Page 1

Extended Mobility (EMT)

RunFlat Tires

Training Manual

Bead Loosening, Demounting, Sensor Installation,

Mounting, and Inflation Procedures

prepared and presented by

FOR DISTRIBUTION

HENNESSY Part No.: 183708B

Name: Date:

Instructor: Location:

Page 2

Page 3

Table of Contents

i

EMT Training Objectives……………………………………………………………ii

Course Timetable…………………………………………………………………iii

Overview……………………………………………………………………Section A

Safety………………………………………………………………………Section B

Tools & Equipment…………………………………………………………Section C

Bead Loosening……………………………………………………………Section D

Demounting

–

Valve-Type Sensor…………………………………………Section E

Sensor Inspection & Installation

–

Valve-Type………………………Section F

Mounting

–

Valve-Type Sensor……………………………………………Section G

Inflation……………………………………………………………………Section H

First Half…Test for Performance Certification for EMT

……………………

Section I

Demounting–Strap-Type Sensor…………………………………………Section J

Sensor Inspection & Installation

–

Strap-Type

……

………………………Section K

Mounting

–

Strap-Type Sensor……………………………………………Section L

Second Half…Test for Performance Certification for EMT

…………………

Section M

Quick Reference……………………………………………………………Section N

Page 4

Page 5

EMT Training Objectives

ii

1. Given a lecture and demonstration, job aid, EMT tire/wheel assembly, tire

machine, accessories and tools the associate will be able to safely remove various

sizes of EMT tires from the wheels without damage to the tire, wheel or band-type

sensor.

2. Given a lecture and demonstration, job aid, EMT tire/wheel assembly, tire

machine, accessories and tools the associate will be able to safely remove various

sizes of EMT tires from the wheels without damage to the tire, wheel or valve-type

sensor.

3. Given a lecture and demonstration, job aid, EMT tire/wheel assembly, tire

machine, accessories and tools the associate will be able to safely install

various

sizes of EMT tires from the wheels without damage to the tire, wheel or band-type

sensor.

4. Given a lecture and demonstration, job aid, EMT tire/wheel assembly, tire

machine, accessories and tools the associate will be able to safely install

various

sizes of EMT tires from the wheels without damage to the tire, wheel or valve-type

sensor.

5. Given a lecture and demonstration, job aid, wheel, tools and a band-type

sensor

assembly, the associate will be able to safely install the sensor on the wheel with the

counter weight in the proper position and tighten the band clamp to the proper

specification.

6. Given a lecture and demonstration, job aid, wheel, tools and a valve-type

sensor

assembly, the associate will be able to safely install

the sensor on the wheel with the

retaining nut tightened to the proper specification.

7. Given a lecture and demonstration, job aid, EMT tire/wheel assembly, tire

machine, accessories, tools, and adequate practice time, the associate will be able

to complete the tasks

as outlined on the Performance Certification document.

8. Given a lecture and demonstration, job aid, EMT tire/wheel assembly, tools,

inflation safety cage

, the associate will be able to safely seat the beads and adjust the

tire inflation pressure to specification.

Page 6

Page 7

Course Timetable

iii

Before starting the program,appoint a time keeper to help maintain a schedule.The time

keeper can fill in the blank spaces below and at the beginning of each study session. Only

fill in the time blanks to the first break as the practice and certification periods can vary

with number of students and available equipment.

…………………………………………………………………Start Time

15 min……………………………………………………Overview of EMT

15 min………………………………………………………………Safety

10 min………………………………………Tools & Equipment Required

10 min……………………………………………………Bead Loosening

10 min……………………………………………Demounting–Valve-Type

10 min……………………………………Sensor Installation–Valve-Type

10 min………………………………………………Mounting–Valve-Type

15 min……………………………………………………………Inflation

15 min………………………………………………………………Break

15 min…Per Student/Per Tire Changer……………………………Practice

15 min…Per Student/Per Tire Changer…Performance Certification–Valve-Type

…………………………………………………………………Start Time

15 min……………………………………………Demounting–Strap-Type

10 min……………………………………Sensor Installation–Strap-Type

10 min………………………………………………Mounting–Strap-Type

15 min………………………………………………………………Break

15 min…Per Student/Per Tire Changer……………………………Practice

15 min…Per Student/Per Tire Changer…Performance Certification–Strap-Type

5 min…………………………………………………Certificate Signing

………………………………………………………………End (estimate)

Description

Lecture

Time

Clock

Time

Page 8

Page 9

The Objective of this Section:

To provide an introduction to tires that remain usable with little to no air pressure inside the tire

and the necessary changes to the mounting, demounting, and inflation procedures for these tires.

Safety Issues Related to this Section:

This manual is intended to supplement the Operator’s Manual provided with your tire changer

only and is not meant as a replacement. ALL safety issues contained in your original Operator’s

Manual remain in effect when changing this type of tire. The safety information contained in this

manual is to be used in addition to the safety information in your Operator’s Manual.

What is this new technology?

The principle behind this new technology is to provide a tire

that will remain “operable” even with a total loss of air pressure inside the tire, thus allowing the vehicle to be driven for

some additional distance without stopping. These tires will

be referred to as Run Flat and/or Extended Mobility Tires

(EMT).

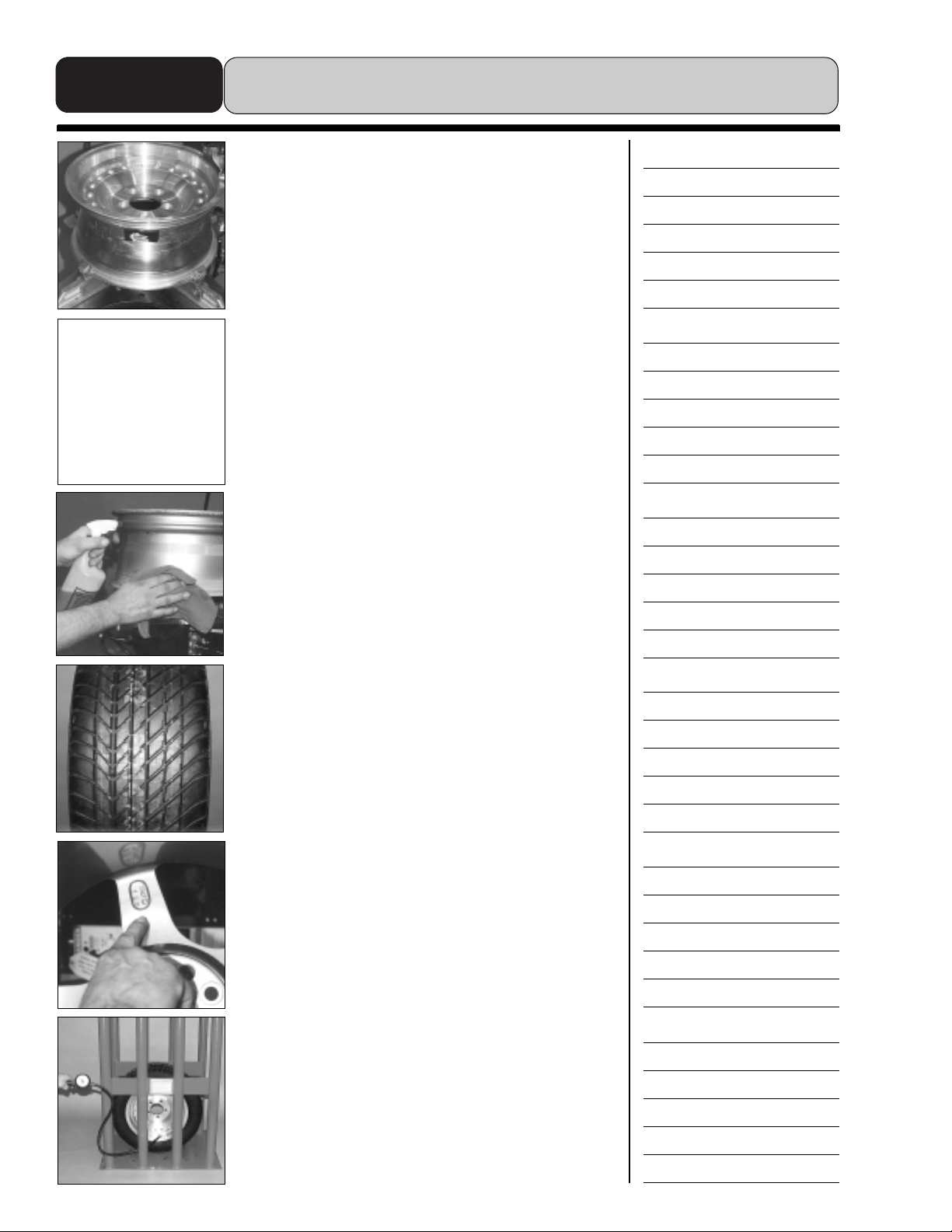

What is the difference in these new tires?

These tires are manufactured with exceptionally stiff sidewalls. These stiff sidewalls are designed to support the

wheel for limited periods of time without air pressure inside

the tire. Of course, stiffening the sidewalls to this degree creates problems for the wheel service technician.

How can I tell when the tire is flat?

Because the stiff sidewalls support the wheel in a drivable

posture even without air pressure, it is nearly impossible to

tell when this type of tire “goes soft.” Regular verification of

air pressure inside the tire is critical. Tire manufacturers are

required to install low pressure sensors on the wheels

(inside the tires) to provide electronic notification of low tire

pressure. These sensors transmit their low pressure warnings to a remote readout inside the vehicle.

This low pressure system is available on some new cars, and

will be available on even more models in the near future.

Today, customers can purchase an aftermarket system and

have it installed on their current vehicle. These systems use

either a valve-stem mounted sensor (O.E.M. only), or a sensor that straps onto the wheel (aftermarket & O.E.M.).

How is this type of tire serviced?

As any tire service technician can tell you, the stiffer the sidewall,

the tougher the tire changing. These new tires are so exceptionally stiff that they require special handling. This special handling

is not only to ease installation and prevent any damage to these

expensive tires, but to help prevent damage to the wheel and the

tire changing equipment. These tires require extra time and

patience to service and to prevent injury to the tire technician. Be

prepared to take your time and not rush the procedures..

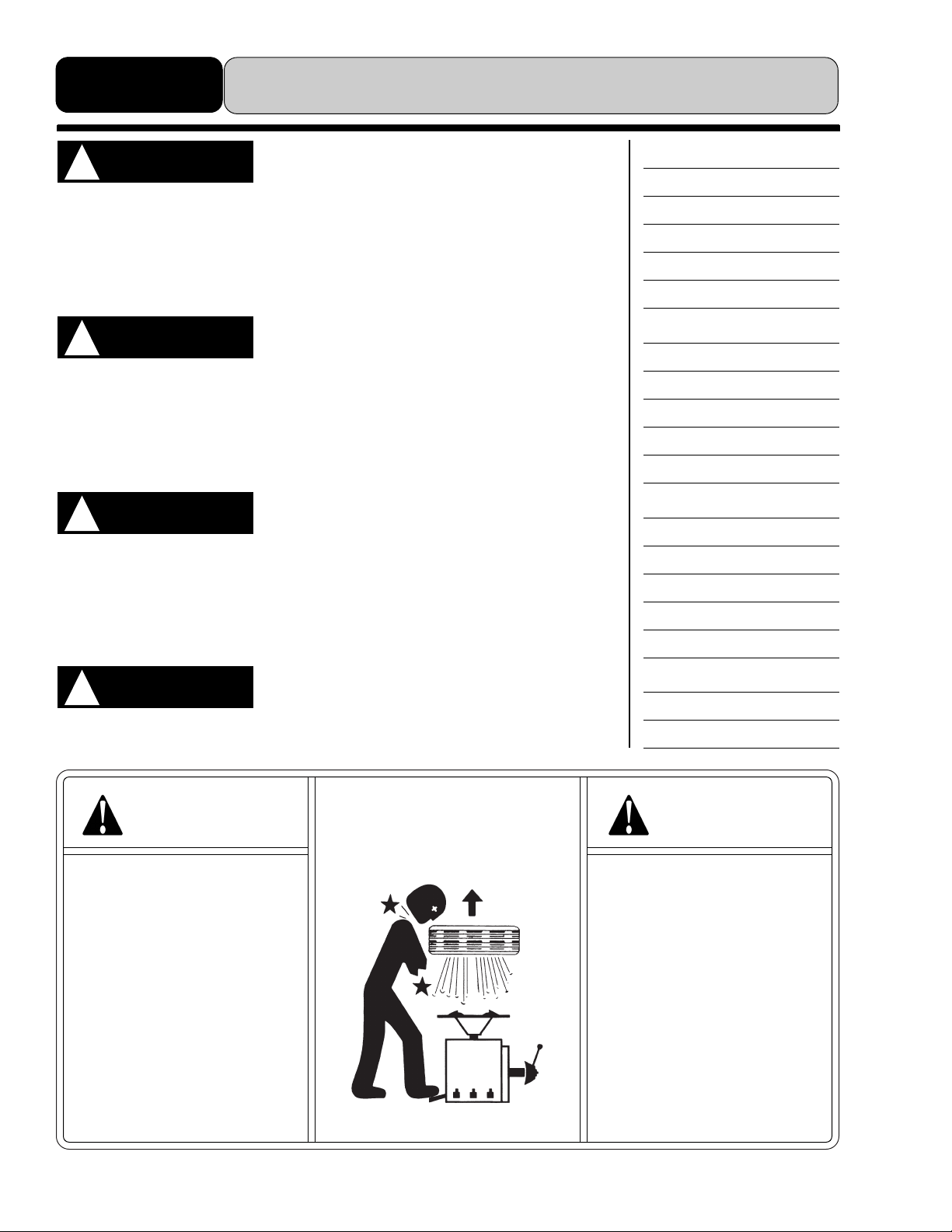

Rotate

Pause

Rotate

Overview

A–1

15

min

Stop Time

A

Page 10

A–2

Overview

These tires also require the tire service technician to be

extra cautious. In every case, there will be a low pressure

sensor of some type installed on the wheel. When standard

tire changing procedures are used on these tires the sensors

will be damaged. If not properly serviced, these sensors are

easily damaged and expensive to replace. Knowing the

proper method of changing a tire on a wheel equipped with

a sensor, and how the sensors themselves are installed, will

save the technician valuable time and resources and avoid

headaches and frustration.

Before you begin, take a good look at the tire and wheel.

There are things that the technician may take for granted

when changing standard tires that can have a dramatic

effect when changing these new tires. For example: on steel

wheels, watch for curb damage on the wheel rim flange that

is rough or sharp. The beads on these tires are pulled tightly

across this flange, and rough, sharp edges can seriously

damage the beads.

The tire service technician will also need to spend increased

time cleaning and polishing the wheel. These tires are very

inflexible, and will pull and slide against the wheel surfaces

much more than a standard tire. Keeping the wheel clean

and polished smooth will reduce friction and allow the tire to

move easier during the mounting and bead sealing process.

These tires made their debut on specialty vehicles like the

Corvette. Because of their “high performance” nature, these

tires are, in many cases, position–and directional–specific.

This means that they may be designed to roll in one direction

only, or to be placed in a front or rear position only. Or, in

some cases, they are totally position-specific, designed for

placement as right front, left rear, etc. This information is

included on the sidewall of the tire. The technician needs to

be aware of these specifics to ensure that tires are properly

mounted and positioned.

Many alloy wheels today are location-specific as well.

These wheels may have additional offsets to compensate for

brakes or other suspension requirements. This information is

usually included on the inside of the wheel. The technician

must also be aware of “reverse mount” wheels–where the

drop center (or short side of the wheel) is toward the inner

plane of the wheel instead of outer. Tires are always mounted from the short side, so reverse mount wheels will be

mounted to the tire changer “upside down” from

normal–with the inside of the wheel facing upwards.

Safe tire inflation is of the utmost importance.

These new tires are much tougher to bead seat and inflate.

Because they are so stiff, a bead seating pressure that

exceeds 40 PSI may be required. For this reason, a safety

cage must be used for bead seating and inflation of

EMT/RunFlat Tires. Read and follow ALL the safety instruc-

tions provided in this publication and your tire changer manual.

This completes Section A.

Page 11

The Objective of this Section:

To clearly identify the safety issues related to tire service and inflation procedures.

Safety Issues Related to this Section:

• Operator Protective Equipment.

• Definitions of Hazard Levels.

• ALWAYS use a safety cage for bead seating and inflation of EMT/RunFlat Tires.

• NEVER inflate tire above manufacturer’s recommended pressure after bead is seated.

This instruction manual is intended to supplement the Operating Instructions manual provided with your tire changer. Read and understand the entire manual before servicing any

tire or wheel. Read and follow all the CAUTION, WARNING, and DANGER notations in the

manual as they apply to these instructions as well. This manual is intended to act only as

an information supplement, and does NOT replace your Operating Instructions manual.

These exceptionally stiff sidewall tires use super-reinforced sidewalls and stiffer composition materials. It is very difficult to mount and demount. These tires may be used on

expensive custom wheels that are easily scratched or damaged. These tire/wheel assemblies will include a low-pressure sensor affixed to the inside of the wheel–either as a strap

on addition or a one-piece valve stem sensor. The operator must use extra care and caution when working with these tire/wheel/sensor combinations to avoid costly damage to

any of the individual components. These special combinations require changes to the

standard mount/demount instructions for your tire changer.

OPERATOR PROTECTIVE EQUIPMENT

Personal protective equipment helps make tire changing safer. However, equip-

ment does not take the place of safe operating practices. Always wear durable

work clothing during tire service activity. Shop aprons or shop coats may also

be worn, however loose fitting clothing should be avoided. Tight fitting leather gloves are

recommended to protect operator’s hands when handling worn tires and wheels. Sturdy

leather work shoes with steel toes and oil resistant soles should be used by tire service

personnel to help prevent injury in typical shop activities. Eye protection is essential during tire service activity. Safety glasses with side shields, goggles, or face shields are

acceptable. Back belts provide support during lifting activities and are also helpful in providing operator protection. Consideration should also be given to the use of hearing protection if tire service activity is performed in an enclosed area, or if noise levels are high.

Definitions of Hazard Levels

Identify the hazard levels used in this manual with the following definitions and signal

words:

Watch for this symbol:

It Means: Immediate hazards which will result in severe personal injury or death.

Watch for this symbol:

It Means: Hazards or unsafe practices which could result in severe personal injury or death.

Watch for this symbol:

It Means:Hazards or unsafe

practices which may result in minor personal injury or product or property damage.

READ AND UNDERSTAND THESE INSTRUCTIONS BEFORE BEGINNING. KEEP THESE

INSTRUCTIONS IN A BINDER NEAR THE MACHINE FOR REFERENCE BY SUPERVISORS

AND OPERATORS.

Safety

B–1

15

min

Stop Time

B

!

DANGER

!

WARNING

!

CAUTION

!

Page 12

DANGER

Explosion Hazard

Never inflate

tire above

manufacturer’s

recommended

pressure after bead

is seated.

DANGER

Explosion Hazard

A safety cage must be

used for bead seating

and inflation of

EMT/RunFlat Tires.

Never exceed 80 PSI to

seat beads on

EMT/RunFlat Tires.

B–2

Safety

The low-pressure sensors used on these tire/wheel

assemblies are very expensive to replace. Do NOT use

the bead loosener where it may come in direct contact

with the sensor. Do NOT use full strokes of the bead loosener to avoid pushing the tire bead into the sensor. ALWAYS

check sensor position before starting any procedure.

Failure to follow DANGER, WARNING, and CAUTION

instructions may lead to serious personal injury or death

to operator or bystander or damage to property. Do not

operate this machine until you read and understand all the

DANGER, WARNING and CAUTION notations in this manual.

This tire changer may operate differently from machines

you have previously operated. Practice with a regular

steel wheel and tire combination to familiarize yourself

with the machine’s operation and function.

The tire changer must be properly operated and main-

tained to help avoid accidents that could damage the

unit and injure the operator or bystanders.

CAUTION

!

CAUTION

!

WARNING

!

CAUTION

!

This completes Section B.

Page 13

The Objective of this Section:

To provide a basic list of the tools and equipment that will be required to change exceptionally

stiff sidewall tires.

Safety Issues Related to this Section:

This manual is intended to supplement the Operator’s Manual provided with your tire changer

only and is not meant as a replacement. ALL safety issues contained in your original Operator’s

Manual remain in effect when changing this type of tire. The safety information contained in this

manual is to be used in addition to the safety information in your Operator’s Manual.

This manual is written based on the use of COATS Rim Clamp®Tire Changers. This includes

models 5030, 5050, 5060, 5065, 6060, and 6065.

Equipment and Tool list:

• Safety Glasses

• Tire Lubricant (slow drying)

• Lube Swab

• Tire Marking Crayon

• Plastic booties (for metal duckheads)

• Drop Center Tool

• Lift Tool

• Shop Towels

• Air Pressure Gauge

• Valve Core Tool

• Valve Stems

• Valve Stem Puller

• Nut Driver (5/16 for strap-type sensor)

• Wrench (7/16 for valve-type sensor)

• Tin Snips

• Air Hose with Remote Valve and Clip On Chuck

• Safety Cage (for inflation)

• Inch Pound Torque Wrench

This completes Section C.

Tools & Equipment

C–1

10

min

Stop Time

C

Page 14

Page 15

The Objective of this Section:

To identify the safe and proper loosening of both inner and outer tire beads.

Safety Issues Related to this Section:

• ALWAYS wear eye protection during tire service activity.

• ALWAYS wear durable work clothing (i.e.; tight-fitting leather gloves, steel-toed shoes, back belts).

• NEVER wear loose fitting clothing or articles, jewelry, or long hair.

• NEVER smoke or have open flames or other ignition sources in or near tire changing area.

1

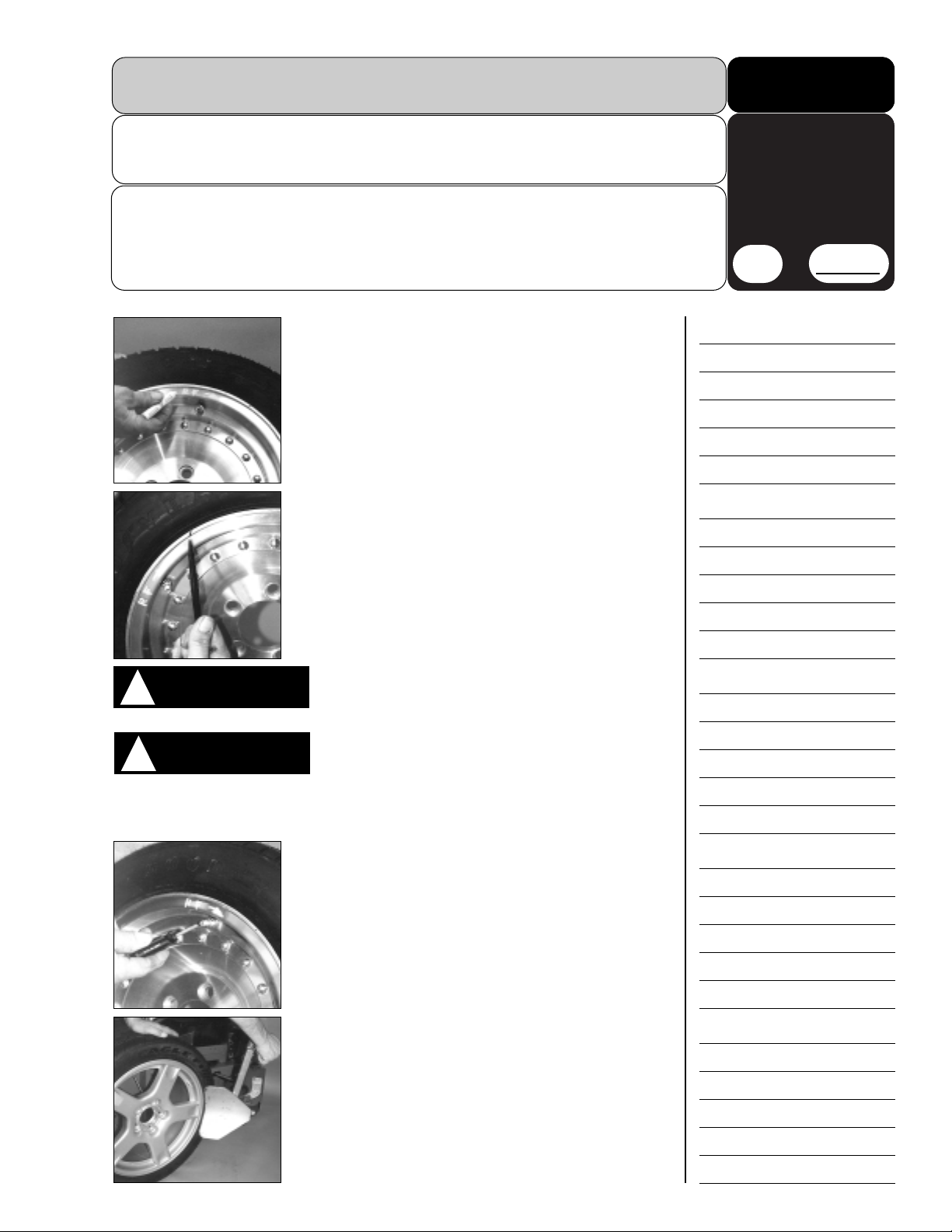

Use a crayon to mark both the tire and wheel with their

location on the vehicle (i.e.; RF, LR, etc.). Check the sidewall of the tire for any rotation and position indicators.

Remember that some low-pressure sensors are locationspecific as well. Note any offsets that may exist between the

front and rear wheels, or any difference in tire width.

Marking the tire and wheel will help you reinstall them in the

correct location later.

2

Inspect the wheel and tire for damage. Pay close atten-

tion to the rim flange–nicks or burrs here may interfere

with the mounting process or damage the tire bead. Make a

note of any damage found, and review with the customer

before continuing.

Safety glasses must be worn at all times. Air is released

from the tire with sufficient force to propel dirt and

debris into the eyes.

Never smoke or have open flames and/or other ignition

sources in or near tire changing area. A flammable gas

may have been used to pressurize the tire, and severe

personal injury or death could result.

3

Remove the valve core and allow the tire to completely

deflate. Remove all wheel weights from the wheel at this

time.

4

Roll the tire and wheel into position at the bead loosener,

with the top bead facing outward and the wheel seated

firmly against the rubber pads. The valve stem should be

positioned towards the top of the bead loosener shoe. This

position works best for wheels with existing pressure sensors, and those wheels with asymmetrical safety humps..

Bead Loosening

D–1

10

min

Stop Time

D

CAUTION

!

WARNING

!

Page 16

D–2

Bead Loosening

5

Loosen the upper bead, making sure not to over com-

press the tire. Allow the shoe to move the tire to a position just past the safety hump and then release. Do not push

the tire any farther into the wheel.

The tire in the photo is compressed too far (as represented

by the white arrow). The black arrow and line represent the

point to which the tire should be compressed.

6

Turn the tire and wheel around and reposition to loosen

the lower bead. Position the valve stem towards the top

of the bead loosener shoe.

Do not over compress the tire. Allow the shoe to move the

tire to a position just past the safety hump and then release.

Loosening the lower bead may require multiple attempts at

different locations around the wheel. Always make the first

attempt with the valve stem positioned as shown here, then

move to other locations.

7

Wheels with an asymmetrical safety hump can be bead

loosened only at the valve stem. This is true for both

upper and lower beads. Note the difference in the safety

hump at the valve stem and at a position 180° away from the

valve stem.

8

Rotate the tire changer table top to position the clamps

at 12, 3, 6, and 9 o’clock positions (when viewed from the

front of the machine).Move the clamps out to their fully

extended position.

9A

Lift the tire and wheel onto the table top…

9B

…and position the wheel rim into the rear clamp.

Lower the wheel and move the clamps into position

to clamp the wheel externally. Always clamp the wheel

externally when mounting and demounting EMT tires.

This completes Section D

.

!

Page 17

The Objective of this Section:

To demonstrate the safe and proper demounting of exceptionally stiff sidewall tires on wheels

with a valve-type low-pressure sensor installed. To demonstrate the use of a metal duckhead.

Safety Issues Related to this Section:

• ALWAYS wear eye protection during tire service activity.

• ALWAYS wear durable work clothing (i.e.; tight-fitting leather gloves, steel-toed shoes, back belts).

• NEVER wear loose fitting clothing or articles, jewelry, or long hair.

• ALWAYS deflate the tire completely and loosen both beads before beginning the demount procedure.

1

Lubricate the upper tire bead and the wheel liberally

with a slow-drying tire lubricant. Use the lift bar to help

push the sidewall down and provide easier access to the

bead and wheel. Rotate the wheel and lubricate the entire

circumference.

1A

Make sure to adequately lubricate the horizontal

wheel surface above the drop center and below the

safety hump. This will help the tire bead slide into the drop

center of the wheel opposite the duckhead.

2

Move the swing arm into position. Adjust the duckhead

so that it is 1⁄8

to

3

⁄16

inch away from the wheel.

NOTE: Always use a plastic bootie on metal duckheads. This

will help prevent damage to the wheel.

3

Rotate the wheel until the valve stem is under the rear

portion of the duckhead.

Position a drop center tool directly across from the duckhead to help the tire slide into the drop center as the bead is

lifted over the duckhead. If a drop center tool is not available,

a valve stem can be used as an aid. Insert it between the tire

and wheel across from the duckhead.

Lubricate the end of the lift bar. Insert the lift bar between the

tire and wheel, immediately next to the duckhead.

4

Begin rotating the lift bar down over the duckhead to pull

the tire bead up and over the duckhead. Move the tool

slowly and do not rush.

Remove the drop center tool (or other aid) as the bead slides

into the drop center of the wheel.

Demounting–Valve-Type Sensor

E–1

10

min

Stop Time

E

Page 18

E–2

Demounting–Valve-Type Sensor

5

Continue to pull the lift bar down and lift the tire bead

onto the duckhead. Pull the tool down slowly to allow the

tire bead to move into position without damaging the bead.

6

Once the upper bead is in position on the duckhead,

carefully remove the lift bar.

NOTE: Leaving the lift bar in place increases the arc of the

tire bead over the duckhead, thereby increasing the resistance. Removing the tool lessens the resistance and helps

prevent damage to the bead.

7

Begin removing the bead by rotating the wheel a short

distance–3 to 4 inches only–and stopping. Allow the

bead and sidewall to relax. Rotate the wheel again for a

short distance then stop to allow the tire to relax. Continue in

this manner until the upper bead is free of the wheel.

8

To remove the lower bead, begin by rotating the wheel

until the sensor/valve stem is once again under the rear

portion of the duck head. Lift the tire and carefully guide the

lower bead into position above the sensor.

NOTE: Positioning the sensor under the duckhead allows the

tire bead to slide into the drop center on the opposite side of

the wheel without interference.

9

Use the lift bar to lift the lower bead over the duck head.

Begin rotating the wheel very slowly, using the lift bar to

help keep the lower bead above the wheel.

NOTE: It may be advisable to place a shop rag between the

lift bar and the wheel to prevent damaging the wheel surface.

10

Continue rotating the wheel very slowly until the

lower bead is free of the wheel. Use the lift bar to help

keep the demounted bead above the wheel.

This completes Section E

.

Rotate

Pause

Rotate

Page 19

The Objective of this Section:

To identify the component parts of a valve-type sensor and the proper installation of the sensor

assembly.

Safety Issues Related to this Section:

• Protective eyewear must be worn at all times.

1

Identify the various parts that make up the valve-type

sensor: sensor with metal valve stem; O-ring;

nut, valve cap.

Inspect the O-ring carefully. If it is damaged, replace it with

a new ring before proceeding.

NOTE: Some sensors are location-specific (i.e.; front left,

right rear, etc.). Always install the correct sensor on the correct wheel so that the sensor is in the correct position.

2

Inspect the valve mounting hole. Be sure to inspect both

sides of the hole. Make sure it is clean and free of burrs

and nicks that may keep the valve from sealing properly

around the hole. Wipe away any dirt or debris.

3

Verify that air flows freely through the valve. Make sure

the valve core is installed, then apply air pressure to the

valve. Air should flow freely through the valve and sensor,

escaping through the air pressure port in the sensor.

4

Install the sensor by inserting the valve stem through the

mounting hole in the wheel. The sensor should lay back

towards the wheel with the O-ring in full contact with the

inner wheel surface. If a washer is used, place it over the

valve stem and against the outer wheel surface. Screw the

nut down onto the valve stem and finger tighten only. Use a

torque wrench to tighten the nut down to 90-105 inch pounds

(or to the sensor manufacturer’s specifications).

5

When removing a valve-type sensor, use care to avoid

damaging the sensor. Hold on to the sensor to keep it

from falling off the wheel once the nut is removed.

If the sensor is location-specific, make sure it is reinstalled

on the proper wheel.

This completes Section F.

Sensor Inspection & Installation–Valve-Type

F–1

10

min

Stop Time

F

Page 20

Page 21

The Objective of this Section:

To demonstrate the safe and proper mounting of exceptionally stiff sidewall tires on wheels with

a valve-type low-pressure sensors installed. To demonstrate the use of a metal duckhead.

Safety Issues Related to this Section:

• ALWAYS wear eye protection during tire service activity.

• ALWAYS wear durable work clothing (i.e.; tight-fitting leather gloves, steel-toed shoes, back belts).

• NEVER wear loose fitting clothing or articles, jewelry, or long hair.

1

Clean and polish the wheel. Check for any burrs or dam-

age to the wheel that might damage the tire during the

mounting process. Stiff sidewall tires of this type are exceptionally snug-fitting, and a clean, polished surface will

reduce friction and aid in the mounting and bead seating

process.

NOTE: Always clamp the wheel externally. This prevents the

wheel from moving upwards during the mounting process.

2

Lubricate the entire surface of the wheel liberally with a

slow-drying lubricant. Pay special attention to the bead

seat area, the safety humps, and the drop center.

3

Lubricate the lower tire bead.

NOTE: Pay strict attention to any specific tire location information on the wheel. The tire may have been marked earlier

with a location and/or rotation direction. The imprinting on

the tire sidewall may also give you specific location and

directional information. Remember that the low-pressure

sensor may also be location specific. Make sure you are

mounting the correct tire on the correct wheel.

4

Rotate the tabletop so that the valve stem and pressure

sensor are at the 6 o’clock position.

5

Position the tire over the wheel, with the lower bead

resting on the back of the duckhead. Position the duckhead so that it is 1⁄8 to 3⁄16 inch away from the wheel.

Remember to use the plastic bootie on metal duckheads.

Hold the tire down with the lower bead in the drop center

and rotate the wheel slowly. The lower bead should be

eased over the wheel slowly and carefully, giving the sidewall time to relax. Hold the tire so that the bead stays in the

drop center.

Mounting–Valve-Type Sensor

G–1

10

min

Stop Time

G

Page 22

G–2

Mounting–Valve-Type Sensor

6

Once the lower bead is mounted, rotate the table top

until the valve stem and pressure sensor are once again

in the 6 o’clock position.

Lubricate the upper bead liberally. Apply lubricant to both the

edge of the tire bead and the underside of the bead.

Adequate lubrication is vital to the upper bead mounting

process.

7

Position the upper bead over the duckhead. Put the tip of

the lift tool under the wheel rim flange and push the bar

down to hold the upper bead below the wheel and duckhead.

Use a shop towel on the lift tool to avoid damaging the wheel.

8

Rotate the wheel a short distance–only 3 to 4 inch-

es–and stop. Continue to hold the bead in the drop center with the lift bar, or place a drop center tool on the wheel.

Remember that stiff sidewall tires are difficult to mount. The

top bead is always more difficult to work with because the

tire cannot be angled across the drop center and rim flange

as easily as the lower bead.

9

Continue rotating the wheel, moving only a few inches

and then stopping.

Continue to hold the bead in the drop center with the lift bar

or the drop center tool. When the bar or the drop center tool

reach the 10 o’clock position, remove them. Continuing with

either tool in place may cause them to be forcefully ejected

from the wheel.

Continue rotating the wheel until the upper bead is fully mounted.

This completes Section G.

Page 23

The Objective of this Section:

To demonstrate the safe and proper bead seal, bead seat, and inflation of exceptionally stiff

sidewall tires.

Safety Issues Related to this Section:

• ALWAYS wear eye protection during tire service activity.

• ALWAYS wear durable work clothing (i.e.; tight-fitting leather gloves, steel-toed shoes, back belts).

• NEVER wear loose fitting clothing or articles, jewelry, or long hair.

• NEVER exceed the maximum safe air pressure during inflation process.

Tire inflation is performed in three (3) steps: bead seal, beat

seat, and inflation. These steps are explained in detail on

page H–5. Read the explanation of each step and understand

them thoroughly before proceeding.

Make sure the tire changer inflation gauge is operational. Accurate tire pressure readings are important to

safe tire inflation. Do not use a hand held gauge as personal injury could result.

If the wheel has been clamped from the outside for tire

mounting, release the clamps, lift the tire, and move the

clamps to the center of the tabletop.

If the tire/wheel has a diameter larger than 14 inches and

it is difficult to bead seal, the clamps should be moved to

the center of the tabletop for the bead seal operation.

Tire failure under pressure is hazardous. The tire changer

is not intended to be a safety device to contain exploding

tires, tubes, wheels, or bead sealing equipment. Inspect

tire and wheel carefully for match, wear, or defects before

mounting. Always use approved tire bead lubricant during

mounting and inflation.

The inflation pedal controls the flow of air through the inflation hose.

NOTE: The clip-on chuck on the end of the hose should always

be an open style with all parts in proper working order.

Position 1–At Rest–With the inflation hose attached to the

tire valve and the pedal in this position, the air gauge will

register the air pressure in the tire. Whenever the operator’s

foot is removed from the pedal, it will return to this position.

Position 2–Tire Inflation–This is the first activated position.

With the inflation hose attached to the tire valve and the

pedal in this position, line pressure is allowed to flow through

the valve and into the tire for inflation. Tire pressure is not

indicated on the gauge in this position.

Position 3–Bead Sealing–This is the second and last activated position. With the inflation hose attached to the tire valve

and the pedal in this position, line pressure is allowed to flow

through the valve and to the air-flate bead seal jets on the

table top for bead sealing.

Use Position 3 for bead sealing only. Do not use position

3 without a tire and wheel positioned on the tabletop.

Dirt and debris could be blown into the air with enough

force to injure the operator or bystanders. Do not use position 3 to inflate a tire.

Inflation

H–1

15

min

Stop Time

H

CAUTION

!

CAUTION

!

CAUTION

!

DANGER

!

CAUTION

!

Position 1

Tire Pressure

Position 2

Tire Inflation

Position 3

Bead Seal

Inflation Pedal Positions

Page 24

H–2

Inflation

IMPORTANT: Many tire changers are equipped with a pressure limiter to assist the operator with proper tire inflation.

When the inflation pedal is held in position 2, the pressure

limiter cycles the machine between position 2 (inflation) and

position 1 (at rest, no air flow). This cycling helps to prevent

over inflation of the tire. Tires can still be over inflated and

explode with the use of the pressure limiter if all of the

instructions in this manual are not followed completely. The

pressure limiter will keep most car and light truck tires from

inflating beyond 60 PSI (smaller tires may reach higher pres-

sures). It is the operator’s responsibility to follow all instructions and to control inflation pressure as specified in these

instructions. Check the function of the pressure limiter regularly and maintain it according to any provided service

instructions for safe and proper operation. Tires that require

inflation beyond 60 PSI must be inflated in a safety cage.

Bead Sealing

1

Bead sealing is typically not a problem when inflating

EMT/RunFlat Tires. Connect the inflation hose to the tire

valve stem. Hold the tire up against the upper edge of the

wheel. Be sure the top bead of the tire is over the bottom of

the valve stem.

2

Depress the inflation pedal to position 2 and hold about

1 second to begin air flow, then depress the pedal to

position 3 and hold very briefly–less than 1 full second. The

blast of air from the jets will expand the tire and seal the

beads.

3

Release the inflation pedal and allow it to return to posi-

tion 1. Verify that both beads are completely sealed to the

wheel. Repeat these steps if the beads have not been sealed.

NOTE: If the tire and wheel are properly lubricated and the

operator cannot achieve bead seal after 3 or 4 attempts, the

valve core may be removed from the valve stem to allow

more air into the tire to assist with bead seal.

Page 25

Inflation

H–3

Bead Seating–Safety Cage for EMT/RunFlat Tires

Operator should keep hands, arms, and entire body away

from the tire during bead seat and inflation procedures.

Do not stand over the tire as personal injury could result.

Always use a safety cage to bead seat and inflate

EMT/RunFlat tires. Never exceed 80 PSI to seat beads on

EMT/RunFlat tires. If operator is unable to obtain bead

seat, something is wrong. Deflate the tire completely,

inspect both the tire and wheel, correct any problems found,

relubricate both tire beads, and reattempt bead seal and

bead seat procedures. Follow all safety instructions in this

manual and on the machine.

You must inspect all wheels and tires prior to inflation

for condition or improperly matched wheels/tires.

Damaged or improperly matched wheels/tires may fail

upon inflation. Portions of a damaged or improperly

matched wheel/tire may not be restrained by a tire safety

cage resulting in injury or death.

1

Once tire pressure is indicated on the air gauge, remove

the tire/wheel from the tire changer, reinstall the valve

core (if it was removed), and place the assembly in an

approved safety cage.

Stand back during bead seat. Check the pressure frequently.

Keep hands, arms, and entire body away from safety cage

and tire during this procedure.

Tire beads should move outward and “pop” into their bead

seat position. If this does not happen, a problem exists.

Investigate carefully.

Check tire pressure frequently. Never exceed 80 PSI

while seating beads on EMT/RunFlat tires. Once seated,

never exceed tire manufacturer’s recommended air

pressure. Tires can explode, especially if they are inflated

beyond their limits. At all pressure levels when inflating

through the valve stem, keep hands, arms, and entire body

away from inflating tire. An unrestrained exploding tire,

wheel, or bead sealing equipment may propel upward and

outward with sufficient force to cause serious injury or

death to operator or bystander.

2

Use an air hose equipped with a remote pressure gauge and

valve. The air hose should be of sufficient length to allow the

operator to move a safe distance away from the cage.

Stay out of the trajectory as indicated by dotted area.

3

Apply air pressure to the tire in short bursts, checking

the air pressure in the tire in between bursts. Exercise

caution as the air pressure increases. Attempt to seat the

beads with minimum air pressure.

Once the beads “pop” into their seated position, stop the air

flow to the tire immediately.

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

Page 26

H–4

Inflation

INFLATION–Safety Cage for EMT/RunFlat Tires.

NEVER exceed the tire manufacturer’s recommended air

pressure. Tires can explode, especially if inflated

beyond these limits. Keep hands, arms, and entire body

back from the inflating tire. Avoid distraction during inflation. Check the tire pressure frequently to avoid over inflation. Excessive pressure can cause tires to explode, causing serious injury or death to the operator or bystander.

1

Verify that both beads are fully seated. When both beads

are seated, the tire is ready for inflation.

2

Replace the valve core (if removed). Leave the tire

inside the safety cage for inflation.

3

Verify the air pressure inside the tire. If the pressure

exceeds the manufacturer’s recommended pressure,

bleed off the excess pressure until the correct level is

reached.

If the pressure is below the recommended level, attach the

air hose with the remote gauge to the valve stem. Stand

safely away from the cage. Add air pressure to the tire in

short intervals, checking the increasing pressure frequently.

Do not over inflate the tire.

DANGER

!

Page 27

Mis-Matched Tires and Wheels–NEVER attempt to mount and inflate mis-matched tires and wheels.

Mis-matched tires and wheel combinations can explode, causing personal injury or death

to operator and bystanders. For safety reasons, do not attempt to mount and inflate mismatched tires and wheels.

Inflation

H–5

This completes Section H.

Bead Sealing–A 140 PSI air blast from the tabletop jets creates an air

curtain to aid in bead sealing. NEVER exceed 10 PSI in the tire during

bead sealing. The tire will contain about 1⁄2 to 2 PSI when bead seal is

obtained.

Bead Seating–Bead seating usually occurs on the long tapered side of

the wheel first and the shorter side last. Bead seating will usually

require at least 7 PSI in the tire. If the tire is in an approved safety cage,

80 PSI is the maximum safe pressure at this stage, regardless of operating pressure.

Most European import cars and many aftermarket alloy wheels are very

tight and may be difficult to bead seat. Also note that asymmetric hump

and run flat tires are extremely difficult to bead seat. Follow tire manufacturer’s recommended procedure for bead seating.

Inflation–After the beads are seated, the tire is inflated. DO NOT inflate

the tire above the manufacturer’s recommended pressure as stamped

on the tire sidewall. The typical inflation pressure for automobile tires is

between 24 and 45 PSI. Light truck inflation pressure typically covers a

wider range.

DANGER

!

A safety cage must be used for bead seating and inflation of EMT/RunFlat tires.

Page 28

Page 29

Student Name ………………………………………………………………

Signature ………………………………………………… Date……………

Instructor ……………………………………………………………………

Signature for completion of Test ………………………… Date…………

Test for Performance Certification for EMT

I–1

15

min

Stop Time

I

S = Successful Demonstration of Ability N = Needs more Practice

Bead Loosening

1. Mark both tire and wheel with their location

on the vehicle (i.e., LF, LR, LR, RR)

2. Inspect wheel and tire for damage.

3. Remove valve core and allow the tire to

deflate completely. Remove all wheel weights

from the wheel.

4. Roll the tire and wheel into position for bead

loosening, positioning the valve stem near the

top of the bead loosening shoe.

5. Loosen the upper bead without compressing

too far.

6. Turn wheel and tire around and reposition to

loosen the lower bead.

7. Rotate the tire changer table top to position

the clamps at 12, 3, 6, and 9 o’clock and extend

clamps out.

8. Lift the tire and wheel onto the table top and

position into rear clamp. Lower wheel and

clamp wheel externally.

Demounting

–(

Metal Duckhead) Valve-Type Sensor

1. Lubricate the upper tire bead and wheel lib-

erally.

2. Move swing arm into position and adjust so

that the duckhead is 1/8 inch to 3/16 inch away

from the wheel.

3. Rotate wheel to position the valve at the rear

of the duckhead. Position a drop center tool

directly across from the duckhead. Lube the

end of the lift tool and insert it between the

wheel and tire at the duckhead.

4. Slowly rotate the lift tool over the duckhead

towards the wheel and remove the drop center

tool as the tire bead slides into the drop center

of the wheel.

5. Continue to rotate lift tool until the tire bead

is on the duckhead.

6. Once the upper bead is in position, carefully

remove the lift bar.

7. Remove the upper bead with short table

rotations–3 to 4 inches–until the upper bead is

removed from the rim.

8. Position the sensor/valve once again at the

rear portion of the duckhead.

9. Use lift tool to lift lower bead over the duckhead. Use a shop rag between the lift tool and

wheel as you begin to rotate the wheel slowly.

10. Continue rotating slowly until the lower

bead is free from wheel.

S N

S N

Page 30

Test for Performance Certification for EMT

I–2

S = Successful Demonstration of Ability N = Needs more Practice

Sensor Installation–Valve-Type

1. Identify the various parts that make up the

valve-type sensor.

2. Inspect the valve mounting hole.

3. Install the sensor by inserting the valve stem

through the mounting hole in the wheel.

4. Once nut is installed, torque to 90-105 inch

pounds to prevent leaking.

Mounting

–(

Metal Duckhead) Valve-Type Sensor

1. Clean and polish the wheel. Check for any

burrs or damage to the wheel that might damage the tire during the mounting process.

2. Lubricate the wheel.

3. Lubricate the lower tire bead.

4. Rotate the tabletop so that the valve stem

and pressure sensor are at the 6 o’clock position.

5. Position the tire over the wheel, with the

lower bead resting on the back of the duckhead. Position the duckhead so that it is

1

⁄8 to 3⁄16

inch away from the wheel. Remember to use

the plastic bootie on metal duckheads.

6. Hold the tire down with the lower bead in the

drop center and rotate the wheel slowly. The

lower bead should be eased over the wheel

slowly and carefully, giving the sidewall time to

relax. Hold the tire so that the bead stays in the

drop center.

7. Once the lower bead is mounted, rotate the

table top until the valve stem and pressure

sensor are once again in the 6 o’clock position.

8. Lubricate the upper bead liberally. Apply

lubricant to both the edge of the tire bead and

the underside of the bead. Adequate lubrication is vital to the upper bead mounting

process.

9. Position the upper bead over the duckhead.

Put the tip of the lift tool under the wheel rim

flange and push the bar down to hold the upper

bead below the wheel and duckhead. Use a

shop towel on the lift tool to avoid damaging

the wheel.

10. Rotate the wheel a short distance–only 3 to

4 inches–and stop. Continue to hold the bead in

the drop center with the lift bar, or place a drop

center tool on the wheel.

11. Continue rotating the wheel using 3 to 4

inch jogs until the upper bead is fully mounted.

S N

S N

Page 31

Test for Performance Certification for EMT

I–3

S = Successful Demonstration of Ability N = Needs more Practice

Inflation (1-4 For bead sealing only)

1. Connect the inflation hose to the tire valve

stem. Hold the tire up against the upper edge

of the wheel. Be sure the top bead of the tire is

over the bottom of the valve stem.

2. Depress the inflation pedal to position 2 and

hold about 1 second to begin air flow, then

depress the pedal to position 3 and hold very

briefly–less than 1 full second to seal the

beads.

3. Release the inflation pedal and allow it to

return to position 1. Verify that both beads are

completely sealed to the wheel.

4. Once tire pressure is indicated on the air

gauge (with the inflation pedal in position 1 and

foot removed from the pedal), unclamp the

wheel from the clamps.

5. Remove the tire/wheel from the tire changer,

reinstall the valve core (if it was removed), and

place the assembly in an approved safety

cage.

6. Use an air hose equipped with a remote

pressure gauge and valve.

7. Apply air pressure to the tire in short bursts,

checking the air pressure in the tire in between

bursts. Attempt to seat the beads without pressurizing the tire any more than necessary.

Once the beads “pop” into their seated position, stop the air flow to the tire immediately.

8. Verify that both beads are fully seated. When

both beads are seated, the tire is ready for

inflation. Leave the tire in the safety cage for

inflation.

9. Adjust, per vehicle specifications, the air

pressure inside the tire.

All EMT/RunFlat inflation must be completed in a

safety cage except for bead sealing. Bead sealing is typically not a problem when inflating

EMT/RunFlat tires.

S N

Page 32

Page 33

The Objective of this Section:

To demonstrate the safe and proper demounting of exceptionally stiff sidewall tires on wheels with

a low-pressure sensor strapped into the drop center. To demonstrate the use of a plastic duckhead.

Safety Issues Related to this Section:

• ALWAYS wear eye protection during tire service activity.

• ALWAYS wear durable work clothing (i.e.; tight-fitting leather gloves, steel-toed shoes, back belts).

• NEVER wear loose fitting clothing or articles, jewelry, or long hair.

• ALWAYS deflate the tire completely and loosen both beads before beginning the demount procedure.

1

Lubricate the upper tire bead and the wheel liberally

with a slow-drying tire lubricant. Use the lift bar to help

push the sidewall down and provide easier access to the

bead and wheel. Rotate the wheel and lubricate the entire

circumference.

1A

Make sure to adequately lubricate the horizontal

wheel surface above the drop center and below the

safety hump. This will help the tire bead slide out of the drop

center and off the wheel easier.

2

Move the swing arm into position. Adjust the duckhead

so that it rests against the wheel.

3

Rotate the wheel until the valve stem is opposite the

duckhead. Position the sensor under the rear portion of

the duckhead. This will allow the lift bar to be inserted with

out hitting the sensor.

Position a drop center tool directly across from the duckhead to help the tire slide into the drop center as the bead is

lifted over the duckhead. If a drop center tool is not available,

a valve stem can be used as an aid. Insert it between the tire

and wheel across from the duckhead.

Lubricate the end of the lift bar. Insert it between the tire and

wheel, under the front extension of the duckhead.

4

Begin rotating the lift bar down over the duckhead to pull

the tire bead up and over the duckhead. Move the tool

slowly and do not rush.

Remove the drop center tool (or other aid) as the bead slides

into the drop center of the wheel.

Demounting–Strap-Type Sensor

J–1

15

min

Stop Time

J

Page 34

J–2

Demounting–Strap-Type Sensor

5

Continue to pull the lift bar down and lift the tire bead

onto the duckhead. Pull the tool down slowly to allow the

tire bead to move into position without damaging the bead.

6

Hold the lift bar down against the wheel.

7

Rotate the wheel a short distance -3 to 4 inches only-

and stop. Allow the bead and sidewall to relax. Rotate

the wheel again for a short distance then stop to allow the

tire to relax. Continue in this manner until the upper bead is

free of the wheel.

8

Rotate the wheel until the sensor is once again under

the duck head. Lift the tire and carefully guide the lower

bead into position above the sensor.

9

Use the lift bar to lift the lower bead over the duck head.

Begin rotating the wheel very slowly, using the lift bar to

help keep the lower bead above the wheel.

NOTE: It may be advisable to place a shop rag between the

lift bar and the wheel to prevent damaging the wheel surface.

10

Continue rotating the wheel very slowly until the

lower bead is free of the wheel. Use the lift bar to help

keep the demounted bead above the wheel.

This completes Section J.

Rotate

Pause

Rotate

Page 35

The Objective of this Section:

To demonstrate the proper installation of a strap on sensor assembly.

Safety Issues Related to this Section:

• Protective eyewear must be worn at all times.

1

Locate the drop center on the wheel. The strap on sen-

sor should be positioned as low on the drop center as

possible (photo 2). Do not strap the sensor to the slanted portions of the wheel. The strap will come loose and the sensor

assembly will flop freely around the inside of the tire. Photo

1 shows a properly installed strap-type sensor.

Strap sensors are location specific. Be sure to match the

sensor location (as indicated on the sensor label) to the correct wheel location.

2

Lay the strap around the drop center and overlap the

ends. Trim the strap down so that it overlaps itself by 2 to

3 inches.

The photo shows the correct mounting area.

3

Slide the counterweight onto the strap. Note the cres-

cent shape cutout on the weight. This cutout should be

on the top of the counterweight, and will position directly

below the valve stem.

4

Slide the sensor onto the strap with the label side facing

upwards. Feed the strap end into the tensioner and begin

tightening the strap. As the strap tightens, be sure to adjust the

positioning of the counterweight, strap tensioner, and sensor

–the counterweight should be directly beneath the valve stem,

the strap screw tensionor should be within two inches of the

sensor, and the sensor should be directly across from the weight

(180° around the wheel, photo 1). Tighten the strap securely, and

torque to 30 inch/pounds. The strap should be level and the

weight and sensor in proper position before proceeding.

5

Trim the excess strap to leave no more than 1 inch.

This completes Section K.

Sensor Inspection & Installation–Strap-Type

K–1

10

min

Stop Time

K

Mount low in

this area

Page 36

Page 37

The Objective of this Section:

To demonstrate the safe and proper mounting of exceptionally stiff sidewall tires on wheels with

a strap-type low-pressure sensor installed. To demonstrate the use of a plastic duckhead.

Safety Issues Related to this Section:

• ALWAYS wear eye protection during tire service activity.

• ALWAYS wear durable work clothing (i.e.; tight-fitting leather gloves, steel-toed shoes, back belts).

• NEVER wear loose fitting clothing or articles, jewelry, or long hair.

1

Determine the correct length rubber valve stem. Clean

the valve hole. Lubricate the valve thoroughly to insure a

good, leak-free installation.

2

Install the valve stem. Use a shop towel to prevent dam-

age to the wheel.

3A

Use only rubber valve stems. The hex nut on metal

valve stems will catch the tire during the mounting

process and can peel the rubber away from the bead wire.

3B

Metal valves with chamfers on the ends will also

catch and tear the rubber during mounting.

3C

Note the damage that metal valve stems can cause.

Mounting–Strap-Type Sensor

L–1

10

min

Stop Time

L

Page 38

L–2

Mounting–Strap-Type Sensor

4

Clean and polish the wheel. Check for any burrs or dam-

age to the wheel that might damage the tire during the

mounting process. Stiff sidewall tires of this type are exceptionally snug-fitting, and a clean, polished surface will

reduce friction and aid in the mounting and bead seating

process.

NOTE: Always clamp the wheel externally. This prevents the

wheel from moving upwards during the mounting process.

5

Lubricate the entire surface of the wheel liberally with a

slow-drying lubricant. Pay special attention to the bead

seat area, the safety humps, and the drop center.

6

Lubricate the lower tire bead.

NOTE: Pay strict attention to any specific tire location information on the wheel. The tire may have been marked earlier

with a location and/or rotation direction. The imprinting on

the tire sidewall may also give you specific location and

directional information. Remember that the low-pressure

sensor is location specific. Make sure you are mounting the

correct tire on the correct wheel.

7

Rotate the tabletop so that the valve stem is at the 12

o’clock position and the sensor is at the 6 o’clock position.

Lubricate and position the duckhead so that

it is against the wheel with the lower bead

resting on the back of the duckhead. Position

the tire over the wheel.

8

Hold the tire down with the lower bead in the drop cen-

ter and rotate the wheel slowly. The lower bead should

be eased over the wheel slowly and carefully, giving the

sidewall time to relax. Hold the tire so that the bead stays in

the drop center.

9

Carefully guide the lower bead over the sensor; the tire

should then drop down–for the upper bead mounting.

Rotate

Pause

Rotate

Page 39

Mounting–Strap-Type Sensor

L–3

10

Before beginning to mount the upper bead, rotate

the table top until the valve stem is once again in the

12 o’clock position and the sensor is in the 6 o’clock position.

Lubricate the upper bead liberally. Apply lubricant to both the

edge of the tire bead and the underside of the bead.

Adequate lubrication is vital to the upper bead mounting

process.

11

Position the upper bead over the duckhead. Put the tip

of the lift tool under the wheel rim flange and push the

bar down to hold the upper bead below the wheel and duckhead. Use a shop towel on the lift tool to avoid damaging the

wheel.

12

Rotate the wheel a short distance -only 3 to 4 inches-

and stop. Continue to hold the bead in the drop center

with the lift bar, or place a drop center tool on the wheel.

Remember that stiff sidewall tires are difficult to mount. The

top bead is always more difficult to work with because the

tire cannot be angled across the drop center and rim flange

as easily as the lower bead.

13

Continue rotating the wheel, moving only a few inch-

es and then stopping.

Continue to hold the bead in the drop center with the lift bar

or the drop center tool. When the bar or the drop center tool

reach the 10 o’clock position, remove them. Continuing with

either tool in place may cause them to be forcefully ejected

from the wheel.

14

Continue rotating the wheel until the upper bead is

fully

mounted.

This completes Section L.

Rotate

Pause

Rotate

Page 40

Page 41

Student Name ………………………………………………………………

Signature ………………………………………………… Date……………

Instructor ……………………………………………………………………

Signature for completion of Test ………………………… Date…………

Test for Performance Certification for EMT

M–1

15

min

Stop Time

M

S = Successful Demonstration of Ability N = Needs more Practice

Demounting–Strap-Type Sensor

1. Rotate the wheel and lubricate the entire cir-

cumference of the upper bead of the tire and

wheel.

2. Make sure to adequately lubricate the horizontal wheel surface above the drop center

and below the safety hump.

3. Move the swing arm into position. Adjust the

duckhead so that it rests against the wheel.

4. Rotate the wheel until the valve stem is

opposite the duckhead and the sensor is under

the rear portion of the duckhead. Lubricate and

insert the lift bar between the tire and wheel

under the front extension of the duckhead.

5. Begin rotating the lift bar down over the

duckhead to pull the tire bead up and over the

duckhead. Remove the drop center tool (or

other aid) as the bead slides into the drop center of the wheel.

6. Continue to pull the lift bar down and lift the

tire bead onto the duckhead.

7. Hold the lift bar down against the wheel.

8. Rotate the wheel until the upper bead is free

of the wheel.

9. Rotate the wheel until the sensor is once

again under the duck head. Lift the tire and

carefully guide the lower bead into position

above the sensor.

10. Use the lift bar to lift the lower bead over

the duck head.

11. Rotate-pause-rotate the wheel until the

lower bead is free of the wheel.

S N

Page 42

Test for Performance Certification for EMT

M–2

S = Successful Demonstration of Ability N = Needs more Practice

Sensor Installation–Strap-Type

1. Find the correct sensor for the specific

wheel location and identify the correct location

on the wheel.

2. Lay the strap around the drop center and

overlap the ends. Trim the strap so that it overlaps itself by 2 to 3 inches.

3. Slide the counterweight onto the strap.

4. Slide the sensor onto the strap with the label

side facing upwards.

5. Feed the strap end into the tensioner and

begin tightening the strap. As the strap tightens, be sure to adjust the positioning of the

counterweight and sensor–the counterweight

should be directly beneath the valve stem and

the sensor should be directly across from the

counterweight 180° around the wheel, the tensioner should be 2 to 3 inches away from the

sensor.

6. Tighten the strap securely, and torque to 30

inch/pounds. The strap should be level and the

weight and sensor in proper position before

proceeding.

7. Trim the excess strap to leave no more than

1 inch.

Mounting–Strap-Type Sensor

1. Determine the correct length rubber valve

stem. Clean the valve hole. Lubricate the valve

thoroughly to insure a good, leak-free installation.

2. Install the rubber valve stem. Use a shop

towel to prevent damage to the wheel.

3. Clean and polish the wheel. Check for any

burrs or damage to the wheel that might damage the tire during the mounting process.

Always clamp the wheel externally.

4. Lubricate the entire surface of the wheel liberally with a slow-drying lubricant.

5. Lubricate the lower tire bead.

6. Rotate the tabletop so that the valve stem is

at the 12 o’clock position and the sensor is at

the 6 o’clock position. Lubricate and position

the duckhead so that it is against the wheel.

7. Hold the tire down with the lower bead in the

drop center and rotate the wheel slowly. The

lower bead should be eased over the wheel

slowly and carefully, giving the sidewall time to

relax. Once the lower bead is mounted, grasp

the tire and carefully guide the lower bead

over the sensor.

8. Before beginning to mount the upper bead,

rotate the tabletop until the valve stem is once

again in the 12 o’clock position and the sensor

is at 6 o’clock. Apply lubricant to both the edge

of the tire bead and the underside of the bead.

9. Position the upper bead over the duckhead.

Put the tip of the lift tool under the wheel rim

flange and push the bar down to hold the upper

bead below the wheel and duckhead. Use a

shop towel on the lift tool to avoid damaging

the wheel.

10. Rotate the wheel a short distance–only 3 to

4 inches–and stop. Continue to hold the bead in

the drop center with the lift bar, or place a drop

center tool on the wheel.

11. Continue rotating the wheel short distances

until the upper bead is fully mounted removing

the lift bar or drop center tool at the 10 o’clock

position.

S N S N

Page 43

Quick Reference

N–1

SmarTire

Description

1.

Sensor Module ID=4 (right rear ORANGE)

2. Sensor Module ID=2 (left rear YELLOW)

3. Sensor Module ID=3 (left front GREEN)

4. Sensor Module ID=4 (right front BLUE)

5. Display Module

6. Sensor Module Counterweights

7. Sensor Module Mounting Bands

8. Owner’s Manual

P/N

200.0031.01

200.0031.02

200.0031.03

200.0031.04

200.0035

264.0064

264.0070

050.0200.um

Sales: 1-888-982-3001

Technical support: 1-419-668-426

Web Site: www.smartire.com

Schrader Bridgeport

Description

1.

Sensor with metal valve stem

2. O-ring washer

3. Nut

4. Valve Cap

P/N

These units are

unique to the type

of automobile.

Contact the car

dealer for replacements.

Sales

Technical support: 1-800-331-4062

Web Site: www.schrader-bridgeport.com

Page 44

N–2

Quick Reference

Mount/Demount Start Position

Page 45

Notes

Page 46

Page 47

Page 48

Loading...

Loading...