October 2014

Ref.: 100-090TO Rev. 1.0

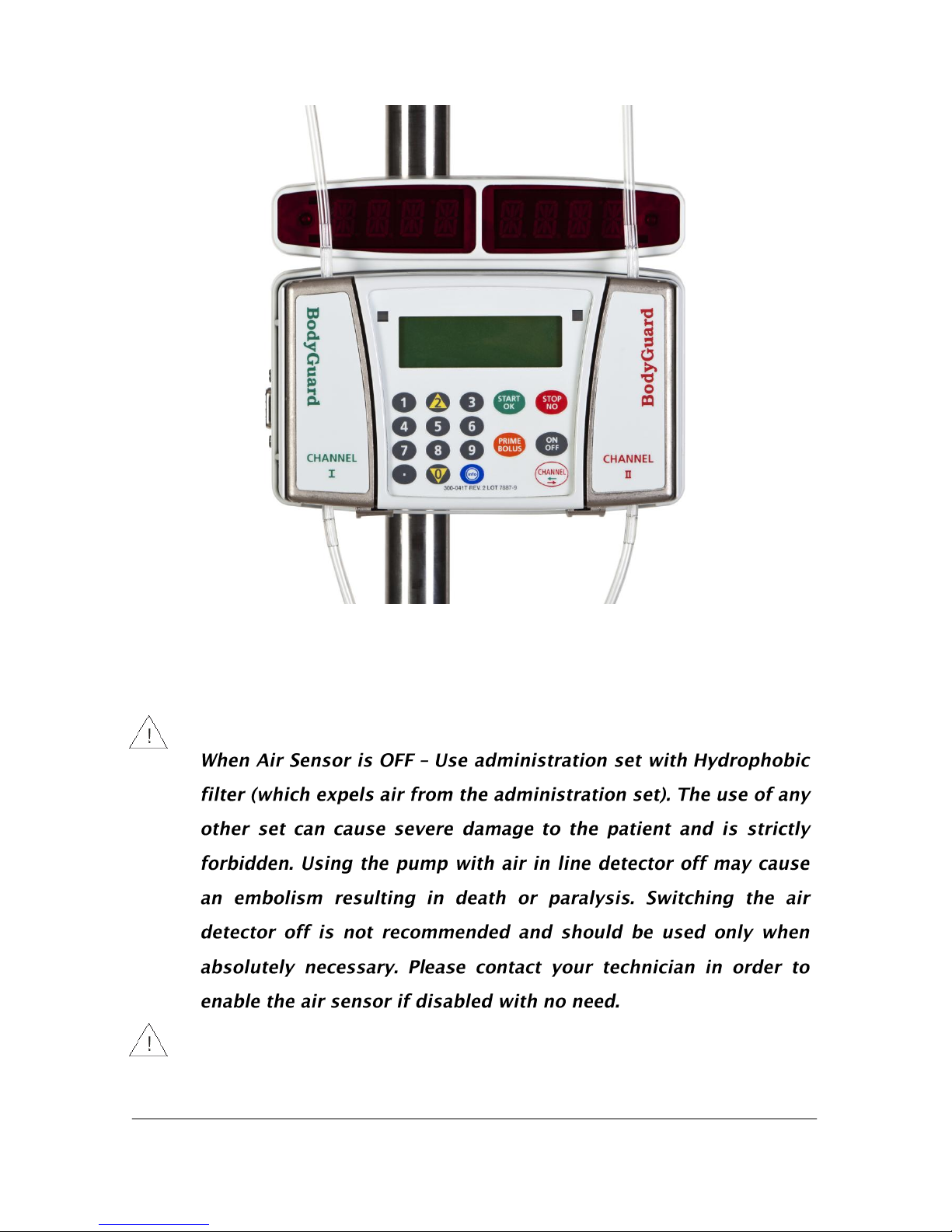

BodyGuard 121

Twins

Infusion System

Operator Manual

MedNet GmbH.

Borkstrasse 10

48163 Muenster

Germany

T: +49 251 32266 0

Caesarea Medical Electronics Ltd.

16 Shacham street

Industrial Park Caesarea North

P.O.Box 4294 Caesarea 38900, Israel

E: sales@cme-infusion.com

W: www.cme-infusion.com

0344

2

NOTE: To assure proper use of the , C.M.E urges all users to read this manual carefully,

become familiar with the procedures and system functions, and follow all recommendations

herein.

U.S.A. federal law restricts this device to sale by or on the order of a physician.

3

Table of Contents

1- Introduction ............................................................................................................. 5

Overview ................................................................................................................... 5

Button Descriptions and Functions ........................................................................ 7

BodyGuard Pump with Door Open ........................................................................ 9

The Charger ........................................................................................................... 10

System Safety Checks ............................................................................................ 11

Pump Accuracy ...................................................................................................... 12

2 – Symbols, Warnings and Cautions ...................................................................... 16

System Symbols ...................................................................................................... 16

Intended Use ........................................................................................................... 17

Warnings ................................................................................................................. 17

Cautions .................................................................................................................. 19

3 – - Installation and Setup ...................................................................................... 19

Unpacking ............................................................................................................... 19

Charging the Pump ................................................................................................ 20

4 – Operation .............................................................................................................. 20

Before Operating the Pump .................................................................................. 20

Pump Operation Test (Channel 1) ....................................................................... 21

Air in Line – Alarm Test ( Channel 1) ................................................................. 22

Down Occlusion – Alarm Test (Channel 1) ......................................................... 22

Door Open – Alarm Test (Channel 1) .................................................................. 23

Battery Test ............................................................................................................ 24

Charger Indicator Test .......................................................................................... 25

Dedicated BodyGuard 121 Twins Administration Sets ..................................... 25

The BodyValve ....................................................................................................... 25

The BodySet ............................................................................................................ 26

Loading the Administration Set ........................................................................... 27

Priming the Line (same for both channels) ......................................................... 28

Priming Operation – before starting a program ................................................. 28

Prime Operation – after air in line alarm ............................................................ 29

Operation steps ....................................................................................................... 30

Pump Mounted on IV Pole .................................................................................... 30

Portable Connection .............................................................................................. 30

Programming .......................................................................................................... 31

Changing Current Program .................................................................................. 33

Changing Current Program – short way ............................................................. 33

4

Continuous Infusion............................................................................................... 34

TPN Infusion .......................................................................................................... 39

Setting Down Occlusion .................................................................................... 42

Program Delay .................................................................................................. 43

Dose Program ......................................................................................................... 44

Intermittent Infusion (Optional) .......................................................................... 47

Program Delay .................................................................................................. 51

25 Steps Protocol (Optional) ................................................................................ 54

PCA Infusion (Optional) ....................................................................................... 56

Lock Mode .............................................................................................................. 64

How To Lock .......................................................................................................... 64

Info Mode ................................................................................................................ 65

View set up .............................................................................................................. 67

Change set up ......................................................................................................... 67

5 – Alarm Conditions and Troubleshooting ............................................................ 71

Alarm Condition .................................................................................................... 71

Troubleshooting (relevant channel) ..................................................................... 72

6 – Specifications ........................................................................................................ 75

7 – Service and Maintenance .................................................................................... 79

Cleaning .................................................................................................................. 79

Storage .................................................................................................................... 79

Battery Operation .................................................................................................. 80

LIMITED WARRANTY ........................................................................................... 81

5

1- Introduction

Overview

The BodyGuard 121 Twins provides the following features:

2 Channels pump

Small, light, and compact pump.

Multi Program:

Continuous program.

Infusion Rate: 0.1 to 1200ml/hr.

Volume: 0.1 to 9999ml.

Bolus Volume: 0-100ml

Rate taper program, with programmable up and down time.

Dose program.

Dose: 0.1 to 250kg in 0.1kg units

Volume: 0.1 to 99.9ml in 0.1ml units

100 to 9999ml in 1ml units

Optional

Patient controlled analgesia: Continuous delivery plus/or

programmable boluses.

Bolus volume: 0-25.5ml

Clinician bolus volume: 0.1-100ml

Bolus rate: 0.1-1200ml/hr

Optional

A set dose delivered in set intervals. Between intervals the pump

will keep vain open (KVO mode)

Optional

Operator can design a specific protocol for drug delivery which

contains up to 25 steps.

Infusion rate: 0.1-1200ml/hr

Volume: up to 9999ml, for each step

Accumulated volume for all steps – up to 10 liters

Continuous

TPN

Dose

PCA

Intermittent

25 Steps

6

Highly accurate fluid delivery on either or both channels.

Operated with a customized safe administration set

Rechargeable internal lit-on battery.

Can be latched into a Charger, which is mounted on an IV pole

Anti-free flow protection valve on CME administration sets (optional).

A.B.S. Anti-Bolus System

Silent operation

Drop sensor control (optional on both channels)

RS232 data collection

Bolus Cable (optional)

7

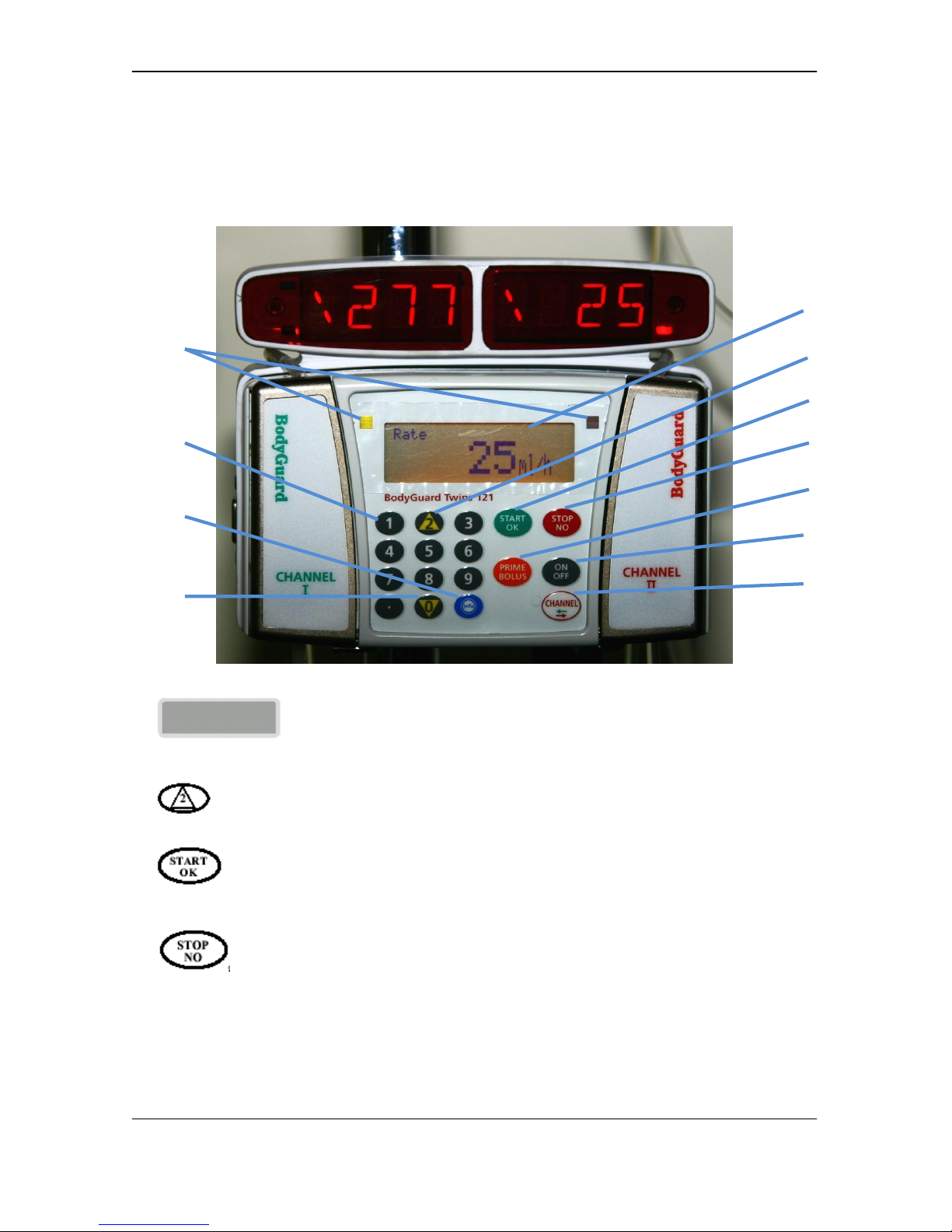

Keypad Description and Functions

Front of BodyGuard Infusion Pump

1. Display Screen

Displays pump/infusion status

Displays programming choices & instructions

2. Up Arrow

Scrolls up through options

3. START/ OK

Starts infusion.

Confirms selection and setting.

4. STOP/NO

Stops infusion.

Silences an alarm condition.

Pauses priming.

Zeroes the displayed value during programming

Erases the last digit during programming.

Returns to previous screen

11

1 3 2 5 6

4 8 10

8

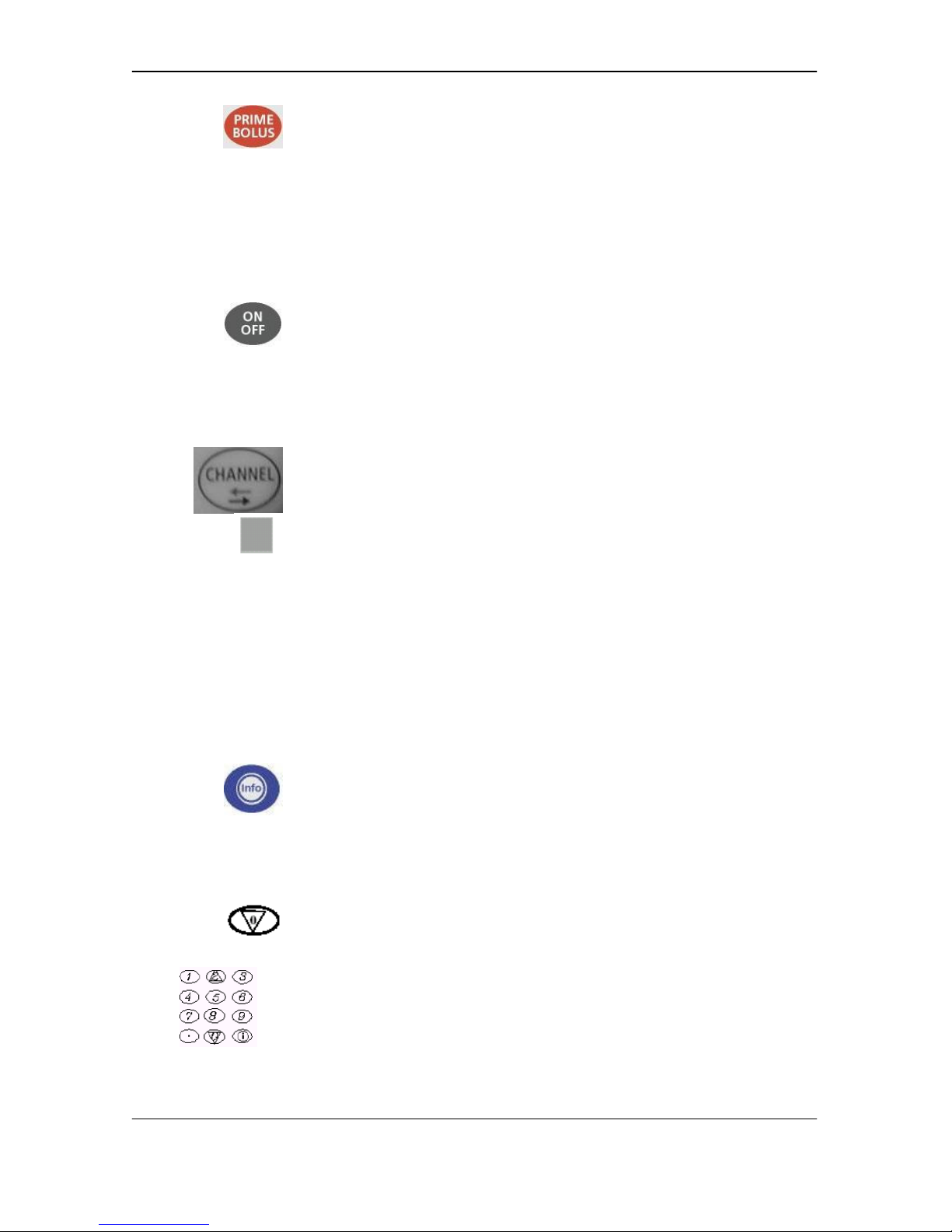

5. Prime Bolus

Pressing Prime/Bolus key followed by Start/OK key during data setting:

Enable Priming procedure. A graph appears on the display screen

showing the priming volume with the current value increasing until

reaching the set volume. Priming default volume: 20 ml.

Pressing Prime/Bolus key during operation enables the user to se an

infusion of a piggyback bag.

6. Power ON/OFF

Turn the system on, by pressing and holding the button until the self-test

screen appears.

Turn the system off, by pressing and holding the button until the graph is black and

a beep is generated.

7. Select Channels key

Allows the user to move between channels

8. Two Operation LED ( one for each channel)

Green Indicator

Lights RED during system self-test

An intermittent green light indicates infusion delivery on the

selected channel and lights continuously on the other channel.

Red Indicator

Indicates an alarm state with a continuous red light

Blinks when the pump is in a stand-by mode during programming,

on the selected channel or when the pump indicts low battery.

9. INFO

Supplies information about the pump and its programs (see info mode

chapter).

Pressing continuously locks and unlocks the keypad to prevent accidental

or deliberate change to pump operation.

10. Down Arrow

Scrolls down through options

11. Numeric Keys

Enters numeric parameters during programming

9

BodyGuard 121 Twins with Door Open

#

Area

Function

1. Latch

holder

Holds the door closed when

latch is in vertical position.

2. Pressure

sensor

Detects downstream tubing

restriction and occlusion.

Alarm level can be adjusted to

suit patient needs.

3.

Keyway

(Optional)

Guides the IV line

4. Pressing

Plate

Connected to the door by two

springs.

5.

Pump door

Covers the pressing plate.

6.

Air sensor

front

Ultrasonic air detector, which is

mounted on the front housing.

7. Air sensor door

Mounted on the door.

8.

Flow

Direction

Shows direction of pump

operation.

1 6 7 2 3 8 5

4

10

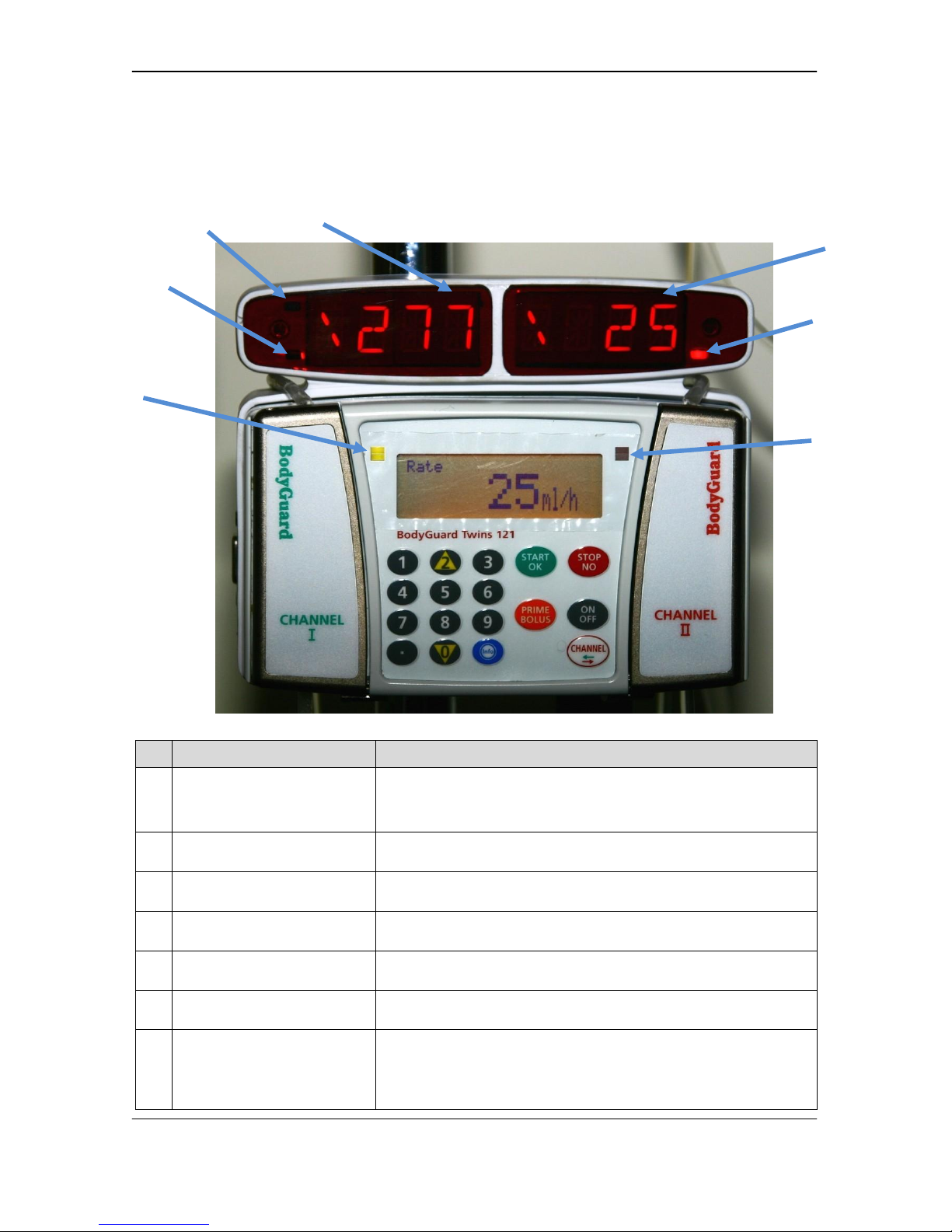

The Charger

Led

Description

1.

Pump channel one led

Green when channel I is infusing, Red when channel I is being

programmed or under alarm, idle when channel II is on display.

2.

Battery charging led

Red when the battery is empty and being charged

3.

Battery charged led

Red when the battery is fully charged

4.

Channel one charger display

Displays channel I data

5.

Channel two charger display

Displays channel II data

6.

Mains led

Red when the pump is connected to mains

7.

Channel two pump led

Green when channel II is on display, Red when channel II is

being programmed or under alarm, idle when channel I is on

display.

6

7

2

1

3

4

5

11

The following details outline the safety checks designed into the BodyGuard 121 Twins infusion

system in order to minimize the possibility of under or over infusions.

Anti-Bolus Function

The anti-bolus function is designed to reduce the bolus that may occur upon the release of an

occlusion following a downstream occlusion alarm. Upon the detection of a downstream occlusion,

the alarm is activated and the pump returns the IV line pressure to neutral within 15 seconds.

Neutral line pressure is achieved by the reverse operation of the pumping mechanism, and

measurement of the IV line pressure through the in-line pressure detection system.

Air-in-Line Accumulation

To improve the detection of air in the IV line, the BodyGuard 121 Twins Infusion system utilizes an

air-in-line accumulation system in addition to the standard single bubble detection. This feature

monitors the volume of air that passes through the IV line by accumulating the volume of individual

bubbles of 1 ml over a moving window of 15 minutes. The limit is not configurable. Although an

individual bubble may not exceed the pre-programmed threshold, the cumulative volume of bubbles

of 1-milliliter volume may exceed the limit during the 15 minutes window and initiate an air-in-line

alarm. This accumulation feature is particularly useful with infusions for patients who are highly

sensitive to air (i.e. infants, neonates, children) or when infusing products that create significant

volumes of small air bubbles.

12

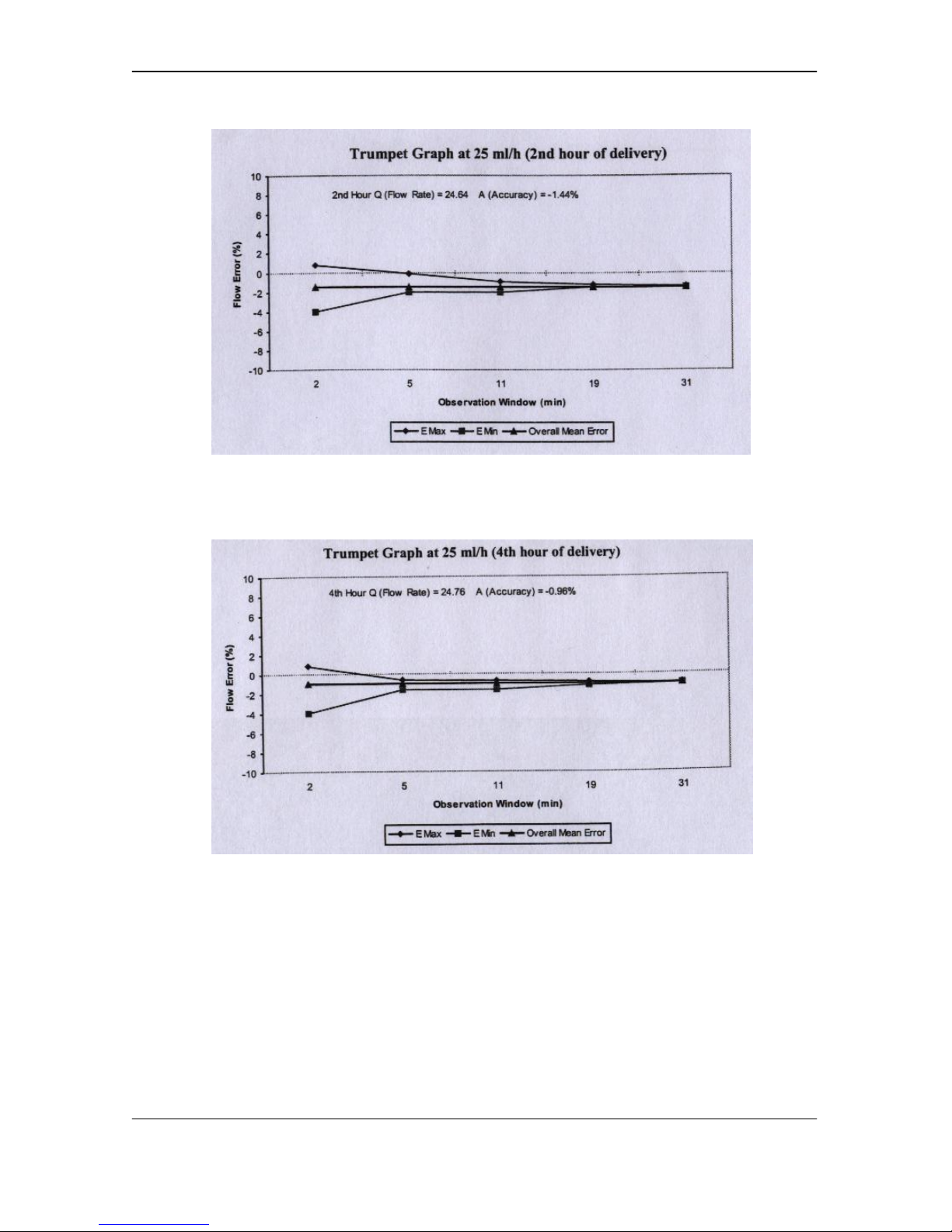

Pump Accuracy

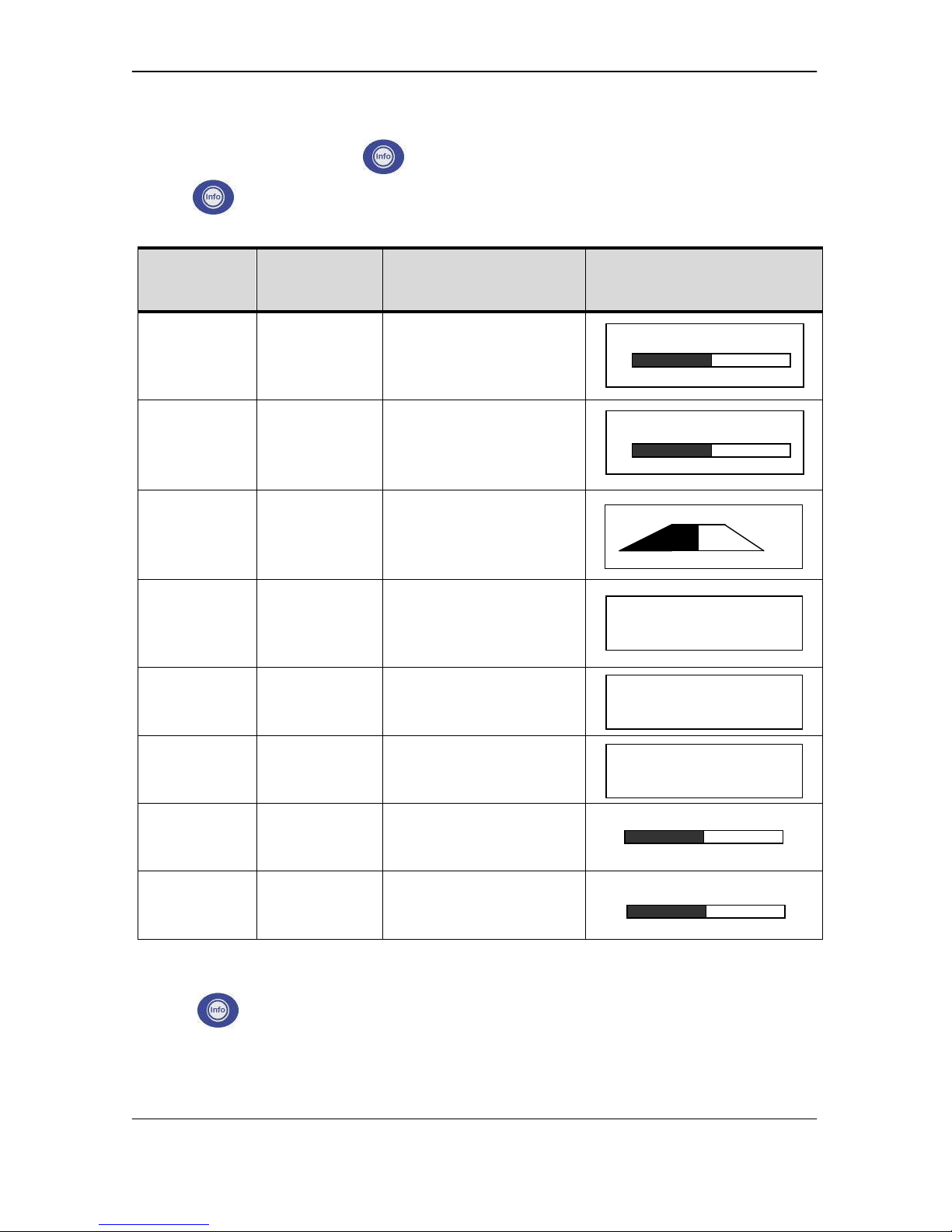

The following graphs and curves were derived from testing described in IEC60601-2-24. Testing was

performed under normal conditions at room temperature (720 F). Any deviations from normal conditions

and room temperature may cause changes in the accuracy of the pump.

Start-up Curves

The Start-up curves represent continuous flow versus operating time for two hours from the start of the

infusion. They exhibit the delay in onset of delivery due to mechanical complexity and provide a visual

representation of uniformity. Trumpet curves are derived from the second hour of this data. Tests

performed according to IEC 60601-2-24 standard.

13

Trumpet and Flow Rate

With the BodyGuard 121 Twins, as with all infusion systems, the action of the pumping mechanism and

variations cause short – term fluctuations in rate accuracy.

The following curves show typical performance of the system in two ways:

1. The accuracy of fluid delivery over various time periods is measured (trumpet curves).

2. The delay in onset of fluid flow when infusion commences is measured (start up curves).

Trumpet curves are named for their characteristic shape. They display discrete data averaged over

particular time periods, “Observation windows”, as opposed to continuous data versus operating time.

Over long observation windows, short-term fluctuations have little effect on accuracy as represented by

the flat part of the curve. As the observation window is reduced, short-term fluctuations have greater

effect as represented by the “mouth” of the trumpet.

Knowledge of system accuracy over various observation windows may be of interest when certain drugs

are being administered. Short-term fluctuations in rate accuracy may have clinical impact depending on

the shelf life of the drug being infused and the degree of inter-vascular integration; the clinical effect

cannot be determined from the trumpet curves alone.

14

15

16

2 – Symbols, Warnings, and Cautions

System Symbols

The following symbols are used with the BodyGuard Infusion System and components. Labels on the

system or statements in this manual preceded by any of the following words and/or symbols are of special

significance intended to help you operate the pump in a safe and successful manner.

Attention, consult accompanying Instructions.

CSA mark

CE mark indicates conformance to Medical Device Directive 93/42/EEC.

Do not dispose of in municipal waste. Symbol indicates separate collection for

electrical and electronic equipment. (WEEE Directive 2002/96/EEC). NOTE: Does not

apply to the battery.

Do not dispose of battery in municipal waste. Symbol indicates separate collection for

battery is required.

The use of single-use disposable components on more than one patient is a biological

hazard. Do not reuse single-use disposable components.

Type CF applied part.

Date of Manufacture

Serial Number

Expiry Date of disposable

Lot Number

Sterilized with Ethylene Oxide

LOT

STERILE EO

17

Warning: Indicates that the information is a warning. Warnings advise you of

circumstances that could result in injury or death to the patient or operator. Read and

understand this manual and all warnings completely before operating the BodyGuard Infusion

System.

Caution: Indicates that the information is a caution. Cautions advise you of circumstances

that could result in damage to the device. Read and understand this manual and all cautions

completely before operating the BodyGuard Infusion System.

NOTE: Indicates that the information that follows is additional important information or a tip

that will help you operating the BodyGuard Infusion System.

Intended Use

The BodyGuard 121 Twins™ infusion pump system is designed for infusion of medications or fluids

requiring continuous or intermittent delivery at precisely-controlled infusion rates through clinically

acceptable routes of administration, including intravenous, subcutaneous, percutaneous, intra-arterial,

epidural, enteral, in close proximity to nerves, and into an intraoperative site (soft tissue/body

cavity/surgical wound site). The system is intended for patients who require maintenance medications,

analgesics, PCA therapy, parenteral and enteral nutrition fluids, chemotherapeutic agents, blood or blood

products infusion, and general fluids therapy in hospital and home care environments.

Warnings

To avoid possible personal injury or loss of life, observe the following:

When Air Sensor is OFF – Use administration set with hydrophobic filter (which expels

air from the administration set). The use of any other set can cause severe damage to

the patient and is strictly forbidden. Using the pump with air-in-line detector off may

cause an embolism resulting in death or paralysis. Switching the air detector off is not

recommended and should be used only when absolutely necessary. Please contact your

technician in order to enable the air sensor if disabled with no need.

Read the entire Operation Manual before using the pump, since the text includes important

precautions.

The maximum volume that may be infused under SINGLE FAULT CONDITION is 0.1 ml

18

Voltage present in internal components may cause severe shock or death upon contact.

Disconnect the Charger from the mains prior to opening the casing. Only trained service

personnel should open the pump cover.

Blown fuses could pose a fire hazard. Replace blown fuses on the charger only with fuses of

the same type and rating (see fuse values on the Charger PCB).

The equipment is not suitable for use in the presence of flammable anestheticair/oxygen/nitrous oxide mixture. Do not use the system in the presence of theses gases.

Make sure the pump is securely attached to the Charger, which is connected firmly to an IV

pole.

A kinked or occluded IV line may impair the operation of the pump and the accuracy of the

infusion. Before operation, verify that the IV line is not kinked or occluded.

The BodyGuard 121 Twins should be operated only with IV lines approved for use by the

manufacturer and distributor. Use of IV lines other than the approved type may impair the

operation of the pump and the accuracy of infusion.

Drugs must not be administered to the epidural space unless the drugs are indicated for this

purpose and are administered in accordance with the indications included in the manufacture’s

package. Epidural administration of drugs other than those indicated for epidural use could

result in serious injury to the patient. For epidural administration of drugs use MicroSet only.

Any adjustments, maintenance, or repair of the uncovered pump may impair the operation of

the BodyGuard 121 Twins Infusion System and/or the accuracy of infusion. Any adjustments,

maintenance, or repair of the uncovered pump should be performed by authorized skilled

technicians. Any adjustments, maintenance, or repair of the uncovered pump while connected

to mains should be avoided.

The BodyGuard 121 Twins Infusion System should be operated within a temperature range of

15C (59F) to 45C (113F) and up to 85% humidity. Operating the pump at temperatures

and/or humidity outside that range may affect accuracy.

Use of improper accessories represents unsafe operation. Use only accessories and options

designed for this system.

Disposables must be compatible with the medicine delivered.

Battery charging is enabled as long as the charger cord is connected to the mains and the

pump is in the charger. Switching the pump off does not disconnect it from the mains. To

disconnect from mains, remove the charger cord from the power outlet. To disconnect pump

from mains, remove it from the charger.

Dropping the BodyGuard 121 Twins Infusion System could cause damage to components. If

the pump is dropped, return the pump for inspection by qualified service personnel.

19

Use aseptic technique. Patient infection may result from the use of non-sterile components.

Maintain sterility of all disposable components and do not re-use single use IV sets.

Watch your fingers / nails when opening the pump door.

Do not operate the pump near high-energy radio-frequency emitting equipment, such as

electro-surgical cauterizing equipment, and cellular telephones. False alarm signals may occur.

Cautions

To avoid possible damage to the equipment, observe the following:

Leaving the battery in a discharged state for a long period of time may damage the battery.

Connect the pump to the mains via the charger whenever possible to recharge the battery.

Do not store the pump with the battery fully depleted.

Xylene, Acetone, or similar solvents could cause damage to components. Do not clean the pump

with these chemicals. Clean solution spills on the pump immediately. Use a damp cloth or

sponge. A mild detergent may be used. Wipe thoroughly with a dry cloth.

Immersing the BodyGuard 121 Twins Infusion pump into liquid could cause damage to

components. Do not immerse the pump into any type of liquid.

Battery damage could occur if left in a temperature higher than 500C (122F).

3 – Installation and Setup

Unpacking

1.

Carefully remove the pump and Charger from the box.

2.

Make sure no items were damaged during shipment

3.

Make sure you have the following items:

BodyGuard 121 Twins Infusion Pump

Charger

Operation Manual

If any items are missing or damaged, contact your BodyGuard 121 Twins dealer.

20

Charging the Pump

NOTE: The pump is protected against overcharging. Connect the pump to the mains via the

charger whenever possible to be sure that the battery is fully charged at all times.

Warning: If the battery is damaged during operation, while pump and charger are

disconnected from mains, the pump will turn off.

1. Connect the charger unit to AC power, and verify that the AC indicator is lit (charger right side above

channel II).

2. Put the pump into the charger and tighten the safety screw. Please see drawing on the charger.

3. The battery is charging when the red battery LED on the front of the charger is lit. (charger lower left

side above channel I) The battery is fully charged when the full battery LED symbol turns red

(charger upper left side above channel I).

4. Remove the pump from the charger by releasing the safety screw and lifting the pump out of the

charger.

Caution: Leaving the battery discharged for a long period of time may damage the battery.

4 – Operation

Before Operating the Pump

Before attaching the system to a patient, run the following tests to verify that all indicators and

alarms work properly. Perform the test on both channels.

When an alarm is activated the following occurs:

An alarm message appears on the pump and charger display. Each channel has its own display.

The alarm message will be shown on the display relevant to the channel in which the alarm

An audible alarm sounds.

Infusion ceases.

The operation LED changes from green to red.

NOTE: All tests should be performed in the Continuous program on both channels.

21

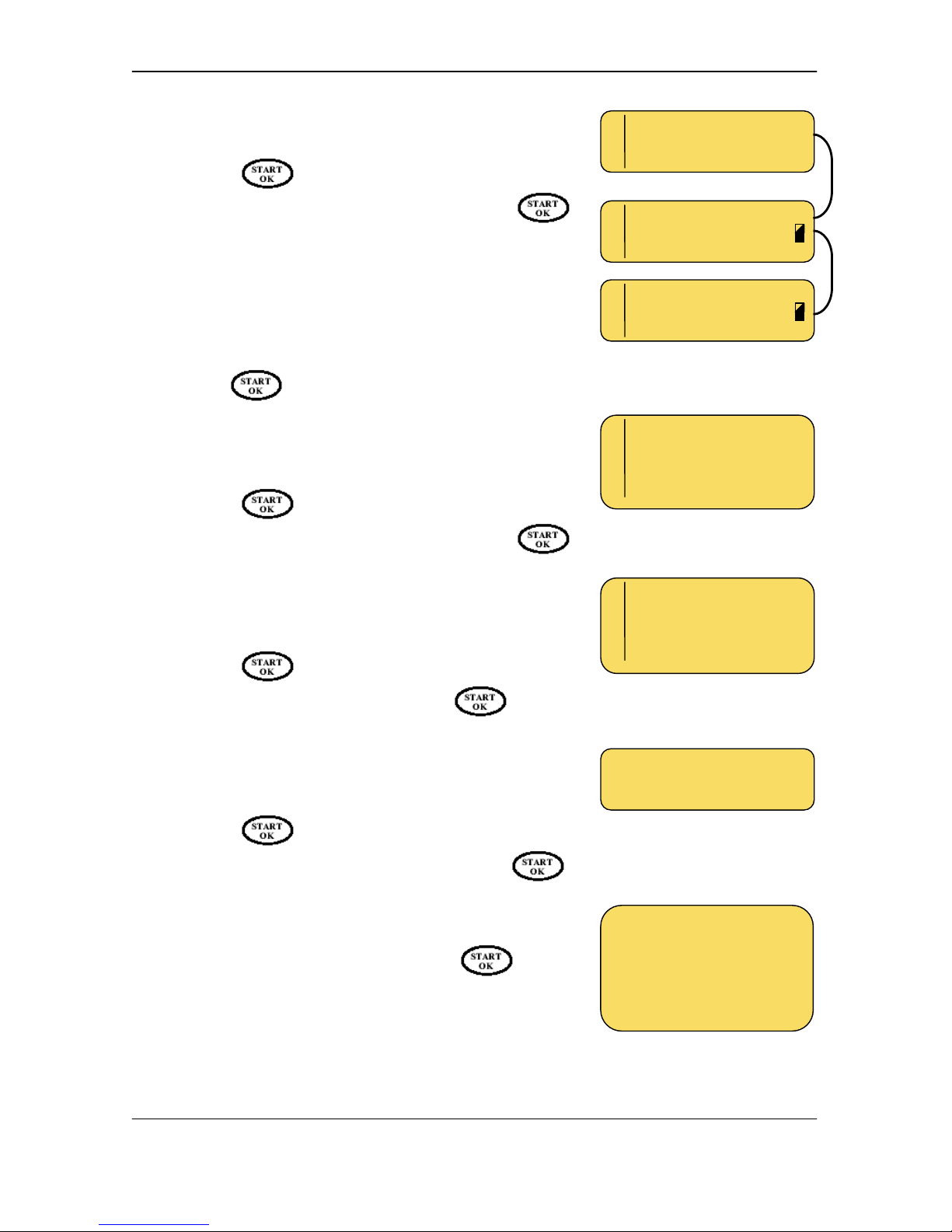

Pump Operation Test (Channel 1)

1.

Click the pump into a Charger connected to AC power. Verify that the CHARGE

indicator is on (on charger).

Red LED on

the charger

2.

Insert an administration set, on left (green) channel, and close the pump door. Press the door

until a click is heard.

NOTE: For instructions on how to load and prime an administration set refer to sections

“Loading the Administration Set” & “Priming the Line”.

3.

Press key until the self-test screen appears. The pump will enable setting data of

channel 1. Press the Start/Ok key to confirm channel 1 or press Channel key to enter channel 2

data.

4.

After switching the pump on, Channel 1 and the program selected will be displayed on the

screen. During the self-test a long beep will be heard. This procedure verifies that the pump’s

acoustic and visual features are working properly. After overview, press Start/Ok key to display

the last set rate. If air sensor is off, Press to confirm.

5.

Press to prime the IV line.

Warning: Ensure the set is not connected to a patient!!

6.

Press to start priming. The screen shows the

progress bar of the priming operation.

7.

When priming has completed, wait 2 minutes without

pressing any key. After two minutes the screen displays

“Pump Unattended” and an alarm will sound.

8.

Press to silence the alarm.

NOTE: Same tests should be performed for channel 2.

PRIME

DISCONNECT PATIENT

Pump Unattended

PRIME 10ml

22

Air in Line – Alarm Test ( Channel 1)

1.

Insert an administration set in Channel 1 and close the pump door. Press the door until a click is

heard. Switch the pump on.

NOTE: For instructions on how to load and prime an administration set refer to sections

“Loading the Administration Set” & “Priming the Line”.

2.

The pump will display channel 1 and the program selected. In order to edit channel 2 press the

CHANNEL key once.

3.

The pump displays Channel 1 and the program selected. Press to show the last rate

setting. If air sensor is off, Press to confirm.

4.

Set/change the infusion rate at 500ml/hr, using the numeric

keypad and press to confirm setting. Verify that

the charger’s display shows 500.

5.

Set Volume at 20 ml. press key.

6.

The pump display will show the accumulation screen where

all set data is shown, check the settings, if correct, press

to start operation

6.

Disconnect the IV line from the IV bag or turn the drip chamber upside down to allow an air

bubble greater than 5 mm to enter into the administration set.

7.

Air-in-line alarm will be activated as soon as the air bubble enters the set segment located

behind the pump door.

8.

Press to turn the alarm off.

NOTE: Same tests should be performed for channel 2.

Down Occlusion – Alarm Test (Channel 1)

1.

Insert an administration set in channel 1 and close the pump door. Press the door until a click is

heard.

2.

Make sure room temperature is 21-23 oc.

NOTE: For instructions on how to load and prime an administration set refer to sections

“Loading the Administration Set” & “Priming the Line”.

Rate 500 ml/h

Volume 20 ml

Rate 500 ml/h

Volume left 20 ml

Infused 0 ml

Press Ok to Start

23

3.

Press until the self-test screen appears. The pump displays Channel 1 and the program

selected. Press the Start/OK key to display the last rate setting. If air sensor is off, press

to confirm.

4.

Set the infusion rate at 500ml/hr, using the numeric keypad

and press to display last volume set.

5.

Set Volume at 20 ml.

6

The pump display will show the accumulation screen where

all set data is shown, check the setting, if correct, press

to start operation.

7.

Wait 5 minutes and connect a pressure gauge at a distance of 1 meter from the exit of the pump.

Place both the pump and the pressure gauge at the same level (on a table)

8.

Wait 5 more minutes and occlude the IV line downstream of the pump (between the pump and

the patient).

9.

The Down Occlusion alarm occurs at the time and rates listed below (time is measured from

actual occlusion time to alarm, with accuracy of +30%-20%):

500 ml/h up to 20 seconds

60 ml/hr up to 1 minute

NOTE: The pressure threshold can be changed to suit patient need (refer to section on

changing the current Default Pressure Limit).

10

Depending upon the set flow rate and pressure threshold,

the Down Occlusion alarm will be activated.

11.

Press key to mute the alarm.

NOTE: Same tests should be performed for channel 2.

Door Open – Alarm Test (Channel 1)

1.

Insert an administration set in channel 1 and close the pump door. Press the door until a click is

heard.

NOTE: For instructions on how to load and prime an administration set refer to sections

“Loading the Administration Set” & “Priming the Line”.

2.

Press until the self-test screen appears.

Rate 500 ml/h

Volume 20 ml

DOWN OCCLUSION

Rate 500 ml/h

Volume left 20 ml

24

3.

The pump displays Channel 1 and the program selected. Press to change the display to

show the last rate setting. If air sensor is off, press to confirm.

4.

Set the infusion rate at 500ml/hr, using the numeric keypad

and press to display the last set volume.

5.

Set Volume at 20 ml. Press the key.

6.

The pump display will show the accumulation screen where

all set data is shown, check the setting, if correct, press

to start operation.

6.

Open the pump door.

7.

“Door Open” alarm will be activated at once.

8.

Close the door. The display will show STOP.

NOTE: Same tests should be performed for channel 2

Battery Test

1.

Insert an administration set in both channels and close both doors. Press the doors until a click is

heard in both channels.

NOTE: For instructions on how to load and prime an administration set refer to sections

“Loading the Administration Set” & “Priming the Line”.

2.

Take the pump out of the charger.

3.

Press until the self-test screen appears.

4.

The pump displays Channel 1 and the program selected. Press to display the last rate

setting. If air sensor is off, press to confirm.

5.

Set the infusion rate at 1200ml/hr, using the numeric keypad

and press for volume.

6. Set Volume at 9999 ml.

Rate 500 ml/h

Volume 20 ml

Rate 1200 ml/h

Volume 9999 ml

Rate 500 ml/h

Volume left 20 ml

DOOR OPEN

25

The pump display will show the accumulation screen where

all set data is shown, check the setting, if correct, press

to start operation.

7.

Wait untill pump displays the “low battery” message

8.

Press to turn the pump off.

9.

Connect the pump to a charger.

10.

Verify that the red LED indicating an empty battery lights on (lower left side of the charger above

channel one).

11.

Verify that the full battery LED lights red after 4-6 hours of charging (upper left side of the charger

above channel one).

Charger Indicator Test

1.

Click the pump into the charger and connect the charger to mains. Disconnect the power cord

from the AC power outlet.

2.

Verify that the CHARGE LED indicator (in the charger right side above channel II) is off.

3.

Connect the power cord to the AC power outlet. Verify that the CHARGE LED indicator is on.

Administration Sets

The BodyGuard 121 Twins infusion System should only be operated with Infusion sets approved for use

by the manufacturer and distributor.

Warning: Do not operate the BodyGuard 121 Twins Infusion system with any

administration set, other than that recommended by the manufacturer or its distributor. The

optional BodySet/MicroSet Infusion Sets are equipped with a free flow protection valve, to

prevent a gravitational free flow hazard. Using a different set may essentially change the

administration rate and expose the patient to free-flow.

Low Battery

Rate 500 ml/h

Volume left 20 ml

Infused 0 ml

Press Ok to Start

26

Set Based Anti Free-Flow Valve

The Anti free flow valve, BodyValve, enhances pump functioning by:

Preventing free-flow in the event the set is detached from the pump.

Preventing back-flow (reflux) in the event several infusion pumps are connected simultaneously

to the same patient.

Preventing free-flow in the event of a mechanical malfunction.

Preventing pump operation if the set has been loaded incorrectly.

Warning: Replace the administration set every 72 hours to lessen the incidence of bacteria

formation.

Warning: Disposables must be compatible with the medicine delivered.

Warning: Patient or operator injury may result if package is opened or damaged, or if

damaged components are used. Visually inspect contents and package before each use.

Warning: Air embolism can cause serious injury or death to the patient. Do not connect a

patient to the BodyGuard Infusion Pump until all trapped air has been cleared from the fluid

path. Carefully read the instruction for loading an administration set. Punctured set

components may cause air embolism as well.

Warning: Drugs must not be administered to the epidural space unless the drugs are

specifically indicated for this purpose and are administered in accordance with the indications

included in the manufacture’s package insert accompanying the drugs. Epidural administration

of drugs other than those indicated for epidural use could result in serious injury to the patient.

Warning: For epidural administration of drugs use MicroSet only.

Caution: Component damage may occur if not installed properly. Assure all connections

are secure; do not over tighten. This will help minimize leaks, disconnection and component

damage.

27

Loading the Administration Set

NOTE: Follow the Instructions supplied with the individual administration set.

1.

Prepare the administration set by remove it from the sterile packaging leaving the end caps on

the line.

2.

Pull the door latch down (on the door’s bottom surface) to open the BodyGuard 121 Twins pump

door.

3.

Make sure the flow direction corresponds to the flow direction arrows inside the pump door.

4.

Insert the IV tubing into the pumping canal. Insert the tubing from top down, and avoid stretching

or pulling the tubing.

5.

Ensure that the distal flow valve is on the right hand side of the pump if using a CME set or one

that contains an anti-siphon valve.

6.

Close the pump door until the latch clicks.

Warning: Use of any administration set, other than that recommended by the manufacturer

or its distributor, may impair the operation of the pump and the accuracy of infusion.

28

NOTE: Ensure that the tubing is inserted completely into the pumping channel. Same

procedure should be applied to both channels.

Warning: Use aseptic technique. Patient infection may result from the use of non-sterile

components. Maintain sterility of all disposable components and only use single use

consumables marked once.

Priming the Line (same for both channels)

NOTE: the optional BodySet and MicroSet administration sets contain a one-way Anti-Siphon

valve also called Free-Flow valve. Therefore, the lines cannot be primed using gravity and

must be primed using the BodyGuard 121 Twins priming function.

Prime function must be used:

1.

Before starting a program

2.

After air in line alarm

Warning: Always disconnect IV tubing from patient before starting priming procedure.

NOTE:

The priming flow rate is performed at a rate of 600 ml/hr. During priming the air in line alarm

is disabled.

The priming volume is adjustable from 0-60 ml (see “Change set up” section) with an initial

default setting at 20 ml.

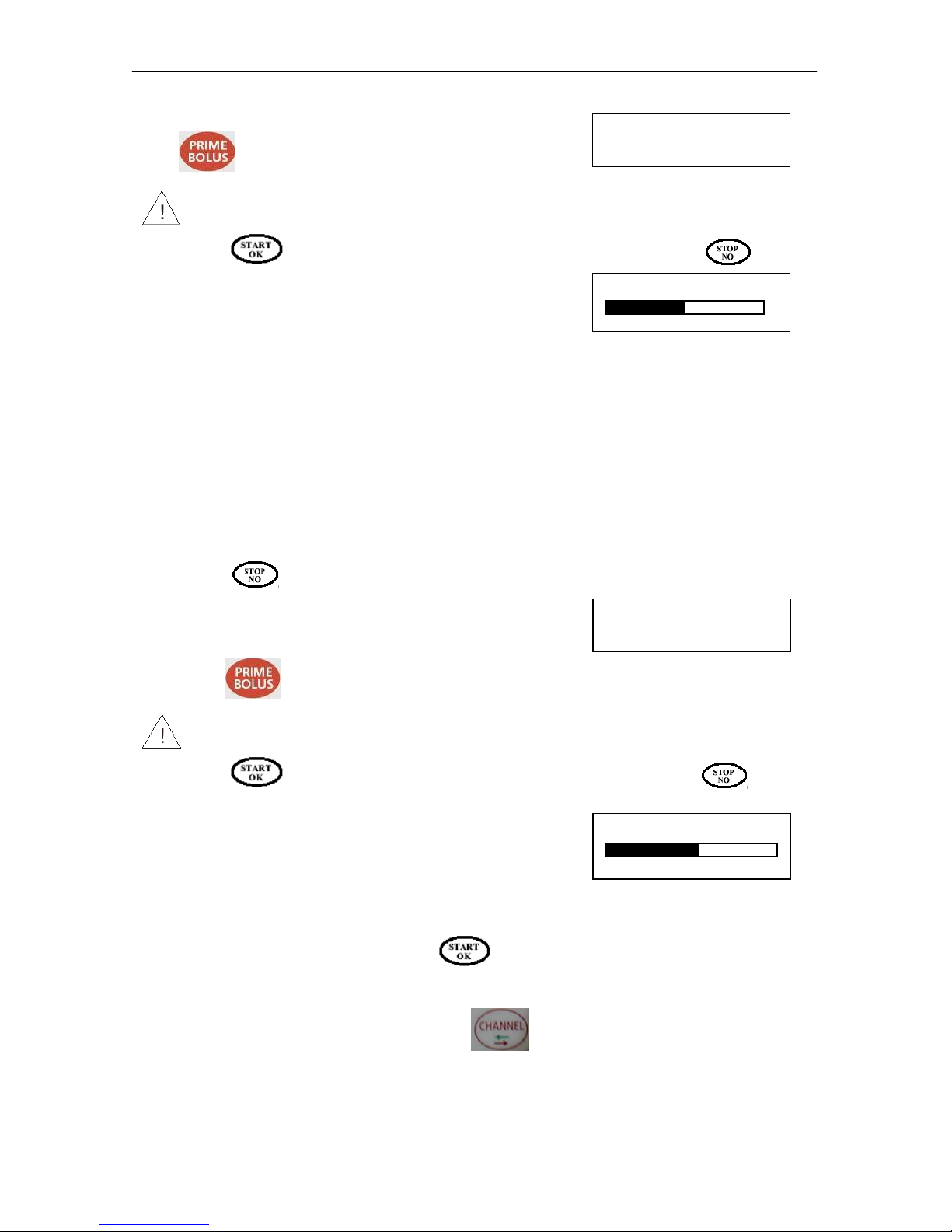

Priming Operation – before starting a program

1.

Insert an administration set in Channel 1 and close the pump door. Press the door until a click is

heard. Switch pump on.

NOTE: For instructions on how to load and prime an administration set refer to sections

“Loading the Administration Set” & “Priming the Line”.

2.

The pump will display channel 1 and program selected. Press the key to confirm

channel 1 or press the channel key to enter channel 2 data.

3.

The pump displays Channel 1 and the program selected. The display will automatically change

and display the last rate setting. If air sensor is off, Press to confirm.

29

4.

When the display screen shows the existing program press

key to prime the administration set.

Warning: Ensure the set is not connected to the patient!!!

5.

Press to start priming. You may stop priming at any time by pressing .

6.

The display screen will show a progress bar indicating the

priming operation.

7.

Once the priming has completed, the display will change back to the previous screen the pump

was in before priming.

Make certain that all air is removed from the IV line before connecting to the patient. To perform

another priming operation, in case all air was not cleared from the set, open a door and close it,

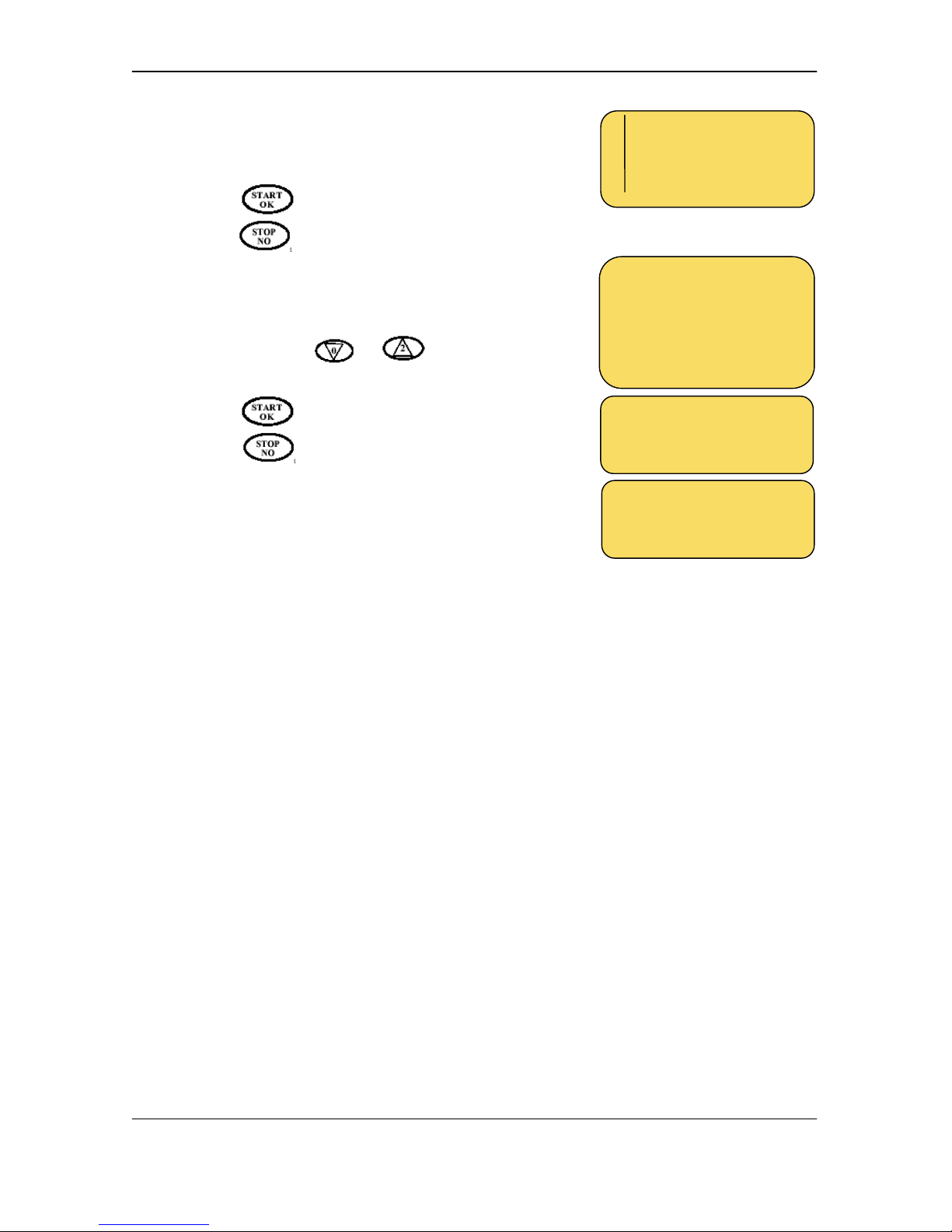

Prime Operation – After Air in Line Alarm

Press to mute the alarm.

2.

Disconnect IV tubing from patient.

3.

Press once.

Warning: Ensure the set is not connected to the patient!!!

4.

Press to start priming. You may stop priming at any time by pressing .

5.

The display screen will show a progress bar indicating the

priming operation.

6.

When priming has completed make certain that all air is removed from the IV line.

7. Connect IV line to the patient and press to resume program.

NOTE: Same tests should be performed for channel 2. To change the display

to channel 2, use the Channel select key . User may prime channel one while setting

program data on channel two.

PRIME

DISCONNECTPATIENT

PRIME 10ml

PRIME 10ml

PRIME

DISCONNECTPATIENT

30

Operation steps

As follows are the steps for starting infusion procedure. For detailed instructions regarding each step refer to the

relevant sections in the Operation chapter.

Pump Mounted on IV Pole

1.

Connect the administration set to medication bag; for each channel a bag (if necessary). Mount

the bag on an IV pole.

2.

Attach the pump into the charger. Mount the charger on an IV pole.

3.

Connect the charger via a standard power cord to a grounded AC outlet.

4.

Open channel 1 pump door and load the administration set into the pump’s tubing canal.

Repeat, same operation, if necessary, for channel 2.

5.

Turn on the BodyGuard 121 Twins pump, by pressing key until the self-test screen

appears.

6.

The display will show Channel 1 and the program selected. Press the key to display

the last rate setting.

7.

Prime the administration set.

Warning: Make sure patient is not connected to the pump during priming!!! Repeat the

same operation for channel 2 if necessary.

8.

Set the required program and continue as described for every program setting.

Warning: Verify that infusion proceeds normally before leaving the pump unattended.

Portable Connection

1.

Connect the administration set to the medication bag, for each channel, if necessary.

31

2.

Open the door of channel one and load the administration set into the pump’s tubing canal. Do

the same for channel two.

3.

Turn on the BodyGuard 121 Twins, by pressing until the self-test screen appears.

4.

The display will show channel 1 and the selected program. Press the to display the last

program, rate setting. If air sensor is off, Press to confirm.

5.

Prime the administration set.

Warning: Make sure patient is not connected to the pump during priming!!! Perform the

same procedure for channel 2, if necessary.

6.

Set the required program and continue as described for every program setting.

Warning: Verify that infusion proceeds normally before inserting the infusion bag and

pump into the carrying bag.

Programming

The BodyGuard 121 Twins infusion system features two different programming options:

Dose Program

Dose: 0.1 to 250 kg in 0.1kg units.

Volume: 0.1 to 99.9 ml in 0.1ml units

100 to 9999 ml in 1 ml units

Concentration: 0.1 to 1000 mg/ml in 0.1 mg/ml units

Dose: 0.1 to 1000 µg/kg/min in 0.1 µg/kg/min units

Continuous Program

Rate: 0.1 to 100 ml/hr in 0.1 ml increments, and 100 to 1200 ml/hr in 1 ml increments

Total Volume to be Infused: 0.1 to 9999 ml

Program as Rate Over Volume or Volume Over Time

Secondary Infusion (Piggy) Rate: 0.1 to 100 ml/hr in 0.1 ml increments, and 100 to 1200 ml/hr

in 1 ml increments

Secondary Infusion (Piggy) Volume: 0.1 to 9999 ml

TPN Program

32

Used for Total Parenteral Nutrition

Volume: 1 to 9999 ml

The program has a taper up/taper down pattern. The parameters to be set are: Total Volume,

Time Up, Time Down and Total Time. The pump will calculate the ramping infusion rates.

Intermittent Program (optional)

Used for setting a dose protocol at set intervals from 0.1 to 100 ml/hr in 0.1 ml increments,

and 100 to 1200 ml/hr in 1 ml increments

Volume: 0.1 to 9999 ml

Interval Time: 0:01 minute to 20:00 hours

25 Steps Program (optional)

Used for setting specific protocol that contains up to 25 steps

Rate: 0.1 to 100 ml/hr in 0.1 ml increments, and 100 to 1200 ml/hr in 1 ml increments

Volume: 0.1 to 9999 ml for each step

Accumulated volume for all steps is up to ten liters

PCA Program (optional)

Used for PCA applications. Combines basal rate and pre-programmed boluses

Rate: 0.0 to 100 ml/hr in 0.1 ml increments

Volume: 0.1 to 1000 ml

Bolus Volume: 0 to 100 ml

Bolus Rate: 0.1 to 100 ml/hr in 0.1 ml increments, and 100 to 1200 ml/hr in 1 ml increments

Keep Vein Open Mode

The BodyGuard 121 Twins Infusion pump uses a Keep Vein Open (KVO) mode that runs automatically at the

end of a program, if desired. KVO can also be set to run during a delay at the start of a program. The KVO rate

can be set from 1-5 ml/hr with an initial default setting of five ml/hr. The KVO rate is adjustable through the

“change setup” mode. To disable the KVO mode – set the KVO rate at 0ml/hr. If the programmed infusion rate

is lower than the KVO rate, the KVO will run at the programmed infusion rate.

KVO during End Program is limited to a volume of 5 ml.

NOTE: To use the automatic KVO at the end of a protocol, make sure that the IV bag

contains an additional dose over the volume to be infused.

33

End Program Mode

When a protocol has completed, an audible alarm will sound continuously and the display will indicate END

PROGRAM – KVO (assuming KVO is enabled). To stop the alarm and enter a new program, press . If

the stop key is not pressed before the first 4 beep have sounded, KVO will begin automatically. KVO will run for

four minutes. The pump screen then displays it is in KVO mode and continues into 4 more minutes of KVO

administration at the set preset rate.

Changing Current Program

1.

Turn on the BodyGuard Pump, by pressing until the self-test screen appears and the

screen will change to channel 1 and the set program. Press to enter channel 1 and

display the last set mode.

2.

When the Rate screen is displayed, press twice.

3.

Scroll to "Change set up" option. Press .

4.

Scroll to "More" and press .

5.

Enter code 901, using the numeric keyboard and

press .

6.

Scroll to "Select Program" option. Press .

7.

Scroll to the required program and press .

8.

Press to restart the pump.

NOTE: The selected program will remain in the pump’s memory until changed by the

operator.

Changing Current Program – Shortcut

Volume Infused

View set up

Buzzer Level

> More …

Code

Technician

901

Pressure Default

> Select Program

Select Program

> CONTINUOUS

History

> Restart Pump

34

1.

Turn on the BodyGuard Pump, by pressing until the self-test screen appears. Press

key to enter channel 1 and display the program selected.

2.

Immediately press and hold for two seconds.

3.

Scroll to the required program and press .

Continuous Infusion

Rate over Volume (Channel 1)

NOTE: Before operating the pump in Rate Over Volume, make sure that you are in the

Continuous Program and that the IV bag contains an additional 5 ml of volume. This ensures

adequate volume for KVO during End Program. If Delay Before Start is set, you must include

enough volume for the delay period, in addition to the 5 ml KVO volume.

1.

Turn the pump on by pressing and holding the until the self-test screen appears.

2.

Pump displays Channel 1 and the program selected.

Press . Wait for the rate screen to display.

NOTE: If pump is not already in Continuous program refer to changing program section for

instructions on how to change the program.

NOTE: Whenever you decide to set a new program, follow instructions at the bottom of each

screen.

3.

Do one of the following:

Press to confirm the existing parameters.

Enter the desired rate using the numeric keypad and

Press .

NOTE: The screen will be blank upon initial setup.

Select Program

> CONTINUOUS

Channel l

Continuous

Rate 500 ml/h

35

4.

The screen displays the last set volume.

Do one of the following:

Press to confirm the existing parameters.

Enter the desired volume using the numeric keypad and

press .

5.

Enter delay time, if applicable. For further information regarding delay option – refer to delay

program section.

6.

Pump displays program accumulation screen.

Do one of the following:

Press to confirm the existing parameters

and start infusion.

Press to go back to rate setting screen.

7.

During program operation the charger displays the rate in which the program is operating. The

pump displays the volume to be infused (vtbi) of each channel.

NOTE: -If one of the values is changed during the programming mode, the pump will not

recall the new value, unless changes are confirmed by pressing within 10 seconds.

If prime procedure is activated during data setting, the pump will return to the original

(previous) screen, once priming has completed.

Changing the Rate

The pump allows rate adjusting during the Rate Over Volume Program.

To change the rate during the infusion:

1.

Use numeric keypad to enter the new desired rate, during

operation and press within ten seconds to

confirm. The pump will bip once and the infusion will resume

at the adjusted rate.

NOTE: If the rate change is not confirmed within ten seconds, the pump will continue

operation at the original rate and the display will return to the previous setting.

2.

To stop the infusion press

Volume 456 ml

Rate 500 ml/h

Rate 500 ml/h

Volume 456 ml

Press OK to start

36

To change the rate while in Stop mode:

1.

Press first during infusion.

2.

Press any number on the keypad to return to the Continuous screen.

3.

Press to proceed to the rate screen.

Adjust the rate and press .

Adjust the volume and press .

NOTE: During programming you may backspace by using :

Pressing STOP/NO once clears the last entered digit.

Pressing STOP/NO again clears the next number.

Pressing STOP/NO when the value is empty displays the original value or the previous screen.

Volume over Time

NOTE: Before operating the pump in Volume Over Time, make sure that you are in the

Continuous Program and that the IV bag contains an additional 5 ml of volume to be infused.

This ensures adequate volume for KVO during End Program. If Delay Before Start is set, you

must include enough volume for the delay period, in addition to the 5 ml KVO volume.

To set Volume Over Time enable the time function by following the steps below (while pump is “stopped”:

1.

Press twice.

2.

Scroll to "Change set up", then press .

3.

Scroll to "More" and press .

4.

Enter code 901, using the numeric keypad and press .

Volume Infused

View set up

> Change set up

Buzzer Level

> More

Change set up

Technician

Code

XXX

37

5.

Scroll to "Time Option" and press .

6.

Press or , to turn Time Option ON.

7.

Press twice.

8.

If the previous program was not completed, the pump disaplys the following screen:

9.

Do one of the following:

To resume this program, press . The accumulation screen will dispaly the remaining

Volume.

To restart the program and /or set new parameters press and continue as follows:

10.

The screen displays the last set volume.

Do one of the following:

Press to confirm the existing parameters.

Enter the desired volume using the numeric keypad and

press .

NOTE: The screen will be blank upon initial setup.

11.

The screen displays the last set total time.

Do one of the following:

Press to confirm the existing parameters.

Enter the desired total time using the numeric keypad

using the format HH:MM (for example, enter 0-2-0-0 for

two hours) and press .

NOTE: First two digits represent hours and last two digits represent minutes. Use digital

point to move from hours to minutes.

12.

The pump calculates the rate based on the time and volume entered, the accumulation screen is

then displayed. Do one of the following:

Press to confirm the existing parameters and start infusion or enter delay time, if

applicable. For further information regarding delay option – refer to delay program section.

Press to go back to volume setting screen.

Operation Led

> Time Option

Delay Before Start

Volume 500 ml

Total Time 2:00

Resume Press OK

Repeat Press NO

38

13.

During program operation pump displays the time left for the current program in each channel.

The charger will display operation rate on each channel.

NOTE: If one of the values is changed during the programming mode, the pump will not recall

the new value, unless changes are confirmed by pressing .

If prime procedure is activated during data setting, the pump will return to the original

(previous) screen, once priming has completed.

NOTE: Whenever required to stop infusion, press . Stop displayed on screen. Stop

mode is limited for two minutes. After two minutes alarm is sounded. Press to mute.

The specific channel will show the rate on the charger’s display.

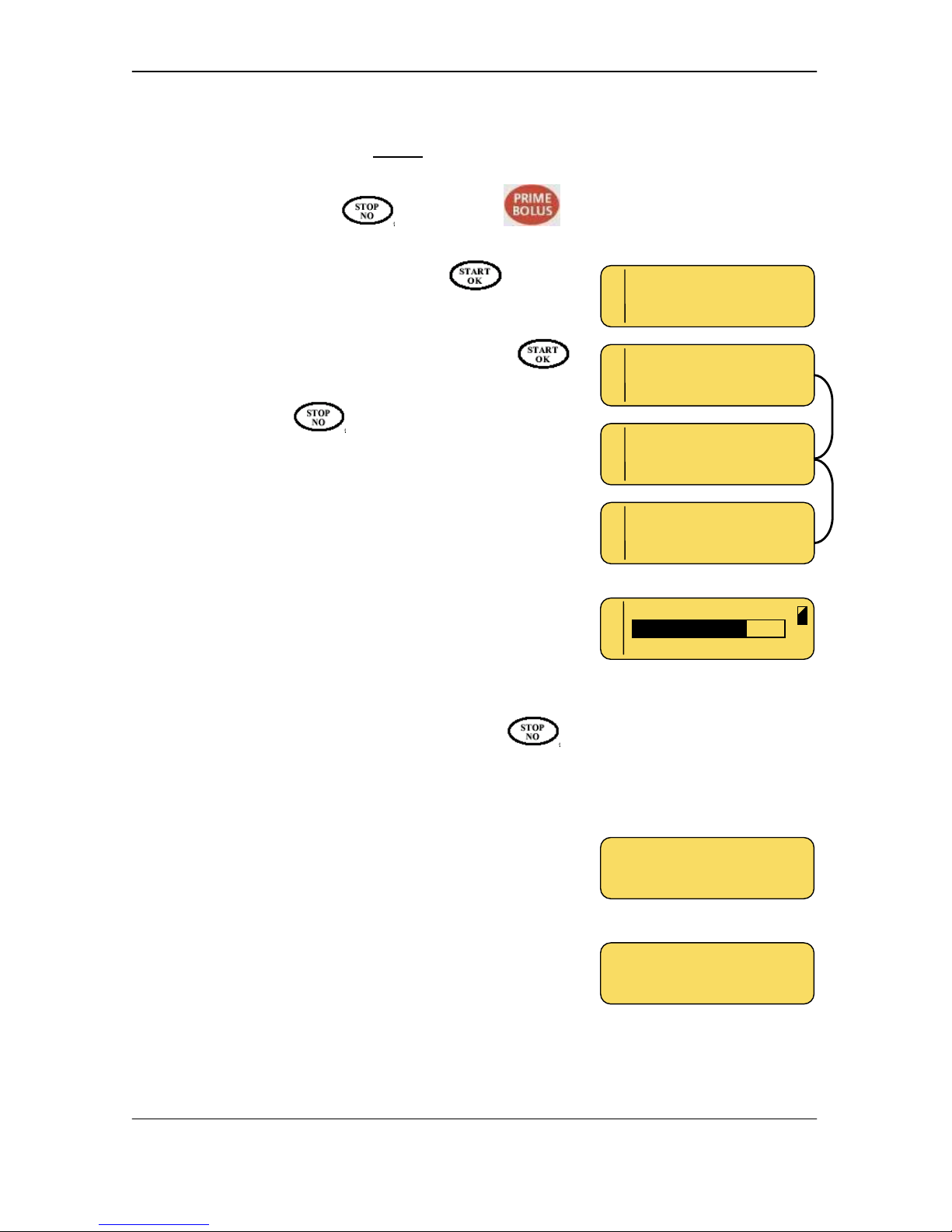

Bolus During Continuous Operation

The pump allows additional Bolus dose during Continuous operation.

1. Press on .

2. Set Bolus volume and press to start Bolus infusion.

3. After bolus is completed, the pump will return to Basic program.

4. User can stop the bolus infusion at any time by pressing

Clinical Bolus

Volume 5 ml

Press OK to start

Volume 5ml

0

2.5

4-Operation – Intermittent Infusion

39

TPN Infusion

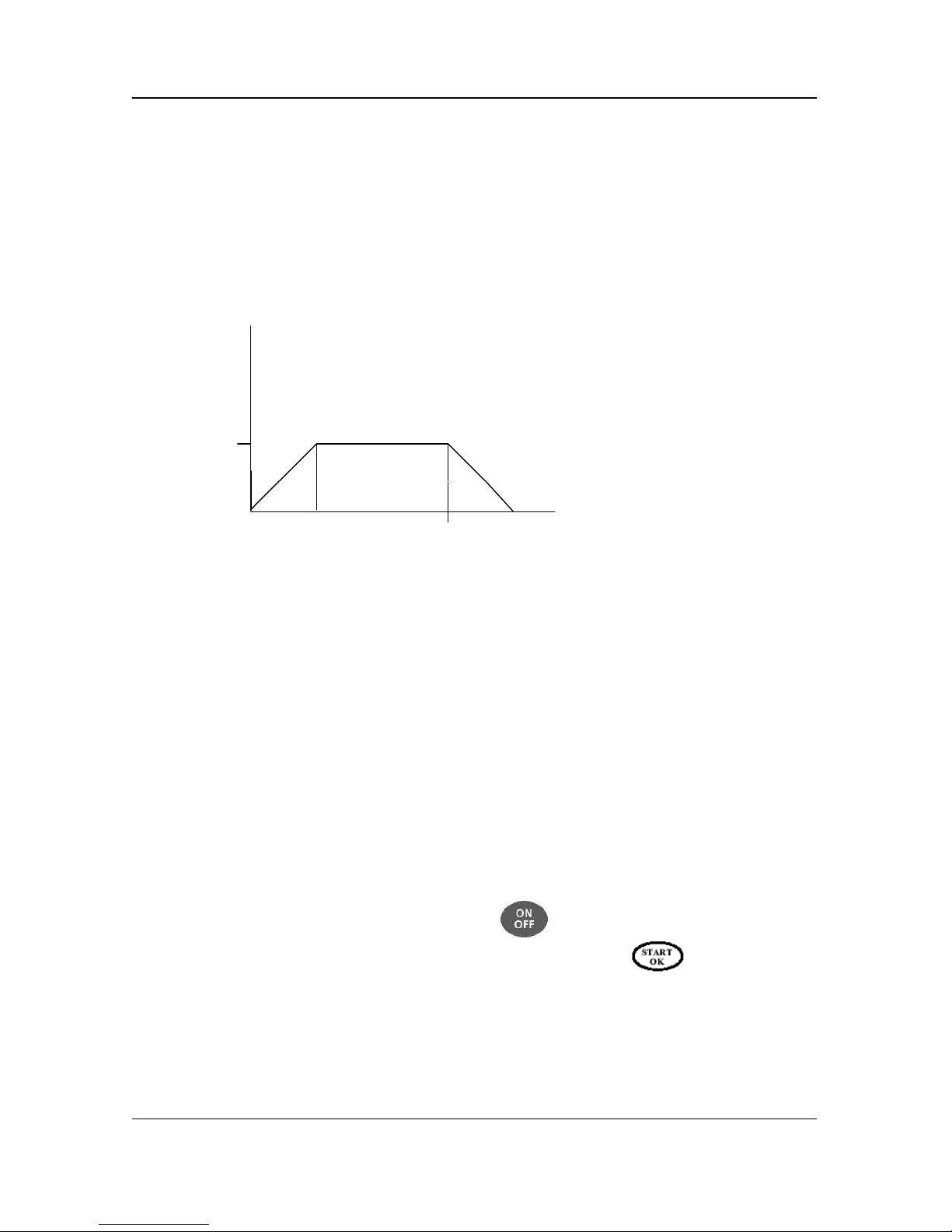

Total Parenteral Nutrition - This mode delivers an infusion while automatically tapering up and down. The

pattern of the program is a trapezoid.

Rate TPN Trapezoid Program

Time

On a TPN Program the operator may set the total volume which corresponds to the size of the bag to be

infused, the total time, and the up and down time. Program operation will start from 2 ml/h and will

increase to the maximal rate. During the flat session (T2) the rate will not change. During the last part of

the program (T3), the program will start to decrease the infusion rate according to the set taper down time.

Up and down time can be set to zero. A TPN program with up and down time set to zero, is a continuous

program.

NOTE: Before operating the pump in TPN program, make sure that the IV bag contains an

additional 5 ml to total volume to be infused. This ensures adequate volume for KVO during

End Program. If Delay Before Start is set, you must include enough volume for the delay period

in addition to the 5 ml KVO volume.

1.

Turn the pump on by pressing and holding the until the self-test screen appears. The

pump display will show channel 1 and the selected program. Press to display the first

TPN screen – “Total Volume”.

T1 T2 T3

Max Rate

T1 = Time UP

T2= Time FLAT

4-Operation – Intermittent Infusion

40

2.

Press . Wait for the Volume screen to display.

NOTE: If pump is not already in TPN Program refer to changing program section for

instructions.

NOTE: Whenever you decide to set a new program, follow instructions at the bottom of each

screen.

3.

If the previous program was not completed, the pump

disaplys the following screen:

4.

Do one of the following:

To resume this program, press . The accumulation screen dispalys. The Volume

remaining will be infused.

To restart the program and /or set new parameters press and continue as follows:

5.

Pump displays the last set volume (volume for the TPN

bag). Do one of the following:

Press to confirm the existing parameters.

Enter the desired volume using the numeric keypad and

press .

NOTE: The screen will be blank upon initial setup.

6.

The screen displays the last set time (total time for the

program to run). Press to confirm the existing

parameters or enter the desired time using the numeric keys

and press .

NOTE: First two digits represent hours and last two digits represent minutes in the format

HH:MM (for example, enter 0-2-0-0 for 2 hr.). Use digital point to move from hours to minutes.

7.

The screen displays the time for rate to taper up. Press

to confirm the existing parameters or enter the

desired value (up to 4:15 h) and press .

Channel 1

TPN PROGRAM

Total volume

__ml

Resume Press OK

Repeat Press NO

Volume 1500 ml

Total Time 12:30

Up Time 01:00

4-Operation – Intermittent Infusion

41

8.

The screen displays the time for rate to taper down. Press

to confirm the existing parameters or enter the

desired value (up to 4:15 h) and press .

9.

The pump calculates the set data and displays the

accumulation screen, including the maximal rate for the

program (to be infused during flat period).

Do one of the following:

Press to confirm the existing parameters and

start infusion or enter delay time, ifapplicable. For further

information regarding delay option – refer to delay program

10.

During program operation pump displays the time left for

the current program and program direction (Up/Flat/Down).

Early Taper Down

If the program must be interrupted early, and the planned taper down time must commence immediately, do as

follows:

1.

During TPN program press Stop/NO key the display will

show STOP.

2.

Press continually (2 sec) to stop the pump operation

and display Taper Down screen.

3.

Do one of the following:

Press to start the taper down process immediately with the existing parameters.

Set time for taper down, using numeric keys and press to start the taper down process.

NOTE: Pressing from taper down screen will start the taper down process

immediately.

NOTE: If one of the values is changed during the programming mode, the pump will not recall

the new value, unless changes are confirmed by pressing .

If prime procedure is activated during data setting, the pump will return to the original

(previous) screen, once priming has completed.

Down Time 0:30

Volume 1500 ml

Maximal Rate: 127 ml/h

Press OK to start

U Rate

P

Taper Down: 0:30

Press OK key

4-Operation – Intermittent Infusion

42

NOTE: Whenever required to stop infusion, press . Stop message is then displayed

on the screen. Stop mode is limited for two minutes. After two minutes an audible alarm

sounds. Press again to mute the alarm.

NOTE: During programming you may backspace by using :

Pressing STOP/NO once clears the last entered digit.

Pressing STOP/NO again clears the next number.

Pressing STOP/NO when the value is empty displays the original value or the previous screnn.

NOTE: user may set TPN PROGRAMS on both channels.

Setting Down Occlusion

1.

Turn the pump on by pressing and holding the until the self-test screen appears.

2.

Pump displays channel 1 and the program selected.

Press . Wait for the Rate screen to display.

3.

Press twice.

4.

Scroll to "Change set up", then press .

5.

Scroll to "Pressure Level" and press .

6.

Press or to adjust the level (high, normal,

low).

7.

Press to store the parameter in memory.

Volume Infused

View set up

> Change set up

Change set up:

> Pressure Level

Buzzer Level

Pressure Setting

High 10 psi

Adjust ↑↓ & press OK

4-Operation – Intermittent Infusion

43

NOTE:

The following pressure parameters can be set:

Low - 5 psi (0.3 bar)

Normal - 7.5 psi (0.5 bar)

High - 10 psi (0.7 bar)

The selected pressure level will remain in memory until it is changed or the pump is

turned off.

In the event a down occlusion situation occurs, the patient is protected by an anti-bolus

feature, which prevents bolus delivery to the patient when the downstream occlusion is

released.

When turning the pump on, the pressure default will be recalled and not the pressure

level.

After down stream occlusion, infusion will restart from the stop point.

Program Delay

The option to delay the program before start can be set in Continuous program, TPN and 25 steps

programs.

Turning the delay option ON:

1.

Press twice from STOP or settings mode.

2.

Scroll to "Change set up" option. Press .

3.

Scroll to "More" and press .

4.

Enter code 901, using the numeric keypad and press .

Volume Infused

View set up

Change set up

Buzzer Level

> More

Change set up

Technician

Code

901

4-Operation – Intermittent Infusion

44

5.

Scroll to select “delay before start” and press .

6.

Turn delay option ON by pressing or .

7.

Press and the screen displays Restart Pump

8.

Press to continue.

Setting delay befor start

1.

After setting the program data pump enables setting the

delay (if applicable).

2.

Use numeric kepad to set delay time (up to 20 hours).

NOTE: pressing without setting delay time will start infusion immediately.

3.

During delay time, pump will operate in KVO mode. Time left will count down until 00:00.

NOTE: After delay time infusion will start automatically.

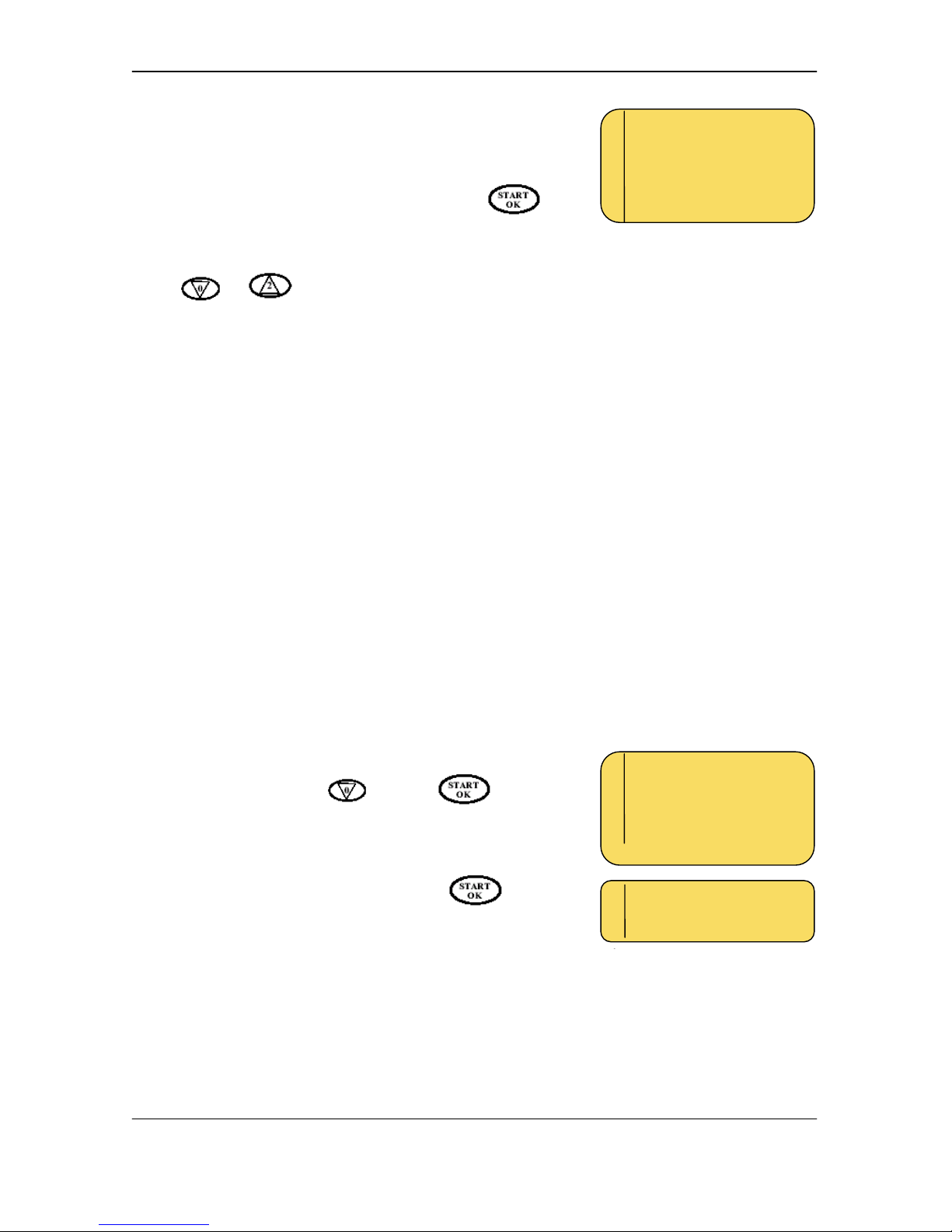

Dose Program

The Dose program is the second program in the BodyGuard software, behind the Continuous program.

Programming the pump using ml/hr in Continuous mode is a standard default setting, yet an operator is

able to quickly select the Dose program in the event that this mode is desired.

The ability to program and adjust medication administration based on dose (mcg/kg/min), and not only

flow rate, provides flexibility for the medical staff and a higher level of safety and care for the patient.

Operating the Dose Program

1.

After power on and Self Test the following screen is appears:

Time option

> Delay before start

Language

Volume 456 ml

Press OK for delay

C Continuous

O Program

N Press No to Change

4-Operation – Intermittent Infusion

45

2.

Press and hold the Stop/No key to enable the program

selection menu. Use one of the arrow keys to scroll to Dose

option and press Start/OK.

3.

In the following four screens the user will have to set the

patient’s weight, the concentration of the drug, the actual

dose, and the volume to be delivered. The first three are the

parameters required to calculate the flow rate in ml/hr. Use

NOTE: Patient Weight is configurable from 0.1 to 250 kg

in 0.1 kg increments.

NOTE: Concentration is configurable from 0.1 to 1000

mg/ml.:

NOTE: Dose is configurable from 0.1 to 999 mcg/kg/min.

To program in mg/kg/min, press Stop/No while the cursor is

blank, and the screen will display the following:

NOTE: At this point, if the rate calculated by the pump is outside the pump’s flow rate range,

which will be .1 to 1200 ml/hr, the pump will deny the user from proceeding to the next screen.

NOTE: As a safety feature, especially in pediatric care, the pump can be configured to have

a Flow Rate Limit option in the Adjust Settings menu. The operator can set the rate so that

under no circumstances can any infusion be programmed over 100 ml/hr, for example.

NOTE: Volume is configurable from 0.1 to 9999 ml (0.1

increments to 99.9 ml, and 1 ml increments from 100 to

9999 ml.)

4.

After inserting the patient’s weight, drug concentration,

dose, and volume to be delivered, two confirmation screens

are displayed. The rate, displayed on the second screen, is

a confirmation number, which is a result of all data

parameters (Note: 6ml/hr is the flow rate calculated by the

pump based on the input parameters).

Press Start/OK to confirm and start the infusion, or

Stop/No to return to the previous screens and change the

input parameters.

Continuous

Dose

D Patient weight?

O 10 kg

S

E Press OK for Conc.

D Weight 10 kg

O Conc 10 mg/ml

S Dose 100 mcg/kg/min

E Press OK to Continue

D Volume 60 ml

O Rate 6 ml/hr

S

E Press OK to Start Infusion

D Volume?

O 60 ml

S

E Press OK to Review

D Concentration?

O 10 mg/ml

S

E Press OK for Dose

D Dose?

O 100 mcg/kg/min

S

E Press OK for Volume

4-Operation – Intermittent Infusion

46

5.

After pressing Start/OK, the pump would begin the infusion

and would display the screen below. The LED would blink

green and the battery icon would be displayed on the right

side of the display screen.

NOTE: Pressing the “Info” key during the infusion will display the following:

Volume Infused (in ml)

Battery Level

Concentration (in mg/ml)

Tube Temperature

Time Left

Actual pressure in psi, that is a bar starting from 0 to 10 showing the actual pressure

6.

Dose Adjustment: The pump allows dose changing during infusion. Use numeric keys to set

the new dose value and press Start/OK within 10 seconds. The pump will briefly alarm and

the infusion will resume at the adjusted dose. For example, the infusion below is running at

100 mcg/kg/min. If the operator wishes to change to 200 mcg/kg/min, he would press “200”,

and press Start/OK within 10 seconds. The second screen below would then be displayed.

Note that the pump displays the new dose and the new flow rate.

Before Change:

After Change:

7.

Bolus operation: In order to program a bolus during the infusion, perform the following steps:

o Press the orange key containing a syringe (this key operates the priming function prior

to programming an infusion and when the pump activates the “Air in Line” alarm).

o The screen will appear as indicated below. Use numeric keys to set the volume of the

bolus.

NOTE: Bolus volume is configurable from 0.1 to 99.9 ml in

0.1 increments

Dose 100 mcg/kg/min

Weight 10 kg

Rate 6 ml/hr

Dose 200 mcg/kg/min

Weight 10 kg

Bolus Volume?

____ ml

Dose 100 mcg/kg/min

Weight 10 kg

4-Operation – Intermittent Infusion

47

NOTE: As a safety feature, especially in pediatric hospitals, the pump can be configured to

have a Max. Bolus Limit option in the Adjust Settings menu.

NOTE: The rate at which the bolus is infused is configurable in the Adjust Settings menu –

it will not be adjustable every time a bolus is initiated.

o After programming the Bolus Volume, press Start/OK

within ten seconds to initiate the bolus. (If the

Start/OK is not pressed the infusion will remain at the

normal rate.) Upon pressing Start/OK within ten

seconds, an audible alarm would sound and the

following screen would be presented, which shows the

progression of the bolus injection. After the bolus is

completed, the screen would revert back to the normal

infusion screen (see Step 5). At any time, user can

press Stop/No to stop the bolus injection.

Intermittent Infusion (Optional)

The Intermittent Infusion program is a special program which enables the design of a dose delivery

protocol at set intervals. Each dose is given at a set time. The pump will “Keep Vein Open” between the

doses. The infusion program continues until the total volume to be infused is delivered.

Rate over Volume

1.

Turn the pump on by pressing and holding the until the Self-Test screen appears.

If air sensor is off, please contact your technician in order to enable the air sensor. Using the pump

with air in line detector off may cause an embolism resulting in death or paralysis. Switching the air

detector off is not recommended and should be used only when absolutely necessary.

2.

Pump displays program name.

NOTE: When pump is in lock out mode, parameters can be viewed, but cannot be changed.

NOTE: If pump is not already in Intermittent Program, refer to Changing Program section.

NOTE: Whenever you decide to set a new program, follow instructions at the bottom of screen.

Channel I

Intermit

Bolus Running

Press No to Stop

4-Operation – Intermittent Infusion

48

NOTE: When returning to a program, the screen will display the last set program.

3.

Bag Volume Screen

Do one of the following:

Press to confirm the existing parameters.

Enter the Bag Volume and press .

4.

Dose Volume Screen

Do one of the following:

Press to confirm the existing parameters.

Enter the Dose Volume and press .

5.

Dose Rate Screen

Do one of the following:

Press to confirm the existing parameters

Enter the Dose Rate and press .

6.

Interval Time Screen

Do one of the following:

Press to confirm the existing parameters

Enter the time between the each dose and press .

NOTE: Interval time is counted from starting time of

7.

KVO Rate Screen

Do one of the following:

Press to confirm the existing parameters

Enter desired KVO rate (from .1 to 5 ml/h), press .

8.

Accumulation Screen

Do one of the following:

Press to confirm the existing parameters and

start infusion.

Press to go back and adjust program parameters.

Interval Time: __:__

Enter & press OK

Dose Vol: 200 ml/h

Dose Rate 200 ml/h

Interval Time 1:00

KVO Rate 0.2ml/h

KVO Rate: __ ml/h

Enter & press OK

Dose Rate: ___ ml/h

Enter & press OK

Dose Vol: ___ ml

Enter & press OK

Bag Vol: 200 ml/h

VolumeLeft 200 ml/h

Infused 1:00

Press OK to continue

Bag Vol: ___ ml

Enter & press OK

4-Operation – Intermittent Infusion

49

NOTE: If pump is in Delay Mode, enter Start Time (24 Hour Clock) and Start Date. For further

information regarding the Delay Option, refer to Delay Program section.

9.

Press to Start Infusion. Delay time option is

disablde, screen will show start time as “Immediate”.

10.

During program operation, the pump displays the rate in

which the program is operating.

NOTE: If one of the values is changed during the programming mode, the pump will not recall

the new value unless changes are confirmed by pressing .

NOTE: If prime procedure is activated during data setting, the pump will return to the original

(previous) screen once priming has completed.

NOTE: Whenever required to stop infusion, press . Stop displays on the screen. Stop

mode is limited to two minutes. After two minutes an audible alarm sounds. Press

again to mute the alarm or press STOP/NO until the pump powers off.

Rate Adjustment

It is necessary to stop infusion in order to change any or all parameters of the current infusion program

To change the rate while in Stop mode:

1.

Press any number on the keypad and then press .

2.

Adjust the rate and press .

3.

Adjust all other parameters and press to restart infusion.

Next Dose

Start Time: Immediate

Press OK to start

Rate

25 ml/h

4-Operation – Intermittent Infusion

50

NOTE: During programming, you may backspace by using :

Pressing once clears the last entered digit.

Pressing again clears the next number.

Pressing when the value is empty displays the original value or the previous screen.

Resume Infusion, Start New Bag, or Reprogram Infusion

When an Intermittent infusion is stopped and the pump is re-started, the operator has the following

options:

(1) Resume: Resume the original infusion exactly where it left off

(2) New Bag: Resume the original infusion with a new bag

(3) Repeat: Repeat or re-program the infusion

1.

Intermittent Stop Screen

Press or to scroll to the appropriate selection

and press .

2.

Resume – New Bag – Reprogram Screen

Display shows a summary of the current infusion to be

started. User can scroll through the details by pressing

or . Press to start infusion.

=<

R

E

S

Resume

New Bag

Repeat

Dose Rate 100 ml/h

Dose Vol. 100 ml

Pause 5:00

Press OK to start

I

N

T

R

4-Operation – Intermittent Infusion

51

Program Delay

The option to Delay Program Before Start can only be used in the Intermittent Mode.

Turning the Delay Option ON

1.

Press twice from STOP or setting mode.

Warning: If air sensor is off, please contact your technician in order to enable the air sensor.

Using the pump with air in line detector off may cause an embolism resulting in death or

paralysis. Switching the air detector off is not recommended and should be used only when

absolutely necessary.

3.

Scroll to "Change Set up" option and press .

4.

Scroll to "More …" and press .

5.

Enter Change Set up level 1 code, using the numeric

keyboard and press .

Volume Infused

Review Set up

Change Set up

Buzzer Level

More …

Change Set up:

Code

Technician

XXX

4-Operation – Intermittent Infusion

52

6.

Scroll to "Delay Before Start" option and press .

6.

Turn delay option ON by pressing or .

7.

Press and the screen displays Restart Pump

8.

Press to continue.

Setting the Time for “Delay Before Start”

After entering the program data, the pump enables setting the Delay Before Start time (when Delay

Before Start is turned ON).

NOTE: The delay time format is a 24 hour clock. This means that hours are viewed as follows

10:00, 11:00, 12:00, 13:00, 14:00, 15:00 etc.

NOTE: The pump automatically displays the current time and date. To start pump

immediately, press to confirm the existing time and date and start infusion.

NOTE: If the time and/or date automatically displayed by the pump are incorrect, go to the

Settings Menu and select “Set Time & Date” to reset the clock in the pump.

1.

Start Time Screen

To change the Start Time, type the desired start time using

the numeric keypad and press . To start pump

immediately, do not change the time and press .

NOTE: To start pump at 9:30 AM, enter 0-9-3-0. To start the pump at 9:30 PM, enter 2-1-3-0.

2.

Start Date Screen

To change the Start Date, type the desired start date using

the numeric keypad and press . To start pump on

the same day, do not change the date and press .

Start Date __/__/__

Press OK key

D

E

Start Time __:__

Press OK key

Time Option

Delay Before Start

Language

D

E

L

A

4-Operation – Intermittent Infusion

53

3.

KVO During Delay Screen

During delay time, pump will operate in KVO mode. Time left

will count down until 00:00 and will then automatically start

the progrmamed infusion. During the delay, this screen will

be displayed showing when the infusion will start.

NOTE: After delay time, pump will beep once then infusion will start automatically.

Turning Pump Off During an Intermittent Infusion

When the pump is turned off during an intermittent infusion, the internal clock in the pump will continue to

monitor the timing of the infusion.

If the pump is stopped during a dose, the operator will be able to resume the dose if the infusion is