Page 1

Wheel Lift

Kit 85608609

For use with COATS Models 50xx, 60xx, 70xx

This is a supplement to your operating manual and covers the setup and use of the COATS® Wheel Lift. If you

do not have your original operating manual, please call COATS at 1-800-688-6359 to request an additional copy.

User Instructions

with Parts Identifi cation

READ these instructions before placing unit in

service. KEEP these and other materials delivered

with the unit in a binder near the machine for ease

of reference by supervisors and operators.

1601 J. P. Hennessy Drive, LaVergne, TN USA 37086-3565 615/641-7533 800/688/6359 www.ammcoats.com Manual Part No.: 85608611 02

HENNESSY INDUSTRIES INC. Manufacturer of AMMCO

®

, COATS® and BADA® Automotive Service Equipment and Tools. Revision: 01/14

Page 2

Wheel Lift Setup

CAUTION

Always DISCONNECT THE ELECTRICAL

POWER before servicing equipment. This

prevents electrical shock or accidental

movement of the systems operated by the

electrical power.

CAUTION

Always DISCONNECT AIR SUPPLY before

servicing equipment. This prevents accidental movement of systems operated by compressed air which may result in personal

injury. BLEED THE AIR SYSTEM by actuating

all the valves.

CAUTION

STAY CLEAR OF MOVING PARTS when

reconnecting the unit of the air supply. The

position of control valves may have changed

during the servicing of the machine.

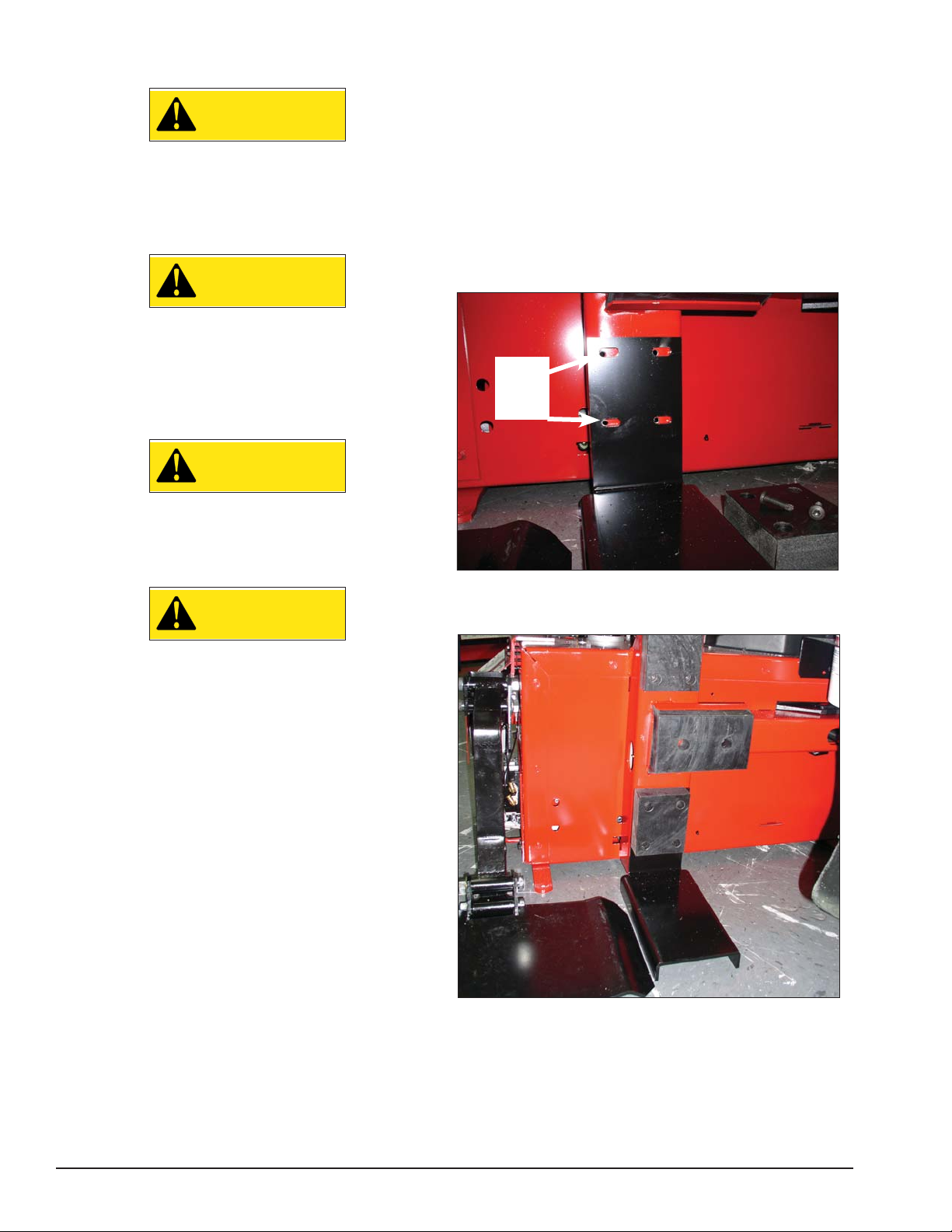

50xx, 60xx, 70xx Series Instructions

Before beginning this modification or attempting

any maintenance, remove the electrical power and air

source from the machine; also, bleed off any stored

compressed air by exhausting through the air blast foot

valve.

1. Remove the lower bead loosener pad; reserving

the bolts.

2. Next, align slots in the anit-tip bracket with the

holes in the chassis were the lower bead loosener pad

was attached.

Align to

Left End

of Slots

CAUTION

Do not operate machine without the anti-tip

bracket installed. It is required for maximum

machine stability, when wheel lift is operated under load that would shift the center

of gravity.

3. Now reassemble the lower bead loosener pad over

the anti-tip bracket, as shown.

2 • COATS

Page 3

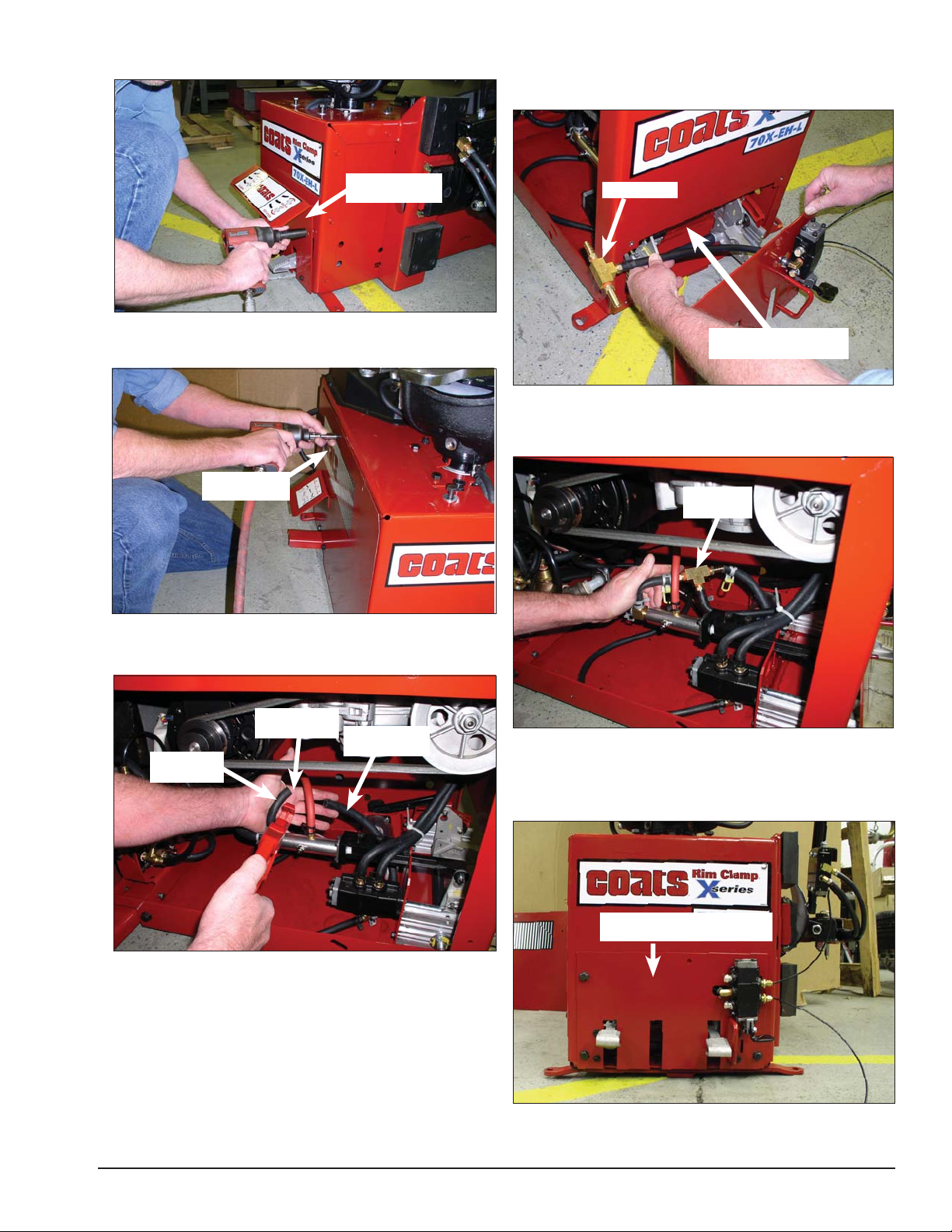

4. Remove pedal bracket guard and reserve the bolts.

7. Find the tee fitting, on the new pedal bracket

assembly, and route it through the front opening to the

inside of the chassis.

Remove Pedal

Bracket Guard

5. Remove the machine’s side panel using a speed

handle or drill and 3/8-inch socket.

Remove Side

Panel

Tee Fitting

Route Hose with Tee

Fitting Inside Chassis

8. Install the tee fitting, from the new pedal bracket

assembly, into the just cut 3/8-inch hose and secure

using hose clamps.

Install Tee

Fitting

6. Locate and cut in half the 3/8-inch hose that con-

nects the oil injector to the first pedal valve.

Cut 3/8-inch

Hose

Hose From

Oil Injector

Hose To First

Pedal Valve

9. Use three of the four reserved bolts to fasten the

new pedal bracket assembly to the front of the machine

chassis. Note the pedal valve’s position makes it so the

fourth both cannot be fastened.

Fasten Pedal Bracket

Assembly To Chassis Front

COATS • 3

Page 4

10. Remove two bolts from transmission (see step

8). Reserve bolts for later use.

11. Place lift mounting bracket on chassis and align

on the holes. Now install the lift mounting bracket to

the chassis using the two reserved bolts from step 10.

Important: Torque bolts at 30 foot pounds.

14. Assemble the lift pad to the lift assembly using

the supplied shoulder bolt. Be sure to grease the shoulder bolt and tighten it securely.

Install Lift Mounting

Bracket

12. Install the wheel lift assembly to the lift mount-

ing bracket using three thread cutting screws.

13. Route the two 1/8-inch tubes, from the lift pedal

valve, behind the lift bracket and connect the tubes to

the lift cylinder.

Fasten Wheel Lif t

Assembly

Fasten Lift Pad

Using Should Bolt

15. Reconnect air supply and machine test checking

for air leaks.

Important: Upon initial air supply connection, it is

normal if the Tire Lift jumps 2 or 3 inches the first time

it lifts, so be careful and expect that to happen.

16. Attach the new pedal bracket cover using sup-

plied thread cutting screws.

Fasten New

Pedal Guard

Apply Pedal And

Clamp Decals

Connect Cylinder

Tub es

17. Apply new pedal and clamp instruction decals.

18. Reassemble side panel.

4 • COATS

Page 5

Wheel Lift Operating Instructions

CAUTION

Do not operate machine without the antitip bracket installed. It is required for maximum machine stability, when wheel lift is

operated under load that would shift the

center of gravity.

1. Position table top as shown with open portion of

the table top facing the wheel lift.

3. Roll tire off wheel lift platform and onto the back

of the clamp that is located at the back of the machine

closest to wheel lift.

2. With wheel assembly on wheel lift. Keep wheel

vertical and push foot pedal down to raise wheel up.

4. With the tire resting on the back of the clamp,

lower it so that the rim fits in the clamps.

5. Push foot pedal up to lower wheel lift before performing tire change.

COATS • 5

Page 6

Parts Identifi cation

Note: Fittings have a sealant coating as

purchased. If absent, be sure to apply teon

tape or thread sealant at installation.

6

5

4

3

2

5

16

15

17

3

1

14

8

32

29

30

33

31

34

33

32

37

7

13

12

21

20

20

19

22

9

10

23

11

27

25

24

Lift Pedal

Valve

25

26

26

28

16

18

11

6 • COATS

Page 7

ITEM PART NO. DESCRIPTION

1 85608597 Lift Cover

2 8106301 1/4” Hex Hd Self Tap Screw, Gr.5

3 85606919 Ext. Retaining Ring

4 85606917 Flat Washer

5 8181996 Male Straight Fitting

6 85608531 Lift Cylinder Assembly

7 8102459 3/8” Self Tap Screw Gr.5

8 85608587 Chassis Mount Bracket

9 85608588 Lift Mount Assembly

10 8106303 3/8” Whiz Lock Nut, Gr.5

11 8120055 Clamp Carrier Nut

12 85608592 Lift Upper Arm

13 85608595 Lift Lower Arm

14 85608591 Lift Pivot Bracket

15 8106302 3/8” Whiz Lock Screw, Gr.5

16 85608606 SHSS Screw

17 85608602 Lift Pivot Cylinder Rod

18 85608598 Lift Pad

19 8105822 9/16 I.D. Hose Clamp

20 85607855 1/4 NPT Muffler, Small

21 8000376 ELL 90º 1/4 Hose Fitting

22 8181983 0.375-16 Hex Whizlock Nut

23 85608603 Valve Pedal

24 8182682 10-24 Nylon Insert Lock Nut Gr.5

25 8109481 1/4 NPT x 1/8 NPT RDCR Fitting

26 8181997 90º Elbow 1/8 NPT x 1/8” Fitting

27 85608534 Lift Valve

28 85608571 Bracket Assembly

29 902189 1/4-20 x.504 HHCS

30 85606362 13mm Spring Hose Clamp

31 8000378 1/4” Brass St. Fitting

32 85606363 16mm Spring Hose Clamp

33 8101898 St. 1/4” NPT 3/8” Hose Fitting

34 8000643 1/4” NPT Tee

**35 8099050 1/4” Hose

**36 8099075 1/8” Tube

37 85609355 Anti-tip Bracket

**Not Shown

COATS • 7

Page 8

85608611 02 01/14 © Copyright 2013 Hennessy Industries and COATS All Rights Reserved

Loading...

Loading...