Page 1

Locking Swing Arm

Kit 85607983

For use with COATS 50/70X and Tire Changers

This is a supplement to your operating manual and covers the installation of a COATS® Locking Swing Arm. If you

do not have your original operating manual, please call COATS at 1-800-688-6359 to request an additional copy.

User Instructions

with Parts Identifi cation

READ these instructions before placing unit in

service. KEEP these and other materials delivered

with the unit in a binder near the machine for ease

of reference by supervisors and operators.

1601 J. P. Hennessy Drive, LaVergne, TN USA 37086-3565 615/641-7533 800/688/6359 www.ammcoats.com Manual Part No.: 85607955 00

HENNESSY INDUSTRIES INC. Manufacturer of AMMCO

®

, COATS® and BADA® Automotive Service Equipment and Tools. Revision: 05/12

Page 2

Locking Swing Arm

Installation

CAUTION

Always DISCONNECT THE ELECTRICAL

POWER before servicing equipment. This

prevents electrical shock or accidental

movement of the systems operated by the

electrical power.

CAUTION

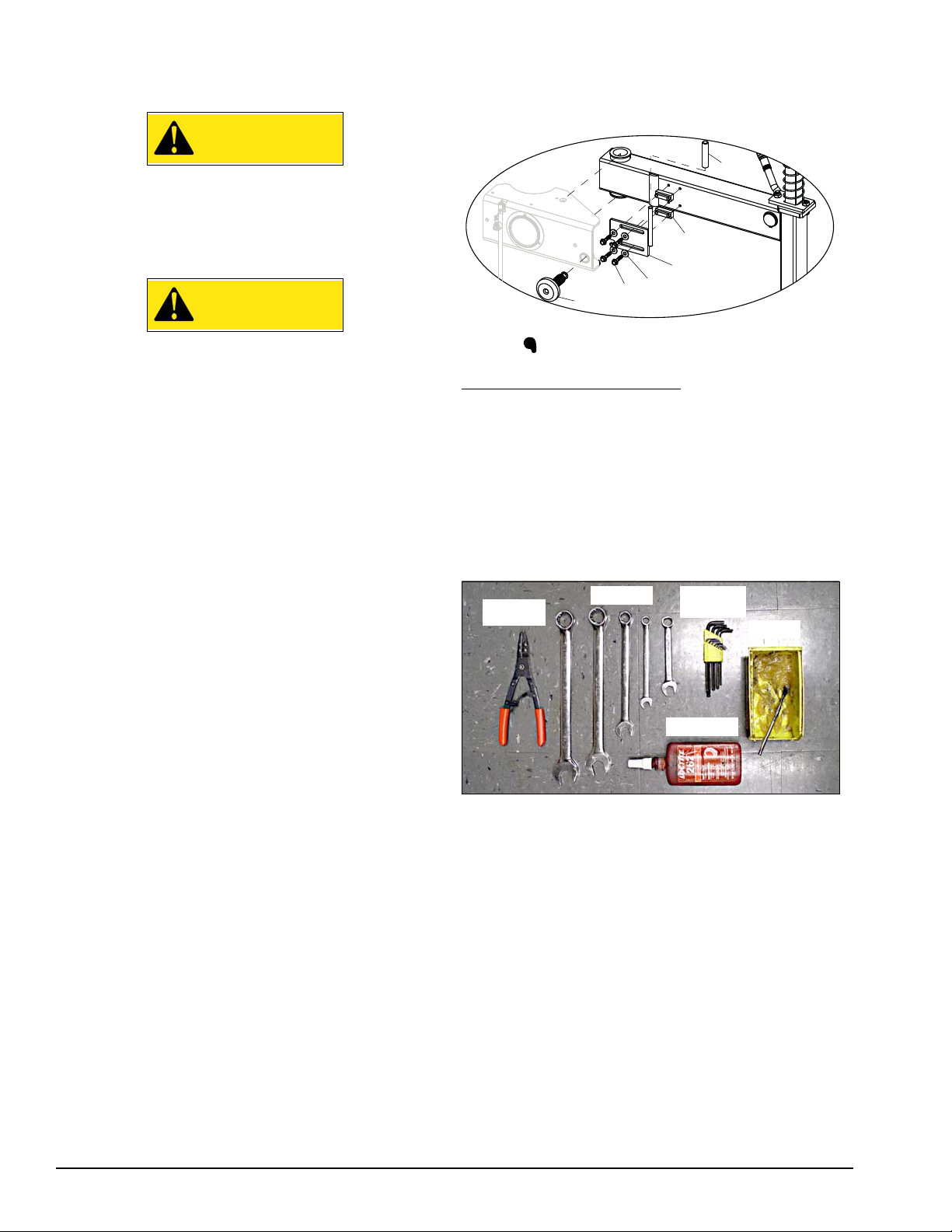

Parts Identification

Swing Arm Locking Mechanism

(Leverless Unit)

2

1

6

5

4

3

Always DISCONNECT AIR SUPPLY before

servicing equipment. This prevents accidental movement of systems operated by compressed air which may result in personal

injury. BLEED THE AIR SYSTEM by actuating

all the valves.

Apply Grease To These Locations

Item Part No. Description

1 85607820 Adjusting Lock Knob

2 85000317 5/16-18 x 1-1/2 HSWHCS Screw,

Zinc

3 8107635 5/16-inch Plain Washer

4 85607814 Swing Arm Lock Plate

5 83030571 Lock Block

6 7000230 1/2 x 3 Handle Grip

Tools Required:

Snap Ring

Pliers

Wrenches

Allen

Wrenches

Grease

Threadlock

Grease

Threadlock

Snap Ring Pliers

Allen Wrenches

Wrenches, 1-1/8", 1-1/16", 3/4", 5/8", 1/2"

2 • Important: Always read and follow the operating instructions.

Page 3

Instructions

1. Before beginning any work, clear the area and

position the machine for easy access. Disconnect

the electrical power and air supply from the machine;

empty all residual air.

2. Disconnect the leverless bead lifter coil air hose

from fitting installed on top of the swing arm bracket

(figure 1).

Disconnect Coil

Air Hose

Figure 1 - Disconnect Coil Air Hose From Fitting

3. Next, remove the vertical slide with leverless

assembly from the swing arm (figure 2). First, lock

vertical slide in the fully up position. Using an allen

wrench, remove bolt and knob at top of vertical slide;

then remove vertical slide spring. Now unlock the vertical slide and lower it out of the swing arm shaft.

5. Use wrenches to loosen swing arm bolt and nut.

While supporting the swing arm, remove and reserve

the bolt, nut, and pivot pin, then remove old swing arm

from tower (figure 3).

Figure 3 - Remove Old Swing Arm From Tower

Note: This would be a good opportunity to grease

parts.

6. Next, install the new swing arm using the reserved

bolt, nut and pivot pin. Assemble with the bolt pushed

up from bottom and torque to 240 ft. lbs.

7. Use reserved snap ring (figure 4) and reinstall the

lock handle/lift cam onto the new swing arm.

Remove Screw,

Knob & Spring

Unlock Vertical

Slide

Lower Assembly

& Remove

Figure 2 - Remove Vertical Slide With Leverless Assembly

4. Remove the vertical lock plate assembly and snap

ring holding the lock handle/lift cam. Reserve parts for

later use.

Snap Ring

Figure 4 - Reinstall Snap Ring To Lock Handle/Lift Cam

8. Reassemble the vertical slide with leverless

assembly to the new swing arm. Verify the lock handle

is working correctly.

9. Reattach the reserved vertical lock plate assembly

to the new swing arm Refer to owners manual for

adjustment procedure.

10. Reinstall vertical slide spring. Apply threadlock

to the reserved bolt, then reassemble knob and bolt.

11. Reconnect the leverless bead lifter coil air hose

to the fitting installed on top of the swing arm bracket.

Important: Always read and follow the operating instructions. • 3

Page 4

11. Remove existing adjusting knob and replace

with supplied adjusting lock knob (figure 7).

12. Now install handle grip onto swing arm lock

plate. Grease both sides of the lock plate grooves.

(figure 5)

Grease Lock

Plate Grooves

Install Handle

Grip

14. Mount the swing arm lock plate assembly to the

swing arm. Tighten in a criss-cross pattern. Verify swing

arm lock engages adjuster knob correctly. Final tighten

bolts and verify that the lock moves freely. (figure 7)

Adjusting

Lock Knob

Verify Lock

Engages Properly

Figure 7 - Verify Swing Arm Lock Function

Figure 5 - Prepare Swing Arm Lock Plate

13. Position lock blocks in plate grooves; then add

the four washers and bolts (figure 6). Apply threadlock

to bolts before tightening bolts.

Figure 6 - Assemble Swing Arm Lock Plate Hardware

Remember: Generously lubricate all friction points for

improved function.

15. Apply instruction decal below table top on top of

chassis (figure 8).

Figure 8 - Instruction Decal Placed On Chassis

16. Perform machine functional test.

85607955 00 05/12 © Copyright 2012 Hennessy Industries and COATS All Rights Reserved

Loading...

Loading...