Page 1

-

8

-

2

MODEL GL-C

INSTALLATION & OPERATION

Rev. 1.00A

CMA DISHMACHINES

12700 KNOTT AVENUE

GARDEN GROVE, CALIFORNIA 92841

800-854-6417

FAX 714

95

www.cmadishmachines.com

141

Page 2

TABLE OF CONTENTS

MODEL GL-C

1. RECEIVING ...................................................................................................2

2. SPECIFICATIONS.........................................................................................3

3. INSTALLATION.............................................................................................4

3.1. ELECTRICAL .................................................................................................................................... 4

3.2. PLUMBING....................................................................................................................................... 4

4. GLC FLOW DIAGRAM..................................................................................4

5. OPERATION..................................................................................................6

5.1. FILLING THE WASH TANK ............................................................................................................... 6

5.2. OPERATING INSTRUCTIONS ............................................................................................................. 6

3.2.1. Proper Chemical Dosage........................................................................................................ 6

5.3. CLEANING INSTRUCTIONS ............................................................................................................... 7

3.3.1. Daily Cleaning Instructions.......................................................................................................... 7

3.3.2. Weekly Cleaning Instructions....................................................................................................... 7

6. MAINTENANCE.............................................................................................8

6.1. TROUBLESHOOTING......................................................................................................................... 8

7. ELECTRICAL DIAGRAM ............................................................................10

Page 3

Receiving

1. Receiving

1. Remove the packing material from the top of the conveyor stack.

2. Remove all packing material and tape securing components within the machine. Check

that both trays are positioned properly.

3. Check for the following component parts:

A. Check that the deflector screen is secure in the rinse drain.

B. Check the position of the GL-C curtain.

C. Chec k that the conveyor is level and the drive gear is engaged in the conveyor’s outer

rim grooves.

D. Check that overflow drain tube is in position in detergent tank.

E. Check that the detergent tank screen in the detergent tank is in position.

F. Check that the drain screen is in position.

4. Important: Read and follow up instructions completely.

MODEL GL-C Installation & Operation Manual Rev. 1.00A –2/23/06 Page 2

Page 4

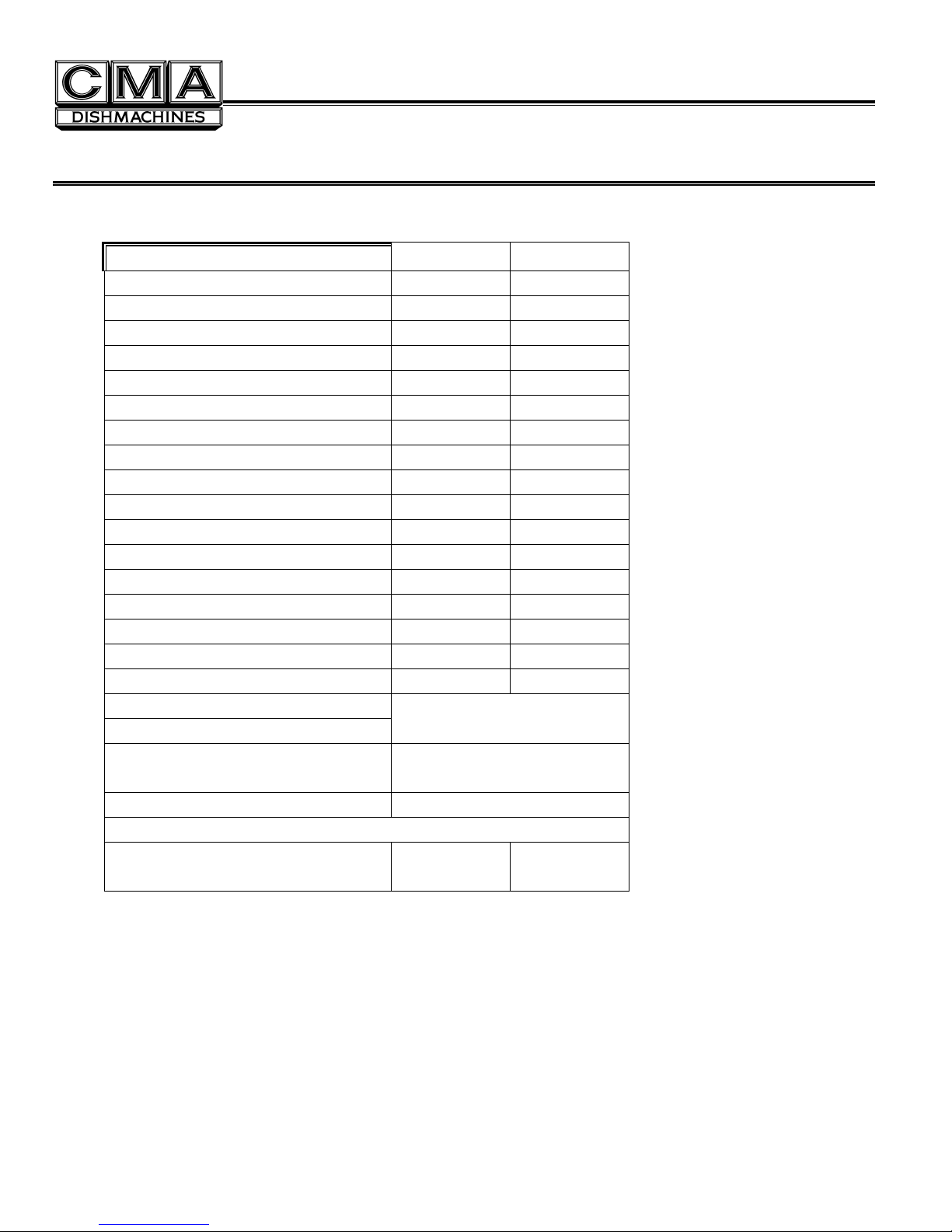

Specifications

2. Specifications

WATER CONSUMPTION

HOT WATER INITIAL FILL 3 GAL. 11.35 L.

HOT WATER PER HOUR (max) 12 GAL. 45.42 L.

COLD WATER PER HOUR 168 GAL. 636 L.

OPERATING CAPACITY

(2-1/2”) GLASSES PER HOUR 1000 -

WATER REQUIREMENTS

COLD WATER INLET 1/2” HOT WATER INLET 1/2” DRAIN CONNECTION 1-1/2” TEMPERATURES

INLET COLD WATER

INLET HOT WATER (recommended)

FRAME DIMENSIONS

DEPTH 25-1/8” 63.8CM

WIDTH 25-1/4” 64CM

HEIGHT 39”-40” 99.1-101.6CM

MAX CLEARANCE FOR GLASSES 10” 25.4CM

ELECTRICAL

TANK HEATER

(Not Booster Heater)

WASH PUMP MOTOR .1HP

SHIPPING WEIGHT

GL-C (Approximate)

156#

75

°F 24°C

140

°F 60°C

240 VAC

15 AMPS

3KW

71 kg

MODEL GL-C Installation & Operation Manual Rev. 1.00 –2/23/06 Page 3

Page 5

Instructions

3. Installation

3.1. Electrical*

A 15 Amp, 240 Volt, 60 Hz dedicated circuit should be used to supply electrical power to the GL-C machine (see

specification sheet page 2). The power connection with the leads L-1,L-2 and Ground must be such that there is

sufficient length of flexible conduit to permit the machine to be moved for cleaning. This machine operates from 208 to

240 Volts.

3.2. Plumbing*

Hot Water Connection

1. Connect a minimum 1/2” water line to the hot water solenoid valve. Supply temperature must be minimum

140°F/60°C,with flow pressure between 25-95 PSI.

2. Hot water consumption is approximately 12 U.S. gph.

Cold Water Connection

1. Connect a minimum 1/2” water line to the cold water solenoid valve. Flow pressure must be between 25-95

PSI.

2. Open ball valve located between hot and cold solenoid valves until temperature reaches 75°F for areas with

very cold rinse water to heat the rinse water which will prevent glasses from cracking.

3. Cold water consumption is approximately 2.8 U.S. gpm.

Drain Connection

1. Connect a 1-1/2” drain line where indicated.

2. PVC pipe is generally recommended, as copper is prone to attack by the sanitizing chemicals.

*Electrical and plumbing connections must be made by a qualified

person who will comply with all available Federal, State, and Local

Health, Electrical, Plumbing and Safety codes.

MODEL GL-C Installation & Operation Manual Rev. 1.00A –2/23/06 Page 4

Page 6

Flow Diagram

4. GLC Flow Diagram

MODEL GL-C Installation & Operation Manual Rev. 1.00 –2/23/06 Page 5

Page 7

Operation

5. Operation

5.1. Filling the Wash Tank

• Ensure that the overflow drain tube is in place in the detergent tank.

• Flip power on-off/flush switch to the “ON” position. The water will fill until the proper level is

reached then turn the heating element “ON”.

• The water temperature is controlled by a heater and a thermostat .The thermostat should be set

for minimum 140°F/60°C.

5.2. Operating Instructions

• Open the door; flip power on-off/flush switch to the “ON” position. Wash tank will automatically fill.

• Ensure there is product in the detergent, sanitizer and rinse agent containers.

• Detergent is fed from the supply container into the detergent tank in controlled am ounts by the

detergent pump. Use detergent at strength recommended by your chemical supplier.

• Load glasses on the conveyor. Start machine with GL-C rocker switch located on front right side of

unit. Machine now will stop and start with conveyor shut-off rod.

3.2.1. Proper Chemical Dosage

The amount of chemical delivered, whether it is detergent, sanitizer or rinse aid, can be obtained by counting

the revolutions of the injector rotors.

• For detergent, contact your chemical supplier for proper type and deterge nt concentration.

Note: Detergent pump only operates when hot water tank is filling.

• For sanitizer, one revolution in 5 seconds equals approximately 12.5ppm Iodin e or 50ppm

chlorine.

• For rinse agent, one revolution in 8 seconds i s re commended.

To Adjust Detergent Injector:

• When a new detergent container is installed, push the prime button in and hold until the detergent feed tube is

full.

• Install the overflow drain tube and switch power on-off/flush switch to the “ON” position. The detergent feeder

will now feed detergent into the detergent tank with water fill.

• To increase detergent volume, turn the detergent adjustment screw clockwise.

• To decrease the detergent volume, turn the detergent adjustment screw counter-clockwise.

To Adjust Sanitizer Injector:

• When a new sanitizer container is installed, push the prime button in and hold until sanitizer feed tube is full.

• Start the washer with rocker switch located on the front of the machine. Take a sample from the final rinse

spray tube to check sanitizer level.

• To increase the volume of sanitizer, turn the adjustment screw clockwise.

• To decrease the volume of sanitizer, turn the adjustment screw counter-clockwise.

To turn rinse agent injector “OFF” in this case, turn the adjustment screw counter-clockwise until the pump

stops turning.

Note: If a sodium Hypochlorite (Chlorine) based sanitizer at a minimum concentra t ion of 50ppm in the final

rinse is used, use chlorine test papers to verify and monitor the 50ppm chlorine level

MODEL GL-C Installation & Operation Manual Rev. 1.00 –2/23/06 Page 6

Page 8

Operation

To Adjust Rinse Agent Injector:

• When a new rinse agent container is installed, push the prime button in and hold until the rinse

injector feed tube is full.

•

•

•

Start the washer. Take a sample from the final rinse spray tubes.

To increase the volume of rinse agent, turn the adjustment screw clockwise.

To decrease the volume of rinse agent, turn the adjustment screw counter-clockwise.

Note:To meet the requirements of N.S.F. standards, Iodophor in a concentration of 12.5ppm

or chlorine at 50ppm must be used in the final rinse.

5.3. Cleaning Instructions

3.3.1. Daily Cleaning Instructions

Remove optional GL-C drain tray & waste collection, from the front of your glasswasher and clean.

Turn glasswasher off by flipping the power on-off/flush switch to the “OFF” position.

Remove right and left trays and GL-C curtain. Wash them with hot soapy water, rinse t horoughly, a nd

then dry.

Remove the conveyor as follows: Remove conveyor hub, flip conveyor shut-off rod to the side, lift

conveyor from the center and pull out.

Remove lower wash and rinse arms. Clean wash and rinse areas with hot soapy water. Rinse

thoroughly, and then dry.

Note: Do not twist spray arms, pull straight out or they will break.

Replace lower wash and rinse arms (they only fit one way). Replace conveyor as follows: With back

end of conveyor raised, mesh drive gear with side of conveyor, pull conveyor towards you until center

of conveyor drops onto pivot. Replace conveyor hub in center of conveyor, flip shut-off bar back to

normal position. Replace left tray ensuring shut-off arm rests within the retainer, then replace right

tray. Replace curtain.

Remove and clean upper and lower wash tank screens.

Remove overflow drain tube from the detergent tank, wash down the interior of the detergent tank.

Replace overflow drain tube and upper and lower wash tank screens.

Note: Do not leave water in tank overnight!!!

Replace optional GL-C drain tray & waste collection making sure hose is connected.

Ensure there is product in the detergent, sanitizer and rinse agent containers. Close the door.

3.3.2. Weekly Cleaning Instructions

Remove upper and lower wash and rinse arms from the manifold and clean spray tubes with Cleaning

Drill p/n 00899.01, Cleaning Brush p/n 00899.02 provided.

Remove detergent, sanitizer, and rinse agent feed lines from containers and place them in a

container of hot water. Hold prime buttons in until the feed lines have been thoroughly flushed.

Replace the feed lines to their proper container and prime product through lines.

MODEL GL-C Installation & Operation Manual Rev. 1.00A –2/23/06 Page 7

Page 9

Maintenance

6. Maintenance

6.1. Troubleshooting

PROBLEM LIKELY CAUSE SOLUTION

Conveyor doesn’t turn

Excessive overspray from

hood section

Lack of pressure in wash

spray tubes

Lack of pressure in rinse

spray tube

Power off at circuit breaker Reset circuit breaker

Drive motor burn out Replace drive motor

Obstruction in wash or rinse

Micro switch on switch support

bracket faulty or not making

contact

Conveyor not in position

Splash curtain not in position Install or adjust

Washer running without any

glasses on conveyor

Spray tubes fallen off hub

Spray tubes plugged Clea r and clean with reamer,

No water in detergent tank

Obstruction in wash arm

Pump not operating

Pump operating but no pressure

Rinse spray tubes dirty

Shut-off valve on supply line

closed

Low water pressure

Remove obstruction

Replace or adjust

Position properly

Keep conveyor loaded with

glasses

Ensure spray tube is pushed

firmly on to hub connection

scraper, and brush

Ensure water supply is on

Ensure detergent tank stand

pipe is in position

Ensure the tank fill switch is in

On-Fill position and that tank

fills with water

Ensure the float switch is

activated by the float cam

Ensure the tank fill solenoid is

operational

Clear obstruction

Check power supply to

machine

Check pump capacitor

Replace pump if required

Check condition of impeller

and stub shaft

Replace if needed

Clean thoroughly with reamer,

scraper, and brush provided

Open valve

Minimum 25PSI flow pressure

required

MODEL GL-C Installation & Operation Manual Rev. 1.00 –2/23/06 Page 8

Page 10

Maintenance

PROBLEM LIKELY CAUSE SOLUTION

Lack of pressure in rinse

spray tube

Water continues to flow to

detergent tank or spray

tubes with machine off

Water temperature low in

detergent tank

Rinse solenoid valve will not

operate

Check coil

Check and install rebuild kit

Replace if necessary

Rinse solenoid valve strainer

Remove screen and clean

plugged

Solenoid valve not sealing Clean seat

Install diaphragm kit

Replace valve

Thermostat setting low

Thermostat defective

Adjust thermostat

Replace

Water on floor around

machine

Chemical containers filling

with water

Chemicals not feeding

Defective float switch

Heater burnt out

Replace

Check and replace

Ensure water level is above

element

Incoming water temp. low

Hot water supply

min.140°F/60°C

Pump seal leaking Replace

Rinse drain in wash area plugged

Clear obstruction, clean

machine

Wash return screen in detergent

Clean

tank plugged

Drain screen under detergent

Clean

tank plugged

Main drain plugged Clean

Detergent tank covers are not

positioned properly causing

Position all top covers to

completely cover top of tank

condensation

Fill chute has lime build-up De-scale detergent tank

Dirty rinse tubes Clean

Worn flow washer in solenoid

Replace

valve

No product in containers Refill containers

Product gelling or crystallizing in

chemical line

Flush all lines with hot water

and use fresh supply of

chemical

Chemical supply strainer plugged

Speed adjustment set too low

Clean with hot water

Increase by turning clockwise

while machine is running/filling

No power to pump

Pump motor defective

Check LED signal

Replace pump motor

MODEL GL-C Installation & Operation Manual Rev. 1.00 –2/23/06 Page 9

Page 11

Electrical Diagram

7. Electrical Diagram

R

O

R

Y

O

E

T

V

O

N

M

O

C

R

P

O

M

T

U

O

P

M

D

I

E

O

H

V

S

N

L

E

A

A

L

W

V

O

S

R

E

T

A

E

H

D

I

E

E

O

V

S

N

L

N

E

I

A

L

R

V

O

S

I

T

E

D

6

8

4

2

C

O

C

N

N

1

5

3

7

B

6

9

3

C

O

C

N

N

1

7

4

A

2

3

1

6

R

F

O

F

H

Y

C

O

-

E

T

I

T

V

U

W

N

H

S

O

S

C

H

T

C

A

T

I

O

L

W

F

S

V

0

4

2

R

E

M

R

V

O

4

F

2

S

N

A

R

T

D

R

A

O

B

T

I

U

C

R

I

C

N

A

S

D

R

A

O

B

T

I

U

C

R

I

C

E

S

N

I

R

D

R

A

O

B

T

I

U

C

R

I

C

R

H

E

C

K

T

I

C

W

O

S

R

MODEL GL-C Installation & Operation Manual Rev. 1.00A –2/23/06 Page 10

H

S

U

L

F

F

R

F

E

O

/

W

N

O

O

P

I

P

R

E

M

R

D

E

E

N

G

T

E

R

T

E

M

I

R

P

R

S

I

N

A

P

E

M

I

R

R

S

E

N

I

R

Loading...

Loading...