Page 1

Service Manual

for

BodyGuard 323, 545, & 575

Infusion pumps

0344

Manufacturer:

Caesarea Medical Electronics Ltd.

International Toll Free: +800-323-575-00

European address:

Staufenburgstr. 23 Lichtenstein

P.o.b. 1248 Lichtenstein 72805 Germany

E-mail: sales@cme-infusion.com

www.cme-infusion.com

PN 100-091X ver. 191009

Page 2

Table of Contents

Introduction ........................................................................................... 3

Warnings and Cautions.........................................................................4

Service Process Diagram ....................................................................... 7

Tools and Test Equipment...................................................................10

Adjustable Operating Parameters and Options................................. 12

Operational Checklist and Performance Acceptance Test ................ 19

Calibration ........................................................................................... 22

Troubleshooting ................................................................................... 29

Service actions...................................................................................... 34

Service Center Recommended Parts...................................................48

Cleaning and Storage........................................................................... 48

APPENDIX A....................................................................................... 49

of 502

Page 3

Introduction

This manual provides instructions for the service of BodyGuard infusion pump

models 323, 545, and 575 and their software, and mechanical service for pole

mount chargers. Sets are single use and are not serviceable.

The following requirements and conditions apply when performing service on

BodyGuard products, failure to follow these instructions will invalidate warranty

and creates unacceptable risk:

• Service of BodyGuard pumps, chargers and accessories may only be

performed by CME authorized service personnel. Service can only be

performed with the recommended equipment and CME approved

parts.

• This manual is intended to support CME authorized service technicians

performing service.

• Clinical personnel, patients, and other users are advised to return pumps to

an authorized service center for service.

• Refer to operation manual for pump operation instructions, cautions and

warnings.

• Refer to BodyComm operations manual for BodyComm operation

instructions.

• Document service performed in accordance with service provider’s

prevailing procedures.

of 503

Page 4

Warnings and Cautions

Warning: Warnings advise you of circumstances that could result in

injury or death to the patient or operator. Read and understand this

manual and the Operation’s Manual taking note of all warnings before

operating or performing service on the BodyGuard Infusion System.

Caution: Cautions advise you of circumstances that could result in

damage to the device. Read and understand this manual and the

Operation’s Manual taking note of all cautions before operating or

performing service on the BodyGuard Infusion System.

Note: Indicates that the information that follows is additional important

information or a tip that will help you when operating or performing

service on the BodyGuard Infusion System.

Warnings

To avoid possible personal injury or loss of life, observe the following:

Read the entire Operation’s Manual before using the pump, since the text

includes important precautions.

The maximum volume that may be infused under SINGLE FAULT

CONDITION is 0.1 ml.

Voltage present on internal components may cause severe shock or death

upon contact. Disconnect the charger from AC power prior to opening the

casing. Only authorized service personnel should open the pump cover.

Blown fuses could cause a fire hazard. Replace blown fuses on the

charger only with fuses of the same type and rating (see fuse values on

the charger PCB).

The equipment is not suitable for use in the presence of flammable

anesthetic-air/oxygen/nitrous oxide mixture. Do not use the system in the

presence of these gases.

Make sure the pump is attached securely to the charger, which is

connected snugly to an IV pole.

A kinked or occluded IV line may impair the operation of the pump and

the accuracy of the infusion. Before operation, verify that the IV line is

not kinked or occluded.

The BodyGuard should be operated only with BodyGuard tubing sets.

Use of administration sets other than manufacturer-produced BodyGuard

tubing set may impair the operation of the pump and the accuracy of an

infusion.

of 504

Page 5

Drugs must not be administered to the epidural space unless the drugs are

indicated for this purpose and are administered in accordance with the

indications included in the manufacturer’s package insert accompanying

the drugs.

Epidural administration of drugs other than those indicated for epidural

use could result in serious injury to the patient.

Any adjustments, maintenance, or repair of the uncovered pump may

impair the operation of the BodyGuard Infusion System and/or the

accuracy of the infusion. Only CME authorized technicians should

perform any adjustments, maintenance, or repair of the uncovered pump.

Any adjustments, maintenance, or repair of the uncovered pump while

connected to the power should be avoided.

The BodyGuard Infusion System should be operated within a temperature

range of 15°C (50°F) to 45°C (115°F) and at up to 85% humidity.

Operating the pump at temperatures and/or humidity other than within

this range may affect accuracy.

Unsafe operation may result from using improper accessories. Use only

accessories and options designed for this system and supplied by

manufacturer.

The BodyGuard tubing sets should not be use for blood, blood products or

nitroglycerin administration.

Battery charging is enabled as long as the charger cord is connected to

AC power and the pump is in the charger. Switching the pump off does

not disconnect it from AC power. To disconnect from AC power, remove

the charger cord from AC power. To disconnect pump from AC power,

remove it from the charger.

Dropping the BodyGuard Infusion System could cause damage to

components. If the pump is dropped, return the pump for inspection by

qualified service personnel.

Use aseptic technique. Patient infection may result from the use of nonsterile components. Maintain sterility of all disposable components and

do not re-use single use IV sets.

When operating the pump in PCA mode with a rate of 0.0 ml/hr there is a

hazard of blood clot formation. Connect saline infusion in parallel to

avoid this problem.

Do not operate the pump near high-energy radio-frequency emitting

equipment, such as electro-surgical cauterizing equipment. False alarm

signals may occur.

Watch your fingers / nails when opening and closing the pump door.

of 505

Page 6

Cautions

To avoid possible damage to the equipment, observe the following:

Leaving the battery in a discharged state for a long period of time may

damage the battery. Connect the pump to the AC power via the charger

whenever possible to recharge the battery.

Do not store the pump with the battery fully depleted.

Xylene, acetone or similar solvents could cause damage to components.

Do not clean the pump with these chemicals. Clean solution spills on the

pump immediately. Use a damp cloth or sponge. A mild detergent may be

used. Wipe thoroughly with a dry cloth.

Immersing the BodyGuard Infusion pump into liquid could cause damage

to components. Do not immerse the pump into any type of liquid.

Battery damage could occur if left in a temperature warmer than 500C.

of 506

Page 7

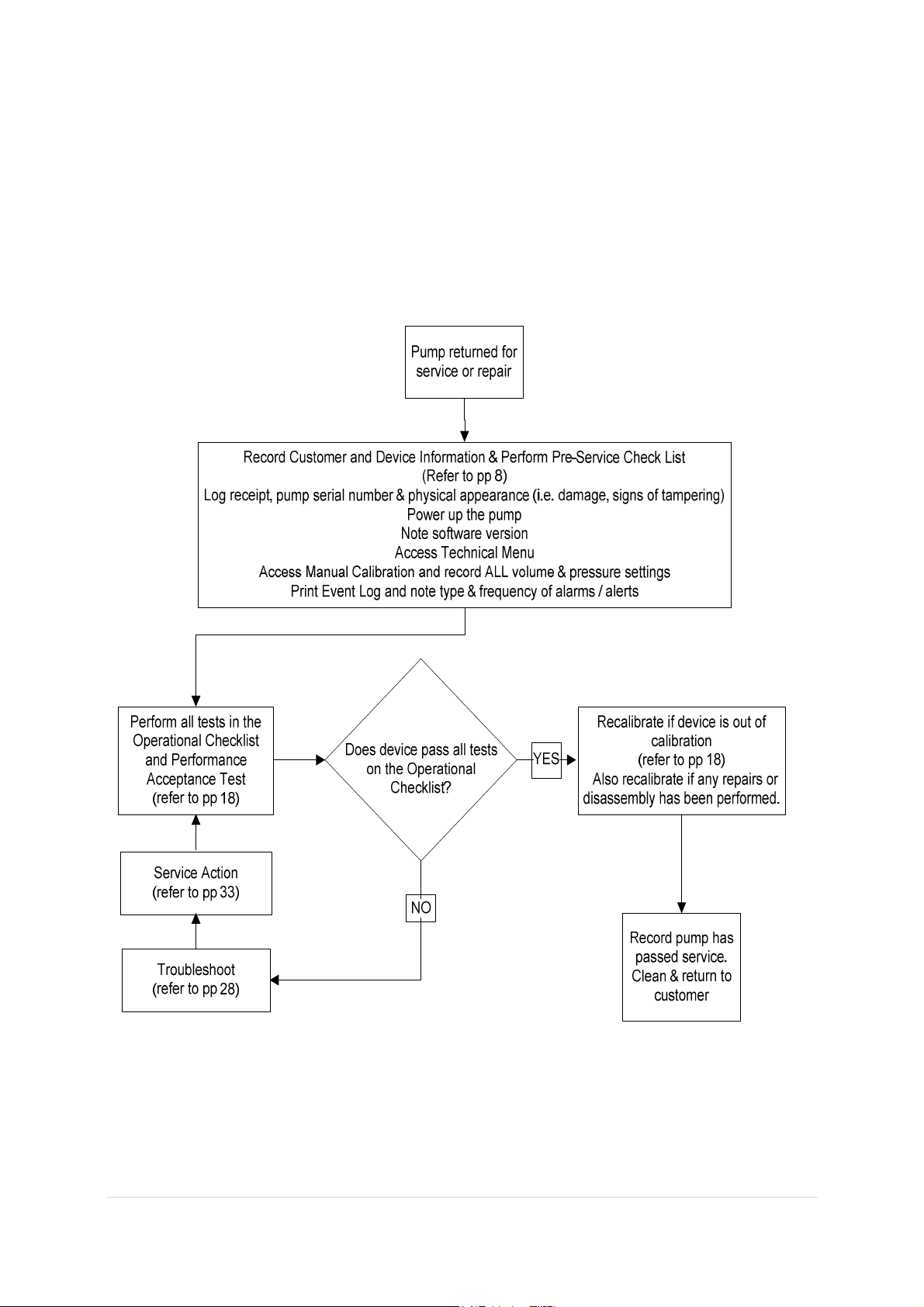

Service Process Diagram

The service operation is diagrammed below:

of 507

Page 8

Customer and Device Information & PreService Checklist

Before performing any service procedure:

1. Authorized service personnel

Service of BodyGuard pumps may only be performed by authorized

service personnel. Service can only be performed with the recommended

equipment and CME approved parts.

2. Confirm Customer Information

Confirm proper document record has been completed for, Log receipt,

pump serial number & physical appearance (i.e. damage, signs of

tampering).

3. Disinfect the pump according to cleaning instructions as described in the

user manual.

4. Open a service file to include all required documentation.

5. Download or View the Event Log - The event log records program and

calibration settings, and notes the frequency and nature of any

alarms/alerts that may be associated with past pump performance or a

complaint.

Download the Event Log

a. Use the BodyComm Software and Communication charger.

b. Refer to the BodyComm Operations Manual:

i. Connect BodyGuard to a PC using BodyComm.

ii. Download and Record the Event Log

iii. Download and Record Pump Settings.

iv. Once done Power down the pump.

Manual View the Event Log and History

BodyGuard 323

a. Start pump normal operation mode

b. Enter Change Set up Mode by pressing INFO key until

options are displayed.

of 508

Page 9

c. Select Change Set Up, Press START/OK key

d. Scroll down to option “More”, Press START/OK

e. For BodyGuard 323 Enter Change Set Up Code

f. Scroll to option History, Press START/OK key.

g. Using arrow key scroll through events, Press INFO key for

more detail.

h. Exit by pressing start/OK key

BodyGuard 545, & 575

a. Start pump normal operation mode

b. Enter Level 1 code, Press START/OK to enter Main Menu

c. Scroll down to Event Log, Press START/OK

d. Using arrow keys scroll through events, Press INFO key for

more detail.

e. Exit by pressing START/OK key

Manual Review of Pump settings

a. Enter the Technician Menu (power up the pump while holding

down the INFO & POWER keys simultaneously until the

Technician Code prompt appears).

b. Enter Technician Code.

c. Scroll to ‘Manual Calibration’ and record all pump calibration

settings (volume and pressure calibration) by pressing

START/OK continuously to review each setting.

d. Scroll to and perform ‘Main Self-Test’ and record any failures

or issues identified during the test.

6. Review Customer supplied Service Request Information

a. Has the user operated the pump correctly? Cross reference their report

with the Operation’s Manual to ensure the steps they took prior to the

incident did not cause, or result in, an alarm state or error code.

7. When the Pre-Service checklist has been completed, begin Service by

performing the Operational Checklist.

a. If a charger was returned as a complaint item, test the charger with the

associated pump cited in the complaint. If no pump was returned with

the charger, process the charger as usual.

of 509

Page 10

Tools and Test Equipment

The following tools and test equipment are required to perform the procedures

contained in this manual. Since all fasteners on this device are metric, ensure that

all tools used are for metric fasteners.

Test Equipment

• Digital voltmeter (Fluke 115 or equivalent)

• BodyGuard Operations Manual

• PC with a RS232 9way Serial port

• BodyComm Communication Software*

• BodyComm Operations Manual*

• BodyComm Communications Charger (150-318X)*

• BodyGuard Charger may be required (pulse oximeter charger for 545,

and 575)

• RS 232 cable (197-000X)**

• ESD work station Mat and Wrist Strap

• BodyGuard tubing set with proximal Y-Site**

• Infusion Bag (sterile water for injection)

• Scale (.01g resolution)

• Pressure Gauge, maximum pressure 30psi, .01 psi resolution

• Timer (seconds resolution)

• Burning Station PN 100-405X* (for software updates)

• 5 pin male to male connection wire*

• Prog08sz software*

Tools

• Phillips screwdriver, M3

• Flat screwdriver, M3

• Allen key 2.5 mm

• Forceps

• 2mm Push shaft

• Air Sensor ‘Go No-Go’ gauge/or gauge pins (GO, 2.2 mm, No-GO, 2.3 mm)

• Sharp knife

• 3 ml Syringe with graduated markings

• DC Cable BG (196-000X)*

of 5010

Page 11

*Available only from CME

** Optional Equipment

Note: CME prefers the download of the pump settings, event log and/or history

review be performed with BodyComm Software available from CME.

However, when the software is not available the review and/or download can be

performed manually.

of 5011

Page 12

Adjustable Operating Parameters and Options

BodyGuard 323

The BodyGuard 323 pump has adjustable operating parameters. These operating

parameters and options may be viewed and adjusted to modify the operation of the

pump. The operating parameters and options available for the BodyGuard 323 are

described below in the Techncian Menu, Change Set Up Menu, Program Lock, and

Keypad Lock sections. If access to a specific mode of operation is required (i.e.

Continuous, Intermitent, PCA, TPN, or 25 steps), refer to the operation manual for

instructions.

Technician Menu

To

access the Technician Menu, press and hold the INFO key during the power on

operation until ‘Technician Code’ prompt appears. The display will show the software

version for 2 seconds before the access code prompt. Enter Technician Code to access

the Technical Menu.

The pump will display all the parameters that can be set, calibrated or tested. The

technician can scroll through all parameters using the ARROW keys (2 & 0 keys on

the pump).

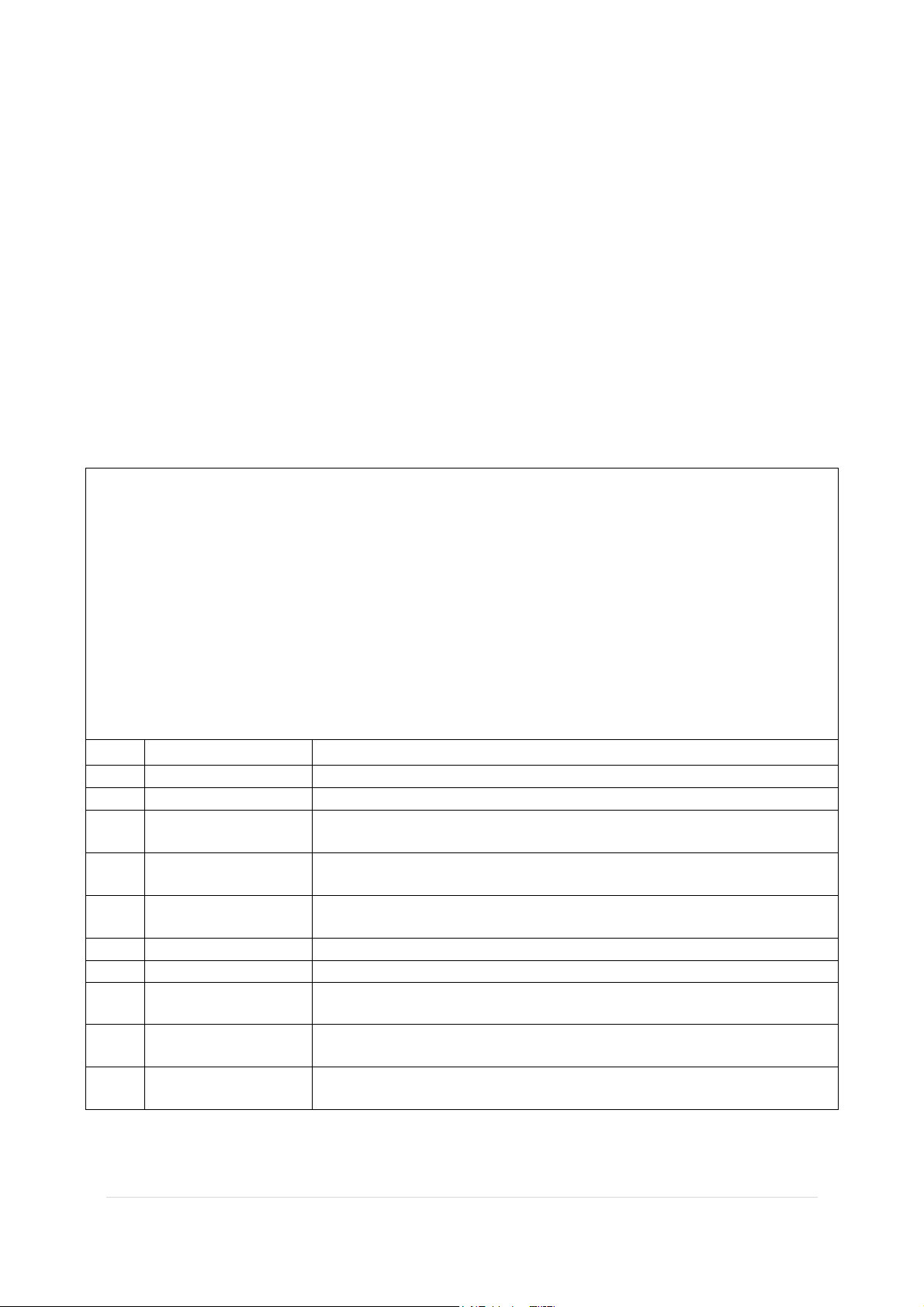

Item Parameter Description

Restart Pump Exit Technician Mode.

1

Serial Number Displays serial number & production date.

2

Manual Calibration Summary of volume & pressure calibrations and ability to check/re-

3

enter software default calibrations after service.

Main Self-Test Performs keypad, display, alarm sound, door sensor, air sensor,

4

temperature, motor & encoder, and pressure sensor tests.

Manual Test Same as Main Self-Test but with a menu so technician can focus on

5

individual tests.

Pressure Calibration Allows manual calibration of pressure settings.

6

7 Volume Calibration Allows manual calibration of pumping mechanism.

8

9

10

Software default

Setting

Reset Calibrations Caution: pressing START/OK restores default settings. Pump must

Operating time/

hours counter

Caution: pressing START/OK will restore software defaults and

delete all pre-set protocols and set-up changes.

be re-calibrated after reseting calibrations.

Hours from last service – reset to zero by pressing STOP/NO key.

of 5012

Page 13

Change Set Up Menu

To access Change Set Up Menu:

1. Turn the pump on in the normal operation mode.

2. To access the Change Set Up Menu, press the INFO key multiple times until

the “Change Set Up” option is displayed,(it is always displayed as the 4th

option).

3. Select “Change Set Up”, press OK.

4. Scroll down to the option “More”, press OK.

5. Enter access “Change Set Up” Code, press OK.

The Change Set Up Menu is intended for use by clinical personnel and authorized

service technicians.

Item Parameter Description

1 restart pump Allows clinical personnel to return pump to normal operation mode.

2 pressure default Allows clinical personnel to set the default occlusion alarm pressure.

The pump will default to this pressure setting each time the pump is

started.

3 select program Allows clinical personnel to select program from list (Continuous,

Intermitent, PCA, TPN, or 25 steps).

4 priming rate Allows clinical personnel to set priming rate.

5 max bolus volume Allows clinical personnel to set maximum bolus volume (0-100 ml).

6 titration bolus Allows clinical personnel to set titration bolus (On/ Off).

7 bolus rate Allows clinical personnel to set bolus rate (0-1200 ml/h).

8 maximal rate Allows clinical personnel to set maximal rate (0.1-1200 ml/h).

9 KVO rate Allows clinical personnel to set KVO rate (0.0-5.0 ml/h).

10 flow control Allows clinical personnel to set flow control (0 - 20 drops/ml).

11 set loading test Allows clinical personnel to activate set loading test (On/Off).

12 air bubble size Allows clinical personnel to set air bubble size (0.1 - 2.0 ml).

13 store last program Allows clinical personnel to store last program (On/Off).

14 operation LED Allows clinical personnel to set operational indicator LED (On/Off)

15 time option Allows clinical personnel to set time option (On/Off).

16 delay before start Allows clinical personnel to set delay before start (On/Off).

17 language Allows clinical personnel to choose language (English, Spanish).

18 set time and date Allows clinical personnel to date and time (dd, mm, yy, hh, mm).

19 history Allows clinical personnel to review event history settings and alarms

(for last 500 events)

of 5013

Page 14

Program Lock

To access Program Lock:

1. Turn the pump on in the normal operation mode.

2. To access the Change Set Up Menu, press the INFO key multiple times until

the “Change Set Up” option is displayed,( it is always displayed as the 4th

option).

3. Select “Change Set Up”, press OK.

4. Scroll down to the option “More”, press OK.

5. Enter Program Lock Code, press OK.

6. Select ON to activate lock (Off/On).

The Program Lock is intended for use by clinical personnel and authorized service

techncians.

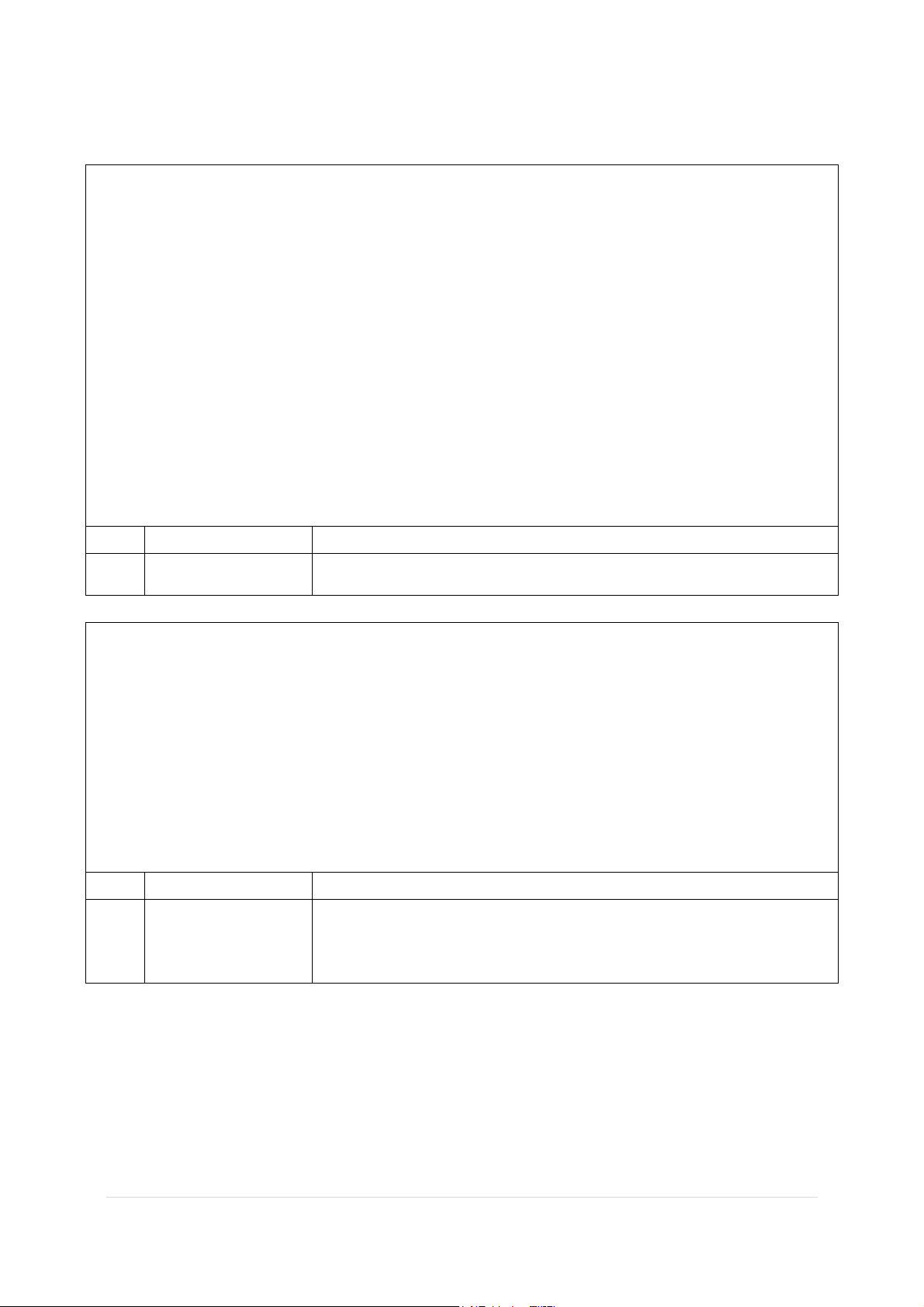

Item Parameter Description

1 Locks ability to

change programs

Enables clinical personnel to lock out the pump so that programs can

only be started or stopped.

Keypad Lock

To access Keypad Lock:

1. With the pump operating in normal operation mode, to activate the Keypad

Lock: Press and Hold the INFO Key until the bar graph is filled.

2. Repeat step 1 to deactivate.

The Keypad Lock is intended for use by clinical personnel and authorized service

technicians.

Item Parameter Description

1 Locks all keypad

buttons except the

INFO START/OK

and STOP keys

Enables clinical personnel to lock all buttons but the INFO,

START/OK and STOP keys to prevent tampering with the pump

during normal operation.

of 5014

Page 15

BodyGuard 545 and BodyGuard 575

The BodyGuard 545 and 575 pumps have adjustable operating parameters. These

operating parameters and options may be viewed and adjusted to modify the

operation of the pump. The operating parameters and options available for the

BodyGuard 545, and 575 are described in the Technician Menu, Level 1 Menu and

Keypad Lock.

Technician Menu

To access the Technician Menu, press and hold the INFO key during the power on

operation until ‘Technician Code’ prompt appears. The display will show the software

version for 2 seconds before the access code prompt. Enter Technician Code to access

the menu.

The pump will display all the parameters that can be set, calibrated or tested. The

technician can scroll through all parameters using the ARROW keys (2 & 0 keys on

the pump).

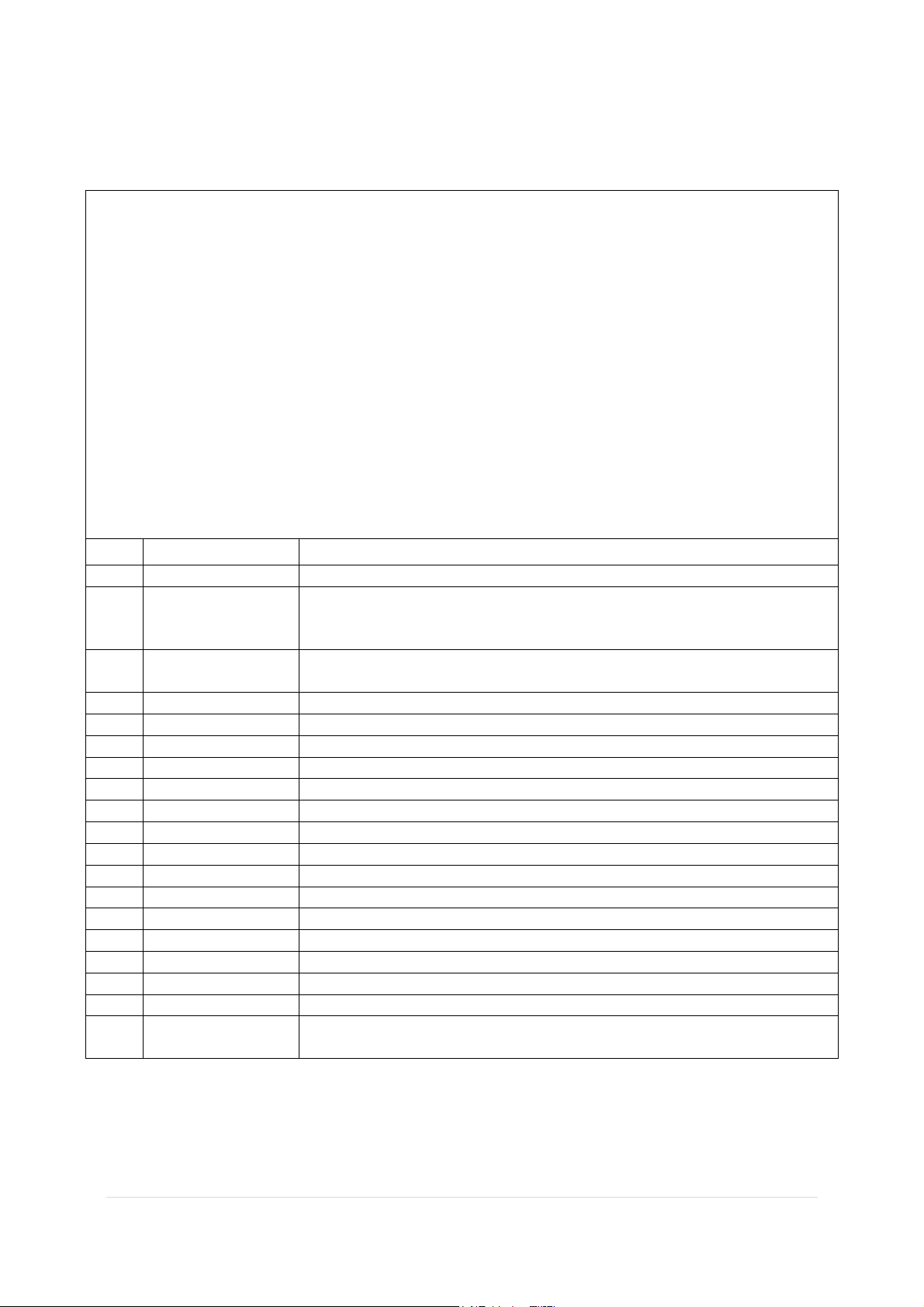

Item Parameter Description

Restart Pump Exit Technician Mode.

1

Serial Number Displays serial number & production date.

2

Manual Calibration Summary of volume & pressure calibrations and ability to check/re-

3

enter software default calibrations after service.

Main Self-Test Performs keypad, display, alarm sound, door sensor, air sensor,

4

temperature, motor & encoder, and pressure sensor tests.

Volume Test

5

Manual Test Same as Main Self-Test but with a menu so technician can focus on

6

Pressure Calibration Allows manual calibration of pressure settings.

7

8 Volume Calibration Allows manual calibration of pumping mechanism.

Software default

9

Setting

Reset Calibrations Caution: pressing START/OK restores default settings. Pump must

10

Operating hours Hours from last service – reset to zero by pressing STOP/NO key.

11

Access Codes Displays current access codes and allows change.

12

Program rate & volume to be delivered during flow rate test.

individual tests.

Caution: pressing START/OK will restore software default defaults

and delete all pre-set protocols and set-up changes.

be re-calibrated after reseting calibrations.

of 5015

Page 16

Level 1 Menu

To access Level 1 Menu:

1. Turn pump on.

2. Prompt reads “Press OK to Resume or Press NO for Menu”.

3. Press No to access menu

4. Enter Level 1 Code, Press OK

The Level 1 Menu is intended for use by clinical personnel and authorized service

technicians.

Access to specific parameters requires entering Admin or Clinician Activate Bolus

access codes.

Item Parameter Description

1 Prime Allows clinical personnel to prime set.

2 Select Protocol Allows clinical personnel to select protocol (New patient, Previously

programmed).

3 Change Bag Allows clinical personnel to change bag.

1. Start New Bag

2. Confirm bag volume (Ok/No)

3. Start Infusion (Ok/No)

4 Modify Protocol Allows clinical personnel to modify protocol by entering Admin Code.

5 Clinician Bolus Allows clinical personnel to deliver a bolus regardless of preset limits by

entering Clinician Activated Bolus Code.

6 Patient History Allow clinical personnel to display infusion history for last 24 hours.

7 Event Log Allow clinical personnel to review event history settings and alarms for

last 500 events)

8 Battery Test Allow clinical personnel to perform battery capacity test.

9 Review Set Up Allows clinical personnel to review:

1. Pulse Oximeter

2. Battery Level

3. Program Lock

4. Time and Date

5. Tube temperature

6. Key Stroke Volume

7. Occlusion Pressure

8. Priming Volume

9. Priming Rate

10. Max CA Bolus

11. Default Bolus Rate

12. Maximum Basal Rate

13. KVO Rate

14. Program Limits

15. Air In Line Limits

of 5016

Page 17

10 Change Set Up

16. LED Indicator

17. Bolus Key

18. Titration Option

19. Serial Number

20. Production date

21. Operating Hours

22. Software Version

23. Volume Calibration

24. Pressure Delta

25. Pressure Cap

26. Exit

Allow clinical personnel to Change Set Up by entering Admin Code.

1. Pulse Oximeter

a. Enable/Disabled (Requires a pulse oximeter charger)

b. Program alarm limits

i. Pulse Limit (< Limit,> Limit)

ii. SPO

c. Sync Pulse Audible

i. Enable/Disable

2. Key Stroke Volume (bar graph)

3. Occlusion Pressure [545 (7/14/21psi)], [575 (5/7.5/10 psi)]

4. Priming Volume (0-20 ml)

5. Priming Rate (300-1200 ml/h)

6. Max CA Bolus (disable/limit max clinician bolus dose to 0-20 ml)

7. Default Bolus Rate (0-1000 ml/h)

8. Maximum Basal Rate (0.0-30 ml/h)

9. KVO Rate (0.0 - 5.0 m/h)

10. Program Limits - Set MediGuard limits for body weight (On/Off)

11. Air In Line Limits - (0.0 - 1.0 ml)

12. LED Indicator - Set operational indicator LED (On/Off)

13. Bolus Key - Allows clinical personnel to enable/disable the keypad

bolus key.

14. Titration Option - Allows clinical personnel to set titration Option

(On/ Off).

15. Set Time and Date - Allows clinical personnel to date and time

(dd, mm, yy, hh, mm).

16. Restart Pump - Allows clinical personnel to return pump to normal

operation.

saturation (< Limit)

2

of 5017

Page 18

Keypad Lock

To access Keypad Lock:

1. With the pump operating in normal operation mode, to activate the Keypad

Lock: Press and Hold the INFO Key until the bar graph is filled.

2. Repeat step 1 to deactivate.

The Keypad Lock is intended for use by clinical personnel and authorized service

techncians.

Item Parameter Description

1 Locks all keypad buttons except the

INFO START/OK and STOP keys

Enables clinical personnel to lock all buttons but the

INFO, START/OK and STOP keys to prevent

tampering with the pump during normal operation.

of 5018

Page 19

Operational Checklist and Performance

Acceptance Test

Introduction

The Operational Checklist and Performance Acceptance Test detailed in this

section determines if the device is operating correctly. The Operational

Checklist and Performance Acceptance Test should be carried out before any

service work is performed. If the device fails any test in the checklist, the fault

must be recorded and corrected prior to placing the device back into clinical

use. Any test failures should be analyzed using the troubleshooting procedure

that follows to determine service action. After all service is completed, the

Operational Checklist and Performance Acceptance Test should be repeated and

the device should be re-calibrated if required.

If the returned device is a complaint, the device should be tested with any

associated products (i.e. sets, etc). Devices subject to complaint evaluation

should be tested to try to duplicate the customer’s complaint. Once the

complaint evaluation with the associated product has been completed the device

should be retested without the associate product to the normal service process.

1. Main Self Test

a. Keypad test - Tests operation of all keypad keys.

i. Test passes if all keys work

b. Display Test - Tests all pixels back light.

i. Test passes if all pixels work

c. Acoustic alarm test - Tests volume of alarm.

i. Test passes if alarm volume can be heard from 20 feet.

d. Door position test - Tests door open alert.

i. Test passes if screen displays “Closed” when door is closed,

and “Open”, when door is open.

e. Air sensor test - Qualitative test of air sensor functionality.

i. Test passes if alert activates when air is present in front of air

sensor.

f. Motor Test - Qualitative test of motor functionality.

i. Test passes if display reads “pass”.

g. Pressure Sensor Test - Qualitative test of pressure sensor functionality.

i. Test passes if screen displays 50+/- 2.

of 5019

Page 20

2. Open Door Alert Function

a. Perform door open test – Open door during infusion and verify alarm.

b. Open door alert test is passed if alert activates when door is opened.

3. Air Detect Function

a. Load a primed BodyGuard tubing set into pump.

b. Attach a y-site upstream of the pump.

c. Using a 3 ml syringe, inject 1.1 ml of air into the line - alarm should

activate once the air bubble passes the sensor. This test will demonstrate

the accumulation of air bubbles of 1 ml over 15 minutes (user should

check Air Limit is set to 1ml under ‘Change Set Up’).

d. Test is passed if air alarm activates under 1 ml.

4. Battery Operation Test

a. Discharge battery to “End Battery”.

b. Charge battery until green charge indicator light turns on.

c. Program pump to 1200ml/hr.

d. Start pump and start timer and run to “End Battery”.

e. Record time to discharge pump.

f. If battery ran for at least 3 hours, battery passes, if battery did not,

replace battery.

5. Restore Software Default Settings (page 46)

a. Check software default settings are restored. (User programmable

protocols should be blank)

b. Test is passed if they are set to Software default values.

Note: Complaint pumps will have software default settings restored after

notification of complaint closure.

c. Check that Software Default Settings were restored

d. Software default settings should only be restored before beginning the

last Operational Checklist and Performance Acceptance Test after service

has been completed.

6. Pole Mount Charger Voltage Test (page 35)

a. Using voltmeter, measure pin voltages diagrammed in section 1.3

Replacing Charger PCB

of 5020

Page 21

7. Verify DC Extension Cable Connector Operation

Turn pump on and start an infusion. Plug DC extension cable to charger and

pump. Verify that battery charge icon on charger is lit. Verify that the

battery icon on the pump turns off.

8. Volume Delivery (page 22)

a. Perform Volume Delivery Calibration procedure to obtain assessment.

b. Volume delivery test passes if volume delivered is setting +/- 5%.

9. Occlusion Pressure (page 26)

a. Perform Occlusion Pressure Calibration procedure to obtain assessment.

b. Occlusion pressure test passes if pressure limit +/- 2 psi is achieved.

10. Ground Strap Test

a. Test continuity between center charger connector pin and door hook. If

no continuity, ship to CME America for installation.

11. QC and Calibration Labels

a. Upon completion of the Service and the Operational Checklist and

Performance Acceptance Test, place a QC label on the pump

indicating “QC Approved” as a tamper proof indicator and place a

calibration label on the pump indicating the “date of calibration” and

“initials of the technician” performing the calibration.

of 5021

Page 22

Calibration

Volume Calibration

Background:

Volume calibration is performed to enable the pump to deliver

accurately.

Perform the volume calibration using the test set-up diagramed below.

Acceptance Criteria:

The pump must be within +/- 5% to pass this test.

Required Equipment:

Scale with 0.01 gm degree accuracy

BodyGuard tube set

Collection vessel

IV bag

BodyGuard pole mount charger and power cord

IV pole or similar mounting surface

BodyGuard Pump

of 5022

Page 23

Procedure:

1. Fill the IV bag with room temperature sterile water. It is important that the

water be room temperature so that it does not affect the elastic properties of

the silicone replacement pumping segment. Once the IV bag has been filled,

use a BodyGuard tube set to spike the IV bag. Hang the IV bag and the tube

set from the IV pole. To prevent fluid coming into contact with the air

sensor and pumping mechanism, the infusion bag should be spiked before

opening the pump door. Position the bag so that the risk of spillage onto/into

the device is minimized. Do not stretch the set when removing it from its

packaging or installing it in the pump.

2. Attach the BodyGuard pole mount charger so that the pumping chamber is

10” below the IV bag on the IV pole. This will ensure that the pumping

segment will reach the pumping chamber once the pump has been inserted

into the pole mount charger. Load the pump into the pole mount charger and

insert the pumping segment of the tube set into the pumping chamber.

3. Power on the pump and set the BodyGuard 323 parameters in the following

table using steps below:

Scroll through the menu and adjust the values so that

Required Value

they match the table below. Setting

Pressure Default 14 PSI

Pump Program Continuous

Maximal Rate 1200 ml/hr

KVO Rate 0.0 ml/hr

Set Loading Test Off

Time Option Off

a. Press the INFO button until the option “Change Setup” appears. Press

the Start/OK button.

b. Using the down arrow (zero button scroll to the option) “More” and press

the Start/OK button.

c. Enter Change Set Up Code and press the Start/OK button.

d. Scroll through the menu and adjust the values so that they match the

table above.

e. Once all values have been confirmed, select the option “Restart Pump”.

4. To calibrate volume for the BodyGuard 545 and 575, use the “Volume Test”

found in the technician menu and disregard step 3.

of 5023

Page 24

5. Prime the tube set by pressing the Prime/Piggy button (for 323) or Bolus

button (for the 545/575) and set a volume that will completely prime the

tube set. The priming volume of the set will be listed on the tubing package

(in most cases 20 ml will be more than enough volume to expel all air from

the set). After priming place the open end of the tube set into the collection

vessel and begin the priming function. Once priming is complete, weigh the

collection vessel and record the result.

6. Insert the open end of the tube set into the collection vessel and start an

infusion at a rate of 125 ml/hr at a volume of 20 ml.

7. Once the infusion has finished, weigh the collection vessel and record the

result. Subtract the pre delivery weight (the amount from the priming

operation in Step 5) from the post delivery weight. This number is the actual

volume delivered. The expected delivery is the volume programmed on the

pump to be delivered. Use the following equations to calculate the infusion

rate error:

8. If the results from step 7 is not within the +/- 5% range the pump must be

recalibrated. Begin this process by entering the Technician Menu using the

appropriate Technician Code.

9. Scroll to the option titled “Manual Calibrations” and press the start OK key.

10. Use the following equation to determine the amount of adjustment needed to

recalibrate the volume delivery.

11. Adjust the four volume settings in the Manual Calibration menu by the

Correction Value obtained in step 10.

Note: If the Correction Value from step 10 is a positive number subtract this

number from the current calibration number. If the Correction Value from step 10

is a negative number add this number to current calibration number.

of 5024

Page 25

Example: (positive correction value)

Percent difference error = 4

Correction value = 5x4=20

Current calibration value = 535

Corrected calibration value = 535-20 = 515

Example: (negative correction value)

Percent difference error = -3

Correction value = 5x-3 = -15

Current calibration values = 535

Corrected calibration value = 535- (-15) = 550

12. Repeat step 5 through step 10 until the pump is within the +/- 5%

specification criteria. A result from the test in Step 5 that is within +/- 5%

for the pump meets the acceptance criteria.

Note: Should you have any questions about the procedures described herein or any

other BodyGuard product questions, please contact the CME America Service

Center.

of 5025

Page 26

Occlusion Pressure Calibration

Background:

Occlusion pressure calibration will allow the pressure alerts to activate

correctly. The calibration is accomplished by adjusting the pump to display

the correct pressure at two different pressure levels. This will enable the

pump to display the pressure accurately anywhere within the operational

range to the specification tolerance. Perform the Occlusion Pressure

Calibration using the test set-up diagramed below.

Acceptance Criteria:

Alarm should occur at 10+4/-2psi for BodyGuard 575 and 14+4/- 2 for the

BodyGuard 323, & 545.

Required Equipment:

Pressure Gauge (.1 psi resolution)

BodyGuard tube set

Collection vessel

IV bag

BodyGuard pole mount charger and power cord

IV pole or similar mounting surface

BodyGuard Pump

of 5026

Page 27

Pressure

Sensor Test

Pressure Calibration

Pressure Calibration

Pressure Calibration

Procedure:

1. Press and hold the INFO key, while switching the pump on. Wait until the

screen displays ‘Technician Code.’ Enter the appropriate Technician Code,

and press START/OK key to enter.

2. Use the ARROW keys to scroll to Pressure Calibration option. Once this

option is displayed (in double size letters) press START/OK key to enter.

3. Pressure Cal shows on display:

50 (2.1v)

Press OK to continue

Pump door should be open without a BodyGuard tubing set installed. The

value on the screen will set 50±2. Press START/OK key to store this setting.

This value represents the zero level of the pressure sensor when the

BodyGuard tubing set is not in place. The voltage value in brackets should

be less than 5V. If this voltage is over 5V, the pressure sensor may be

faulty. Replace sensor and recalibrate.

4. The (2.1V) is showing the status of the pressure Potentiometer.

5. Load an unprimed BodyGuard tubing set into the pump. Insert the key in

the key recess and close the pump door. The reading of the pressure sensor

will change; wait about 10 seconds until this reading stabilizes.

85

Set 0 PSI, Press OK

6. Press the START/OK key. This sets the zero level of the pressure sensor

with a set loaded.

Note: The zero level data will remain in the pump memory until changed.

BodyGuard 323, & 545 BodyGuard 575

85

Set 14 PSI, Press OK

85

Set 10 PSI, Press OK

of 5027

Page 28

7. Prime the BodyGuard tubing set and connect a pressure gauge to the end of

Pressure Cali

bration

the administration set. The pump will display the pressure required.

8. Press the ARROW UP key to increase the pressure to the required level.

9. If in adjusting the pressure setting, the desired value is exceeded, relieve the

pressure in tube and start again at step 11.

10. Once the pressure gauge shows the correct pressure level, press the

START/OK key.

11. Increase pressure to 30 PSI and confirm with START/OK key.

12. The pump will use these values to automatically calculate the values

13. Release the built-up pressure by disconnecting the set from the pressure

14. Enter Manual Calibration (in Technician Mode) change pressure cap option

15. Test pressure alarm under normal operation. Connect a pressure meter at the

16. Repeat calibration procedure if result of 1st calibration does not meet

119

Set 30 PSI, Press OK

required for pressure calibration.

gauge and reconnecting it.

to 255 using the keypad.

end of the tubing. Alarm should occur at 10psi +4/-2psi for BodyGuard 575

and 14+4/- 2 for the BodyGuard 323, & 545.

acceptance criteria.

of 5028

Page 29

Troubleshooting

Use the troubleshooting guide below to identify probable service action.

Once a service action plan has been developed refer to service action section for

service action procedure.

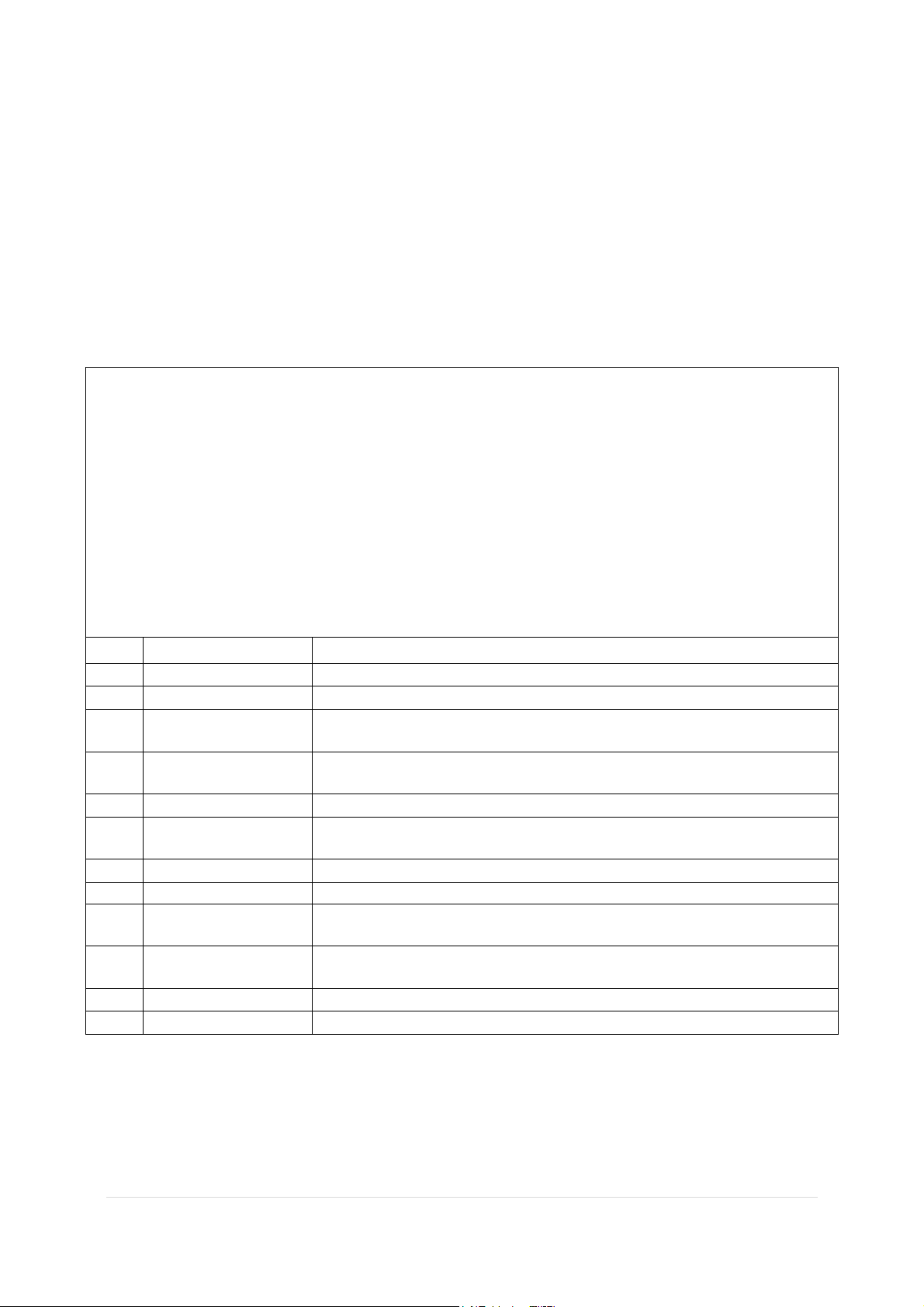

Alarm or

Problem

Pump does not

switch on

Possible cause Action

Battery depleted

Click the pump into a charger connected to

AC power

Battery malfunction Replace Battery

On/off key malfunction Replace the main PCB (ref. sec. 5.1)

Missing Key

Unauthorized set used Replace non-CME set. Use only BodyGuard

tubing set

Pressure calibration

Repeat pressure calibration

incorrect

Error 1, Motor

turns without

control or motor

can’t turn

Error 7

Mechanical malfunction Check for mechanical obstruction of the

cam shaft and gears.

Electronic malfunction Replace Motor PCB

(ref. sec. 5.1)

Wrong pressure

calibration

Pressure sensor

malfunction

Repeat pressure calibration procedure if

persists, replace pressure sensor

Replace pressure sensor and recalibrate.

(ref. sec. 3)

Error 10 Mechanical malfunction Turn the pump off and on again and set

pump to operate on 0.1 ml/hr

Error 11 Mechanical malfunction When the motor can’t turn, check for

mechanical obstruction. If the problem

persists, replace motor PCB.

Error 12 Mechanical malfunction Turn the pump off and on. If the problem

persists, replace motor PCB.

Error 13

Encoder malfunction Visually check encoders and verify no

mechanical obstruction

Microprocessor

Replace main PCB (ref. sec. 5.1)

malfunction

Error 15 Microprocessor

Replace main PCB (ref. sec. 5.1)

malfunction

Error 16 Electronic malfunction Replace main PCB (ref. sec. 5.1)

of 5029

Page 30

Error 17 Electronic malfunction Replace main PCB (ref. sec. 5.1)

Error 19 Electronic malfunction Turn the pump off and on. If the problem

persists, replace main PCB.

Error 20 Microprocessor

Replace main PCB (ref. sec. 5.1)

malfunction

Error 21 Microprocessor

Replace main PCB (ref. sec. 5.1)

malfunction

Error 23 External Timer Battery

depleted

Error 24 External interrupt or

electronic malfunction

Error 25

Battery malfunction Ensure pump can be operated on battery

Turn the pump off and on again - if problem

continues replace Li-ion 3V battery

Turn the pump off and on again - if problem

continues replace main PCB (ref. sec. 5.1)

power

Pump contacts are not

Make sure pump contacts are clean

clean

Short in DC connector Remove mechanical obstruction from DC

connector

Electronic malfunction Replace main PCB (ref. sec. 5.1)

Error 26

Mechanical

obstruction,

motor connector

Motor Test Failed

Check for mechanical obstruction, verify

the motor is connected, and verify the gear

box has not separated from the motor.

Motor PCB malfunction (ref. sec. 5.1)

not reconnected,

or gear box

separation.

Error 27 Electronic malfunction Replace main PCB (ref. sec. 5.1)

Error 28

Encoder detects external

light

Make sure pump case is closed with 4

screws (ref. sec. 2.1)

Encoder malfunction If pump is properly closed, replace motor

PCB (ref. sec. 5.1)

Error 30 Memory malfunction Turn the pump off and on again - if problem

continues:

1. Restore Software Default Settings (ref.

Sec. 8 steps 1-8)

2. Recalibrate pump

If problem continues:

3. Replace main PCB (ref. sec. 5.1)

Error 32 External interrupt Turn the pump off and on again - if problem

continues replace main PCB (ref. sec. 5.1)

Error 33 Microprocessor Replace main PCB (ref. sec. 5.1)

of 5030

Page 31

malfunction

Error 34 Microprocessor

malfunction

Error 35

Wrong Pressure

calibration

Pressure sensor

malfunction

Error 39 Microprocessor

malfunction or software

code corrupted

Air in Line

alarms

Dirty air sensor surface Clean air sensor surface

Scratches on the air

sensor surface

Air sensor malfunction Perform air sensor test at Technician Menu,

Main PCB malfunction

(Door or front sensor)

Door open

alarm

The door magnet has

fallen out

The door does not close

properly

The reed switch has

malfunctioned

Operation LED

is not working

The operation LED is

turned off (Change SetUp)

Operation LED

malfunction

Battery life

Battery weak/damaged Perform battery test described in

limited

Unable to set

higher flow rate

The maximal rate has

been capped in ‘Change

Set up’

The charging

LED does not

illuminate when

the charger is

AC plug is not securely

inserted into the charger

socket or mains.

Replace main PCB (ref. sec. 5.1)

Repeat occlusion pressure calibration

procedure. If persists, replace pressure

sensor.

Replace pressure sensor per instructions.

(ref. sec. 3)

Burn software again - if an error occurs

during or after burning the software, replace

main PCB (ref. sec. 5.1)

Replace air sensor per instructions.

(ref. secs. 4.1 and 4.2)

under Manual Test - air sensor

Perform air sensor test If persists, replace

door air sensor. If persists, replace main

PCB.

Install a door magnet (ref. sec. 2.3)

Clear or adjust the door mechanism

(ref. sec. 2.4)

Replace the Main PCB. (ref. sec. 5.1)

Enter Change Set-Up and switch LED to

“On”

Change the main PCB (ref. sec. 5.1)

Operational Checklist and Performance

Acceptance

Change the maximal rate to higher limit in

‘Change Set Up’

Press power plug firmly into the charger

socket and AC plug.

of 5031

Page 32

connected to

AC power

The battery

LED indicator

does not

illuminate while

the pump is in

the charger and

connected to

AC power

The green

battery LED

does not

illuminate while

the pump is

connected to

charger (AC

connected)

within 2 to 4

hours after

charging from

Low Battery”

Date of

Manufacturer is

0,

S/N is 0

Pulse Oximeter

is not working

properly

The power cord is in

poor condition

Check output pins of

AC/DC Should be 10v±

0.5v

Poor battery output

Connectors between

charger and pump are

dirty

Motor PCB malfunction

Check output of battery

(5 – 8.4v)

Real Time Clock Battery

power has been

disconnected

Pulse oximeter is not

connected

Pulse oximeter function

is not enabled

Pulse oximeter is not

working

Replace power cord if necessary

If 0v, check fuses or replace charger PCB

(ref. secs. 1.1 and 1.2)

Replace battery if required

Clean connectors

Replace motor PCB (ref. sec. 5.1)

Replace battery if required. If persists,

replace charger PCB

When the Real Time Clock battery

has been disconnected or replaced, all

program settings will reset. Reenter

Manufacturer Date and S/N through

S/N option in Technician Menu.

Service per (Ref. sec. 1.4)

(Ref. sec. 1.4)

of 5032

Page 33

Down level

software version

on pump

Request for

specific

software version

Programmable

protocols are

still

programmed

If after

exhausting all

diagnostic and

service options

the pump still

does not operate

correctly.

Pulse oximeter charger

not working

Release of new software

version

Upgrade software version of pump.

(ref. sec. 7)

Customer request Program pump with requested

software version (ref. sec. 7)

Software default setting

have not been restored

Restore software default settings (ref.

sec. 8)

Unknown Return pump to customer with

recommendation to remove from use.

of 5033

Page 34

M3x10

M3x20

M3x

3

0

M3x25

M2x15

Service actions

Introduction

Once the cause of failure has been identified, use the appropriate service action

below to correct the problem.

To ensure the device is operational, ALWAYS repeat the Operational Checklist

after completing any of the procedures in this section.

General Disassembly / Assembly of Pump and Charger

Disassembly of the pumps and charger is limited to complete subassemblies and

mechanical components. It is recommended that electrical problems be corrected

by replacing the entire PCB. Use only the replacement parts supplied by the

manufacturer or an authorized distributor. Read ALL steps in a procedure before

undertaking the work. The procedures are given in order of disassembly and then

reassembly. Disassemble the device only as far as required to complete a service.

All fastening components such as screws, washers and nuts used in the device are

metric - be sure to use metric tools and replace only with metric components. Refer

to Appendix A for pictures of disassembled pumps and chargers.

Caution: The components inside the device are sensitive to electrostatic discharge

(ESD). Always wear a grounded wrist strap and use a protective ESD mat when

performing service on the device to prevent damage to components.

1. Disassembly / Assembly of Pole Mount Charger

Warning: When servicing the charging device, ensure the device is unplugged

before disassembling. Failure to do so can result in personal injury, death and /or

damage to the device.

1.1 Disassembly of the Charger:

1

. Remove pump from charger.

2. Disconnect charger from AC

power.

3. Remove the 6 screws as shown in

the diagram and separate the case.

4. The PCB is now loose and can be

removed from the front housing.

Caution:

When separating the

of 5034

Page 35

5. To reassemble the charger, ensure

all connecting wires are secure.

case, be careful of connecting

wires.

6. Insert the correct length of screw

into the hole shown and tighten.

1.2 Replacement of AC Power Fuses in Charger Unit

1. Remove the pump from charger.

2. Connect the charger to AC power.

3. Check that the AC power icon is displayed, if not perform the following

steps:

a. Remove the AC cable from the power outlet.

b. Disassemble the charger following the “Disassembly /

Assembly of Charger” instructions above.

c. The fuses are protected by a plastic cover on the back of

the AC power inlet, remove this cover.

d. Remove the fuses from the fuse holder on the charger

PCB, and using an ohmmeter check electrical continuity.

e. If necessary, replace with a new fuse of same value, type

and voltage. F1, F2 20mm 800mA Slow Blow.

f. Replace plastic fuse protection cover.

g. Reassemble charger in reverse order.

4. Perform Operational Checklist and Performance Acceptance Test

1.3 Checking Charger Voltage

WARNING: Voltage present on internal components may cause

severe shock or death upon contact. The following procedure requires

measuring voltages with the case open. Use care when making these

measurements.

1. Check the input voltage on the AC/DC converter (should be between

100-240 V). If not, check fuses. If so, check the output pins of the

AC/DC converter should be 10V±0.5v. If 0v, replace the PCB.

2. Verify the voltages diagrammed below.

3. Perform Operational Checklist and Performance Acceptance Test

of 5035

Page 36

1.4 Pulse Oximeter Charger

1. Plug in Pole Mount Charger with Pulse Oximeter connector.

2. Attach working pump to charger.

3. Enable Pulse Oximeter feature through Change Set Up Menu

4. Note on service record, if Pulse Oximeter feature was not enabled.

5. If it was enabled, attach working Pulse Oximeter to connector.

6. Activate Pulse Oximeter by starting program.

7. If it does not work replace Charger.

8. Perform Operational Checklist and Performance Acceptance Test

of 5036

Page 37

2. Disassembly / Assembly of Pump

M

M

2.1 Separation of front and rear housing

Note: Always disassemble the pump on and ESD work surface with wrist strap

secured. Failure to do so could cause damage to the internal components of the

pump.

1. Turn the pump off and place it face down on an anti-static mat or ESD-

grounded work surface. Make sure there are no metal parts (including screws

and nuts) on the working surface in order to avoid scratching the pump housing.

2. Remove the battery from the rear housing. First lift up the battery release

handle and pull out the battery bottom first.

3. Remove the 4 mounting screws. These 4 screws

connect the front and rear housing. 2xM2 screws are

located under the battery compartment. 2xM3 screws

are located on the lower portion of the housing.

Remove the QC approval label to reveal these two

screws.

4. Separate the front and rear housing by holding

the front housing firmly against the ESD mat and

lifting the rear housing vertically away from the front

housing. Remove the screws from the rear housing

and set them aside for later use.

2.2 Reassemble the housing

1. Place the front housing face down on the ESD mat and lower the rear housing

onto it so that the seams of the two parts line up correctly. Do not use excessive

force to reassemble the front and rear housing. If resistance is encountered,

ensure that the connector between the front and rear housing is lined up

properly.

2. Reinstall the 4 mounting screws.

3. After reassembling, switch the pump ON and perform the Self Test.

4. If service has been completed, perform Operational Checklist and Performance

Acceptance Test

of 5037

Page 38

2.3 Replacement of Pump Door Magnet

1. Replace missing door magnet by securing new magnet into recess in top of

door with press fit or glue.

2. Assure that magnet triggers door open alert and does not interfere with door

operation.

3. If service has been completed, perform Operational Checklist and

Performance Acceptance Test.

2.4 Replacement of Pump Door or Replacement of Pressing Plate

1. Use a 2.5 mm hex key to remove the security

grub screws (M2 x 5) at both ends of the hinge

(as shown on the diagram).

2. Using a Phillips head screw driver, remove

the door-mounted air sensor, fixed with one

M2 screw. Pull the sensor out from its

recess.

Door Air Sensor

2.5 mm security grub screws

3. Lift the air sensor cable and carefully using a 2 mm shaft, push the hinge

pin from the air sensor side (left side) and remove it from the pressure

sensor side. THE HINGE PIN WILL ONLY GO ONE WAY. The hinge

pin must be removed from the right side of the pump and reinserted into

the right side of the pump. Pushing the hinge pin the wrong way will

cause damage to the pump.

4. Removing the hinge pin allows for separation and removal of the door, pressing

plate, and springs.

of 5038

Page 39

5. Replace the door, pressing plate and springs as needed.

Note: Use caution when removing the door from the pump as the

pressing plate springs are not attached to the door or the pressing plate.

6. Reassemble the door, pressing plate and springs as follows:

7. Place the door between the two

visible parts of the hinge pin support

features on the chassis block.

hinge pin support features

8. Place the pressing plate into the

recess in the door.

door recess

9. Lift the pressing plate and place the

two door springs into their recesses

in the door and pressing plate.

door springs

10. If you are fitting a new door or

pressing plate ensure that Nylon

bushings are present. Place bushings

into the hinge holes of the new part.

6 bushings total are required for the

door, pressing plate, and hinge

support features.

Nylon bushing

of 5039

Page 40

11. Push the hinge shaft from right to left

through the door, pressing plate and

the chassis block.

12. 12. Ensure the shaft has been inserted

all the way into the hinge. Ensure the

hinge pin does not interfere with the

Door air sensor wiring.

13. To obtain correct door hook

alignment, close the door. Make sure

the door does not rub on the door

hook. If it rubs, readjust the door

hook by bending it slightly. Operate

the door and readjust the door hook if

necessary until a click is heard from

the door catch.

14. Verify the door releases when door

latch is ¾ open. Close the door. Pull

the door latch out about ¾ open and

verify that the door opens. If the door

does not open at this point, use a flat

tip screw driver to adjust the latch

mechanism by turning the screw as

shown in the picture. Repeat this

adjustment until the door operates as

specified.

15. Perform Operational Checklist and Performance Acceptance Test

2.5 Replacement of Pump Assembly

1. Separate the front and rear housing as described above.

2. Remove the pump door as described above.

3. Remove the flow direction label.

4. Remove the door hook screws (M2 x 2) and remove door hook.

of 5040

Page 41

5. Remove the 4 pumping block screws. These screws secure the pumping block

to the front housing.

4 pumping block screws

6. Disconnect the motor connector

on the motor PCB.

7. With the keypad facing up,

observe the two metal hinge support features protruding from the front of the

front housing assembly. Apply pressure evenly to the two hinge support

features to push the motor block assembly out of the front housing assembly.

8. Install the old pumping fingers into the new pump block as illustrated below.

Position fingers into slots in the pump block above cam.

Ensure beveled side of fingers face encoder plate.

Position of Pumping Fingers in Pumping Block

9. Replace the motor block assembly by turning the front housing assembly so that

the key pad is facing up.

10. Insert the new motor block assembly through the back side of the front housing

so that the assembly is seated firmly against the inside of the front housing.

11. Reassemble in reverse order.

12. Perform Operational Checklist and Performance Acceptance Test.

3. Replacement of Pressure Sensor

1. Remove the pump door as described above.

2. Remove the pumping block assembly as described above.

3. Remove the 3 screws holding the motor PCB in place, carefully remove

the Motor PCB.

of 5041

Page 42

4. Remove the M2 screw from the inside of the pumping chamber located

lace the sensor with a new one.

on the front housing near the pressure sensor.

M2 screw

5. Turn pump over and remove the self

tapping screw holding the pressure sensor in

place.

6. Pull the pressure sensor out of its recess.

7. Install new pressure sensor.

8. Reassemble in the reverse order.

9. Perform Operational Checklist and Performance Acceptance Test.

4. Replacement of Air Sensors

4.1 Front housing mounted air sensor:

1. Separate the front and rear housing.

2. Disconnect the front housing mounted

air sensor at connector JP4 on main PCB.

Front housing mounted

Air sensor connector JP4

3. The air sensor is glued to the front

housing. Using a screwdriver, apply enough pressure to the ‘ears’ on the back

of the sensor to break them off, and then push the sensor out of its recess.

4. Rep

Use the Go No-Go gauge pins, (2.2

mm GO and 2.3 mm NO-GO) to

ensure that the distance between the

door mounted air sensor and the

onboard air sensor is 2.3 mm.

of 5042

Page 43

5. Put a few drops of super glue on the

sensor ‘ears’. Keep the ‘Go-No-Go’

gauge in between the sensors to

ensure correct distance until the glue

is dry.

6. Reassemble in reverse order.

7. Perform the Operational Checklist Performance Acceptance Test.

4.2 Door Air Sensor:

1. Separate the front and rear housing.

2. Disconnect the door mounted air sensor at

connector JP5.

Door Mounted Air sensor connector JP5

3. Remove the air sensor door screw.

4. Remove the sensor by using a sharp knife to remove the connector pins from

the air sensor connector. Save this connector for later use.

5. Replace the sensor with a new one.

6. Insert the leads of the air sensor through the hole in the front housing.

7. Insert the blue and white lead connector pins into the air sensor connector

housing. Insert pins into the connector housing so that when connected to the

JP5 connector, the blue wire is inserted in the outside position, the white wire

is inserted in the inside position.

8. Check that the distance is 2.3mm between the air sensors using the ‘Go-NoGo’ gauge and perform the air sensor testing procedure, as described on p. 19.

9. Perform Operational Checklist and Performance Acceptance Test.

of 5043

Page 44

5. Replacement of Pump Motor

1. Separate front and rear housings of the pump.

2. Remove the pump door as described above.

3. Remove pump assembly as described above.

4. Carefully place the pump assembly at a position in which the pumping

fingers are facing upwards.

5. Apply a piece of insulation tape across the fingers to prevent them

from falling out [if they do fall out, refer to diagram: “Position of

Pumping Fingers in Pumping Block” for proper finger placement.]

6. Carefully place the pump assembly at a position in which the gear

wheels are facing up.

7. Remove the nut, securing the single slotted encoder disc and remove

the encoder.

8. Remove the retainer ring from the end of the motor and remove the

encoder and motor gear.

9. Remove the 2 screws that hold the motor to the housing and remove

motor.

10. Install a new motor. Refit the 2 screws using thread locking glue.

11. Reassemble in reverse order.

12. Perform Operational Checklist and Performance Acceptance Test.

5.1 Replacement of PC Boards – motor and main

1. Separate front and rear housings of the pump.

2. Remove the pump door as described above.

3. Remove pump assembly as described above.

4. Carefully place the pump assembly at a position in which the pumping

fingers are facing upwards. Apply a piece of insulation tape across the

fingers to stop them falling out (if they do fall out, refer to diagram:

“Position of Pumping Fingers in Pumping Block” for proper finger

placement).

5. Remove the 3 screws that are holding the motor PCB.

6. Remove the screw holding the main PCB to the front housing.

7. Remove PCBs.

8. Install a new motor PCB or a new main PCB.

9. Reassemble in reverse order.

10. Perform Operational Checklist and Performance Acceptance Test.

of 5044

Page 45

6. Replacement of LCD

1. Separate front and rear housings of the pump.

2. Remove the pump door as described above.

3. Remove the pump assembly as described above.

4. Carefully place the pump assembly at a position in which the pumping

fingers are facing upwards.

5. Apply a piece of insulation tape across the fingers to keep them from

falling out (if they do fall out, refer to diagram: “Position of Pumping

Fingers in Pumping Block” for proper finger placement).

6. Remove the 3 screws that are holding the motor PCB.

7. Remove the screw holding the main PCB to the front housing.

8. Place the main PCB face up on the ESD mat so that the push buttons

are facing up.

9. Rotate the main PCB so that one hand can be used to grip the LCD

and the other can be used to cut the adhesive foam which holds the

LCD to the main PCB.

10. Gently lift on the LCD and use the sharp knife to score the adhesive

foam. After scoring the foam, disconnect the LCD from the main

PCB by pulling the collar out of the LCD connector.

11. Remove all leftover adhesive foam.

12. Install a new LCD by plugging it into the connector and engaging the

collar.

13. Place the LCD inside the white square that is printed on the Main

PCB.

14. Reassemble the pump in reverse order.

15. Perform Operational Checklist and Performance Acceptance Test

7. Software Update and Replacement

Note: Before disassembling the pump, make sure to make note of the calibration

settings, serial number, and date of production. Do not open pump without using

the Electro Static Discharge (ESD) equipment. Failure to do so could result in

damage to the internal circuitry of the pump.

Note: Software Updates will only be performed at the CME America Service

Center in order to maintain device DHR.

of 5045

Page 46

1. Place the BodyGuard unit face down on the electro static discharge mat.

Ensure that the ESD mat is free of debris and other objects that could cause

scratches to the pump housing.

2. Using the #0 x 2-½ Phillips screwdriver remove the four screws from the back

of the unit. Two of the screws are located at the top of the unit underneath the

battery pack. The remaining screws are located at the bottom of the unit

underneath the quality check label.

3. After removing the four screws from the back of the unit gently separate the

back portion of the case from the front portion of the case. Set the back portion

of the case aside and remove the screws from the case. Set the screws aside for

later use.

4. Insert the battery into back portion of the case.

5. Using the five pin male to male wire, connect the PCB to the BodyGuard

programming board by connecting the five pin connector wire to pin JP1.

6. Connect the RS-232 cable to the BodyGuard programming board and the com

port on the back of the computer.

7. Carefully place the rear portion of the case onto the front portion of the case

without disturbing the five pin wire connection.

8. Open the Prog08sz software. If the setup is connected properly the pump will

begin to beep shortly after the programming software is opened.

9. Select the button labeled “Close COM Port”.

10. Set the correct port for the RS-232 cable by using to drop down menu labeled

“Port”.

11. Change the baud rate to 8861 by using the drop down menu labeled “Baud”.

12. Check the box next to “IGNORE security failure and enter monitor mode”.

13. Select “Contact target with these settings”.

14. Select the program algorithm “908_az60a_highspeed.08p”. Make sure to select

the program algorithm that was saved as a file not the algorithm that is included

with the programming software.

15. Specify the S record by selecting it from the pick window. Use the proper file

(i.e. USA35E13.s19).

16. Erase the module by selecting EM from the pick window. After the module has

been erased reconnect with security.

17. Program the module by selecting PM from the pick window.

18. Select Quit from the pick window.

19. Disconnect the pump from the programming board.

20. Reassemble the pump and recalibrate.

21. Perform Operational Checklist and Performance Acceptance Test

of 5046

Page 47

8. Restore Software Default Settings

Note: Software default settings should only be restored before beginning the

last Operational Checklist and Performance Acceptance Test after service has

been completed.

Note: Complaint pumps will have software default settings restored after

notification of complaint closure.

1. Power the pump on while pressing the INFO key to enter the Technician Menu.

2. Enter the appropriate Technician Code for the device.

3. Use the arrow keys to scroll to the option “Software Factory Setting”.

4. Press the START/OK key.

5. Press the START/OK key to reset the software factory settings to default.

6. Select the “Restart Pump” option.

7. Press the START/OK key.

8. Verify factory default settings have been reset to default values in chart below.

To assure default settings are restored for BodyGuard 545, and 575, check that

protocol parameters in the “Select Protocol” option have been erased.

9. Add “Software Default Settings Restored” insert to pump packaging. This

notifies customer that any desired customer programmed setting must be

reprogrammed prior to use.

10. Perform Operational Checklist and Performance Acceptance Test

BodyGuard Pump Software Default Settings

BG 323

Settings Default

Value

Pressure default 14 psi Pulse Ox Enabled Pulse Ox Enabled

Program Continuous Key stroke Volume Lowest setting Key stroke Volume Lowest setting

Priming rate Not adjustable Occlusion Pressure High 21 PSI Occlusion Pressure High 10 PSI

Max bolus volume 100 ml Priming Volume 5 ml Priming Volume 5 ml

Titration bolus On Priming Rate 400 ml/hr Priming Rate 400 ml/hr

Bolus rate 600 ml/hr Maximum CA Bolus 5 ml Maximum CA Bolus 5 ml

Maximal rate 1200 ml/hr Default Bolus Rate 0 ml/hr Default Bolus Rate 0 ml/hr

KVO rate 0.0 ml/hr Maximal Basal Rate 30 ml/hr Maximal Basal Rate 5 ml/hr

Flow control 0 drops/ml KVO Rate 0 ml/hr KVO Rate 0 ml/hr

Set loading test Off Program Limits OFF, volume Program Limits OFF, volume

Air bubble 0.3 ml Air In Line Limit 0.5 ml Air In Line Limit 0.5 ml

Store last program Off LED Indicator ON LED Indicator ON

Operation led On Bolus Key OFF Bolus Key OFF

Time option Off Titration Option OFF Titration Option OFF

Delay before start Off

BG 545

Setting Default

Value

BG 575

Setting Default

Value

of 5047

Page 48

Service Center Recommended Parts

Service center recommended parts may be ordered from CME Distributor

Recommended BodyGuard Parts List according to specific pump model.

Cleaning and Storage

Cleaning

Before connecting the pump to a patient, and periodically during use, clean the unit

using a lint-free cloth lightly dampened with warm water and a 1:10 (10%)

solution of bleach (bleach based disinfectant).

Warning: Always turn the pump off and remove the battery before

cleaning.

Warning: Always unplug the charger from AC power before cleaning.

Caution: Do not clean the pump or charger with chemicals such as

Xylene, Acetone or similar solvents. These chemicals can cause damage

to plastic components. Use a lint-free cloth dampened with warm water

and a mild detergent or disinfectant.

Caution: Do not soak or immerse any part of the pump or charger in

water

Storage

If the pump is to be stored for an extended period it should be cleaned and the

battery fully charged. Store in a clean, dry atmosphere at room temperature and, if

available, utilize the original packaging for protection.

Perform functional tests and ensure that battery is fully charged once every three

months.

of 5048

Page 49

APPENDIX A

Front Housing (Rear View) Rear Housing ( Rear View)

Main PCB (Rear View) Main PCB (Front View with Display)

Motor PCB (Rear View) Motor PCB (Front View)

of 5049

Page 50

Display (Rear View) Display (Front View)

Motor Block

Motor Gear Encoder Cam

Motor Block Assembly

of 5050

Loading...

Loading...