Page 1

8113006 00 05/09 © COPYRIGHT 2004 ALL RIGHTS RESERVED PRINTED IN U.S.A.

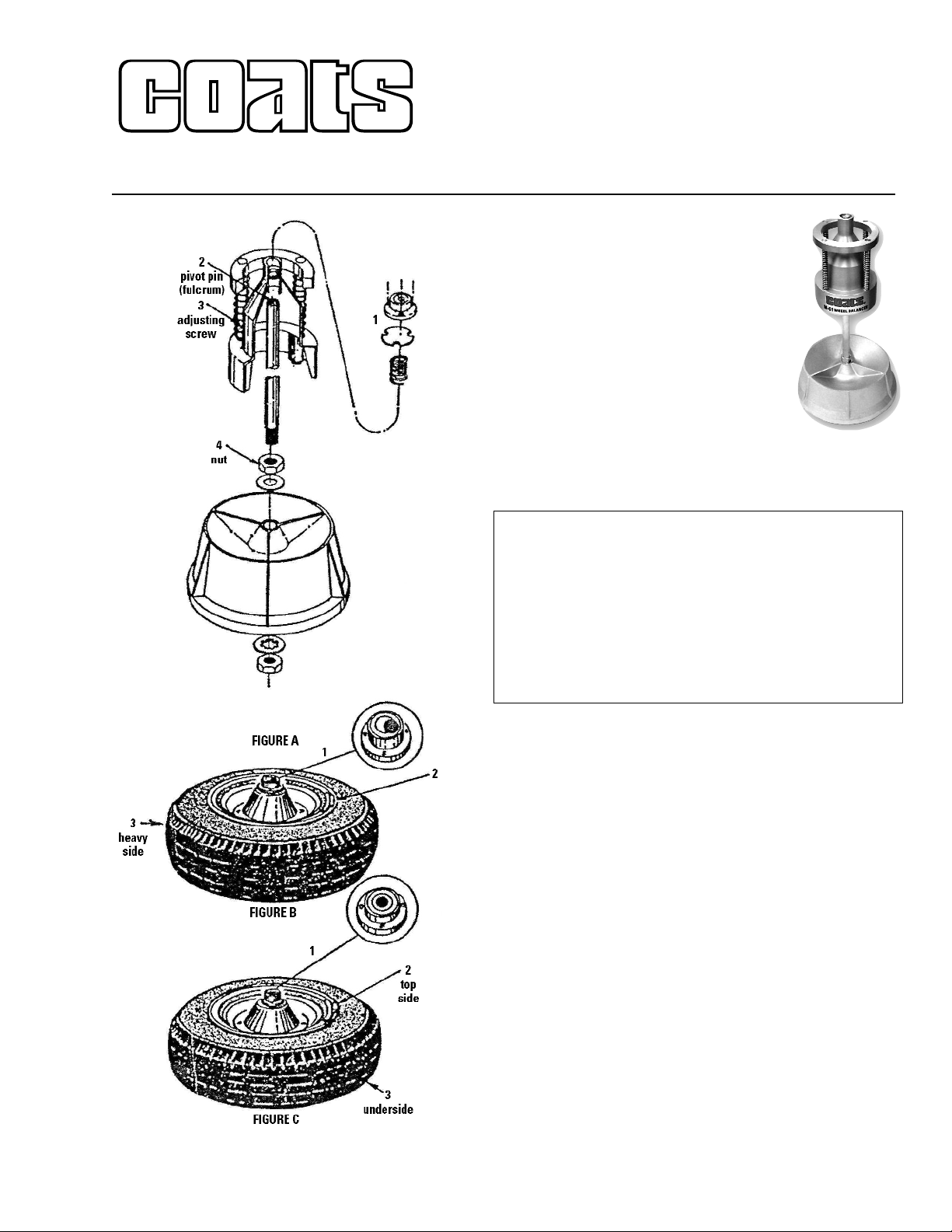

Instructions

1. Assemble the M-61 wheel balancer as

shown in figure A.

2. After assembling the wheel balancer,

view the circular level (bubble) at the top of

the bead. See arrow 1, figure B. Make certain

the bubble rests in the middle of the

black circle before using the balaner.

Adjustments are made while the head

rests on the support shaft (X-065). The

bubble on the M-61 wheel balancer is

mounted onto the top of the head assembly

cone by three (3) adjusting screws. Take care to make certain that the bubble rests squarely in the center of the black

circle.

3. Remove the tire and wheel from the vehicle. Clean off

any debris from the inside/underside of the rim. Check the

hub hole on the rim to insure that it is clean to allow for uniform seating on the balancer cone (head assy.).

Place the tire/wheel assembly on the balancer. Listen for

uniform seating when tire/wheel assy. engages cone. Let

the tire/wheel settle to a stop.

There exists an out-of-balance condition when the heavy

side of the tire/wheel causes the bubble to move outside

the black circle in the opposite direction from the heavy

side. See arrow 1, figure B.

Place a weight on the light side of the rim closest to the

bubble. See arrow 2, figure B. If the first weight does not

bring the bubble back to the middle of the black circle, then

try a larger (heavier) weight , or a smaller (lighter) weight to

bring the bubble into the middle of the circle as shown in

arrow 1, figure C.

4. Remove the tire/wheel from the balancer and place

the proper amount of weight needed equally on both sides

of the wheel, attach 1 1/2 ounce weight on the top of the

wheel rim and 1 1/2 ounce weight on the underside of the

wheel rim at the same location.

M-61 Operating Instructions

COATS, Inc. • Hennessy Industries • 1601 J.P. Hennessy Drive, LaVergne, TN 37086-3565

(800) 688-6359 • (615) 641-7533 • (615) 641-5104 FAX • www.ammcoats.com

Care and Maintenance

1) Always keep No. 10 weight oil (or equivalent) around

the pivot pin located in the upper end of the support

shaft (X-065). [Arrow 2, Fig. A]

2) Make certain the four (4) guide posts on the head

assembly are free of dirt and debris and kept treated

with a light lubricant.

3) Keep dirt and any foreign materials from gathering on

bottom flange of the head assembly.

Loading...

Loading...