Page 1

®

Pit Tire Changer

For servicing NASCAR type tire/wheel assemblies

(with and without liners)

1601 J. P. Hennessy Drive, LaVergne, TN USA 37086-3565 615/641-7533 800/688-6359 Manual Part No.: 85000681 00

HENNESSY INDUSTRIES INC. Manufacturer of AMMCO

®

, COATS®and BADA®Automotive Service Equipment and Tools. Revision: 10/07

See

Operating

Instructions

on page 3.

Operating Instructions

with Parts Identification

READ these instructions before placing unit in

service KEEP these and other materials delivered

with the unit in a binder near the machine for

ease of reference by supervisors and operators.

Page 2

ii • Important: Always read and follow the operating instructions.

Table of Contents

Safety Instructions . . . . . . . . . . . . . . . . . . . . .iii

Owner’s Responsibility . . . . . . . . . . . . . . . . . . . . . .iii

Operator Protective Equipment . . . . . . . . . . . . . . . .iii

Definitions of Hazard Levels . . . . . . . . . . . . . . . . . .iii

Safety Notices and Decals . . . . . . . . . . . . . . . . . . .iv

Remember R.I.M. . . . . . . . . . . . . . . . . . . . . . . . . . .iv

Principle Operating Parts . . . . . . . . . . . . . . . . .1

Know Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Operating Instructions . . . . . . . . . . . . . . . .2 - 6

Demounting a NASCAR Type Tire with

Liner using a COATS PIT Tire Changer . . . . . . . .2 - 4

Mounting a NASCAR Type Tire with

Liner using a COATS PIT Tire Changer . . . . . . . .5 - 6

Inflation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Mismatched Tires and Wheels . . . . . . . . . . . .8

Stages of Inflation . . . . . . . . . . . . . . . . . .9 - 10

Bead Sealing . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Bead Seating . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Inflation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 - 11

Maintenance Instructions . . . . . . . . . . .11 - 12

Separator/Lubricator Maintenance . . . . . . . . . . . . .12

Air Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Electrical Source . . . . . . . . . . . . . . . . . . . . . . . . . .12

Parts Identification . . . . . . . . . . . . . . . . .13 - 23

Chassis Assembly . . . . . . . . . . . . . . . . . . . . . . . . .13

Foot Pedal Assembly . . . . . . . . . . . . . . . . . . . . . . .14

Table Top Assembly . . . . . . . . . . . . . . . . . . . . . . . .15

Shaft Housing Assembly . . . . . . . . . . . . . . . . . . . .16

Horizontal Slide Assembly . . . . . . . . . . . . . . . . . . .17

Pressure & Inflation Bracket System . . . . . . .18 - 19

Robo Arm Assembly . . . . . . . . . . . . . . . . . . . . . . .20

Auxiliary Arm Assembly . . . . . . . . . . . . . . . . . . . . .21

Cylinder Assembly . . . . . . . . . . . . . . . . . . . . . . . . .22

Valve Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . .23

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . .23

NOTICE

Read entire manual before assembling,

installing, operating, or servicing this

equipment.

Page 3

Important: Always read and follow the operating instructions. • iii

Safety Instructions

Owner’s Responsibility

To maintain machine and user safety, the responsibility of the owner is to read and follow these instructions:

• Follow all installation instructions.

• Make sure installation conforms to all

applicable Local, State, and Federal Codes,

Rules, and Regulations; such as State and

Federal OSHA Regulations and Electrical

Codes.

• Carefully check the unit for correct initial

function.

• Read and follow the safety instructions.

Keep them readily available for machine operators.

• Make certain all operators are properly

trained, know how to safely and correctly operate the unit, and are properly supervised.

• Allow unit operation only with all parts in

place and operating safely.

• Carefully inspect the unit on a regular

basis and perform all maintenance as required.

• Service and maintain the unit only with

authorized or approved replacement parts.

• Keep all instructions permanently with the

unit and all decals/labels/notices on the unit

clean and visible.

• Do not override safety features.

Operator Protective Equipment

Personal protective equipment helps make tire servicing safer. However, equipment does not take the

place of safe operating practices. Always wear durable

work clothing during tire service activity. Loose fitting

clothing should be avoided. Tight fitting leather gloves

are recommended to protect operator’s hands when

handling worn tires and wheels. Sturdy leather work

shoes with steel toes and oil resistant soles should be

used by tire service personnel to help prevent injury in

typical shop activities. Eye protection is essential during tire service activity. Safety glasses with side

shields, goggles, or face shields are acceptable. Back

belts provide support during lifting activities and are

also helpful in providing operator protection.

Consideration should also be given to the use of hearing protection if tire service activity is performed in an

enclosed area, or if noise levels are high.

Definitions of Hazard Levels

Identify the hazard levels used in this manual with the

following definitions and signal words:

DANGER

Watch for this symbol:

It Means: Immediate hazards, which will result in

severe personal injury or death.

WARNING

Watch for this symbol:

It Means: Hazards or unsafe practices, which could

result in severe personal injury or death.

CAUTION

Watch for this symbol:

It Means: Hazards or unsafe practices, which may

result in minor personal injury or product or property

damage.

Watch for this symbol! It means BE ALERT! Your

safety, or the safety of others, is involved!

DANGER

WARNING

CAUTION

Page 4

iv • Important: Always read and follow the operating instructions.

Safety Notices and Decals

Failure to follow danger, warning, and caution instructions may lead to serious personal injury or death to operator or

bystander or damage to property. Do not

operate this machine until you read and

understand all the dangers, warnings and

cautions in this manual. For additional

copies of either, or further information, contact:

Hennessy Industries, Inc.

1601 J.P. Hennessy Drive

LaVergne, TN 37086-3565

(615) 641-7533 or (800) 688-6359

www.ammcoats.com

For additional information contact:

Rubber Manufacturers Association

1400 K Street N. W.

Washington, DC 20005

(202) 682-4800

Tire Guides, Inc.

The Tire Information Center

1101-6 S o u t h Rogers Circle

Boca Raton, FL 33487-2795

(561) 997-9229

www.tireguides.com

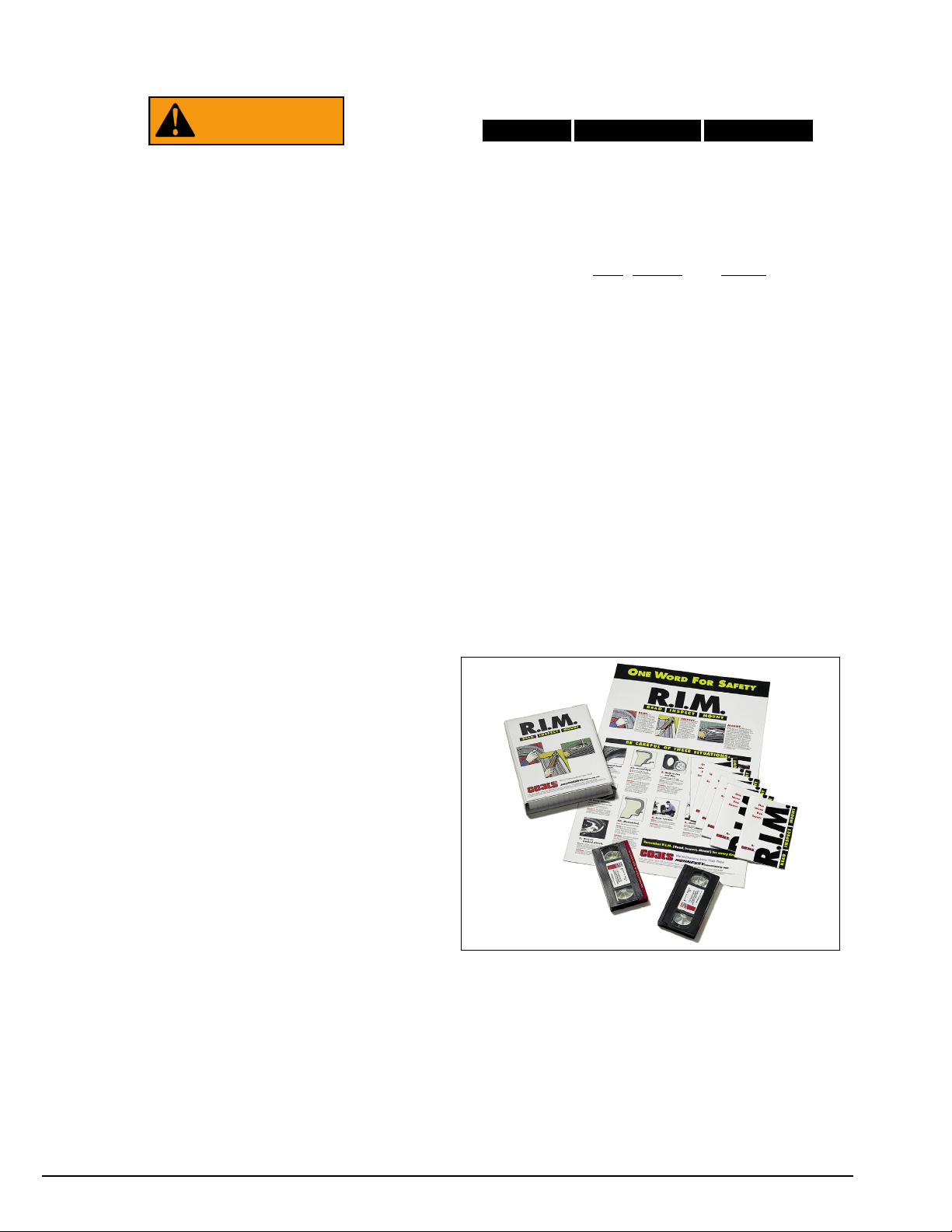

Remember R.I.M.

Three Simple Steps To Help Keep Shops Safe

R.I.M. is a training program developed by Hennessy

Industries to help keep tire technicians safe. By following the basic principles of R.I.M., technicians can avoid

situations that can cause catastrophic accidents like

tire explosions.

R.I.M. stands for read, inspect, and mount:

Read the tire size on a new tire before mounting to

make sure it is the proper size for the wheel.

Inspect the wheel for cracks, rust, and or other damage that could cause an unsafe situation.

Mount the tire safely, making sure not to put any part

of your body over the tire during inflation.

The most serious of possible accidents is a tire explosion. This is often caused by a tire/rim mismatch.

If a tire explodes on a tire changer, pressure causes it

to fly straight up at tremendous speed. If a technician

is standing over the tire, he can be seriously injured or

killed.

Hennessy’s R.I.M. program allows the technician to

avoid situations that can cause tire explosions and

other accidents. The full program, including training

videos, brochures, posters, and other materials, is

available from Coats distributors nationwide.

For more details, contact your Coats distributor or e-mail us.

WARNING

READ

INSPECT MOUNT

Page 5

Important: Always read and follow the operating instructions. • 1

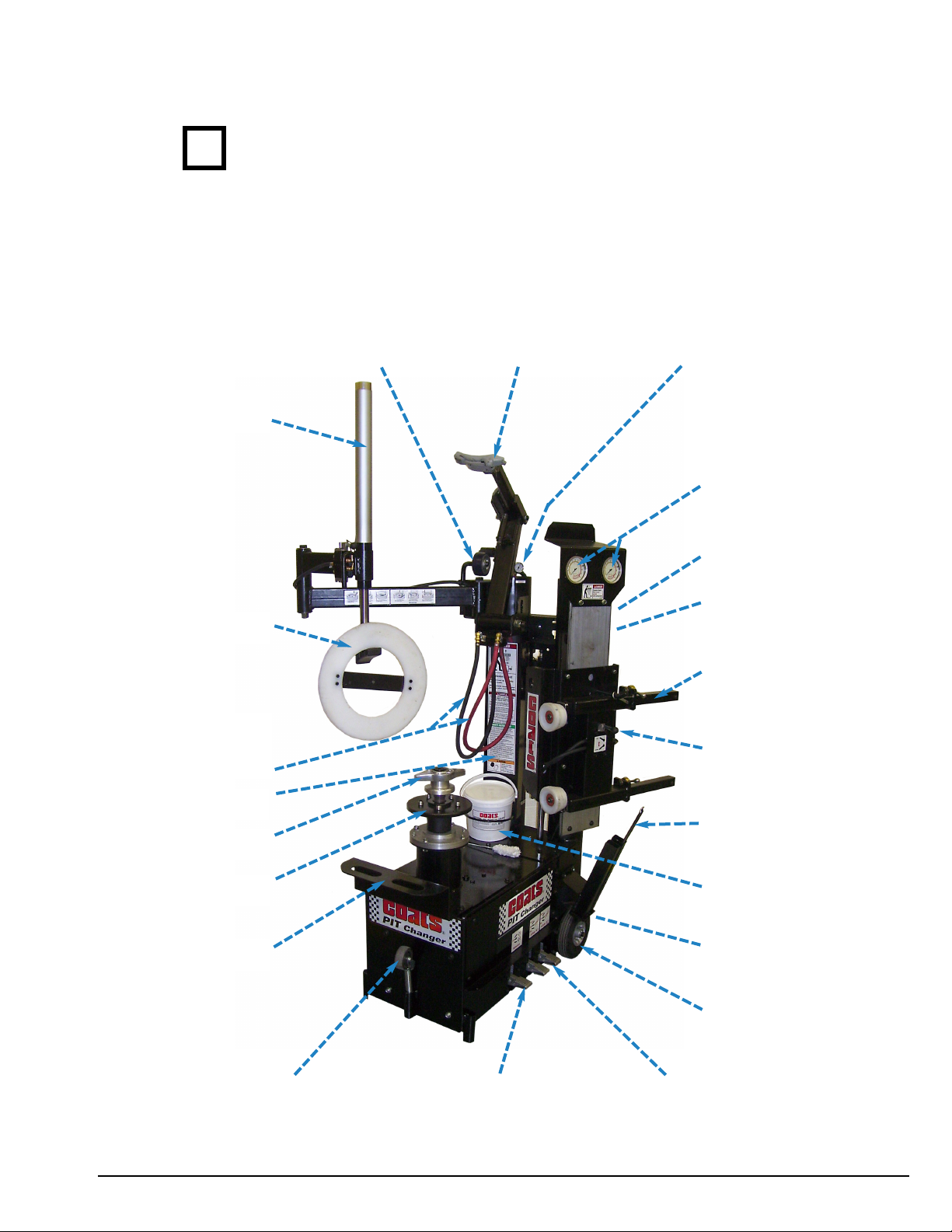

Principal Operating Parts

Know Your Unit

Compare this illustration with the unit before placing it

into service. Maximum performance and safety will be

obtained only when all persons using the unit are fully

trained in its parts and operation. Each user should learn

the function and location, of all controls.

Prevent accidents and injuries by ensuring the unit is

properly installed, operated and maintained.

Do It Now!

Now is a good time

to fill out the Owner’s

Registry Card.

Duckhead® Detent

System

Robo Arm &

Control

Twin Inflation

Hoses & Clip-on

Chucks

Protector Ring

Safety Decal

Hold Down Nut

Wheel Face/Plate

Tire Rim Shelf

Caster Wheel &

Storage

Floating Duckhead

System - with Gray

Duckhead

Air Accumulator

Gauges & Safety

Val ve s

Twin Inflation Gauges

Dolly Handle

Filter/Lubricator

Upper & Lower

Powered Roller

System with Lock &

Pin

Power Roller Actuator

Val ve

Dolly Wheels

110 VAC Electrical

Cord

Paste Lube, Holder, &

Paste Mop

Lift Lever & Storage

Tube

Face Plate Rotation

Twin Inflation & Bleed

Val ve s

✓

Page 6

2 • Important: Always read and follow the operating instructions.

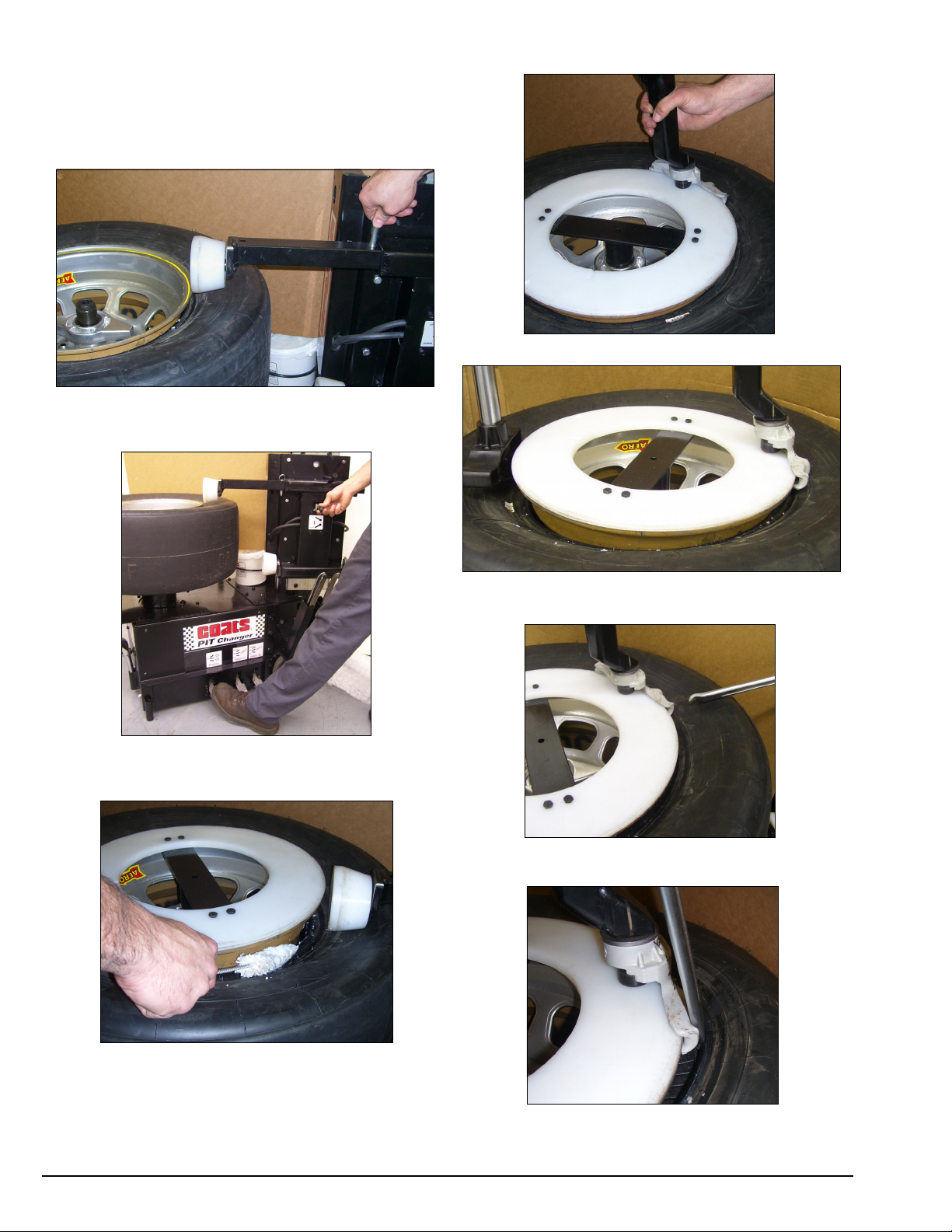

Operating Instructions

Demounting a NASCAR Type Tire with

Liner using a COATS PIT Tire Changer

Following are the steps:

1. Begin the demounting process by placing the top

Power Roller at the edge of the rim and lock or pin the

movement.

2. Start by rotating the wheel using the foot pedal;

then use the hand valve lever and move the powered

roller downward to loosen the top tire bead.

3. Once the top bead has been pushed even with

the rim’s drop center, stop. Apply an ample amount of

lubricant to tire and liner beads. If the plastic protector

is to be used, place it on the rim.

4. Place duckhead on the rim’s top edge as shown.

5. Next, place the Robo Arm opposite duckhead and

press tire sidewall down even with rim’s drop center.

6. Retrieve lift tool and observe ends of lift tool. Use

end with small hook.

7. With the small hook end of the lift tool, position

the tool as shown. Be careful to only lift the tire bead;

do not lift the liner bead.

Page 7

Important: Always read and follow the operating instructions. • 3

8. Rotate lift bar over slowly to position tire bead on

top of duckhead.

9. Move Robo Arm up and away from the tire and

rotate the wheel. Dismount top tire bead completely.

10. Use opposite end of lift tool to begin process of

removing the liner top bead. Use powered roller if necessary to press the tire sidewall down far enough to

grasp the liner’s top bead with the lift tool.

11. Rotate the lift bar over duckhead to lift the liner’s

top bead on to duckhead. Remove the liner’s top bead

completely.

12. Begin lower bead removal by positioning lower

powered roller near tire/rim intersection; place pin in

bar or lock to hold position.

13. Rotate tire and rim while moving bead loosener

roller slowly upward using hand valve. Continue bead

loosening until roller has pushed bead near the drop

center of wheel.

Page 8

4 • Important: Always read and follow the operating instructions.

14. Position the robo arm opposite the duckhead, fix

the robo head under the tire and liner sidewalls and lift

up as shown.

15. Lubricate the tire and liner’s lower bead.

16. Insert the lift bar over the duckhead and under

the tire and liner’s lower bead.

17. Rotate the wheel and remove both tire and liner

lower beads.

Optional lower bead removal if plastic protector

has been removed.

18. After the lower beads have been loosened, posi-

tion the robo arm over the roller and pull UP on the tire

and liner.

19. Move the lower roller UP slowly to position

lower beads above the top flange of the rim. Next

rotate the rim and remove the tire and liner.

Page 9

Important: Always read and follow the operating instructions. • 5

Mounting a NASCAR Type Tire with a

Liner using the COATS PIT Tire Changer

Following are the steps:

1. Mount inspected wheel on faceplate and engage

lug pins. Next thread centering nut on shaft. If the plastic protector is to be used, this would be the time to

install it with the small notch over the wheel’s inflation

valves.

2. Inspect tire and liner; next lubricate tire beads and

liner beads. Use ample amount of lubricant.

3. Position the tire/liner over rim and place duckhead

at the rim’s top edge; next position bottom bead of tire

onto duckhead; do not include lower liner bead.

4. Angle the tire as shown and press pedal to rotate

rim; first tire bead will mount onto rim; stop when

mounted.

5. Use rotation pedal (raise pedal upward) and

reverse rotation until the liner’s lower bead drops in a

mounting position on the duckhead. Next rotate wheel

in forward direction to mount lower bead of the liner.

Page 10

6 • Important: Always read and follow the operating instructions.

6. Next, maneuver the top sidewall of liner using the

bar as aid and press upper liner bead down over the

leading part of duckhead. Rotate wheel forward to

mount top liner bead.

7. Follow the bead lock around with bar until top liner

bead has been mounted.

8. Next, position top tire bead on duckhead as

shown, move upper powered roller on sidewall and

lower roller bottom edge until even with rim’s top drop

center. Next, position Robo arm as shown and press

sidewall down even with roller’s bottom edge.

9. Rotate rim and mount top bead, use care and

observe that the bead is flowing into the rim’s drop

center. Mount top bead complete and return the roller

to stowed position and return Robo to stowed position.

Page 11

Important: Always read and follow the operating instructions. • 7

Inflation

Tire inflation is performed in three steps: BEAD

SEAL, BEAD SEAT, and INFLATION. These steps are

explained in detail on page 14. Read the explanation of

each step and understand them thoroughly before proceeding.

Tire failure under pressure is hazardous.

This tire changer Will Not Restrain

Exploding Tires, rims or other related equipment. Inspect tire and wheel carefully for

match, wear, damage, or defects before

mounting. Always use approved tire bead

lubricant during mounting and inflation.

The clip-on chuck allows the operator to

keep hands and entire body back from

inflating tire. The chuck must be an

open/freeflow style with all parts in proper

working order.

Check for proper inflation gauge operation.

Accurate pressure readings are important to

safe tire inflation. Refer to the Operating

Maintenance section of this manual for

instructions.

The inflation pedals, located at the rear of the right

side of the machine, controls the flow of air through

the inflation hose, and has three positions.

Note:The clip-on chuck on the end of the hose should

always be an open/freeflow style with all parts in

proper working order.

Position 1 - Tire Pressure – With the inflation hose

attached to the tire valve and the pedal in this position,

the air gauge will register the air pressure in the tire.

Whenever your foot is removed from the pedal, it will

return to this position.

Position 2 - Tire Inflation – This is the DOWN activated position. With the inflation hose attached to the

tire valve and the pedal in this position, line pressure is

allowed to flow through the valve system and into the

tire for inflation. Correct tire pressure is not indicated

on the gauge in this position.

Position 3 - Pressure Bleed – This is the UP activated

position. With the inflation hose attached to the tire

valve and the pedal in this position, tire pressure can

be bleed from the tire.

Note the Inflation Pedal Positions (See Diagram)

Inflation Foot Pedals (two on right)

Note that this machine has two inflation circuits. One

for the tire and one for the liner.

Inflation Gauges

Note: Actual gauge face may vary depending on

model.

Note that there are two gauges. The front (left) gauge

is connected into the “A” inflation circuit. The rear

(right) gauge is connected to the “B” inflation circuit.

Twin Air Circuits

Clip-on air chucks attached to rim valves for tire and

liner inflation or bleed.

CAUTION

CAUTION

DANGER

Bleed

Pressure

From

Tire

POS 1 POS 2

POS 3

Page 12

8 • Important: Always read and follow the operating instructions.

Mismatched Tires and Wheels

Never attempt to mount and inflate mis-matched tires

and wheels.

Mismatched tire and wheel combinations can explode,

causing personal injury or death to operator and/or

bystanders.

DANGER

Half Size Tires

14.5, 15.5, 16.5, 17.5, etc.

Even Size Wheels

14.0, 15.0, 16.0, 17.0, etc.

15°

5°

Note the gap in sealing area

Bead may seal; but it

will not seat properly

Half Size Wheels

14.5, 15.5, 16.5, 17.5, etc.

Even Size Tires

14.0,15.0,16.0,17.0, etc.

Note 15° bead seat

Page 13

Important: Always read and follow the operating instructions. • 9

Stages of Inflation

Review these descriptions and diagrams carefully. Refer to them as

necessary during bead sealing, bead seating, and inflation to verify

that you are proceeding properly and safely.

Bead Sealing

Bead sealing is the process of capturing air pressure between the

tire and the rim. The tire will usually contain about 1/2 to 2 PSI at initial bead seal

Bead Seating

Bead seating usually occurs on the long tapered side of the wheel

first and the shorter side last. Bead seating will usually require at

least 7 PSI in the tire. 40 PSI is the maximum safe pressure at this

stage regardless of tire operating pressure.

Inflation

After the beads are seated, the tire is ready to be inflated. Do not

inflate the tire above the manufacturer’s recommended pressure as

stamped on the tire sidewall.

Air flow through valve requires about

140 PSI air pressure drop to ensure

sufficient flow on difficult tires.

Requires visual

conformation of

bead seat.

Stand clear of the tire during bead seat and inflation.

Stand clear of the tire during inflation.

Requires rubber lubricant on both upper

and lower beads.

Page 14

10 • Important: Always read and follow the operating instructions.

Bead Sealing

1. Position valve stem in front of operator and con-

nect the inflation hose with the clip-on chuck. Be sure

tire’s top bead does not cover the bottom of the valve

stem

2. Depress inflation pedal to position 2 and hold

about five seconds to begin air flow through tire valve.

3. Release the inflation pedal and allow it to return to

position 1. Verify that beads are completely sealed to

the wheel. Repeat these steps if beads have not

sealed. It may be necessary to wait a few seconds for

the air storage tank pressure to recover before

attempting again.

S. If tire and wheel are properly lubricated and

operator cannot achieve bead seal after three

or four attempts, the valve core may be

removed from the valve stem to allow more air

flow into the tire to assist with bead seal. After

bead seal is achieved, remove the clip-on

chuck and reinstall the valve core. Reattach the

clip-on chuck after core is installed.

Bead Seating

NEVER exceed 40 PSI to seat beads while

using this tire changer. If more than 40 PSI is

permitted by tire manufacturer, ALWAYS use

safety cage and clip-on chuck. NEVER

exceed recommended pressure after seating beads. ALWAYS keep hands and entire

body back from inflating tire.

An exploding tire, wheel, or bead sealing

equipment may propel upward and outward with sufficient force to cause serious

injury or death to operator or bystander.

Check tire pressure frequently. If operator is

unable to obtain Bead Seat, something is

wrong. Deflate tire completely, inspect tire

and wheel, correct any problems found,

relubricate both tire beads, and reattempt

Bead Seal and Seat procedures. Follow all

safety instructions in this manual and on

machine.

1. Once tire pressure is indicated on the air gauge

(inflation pedal in position 1; foot removed from pedal),

continue to inject air into the tire (inflation pedal position 2) in short intervals. Check the pressure frequently. Stand back during bead seat. Keep hands,

arms, and entire body away from tire during this procedure.

Inflation

NEVER exceed tire manufacturer's recommended air pressure. Tires can explode,

especially if inflated beyond these limits.

Use clip-on air chuck, keep hands, arms and

entire body back from inflating tire. Avoid

distraction during inflation. Check tire pressure frequently to avoid over inflation.

Excessive pressure can cause tires to

explode, causing serious injury or death to

operator or bystander.

1. Make sure both beads are seated. When both

beads are seated, the tire is ready for inflation.

2. Replace the valve core if it was removed.

3. Depress the inflation pedal to position 2 to inflate

the tire.

WARNING

WARNING

DANGER

Explosion Hazard

Never inflate tire

above

manufacturer's

recommended

pressure after bead

is seated.

DANGER

Explosion Hazard

Never exceed 40

PSI while seating

beads.

Remember R.I.M.

(see page iv and back cover)

DANGER

Remember R.I.M.

(Read, Inspect, Mount)

for every tire.

Page 15

Important: Always read and follow the operating instructions. • 11

4. Release air pressure from tire by raising up on the

inflation pedal (inflation hose must be attached to the

valve stem. Never add or adjust tire pressure using an

air hose without a clip-on air chuck and in-line valve. Do

not use a hand-held style chuck (figure 1).

5. Important: When inflating tires that require more

than 60 PSI, always use a safety cage and air hose with

a clip-on air chuck and in-line valve. The air hose must

have enough length between the chuck and the operation/in-line valve to allow the operator to stand outside

the trajectory.

Note: If you change tires defined as truck tires, they

must be inflated per OSHA instructions.

Figure 1 - Do Not Use a Hand-held Style Air Chuck

Maintenance

Instructions

Read and follow all the maintenance instructions provided in this manual to keep the machine in good operating condition. Refer to the other materials received

with the unit and to the service bulletins from the manufacturer for additional instructions on proper maintenance and service. Regular inspections and proper

maintenance are essential to preventing accidents and

injuries.

Before making any inspection, adjustment,

or repair, disconnect all power sources and

block out all moving parts to prevent injury.

Keep the machine and the immediate work

area clean. Do not use compressed air to

remove dirt and debris from the machine.

Foreign material may be propelled into the

air and into operator or bystander causing

personal injury.

Wear protective clothing, equipment and

eye protection when making any adjustments or repairs to the machine.

A. Check the adjustment of the Duckhead once a

month.

B. The transmission in this machine is a sealed unit

packed with grease and should need no normal maintenance.

C. Check the tire pressure gauge function daily, and

check the accuracy monthly. Use a pressurized tire and

a high quality stick-type pressure gauge. If necessary,

adjust the dial of the machine gauge. If the gauge is

defective, replace it immediately. Contact COATS at

(615) 641-7533.

D. Make sure all fasteners are securely tightened.

E. Make certain that all guards and covers are in

place.

F. Check for worn, damaged or missing parts including grips and protective covers. Replace them before

allowing the unit to be used.

WARNING

WARNING

WARNING

Page 16

G. On a daily basis, inspect the unit and check to be

certain that all systems are operating normally.

Detailed inspection and testing procedures are specified for various components at regular intervals. Set up

a chart and assign responsibility for these items.

Replace any damaged or missing safety

decals. They are available from COATS, (800)

688-6359.

Important: These instructions will help you service

the unit. Instructions are for a person with some

mechanical ability and training. No attempt has been

made to describe all basic steps. For example, how to

loosen or tighten fasteners. Also basic procedures

such as cycling systems and checking operation of the

equipment are not fully described since they are

known to anyone who does mechanical and service

work. Do not attempt to perform work beyond your

ability or at which you have no experience. If you need

assistance, call an authorized service center or contact

COATS directly, (800) 688-6359.

Separator/Lubricator Maintenance

Check oil and water levels regularly, and perform

these maintenance items weekly:

A. Disconnect air supply to machine.

B. The Separator (Filter) unit is equipped with an auto-

matic drain and should not normally need draining.

C. If the fluid level is greater than 1/4" from the top of

the gauge, add oil. Remove the filler plug on top of the

lubricator and add SAE 10W non-detergent oil or an air

tool oil to bring the level up to 1/4" from the top of the

gauge. Replace filler plug and clean up any spilled oil.

D. Adjust the oil flow by turning the black flow adjust-

ment knob and turning it to increase or decrease the

flow. Watch the formation of oil drops in the seethrough oil chamber. Reconnect the air supply and continually cycle the bead loosener through full strokes

and count the drips during the cycles. The delivery of

oil to the airline should be about 1 drop per 10 cylinder

cycles. Adjust flow as required.

Never inflate tire above manufacturer’s recommended pressure after bead is seated.

Any required inflation above 60 PSI should

be performed in an inflation chamber/safety

cage or securely mounted on the vehicle if

an inflation chamber is not available. A tire

explosion may cause personal injury or

death to operator or bystanders.

Air Source

This model requires a a 5 CFM air source at 150 PSI.

The operating pressure range for all models is between

125 PSI and 175 PSI at the machine.

Electrical Source

Electric models require power from a 30 amp, 120

volt electrical circuit. Have a licensed electrical technician perform any necessary changes to the power

source before plugging in the unit. The electrical source

must have a solid connection (less than 1 ohm)

between ground and building ground.

DANGER

CAUTION

12 • Important: Always read and follow the operating instructions.

Oil Flow

Adjuster

Knob

Air Out

Reg

G

Auto Drain

Outlet

Separator

Lubricator

Oil Fill

(Behind Oil

Flow Adjuster)

Oil Level

Check

A

Regu

Adjus

Kn

Air Out

Page 17

Important: Always read and follow the operating instructions. • 13

Parts Identification

Chassis Assembly

1 1

2 2

3 3

4 4

5 5

6 6

7 7

11 11

8 8

9

10

10

CHASSIS ASSEMBLY

Ref Part No. Description

1 8106301 1/4-20 x 3/4" Hex Washer Screw

2 8185649 Front Cover

3 8185473 Chassis w/c NASCAR

4 8140567 1/2-13 UNC Nut

5 85000638 Pilot Shaft

6 85000637 Spacer Block

7 85000636 3 x 1-1/4" Swivel Caster Wheel

8 905659 1/2-13 UNC - 2 x 1-1/2 Hex Hd Cap

Screw

9 8185628 Motor Side Cover

11 85000493 Shaft Housing, w/c

12 8106302 3/8-16 x 7/8 Hex Washer Screw

Page 18

Foot Pedal Assembly

14 • Important: Always read and follow the operating instructions.

1 1

2 2

3 3

4 4

5 5

6 6

7 7

8 8

9 9

11 11

12 12

13 13

17 17

18 18

19 19

20 20

21 21

23 23

24 24

27 27

15 15

33 33

31 31

35 35

36 36

32 32

25 25

10 10

34 34

14 14

29 29

16 16

30 30

TORQUE TO 4 - 8 ft./lb.TORQUE TO 4 - 8 ft./lb.

Ref Part No. Description

1 8106301 1/4-20 x 3/4" Hex Washer Screw

2 8183398 Pedal Shaft

3 8111609 Hairpin Cotter

4 8181948 Nylinder Bearing

5 8181911 Pedal Spacer

6 8181675 Standard Pedal

7 85000580 Pedal Spacer

8 8182670 Guide Bracket

9 8181918 Bar Spacer

10 8181707 Torsion Spring

11 8181977 Pin Clevis

12 8120469 Hair Pin Clip

13 8301121 0.562 ID Plain Washer

14 8181983 10-24 x 0.75, BHSCS Screw

15 8181699 Lever Cam Follower

16 8182363 Electric Bracket, Switch Ext.

17 8181982 3 x .5 x 12 mm Lg HHCS Screw

18 8301072 #6 Internal Washer

19 8182682 10/24 UNC Nylock Hex Nut

20 8107635 5/16 Std Flat

Ref Part No. Description

21 8181728 Switch Actuator Lever

23 8184389 Reversing Switch, Switch Only

(Note: Cord/Plug & Motor Wiring

Part of 81827336 Switch Assembly

Complete, Not Shown.)

81827336 Switch/Cord Wiring Assy Complete

24 8181959 Rubber Boot Cover

25 *** 4/way Valve Assembly

27 85000491 Switch/Valve Bracket

29 8184376 25 AMP Circuit Breaker

30 8181989 10-24 x 3/8, Gr 8 SHCS Screw

31 8182743 10-24 x 1/2, Gr 8 SHCSS Screw

32 8181984 1/4-20 x 1" HHC Screw

33 8182682 #10-24 Rvrsble Lk Hex Nut

34 8181369 1/4-20 Nylock Hex Nut

35 8181923 STOP WASHER (K)

36 8104945 SCREW-HWHSTC, 1/4x1, GR.5

*** See Valve Assemblies page 23.

Page 19

Important: Always read and follow the operating instructions. • 15

Table Top Assembly

1

6

8

9

10

11

12

2

7

3

4

5

Ref Part No. Description

1 85000489 Table Top Hub

2 85000490 1/2-13 x 3/4" Stud

3 8182979 Special Shaft Washer

4 85000664 40mm Stub Shaft

5 85000665 5/8-11 x 6" SHCS

6 85000662 Small Pressure Drum

7 8110514 Retainer Spring

8 85000661 Hub Nut Handle

9 8143169 1/4-20 Whz Lk Hex Nut

10 85000692 Tube & Bar/Handle w/c

11 85000645 NASCAR Locator Ring

12 8120321 1/4-20 NC x 1-1/4 HHCS

12

11

10

9

8

7

6

5

4

3

2

1

Page 20

Shaft Housing Assembly

16 • Important: Always read and follow the operating instructions.

Ref Part No. Description

1 904425 Hex Cap Screw

2 8106303 3/8-16 UNC Nut

3 8110653 3/8-16 x 6" Screw

4 8185546 Transmission Assembly

5 85000287 2 HP Motor

6 8301032 3/8" Flat Washer

7 8106303 3/8-16 UNC Nut

8 85000762 4L3100 V Belt

9 8120325 5/16 x 1.00 Serrated

10 8184674 Motor Pulley

11 8185485 Motor Bracket

12 8182178 Whiz Lock Nut

13 85000486 Housing Support Assembly

13

1

2

3

TORQUE TO

20-25 ft. / lb.

4

5

6

7

12

11

10

9

8

Page 21

Important: Always read and follow the operating instructions. • 17

Horizontal Slide Assembly

2

4

3

9

11

10

12

13

15

16

17

19

6

5

1

14

8

18

22

23

24

26

25

Ref Part No. Description

1 ** Cylinder Assembly

2 8185555 Flange Bushing

3 8185558 1/2" Shoulder Screw

4 8185575 Shaft Assembly

5 920861 20 x 47 x 14 Bearing

6 8185544 4" Nylon Roller

8 8185550 0.5100-78 Retaining Ext. Ring

9 8120424 3/8-16 UNC Washer

10 85000408 Gib Backup Bar

11 8184837 Long Guide Gib

12 8301122 1/2-13 Hex Nylock Nut

13 8185614 Horizontal Slide Assy.

14 8185562 Cam-lock Assmy w/handle

15 906101 3/8-16 x 2.00 HHCS

Ref Part No. Description

16 *** Vert. Slide Valve Assmy

17 8185615 Valve/Lube Brkt Mount Bracket

18 8143844 1/4-20 x 1/2" Hex Washer Hd Scrw

19 8106301 Hex Washer Head Screw

22 8185553 Wave Spring Washer

23 8000516 Nut, Hex, Lock, 3/8-16

24 8102278 1/8 x 1" Cotter Pin

25 8107238 7/16 x 2-1/8" Clevis Pin

26 8120088 7/16 x 1-3/4" Detent Pin

** See Cylinder Assembly page 22.

*** See Valve Assemblies page 23.

24

26

9

10

11

12

13

22

14

15

23

16

17

18

19

2

3

4

5

6

8

25

1

APPLY GREASE TO THESE LOCATIONS

Page 22

18 • Important: Always read and follow the operating instructions.

Pressure & Inflation Bracket System

1

2

3

4

5

7

10

13

14

17

18

15

25

28

29

31

32

35

36

37

27

26

16

34

11

44

8

45

46

39

38

42

41

40

48

49

12

43

24

47

6

9

19

30

21

22

23

TORQUE TO 240 ft./lb.

33

TORQUE TO 240 ft./lb.

11

10

9

8

44

12

13

47

14

37

36

35

15

16

17

18

19

45

39

25

21

26

38

22

27

23

24

46

28

29

30

31

34

41

32

33

42

43

1

48

49

40

Page 23

Important: Always read and follow the operating instructions. • 19

Ref Part No. Description

1 8108852 3/8 Whiz Lock Screw

2 85000499 Rear Leg

3 8185475 Welded Tower Assembly

4 8106303 3/8-16 UNC Nut

5 85000609 Lube Bracket

6 8143844 1/4-20 x 1/2 Hex Washer Hd

7 8183710 Mounting Cream

8 8185636 Channel

9 8182221 Clamp

10 85000658 Plate/Shaft Assembly

11 8140825 1/2-13 x 1-1/4" HHCS

12 8101253 7/8 x 1-1/2"

13 8120099 BL Cylinder Wheel

14 8102278 1/8 x 1 Cotter Pin

15 8182458 Tower/Reservoir Cap

16 8182599 1/4 NPT Relief Valve

17 8108968 1/8" NPT Air Gauge, 0-300

18 8183434 Manifold

19 8101898 3/8 x 1/4 NPT Fitting Hose

21 8100979 Handle Grip

22 8106302 3/8-16 x 7/8 Hex Washer Screw

23 85000605 Handle Assembly

24 8106301 Hex Washer Head Screw

25 8183770 Filter/Lubricator Bracket

26 8184868 Vertical Slide Plate

27 8182827 Filter/Lubricator w/Auto Drain

28 8185533 Gauge Mount Bracket

29 8108852 3/8 Whiz Lock Screw

30 85008946 Air Gauge, 100 PSI

31 8301063 #6-32 x 1/2" Screw

32 8120325 5/16 x 1.00 Serrated

33 8185651 Tool Holder Assembly

34 8181354 Lift Tool

35 8182016 3/4-10/E23 Nylock Hex Nut

36 8182457 3/4 SAE Flat Washer

37 8181172 3/4-10 x 7-1/2, Gr5 HHCS Screw

38 8301066 #6-32 Kep Nut

39 8120424 3/8-16 Hex Washer Hd.

40 8112842 950 Racer Wheel

41 8185623 NASCAR Wheel Shaft

42 8103006 5/32 x 1-1/4 Cotter Pin

43 8100994 3/4 x 2" Flat Washer

44 8000491 Lube Applicator

45 8106278 Tee Male Branch

46 8184467 1/4 NPT x 3/8 x 3/8 Tee Fitting

47 8181369 1/4-20 Nylock Hex Nut

48 8120491 3/4 x 3/8 NPT Reducer Fitting

49 85000083 90° ELL 3/8 NPT x 3/8 Hose Fitting

Page 24

20 • Important: Always read and follow the operating instructions.

Robo Arm Assembly

17

18

19

20

21

11

12

14

15

16

1

2

3

4

5

6

7

8

9

10

13

Ref Part No. Description

1 8183703 Hex Head Cap Screw

2 8100994 Flat Washer

3 8183641 Foot

4 905563 Roll Pin

5 8 301017 Steel Ball

6 8183637 Retaining Ring

7 7000230 Handle Grip

8 8181983 10-24 x 0.75 BHSCS Screw

9 *** Helper Arm Valve Assembly

10 8183644 Special Cylinder

11 8181997 90° ELL Fitting

12 8181996 Straight Male Fitting

13 8182016 3/4-10 UNC Lock Nut

14 8100994 Flat Washer

15 85000640 Arm Front Weldment

Ref Part No. Description

16 8183649 Socket Hd. Set Screw

17 8184226 1/4-28 Grease Fitting

18 8181038 Pivot Pin

19 8184904 Rear Arm Weldment

20 8182044 Neoprene Cushion Clamp

21 8106301 Hex Washer Head Screw

*** See Valve Assemblies, page 23.

10

11

12

13

14

9

15

8

7

6

16

5

4

3

17

18

19

20

21

TORQUE TO 240 ft. / lb.

APPLY GREASE TO THESE LOCATIONS

Page 25

Important: Always read and follow the operating instructions. • 21

Auxiliary Arm Assembly

1

2

3

4

5

11

13

14

15

6

7

8

9

10

18

19

12

16

17

Ref Part No. Description

1 8113583 3/8-16 x 1-3/4 Flat Hd Soc Cap Scr

2 85000644 Duckhead Spacer

3 8184426 Mount/Demount Head

4 8183033 Washer/Spacer

5 85000513 Mount/Demount Arm

6 8102278 Cotter Pin

7 85000542 Spring Plunger Assembly

8 8143168 Whiz Lock Screw

9 8104149 Valve Spring

10 8104154 5/8 x 4-1/2" Clevis Pin

Ref Part No. Description

11 8184226 1/4-28 Grease Fitting

12 8101039 1/2-13 Hex Center Lock Nut

13 309008 Stop Mounting

14 8106301 Hex Washer Head Screw

15 85000660 Plate/Shaft Assem w/c

16 8181038 Pivot Pin

17 8185639 Duckhead Arm Assembly

18 85000538 Bearing Bushing

19 8107662 1/2-13 x 5" Screw

10

12

11

13

14

16

17

15

18

19

1

Page 26

22 • Important: Always read and follow the operating instructions.

Cylinder Assembly

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Ref Part No. Description

1 8184892 Aux Cylinder Shaft

2 85008900 Tie Bolt Clamping

3 8183772 1/16 x 1/2 x 5/8 O-ring

4 85000332 90° Elbow Fitting

5 8110497 90° Elbow Fitting

6 8181620 Cylinder Bottom Casting Cap

7 8181631 O-ring Seal

8 8183786 Cylinder Rod Seal

9 8181632 Nyliner Sleeve Bearing

10 8184525 Piston/Washer Assembly

11 8182719 Hex Lock Nut

12 85008899 Cylinder Sleeve

13 8181622 Cylinder Bottom Casting Cap

14 8181183 5/16-18 Nylon Insert

15 85008898 Cylinder Assembly

1

2

3

4

5

6

7

8

9

10

11

12

13

14

*HOR. SLIDE CYLINDER ASSY.

Page 27

Important: Always read and follow the operating instructions. • 23

Valve Assemblies

2 2

1 1

3 3

3 3

2 2

1 1

4 4

5 5

1 1

2 2

3 3

4 4

5 5

HOR. SLIDE ASSEMBLY VALVEHOR. SLIDE ASSEMBLY VALVE

ROBO ARM ASSEMBLY VALVE ROBO ARM ASSEMBLY VALVE

PEDAL ASSEMBLY VALVE (ELEC.)PEDAL ASSEMBLY VALVE (ELEC.)

*

Ref Part No. Description

1 906960 1/4 NPT Bronze Muffler

2 8185621 3-Position Valve

3 8000378 Straight Fitting

Ref Part No. Description

1 8181997 Fitting

2 8109481 1/4-1/8 NPT Reducer Fitting

3 8185585 3-Position Valve

4 8105615 1/4 NPT Muffler

5 8000378 Straight Fitting

Ref Part No. Description

1 8184256 90° ELL Fitting

2 906960 1/4 NPT Bronze Muffler

3 8184369 Pedal Operated Valve

4 8120344 1/4 NPT Pipe Plug

5 8107234 1/4-3/8 Brass Tee Fitting

* 85008891 Four Way Valve Assembly

Page 28

85000681 00 10/07 © Copyright 2007 Hennessy Industries and COATS All Rights Reserved Printed in USA

Wiring Diagram

Loading...

Loading...