Page 1

Model H.I.T. 6000

TRUCK TIRE CHANGER

Safety Instructions

Installation Instructions

Operating Instructions

Maintenance Instructions

READ these instructions before placing unit in

service. KEEP these and other materials delivered

with the unit in a binder near the machine for ease

of reference by supervisors and operators.

1601 J. P. Hennessy Drive, LaVergne, TN USA 37086 615/641-7533 800/688/6359 www.ammcoats.com Manual Part No.: 8120583 03

HENNESSY INDUSTRIES INC. Manufacturer of AMMCO

®

, COATS® and BADA® Automotive Service Equipment and Tools. Revision: 07/14

Page 2

Table of Contents

Safety Instructions ......................................................................................1 - 2

Owner’s Responsibility ......................................................................................................1

Operator Protective Equipment ........................................................................................1

Defi nitions of Hazard Levels ..............................................................................................1

Safety Instructions .............................................................................................................2

Bead Loosening ..................................................................................................................2

Demounting & Mounting ...................................................................................................2

Infl ation ...............................................................................................................................2

Installation Instructions ..............................................................................3 - 4

Electrical Installation ..........................................................................................................4

Air Installation ....................................................................................................................4

General ................................................................................................................................4

Principal Operating Parts ...................................................................................................4

Operating Instructions .............................................................................. 5 - 11

Tubeless Tire Bead Loosening ..................................................................................... 5 - 6

Multiple Piece Rim Bead Loosening .................................................................................6

Clamping ....................................................................................................................... 6 - 7

Demounting .................................................................................................................. 7 - 8

Mounting ....................................................................................................................... 8 - 9

Infl ation ...............................................................................................................................9

Special Instructions for “Duplex” or “Super Single” Tires ...........................................10

Mounting ........................................................................................................................... 11

Maintenance Instructions ......................................................................... 12 -13

ii • COATS Heavy Duty Tire Changer

Page 3

Safety Instructions

WARNING

Failure to follow danger, warning, and caution

instructions may lead to serious personal

injury or death to operator or bystander or

damage to property. Do not operate this

machine until you read and understand all

the dangers, warnings, and cautions in this

manual. For additional copies of either, or

further information, contact:

Hennessy Industries, Inc.

1601 J. P. Hennessy Drive

LaVergne, TN 37086

(615) 641-7533 or (800) 688-6359

www.ammcoats.com

Owner’s Responsibility

To maintain machine and user safety, the responsibility

of the owner is to read and follow these instructions:

• Follow all installation instructions.

• Make sure installation conforms to all applicable

Local, State, and Federal Codes, Rules, and Regulations; such as State and Federal OSHA Regulations

and Electrical Codes.

• Carefully check the unit for correct initial function.

• Read and follow the safety instructions. Keep

them readily available for machine operators.

Operator Protective Equipment

Personal protective equipment helps make tire servicing safer. However, equipment does not take the place

of safe operating practices. Always wear durable work

clothing during tire service activity. Loose fitting clothing

should be avoided. Tight fitting leather gloves are recommended to protect operator’s hands when handling

worn tires and wheels. Sturdy leather work shoes with

steel toes and oil resistant soles should be used by tire

service personnel to help prevent injury in typical shop

activities. Eye protection is essential during tire service

activity. Safety glasses with side shields, goggles, or

face shields are acceptable. Back belts provide support

during lifting activities and are also helpful in providing

operator protection. Consideration should also be given

to the use of hearing protection if tire service activity

is performed in an enclosed area, or if noise levels are

high.

Definitions of Hazard Levels

Identify the hazard levels used in this manual with the

following definitions and signal words:

DANGER

Watch for this symbol:

DANGER

It Means: Immediate hazards, which will result in

severe personal injury or death.

WARNING

Watch for this symbol:

• Make certain all operators are properly trained,

know how to safely and correctly operate the unit,

and are properly supervised.

• Allow unit operation only with all parts in place

and operating safely.

• Carefully inspect the unit on a regular basis and

perform all maintenance as required.

• Service and maintain the unit only with authorized or approved replacement parts.

• Keep all instructions permanently with the unit

and all decals/labels/notices on the unit clean and

visible.

• Do not override safety features.

WARNING

It Means: Hazards or unsafe practices, which could

result in severe personal injury or death.

CAUTION

Watch for this symbol:

CAUTION

It Means: Hazards or unsafe practices, which may

result in minor personal injury or product or property

damage.

Watch for this symbol! It means BE ALERT! Your

safety, or the safety of others, is involved!

COATS Heavy Duty Tire Changer • 1

Page 4

Safety Instructions

WARNING

Only properly trained personnel should service tires on the H.I.T. 6000. Read all safety

and operation instructions thoroughly

before using the tire changer.

ALWAYS remove all wheel weights and the valve core

to deflate the tire before servicing.

ALWAYS cover the electric motor and switch box

before hosing down the tire changer. Be sure water

does not enter the motor or switch box.

ALWAYS disconnect the electric power and air supply

before attempting any maintenance.

ALWAYS keep all working surfaces clean and free of

tire lube buildup.

ALWAYS be aware of what each person is and will do

before attempting any two-person operation.

Bead Loosening

NEVER place anything between the bead loosener

disc and the tire/wheel.

NEVER place any part of your body between the bead

loosener disc and the tire/wheel, severe bodily injury

may result.

NEVER allow the bead loosener to contact the wheel,

wheel damage may occur.

Demounting & Mounting

NEVER stand on the working table while demounting

or mounting a tire.

Inflation

ALWAYS follow all applicable Local, State, and Federal

Codes, Rules, and Regulations; such as the Federal

OSHA Standard Number 1910.177.

NEVER seat beads or inflate a tire on the tire changer.

The H.I.T. 6000 is not designed as a safety device or

stand for bead seating or inflation.

ALWAYS use an approved inflation chamber or inflation

cage.

The following safety instructions are for one piece

wheels only. Refer to the manufacturer’s or R.M.A. procedures for multi-piece wheels.

ALWAYS use an approved inflation chamber or inflation

cage equipped with a grip chuck and a remote inflation

gauge and valve. DO NOT OVER INFLATE! Tire or wheel

failure during and after inflation may result in an explosion capable of causing severe injury or death.

ALWAYS inflate the tire to manufacturer’s recommended cold operating pressure.

NEVER reinflate a tire that has been run under-inflated

or flat without first demounting the tire and checking for

wheel and tire damage.

ALWAYS inspect the tire interior for loose or broken

cords, cuts, penetrating objects, and other damage

to the carcass. Discard tires that cannot be properly

repaired.

NEVER rework, weld, heat or braze wheels.

NEVER strike the tire or wheel with a hammer.

ALWAYS be sure the tire diameter exactly matches the

wheel diameter.

ALWAYS keep hands, feet, and other objects away

from moving parts while the machine in turned on.

ALWAYS place the narrow bead seat to the outside

when clamping. Failure to demount the tire from the

narrow bead seat side may cause damage to the tire

beads.

ALWAYS apply an approved rubber lubricant to rim

flanges and both tire beads before demounting or

mounting and seating the beads. NEVER use antifreeze,

silicone, or petroleum base lubricants.

ALWAYS clean and inspect the wheel.

NEVER mount a tire on a damaged or rusty wheel.

Wheel damage or rust may cause tire or wheel failure

during inflation. Explosion from failure may result in

severe injury or death of the operator and bystanders.

ALWAYS be sure the bead opposite the tool is in the

drop center before rotating the tire when demounting

or mounting to avoid damage to the tire beads.

DANGER

Tire failure under pressure can be hazardous.

Place the wheel inside an approved inflation

chamber or cage before inflating. Use an

approved remote inflation valve, hose, and

gauge. ALWAYS wear safety goggles for eye

protection. Do not stand beside the wheel

or cage during inflation. Keep hands and

other parts of the body out of the cage during inflation. Observe the tire pressure frequently. Do not exceed the manufacturer’s

recommended maximum inflation pressure.

Failure to follow these instructions may

cause the tire and rim to separate with tremendous force, resulting in serious personal

injury or death.

2 • COATS Heavy Duty Tire Changer

Page 5

Installation Instructions

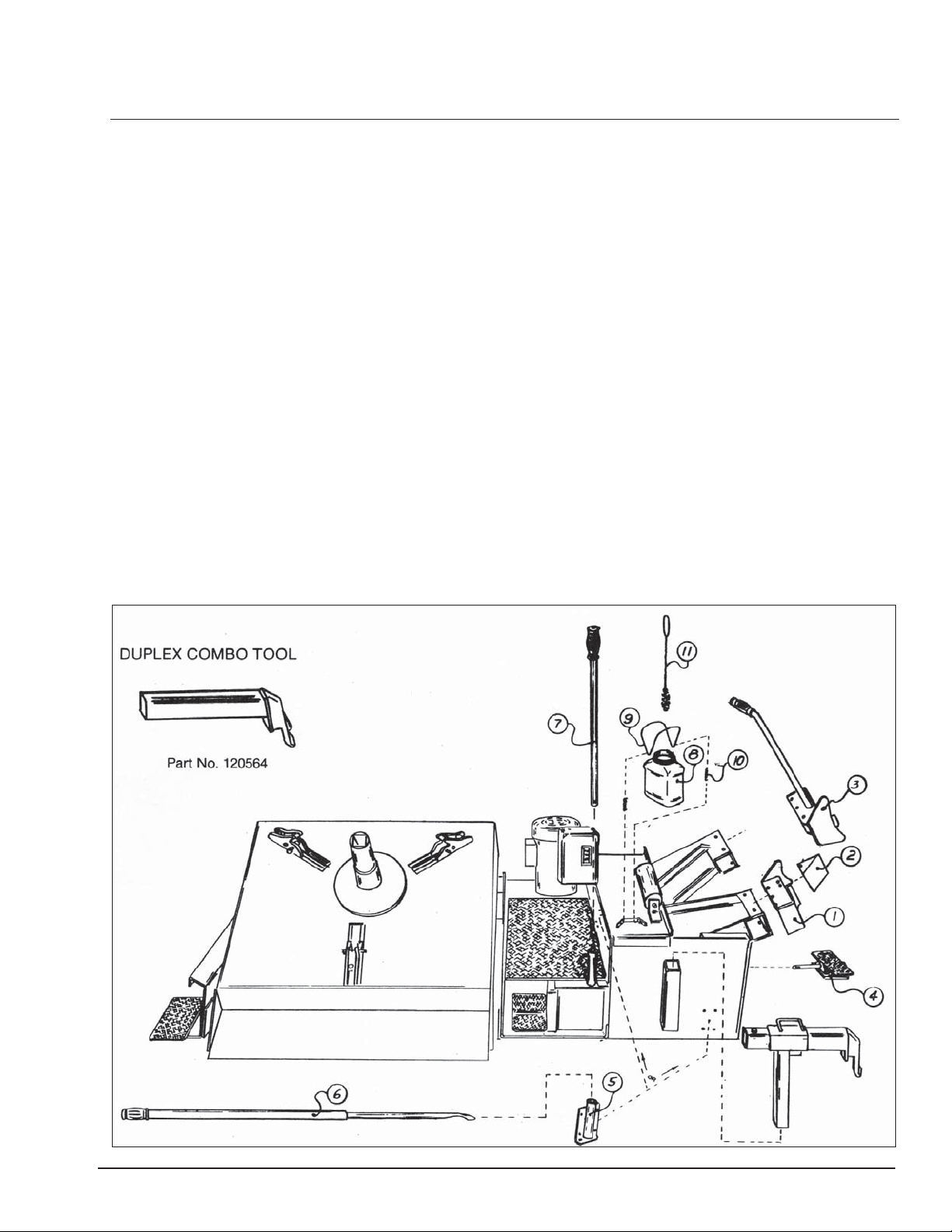

Parts Box Check List

Ref. Name Part No. Qty. Assembly Instructions

0 Fastener Package 7120393 1 Contains the following: nuts, bolts, pins, and screws

Detent Pins 7120326 5 B.L. shoes and stop connections

1/4 x 1/2" Cap Screw 7105390 1 B.L. pedal assembly

1/4" Locknut NC 7000591 2 B.L. pedal & handle connection

3/8 x 3/4" Self-Tap Bolt 7106300 4 Fastener bead lifter holder

1/4 x 1-1/4" Cap Screw 7120321 1 Secures PN 8120391 handle

Breather Cap 7120291 1 Switch with solid cap in reservoir

Quick Coupler-Female Fit. 7120440 1 To be used on owners air supply connection to machine air inlet

1 B.L. Shoe W/C 7120112 1 Install with (2) PN 7120326 detent pins

2 B.L. Rim Stop 7120513 1 Install with (1) PN 7120326 detent pins

3 Pivotal Shoe Assy. 7120545 1 Install with (2) PN 7120326 detent pins

4 B.L. Pedal Assy. 7120396 1 Attach to pedal extension with (1) PN 7105390 1/4 x 1-1/2" cap

screw and (1) PN 7000591 1/4" lock nut

5 Bead Lifter Holder 7120328 1 Can be installed in two positions, see diagram. Secure with (4)

PN 7106300 3/8 x 3/4" self tapping bolts

6 Bead Lifter Tool 7120332 1 Insert in bead lifter holder

7 Handle 7120391 1 Fits over valve shaft. Secure with (1) 1/4 x 1-1/4" NC screw & 1/4"

lock nut

8 Lube Bottle 7120347 1 Place in bracket on top of B.L. cover

9 Hold Down-Lube Bottle 7120346 1 Place over lube bottle “v” down. Bottom of “v” must be located

over holes in bracket.

10 Spring 7101106 2 Hook to hold down and bracket on B.L. cover

11 Swab 7120366 1 Place in lube bottle (Note: Fill lube bottle with approved lubricant)

COATS Heavy Duty Tire Changer • 3

Page 6

Electrical Installation

The H.I.T. 6000 requires 220 volt, 3 phase or optional

single phase power source. CAUTION: Only a licensed

electrician should install power source and hook up the

H.I.T. 6000.

Air Installation

A quick coupler is provided for disconnecting the air

supply during maintenance procedures. The male fitting

is on the inset hose. The female is in the parts bag for

installation on the owner’s air supply hose.

Important: Installation of this unit in an area where

gasoline, gasoline fumes, or other flammable vapors are

present requires a motor/switch riser kit (PN 7120433)

to meet national electrical codes; including paragraphs

500-4, 501 (1-8), 511 (1-5), PP 70-377.

Disconnect power source and check with volt-ohm

meter to assure power is off before connecting wires

of machine.

CAUTION

Motor rotation must be clockwise looking

at top of motor. If counterclockwise, reverse

any two of the power wires.

For lubrication of internal air system, a lubricator

should be installed in the air supply line.

General

The H.I.T. 6000 does not require bolting to the floor.

However, if desired, the two holes located at the

back of the machine, used for mounting on the pallet,

should be used. DO NOT BOLT AT THE FRONT OF THE

MACHINE.

Principal Operating Parts

4 • COATS Heavy Duty Tire Changer

Page 7

Operating Instructions

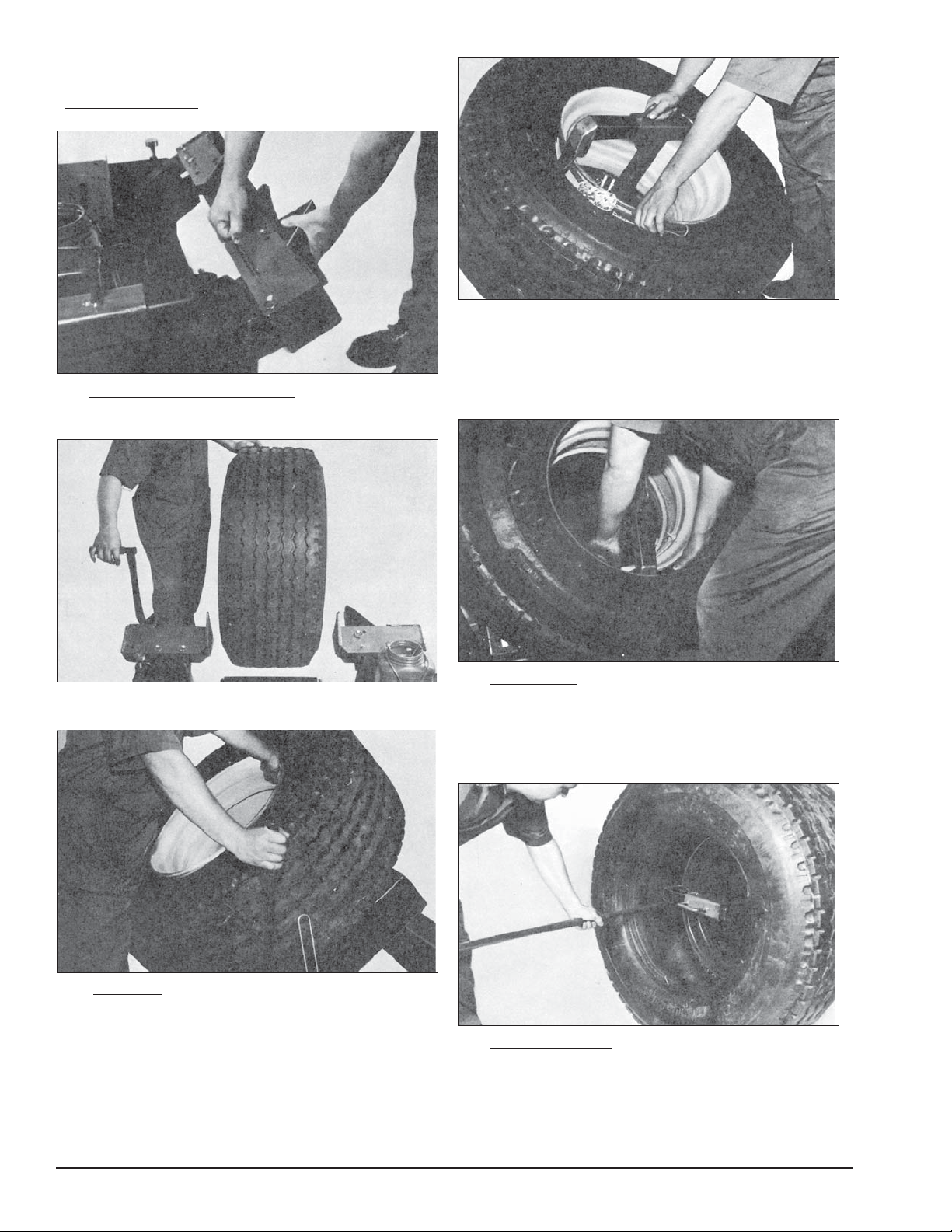

Tubeless Tire Bead Loosening

Remove the valve core and allow tire to deflate com-

pletely. Remove all weights from wheel.

3. For most tires, one operation of the bead loosener

shoes will loosen both beads. However, some difficult

tires on rusty rims may require an additional operation

to loosen the second bead. Here are three methods

that can help loosen the second bead.

1. Install rim stop in the appropriate position for tube-

less tires. See illustration.

Position tire between bead loosener shoes: short drop

center side toward shoe with rim stop.

WARNING

Do not place any part of body between bead

loosening shoes while machine is running.

2. Adjust shoes and loosen beads: using handle,

adjust bead loosener shoes on tire sidewalls 1/4-inch

from rim contour. Depress left side of foot pedal to

loosen beads. Depress right side to retract shoes. Note:

for handling several wheels of the same size, an adjustable stop is provided for convenience. (See arrow.)

Spin Wheel: Retract shoes completely. Roll wheel

back, spin 180 degrees and loosen opposite side as in

step 2 above.

Roll Wheel: Retract shoes completely. Roll wheel

forward firmly against the rollers and rotate it to a new

position. Reposition and loosen bead as in step 2 above.

CAUTION

Never allow both bead loosening shoes to

contact rim, since this could cause rim damage.

Angle Tire: (not recommended for aluminum rims) The

shoe with the rim stop may itself be used as a rim stop.

Angle the wheel so that this shoe contracts the rim and

the opposite shoe contacts the unloosened bead.

COATS Heavy Duty Tire Changer • 5

Page 8

4. Disengage bead loosener shoes and turn tire 90

WARNING

degrees and repeat steps 1, 2, & 3 until bead is loosened.

Allowing both shoes or one shoe and the

rim stop to contact the rim during bead loosening may cause rim damage.

Multiple Piece Rim Bead Loosening

CAUTION

Before attempting to loosen beads, remove

the valve core and be sure the tire is completely deflated. Do not place any part of the

body between bead loosener shoes.

1. Place rim stop in tube type tire position; see illus-

tration.

5. Use bead loosener shoes to hold tire and remove

lock ring.

6. To loosen other bead, remove wheel assembly

from between the shoes and pivot tire 180 degrees

to position the ring side of the wheel near rim stop.

Repeat steps 2, 3, and 4 above.

WARNING

Always inflate tires inside a safety inflation cage. Tire explosion during inflation can

cause serious injury or death.

Clamping

2. Position tire between bead loosener shoes with

the ring(s) toward the kicker shoe.

Position bead loosener shoe with 1/4" of lock ring.

CAUTION

Do not let shoes push on rim or lock ring(s).

Rim or rings may become warped and damaged.

3. Actuate bead loosener so that the bead loosener

shoe pushes bead in. As the kicker shoe passes the

ring, pull handle to bring the kicker shoe up to the bead.

Continue to full stroke of bead loosener.

1. Raise working table: Raise working table to almost

vertical position by pulling back on the control handle.

Open clamps by twisting the control handle counterclockwise.

2. Clamp Adjustment: Adjust all three clamps to the

proper wheel diameter range. The front hole position

is for 19.5" to 24.5". The rear hole position is for 16" to

19.5".

6 • COATS Heavy Duty Tire Changer

Page 9

3. Position Wheel: Roll wheel onto the safety skirt as

close to the working top as possible. Position rim flange

into the lower clamp.

Aluminum Wheels: Many aluminum wheels are

designed for the tire to be mounted from either side.

For these wheels it is recommended to clamp with

the disc side down. However, if the wheel does have

a short drop center side, it should always be clamped

with this side up.

5. Lubricate both beads thoroughly: Both beads and

the rim flange should be thoroughly lubricated with an

approved tire lubricant before attempting to demount

the tire. It may be easier to lubricate the bottom bead

while the tire is in the bead loosener.

4. Clamp Rim: With the left hand on the top front of

the rim, push the rim toward the upper two clamps.

Then close the clamping jaws by twisting the control

handle clockwise. Observe the clamping action to make

sure all three clamps are properly engaged. Lower

working table to desired angle by pushing forward on

control handle.

CAUTION

Make sure the short drop center side of the

wheel is toward the operator. Attempting to

demount tire from the long drop center side

may damage the tire bead.

Demounting

1. Install Mount/demount Tool: Insert mount/demount

tool in square drive socket and position tool head on the

rim flange. Rotate the tool head to approximately a 12

o’clock position by depressing either foot pedal.

COATS Heavy Duty Tire Changer • 7

Page 10

2. Lift Top Bead: Insert bead lifter under top bead

to left of mount/demount tool and lift bead over lower

blade of the tool head. Note: Make sure the top bead at

the 6 o’clock position is in drop center.

CAUTION

Always demount by rotating tool clockwise.

5. Remove Tire: The demounted tire can now be

removed. On heavier tires raising the working table will

help lift the tire to a vertical position.

Mounting

1. Before mounting tire on a used rim, be sure

flange area (particularly the bead seat area) is clean and

smooth. Remove any buildup of rust, corrosion or old

rubber with wire brush.

CAUTION

3. Demount Top Bead: Holding the bead lifter down

as shown, depress the front side of either foot pedal

thus rotating the tool head clockwise and demounting

the top bead. Make sure mount/demount tool does not

rotate into bead lifter during the operation.

4. Demount Bottom Bead: Return mount/demount

tool to the 12 o’clock position and insert bead lifter

under bottom bead to the left of head. Again, make sure

the opposite side of the bottom bead goes into drop

center. Lift bottom bead over tool blade. Hold the bead

lifter mount/demount tool clockwise and demounting

bead. Make sure tool does not rotate into bead lifter

during the operation.

Never mount a tire on a rim where any parts

show cracks, damage, or have been repaired

by welding or brazing. Thoroughly inspect

inside of casing for damage or foreign material. Make sure that the tire is completely dry,

as moisture deteriorates the cord fabric of the

tire and may result in eventual failure of the

tire. Lubricate both beads with an approved

rubber lubricant. Never use silicones, antifreeze, or petroleum base solutions.

2. Lubricate Rim: After inspecting rim, thoroughly

lubricate both bead seats with approved tire lubricant.

8 • COATS Heavy Duty Tire Changer

3. Lubricate Tire Beads: After inspecting tire thoroughly, lubricate both beads inside and out with an

approved lubricant.

Page 11

4. Position Tire: Lower table to a comfortable angle

and rotate tool to approximately the 7 o’clock position.

Lean tire over the rim and hook lower bead on mount/

demount tool handle.

tool clockwise and mounting the top bead. Make sure

that the bead following the tool keeps sliding into drop

center as the tool rotates.

WARNING

Never inflate tire on the H.I.T. 6000. It is not

intended as a safety device for inflation.

Always use an approved safety cage.

7. Remove Wheel: Remove mount/demount tool

from drive socket. If tool appears jammed, reverse the

tool slightly by depressing the back of either foot pedal.

Raise working table and release clamps by twisting

control handle counter-clockwise.

Inflation

These instructions are for tubeless one piece rim

wheels only. Follow tire manufacturer’s or RMA recommended procedures for multi piece rims.

DANGER

Do not attempt to inflate tire on the tire

changer. It is not intended as a restraining or

safety device for inflation.

5. Mount Bottom Bead: Depress front of either foot

pedal, thus rotating the tool clockwise. Hold down on

the tire until the tool begins to mount the bottom bead.

Make sure the bead goes into drop center behind the

tool head.

CAUTION

Keep hands away from the tire beads and

tool head during operation.

6. Mount Top Bead: With tool head at approximately

the 7 o’clock position, push top bead over tool head and

hold bead into rim drop center with the bead lifter as

shown. Depress front of right foot pedal, thus rotating

Always use approved safety cage and safety

procedures.

Tire failure under pressure can be hazardous,

place wheel completely inside an approved

safety cage before inflating. Use an approved

remote inflation valve, hose and gauge. Wear

safety goggles for eye protection. Do not

stand beside wheel or cage during inflation.

Observe pressure frequently and do not

exceed the tire’s recommended maximum

inflation pressure. Failure to follow these

instructions can cause tire or rim to separate

with tremendous force and can lead to serious personal injury or death.

COATS Heavy Duty Tire Changer • 9

Page 12

Special Instructions for “Duplex” or “Super

Single” Tires

Wheel Preparation: Remove valve core and allow tire

to deflate completely. Remove all wheel weights.

1. Adjust Bead Loosener Shoes: For tire width of 10"

and over, one or both bead loosening shoes should be

adjusted.

4. Lubricate tire beads and rim flange thoroughly: It

may be easier to lubricate the top bead by letting the

mount/demount tool push down on the bead and then

rotating the tool with the lube swab following the tool.

Demount the top bead in the usual manner). See section one.

2. Position tire and loosen beads as explained in the

bead loosening section.

3. Clamping: Due to the stiff sidewall, it may be

necessary to push down on the rim at the top as the

clamps are being closed, to engage the rim. Lowering

the table slightly will let the wheel’s weight help in

clamping.

5. Position Tire: It will be necessary to get the bottom

bead into drop center by raising the working table to

almost vertical (do not allow the tire to touch floor). Pull

out on tire as shown until bottom bead moves into drop

center. Then raise working table until tire rests on floor

to hold it in drop center.

6. Insert Bead Lifter: With bottom bead in drop center

and tire resting on the floor, rotate tool to 9 o’clock position and insert bead lifter under bottom bead just below

the tool head.

10 • COATS Heavy Duty Tire Changer

Page 13

7. Demount Bottom Bead: Lift bead over mount/

demount head. Rotate tool clockwise to demount bottom bead.

8. Remove Tire: After demounting the bottom bead,

lower table to free rim from tire.

Mounting

2. Position Top Bead: Manipulate and position the tire

so that the bottom bead slips down toward its bead

seat and the top bead rests evenly around the upper

rim flange.

3. Mount Top Bead: Use bead lifter to hold top bead

into drop center while tool rotates.

1. Mount Bottom Bead: With the table at a comfortable angle, mount the bottom bead in the usual manner.

It may be necessary to lift the bottom bead into drop

center as the mount/demount tool rotates.

WARNING

Never inflate tire or seat beads while on the

tire changer. It is not intended as a safety

device for inflation. Always use an approved

safety cage for tire inflation.

COATS Heavy Duty Tire Changer • 11

Page 14

Maintenance

WARNING

Before attempting any maintenance, disconnect electrical power and air supply.

12 • COATS Heavy Duty Tire Changer

Page 15

CAUTION

Loss of power and/or excessive pump noise

indicates low oil. Shut off machine immediately or damage to pump and motor will

result. Damage resulting from insufficient oil

is not covered under warranty.

1. Oil Level Check: Remove filler cap and check oil

level on dip stick. Fill to proper level as needed. Use

hydraulic oil only.

6. Lubricate Ring Gear: To gain access to the pinion

and ring gear, remove the COATS name plate located

on the working table. With a small brush or grease gun,

apply AGMA #1 or #2 grease liberally on the ring gear

teeth.

3. Oil Air Lines: Disconnect air supply at rear of

machine. Remove cover plate and disconnect quick

coupler connection between air valve and cylinder. Use

fair amount of spray lubricant.

7. Oil Filter Change: Disconnect electrical power.

Remove cover panel and place a shallow pan under oil

filter. Remove oil filter with standard auto oil filter grip or

wrench. Replace with service part #8120222.

COATS Heavy Duty Tire Changer • 13

Page 16

8120583 03 07/2014 © Copyright 2010 Hennessy Industries and COATS® All Rights Reserved. Printed in USA

Loading...

Loading...