead loosening......................................................................................................................24

17.3_Lower bead loosening on special wheels........................................................................................25

18.0_Demounting tire..........................................................................................................................................26

18.1_Upper bead demounting..................................................................................................................26

18.2_Lower bead demounting..................................................................................................................27

19.0_Mounting tire...............................................................................................................................................28

19.1_Lower bead mounting......................................................................................................................28

19.2_Upper bead mounting......................................................................................................................28

19.3_UHP (low profi le) and RUN-FLAT (self-supporting) tires mounting..................................................30

Operation Manual - COATS PRO GUARD PLUS - 3

Page 4

20.0_Infl ation........................................................................................................................................................31

21.0_Standard accessories................................................................................................................................32

21.1_Optional accessories.......................................................................................................................32

22.0_Repositioning..............................................................................................................................................37

23.0_Storage........................................................................................................................................................37

24.0_Scrapping....................................................................................................................................................37

25 .0_Maintenance...............................................................................................................................................37

25 .1_General warnings............................................................................................................................37

25 .2_Routine maintenance......................................................................................................................38

26.0_Oil treatment................................................................................................................................................39

26.1_General precautions.........................................................................................................................39

26.2_First Aid instructions.........................................................................................................................39

26.3_Disposing of old oil...........................................................................................................................39

26.4_Oil spillages or leakages..................................................................................................................39

27.0_Technical specifi cations............................................................................................................................40

Operation Manual - COATS PRO GUARD PLUS - 4

Page 5

INTRODUCTION

We thank you for purchasing one of our tire changers, which are particularly suitable for mounting/demounting convetional, low profi led and RUN-FLAT tires.

The machine is manufactured using the best of quality principles.

To ensure correct operation and long life of the machine, read and follow these instructions.

DETAILS OF THE TIRE CHANGER

When contacting our Service Department or when requesting spare parts, please provide a complete description of the

tire changer model and its Serial Number.

For the sake of convenience, the details of your tire changer are written in the name plate placed on the back of it.

If the details given in this manual do not match those written in the nameplate of your tire changer, those written on the

nameplate are the ones to be considered as valid.

NOTE: some of the illustrations shown in this manual have been taken from pictures of prototypes.

As a consequence, some parts or components of standard production machines may differ from what is illustrated.

Operation Manual - COATS PRO GUARD PLUS - 5

Page 6

1.0_GENERAL INFORMATION

The tire changer is designed to demount and mount tires of passengers cars and light commercial vehicles with rims

from 10” to 34” (254 - 863 mm) and maximum tire diameter of 47” (1200 mm).

The tire changer is designed to demount and mount conventional tires, as well as new generation types, such as “selfsupporting” RUN-FLAT and low profi led tires (UHP) with steel and/or light alloy rims, even of considerable dimensions.

The tire changer is NOT suitable for demounting infl ated or dirty tires, to straighten rims or to remove wheel bead wires.

As a consequence, all these procedures are FORBIDDEN.

.

2.0_GENERAL SAFETY INSTRUCTIONS

The tire changer is to be used exclusively by qualifi ed and authorised personnel.

A qualifi ed operator is someone who has fully understood the instructions described in the use and maintenance manual

supplied by the manufacturer, who has been specifi cally trained and who is aware of safety standards at the workplace.

Those in charge of using the machine shall not be under the infl uence of drugs, alcohol or other substances, which

could compromise their physical and mental work capabilities.

For greater safety , operators shall wear health & safety footwear, gloves, protection goggles and shall NOT wear any

form of clothing that could get caught up or restrict the operator’s movements.

The operator must be able to:

- read and understand the danger warnings.

- understand the characteristics of the machine.

- keep unauthorised people away from the work area.

- make sure the machine is started in full observance of all the applicable safety standards and regulations.

- make sure all operators are familiar with the machine and how to use it safely and correctly.

- avoid touching moving parts or pressurised parts without fi rst disconnecting the machine from the electrical and

air power supply.

- read and ensure full comprehension of the use and maintenance manual to be able to use the machine correctly and

safely.

- keep the use and maintenance manual with care in an easily accessible place, so that it can be consulted whenever

needed.

The tire changer may only and exclusively be used by expert, specifi cally trained and

authorised personnel.

- T ampering or modifi cations to the equipment that are not authorised in advance by the manufacturer, relieve the latter

from all forms of liability as regards to damages deriving from or referable to such actions.

- Removal or tampering with the safety devices provides grounds to immediately cancel the warranty and involves

violation of State and Federal OSHA regulations and codes.

- The tire changer is equipped with informative and warning decals, which are designed and produced to last in time.

If they should deteriorate, user may request replacement decals.

Operation Manual - COATS PRO GUARD PLUS - 6

Page 7

2.1_Safety Instructions

Owner’s Responsibility

To maintain machine and user safety, the responsibility of the owner is to read and follow these instructions:

•Follow all installation instructions.

•Make sure installation conforms to all applicable Local, State, and Federal Codes, Rules, and Regulations; such as

State and Federal OSHA Regulations and Electrical Codes.

•Carefully check the unit for correct initial function.

•Read and follow the safety instructions. Keep them readily available for machine operators.

•Make certain all operators are properly trained,know how to safely and correctly operate the unit,and are properly supervised.

•Allow unit operation only with all parts in place and operating safely.

•Carefully inspect the unit on a regular basis and perform all maintenance as required.

•Service and maintain the unit only with authorizedor approved replacement parts.

•Keep all instructions permanently with the unit and all decals/labels/notices on the unit clean and visible.

•Do not override safety features.

Operator Protective Equipment

Personal protective equipment helps make tire servicing safer. However , equipment does not take the place of safe operating practices. Always wear durablework clothing during tire service activity. Loose fi tting clothing should be avoided.

Tight fi tting leather glove are recommended to protect operator’s hands when handling worn tires and wheels. Sturdy

leather workshoes with steel toes and oil resistant soles should be used by tire service personnel to help prevent injury in

typical shop activities. Eye protection is essential during tire service activity . Safety glasses with sideshields, goggles, or

face shields are acceptable. Backbelts provide support during lifting activities and are also helpful in providing operator

protection.Consideration should also be given to the use of hearing protection if tire service activity is performed in an

enclosed area, or if noise levels are high.

Defi nitions of Hazard Levels

Identify the hazard levels used in this manual with thefollowing defi nitions and signal words:

DANGER

Watch for this symbol:

DANGER

It Means: Immediate hazards, which will result in severe personal injury or death.

WARNING

Watch for this symbol:

WARNING

It Means: Hazards or unsafe practices, which could result in severe personal injury or death.

CAUTION

Watch for this symbol:

CAUTION

It Means: Hazards or unsafe practices, which may result in minor personal injury or product or property damage.

Watch for this symbol! It means BE ALERT! Your safety, or the safety of others, is involved!

Operation Manual - COATS PRO GUARD PLUS - 7

Page 8

3.0_SAFETY DEVICES

The tire changer is equipped with safety devices that are designed to guarantee the safety of the machine operator:

- Pneumatic safety valve, arranged inside the machine that prevents the pressure from exceeding 58 PSI (4 bar) during

infl ation.

- Pressure regulator and gauge that limits the maximum pressure of the circuit to 145 PSI (10 bar).

- Maximum tank pressure valve, fi tted on the tank, to prevent the maximum pneumatic pressure from exceeding 160

PSI (11 bar) (optional auxiliary bead seater)

- Removal or tampering with the safety devices provides grounds to immediately cancel the warranty and

represents a breach of State and Federal OSHA regulations and codes.

4.0_SAFETY NOTICES AND DECALS

WARNING

Failure to follow danger, warning, and caution instructions may lead to serious personal injury or death to operator orbystander or damage to property. Do not operate this machine until you read and understand all the dangers, warnings

and cautions in this manual. For additional copies of either, or further information, contact:

Hennessy Industries, Inc.

1601 J.P. Hennessy Drive

LaVergne, TN 37086-3565

(615) 641-7533 or (800) 688-6359

www.ammcoats.com

For additional information contact:

Rubber Manufacturers Association

1400 K Street N. W.

Washington, DC 20005

(202) 682-4800

Tire Guides, Inc.

The Tire Information Center

1101-6 South Rogers Circle

Boca Raton, FL 33487-2795

(561) 997-9229

www.tireguides.com

Operation Manual - COATS PRO GUARD PLUS - 8

Page 9

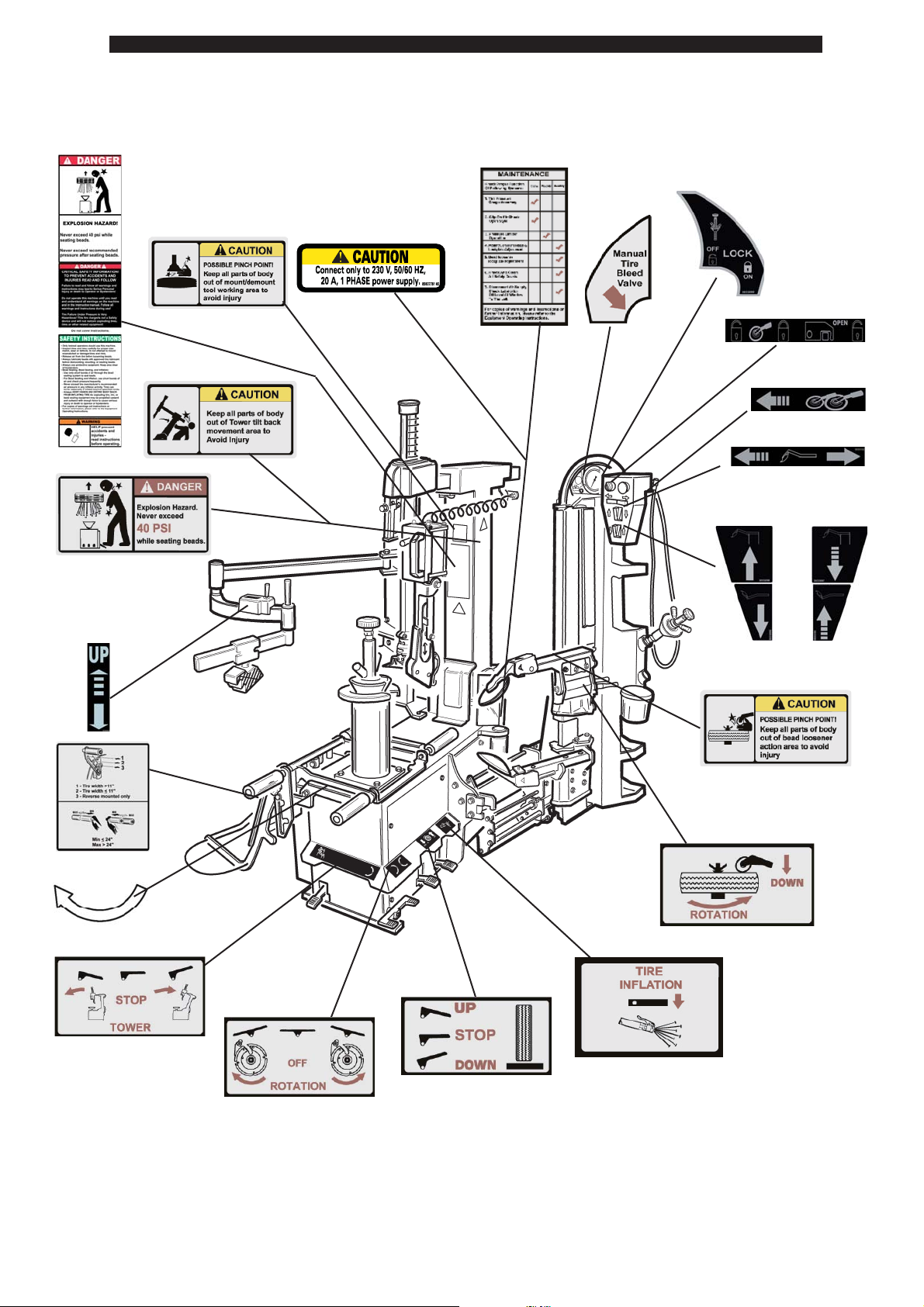

4.1_Safety Decals (p/n 82031373)

Operation Manual - COATS PRO GUARD PLUS - 9

Page 10

5.0_REMEMBER R.I.M.

Three Simple Steps To Help Keep Shops Safe

READ INSPECT MOUNT

R.I.M. is a training program developed by HennessyIndustries to help keep tire technicians safe. By

following the basic principles of R.I.M., technicians can avoid situations that can cause catastrophic

accidents like tire explosions.

R.I.M.stands for read, inspect, and mount:

Read the tire size on a new tire before mounting to make sure it is the proper size for the wheel.

Inspect the wheel for cracks, rust, and or other damage that could cause an unsafe situation.

Mount the tire safely, making sure not to put any part of your body over the tire during infl ation.

The most serious of possible accidents is a tire explosion. This is often caused by a tire/rim

mismatch.

If a tire explodes on a tire changer, pressure causes it to fl y straight up at tremendous speed. If a

technician is standing over the tire, he can be seriously injured or killed.

Hennessy’s R.I.M. program allows the technician to avoid situations that can cause tire explosions

and other accidents. The full program, including training videos, brochures, posters, and other materials, is available from Coats distributors nationwide.

For more details, contact your Coats distributor or e-mail us.

Operation Manual - COATS PRO GUARD PLUS - 10

Page 11

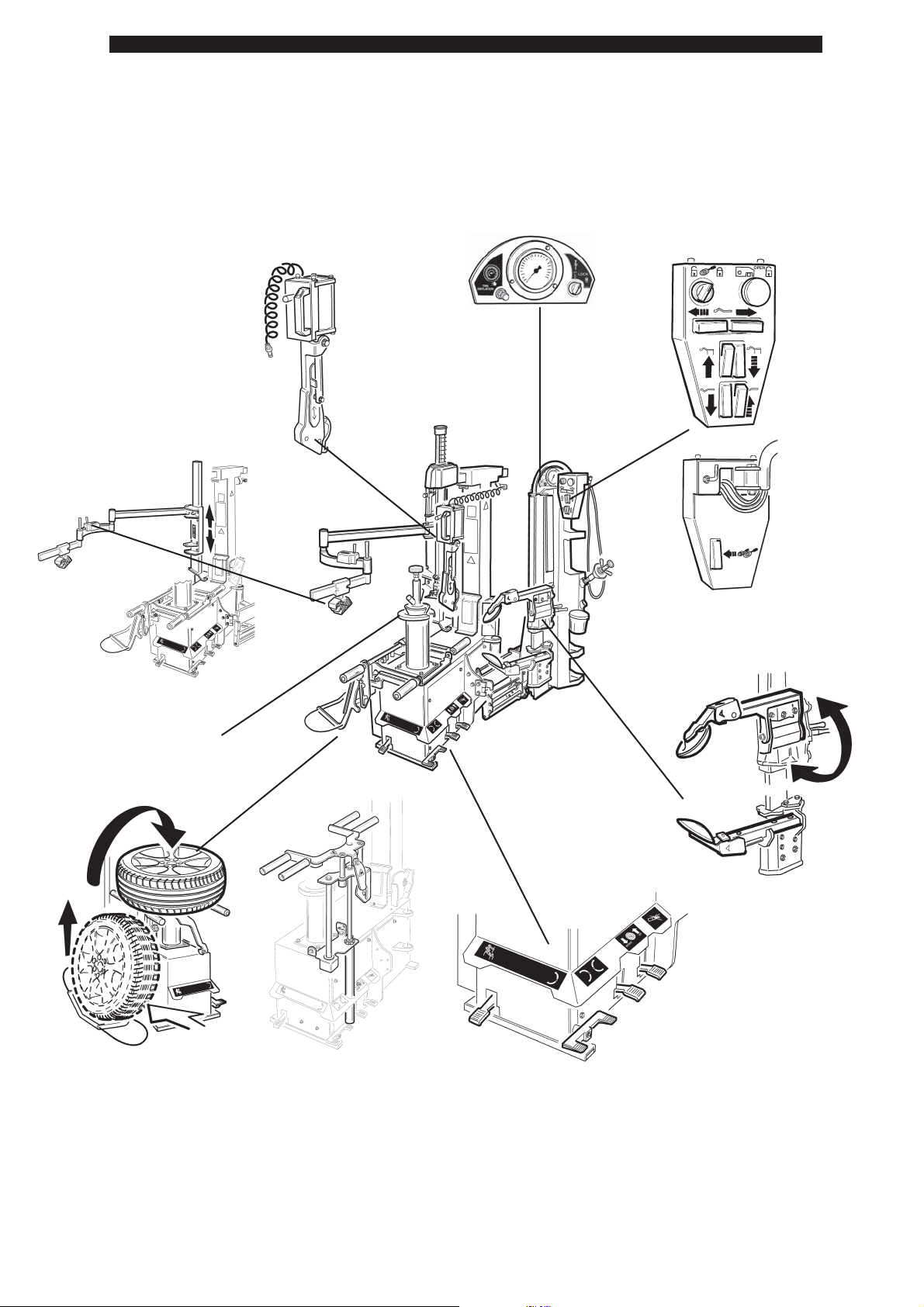

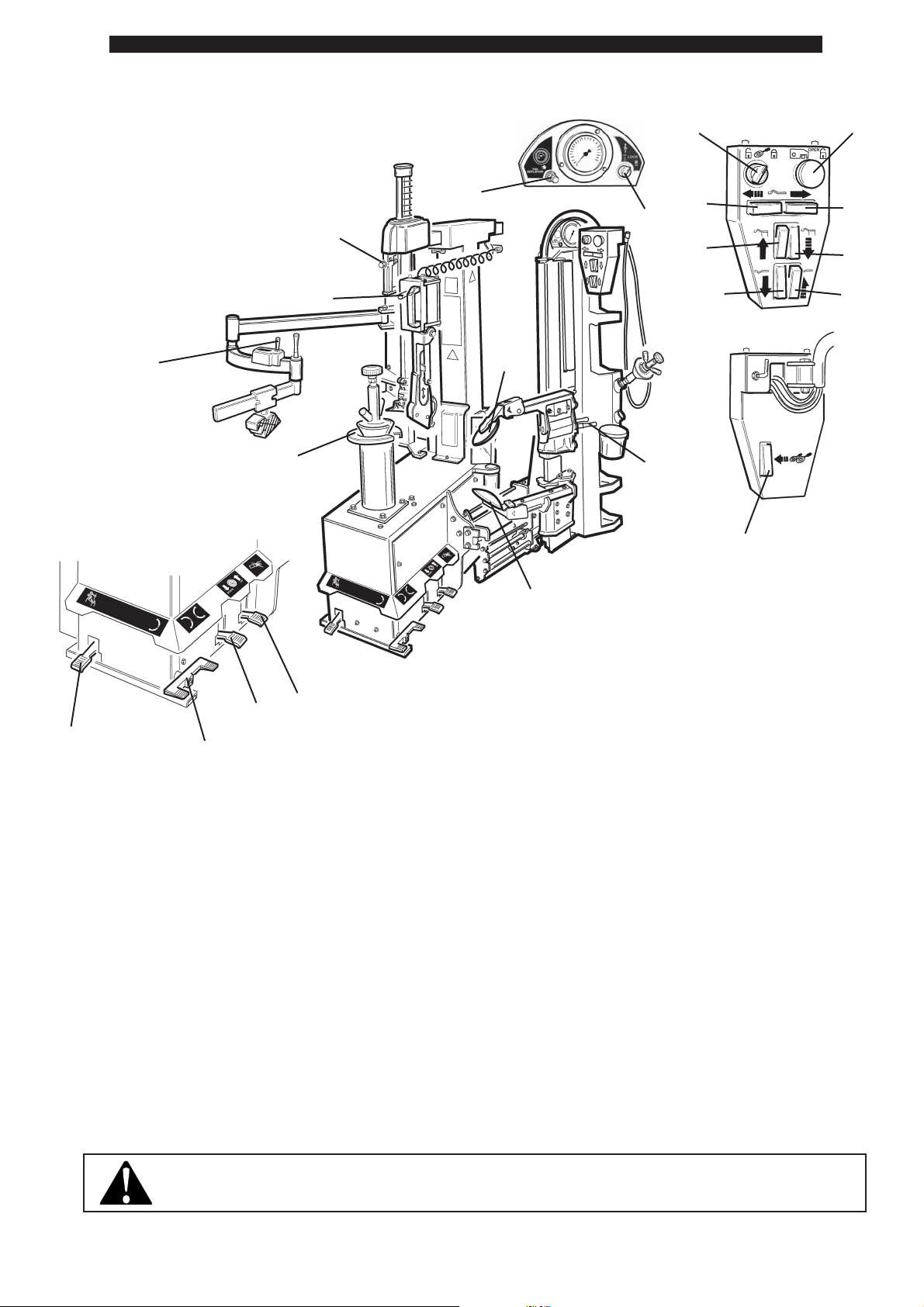

6.0_PRINCIPLE OPERATING PARTS

Leverless Bead Lifter

Helper Arm

Infl ation

Control panel

Spindle fl ange

Bead loosening disc

Pedal controlsLift

Operation Manual - COATS PRO GUARD PLUS - 11

Page 12

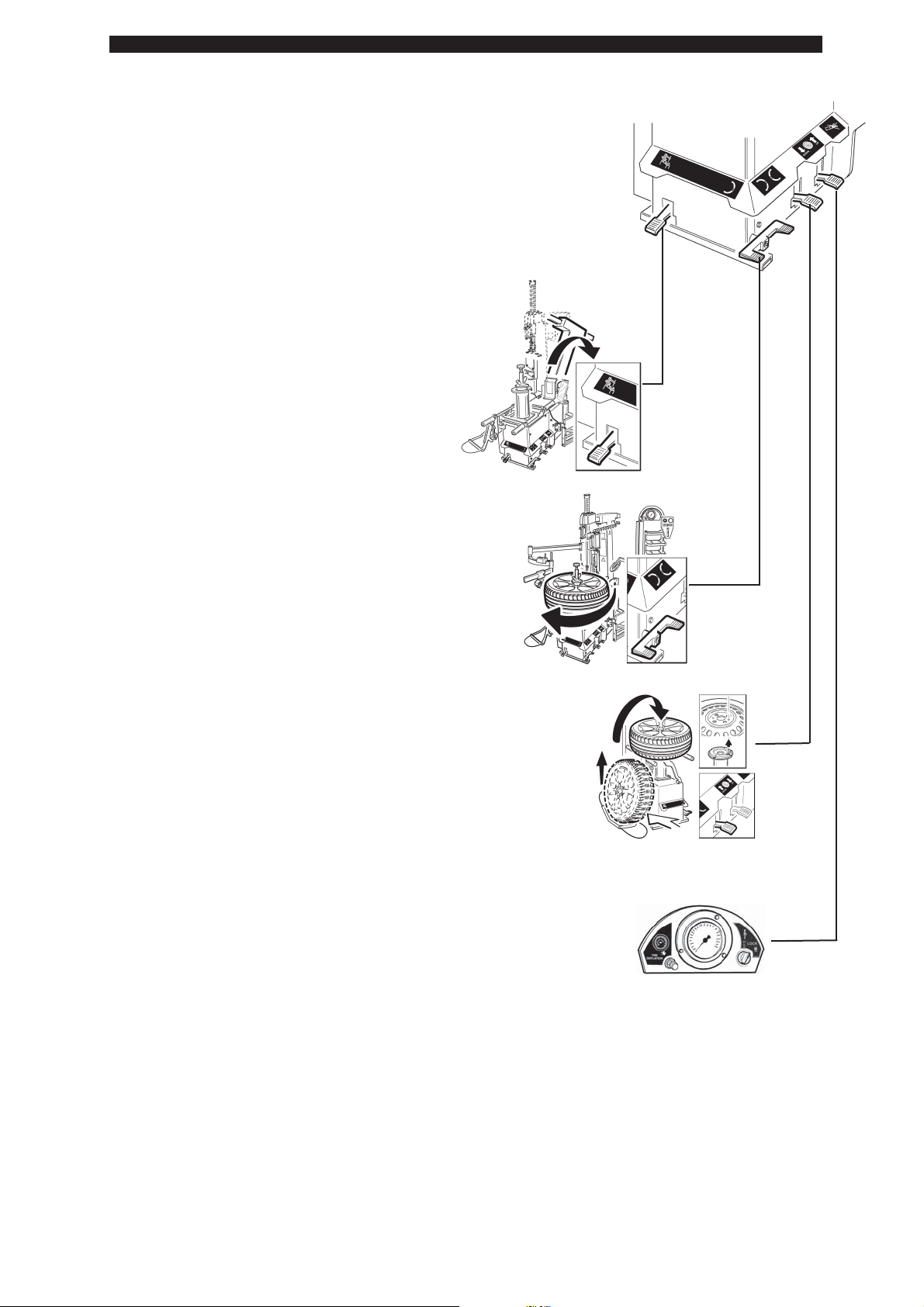

7.0_DESCRIPTION OF THE MACHINE’S CONTROLS

O

The pedal control (L) is used to move the vertical arm

out of the working position, once the tire has been demounted, or in the working position while mounting and

demounting the tire.

The pedal control (M) is used to turn the spindle fl ange

clockwise, (low and rotation mode) and counter-clockwise

(low rotation mode).

L

N

M

The pedal control (N) is used to lift the tire off the ground to clamp it on the

fl ange and vice versa to lower it back down to the ground after mounting

it. Press the pedal to raise the lift, push the pedal upwards to lower the lift.

The pedal control (O) is used to infl ate the tire. Connect the infl ation hose to the

pneumatic valve and press the pedal to infl ate; to reduce the tire’s pressure, press

the button at the side of the gauge. Before infl ating, read the instruction ma-

nual of the vehicle fi rst to fi nd out the recommended pressure of the tires.

Operation Manual - COATS PRO GUARD PLUS - 12

Page 13

7.1_Control Overview

67

17

15

20

19

14

16

18

22

21

8

10

12

9

11

13

5

4

3

1

2

1-Tower tilt pedal control

2- Clockwise and counterclockwise center plate (ref. 15)

rotation pedal control

3-Wheel positioning device control pedal (optional)

4-Infl ation pedal control

5-Bead loosening rollers override engaging button

6-Bead loosener locking and override (ref. 5) activation

switch.

7-Bead loosener releasing button.

8-Bead loosener “forward” movement button

9-Bead loosener “back” movement button

10-Upper bead loosening roller lifting button

11-Upper bead loosening roller lowering button

12-Lower bead loosening roller lowering button

13-Lower bead loosening roller lifting button

14-Defl ation button (infl ating: by pedal 4)

15-Center plate

16-Upper bead loosener roller

17-Press arm control switch

18-Lower bead loosener roller

19-Operating arm control button

20-Leverless system control switch

21-Upper bead loosener tilting control

22-Center plate pneumatic locking switch

Any test must be operated without a tire on the machine.

Be mindful of any component that could interfere with machine testing operations.

Operation Manual - COATS PRO GUARD PLUS - 13

Page 14

23

Leverless Bead Lifter

Push the lever (23) down to be able to take the tool out of its

seat and push it up to put it back in position.

The bead helper arm is used to facilitate the mounting and

demounting phases. It is optional on standard tires but required on Run-Flat and UHP tires (low profi le).

Gauge

Defl ation button

Infl ation control panel consists of the gauge and the tire defl ation button. T o

infl ate the tire, press the pedal at the side of the machine (see illustration

below)

Infl ation pedal

Operation Manual - COATS PRO GUARD PLUS - 14

Page 15

8.0_TRANSPORT

- The tire changer is to be transported in its original packaging and kept in the position indicated on the actual

packaging.

- The packed machine is to be moved using a forklift truck of suitable load-bearing capacity, inserting the forks in

the points indicated in the drawing below (fi g. 1).

9.0_UNPACKING

Remove the cardboard and the securing screws, then take the machine off the original pallet.

Check the integrity of the equipment, making sure no parts are visibly damaged or missing, referring to the illustration on page 11.

In the case of doubt, do not use the machine but contact your dealer.

Packaging elements must not be left at children’s reach because they could be dangerous. Put the packaging

material in dedicated waste collection areas if they are pollutant or non-biodegradable.

NOTE: Exposed parts are covered with special rust inhibiting oil, possible traces of dirt are not due to negligence

but are just leftovers of this oil. Clean if necessary.

Net weight 937 lbs

(425 Kg).

Gross weight 1003

lbs(455 Kg).

fi g. 1 fi g. 2

Operation Manual - COATS PRO GUARD PLUS - 15

Page 16

10.0_INSTALLATION

10.1_Space required to position the machine

When choosing the place of installation, remember to observe current standards on safety at the workplace.

- The tire changer needs to be connected to the electrical mains and to the compressed air supply. The machine should

therefore be installed near such sources.

- Furthermore, the chosen place of installation must have the spaces indicated in drawings 4 - 4/A at least, so that all

of its parts are able to work without any restrictions.

DANGER

It is forbidden to use the tire changer in an explosive environment unless it is a version

specifi cally designed for such purpose.

Lifting point

27,6“

(700 mm)

27,6“

(700 mm)

27,6“

(700 mm)

27,6“

(700 mm)

Fig. 4

Fig. 4a

10.2_Positioning

Position the tire changer on fl at, smooth and non-slippery ground of suitable load-bearing capacity.

It is recommended to secure the tire changer to the garage fl oor using a bolt on each corner.

Use lifting equipment of suitable load-bearing capacity that is able to take the weight of the tire changer (at least 992

lbs -450 Kg.); to lift the machine, use a transport strap with minimum load-bearing capacity of at least 1 102 lbs (500 kg).

The machine must not necessarily be anchored to the ground, but if you prefer to do so, drill 4” (100 mm) deep holes

in the ground by the 4 holes of the machine bed using a 0,40” (10 mm) bit for concrete of suitable length.

Insert suitable metal anchor dowels in the holes drilled and secure fi rmly.

The place where the tire changer is installed must be equipped with an electrical safety system with effi cient grounding

and also supplied with appropriate differential 20A circuit breaker.

The place of installation must have a pneumatic connection with minimum working pressure of 116 PSI (8 bar).

Once you have fi nished positioning the machine, slide the safety pin out that prevents the arm from tipping accidentally

(fi g. 4b). Put the pin away safely with the accessories supplied so that it can be used again if the machine is moved

somewhere else.

Operation Manual - COATS PRO GUARD PLUS - 16

Page 17

10.3_Commissioning

WARNING

Before you connect the machine electrically, check the nameplate fi tted on it to make sure the elec-

trical power supply to which it will be connected matches the electrical arrangement of the manufacturer.

DANGER

Work on the electrical system, must be carried out by professionally qualifi ed personnel.

CAUTION

The manufacturer is not liable for machine damages caused by the incorrect electrical connection.

WARNING

When moving the machine around to position it initially, or if it is moved in the future to a different

location, it must be disconnected from the electrical and pneumatic power sources.

- Connect the machine to the electrical mains, which must have line fuses and an effi cient grounding system, pur-

suant to current standards. It must also be connected to an automatic differential circuit breaker calibrated at 20 A.

NOTE: If the machine is supplied without an electrical plug, the user shall fi t one (at least 20A) that is suitable for

the voltage of the machine and that complies with current standards.

- Connect the machine to the compressed air system using the fi tting on the lubricator at the back of the machine.

- Loosen the control panel bracket locking cap screw and pivot cap screw, adjust it to a convenient position for tha

operation, then tighten the cap screw.

Operation Manual - COATS PRO GUARD PLUS - 17

Page 18

11.0_OPERATIONAL TEST

B

A

H

V

S

S

R

Q

P

- Press pedal M and the lift P should raise; to lower the lift, lift the same

pedal upwards.

- Press pedal L on L2 and the spindle fl ange R should turn clockwise.

Press the pedal L on L1 and the spindle fl ange R should turn anti-clockwise.

C

E

F

I

L2

D

G

L1

T

U

N

M

L

NOTE: If the fl ange should turn in the opposite direction to that indicated, you need to invert two wires on the plug, if

it is three-phase.

- Turn selector A to the right to lock the movement of the bead loosening carriage; in this situation, the carriage will

only move in work mode (over stroke) by pressing button G, at the back of the control panel.

If the selector is turned to the left (unlocked), it will be possible to only move bead loosening carriage right - left, using

buttons C and D.

- Press button E and the bead loosenig carriage will move upwards; press button F and the carriage will lower.

- Press button B and turn the bead loosening carriage Q, the latter will move out from the work position. Release the

button and the hook will lock again. To move the carriage to the work position, turn the latter towards the machine and

make sure the hook locks it.

- To turn the bead loosening disc, move handle U towards handle T and simultaneously accompany the disc support

by hand downwards or upwards.

- With the pedal I right down, the vertical arm V moves to the work position; with pedal I raised, the arm V tilts backwards out of the work position.

- Press pedal N to start infl ating the tire; if you wish to defl ate the tire, use button H at the side of the gauge.

CAUTION

All the procedures are to be performed without using a tire, making sure that no

other parts of the machine interfere with the movements when performing them.

Operation Manual - COATS PRO GUARD PLUS - 18

Page 19

12.0_IDENTIFYING AND CHECKING THE RIM AND TIRE

Before you start to demount the tire, it is of CRUCIAL IMPORTANCE to identify the measurements of the rim and of the

tire. Also make sure neither is damaged.

ATTENTION: These procedures are very important and are to be performed to reduce risks of the tire bursting when

re-mounting the tire on the rim and infl ating it.

All rims bear an indication of their diameter, width, number of humps etc. If we take the picture below as an example,

you can see that:

A= 8 Nominal width of the rim in inches (1 inch =25,4 mm)

B = J Size of the fl ange

C = 15 Nominal diameter of the rim

D = H2 It indicates if there is a double hump (anti bead removing edge)

The tire bears a considerable amount of details, among which are the dimensions, type and maximum speed.

For example: 205/65 R 15 91H TL

A = 205 indicates the width of the tire, in other words the distance between the

sides, expressed in millimetres.

B = 65 is the ratio expressed in percentage between the height of the section

and its width.

C = R Type of tire (R = radial)

A

BC

8Jx15H2

B

A

C

D

E

D

F

G

D = 15 indicates the keying diameter in inches (diameter of wheel), which must

be the same as the rim.

E = 91 is the index of the maximum load born for each wheel.

F = H is the maximum rated speed of the tire. (H= 130,5 Mph -210Km/h)

G = TL means that the tire is Tubeless

WARNING

ATTENTION: It is strictly forbidden to mount tires on rims that have different parameters

(diameter and width). It is also forbidden to mount tires with different dimensions compared

to those stated.

Operation Manual - COATS PRO GUARD PLUS - 19

Page 20

13.0_POSITIONING THE VALVE

Fig. 6 shows a rim in the form of a clock, so that, following the various

processing phases described hereafter, (chapter entitled Mounting and

Demounting), you can position the valve and its sensor correctly so as

not to damage them.

CAUTION

To avoid damaging the valve and the pressure sensor, if

the latter is installed, you must always arrange the valve

in the position indicated, following the instructions when

mounting and demounting the tire. fi g.6

14.0_TIRE CLASSIFICATION

LOW PROFILE tires (UHP) are those in which the height (H) and the width (C) have a ratio lower than 0.5 (i.e. low

profi le series 45 stands for a ratio of H/C = 0.45).

For tires to be considered as LOW PROFILE (UHP), they must also have a maximum speed code of equal to and/or

higher than V.

fi g.6

RUN-FLA T tires are those which, even when they have no internal pressure, allow you to continue to drive the vehicle

for a preset number of miles and at a preset speed. These parameters change from one manufacturer to another.

The market currently offers 2 different types of RUN-FLAT tires:

- Those with REINFORCED SIDE (SELF-SUPPORTING) where, thanks to a different mix and a reinforced structure,

the shoulder of the tire is able to bear the weight of the vehicle even when the pressure in the tire is zero.

- Those with INTERNAL SUPPOR T have a ring inside the rim that bears the side of the tire when there is no pressure

inside it. The internal support may be made of plastic (Pax-System) or of metal (Support-Ring).

The tire changer is able to handle all types of LOW PROFILE (UHP) and all types of RUN-FLAT tires with REINFORCED SIDE; for other types, refer to the specifi c instructions of the dedicated accessories, if available.

The mounting and demounting procedure is the same, be it a RUN-FLAT tire with REINFORCED SIDE (SELF-SUPPORTING) or a LOW PROFILE tire (UHP).

CAUTION

It is of crucial importance to follow the instructions very carefully in order to avoid irreparable

damages to the tire, which could compromise the vehicle’s safety.

Operation Manual - COATS PRO GUARD PLUS - 20

Page 21

15.0_TIRE LIFT

A conventional rim is a wheel of a vehicle with rim made of steel or light aluminium, with a center hole and a drop center

near the edge of the rim.

A reverse mount rim is a wheel of a vehicle with rim made of steel or light aluminium, with a center hole and a drop

center near the bottom patch of the rim.

- Using a special tool, remove any wheel weights on the rim, being particularly careful not to damage the rim.

- Make sure none of the tools are in the work zone of the LIFT so that it is free to position the wheel correctly.

- Position the wheel on the spindle using the LIFT, as follows:

- Move the wheel on the lift platform of the machine, in vertical position with the outside face of the tire facing left.

- Using the lifting pedal, raise the platform and the wheel up to the fl at position and align the center hole of the

wheel with the spindle fl ange.

- Lower the LIFT and center the anti-rotation device.

For wheels bigger than 24-inches or when clamping reverse mount rims wheels, you may need to

widen the plastic rollers of the lift and/or change the angle of the rollers bracket before lifting.

LIFT

Anti rotation device

Spindle center post

LIFT pedal

1 - Tire width > 11”

2 - Tire width _ 11”

3 - Reverse mounted only

<

Min _ 24”

<

Max > 24”

Operation Manual - COATS PRO GUARD PLUS - 21

Page 22

16.0_WHEEL CLAMPING

16.1_Wheel locking

1. Insert the ring nut hub correctly (the cone plastic cover preserving the alloy rims from damages)

2. Turn the ring nut hub clockwise by hand until you fi nd the exact coupling position, then press the hub and

turn it clockwise by 90° to its full-stroke

3. Release the ring nut and make sure it raises by 0,40° (10 mm) approximately, otherwise turn it slightly

clockwise or counter-clockwise lifting up the hub.

4. Make sure the plastic cone is in contact with the rim, perfectly centerd with the drop-center hole, the split of

the nose matching up with the driving pin.

Tighten the ring nut so that it moves up to the cones and continue tightening so that the wheel is pushed

fi rmly on the fl ange of the spindle.

16.2_Pneumatic locking system (optional)

If the tire changer is provided with the optional pneumatic locking system:

1. Insert the ring nut hub correctly (the cone plastic cover preserving the alloy rims from damages).

2. Turn the ring nut clockwise by hand until the exact coupling position, press the ring nut until its end-stroke

and rotate the ring nut hub 90° by hand.

3. Release the ring nut and make sure thet it raises by 0,40° (10 mm) approximately.

4. Rotate the pneumatic locking switch onto the manometer panel to the locking position.

4

Before you start any work on the wheel, make sure it is

mounted securely on the spindle

Operation Manual - COATS PRO GUARD PLUS - 22

Page 23

17.0_BEAD LOOSENING

Do NOT start any work on the wheel before the tire is completely defl ated.

DEFLATE the tire completely by removing the valve core before starting any work.

-Remove all weights from the rim by a proper tool, paying attention not to damage the rim.

-Before starting any operation, please check the eventual presence of a pressure sensor. In positive case, it is prefe

rable to check its effi ciency by a dedicated diagnostic tool.

-The bead loosening rollers are mounted on special tilting supports to ease bead loosening on wheels with high profi le

or soft tires. This procedure is “Over Run”

“OVER RUN” PROCEDURE SHOULD NOT BE USED ON UHP AND RUN FLAT TIRES

Push down the hook

lever to release the

upper roller

Lift up the hook lever

to release the lower

roller.

17.1_Upper bead loosening

Check the correct centering and locking of the wheel onto the center-plate.

Check that the upper disk arm is in the right position (step 1)

-to move the upper disk in its right position: unlock it from rest position by pressing the right lever

to the left (A), then lift the disk arm support by hand and lock it by pressing the right lever to the right (B)

Turn the switch 6 clockwise to free the bead-breaking unit and position it by handling the console, in order to let the

upper roller keep to 5 mm distance from the rim border, then lock the bead-breaking until by turning again te switch 6

clockwise.

Move the bead breaking arm onto the tire by pressing buttons 8-9 an 10-11

Step 1

4

A

B

6

8

10

12

Operation Manual - COATS PRO GUARD PLUS - 23

7

9

11

13

1

3

2

5

Page 24

Pay attention to the valve sensor position during bead loosening steps.

Wrong movements of the upper roller could damage the sensor.

Avoid contact between the lubricating paste and the valve sensor, if any.

- Spin the center-plate until the valve reaches position

at “3 o’clock” position.

- Lower the bead loosening roller until it touches the tire

using controls 10 for lifting and 11 for lowering.

- Start spinning anticlockwise pressing pedal 2.

Note: the center-plate can spin at 2 different speeds, according to

operator’s preferences

- While spinning the wheel, push the bead loosening upper roller down

under the edge of the rim, then press and hold down the “over-stroke”

function button 5 going on lowering the roller until the bead detaches

from the rim.

- As soon as enough space is available, grease both inner surface

of the rim and tire bead carefully with a proper tire lubricating paste.

Avoid contact between the lubricating paste and the valve sensor, if any.

Fase 2

- Once the bead gets loosened, raise and move away the upper roller by acting on button 10.

17.2_Lower bead loosening

Keep the bead-loosening unit set up as for upper bead release: the lower roller is always aligned with the upper one,

at 5 mm distance from rim lower border already.

Lift the lower roller until it touches the lower bead using controls 13

for lifting and 12 for lowering.

Start spinning the wheel anticlockwise by pressing pedal 2.

- While spinning the wheel, push the lower roller up over the edge of

the rim, then press and hold down the “over-stroke” function button 5

going on lifting the roller until the bead detaches from the rim.

- As soon as enough space is available, grease both inner surface of

the rim and tire bead carefully with a proper tire lubricating paste.

Fase 3

Note: for a better control of the lower bead loosening

please refer to the dedicated mirror fi tted onto

the tire changer main frame.

Press on the bead – never on the sidewall of the tire while loosening the bead.

Operation Manual - COATS PRO GUARD PLUS - 24

Page 25

17.3_Lower bead loosening on special wheels

The lower bead of reverse drop center rims with signifi cant width may be hard to break with the lower disk.

In this case it is possible to use the upper bead-loosening disk to break the lower bead of the tire:

-tilt down the upper disk arm support to its lower position (step 1) to get both upper-and lower-bead loosening disks at

the same tilt-angle (step 2);

-follow instructions as per section “17.1_Upper bead loosening and 17.2_Lower bead loosening”.

Step 1

A

B

Step 2

Upper bead loosening arm

Lower bead loosening arm

Operation Manual - COATS PRO GUARD PLUS - 25

Page 26

18.0_DEMOUNTING TIRE

Once the bead loosening process is completed, and the wheel is already positioned onto the center-plate, check and

ensure its locking and centering.

18.1 Upper bead demounting

Mounting tool

- Turn the wheel until the valve is in the “1 o’clock” position

(roughly 10 cm - 4-inch distance from the mounting tool) in order

to avoid possible damages to the valve or the pressure

sensor.

in working

position

10 cm

4

3

1

-Press the pedal ref. 1 to position the mounting arm close to the wheel while driving.

The mounting arm by handling (fi g. 5), lock it in position 1 by ref. 19 (fi g. 5B) to lock the operating arm and the hori-

zontal arm at the same time.

Automatically the mounting tool is moved up and away from the rim border to have a

clearance of approx. 2 mm when locked

- Lower the lever ref. 20 to insert the mounting tool between the bead and the rim edge. The mounting tool should

penetrate enough to hook the tire bead to let the operator complete the tire demounting: spin slowly the wheel until the

mounting tool is positioned correctly.

A gentle pressure on the tire sidewall by the upper roller could help the mounting tool positioning.

2

Valve

Fig. 5

Fig. 5B

19 19 19

Pos. 1 Pos. 2 Pos. 3

- As soon as the bead is perfectly hooked, lift the mounting tool by raising lever ref. 20 to pull out the bead.

To make the lifting easier set the tire pressing unit at “6 o’clock” position and press the tire side (fi g. 6).

Get a further help by contemporarily lifting the lower tire side by the lower bead-loosening roller (fi g. 7).

20

Fig. 7

Fig. 6

- Press down on pedal ref. 2 to rotate the wheel clockwise until the entire bead is lifted from the rim

NOTE: rim and tire must spin together as one.

Operation Manual - COATS PRO GUARD PLUS - 26

Page 27

- In order to help the bead coming out and reduce the stress to the tire:

insert the plastic lever (as shown by picture aside) and spin the wheel

clockwise while lifting the tire by the lower bead-loosening roller.

NOTE: The above mentioned action is compulsory for UHP and RUN-FLAT

tires according to tire regulations.

To avoid damaging the valve and/or the pressure sensor, move it to the “1 o’clock” position before

inserting the tool in the drop center, operating the control lever 20.

18.2_Lower bead demounting

- Before pulling out the lower bead, spin the wheel to let the valve

reach “1” or “2” o’clock position in order to avoid possible

damages to the valve and the sensor - if any.

- Lower the lever ref. 20 to insert the demounting tool under the

lower bead. Raise the lever ref. 20 to lift the demounting tool and

the bead.

- Raise the lower bead loosening roller to lift the tire until the lower

bead is 1 cm over the upper rim edge.

- In order to help the above mentioned operation, lift the tire

manually at “2” or “3” o’clock position and insert the plastic lever

as per tire regulations for UHP and RUN-FLAT tires.

- Spin the wheel clockwise until the tire comes off the rim.

- Press the pedal ref. 1 to move the mounting arm away, push the

rollers bead breaking unit away and pull out the tire.

- Check the status of the pressure sensor - if any - and replace it if

necessary.

4

3

1

2

Operation Manual - COATS PRO GUARD PLUS - 27

Page 28

19.0_MOUNTING TIRE

- Check the rim and the tire carefully, as per instructions at page 19 of this manual.

- If the rim has been moved, lock it again onto the center-plate as per instructions

at page 22 of this manual.

- Lube 3 cm thickness along the whole internal surface of the rim and internal and

external surface of tire beads.

If there is a sensor, do not let it come into contact with the lubricant

19.1 Lower bead mounting

- Put the tire onto the center-plate tilting the tire at “12 o’clock” position in order

to make both upper and lower beads go under the upper rim edge.

- Press pedal ref. 1 to approach the mounting arm and position the mount/demount

head

onto rim edge.

- Incline the tire to the bottom at “3 o’clock” position, driving the lower bead to

the mounting head in order to put the lower bead over the mounting lip on the left side of

the head and under the demounting claw on the right side of the head.

- Rotate the wheel by pressing the pedal ref. 2, contemporarily press the tire at “5

o’clock” position until the bead reaches the drop center level. Keep the tire pressed until

“8 o’clock” position while rotating

to complete the lower bead mounting.

19.2 Upper bead mounting

- Keep the mounting arm and the mount/demount head at working position, then put the tire bead on the rim slightly

tilted down to “3 o’clock” position..

Bead correctly positioned

over the mounting lip.

OK

Bead correctly positioned

under the demounting claw

OK

Bead incorrectly positioned

causing bead damages

between the head lip

and the rim edge

Bead incorrectly positioned

Operation Manual - COATS PRO GUARD PLUS - 28

Page 29

- Press the button ref. 11 to lower the upper bead loosening roller until the upper bead reaches 3 cm level under the

rim edge.

- Make sure that the upper bead of the tire rests on the left lip of the head and under the demountig claw on the

right side of the head.

- Press the pedal ref. 2 to rotate the wheel clockwise, contemporarily press the tire

manually from “5 o’clock” position to force the bead at drop-center position.

Keep it pressed while rotating up to “8 o’clock” position to complete

the upper bead mounting.

17

Make sure that rim and tire always spin together.

- To make the upper bead mounting easier, use the tire pressing unit by setting it at “5

o’clock” position and pressing lever ref. 17 to keep the bead at drop-center level while

rotating up to “8 o’clock” position until the tire complete mounting.

Operation Manual - COATS PRO GUARD PLUS - 29

Page 30

19.3 UHP (low profi le) and RUN-FLAT (self-supporting) tires mounting

- Some precise and careful operations are necessary to mount UHP and RUNFLA T tires. It is compulsory to follow tire regulations to avoid permanent damages

to these tires.

-Lower bead mounting can be performed as per standard instruction

at page 27 of this manual..

-Once the lower bead is mounted, keep the mounting arm and tool at working position and start WDK upper bead mounting procedure putting the tire slightly tilted

down to “3 o’clock” position.

-Use the bead pressing clamp together with the proper rubber protection

( steel rim, alloy rim, convex alloy rim) locking the clamp onto rim edge

• •• •••

with the valve at “3 o’clock” position.

If necessary, press the tire side by the upper bead loosening roller to

help the correct positioning and locking of the clamp (fi g. 1).

-Keep the upper bead loosening roller at drop-center level, spin slightly

to insert the pressing tool between the roller and the clamp and pressing

onto the tire side until the upper bead reaches drop-center level (fi g. 2).

-Make sure that the upper bead of the tire rests on the left lip of the mount head

and under the demounting claw on the right side of the head.

Fig. 1

-Start spinning the wheel paying attention to the bead not going between

the rim edge and the bead loosening roller.

While spinning, when clamp is roughly at “6 o’clock” position make sure

that the whole bead within this section is right inside the drop-center.

-If this necessary condition for a correct mounting is not accomplished,

use the bead pressing unit pushing its tool onto the tire side to insert

the bead into the drop-center (fi g. 3).

Act gently onto tire sidewall during the above mentioned

process

- Go on spinning the wheel until the upper bead is completely mounted.

- Remove the clamp and the rubber protection by the help of the pressing unit.

Pull the pressing tool away and lift the roller away

from the working position by acting on button 10.

Press button 7 to move the bead loosener from working position.

- Press the pedal ref. 1 to push the mounting arm up and move the roller bead

breaking unit away from working position.

Fig. 2

Fig. 3

- Keep the wheel locked onto the center-plate during the infl ating operations.

Read the infl ating instructions at page 23 carefully.

- Once the tire infl ation is completed, unlock the wheel and bring it down

onto the fl oor, taking advantage of the optional wheel positioning unit.

Operation Manual - COATS PRO GUARD PLUS - 30

Page 31

20.0_INFLATION

DANGER

Tires are to be infl ated with utmost caution. Strictly follow the instructions here after as the tire changer

is NOT designed and manufactured to safeguard the user (nor anybody else standing near the machine)

if the tire should accidentally burst.

CAUTION

ATTENTION! If the tire bead fails to fi t in place during infl ation at the maximum pressure of 40 PSI (3.3

bar), you need to repeat the bead loosening and lubricating procedure of the tire itself and then try infl ating again.

DANGER

If the tire should burst or the rim should break under pressure, operators could be seriously injured or even killed.

Make sure the rim and the tire are the same size.

Also check the state of wear of the tire and the rim to make sure there are no defects

before starting to infl ate.

Infl ate the tire with short blasts of air and check the pressure frequently while infl ating.

All our tire changers are automatically limited to an infl ation pressure of 61 PSI (4.2 bar).

NEVER EXCEED THE PRESSURE RECOMMENDED BY THE MANUFACTURER WHATEVER THE CASE.

Keep hands and body as far away as possible from the tire during infl ation.

• Connect the infl ation hose to the valve of the tire.

• Make sure the rim and the tire have the same diameter again.

• Make sure the rim and tire are suffi ciently lubricated; lubricate if necessary.

• Press and release the infl ation pedal continuously, checking the pressure on the gauge frequently until the tire

bead fi ts completely on the rim.

• Continue infl ating to reach the pressure recommended by the manufacturer. Always infl ate in short blasts and

always checking the pressure while doing so.

• Press the defl ation button to defl ate the tire if, during infl ation, the pressure exceeds the value recommended by

the manufacturer.

Operation Manual - COATS PRO GUARD PLUS - 31

Page 32

21.0_STANDARD ACCESSORIES

Supplied in the box

21.1_Optional Accessories

NOTE: before using the following optional accessories (P/N#89231514, 89231512 and 89231513) remove the

wide, rubber coated table top as follow:

-Loosen anti-rotation pin pivot arm locking screw

-Move anti-rotation pin pivot arm aside, to access retaining screw for rubber coated table top.

-Loosen all rubber coated table top retaining screws and remove the table top

-Assemble the horse shoe bracket (always provided in each of the below mentioned accessory kits) on the smaller

table top, by tightening the 3 retaining screws.

4

5

2

3

1

Clamping adaptor for rims without center hole (P/N# 89231514)

This clamping adaptor can be used on all wheels with any number of lug holes.

Remove the rubber coated wide fl ange plate, then position the horse shoe

bracket on the spindle chuck, and secure it by tightening the screws.

4

Fit the fl ange plate on the spindle chuck making

sure to match the assembling holes, securing it

with the 2 knobs supplied. Unscrew the securing

nuts.

Position the pins based on the number of lug holes

in the rim, inserting the anti-rotation pin in the slot

and the securing screw in the threaded hole with

the number desired.

Note: The pin with the yellow screw must never

be removed.

Take the gauge supplied with the kit and measure the center distance of 2 holes, then lock this

measurement on the gauge.

Operation Manual - COATS PRO GUARD PLUS - 32

Page 33

Turn the pins of the fl ange so that the center di-

stance matches the measurement made earlier

on the rim.

Tighten the securing screws of the pins.

Insert the wheel, matching up the clamping holes

with the threaded pins, position and tighten the

wheel securing nuts.

LT TRUCK CONE KIT (P/N# 89231512)

for clamping rims with center hole larger than Ø 4,8”-7,5” (120-190 mm).

Remove the rubber coated wide fl ange plate, then position the horse shoe

bracket on the spindle chuck, and secure it by tightening the screws.

Position the fl ange plate to the spindle chuck, making sure to match the

assembling holes, and secure it with the 2 knobs supplied.

Insert the wheel, matching-up the anti-rotation pin with a lug hole, position

and secure by tightening the clamping shaft over the cone.

Operation Manual - COATS PRO GUARD PLUS - 33

Page 34

LT TRUCK CONE KIT (P/N# 89231513)

for clamping rims with center hole larger than Ø 7,5”-9.0” (190 -220 mm).

Read installation and operations as per

P/N # 89231512

MATCH MOUNTING TIRE HOLDER KIT (P/N# 89231511)

-Install tire holder in bracket on left assist arm and secure with pin.

-Position tire holder on top bead and press by lowering whole left assist arm carriage. Also, position bead loosener

roller on bottom bead and push bead up.

-Once you have both tire beads hold by the two rollers, rotate the spindle chuck to turn the wheel and proceed

match mounting

BEAD LOCK TOOL (P/N # 83018892)

After lifting the top bead by powerduckhead

“Hook”, insert tool between wheel surface

and tire bead, to help removing top bead on

stiff side wall tires. Plastic-made, it never gives chance to damage wheel.

Operation Manual - COATS PRO GUARD PLUS - 34

Page 35

DROP CENTER TOOL (P/N # 89218904)

Provides additional pressing point

and extra help to assist arm, in keeping tire bead into drop center

DROP CENTER BEAD LOCKS (P/N # 89216929)

Provides additional protection against direct

contact between wheel surface and drop

center tool.

POWER DUCKHEAD BOOTIES KIT (P/N # 89231515)

Protects wheel surface against

“metal to metal” contact with power duckhead.

Operation Manual - COATS PRO GUARD PLUS - 35

Page 36

CLAMPING CONE BOOTIES KIT (P/N # 89231516)

TABLE TOP PADS KIT (P/N # 89231517)

ANTI-ROTATION PIN BOOTIES KIT (P/N # 89231518)

Protects center hole of alu wheels

against “metal to metal” contact

with clamping cone.

Protects outside surface of reverse mount alu wheels against direct

contact with table top.

Protects wheel lug holes against

“metal to metal” contact with antirotation pin.

Operation Manual - COATS PRO GUARD PLUS - 36

Page 37

22.0_RE-POSITIONING

To re-position the tire changer in a new workplace, you need to secure the moving parts (i.e. bead pressering

arm etc.) disconnect all the power sources and install it again following all the instructions given in chapter

10.0 “INSTALLATION” of this manual.

Connections to power sources and connections and inspections of the safety systems must be

carried out by trained personnel.

23.0_STORAGE

If the tire changer is to be stored away for extended periods of time, you need to:

- Disconnect the power sources

- Empty the tanks containing operational fl uids

- Protect parts that could be damaged if dust should settle on them

- Grease parts that could damage if they should dry up

When re-commissioning the tire changer:

- Follow the instructions given in chapter 10.0 of this manual

- Replace any damaged parts, referring to the spare parts list. This is to be done by factory authorized service

partners

24.0_SCRAPPING

If you should decide that the tire changer can no longer be used, you are recommended to make it unusable

by removing the power supply connections, emptying the tanks and disposing of the fl uids pursuant to current

state and federal regulation.

The tire changer is considered as heterogeneous waste and must consequently be split-up into parts made of

similar material (electrical parts, plastic parts and ferrous parts), which must be disposed of properly , according

to current State and Federal regulation.

25.0 MAINTENANCE

25.1_General warnings

Non routine maintenance must be carried out by factory authorized service partners

• Routine maintenance, following the relevant instructions, is of crucial importance to ensure the correct operation and

lasting life of the tire changer.

• If routine maintenance is not carried out regularly, the effi cient operation and reliability of the machine could be com-

promised.

WARNING

Before you start any maintenance job, disconnect the electrical power supply by unplugging the machine

from the mains and disconnect it also from the pneumatic supply by shutting off the valve.

Furthermore, to release the compressed air from the circuit, press the infl ation pedal down for a few secon-

ds.

Defective parts should be exclusively replaced with genuine spare parts by factory authorized service partners.

Removal or tampering with the safety devices (max.pressure valve – pressure regulator) represents a breach

of State and federal OSHA regulations and workplace codes.

Operation Manual - COATS PRO GUARD PLUS - 37

Page 38

In particular, Hennssy Industries, Inc. is not liable for claims deriving from the use of non-original spare

parts or for damages caused through removal or tampering with safety systems.

25.2_Routine Maintenance

Before making any inpection, adjustement, or repair, disconnect the power source and block out all moving

parts to prevent injury.

Observe the instructions that follow to ensure the perfect operation and lasting life of your tire changer:

- On a weekly basis, after cleaning thoroughly with vaporizing solvent, lubricate the guides of the bead loosening

carriage (1) and the guide of the Press Arm with chassis grease (2) (fi g. 40).

Keep all machine parts, in contact with the tire and/or wheel, clean.

- Make sure the transmission belt is tensioned correctly.

- On a periodic basis, check the oil level of the lubricator. Top-up if necessary by unscrewing the cup. Use just oil for

pneumatic systems in class ISO HG with viscosity ISO VG 32 such as the following types, for example: ESSO Febis

K32; MOBIL Vacouline Oil 1405; KLUBER Airpress 32

2

1

fi g. 40

Operation Manual - COATS PRO GUARD PLUS - 38

Page 39

26.0_OIL TREATMENT

WARNING

OIL IS HIGHLY POLLUTANT! Do not throw away outdoors or pour on the ground

26.1_General precautions

- Avoid direct and prolonged contact with skin.

- Avoid the formation of oil mists in the air.

- Avoid splashing.

- Wear appropriate clothing, gloves and goggles to protect against oil splashes.

- Do not use greasy rags.

- Do not eat or smoke if your hands are soiled with oil.

26.2_First Aid instructions

- If oil is swallowed, do NOT induce vomiting but go immediately to the nearest medical center with information

on the type of oil swallowed.

- If oil gets in eyes, rinse abundantly with water until irritation ceases, then go to the nearest medical center.

- If oil comes into contact with skin, rinse abundantly with neutral soap and water. Do not use solvents or irritant

products.

26.3_Disposing of used oil

Do not throw used oil away outdoors or pour it on the ground. Drain into a suitable container and forward to

specialised oil disposal centers, or hand it over to authorised collection companies.

26.4_Oil spillages or leakages

Eliminate the cause of the leakage and stop the oil spillage from spreading using absorbent material. Clean

the area where the oil has spilled using degreasing detergents to prevent slipping and dispose of the waste

according to current State and Federal regulations.

Clean up the oil and send to special disposal centers according to current State and Federal

regulations

Operation Manual - COATS PRO GUARD PLUS - 39

Page 40

27.0_TECHNICAL SPECIFICATIONS

SPECIFICATIONS

Electrical Requirements

Power Supply Requirements 230V, 50/60 Hz, 20A, 1Ph

NEMA L6-20P

Air Source Requirement

Service Inlet Air Pressure 110-175 PSI 7.5-12 Bar

14-15SCFM @ 150 PSI

Rim/Tire Specifi cations

Rim Diameter 10” - 34” 254-863 mm

Max Tire Diameter 47” 1200 mm

Max Tire Width 16” 410 mm

Max Wheel Lift Capacity 176 lbs 80 kg

Dimensions

Width 47” 1200 mm

Depth 77” 1960 mm

Height 84” 2120 mm

Net Weight 937 lbs 425 kg

Drive System

Clockwise Spindle Speed 7 or 14 rpm

Counter-clockwise Spindle Speed 7 rpm

Spindle Drive Motor 1 HP 0.75 kW

Operation Manual - COATS PRO GUARD PLUS - 40

Page 41

NOTE

Page 42

ONE WORD FOR SAFETY

R.I.M.

READ INSPECT MOUNT

READ…

Mounting and infl ating the

wrong size tire can get

you hurt. Read the size on

the tire and make sure it

matches the rim. Be especially careful about putting a

smaller tire on a larger rim,

such as a 16-inch tire on a

16.5-inch rim.

Infl ation of a mismatched

tire and rim can cause an

explosion.

BE CAREFUL OF THESE SITUATIONS:

1. Damaged Bead or

Beads.

2. Rusty Wheels.

(particularly in the

bead seat area)

3. Bent or Cracked

Wheels.

4 A. Mismatched.

(A mis-match of a

16-inch tire to a 16.5inch rim causing an

explosion)

4 B. Mismatched.

(16.5-inch tire on a

16-inch rim)

INSPECT…

Before you put any tire on a

rim, inspect the rim for rust,

tough spots, bent edges, or

cracks that could prevent

the tire from seating right.

If you spot any of these

problems, don’t mount the

tire until the rim has been

checked by your shop foreman.

Inspect the tire for bead

damage.

5. Walk-In Tire and

Rim.

6. Back Injuries.

7. Hand or Finger

Injuries.

(Hands or fi ngers too

close to infl ating tire

or bead seats which

may cause injury.)

MOUNT…

Once you’ve made sure the tire is OK

and the right size and the rim is OK,

mount the tire safely . NEVER, ever lean

over the tire when you’re infl ating it. If a

tire does explode, it will go straight up.

You don’t want to be over the tire if that

happens. Also, never over-infl ate the

tire, even if the bead doesn’t seat. Never

infl ate over 40 PSI. If the tire hasn’t

seated, something is wrong. Deflate

the tire and check it and the rim again.

If it doesn’t work the second time, try

another tire.

8. Standing Clear.

(Never put any part

of your body over the

tire changer during

infl ation.)

9. Beads will not

Seat at 40 PSI.

10. Improper

Infl ation.

Remember R.I.M. (Read, Inspect, Mount) for every tire.

TIRE FAILURE UNDER PRESSURE IS HAZ-

FAILURE T O READ AND FOLLOW ALL WARNINGS AND INSTRUCTIONS IN THIS MANUAL

CAN LEAD TO SERIOUS PERSONAL INJUR Y

OR DEA TH TO OPERATOR OR BYST ANDER.

THE OWNER IS RESPONSIBLE FOR MAINTAINING THE OPERATION INSTRUCTIONS

AND DECALS FOR OPERA TOR REFERENCE.

FOR ADDITIONAL COPIES, CONTACT THE

COATS® COMPANY, 1601 J.P. HENNESSY

DRIVE, LAVERGNE, TENNESSEE, 37086 (800) 688-6359.

85606719 02 11/2013 © Copyright 1998 Hennessy Industries and COATS® All Rights Reserved.

DANGER

ARDOUS! This tire changer Will Not Restrain

Exploding Tires, rims or other related equipment.

TIRES CAN EXPLODE, ESPECIALLY IF INFLATED BEYOND SPECIFIED LIMITS. DO

NOT EXCEED TIRE MANUFACTURERS RECOMMENDED AIR PRESSURE.

AN EXPLODING TIRE, RIM, OR BEAD SEATING EQUIPMENT MAY PROPEL UPWARD

AND OUTWARD WITH SUFFICIENT ENERGY

TO CAUSE SERIOUS INJURY OR DEATH TO

OPERA TOR AND/OR BYST ANDERS.

Loading...

Loading...