Page 1

T34™

EC REP

0344

Syringe Pump

rd

(3

Directions For Use

Edition)

Caesarea Medical Electronics Ltd.

16 Shacham Street

Industrial Park Caesarea North

P.O.Box 3009

Caesarea 3088900, Israel

MedNet GmbH

Borkstrasse 10

48163 Muenster

Germany

Tel.: +49 251 32266 0

DFU999-103EN Rev. 04

Page 2

T34™ Syringe Pump (3

rd

Edition)

The information in this document is subject to change and does not represent a commitment on the part of Caesarea

Medical Electronics Ltd. to provide additional services or enhancements. The screens illustrated in the document are for

reference purposes only and might be different than the screens displayed on your pump. Documentation provided with

this product might reference product not present in your facility or not yet available for sale in your area.

BD, CME, CME logo, Plastipak, and T34 are trademarks of Becton, Dickinson and Company or its affiliates. All other

trademarks are the property of their respective owners.

©2019 BD. All rights reserved.

DFU999-103EN Rev. 04

2/60

Page 3

Contents

Section 1: General Information

1.1 Preface

1.2 About this Directions For Use

1.3 Advisory Terms and Warnings

1.4 Intended Use

1.5 Contraindications

1.6 System Symbols

1.7 Syringe Pump Inspection and Unpacking

1.8 Syringe Pump Specifications

Section 2: Disposables and Accessories

2.1 Syringe Brands and Sizes

2.2 Syringe Extension Sets

2.3 Battery Power Supply

2.4 Lockbox (Optional)

2.5 Carry Pouches (Optional)

Section 3: Pump Features and Description

3.1 Overview

3.2 Pump Description

3.3 Event Log

3.4 Post Occlusion Bolus Reduction System (POBRS)

Section 4: Modes of Operation

4.1 Modes of Operation

Section 5: Pump Configuration

5.1 Pump Configuration

5.2 Pump Access Codes

5.3 Pump Info and Configuration Menus

5.4 Pump Configurable Settings for Modes of Operation

5.5 Optional Configurable Settings

5.6 Practice Scenarios for Changing Pump Configuration

Section 6: Starting A New Infusion

6.1 Sequence for Starting an Infusion

6.2 Releasing a Trapped Foreign Object from the Actuator

Section 7: Monitoring and Managing Infusions

7.1 Pump and Infusion Safety Checks

7.2 Keypad Lock

7.3 Program Protection and Resume

7.4 Stopping/Pausing the Infusion and Powering Off

7.5 Alerts, Alarms and Troubleshooting

7.6 Bolus

7.7 Changing Syringes/Syringe Extension Sets

Section 8: Servicing and Maintenance

8.1 Servicing, Maintenance and Periodic Checks

8.2 Cleaning

8.3 Pump Storage

8.4 Disposal/Decommissioning

.............................................................................................4

.......................................................................................7

....................................................................................7

.........................................................................................19

.........................................................................................22

......................................................................................46

.............................................................................................51

..........................................................................................54

.....................................................................................55

............................................................................4

..................................................................................7

.............................................................................14

..............................................................................16

................................................................................18

.................................................................................19

............................................................................24

...............................................................................24

...........................................................................27

...............................................................................27

...............................................................................27

T34™ Syringe Pump (3

.......................................................................4

.......................................................................5

...........................................................9

.......................................................................10

...................................................................13

..........................................................................13

..........................................................................18

................................................................19

...................................................23

...............................................................28

...............................................30

....................................................................31

...............................................33

........................................................................37

..................................................................37

..............................................43

............................................................44

..................................................................44

...................................................................47

...................................................48

................................................................49

.........................................................52

.....................................................................53

.......................................................53

........................................................................55

rd

Edition)

Page

DFU999-103EN Rev. 04

3/60

Page 4

T34™ Syringe Pump (3

Section 1: General Information

rd

Edition)

Section 1: General Information

1.1 Preface

Duplication or distribution of this

written permission of CME Ltd. This

transmitted in any form, or by any means, for any purpose, without the express written permission of CME Ltd. To order additional copies

of this

Directions For Use

The information in this

is assumed for inaccuracies. Furthermore, CME Ltd. reserves the right to make changes to any products herein to improve readability,

function, or design. CME Ltd. does not assume any liability arising out of the application or use of any product described herein; neither

does it cover any license under its patent rights nor the rights of others.

, or other related manuals, contact your BD representative.

Directions For Use

1.2 About this Directions For Use

The operator must be thoroughly familiar with the T34™ Syringe Pump described in this

must read and understand any warnings and precautions stated herein.

All illustrations used in this

syringe pump. These settings and values are for illustrative use only. The complete range of settings and values are listed in the

specifications section of this

Directions For Use

This

the technical specifications reflect specific test conditions defined in this standard. Other external factors such as varying back pressure,

temperature, head height, syringe extension set usage, fluid restrictions, solution viscosity or combinations of these factors, may result in

deviations from the performance data enclosed.

Keep this

Note:

has been developed with consideration to the requirements in relevant Harmonised Standards. Data presented in

Directions For Use

Directions For Use

Directions For Use

has been carefully compiled, and is believed to be entirely reliable. However, no responsibility

Directions For Use

Directions For Use

for future reference during the syringe pump's operational life.

and any information contained within is strictly prohibited without the express

and any information contained within, may not be reproduced, distributed, or

Directions For Use

show typical settings and values that may be used in setting up the functions of the

.

prior to use, and in particular

DFU999-103EN Rev. 04

4/60

Page 5

1.3 Advisory Terms and Warnings

WARNINGS, CAUTIONS AND NOTES

Warnings, cautions and notes will be seen throughout this

Warnings advise of circumstances that could result in injury or death to the patient or operator.

Read and understand this

Cautions advise of circumstances that could result in damage to the T34™ Syringe Pump.

Read and understand this

A Note indicates that the information that follows is additional important information, a tip that will help you recover from an

Note:

error or refer you to related information within the

Directions For Use

Directions For Use

OPERATING PRECAUTIONS AND WARNINGS

T34™ Syringe Pump (3

Section 1: General Information

Directions For Use

and all warnings completely before operating the T34™ Syringe Pump.

and all cautions completely before operating the T34™ Syringe Pump.

Directions For Use

. These are defined as follows:

.

rd

Edition)

Read the entire

Only trained service personnel should open the syringe pump cover.

A kinked or occluded syringe extension set may impair the operation of the syringe pump and the accuracy of the

infusion. Before operation, verify that the syringe extension set is not kinked or occluded.

Unsafe operation may result from using improper accessories. Use only accessories and options designed for this

system and supplied or recommended by the T34™ Syringe Pump distributor.

Do not use this equipment with other infusion systems or accessories that are not designed to be used with this

pump system.

Do not let the syringe pump operate when battery is fully depleted. Pump may turn off during operation on fully

depleted battery. Before beginning infusion, ensure the battery is fully charged.

Use of this equipment adjacent to or stacked with other equipment should be avoided because it could result in

improper operation. If such use is necessary, this equipment and the other equipment should be observed to verify

that they are operating normally.

Directions For Use

before using the syringe pump, since the text includes important precautions.

Use of accessories, transducers and cables other than those specified or provided by the manufacturer of this

equipment could result in increased electromagnetic emissions or decreased electromagnetic immunity of this

equipment and result in improper operation.

Portable RF communications equipment (including peripherals such as antenna cables and external antennas)

should be used no closer than 30 cm (12 inches) to any part of the T34TM Syringe Pump, including cables specified

by the manufacturer. Otherwise, degradation of the performance of this equipment could result.

Although the T34™ Syringe Pump has been designed and manufactured to exact specifications, it is not intended to

replace trained personnel in the supervision of infusions.

The specified accuracy of the syringe pump can only be maintained if the syringe pump is used in accordance with

the

Directions For Use

Adjustments, maintenance, or repair made by un-certified service personnel may impair the operation of the

syringe pump and/or the accuracy of the infusion. Make sure any adjustments, maintenance, or repair of the syringe

pump are carried out only by authorised and skilled technicians.

Refer all service, repair and adjustments only to qualified and certified technical personnel. Unauthorised

modifications or the use of any spare parts, other than those supplied by the manufacturer or their distributor, will

void any warranty.

DFU999-103EN Rev. 04

and is maintained and serviced by a certified CME technician.

5/60

Page 6

T34™ Syringe Pump (3

Section 1: General Information

If the syringe pump is subjected to excessive moisture, humidity or high temperature, or otherwise suspected to

have been damaged, remove it from service for inspection by qualified personnel.

The syringe pump has been designed to be as safe as possible to handle; however, care should be exercised to avoid

trapping of fingers or other body parts in the mechanism.

The T34™ Syringe Pump should be operated within the recommended environmental operating range. Operation at

temperatures and/or humidity outside this range may adversely affect accuracy.

This syringe pump is designed for use and should withstand everyday handling. If the syringe pump is dropped

onto a hard surface, or is suspected of being dropped, the operation and calibration should be checked by a

qualified technician.

Pump should be stored with the battery removed to prevent battery corrosion and decay.

CME Ltd. will assume no responsibility for incidents which may occur if the product is not used, stored or

transported in accordance with the environmental conditions stipulated in this document or on the package

labelling.

rd

Edition)

INFUSION PRECAUTIONS AND WARNINGS

Carefully read and follow accompanying syringe extension set instructions for priming the set and the

recommended set change interval.

The syringe and syringe extension set should be disposed of in an appropriate manner, considering the nature of

the residual fluid that may be contained within and in accordance with the hospital/homecare provider's disposal

practices.

Drugs for infusion to be used with the syringe pump may only be prescribed by a qualified medical practitioner.

Caution must be exercised in the selection of drugs and the amount and rate intended to be delivered via syringe

pump.

If the drug contained in the syringe will be exposed to extreme environmental conditions for prolonged time

periods, it is important to select drugs that will not change pharmacologically upon such exposure.

As with all automatic syringe pumps, whenever a toxic or dangerous level of drug is stored in the reservoir,

constant/frequent monitoring of the infusion is required.

In all applications, time to alarm under occlusion or other fault conditions will depend on the infusion rate and

levels of alarm settings. It is recommended to consider these parameters when using drugs requiring infusion

stability or low flow rates and therefore a quick time to alarm.

Do not use Slip-tip syringes. Luer Lock syringes must always be used to ensure secure connection of the syringe

extension set and the syringe pump.

GENERAL PRECAUTIONS AND WARNINGS

The maximum volume that may be infused under single fault condition is 0.1 ml.

Potential strangulation may occur if the cables/tubing are of excessive length.

Potential choking may occur if small parts are inhaled or swallowed.

DFU999-103EN Rev. 04

6/60

Page 7

T34™ Syringe Pump (3

Section 1: General Information

Potential allergic reactions may occur due to materials used in the syringe pump.

The T34™ Syringe Pump is not certified for use in oxygen-enriched environments.

Do not operate the syringe pump near high-energy radio-frequency emitting equipment, (e.g. Imaging equipment

(i.e., X-Ray, MRI, CT Scan, etc.), High Frequency (RF) Surgical Equipment, Defibrillator, etc.) as this may cause

degradation in performance of the syringe pump, which may affect proper infusate delivery.

Do not use hard or sharp objects on the keypad.

Do not bathe or shower whilst using the syringe pump. The syringe pump is resistant to a limited amount of

splashing, but its construction does not make it resistant to large amounts of spraying or immersion in liquids.

Damage to the internal components may result.

rd

Edition)

1.4 Intended Use

The T34™ Syringe Pump is designed for infusion of medications or fluids requiring continuous or intermittent delivery at precisely

controlled infusion rates through all clinically acceptable routes of administration including intravenous, subcutaneous, percutaneous, in

close proximity to nerves, and into an intraoperative site (soft tissue/body cavity/surgical wound site). The system is intended for patients

who require maintenance medications, analgesics, Immunoglobulins, biosimilar, chemotherapeutic agents and general fluids therapy in

hospital and homecare environments.

1.5 Contraindications

• Infusion of blood and blood products

• Infusion of insulin

• Infusion of critical medications whose stoppage or interruption could cause serious injury or death

• Use in ambulatory regimens by patients who do not possess the mental, physical or emotional capability to self-administer their

therapy, or who are not under the care of a responsible individual

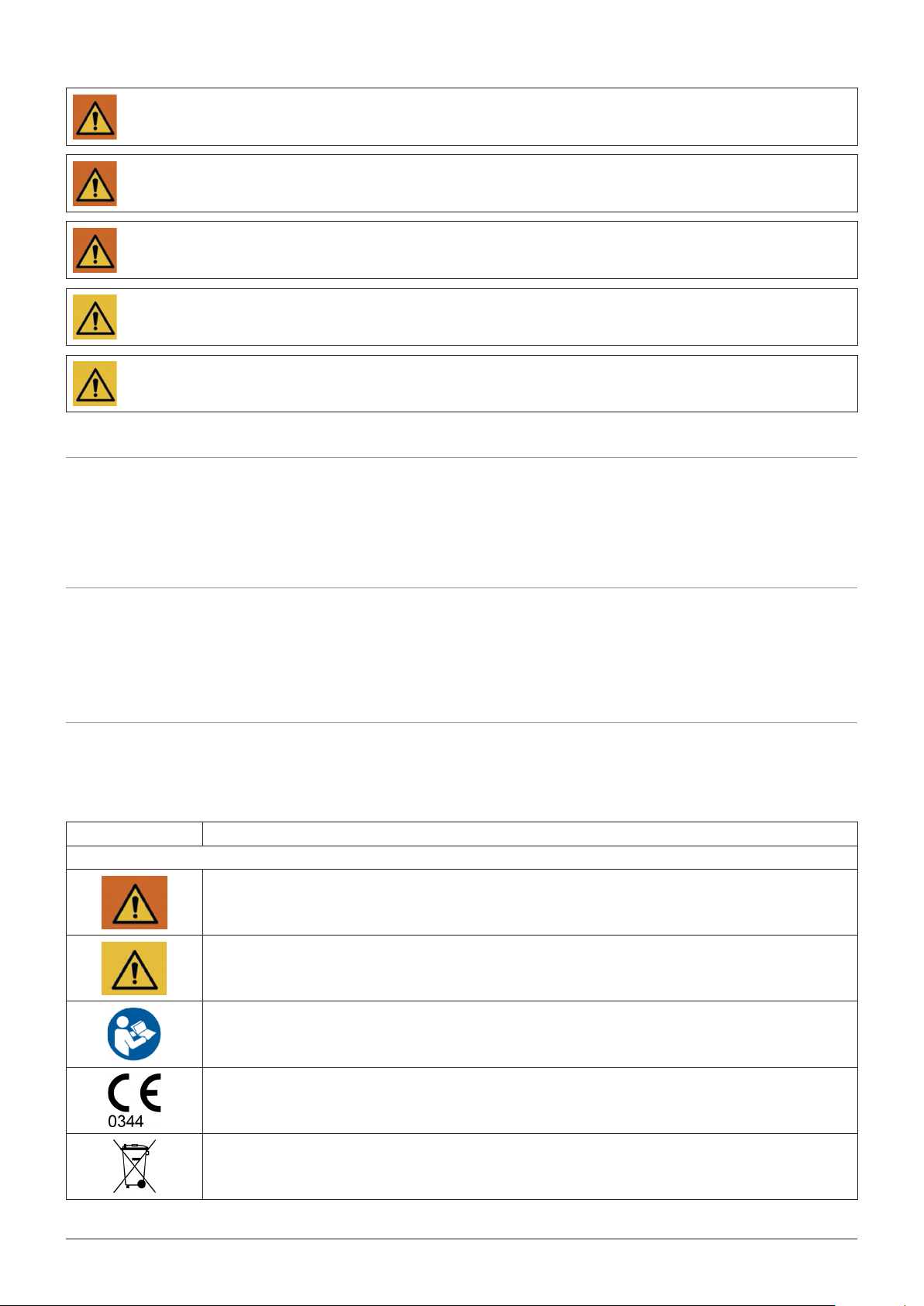

1.6 System Symbols

The following symbols are used on the T34™ Syringe Pump and components. Labels on the syringe pump or statements in this

Directions For Use

operate the syringe pump in a safe and successful manner.

preceded by any of the following words and/or symbols are of special significance and/or are intended to help you to

System Symbol Identification and Description

Symbol Description

Syringe Pump

Warnings

Read and understand this

Pump.

Cautions

Read and understand this

Pump.

Refer to

Read the entire

advise of circumstances that could result in injury or death to the patient or operator.

Directions For Use

advise of circumstances that could result in damage to the T34™ Syringe Pump.

Directions For Use

Directions For Use

Directions For Use

:

before using the syringe pump.

and all warnings completely before operating the T34™ Syringe

and all cautions completely before operating the T34™ Syringe

DFU999-103EN Rev. 04

CE mark indicates conformance to Medical Device Directive 93/42/EEC.

Do not dispose of in municipal waste. Symbol indicates separate collection for electrical and electronic

equipment. (WEEE Directive 2012/19/EU). NOTE: Does not apply to the battery.

7/60

Page 8

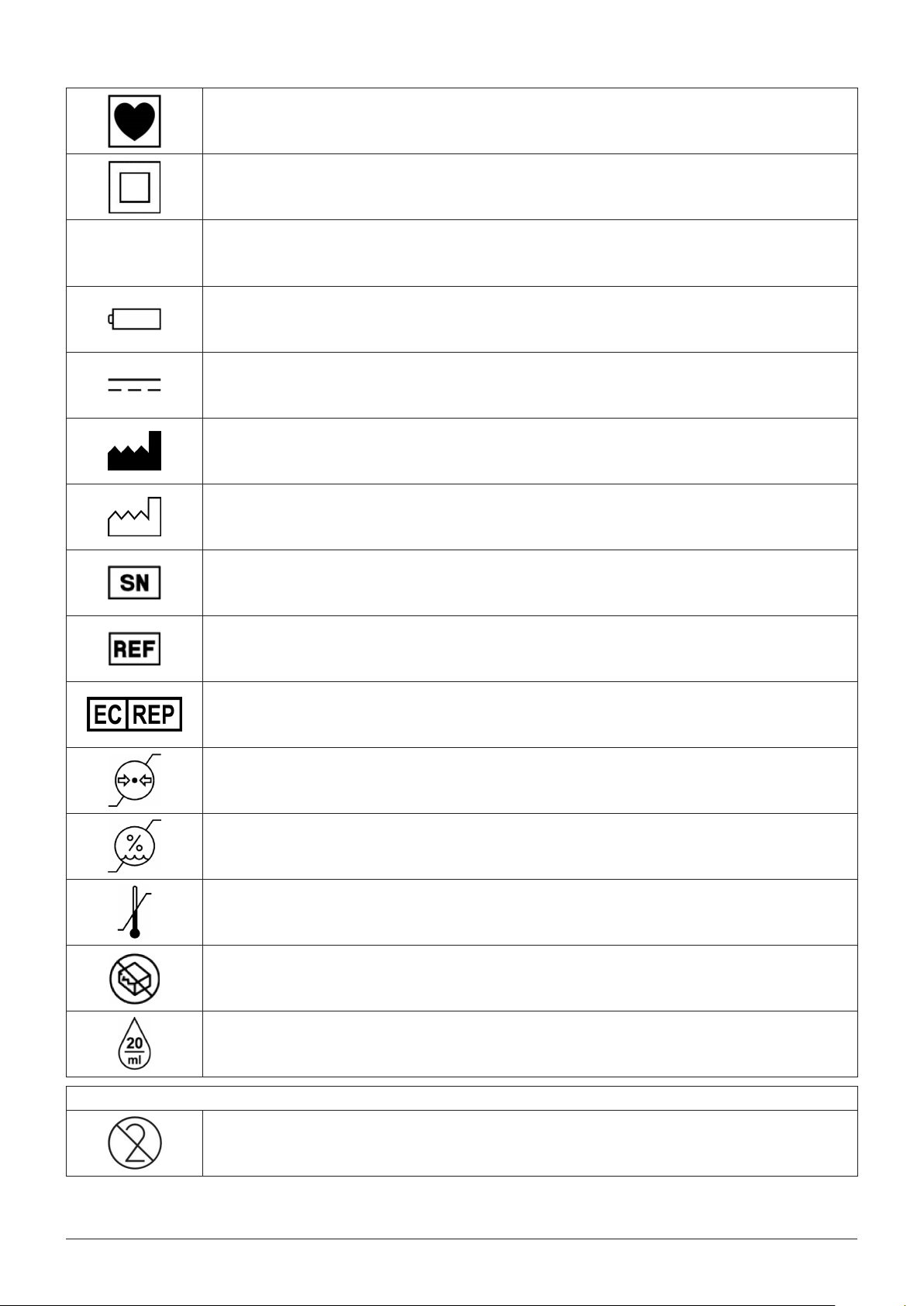

T34™ Syringe Pump (3

Section 1: General Information

Type CF applied part.

Class II Medical Electrical Equipment providing double insulation for operator and patient safety.

rd

Edition)

IP22

Symbol for degree of protection against ingress of water and solid objects.

Battery.

Direct current.

Manufactured by.

Date of manufacture.

Serial number.

Reference number. Indicates the manufacturer's catalogue number so that the medical device can be

identified.

Indicates the authorised representative in the European Community.

Indicates the acceptable upper and lower limits of atmospheric pressure (altitude).

Indicates the acceptable upper and lower limits of relative humidity.

Indicates the range of temperatures to which the medical device can safely be exposed.

Indicates a medical device that should not be used if its packaging has been damaged or opened.

Indicates the number of drops per millilitre.

Disposables

The use of single-use disposable components on more than one patient is a biological hazard.

Do not reuse single-use disposable components.

DFU999-103EN Rev. 04

8/60

Page 9

T34™ Syringe Pump (3

Expiry date (consumables).

Lot number (consumables).

Sterilized with Ethylene Oxide (applies to syringe extension sets).

1.7 Syringe Pump Inspection and Unpacking

INSPECTING THE SYRINGE PUMP BEFORE USE

Remove the T34™ Syringe Pump from the packaging and inspect for damage during shipment or storage.

Make sure you have the following items:

• T34™ Syringe Pump

•

Directions For Use

• Quick Reference Guide for homecare

If any items are missing or damaged, contact your supplies department.

rd

Edition)

Section 1: General Information

Visually inspect packaging and contents before each use.

Do not use the T34™ Syringe Pump and accessories if there are any obvious signs of damage.

Return for inspection by authorised service personnel.

ACCESSORIES (IF PURCHASED)

• Lockbox (supplied with two keys)

• Carry Pouch (re-usable or disposable)

Refer to the product catalogue for more details.

If any items are missing or damaged, contact your supplies department.

Unsafe operation may result from using improper accessories. Use only accessories and options designed for this

system and supplied or recommended by the T34™ Syringe Pump distributor.

DFU999-103EN Rev. 04

9/60

Page 10

T34™ Syringe Pump (3

Section 1: General Information

rd

Edition)

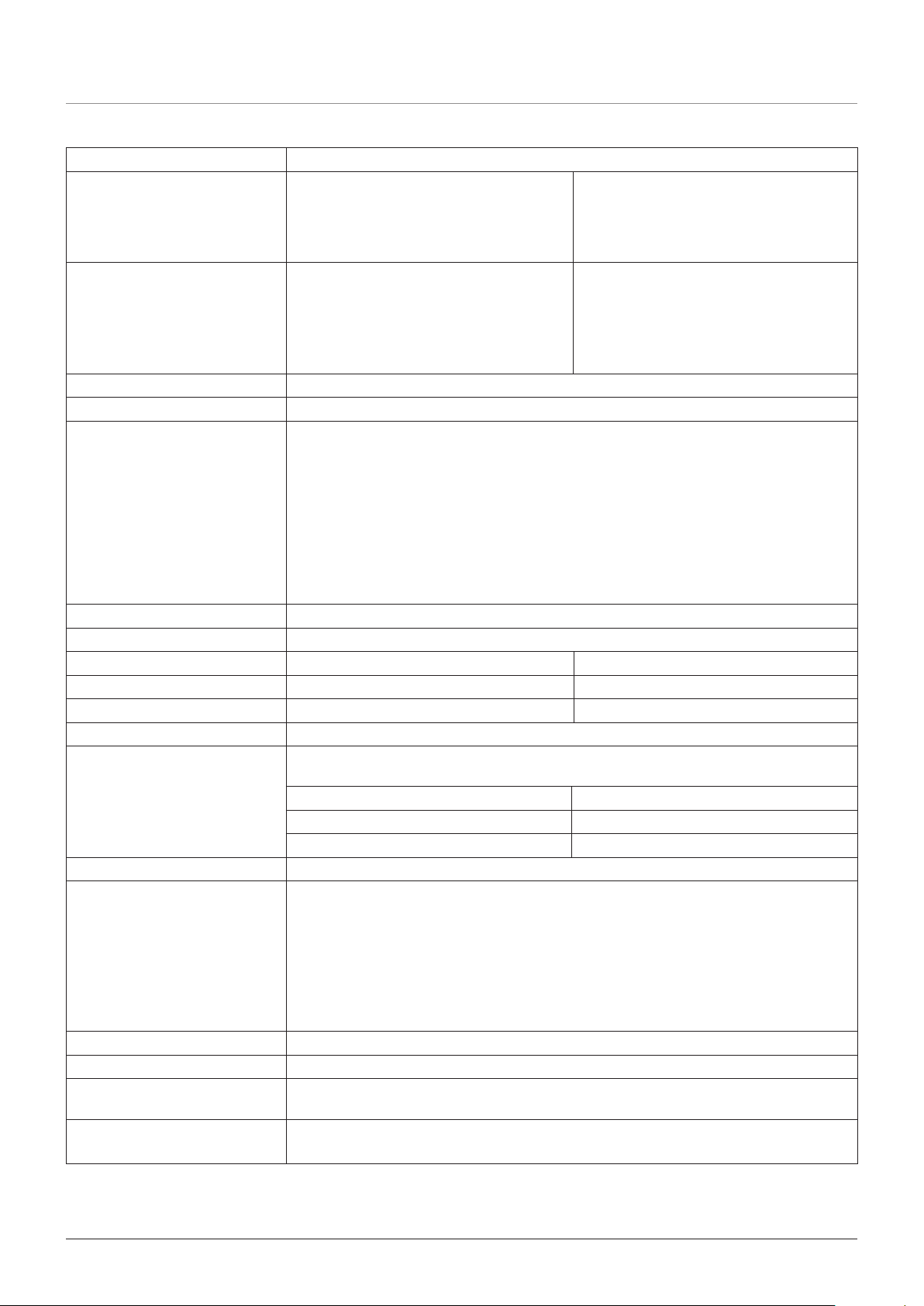

1.8 Syringe Pump Specifications

T34™ SYRINGE PUMP SPECIFICATIONS

Type: Linear syringe driver mechanism, pulsed motion (540 pulses per mm).

0.1–10 ml/h in 0.01 ml/h increments;

Flow Rate:

Bolus Parameters:

Actuator Travel: 67 mm available.

Syringe Sizes: 2 ml to 50 ml (most commonly used manufacturers).

Accuracy:

Occlusion Pressure:

Battery: 9 V alkaline, IEC 6LR61 type.

Operating Time: Rate Approximate battery life

Indicators: 4 line LCD display (122 × 32 pixels), dual color operation LED.

Alarms: When a problem is detected, the T34™ displays the following alarm messages, sounds an audible

Dimensions:

Classification:

Housing: ABS (fire retardant). Complies with standard UL94V-1.

Weight:

Electrical Safety:

Standards:

Flow rate is adjustable between 0.1 ml/h and

650 ml/h

Bolus flow rate 1–650 ml/h:

1–10 ml/h in 0.01 ml/h increments;

10–29.9 ml/h in 0.1 ml/h increments;

30–49.5 ml/h in 0.5 ml/h increments;

50–299 ml/h in 1 ml/h increments;

300–650 ml/h in 5 ml/h increments.

± 5% system accuracy (syringe pump and set combined) by volume under nominal conditions,

defined as follows:

Flow rates: 1 ml/h and 5 ml/h;

Tested with syringe extension set model M100-172SB;

Needle: 18 gauge;

Solution Type: Distilled water;

Temperature: 22°C ± 3°C;

Back Pressure: 0 ± 10 mmHg;

Syringe size and brand: BD Plastipak 20 ml.

Accuracy measured using the trumpet curve test method defined in EN/IEC60601-2-24.

200–1500 mmHg configurable (10 mmHg increments).

1 ml/h 25 hours

5 ml/h 20 hours

alarm and the LED lights red:

Occlusion or Syringe Empty Syringe Displaced during infusion

End Program System Error

End Battery

167 × 68 × 39 mm (L x W x H)

Type CF Equipment, degree of protection against electrical shock;

IP22 protection against ingress of water and solid objects.

Definition of code:

I = Ingress

P = Protection

2 = Protection from solid objects ≥12.5 mm

2 = Protection from dripping water (15° tilted)

230 g without battery.

Complies with: IEC 60601-1, IEC 60601-1-2, IEC 60601-1-6, IEC 60601-1-8, IEC 60601-1-11,

IEC60601-2-24.

Manufactured in accordance with ISO 13485, IEC 62304 and IEC 62366.

CE marked in accordance with the Medical Devices Directive 93/42/EEC.

10–29.9 ml/h in 0.1 ml/h increments;

30–49.5 ml/h in 0.5 ml/h increments;

50–299 ml/h in 1 ml/h increments;

300–650 ml/h in 5 ml/h increments.

Bolus volume:

0–20 ml in 0.1 ml increments.

Maximum bolus volume is 20 ml.

DFU999-103EN Rev. 04

10/60

Page 11

T34™ Syringe Pump (3

Section 1: General Information

Environmental Specifications: Operating Environment Range:

Ambient Temperature: 5°C to 40°C

Relative Humidity: 15% to 90%, non-condensing

Ambient pressure: 70 kPa to 106 kPa.

Transport and Storage Conditions:

Ambient Temperature: −25°C to 70°C

Relative Humidity: 0% to 90%, non-condensing

Ambient pressure: 48 kPa to 110 kPa.

The T34™ Syringe Pump is designed to be in compliance with IEC 60601-1 (safety), IEC 60601-1-2

(EMC), and IEC 60601-2-24 (infusion pump).

The T34™ Syringe Pumps have been tested and found to comply with the limits for a Class B

digital device. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that interference

EMC Specifications:

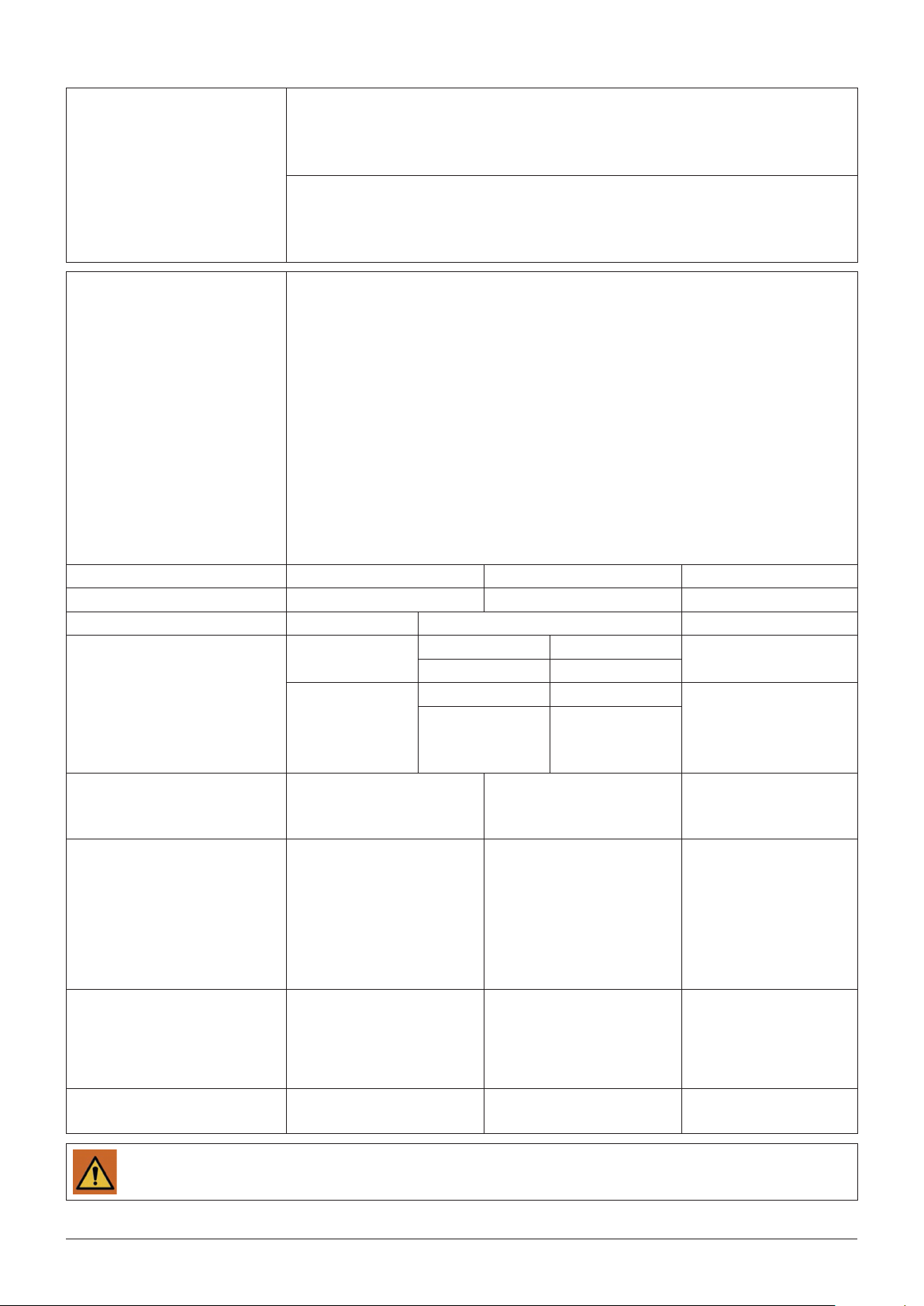

EMC – Emissions Compliance EMC Standard Range Compliance

Radiated emissions CISPR 11:2015

EMC – Immunity Compliance EMC Standard Test level Compliance

Electrostatic Discharge (ESD)

Immunity

Radiated RF Immunity

Proximity fields from RF wireless

communications equipment

Conducted RF Immunity IEC 61000-4-6:2013

Power Frequency Magnetic Field

Immunity

will not occur in a particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

The T34™ Syringe Pump has been tested to comply with the requirements of IEC 60601-1-2:2014.

30 MHz – 1 GHz Class B, Group 1

IEC 61000-4-2

IEC 60601-2-24

IEC 61000-4-3:2006 +A1:2007

+A2:2010

IEC 61000-4-3:2006 +A1:2007

+A2:2010

IEC 61000-4-8:2009

Contact discharge

Air discharge

Contact discharge ± 8 kV Operator intervention may

Air discharge

10 V/m

80 MHz – 2.7 GHz

80% AM at 1 kHz

380 – 390 MHz 27 V/m

430 – 470 MHz 28 V/m

704 – 787 MHz 9 V/m

800 – 960 MHz 28 V/m

1.7 – 1.99 GHz 28 V/m

2.4 – 2.57 GHz 28 V/m

5.1 – 5.80 GHz 9 V/m

3 V/m 0.15 MHz – 80 MHz

6 V/m in ISM and amateur radio

bands between 0.15 MHz and

80 MHz

80% AM at 1 kHz

30 A/m

50 Hz

± 2 kV, ± 4 kV, ± 6 kV

± 2 kV, ± 4 kV, ± 8 kV

± 15 kV

No degradation of

performance

be required as the syringe

pump may intermittently

reset, requiring user to

restart the infusion.

Yes

Yes

Yes

Yes

rd

Edition)

Use of this equipment adjacent to or stacked with other equipment should be avoided because it could result in

improper operation. If such use is necessary, this equipment and the other equipment should be observed to verify

that they are operating normally.

DFU999-103EN Rev. 04

11/60

Page 12

T34™ Syringe Pump (3

10.00

Long Term Rate Accuracy

0.00

0.20

0.40

0.60

0.80

1.00

1.20

1.40

1.60

1.80

2.00

Long Term Rate Accuracy

-4

-3

-2

-1

0 5 10 15 20 25 30 35

T34 Trumpet Curve at 5ml/h

0 5 10 15 20 25 30 35

T34 Trumpet Curve at 1ml/h

rd

Edition)

Section 1: General Information

Use of accessories other than those specified or provided by the manufacturer of this equipment could result in

increased electromagnetic emissions or decreased electromagnetic immunity of this equipment and result in

improper operation.

Do not operate the syringe pump near high-energy radio-frequency emitting equipment, (e.g. Imaging equipment

(i.e., X-Ray, MRI, CT Scan, etc.), High Frequency (RF) Surgical Equipment, Defibrillator, etc.) as this may cause

degradation in performance of the syringe pump, which may affect proper infusate delivery.

Portable RF communications equipment (including peripherals such as antenna cables and external antennas)

should be used no closer than 30 cm (12 inches) to any part of the T34TM syringe pump, including cables specified by

the manufacturer. Otherwise, degradation of the performance of this equipment could result.

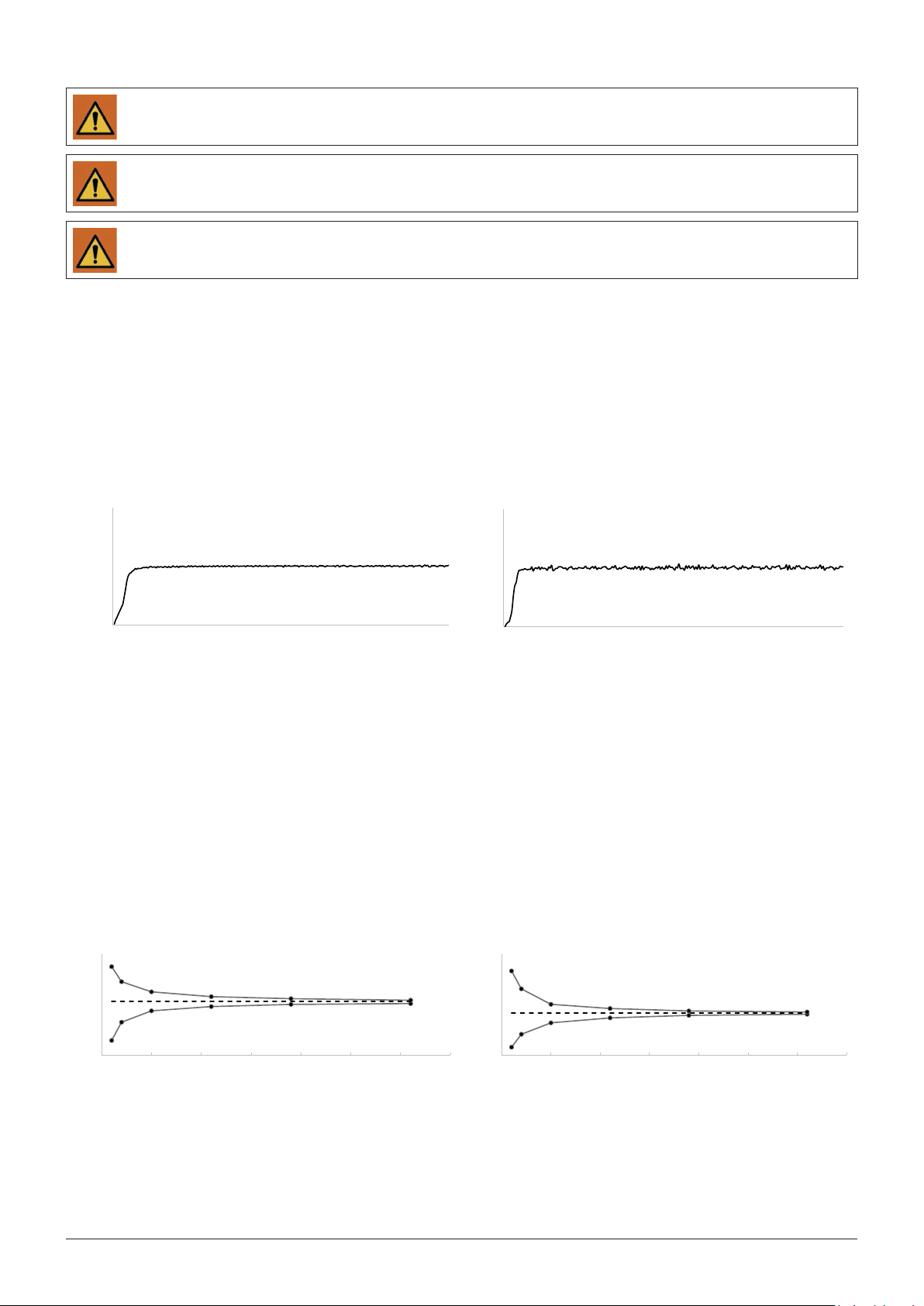

PUMP ACCURACY

The following graphs and curves were derived from testing described in IEC60601-2-24. Testing was performed under normal conditions

at room temperature (72°F or 22°C). Any deviations from normal conditions and room temperature may cause changes in the accuracy of

the syringe pump.

Start-up Curves

The Start-up curves represent continuous flow versus operating time for two hours from the start of the infusion, measured for infusion

rates of 5 ml/h and 1 ml/h. They exhibit the delay in onset of delivery due to mechanical compliance and provide a visual representation

of uniformity. Trumpet curves are derived from the second hour of this data. Tests performed according to IEC 60601-2-24 standard.

T34™LongTermRateAccuracyat5 ml/h T34™LongTermRateAccuracyat1 ml/h

9.00

8.00

7.00

6.00

5.00

4.00

3.00

2.00

Rate(ml/h)

1.00

0.00

0 20 40 60 80 100 120

Rate(ml/h)

0 20 40 60 80 100 120

Time(min) Time(min)

Trumpet Curves

With the T34™, as with all infusion systems, variations cause short term fluctuations in rate accuracy.

The following curves show typical performance of the system in two ways:

1. The accuracy of fluid delivery over various time periods is measured (trumpet curves).

2. The delay in onset of fluid flow when infusion commences (start up curves).

Trumpet curves are named for their characteristic shape. They display discrete data averaged over particular time periods or 'Observation

windows', not continuous data versus operating time. Over long observation windows, short-term fluctuation has little effect on

accuracy as represented by the flat part of the curve. As the observation window is reduced, short-term fluctuations have greater effects

as represented by the 'mouth' of the trumpet. Knowledge of system accuracy over various observation windows may be of interest when

certain drugs are being administered. Short-term fluctuations in rate accuracy may have clinical impact depending on the shelf life of the

drug being infused and the degree of inter-vascular integration. The clinical effect cannot be determined from the trumpet curves alone.

T34™TrumpetCurveat5 ml/h T34™TrumpetCurveat1 ml/h

4

3

3.03

2

1

0

-2.84

1.83

-1.39

1.02

-0.49

0.64

-0.15

0.48

0.02

0.36

0.09

0.257

Flowrateerror(%)

Observationinterval(min) Observationinterval(min)

15

10

-10

Flowrateerror(%)

10.89

6.44

-8.05

-4.84

2.59

-1.99

1.56

-0.77

0.95

-0.15

0.69

0.13

0.397

5

0

-5

DFU999-103EN Rev. 04

12/60

Page 13

T34™ Syringe Pump (3

Section 2: Disposables and Accessories

rd

Edition)

Section 2: Disposables and Accessories

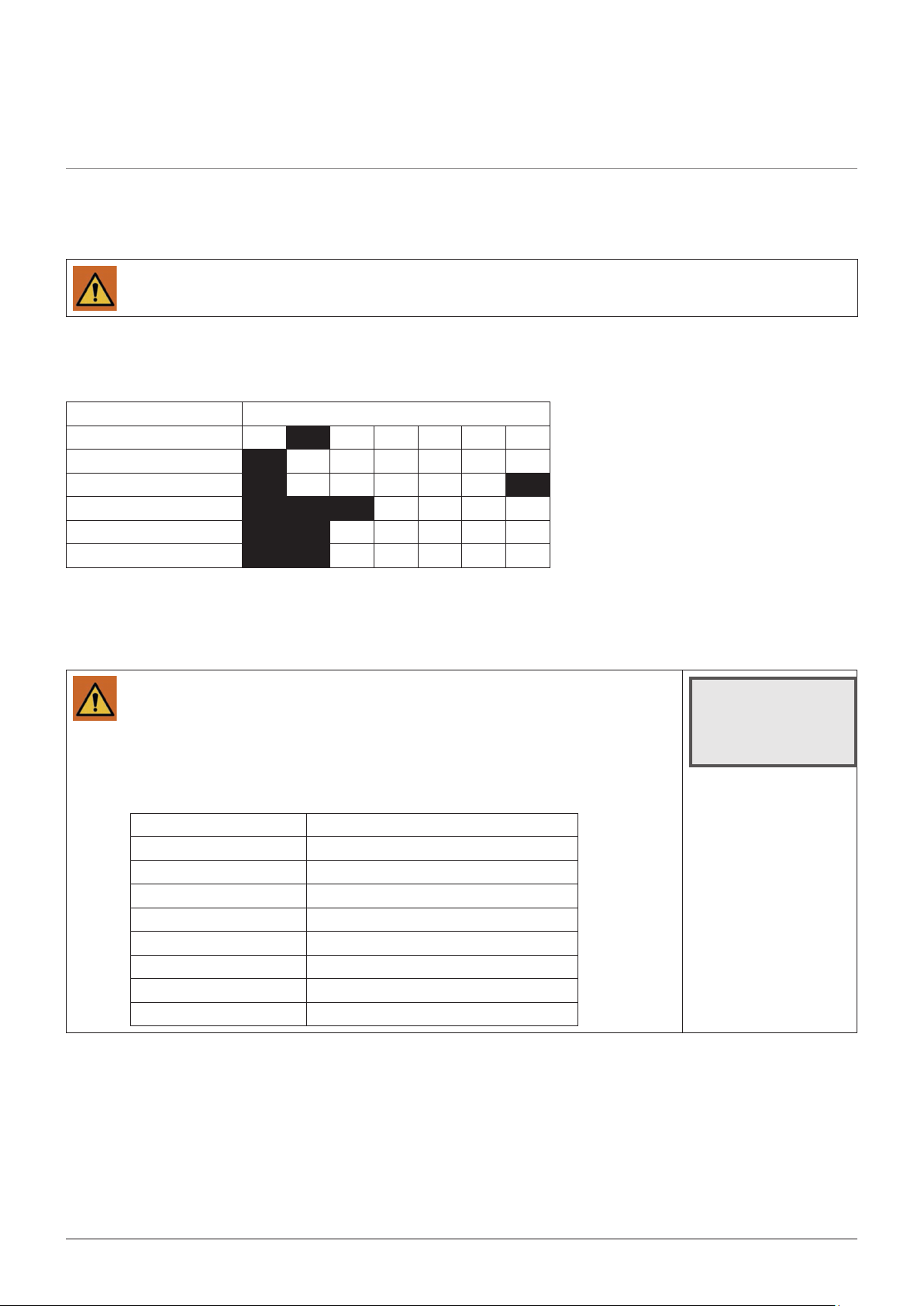

2.1 Syringe Brands and Sizes

The T34™ Syringe Pump is programmed to recognize most commonly used syringes from 2 ml to 50 ml. Luer Lock syringes should always

be used to ensure secure connection of the syringe extension set and syringe.

To avoid accidental selection of an incorrect brand of syringe during setup, it is recommended to disable all syringe types not in regular

use. Unused syringe types can be disabled by an authorised technician.

Do not use Slip-tip syringes. Luer Lock syringes must always be used to ensure secure connection of the syringe

extension set and the syringe pump.

Should you need to operate the T34™ Syringe Pump with a syringe manufacturer and/or brand other than those listed here, please

consult either your local medical engineering department or CME Ltd. Technical Services.

Default Syringe Brands Configured for Use with T34™

Manufacturer Syringe Sizes (ml)

Braun Omnifix 2 5 10 20 30 50

BD Plastipak 3 5 10 20 30 50

Monoject 3 6 12 20 35

Codan/Once 10 20 30 50

Terumo 5 10 20 30 50

Nipro 5 10 20 30 50

Syringe Volumes

Due to the physical length of the screw that drives the syringe plunger forward there are limits to the maximum amount of infusate that

can be delivered from larger syringes and on some smaller syringes there is an undeliverable volume of infusate that will remain in the

syringe once the actuator has driven to the zero position.

Braun 2 ml, BD 10 ml, Codan 10 ml, Monoject 3 ml, Monoject 12 ml, Monoject 35 ml,

Nipro 10 ml and Nipro 20 ml syringes cannot empty completely, potentially a small

volume of infusate will be left in the syringe due to limitations of the syringe pump and

the syringes design. The T34™ Syringe Pump will display the volume as, for example,

Vol 5 (of 5.2)ml. In this example the syringe pump can only deliver 5 ml of the 5.2 ml in

the syringe and when the syringe pump has driven the syringe plunger as far forward

as possible, 0.2 ml will remain in the syringe. The potential volumes that might remain

in the syringes are listed in the table below:

Syringe size and brand Undeliverable infusate volume

Braun Omnifix 2 ml 0.000 ml to 0.114 ml

BD Plastipak 10 ml 0.000 ml to 0.177 ml

Codan/Once 10 ml 0.000 ml to 0.043 ml

Monoject 3 ml 0.000 ml to 0.007 ml

Monoject 12 ml 0.000 ml to 0.388 ml

Monoject 35 ml 0.000 ml to 0.348 ml

Nipro 10 ml 0.000 ml to 0.094 ml

Nipro 20 ml 0.000 ml to 0.006 ml

12 ml Monoject

Vol 5(of 5.2)ml

Change /, Press

DFU999-103EN Rev. 04

13/60

Page 14

Some manufacturers have several brand names within their ranges (e.g. Braun Omnifix and Braun Perfusor). Only

use the brands named above with the T34™, as failing to do so could result in an under- or over-infusion.

Maximum Fill Volume for Syringes 20 ml to 50 ml

Syringe brand Syringe size

20 ml 30 ml 50 ml

Monoject 18.7 ml — —

Braun Omnifix 20 ml 24.4 ml 37.7 ml

BD Plastipak 18 ml 23.5 ml 34.9 ml

Terumo 18.6 ml 24.5 ml 38.0 ml

Codan 20 ml 22.5 ml 35.9 ml

Time to Alarm from Occlusion

T34™ Syringe Pump (3

Section 2: Disposables and Accessories

rd

Edition)

Flow Rate Pressure Threshold

5 ml/h 200 mmHg TTA < 00:06:00

1 ml/h 200 mmHg TTA < 00:35:00

0.1 ml/h 200 mmHg TTA < 06:00:00

5 ml/h 1500 mmHg TTA < 00:25:00

1 ml/h 1500 mmHg TTA < 03:45:00

0.1 ml/h 1500 mmHg TTA < 24:00:00

Note:

Tested at flow rates and occlusion thresholds as described in the table above, using a BD Plastipak 20 ml syringe.

Time to Alarm (TTA)

(hh:mm:ss)

2.2 Syringe Extension Sets

INTRODUCTION

The T34™ Syringe Pump can be operated with any syringe extension set with a Luer connection. However, it is recommended, to

optimise system accuracy and performance, that proprietary syringe extension sets from CME Ltd. are used. All CME Ltd. syringe

extension sets have siphon/free flow protection.

FEATURES AND CHARACTERISTICS

Feature Description

Materials

Tubing

Slide clamp Clamps: to prevent fluid flow to patient (optional on some syringe extension sets).

Pressure activated antisiphon/anti-reflux valve

The syringe extension sets are manufactured using PVC materials that do not contain latex or di-2ethylhexyl phthalate (DEHP).

Micro-bore: require small priming volumes.

Anti-kink: to prevent kinking or occlusion particularly in configuration.

Various lengths available.

All CME Ltd. syringe extension sets contain an anti-syphon valve to prevent uncontrolled flow of fluid

either into or from the patient.

The syringe extension set with pressure activated anti-siphon/anti-reflux valve reduces the potential for

uncontrolled flow and backflow (backtracking).

The pressure-activated anti-siphon valve requires pressure to open. The syringe pump occlusion

pressure setting may require adjustment to prevent occlusion alarms.

The anti-syphon valve enhances pump functioning by:

• Preventing siphoning (uncontrolled flow) in the event the syringe extension set is detached from

the syringe pump or mechanical malfunction, and

• Preventing reflux (back-flow) in the event several infusion pumps are connected simultaneously

to the same patient.

DFU999-103EN Rev. 04

14/60

Page 15

T34™ Syringe Pump (3

Section 2: Disposables and Accessories

rd

Edition)

Luer Lock end connector

Ensure the syringe extension set is NOT connected to the patient during priming.

A kinked or occluded syringe extension set may impair the operation and accuracy of the syringe pump. Before

operation, verify that the syringe extension set is not kinked or occluded.

Note: The recommended syringe extension set change interval is maximum 72 hours.

The syringe extension set is designed to be connected to Luer Lock syringes.

Luer Lock syringes allow a connection between male and female Luer. This provides a secure connection

and prevents accidental removal.

ADVISORY WARNINGS AND NOTES FOR SYRINGES AND SYRINGE EXTENSION SETS

Component damage may occur if the syringe extension set is not correctly attached to the syringe. Assure

all connections are secure: Do not over-tighten connection. This will help minimise leaks, disconnection and

component damage.

Disposables (as with any infusion) used with the syringe pump must be compatible with the drug/fluid being

delivered. Check with the manufacturer of the disposables before use. Consult the fluid or drug manufacturer's

information for precautions, guidelines, and instructions for preparation and use of disposables.

Replace the syringe and/or syringe extension set in accordance with local guidelines.

Use aseptic technique when filling the syringe and priming the syringe extension set. Patient infection may result

from the use of non-sterile components. Maintain sterility of all syringe extension set components and do not

re-use single-use syringe extension sets.

Syringes and syringe extension sets should be disposed of in an appropriate manner, considering the nature of the

residual fluid that may be contained within, in accordance with the hospital/homecare provider's disposal practices.

DFU999-103EN Rev. 04

15/60

Page 16

2.3 Battery Power Supply

Refer to section 7.1 for checking battery levels

BATTERY TYPES AND USE

Always use a 9 volt alkaline disposable battery with the following attributes:

Designation: IEC: 6LR61

Body Size: 46.4 mm × 26.5 mm × 17.5 mm

Impedance: 1700 milli-ohms @ 1 kHz

Do not use batteries marked 6LP3146 or 6LF22 with the T34™ Syringe Pump. 6LP3146 and 6LF22 batteries can cause

issues with the operation of the syringe pump, as the physical construction and internal resistance of this type

of battery are different to the 6LR61 battery. Issues arising from use of 6LP3146 and 6LF22 batteries can include

End Battery messages during Pre-Load, volume test fails, pressure test/calibration issues and reduced amount of

infusions from a battery.

Nominal voltage 9 V

Impedance 1700 milli-ohms @ 1 kHz

Typical weight 45 g (1.6 oz)

Typical volume 22.8 cm3 (1.4 in3)

Terminals Miniature snap

Storage temp. range 5°C to 30°C (41°F to 86°F)

Operating temp. range −20°C to 54°C (−4°F to 130°F)

Designation

ANSI: 1604A IEC: 6LR61

T34™ Syringe Pump (3

Section 2: Disposables and Accessories

rd

Edition)

Note: Tested at flow rates and occlusion thresholds as described in the table above, using a BD Plastipak 20 ml syringe.

If a battery is too tight, do not try to force it into the battery compartment as this may damage the battery contacts.

Only use accessories designed for the system. Unsafe operation may result from using improper accessories. Use

only accessories and options designed for this system and supplied or recommended by the T34™ Syringe Pump

distributor.

BATTERY LIFE

Factors that affect battery life include:

• Pump settings,

• Infusion rate,

• The number of interventions that occur (e.g. stopping/starting infusions, manual movement of actuator and backlight activation),

• The number of key presses that occur, and

• Frequency of LED green light flashing.

The syringe pump battery meter displays battery life remaining as a percentage (%).

• When the battery power is low a low battery alert will activate.

• When the battery power is almost depleted, an end of battery alarm will activate.

• The end of battery alarm will continue until the user presses key to confirm or the battery power is fully depleted.

Refer to alerts, alarms and troubleshooting section for further information on alerts, alarms and troubleshooting.

INDICATIONS TO CHANGE A BATTERY

Guidance for battery changing may vary for different areas according to local policy and where the syringe pump is to be used and who

is managing the syringe pump (healthcare professional or patient).

If the syringe pump is being managed in an environment where designated personnel are available at all times to change a battery if

necessary, the low battery alert can be used as an indication to change a battery.

If the syringe pump is being managed in an environment where designated personnel are unavailable to change a battery

Note:

if necessary, the following rule applies: To ensure delivery of 24 hours at flow rate of up to 1ml/h, always change to a new

battery.

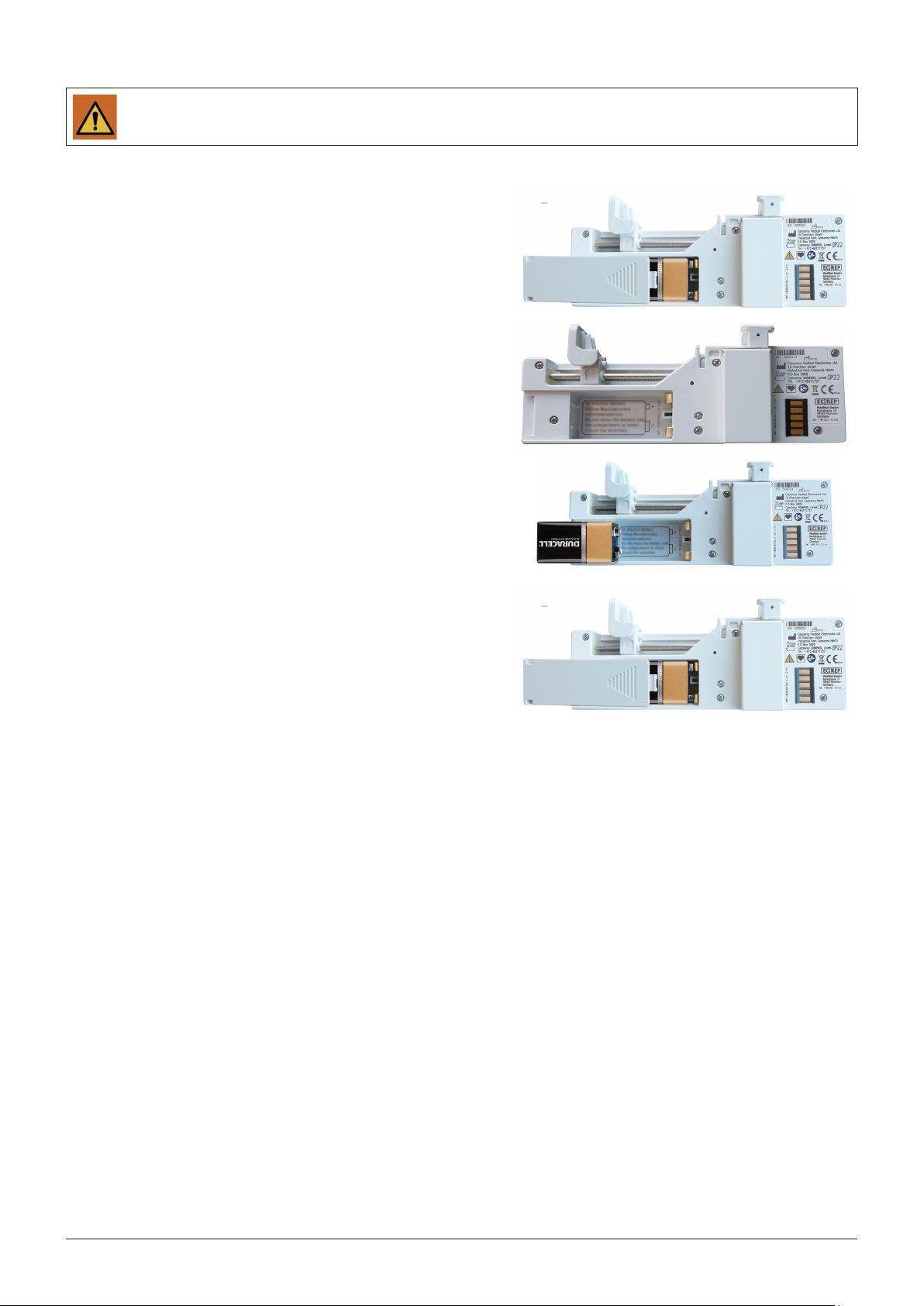

BATTERY FITTING AND REMOVAL

Inserting and removing a battery

The battery should fit securely to ensure good electrical contact.

DFU999-103EN Rev. 04

16/60

Page 17

DO NOT use scissors or metal objects to remove a battery.

To insert the battery into the syringe pump:

1. Slide the compartment cover off at the back of the syringe pump.

2. This reveals the empty battery compartment, with insertion

instructions.

T34™ Syringe Pump (3

Section 2: Disposables and Accessories

rd

Edition)

3. Push the battery into the compartment taking care to ensure

that the battery + / − contacts are aligned on the label inside the

compartment.

4. Slide the cover back on.

To remove the battery from the syringe pump:

1. Slide the compartment cover off at the back of the syringe pump.

2. Remove the battery

3. Slide the cover back on.

DFU999-103EN Rev. 04

17/60

Page 18

T34™ Syringe Pump (3

Section 2: Disposables and Accessories

rd

Edition)

2.4 Lockbox (Optional)

USES AND FEATURES

Lockboxes are designed to help protect the syringe from displacement and/or tampering.

Lock boxes are made from polycarbonate due to its high impact, temperature resistance and optical properties.

TYPES AND SIZES

Lockboxes are available in clear plastic.

• The clear lockbox can be used with any drug delivery route.

• The lockbox will fit most commonly used syringe brands and sizes up to 30 ml.

Refer to your local sales representative for any product-related information.

After the syringe is loaded on the T34™ Syringe Pump and the syringe extension set is connected, place the syringe pump into the

lockbox and carry pouch:

1. Open the lockbox using the standard key that operates all T34™ Syringe Pump lockboxes.

2. Place the syringe pump into the lockbox so that the LCD display and keypad line up with the cut out opening.

3. Close the lockbox, guiding the syringe extension set out of the slot at the side of the top section of the lockbox.

4. Place the lockbox (or the syringe pump without the lockbox) into the carry pouch and secure to the patient.

Note:

You can use the lockbox only with syringes which size is 30 ml or smaller.

Note: Lockboxes are designed for the use with CME Ltd. syringe extension sets. If using an alternate brand of syringe extension set

with a commonly used 30 ml syringe, the syringe extension set design may prevent the lockbox from fully closing and locking.

2.5 Carry Pouches (Optional)

CARRY POUCH USE AND TYPES

Disposable and reusable (washable) pouches are available.

Refer to your local sales representative for any product-related information.

Refer to Section 7.7 for re-usable pouch cleaning/washing instructions.

Using the syringe pump with a CME Ltd. carry pouch or similar receptacle during transportation or patient ambulation whilst the syringe

pump is infusing protects the syringe pump functionality and the medication in the syringe. The carry pouch will also protect the syringe

pump from damage or syringe displacement.

When using the CME Ltd reusable (washable) carry pouch, it is possible to access the screen and keypad of the syringe pump during

infusion by lifting the Velcro flap of the carry pouch whilst the syringe pump remains in the carry pouch.

When using either a CME Ltd reusable (washable) or disposable (single patient use) carry pouch it is possible to remove the forward part

of the syringe pump during infusion from the carry pouch to inspect the syringe without removing the rear section of the syringe pump.

CME Ltd carry pouches can be carried on the shoulder or around the waist for convenience.

DFU999-103EN Rev. 04

18/60

Page 19

Section 3: Pump Features and Description

3.1 Overview

The T34™ Syringe Pump provides the following features:

• Accommodates a range of commonly used syringe brand and sizes

• Three-point syringe detection system

• Capable of small ml/h rate delivery

• Configurable occlusion pressure setting

• LCD display screen with backlight

• Green LED indicator light to indicate if infusion is in progress

• Event log

The following safety features are available:

• Access code protected pump configuration

• Lockable infusion program

• Post Occlusion Bolus Reduction System

• Comprehensive range of alerts and alarms

• Keypad lock

• Lockable lockbox (optional)

T34™ Syringe Pump (3

Section 3: Pump Features and Description

rd

Edition)

3.2 Pump Description

1. Barrel clamp arm sensor 2. Collar sensor 3. Plunger sensor

6. Guide rails

4. Lead screw

5. Actuator

TOP OF PUMP: SYRINGE FITTING

No. Area Function

1. Barrel clamp arm sensor Detects syringe barrel loading and secures syringe in place.

2. Collar sensor Detects correct loading of the syringe collar.

3. Plunger sensor Detects correct loading of the syringe plunger.

4. Lead screw Moves actuator.

5. Actuator Drives the syringe plunger to deliver syringe contents.

6. Guide rails The two guide rails support the actuator position.

DFU999-103EN Rev. 04

19/60

Page 20

FRONT OF PUMP: KEYS AND DISPLAY SCREEN

10. LCD

display screen

1. i+ key

(Info menu)

2. Up

3. Down

4. Start / OK

No. Area Function

• Pressing once during infusion displays an infusion summary.

1.

2.

3.

4.

5.

6.

7.

Info Menu key

Up key

Down key

Start / OK key

Stop / No key

Move Actuator Forward key

Move Actuator Back key

• Pressing a second time during infusion displays the current battery level.

• When pump is in standby mode, accesses the main (Info) menu.

• Activates/deactivates keypad lock.

• Scrolls between options.

• Increases infusion parameters during programming/titration.

• Scrolls between options.

• Decreases infusion parameters during programming/titration.

• Confirms selection.

• Starts infusion.

• Takes user back one step during programming.

• Stops infusion.

• Moves actuator forward when no syringe in place and the barrel clamp

• Accesses purge function (if enabled).

• Accesses bolus function (if enabled).

• Moves actuator backward when no syringe is in place and barrel clamp

5. Stop / No

arm is down.

arm is down.

T34™ Syringe Pump (3

Section 3: Pump Features and Description

Syringe collarBarrel clamp arm sensor Syringe plunger

Plunger sensor

9. LED indicator

8. On / Off key

7. Move Actuator Back

6. Move Actuator Forward,

Purge/Bolus feature

rd

Edition)

Actuator

8.

9. LED indicator

10. LCD display screen

Note:

DFU999-103EN Rev. 04

On / Off key

Instructions on the pump label are for reference only and do not reflect all possible settings. Please, refer to this

Use

for full instructions.

• Powers the syringe pump on and off.

• The LED indicator light is a steady green during system self-tests.

• The LED indicator flashes green to indicate infusion delivery.

• The LED indicator is a steady yellow when the syringe pump is in standby

mode or indicates low priority alarm.

• The LED indicator flashes yellow to indicate medium priority alarm.

• The LED indicator flashes red to indicate a high priority alarm.

• Displays pump and infusion status, programming choices and

instructions.

Directions For

20/60

Page 21

BACK OF PUMP: BATTERY AREA AND PUMP MARKINGS

T34™ Syringe Pump (3

Section 3: Pump Features and Description

rd

Edition)

1. Pump information

2. Battery compartment

No. Area Function

1. Pump information and symbols

2. Battery compartment Includes instructions for inserting the battery correctly.

Labelling (including universal symbols) identify a pump, its manufacturer,

and communicates information on safety, use and performance.

DFU999-103EN Rev. 04

21/60

Page 22

T34™ Syringe Pump (3

Section 3: Pump Features and Description

rd

Edition)

3.3 Event Log

The event log shows a complete time and date stamped record of the last 512 pump events along with a record of pump status (volume

infused, rate, etc.) at the time of the event. Event log data cannot be deleted or altered and it is not patient-specific. i.e. the 512 events

are likely to span multiple patients treated with that particular pump.

Each event is assigned a new number and the syringe pump stores the most recent 512 events in memory. When more than 512 events

have occurred, the oldest event will be deleted each time a new event occurs.

For example, after some time, the first event to appear when you enter the events history might be number 754. This means there have

been 754 events in this pump's life and events 242–754 are currently stored. When event 755 occurs, the oldest event, number 242, will

be deleted and the syringe pump will store events 243–755, then 244–756, and so on.

Events recorded include hourly self-testing when an infusion is running and certain key presses.

When the syringe pump is infusing, the syringe pump will record pump status every hour regardless of any key presses.

The event log can be viewed via the syringe pump menu:

Event log access and navigation

The event log cannot be accessed whilst an infusion is running. If necessary, stop the infusion and remove keypad lock.

1. Press the key:

2. Use / keys to scroll to Event Log

3. Press key.

The most recent event displays:

Event No.: 854

27.07.201 16:01

Start Infusion

Press i+ for Details

When

key is pressed:

VI 1.03ml

VTBI 14.35ml

Rate 0.64ml/h

30ml BD Plastipak

Line 1: Event Number

Line 2: Date and time of event

Line 3: Event description/operating state

Line 4: View details on this event

VI = Volume infused

VTBI = Volume to be infused

Rate = ml/h rate

30 ml BD Plastipak = Syringe brand and size confirmed

Info Menu

Battery Level

Select /, Press

Info Menu

Event Log

Select /, Press

Either use

events or,

Press

/ keys to scroll up/down through

key to display detailed data for the event.

Travel = Actuator travel distance (mm) to deliver 1 ml (for syringe size/brand confirmed)

Travel 2.73mm/ml

1N (0mmHg) = 18mA

10N (540mmHg) = 83mA

Motor Current 0mA

Occlusion 720mmHg

Battery 7.8V

Either use

The event information that displays when key is pressed will vary depending on the operational status of the syringe pump for that

event.

Some events may only record one or two parameters, while other events record numerous parameters.

Note:

DFU999-103EN Rev. 04

/ keys to display further information or to return to the previous screen, press key.

The syringe pump does not automatically change for daylight saving. The date and time can be updated manually via the

syringe pump Change Set up menu.

1 N = Minimum actuator travel force (related to start up motor movement)

10 N = Maximum actuator travel force (related to start up motor movement)

Motor current = Motor current level in mA

Occlusion = Pump occlusion alarm setting

Battery = Battery voltage

22/60

Page 23

T34™ Syringe Pump (3

Section 3: Pump Features and Description

Event Log examples

Switched ON Syringe Removed Anti-bolus Reverse Keypad Lock ON

Switched OFF Occlusion / End Stop Infusion Keypad Lock OFF

Volume Change Purge Pump Operating System Error

rd

Edition)

Other events may be recorded relating to technical information. Refer to the

Note:

Technical Service Manual

for details.

3.4 Post Occlusion Bolus Reduction System (POBRS)

POST OCCLUSION BOLUS REDUCTION SYSTEM

During an occlusion, the pressure in the downstream section of the syringe extension set and/or inside the syringe can increase above

the occlusion pressure defined in pump settings. When the syringe pump alarms the user must check the syringe extension set and

attempt to clear the occlusion. During an occlusion the syringe pump's Post Occlusion Bolus Reduction System feature will reverse the

operation of the motor and drive the actuator to avoid an unintended bolus on release of the occlusion.

When the infusion is resumed, the volume to be infused (VTBI) increases and the volume infused (VI) decreases to indicate the syringe

pump back off feature and the infusion time remaining increases; this protects the ml/h infusion rate.

Following activation of the POBRS and if the user presses

syringe pump back off feature.

Intermediate Rate Occlusion Pressure Unintended Bolus Volume

5 ml/h 200 mmHg (minimum)

1500 mmHg (maximum)

An occlusion may pressurize the syringe extension set and syringe, which can result in an unintended bolus of infusate when the

occlusion is resolved. In order to prevent unintended bolus, disconnect the syringe extension set or relieve the excess pressure through a

stopcock, if present.

The clinician should weigh the relative risks of syringe extension set disconnection with the risks of an unintended bolus.

to resume the infusion VTBI increases and the VI decreases to indicate the

<= 0.5 ml

<= 0.5 ml

OCCLUSION PRESSURE

The occlusion pressure of a pump is the pressure in the system, registered at the syringe pump, when the syringe pump is still operating

but cannot sustain the flow rate. The resultant build-up of pressure sets off the occlusion alarm.

OCCLUSION AND RESPONSE

An occlusion alarm can be activated by:

• A blockage in the syringe extension set – often inadvertently caused by kinking or leaving a roller clamp or a tap closed.

• A clotted-off cannula.

• A partially occluded cannula – if it causes the required driving pressure to rise above the occlusion alarm level.

• A very long or narrow bore cannula or/with syringe extension set.

Occlusion response is characterised in terms of three measurable parameters:

1. Pressure to alarm

2. Time to alarm

3. Bolus release when occlusion is resolved

1. Pressure to alarm

If an occlusion occurs the syringe pump attempts to maintain sufficient pressure on the infusate to cause it to flow through all

restrictions and overcome any additional resistance. Although infusate is incompressible, the syringe extension set and other

components of the system have some give (compliance) and the syringe extension set can expand under the increasing pressure. Other

components of the system, such as the syringe stopper, become compressed. This expansion and compression takes some time to occur.

2. Time to alarm

If the occlusion is present from the beginning of the infusion, the time to alarm will increase. The pressure in the syringe and syringe

extension set increases from zero at the start of the infusion up to the alarm level. Leaving a clamp closed is the most likely cause of

occlusions. Generally, shorter time to occlusion alarm occur with high flow rates and small syringes. Refer to section Time to Alarm from

Occlusion on page 14 for time-to-alarm specifications.

3. Unintended bolus release

In the case of a complete occlusion, there is no flow to the patient whilst pressure in the system is increasing. When the occlusion is

released, the build-up of infusate in the syringe extension set can result in an unintended bolus.

DFU999-103EN Rev. 04

23/60

Page 24

T34™ Syringe Pump (3

Section 4: Modes of Operation

rd

Edition)

Section 4: Modes of Operation

4.1 Modes of Operation

DURATION INFUSION

The primary setting is duration (volume over time infusion) which can be configured with a locked or changeable duration time.

Once the duration time is confirmed, the syringe pump will calculate the ml/h rate.

RATE INFUSION (ML/HOUR)

The primary setting is ml/h rate (rate over time infusion) which can be configured with a locked or changeable ml/h infusion rate.

Once the ml/h rate is confirmed, the syringe pump will calculate the duration time.

COMMON PUMP CONFIGURATIONS

Four common pump configurations are:

• Lock On mode – fixed duration

• Lock Off mode – adjustable duration

• Rate mode (Lock On) – fixed ml/h rate

• Rate mode (Lock Off) – adjustable ml/h rate

Each of these modes can have additional functions enabled or disabled, to suit local requirements.

The syringe pump default mode of operation is Lock On 24 hour duration.

For the correct pump configuration, mode of operation and start-up sequence, you must refer to your local policies.

RESUME

The T34™ Syringe Pump can be configured for a continuous infusion with Rate as the primary setting. The primary setting (e.g. Rate)

is then used to calculate duration. If the Rate is the primary setting it is saved for the current program when Resume is selected after

therapy interruption (e.g. syringe displacement or occlusion). See KEY PRESS OPTIONS OF RESUME AND NEW SYRINGE section for further

instructions.

LOCK ON MODE (FIXED DURATION)

The syringe pump will deliver the syringe volume over the fixed (locked) duration. Once a syringe is detected and confirmed, the syringe

pump calculates the ml/h infusion rate:

syringe volume

fixed duration

• With the Program Lock On, rate change (titration) during infusion cannot be enabled.

• KVO and purge can be enabled if required.

Note:

During programming, the user must check and confirm the infusion summary screen. This includes checking the syringe

volume, duration, and the calculated rate matches the prescription and what is required for that infusion before it

iscommenced.

= ml/h infusion rate

LOCK OFF MODE (ADJUSTABLE DURATION)

The syringe pump will deliver the syringe volume over the confirmed default duration or the duration inputted and confirmed by the

user during programming. The syringe pump then calculates the ml/h infusion rate:

syringe volume

default or duration entered

= ml/h infusion rate

• With Program Lock Off, rate change (titration) during infusion can be enabled if required. There is no option to re-program the

infusion duration during delivery.

• KVO, purge and rate titration can be enabled if required.

Note:

During programming, the user must check, change and/or confirm infusion information and programming screens. This

includes checking that the program summary screen (syringe volume, duration, and the calculated rate) matches the

prescription and what is required for that infusion before it is commenced.

DFU999-103EN Rev. 04

24/60

Page 25

T34™ Syringe Pump (3

COMPARISON OF LOCK ON AND LOCK OFF (DURATION) MODES PROGRAMMING SCREENS

rd

Edition)

Section 4: Modes of Operation

Lock On

(Fixed Duration)

20ml BD Plastipak

Select /, Press

Volume 12.0ml

Duration 24:00

Rate 0.50ml/h

Confirm, Press

Start Infusion?

Lock Off

(Adjustable Duration)

20ml BD Plastipak

Select /, Press

Occlusion 720mmHg

Max. Rate 5ml/h

Program Lock OFF

Battery Status 90%

20ml BD Plastipak

Volume 12ml

Change /, Press

20ml BD Plastipak

Duration 24:00

Change /, Press

20ml BD Plastipak

Rate 0.5ml/h

Confirm, Press

Volume 12.0ml

Duration 24:00

Rate 0.50ml/h

Confirm, Press

Start Infusion?

If the default duration is changed and/or titration is enabled additional screen prompts will display.

There are two alternatives methods for starting an infusion when using a duration (volume over time) mode of operation:

Note:

prime and load or load and prime methods. The method chosen relates to the priming volume of the syringe extension set.

Your local policy will state which method to use.

In Duration mode we recommend using "Prime and Load" and not "Load and Prime". Please be aware if using Load and Prime

Note:

instead of Prime and Load sequence, the rate of delivery will be automatically adjusted to compensate for the lost priming

volume while maintaining the preset duration. If you wish to maintain the rate, please work in Rate mode.

RATE MODE (LOCK ON) – FIXED ML/HOUR RATE

The syringe pump will deliver the syringe volume over the fixed (locked) ml/h rate. Once a syringe is detected and confirmed, the syringe

pump calculates infusion delivery duration:

syringe volume

fixed ml/h rate

= duration

• With the Program Lock ON, rate change (titration) during infusion cannot be enabled.

• KVO and purge can be enabled if required.

Note:

During programming, the user must check and confirm the infusion summary screen. This includes checking the syringe

volume, duration, and the rate matches the prescription and what is required for that infusion before it is commenced.

DFU999-103EN Rev. 04

25/60

Page 26

T34™ Syringe Pump (3

Section 4: Modes of Operation

rd

Edition)

RATE MODE (LOCK OFF) – ADJUSTABLE ML/HOUR RATE

The syringe pump will deliver the syringe volume over the ml/h rate inputted and confirmed by the user during programming the

syringe pump calculates the infusion delivery duration:

syringe volume

confirmed ml/h rate

• With Program Lock OFF, rate change (titration) during infusion can be enabled if required.

• KVO, purge and rate titration can be enabled if required.

= duration

RATE MODE PROGRAMMING SCREENS

a) If the syringe pump is configured with Rate Setting disabled, the default is 0 ml/h.

20ml BD Plastipak

Rate 0ml/h

Change /, Press

b) If the syringe pump is configured with Rate Setting enabled, the programmed rate becomes the default.

20ml BD Plastipak

Rate 2ml/h

Change /, Press

This example shows the default rate is 0 ml/h. The user enters the rate required.

This example shows the default rate is 2 ml/h. The user can either confirm or change the rate.

Note: During programming, the user must check, change and/or confirm infusion information and programming screens.

This includes checking that the program summary screen (syringe volume, duration, and the calculated rate) matches the

prescription and what is required for that infusion before it is commenced.

DFU999-103EN Rev. 04

26/60

Page 27

T34™ Syringe Pump (3

Section 5: Pump Configuration

rd

Edition)

Section 5: Pump Configuration

5.1 Pump Configuration

CONFIGURATION AUTHORISATION

Pump configuration must only be carried out by designated and authorised personnel, you must check with your technical department

and/or line manager if you are designated and have the authority to change the syringe pump configuration.

When configuring a pump, the following must be taken into account, to ensure that:

• The pumps are configured for the required application, e.g. occlusion pressure settings correct for drug delivery route.

• The mode of operation (lock on, lock off and rate modes) configured is correct for the drug prescription. e.g. duration (volumeover-time) or a ml/h infusion

• Optional features and functions that may be required are configured (e.g. Purge, KVO, titration, pump maximum ml/h rate)

Any program/pump changes that are made must be fully documented checked with a second person and against a pump setting

authorisation form which is available from local or CME Ltd. technical service staff.

5.2 Pump Access Codes

ACCESS CODES FOR PUMP CONFIGURATION

The T34™ Syringe Pump has three areas of access code protection to prevent unauthorised changes to set up, configuration or

programming. Certain settings and features may be configured and locked based on patient or clinical need or to configure the syringe

pump for a specific clinical application.

No access code is required to turn the syringe pump on and run an infusion. In normal clinical use the syringe pump user will not see

these fields or be prompted for access codes.

The Change Set Up and Rate Settings menus are available via the syringe pump

The Technician menu code is only provided to fully trained, (by CME Ltd.) and authorised electrical biomedical engineering personnel.

menu.

Do not attempt to access code protected areas if you are not trained or authorised to do so. Authorised personnel

should not share codes with un-authorised personnel and should only give code access to designated personnel.

Codes will only be provided by CME Ltd. to designated and authorised clinical or technical staff when they have been trained

Note:

and certified in their use. No access codes are contained in this

Technical staff must refer to CME Ltd. Technical Services department for access codes and information on pump configuration

Note:

and training.

Directions For Use

.

DFU999-103EN Rev. 04

27/60

Page 28

T34™ Syringe Pump (3

Section 5: Pump Configuration

rd

Edition)

5.3 Pump Info and Configuration Menus

PUMP INFO MENU

The syringe pump Info menu enables the user to navigate to various functions. This includes accessing the syringe pump configuration

settings (Change Set Up and Rate Setting areas).

ACCESSING THE INFO MENU

The menu cannot be accessed during an infusion or with the keypad lock activated.

• With no infusion running, press the key.

• Use / keys to scroll up/down the menu to select the option required, then press key to view the contents.

The tables describes the functions in the menu.

Option Description

Info Menu

Battery Level

Select /, Press

Info Menu

Exit

Select /, Press

View battery life percentage (graph)

Exits Info menu

Info Menu

Rate Setting

Select /, Press

Info Menu

Event Log

Select /, Press

Info Menu

Change Set up

Select /, Press

Change and configure Rate Setting function (access code protected)

View pump event log

Change and configure programming functions (access code protected)

RATE SETTING MENU

The tables shows the configurable parameters in the Rate Setting area.

Parameter Default Range Description

Sets the default rate on Rate Setting Mode.

Rate Setting 0 ml/h

0.1 ml/h – (maximum rate)

Note: Maximum rate can be changed from the technician menu

(Maximum Rate parameter). Default: 5 ml/h. Range: 0.1 ml/h to

650 ml/h.

CHANGE SET UP MENU

The tables shows the configurable parameters in the Change Set Up menu

Parameter Default Range Description

Exit — — Exit the Change Set Up menu.

Language English

Set Time and Date

Key Operation

DFU999-103EN Rev. 04

Current

date/time

5 mm 0.1–100 mm

English,

local language

Month/year

Hour/minute

The syringe pump can be set to English or one local language which

varies according to where the syringe pump is sold.

Sets a date and time stamp for the event log.

This does not automatically change for daylight saving.

Limits the forward movement of the actuator when the key is

pressed with no syringe in place and barrel clamp arm down.

28/60

Page 29

T34™ Syringe Pump (3

Section 5: Pump Configuration

Backlight Duration 5 seconds 0 (OFF)–60 seconds Limits the screen backlight duration following key presses.

rd

Edition)

Info Duration 5 seconds 1–20 seconds

Bolus Dose Rate

Bolus Maximum Volume

Titration Option Disabled Enabled/Disabled

Default Duration 24:00 hours

Occlusion Pressure 720 mmHg

KVO Operation Rate

Program Lock ON OFF/ON With lock on, prevents alteration of default duration or ml/h rate.

300 ml/h 1–650 ml/h

0 ml

(Disabled)

0 ml/h 0 (OFF)–5.0 ml/h

0 (OFF)–20 ml 0–20 ml in 0.1 ml increments.

0:00 hours

(ml/h)

0:01–99:00 hours

(volume over time)

200–1500 mmHg Sets the pressure level at which the occlusion alarm will activate.

Limits the screen information duration which displays when the

key is pressed during an infusion.

1–10 ml/h in 0.01 ml/h increments;

10–29.9 ml/h in 0.1 ml/h increments;

30–49.5 ml/h in 0.5 ml/h increments;

50–299 ml/h in 1 ml/h increments;

300–650 ml/h in 5 ml/h increments.

Enables rate change during infusion. Maximum rate is the syringe

pump max. ml/h rate. Minimum is 0.1 ml/h. Can only be enabled if

program lock is OFF.

With default duration set to 0:00 hours, the syringe pump runs as an

ml/h infusion.

With a nonzero default duration set, the syringe pump runs as a

volume over time infusion.

0–5.0 ml/h in 0.1 ml/h increments.

Activates Keep Vein Open infusion at end program.

DFU999-103EN Rev. 04

29/60

Page 30

T34™ Syringe Pump (3

Section 5: Pump Configuration

rd

Edition)

5.4 Pump Configurable Settings for Modes of Operation

CONFIGURATION SETTINGS FOR LOCK ON AND LOCK OFF (DURATION) MODES

Lock On (Fixed duration) Lock Off (Adjustable duration)

Titration Option Disabled Enable if rate change during infusion is required

Default Duration e.g. 24:00 hours e.g. 24:00 hours

Program Lock On Off

Rate Setting

Occlusion Pressure Set the pressure for the infusate delivery route e.g. subcutaneous, IV.

KVO Set KVO ml/h if required.

Max. Rate

Purge Set purge volume if required. Pump default 0 ml.

0 ml 0 ml

Change if required. Pump default 5 ml/h.

CONFIGURATION SETTINGS FOR RATE (ML/HOUR) MODES

Rate Mode (Lock ON)

(Fixed ml/h rate)

Titration Option Disabled Enable if rate change during infusion required

Default Duration 0:00 hours 0:00 hours

Program Lock On Off

Rate Setting

Occlusion Pressure Set the pressure for the drug delivery route e.g. subcutaneous, IV.

KVO

Max. Rate Change if required. Pump default 5 ml/h.

Purge Set purge volume if required. Pump default 0 ml.

Note: A Pump Configuration Authorisation form is available from CME Ltd. to record authorisation and document pump settings.

Contact your local Sales or Clinical representative.

Pump maximum ml/h rate and purge volume are configured via the syringe pump Technician Menu. If these settings need to

Note:

be changed, you must consult technical staff.

The syringe pump uses an indirect method of pressure detection.

Note:

e.g. 2 ml/h e.g. 2 ml/h

Set KVO ml/h if required. Pump default 0 ml.

Rate Mode (Lock OFF)

(Adjustable ml/h rate)

DFU999-103EN Rev. 04

30/60

Page 31

T34™ Syringe Pump (3

Section 5: Pump Configuration

rd

Edition)

5.5 Optional Configurable Settings

KVO (KEEP VEIN OPEN) OPERATION

The T34™ Syringe Pump can be configured to deliver a KVO infusion to commence at the end of the infusion to keep the patients access

device patent. With KVO enabled the syringe pump applies the KVO rate set until the syringe is empty or to a maximum of 5 ml.

KVO rate can be configured in the syringe pump Change Set Up Menu.

KVO

0.2ml/h

When the KVO volume is delivered the end program alarm activates.

When configuring KVO infusion rate, Medium priority alarm will be heard to confirm the syringe pump

is still infusing in KVO mode.

PURGE

In order to eliminate/reduce mechanical slack (visible spaces at the syringe collar and plunger loading points) and ensure a faster start

up time (time to start delivering the fluid to the patient/reach the programmed infusion rate) the user can purge the system.

• The purge function is available (if enabled) once only, after pre-loading prior to commencing an infusion.

• The purge function is disabled by default (0 ml) and the maximum deliverable is 2.0 ml.

• The purge rate is 650 ml/h.

• The purge function can be configured via the syringe pump Technician menu.

• The purge function can be used with any mode of operation.

Purge sequence (all modes of operation)

1. Turn the syringe pump on without syringe and wait until the preloading process is complete.

2. Load the syringe.

3. Press the key after confirming the syringe size/brand.

20ml BD Plastipak

Select /, Press

Purge

4. Ensure the syringe extension set is disconnected to the patient, confirm by pressing key.

5. Press and hold the key until the slack is removed and purge volume is delivered (a purge volume

will be configured, e.g. 0.2 ml).

Disconnect patient

Press

to Confirm

Purge, hold ! key

Purge 0.00ml

Purge

6. Wait for the next screen to display.

Completed

7. If the syringe size/brand displayed matches the one used, confirm by pressing key. (Use /

keys to select the matching syringe if necessary).

Rate Titration

If enabled, you can titrate (change) continuous infusion flow rates during infusion, it is recommended that the keypad lock is used as an

additional protection against accidental rate change during infusion.

The maximum ml/h rate limit will be the syringe pump maximum rate which is configured via the syringe pump Technician menu. The

minimum rate is 0.1 ml/h. If this setting needs to be changed, you must consult technical staff.

Rate change can be enabled in the following modes of operation:

20ml BD Plastipak

Select /, Press

DFU999-103EN Rev. 04

31/60

Page 32