Page 1

Rev.2.04

www.cmadishmachines.com

Page 2

Table of Contents

EST-44

1. SPECIFICATIONS................................................................................................. 2

1.1. EST- 44 ........................................................................................................................................... 2

2. GETTING STARTED ............................................................................................ 3

2.1. Introduction to CMA Model EST -44............................................................................................. 3

2.2. Receiving and Installation .............................................................................................................. 4

2.2.1. Box Item List ........................................................................................................................... 4

2.2.2. Electrical ................................................................................................................................ 5

2.2.2.1. Control Box Components ............................................................................................... 6

2.2.3. Plumbing ................................................................................................................................. 7

2.2.4. Scrap Tray Assembly Installation ........................................................................................... 9

2.2.5. Conveyor Drive/ Rack Speed .................................................................................................10

2.2.6. Wash Pump Assembly and Impeller .......................................................................................11

2.2.7. Table Limit Switch Installation ..............................................................................................12

2.2.8. Optional Vent Hood Adapter’s Installation ................................................................ ...........13

2.2.9. Chemical Dispenser Connection ...........................................................................................14

2.2.10. Optional Exhaust Fan Control P/N 13578.00 ......................................................................14

2.2.11. (Optional) E-Temp Booster Heater .......................................................................................15

2.3. EST-44 Safety Tips .......................................................................................................................16

3. OPERATION ........................................................................................................ 17

3.1. Beginning Operation ......................................................................................................................17

3.2. Cleaning Instructions .....................................................................................................................19

3.3. Regular Service and Maintenance Checklist .................................................................................20

3.4. Trouble Shooting ................................ ........................................................................................... 21

4. ELECTRICAL DIAGRAM FOR 230V EST-44 ................................................ 22

5. ELECTRICAL DIAGRAM FOR E-TEMP HEATER ONLY ......................... 23

6. ELECTRICAL DIAGRAM FOR 480V EST-44 ................................................ 24

www.cmadishmachines.com

Page 3

2

1. Specifications

WATER CONSUMPTION

PER RACK (FINAL RINSE)

.46 GAL.

.46 GAL.

PER HOUR (FINAL RINSE)

114 GAL.

114 GAL.

CONVEYOR SPEED

FEET PER MINUTE

6.75

6.75

OPERATING CAPACITY

RACKS PER HOUR (NSF rated)

249

249

OPERATING TEMPERATURE

WASH RECOMMENDED

140° - 150° F

150° - 160° F

PUMPED RINSE RECOMMENDED

140° - 150° F

150° - 160° F

FINAL RINSE RECOMMENDED

140° - 150° F

180° - 195° F

WATER REQUIREMENTS

INLET TEMPERATURE (MIN)

140° F

180° F

WATER INLET SIZE

1/2”

FINAL RINSE SIZE

1/2”

DRAIN SIZE

2”

FINAL RINSE PRESSURE

20 PSI

HEATERS

WASH HEATER

13.3 KW/240V(1 phase)

13KW/208V(3 phase)

RINSE HEATER

3KW/240V, 2.25KW/208V

MOTORS

WASH PUMP

1 HP

RINSE PUMP

1/3 HP

CONVEYOR

1/8 HP

DIMENSIONS

DEPTH

25-1/8”

WIDTH

44”

HEIGHT

55 -1/2”-56-1/2”

STANDARD TABLE HEIGHT

32 ½” adjusts to 34”

MAX CLEARANCE FOR DISHES

19”

VENTILATION REQUIREMENTS CFM

600 Total, 400 at exit, 200 at entrance

STANDARD RACKS

19 ¾” x 19 ¾”

VOLTS

PHASE

AMPS

AMPS(Tall)

ELECTRICAL RATING 208

1

69

N/A

240

1

76

N/A

208

3

53

59

240

3

60

67

480

3

24

27

SHIPPING WEIGHT

662#

(300kg)

High temp

Low Temp

1.1. EST- 44

MODEL EST-44 Installation and Operation Manual Rev. 2 .04 Page

Page 4

Getting Started

3

1. Getting Started

1.1. Introduction to CMA Model EST -44

The EST is designed to give maximum cleaning in 44 inches. It represents the cleaning power

of machines twice its length. The curtains incorporated in the dishwasher minimize the transfer

of water from tank to tank during the wash and sanitizing procedures.

The energy costs for running the new EST-44 have been greatly reduced, by the introduction of

our new Stage Washing Process. The EST-44 Conveyor dishwasher (EST is abbreviation for

ENERGY STAR) lowers gallon/rack ratings and is directly related to CMA’s new Power-Rinse

Stage that has been introduced. The EST-44 new Re-circulating Wash and new Power-Rinse

Stage greatly reduce the amount of chemicals being used, thus adding a significant cost

reduction and energy efficiency to its’ operation.

The EST-44 can be used as a high or low temperature dishwasher, with the new wash tank and

power rinse tank designs, both having their own re-circulating pumps. The Power Rinse Stage

provides a fresh cleansing rinse, before the dish rack advances into the Power Rinse and Fresh

Water and Sanitizing Rinse Stages.

The initial-fill water and the final rinse water that is supplied to the EST-44 must be a minimum of

140°F, in low-temperature applications, while high-temperature machines will require two water

lines; one at a minimum water temperature of 140°F to fill the dishwasher, and the second with a

minimum of 180°F for the final rinse. With the introduction of the new optional E-Temp Booster

Heater, it will be offered fully integrated to the dishwasher.

The EST-44 also features a stainless steel scrap accumulator tank and tray, which must be

emptied on a periodic basis, as necessary. The EST machine is designed to deliver 0.49 gallons

of fresh rinse water for each rack. This water flows from the rinse and power-rinse tanks into the

wash tank, and then overflows into the scrap tray, carrying any debris that may have fallen into

the wash tank, thereby providing a much cleaner environment for the washed and rinsed dishes.

If preferred, there are also options such as a Corner Feed System, optional Vent Hood Adapters,

Exhaust Fan Control Circuits and a Drain Tempering Kit. CMA also offers a full line of other

machine accessories, including stainless steel dishtables. (See equipment catalog)

DISCLAIMERS

CMA expressly disclaims any and all warranties, express or implied, relating to the installation of any and all CMA equipment that

is installed by chemical dealers, contracted servicers or third party servicers to CMA equipment. If the installation instructions

are not followed exactly (to the letter), or, if any person or company conducting the installation of the CMA equipment, revise the

installation procedures or alter the instructions in any manner, the CMA warranty becomes void. If, due to the improper

installation of CMA equipment, this equipment ceases to operate properly or affects other parts of the CMA dishwashing

equipment, in that the other parts become defective, the CMA warranty becomes void. CMA will not be liable or responsible or

warrant CMA equipment, due to improper installation of any CMA model dishwasher.

CMA does NOT endorse “Tankless On-Demand” water heaters for use on CMA Dishmachine products. On most applications, the

volume of hot water required for commercial dishmachines exceeds the capacity of these types of heating sources. You will find

that most, if not all, commercial dishmachines have been programmed with auto-filling features that require quick filling, with a

designated limited time.

CMA DOES endorse, and highly recommends, the standard “tank” style water heaters, sized properly to handle each particular

facility with their water heating requirements. A “tank” style water heater stores and supplies a large capacity of preheated water

before providing hot water to the dishmachine. To meet required health codes, there must be a reliable and consistent flow of

adequate hot water supplied to the dishmachine. If the facilities’ “tank” style water h eater is marginal in size, CMA recommends

installing a proper size Hatco Booster Heater, a CMA’s E -Temp 40 or 70-degree-rise Booster Heater (that can be installed on CMA

Conveyors), or a CMA Temp-Sure Booster Heater (for door and undercounter dishmachines). All are designed to adequately

achieve results.

Important: Make sure incoming power supply corresponds to the voltage listed on the data plate. If the voltage is too low (206V or

less), the heating elements will not reach desired temperature specified by manufacturer, and performance will be compromised.

The heating element needs to be sized according to the facilities available voltage, which must be noted on your purchase order

to CMA for a special dishmachine. Special lower voltage higher kilowatt heaters are available upon request.

Make sure a fused disconnect switch or circuit breaker (not supplied) is installed in the electrical service lines supplying this

dishwasher and should meet the requirements of your local electrical code.

MODEL EST-44 Installation and Operation Manual Rev. 2 .04 Page

Page 5

Getting Started

4

EST-44

1

2

3

EXTERIOR

LONG CURTAIN

DISH FLOW

DISHMACHINE FRONT VIEW

INTERIOR

SHORT

CURTAIN

EXTERIOR

LONG CURTAIN

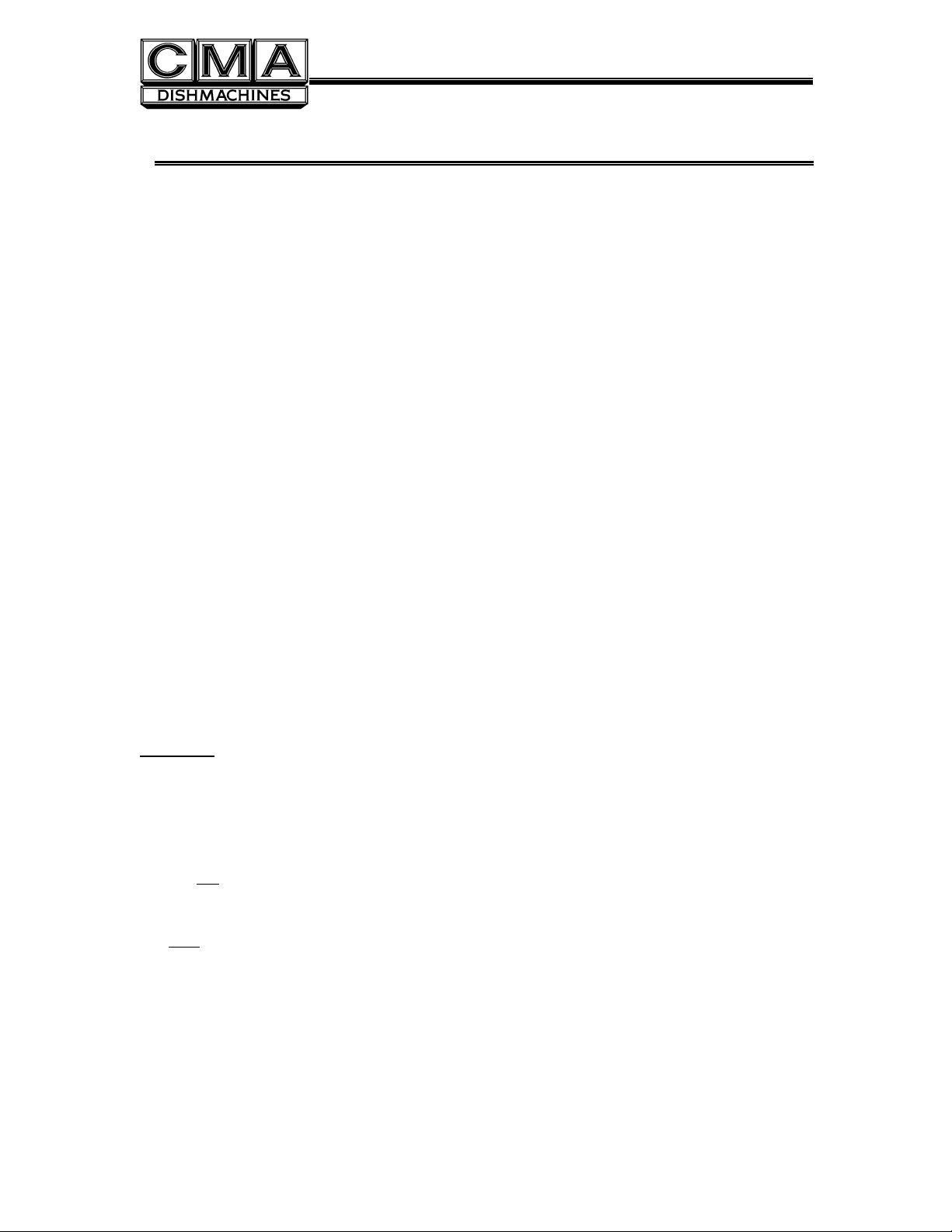

1.2. Receiving and Installation

1.2.1. Box Item List

When you receive your new EST-44, prior to installation of the dishwasher, remove the box

containing the all items needed for the installation. (See item list below)

Literature & Manuals

Instructional Operation Video

Scrap Tank Assembly, w/Mounting Bracket

Curtains Interior and Exterior, w/Rods

Exterior Wrapper Shields

Installation Hardware

Operation Wall Chart

Optional Vent Hood Adapters when ordered.

Start by first installing the Scrap Tray Assembly (see Scrap Tray Assembly, Section 2.2.4),

along with the Overflow Chute, then the two wrapper shields and the exterior and interior

curtains and rods, which are shipped inside the machine. All of the wash-arms are fully

installed over the wash and power-rinse tanks. There are a total of three curtains used in the

EST-44: two long-exterior curtains and one short-interior curtain, all with their own curtain rods.

(See Figure 2.2-1, below)

Figure 2.2.1

MODEL EST-44 Installation and Operation Manual Rev. 2 .04 Page

Page 6

Getting Started

5

Main Power

Knockout

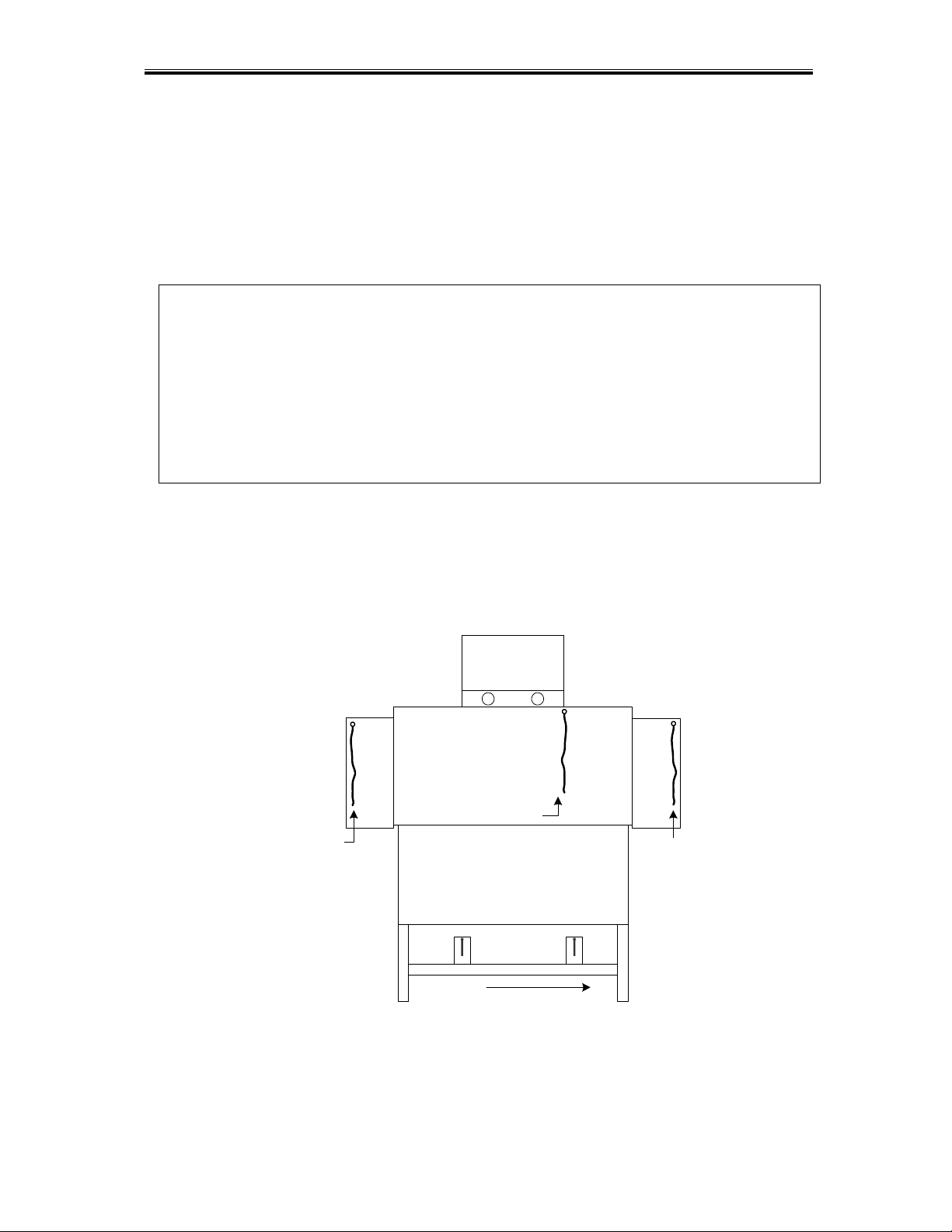

1.2.2. Electrical*

The CMA Model EST-44 Conveyor can be ordered as Single-Phase or Three-Phase, using

208v to 240v. The machine must be connected to a dedicated circuit. (See Figure 2.2.2 below

for amp draw). When installing a Three-Phase machine, check the voltage on all three

incoming lines, and place the highest leg on the L2 terminal. (This is called a high-leg, stingerleg, or Wild-leg.)

Prior to installation make sure the electrical supply is compatible with the specifications on the

machines data plate.

WARNING: Electrical and grounding connections must comply with the applicable portions of the

National Electrical Code and/or other local electrical codes.

Note: For supply connections, use copper wire only rated at 90 degree C minimum.

Warning: To prevent excessive overloads and component damages, it is essential for the

Dispenser Power Supply to be wired to the supplied Power Block on all conveyors. The CMAsupplied power block has been pre-wired to the wash heater contactor L1 and L3 terminals, to

assure a correctly balanced power, as well as accurate surrounding components.

Only for dispensers requiring constant power, connect to L1 and L3 of main contactor;

otherwise, use the Dispenser Power Block that has been provided.

Figure 2.2.2

On a 3-phase machine the water pump motors are also 3-phase and, depending on the terminal

that each phase is connected to, the motor can rotate in either direction. Check the direction of

rotation by removing the dust cap on the back of the motor. The motors must turn clockwise,

when looking at the shaft from the back of each motor. To change the direction of rotation,

switch any two power lead wires at the motor.

DANGER: ALWAYS TURN OFF THE DISHWASHER’S MAIN POWER SUPPLY BEFORE

SERVICING THE DISHWASHER. ALTHOUGH THE MACHINE’S MAIN POWER SWITCH IS

“OFF”, THE MAIN CONTACTOR LEADS WILL STILL HOLD VOLTAGE.

*

Electrical and plumbing connections must be made by a qualified person who will comply with all

available Federal, State, and Local Health, Electrical, Plumbing and Safety codes

MODEL EST-44 Installation and Operation Manual Rev. 2 .04 Page

Page 7

6

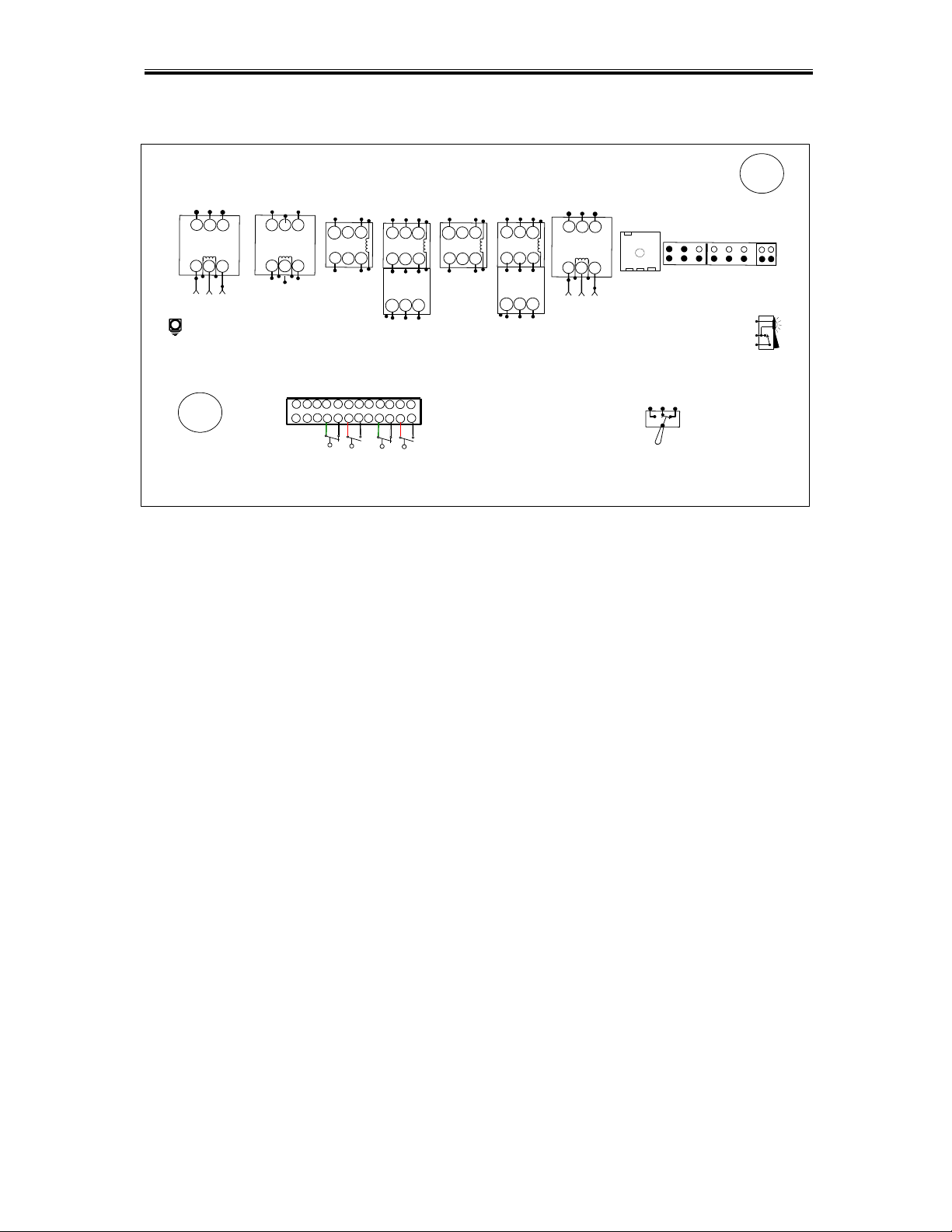

1.2.2.1. Control Box Components

T

1

T2T

3

L1L

2

L

3

POWER

SWITCH

3 2

7

AUT

O

MANUA

L

GROUN

D

123

6

WASH HEATER

CONTACTOR

WASH

TANK

PRE-RINSE

TANK

T1

T2

T3

OVERLOAD

RELAY

95

1

2

3

4

5

6

7

8

T

1

L

1

L

3

T

3

L

2

T

2

A

1

A

2

RINSE HEATER

CONTACTOR

T

1

T

2

L

1

L

2

L

3

T

3

1

A

A

2

RINSE PUMP

CONTACTOR

T

1

L

1

L

3

T

3

L

2

T

2

A

1

A

2

WASH PUMP

CONTACTOR

T

1

T

2

L1L

2

L

3

T

3

1

A

A

2

T1

T2

T3

OVERLOAD

RELAY

95

CONVEYOR

CONTACTOR

MAI

N

CON

TAC

T

O

R

L

3

L

2

L

1

T

3

T2T

1

BOO

STER

H

EATER

CON

T

ACTOR

L

3

L

2

L

1

T

3

T

2

T

1

CHEMICAL

DISPENSER

208-230V

9

10

11

14

16

17 18

19

12

13

15

1.

Main Contactor

11.

Detergent Terminals

2.

Wash Tank Heater Contactor

12.

Dispenser Power Supply Terminals

3.

Power Rinse Heater Contactor

13.

On-Off Power Switch

4.

Power Rinse Motor Contactor w/overload

14.

Auto/Manual Switch

5.

Wash Pump Contactor

15.

E-Temp Power Cable Knockout

6.

Conveyor Contactor w/overload

16.

Main Power Knockout

7.

E-Temp Heater Contactor (Optional)

17.

Wash Tank Float Terminals

8.

Conveyor Timer

18.

Power Rise Float Terminals

9.

Table Limit Switch Terminals

19.

Ground Terminal

10.

Sanitizer/Rinse Terminal Terminals

Getting Started

MODEL EST-44 Installation and Operation Manual Rev. 2 .04 Page

Page 8

Getting Started

7

Main water inlet

valve connection ½”

Final rinse water inlet

valve connection ½”

Pressure

regulator

Vacuum

Breaker

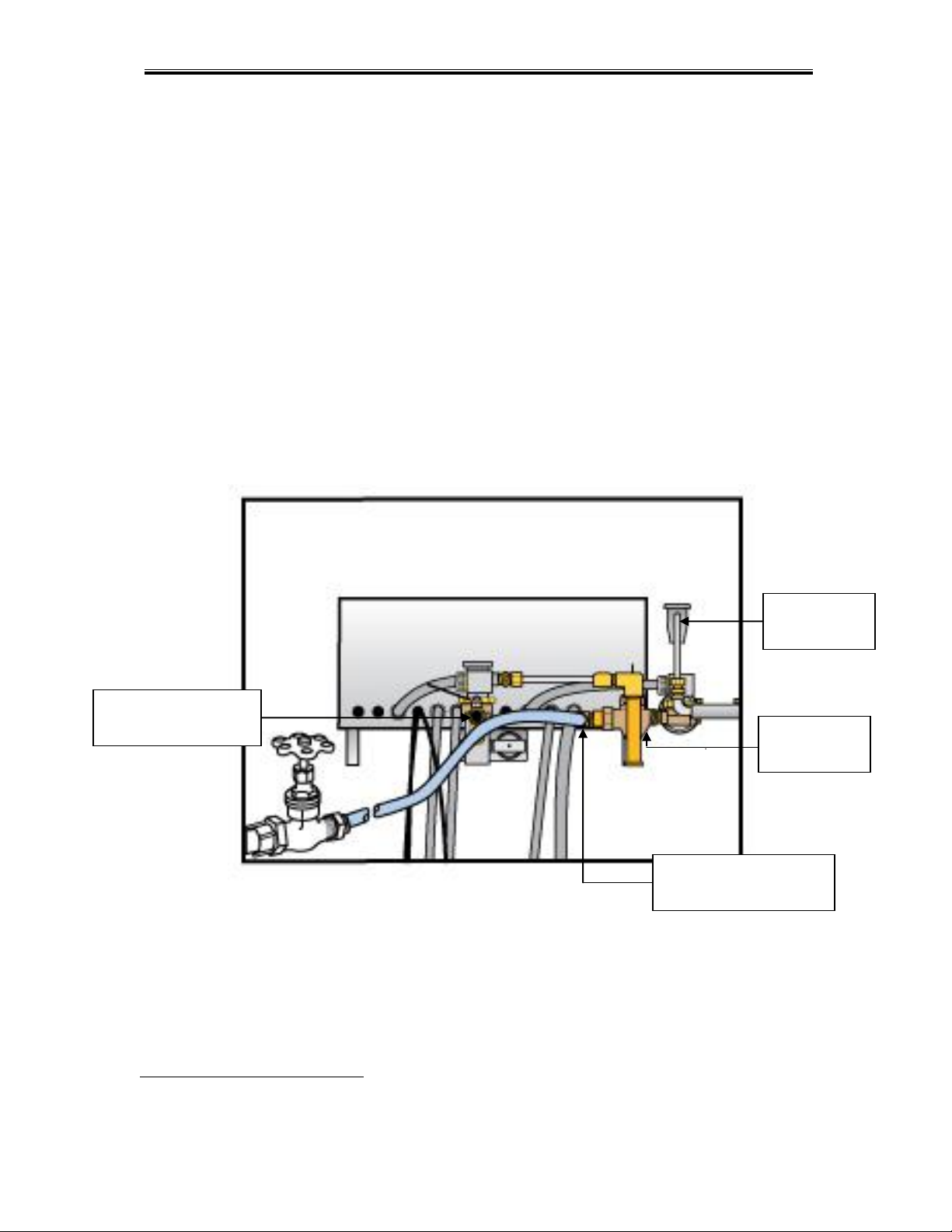

1.2.3. Plumbing*

Note: The required flowing water pressure to the dishwasher is 15-65 PSIG. If pressures higher

than 65 PSIG are present, a pressure regulating valve must be installed in the water line to the

dishwasher (by others). If flowing pressure is lower than 15 psi, improper machine operation may

result.

Notice to Plumber: The plumber connecting this machine is responsible for making certain that

the water lines are THOROUGHLY FLUSHED OUT BEFORE connecting to the dishwasher.

Ask your municipal water supplier for details about your local water conditions prior to installation.

Recommended water hardness is 3 grains per gallon or less.

Note: high iron levels in the water supply can cause staining and may require an iron filter. High

chlorine levels in the water supply can cause pitting and may require a chloride removal system.

If an inspection of the dishwasher or booster heater reveals lime buildup after the equipment has

been in service, water treatment is recommended. If water softener is already in place, ensure

there is a sufficient level of salt.

The water supply connection is made with two ½” hot water lines; the valves are located at the

top of the machine, behind the main control box. The water supplied to the machine must be a

minimum of 140° F to the main fill valve and a minimum of 180° F to 195° F for a high

temperature final rinse, with no more than 140° F for a lower temperature final rinse. (See Figure

2.2.3a below)

Figure 2.2.3a

To set the final rinse pressure, the final rinse must be running. Turn the adjustment screw

clockwise to increase final rinse pressure; and counter-clockwise to decrease the pressure set

the final rinse pressure to 20-psi ±5 psi. (Set to 22 - 23 psi for optimum running pressure)

*

Electrical and plumbing connections must be made by a qualified person who will comply with all

available Federal, State, and Local Health, Electrical, Plumbing and Safety codes

MODEL EST-44 Installation and Operation Manual Rev. 2 .04 Page

Page 9

Getting Started

8

Scrap Tray

Main Drain & Scrap

Drain Connection

Drain Stopper

Cap

Main Drain Line from Wash &

Power Rinse Tanks

There are two 2” drain openings off both ends of the dishwasher, however only one connection

is on the horizontal drainpipe. Place the 2” drain plug, supplied in the end of the pipe not being

connected to the drain line (See Figure 2.2.3.b below).

Note: One of the ends of the horizontal drainpipe has a stopper cap on it – simply move the cap

to the other end, if it’s currently on the end needed for the drain connection.

The Scrap Tray Assembly is placed inside the machine for shipping. Follow the instructions

provided in 2.2.4 Scrap Tray Assembly to properly install to the dishmachine.

Figure 2.2.3b

MODEL EST-44 Installation and Operation Manual Rev. 2 .04 Page

Page 10

Getting Started

9

1.2.4. Scrap Tray Assembly Installation

The Scrap Tray Assembly and Overflow Chute, which were shipped inside the machine, can

easily be installed by executing the following steps: Figure 2.2.4 below illustrates the assembly,

as it would appear for a Left-to-Right machine – (a Right-to-Left machine would simply be the

mirror image).

Caution:

1. For proper spacing, the SS flat washer must not be located between the head of the truss

head bolt and the inside of the machine.

2. The Illustration below shows the correct placements of the scrap trap holder. Do not

install upside down, otherwise water deflection takes place.

Figure 2.2.4

1. Remove items from their packaging and verify that all “installation hardware” was included.

2. Secure the scrap trap holder to the dishmachine by using the four ¼-20 X ½” Hex Head

Bolts, the ¼” SS Flat Washers, and the ¼”-20 Nylon Lock Nuts that were provided.

3. Set the scrap trap body—with the scrap trap drawer inserted—into position on the scrap trap

holder. (Attach the drain as specified in Section 2.2.3)

MODEL EST-44 Installation and Operation Manual Rev. 2 .04 Page

Page 11

Getting Started

10

Conveyor Drive Cam

P/N 13505.14

243 RACKS/HOUR

205 RACKS/HOUR

Conveyor Cam

Bearing

1.2.5. Conveyor Drive/ Rack Speed

The Conveyor Drive Cam below shows the two different conveyor drive cam speed settings; for

standard 243 Racks/Hour and a slower 205 Racks/Hour (See Figure 2.2.5). By changing the

Drive Cam Bearing location, the racks will travel through the machine slower.

Note: If the dishwasher is being used in a very heavy soil environment, changing the rack speed

to 205 racks/hour will slow down the racks as they pass-through the dishwasher, allowing them

to receive more chemical and water “contact time”.

Figure 2.2.5

Caution: DO NOT GET IN THE PATH OF THE CONVEYER DRIVE ASSEMBLY, ROCKER

ARM, OR CONVEYOR BAR, WHILE MACHINE IS IN OPERATION. DO NOT REACH INTO

THE ROCKER ARM ASSEMBLY WITHOUT FIRST MAKING SURE THE DISHWASHER IS

TURNED “OFF” AT THE MAIN PANEL. EVEN WITH THE MACHINE’S POWER SWITCH

“OFF”, THE MAIN CONTACTOR LEADS WILL STILL CARRY VOLTAGE.

MODEL EST-44 Installation and Operation Manual Rev. 2 .04 Page

Page 12

Getting Started

11

1.2.6. Wash Pump Assembly and Impeller

The standard wash pump motor is three-phase and can operate clockwise, as well as counterclockwise; the Nylon Lock Nut used to hold the impeller in place (See Figure 2.2.6), is very

important. When servicing the Wash Pump Assembly and replacing the seals, make sure it is

secured properly; otherwise, if the motor turns the wrong direction, the impeller may spin-off the

motor shaft causing damage to the impeller.

Note: ALWAYS CHECK THAT THE DIRECTION OF THE MOTOR ROTATION IS CLOCKWISE,

WHEN REINSTALLING THE WASH PUMP. IF THE MOTOR IS TURNING COUNTERCLOCKWISE, EXCHANGE L1 AND L3 WIRES ON MAIN CONTACTOR

Figure 2.2.6

Note: The Nylon Lock Nut indicated by the arrow in Figure 2.2.6 must be removed before

attempting to remove the water pump impeller.

MODEL EST-44 Installation and Operation Manual Rev. 2 .04 Page

Page 13

Getting Started

12

1.2.7. Table Limit Switch Installation

The Model EST-44 is shipped with a Table Limit Switch fully wired and connected in the main

control box, ready to be installed on the clean side of the dishtable. The Table Limit Switch

MUST be installed to prevent dishrack and Conveyor Drive damage.

1. Remove the template that was shipped to hold the table-limit switch assembly

together.

2. Remove the activator bar (Figure 2.2.7a).

3. Position the template in the middle of the clean side of the dishtable.

4. Mark the end of the table, where the holes need to be drilled (Figure 2.2.7b).

5. Drill the holes.

6. Attach the Table Limit Switch, using the hardware supplied.

7. Reattach the activator bar removed earlier.

8. Test that it functions properly (Figure 2.2.7c).

Figure 2.2.7a Figure 2.2.7b

Note: This terminal is not actual size ,not to be used

for installation!

Figure 2.2.7c

MODEL EST-44 Installation and Operation Manual Rev. 2 .04 Page

Page 14

Getting Started

13

1.2.8. Optional Vent Hood Adapter’s Installation

CMA Vent Hood Adapters have been designed and engineered to draw only the steam that is

released from underneath the curtains at the entrance and exit of the EST-44 conveyor

dishwasher. This will allow the dishwasher to retain the heat within the machine, reducing the

energy consumption of the dishwasher. To maintain proper CFM’s (600), and not evacuate the

heat from the dishwasher tanks, CMA Vent Hood Adapters (PN # 13901.82) MUST be used.

Note: ON ALL PANT-LEG-STYLE VENT SYSTEMS, BY MODIFYING OR INSTALLING AN

UNAUTHORIZED BRAND OF VENT HOOD ADAPTER, IT WILL VOID THE CMA

MANUFACTURERS’ WARRANTY.

Adjusting the internal baffles of the Vent Hood Adapters:

Once the vent hood adapters have been installed, completely close the internal baffle using two

7/16” wrenches. Run the dishwasher to create heavy steam buildup; start at the exit end of the

dishwasher, open the baffle enough to draw the steam into the vent system. Then repeat the

same process on the entrance side of the dishwasher.

Note: ONLY ONE OF THE TWO NUTS ON EACH BAFFLE IS USED TO TIGHTEN AND KEEP

THE INTERNAL BAFFLE FROM BEING REPOSITIONED.

MODEL EST-44 Installation and Operation Manual Rev. 2 .04 Page

Page 15

Getting Started

14

Sanitizer/Rinse

Signal only

Detergent Signal only

Dispenser Power only

208 to 240 Volts

T1

T2

L1

L2

FAN CONTACTOR P/N 404.81

TERMINAL BLOCK

WIRES FROM THE

POWER SOURCE *

WIRES TO THE FAN

* 220 VAC OR 110 VAC

SUPPLIED BY ELECTRICIAN

DETERGENT SIGNAL

1.2.9. Chemical Dispenser Connection*

The Model EST-44 will supply both the main power and the signals for the Detergent and

Sanitizer/Rinse Aid. Connect the chemical dispenser main power leads, to the supplied power

terminals. (See Figure 2.2.9)

Connect the Detergent and Rinse Aid signal wires to the supplied signal terminals (See Figure

2.2.9)

Figure 2.2.9

Note: Sanitizer/Rinse and Detergent signals can draw more than 0.5 Amps.

Note: Use only commercial-grade detergents and rinse aids recommended by your chemical

professional. Do not use detergents and rinse aids formulated for residential dishwashers.

Low Temperatures chemical-sanitizing dishmachines must not exceed 6% sodium hypochlorite

solution (bleach) as the sanitizing agent. Higher levels may damage stainless or components.

Follow the directions precisely that are on the litmus paper vial and test the water on the surface

of the bottom of the glasses.

1.2.10. Optional Exhaust Fan Control P/N 13578.00

First, when field-installing the Optional Exhaust Fan Control, locate the detergent signal terminals

on the dispenser terminal block; mount the contactor, that was supplied with the kit, securely to

the control box; connect the Blue and Brown wires, also supplied in the kit, to the detergent signal

terminals; attach the power for the exhaust fans to the L1 and L2 incoming terminals of the

contactor, and the T1 and T2 terminals, to the exhaust fan.

Note: Wires for exhaust fan to be supplied by electrician. (See Figure 2.2.10)

Figure 2.2.10

*

Electrical and plumbing connections must be made by a qualified person who will comply with all

available Federal, State, and Local Health, Electrical, Plumbing and Safety codes

MODEL EST-44 Installation and Operation Manual Rev. 2 .04 Page

Page 16

Getting Started

15

1.2.11. (Optional) E-Temp Booster Heater*

The Optional E-Temp Booster Heater can only be ordered with a dishwasher, already installed at

the factory; it cannot be installed in the field. The E-Temp Booster heater will be fully integrated

into the EST-44 conveyors’ plumbing system. It will require its’ own power supply of 208 volts to

240 volts, in single-phase or three-phase. The unit can be specially ordered as a 480-volt unit, in

three-phase only; temperature is available in a 40° rise or 70° rise. The E-Temp Booster heater

contactor is located in the EST-44 Main Control Box (See item 7, page 6).

Note: E-Temp heater is shipped on the machine empty to prevent freezing. When machine

is powered up for the first time, the booster heater must be filled by pressing and holding

rinse switch to prevent heater damage.

Note: 70° degree rise E-temp Booster Heater is only available in Three-Phase.

*

Electrical and plumbing connections must be made by a qualified person who will comply with all

available Federal, State, and Local Health, Electrical, Plumbing and Safety codes

MODEL EST-44 Installation and Operation Manual Rev. 2 .04 Page

Page 17

16

1.3. EST-44 Safety Tips

DANGER:

Always turn off the main circuit breaker at the wall when

installing or servicing this dishmachine and/or an E-Temp

Booster Heater. Even with the machine’s power switch “off”,

there is a live connection being carried to the switch from the

dishmachine contactor.

CAUTION:

Do not get in the path of the Conveyor Rocker Arm or the

conveyor’s moving bar. Do not reach into the rocker arm area

without first making sure the dishmachine is turned “off” at the

circuit breaker.

CAUTION:

Do not open the front door when the machine is in operation.

CAUTION:

Avoid spraying water on or around the electrical control box

located on the top of the machine. When cleaning, do not

spray water directly on the motors.

CAUTION:

When removing the Final Rinse Arms for cleaning, exercise

caution. The Final Rinse Arms may be filled with chemicals or

have additional pressure applied.

Getting Started

MODEL EST-44 Installation and Operation Manual Rev. 2 .04 Page

Page 18

17

Step 1.Close both drains at

the bottom of machine (see

Fig.3.1 items 2,6 above)

Step 2.Turn on main power and

machine will fill with water (see

Fig.3.1 item1 above)

2. Operation

2.1. Beginning Operation

Operation

MODEL EST-44 Installation and Operation Manual Rev. 2 .04 Page

Figure 3.1

Page 19

Operation

18

Wash

Tank

Power-Rinse

Tank

Final Rinse

Temp

150° F

Minimum

160° F

Minimum

180 °to 195° F

Step 3.Allow machine to

come to temperature

Step 4.Rinse rack

thoroughly

Step 5.Place rack in

entrance

Step 6.Remove dishes

from rack

Step 7.Place

properly in rack

Step 8.Pre-soak flatware

Step 9.Wash flatware

Step 10.Place flatware in containers

with handles down; wash a second

time

MODEL EST-44 Installation and Operation Manual Rev. 2 .04 Page

Page 20

19

See Fig.3.1, Items 2,6 See Fig.3.1, Items 4 See Fig.3.1, Items 5 See Fig.3.1, Items 3

2.2. Cleaning Instructions

Operation

MODEL EST-44 Installation and Operation Manual Rev. 2 .04 Page

Page 21

Operation

20

Review installation section before beginning the installation of the Model EST-44

Conveyor Dishwasher. All installation procedures and guidelines MUST BE followed

precisely.

2.3. Regular Service and Maintenance Checklist

Check all electrical connections, assuring they are tight and secure.

Check all Water, Drain, and Plumbing connections for leaks; tighten if needed.

Check Final Rinse Arms: the Rinse Jet Spray should be straight up & down.

Check Wash Pump motor rotation, making sure it is turning clockwise.

Check Dish rack Movement, Conveyor Arm & Bar, and Conveyor Dog Alignment.

Check Tray Track Guide and Rail & Table Alignment throughout dishwasher.

Check Timer Dipswitch Setting; only switch 6 should be in “on” position (32 seconds)

Check Wash-Tank Temperature 150° F Minimum.

Check Power-Rinse Tank Temperature 160° F Minimum.

Check Final-Rinse Temperature 180° to 195° F (High-Temp)

(140° F for Low Temp)

Check Final Rinse Pressure 20 psi, ±5 psi

Check Table-Limit Switch operation (If not installed, Warranty will be voided)

Check Vent Hood adapter baffle position to draw steam. (Optional)

(Keep baffles open to a minimum)

Check and make sure the dishwasher is level.

Check to make sure all curtains are in place.

Read all labeling and follow procedures.

MODEL EST-44 Installation and Operation Manual Rev. 2 .04 Page

Page 22

21

PROBLEM

LIKELY CAUSE

SOLUTION

Wash or power rinse

motor not running

Bad motor or capacitor

Faulty contactor

Replace defective motor or

Replace contactor

Machine inoperative

Fuse is burned out

Replace fuse

Table limit switch

Remove dish rack at switch

Defective door reed switch

Replace reed switch

Defective start reed switch

Replace reed switch

Defective auto/manual switch

Replace switch

Defective Conveyor Timer

Replace timer

Machine runs continuously

Timer or settings@ 60 Sec

Replace timer or change settings

Contactor stuck

Replace contactor

Heater (no heat)

Float switch

Check movement-replace it

Defective thermostat or setting

Replace thermostat or adjust

Defective heater contactor

Replace heater contactor

Defective heater

Replace heater

Wire connections

Check and correct

Racks stuck

Old or broken rack

Replace rack

Tray track alignment

Adjust track to table properly

Wash & Power rinse tank

temperature low

Incoming water supply

(Low temp 120°F-Recommende140°F;

High temp 180°F minimum)

Check hot water supply

Thermostat setting

Adjust thermostat to mach NSF label

Vent hoods baffle setting

Set CMA Vent hood adapter baffles as

instructed on page 13

Low final rinse pressure or

no rinse pressure

Plugged rinse jets

Remove and clean

Pressure regulator out of adjustment

Adjust pressure regulator20psi to 23psi

Water sol. valve coil or diaphragm

Replace or clean

Dirty rinse jets

Remove and clean jets

Defective rinse reed switch

Replace reed switch

Machine using too much

chemical

Quick drain on wash end

Plumb quick drain back into wash tank

Dispenser or settings

Check dispenser troubleshooting guide

Rinse pressure

Set 20 psi.

Soil

Check scrap basket sand float function

Machine loosing water

Quick drain on dirty side table

Check quick drain connections

Sheet pans

Use CMA sheet pan rack

Drain valves open

Close completely

Low wash arm pressure

Debris In wash & power rinse arm

manifolds

Remove arm, check & clean debris from

manifolds

Clogged jets

Clean jets

Motors connected wrong

Connect motors to reverse impeller

direction

2.4. Trouble Shooting

Operation

MODEL EST-44 Installation and Operation Manual Rev. 2 .04 Page

Page 23

Operation

22

T1

L1

L3

T3

T1

T2

L1

L2

L3

T3

PUMP

MOTOR

T1

T2

L1

L2

L3

T3

MAIN

CONTACTOR

T1

T2

T3

L1

L2

L3

L3

L2

L1

T3

T2

T1

1

1

A

2

A

A

2

CYCLE START

TRIP SWITCH

POWER

SWITCH

3

2

7

AUTO

MANUAL

FINAL RINSE

TRIP SWITCH

WATER

SOLENOID

VALVE

RINSE

WATER

SOLENOID

VALVE

DOOR

SAFETY

SWITCH

NOTE 1

NOTE 2, 3

NOTE 4,5

}

220V SIGNAL FOR USER SUPPLIED

FAN MOTOR CONTROL CONTACTOR

COIL.

3 AMP

SLOW BLOW

FUSE (x2)

GROUND

A

2

PUMP

MOTOR

A

A

T1

T2

L1

L2

L3

T3

1

CONV

MOTOR

TANK

HEATER

10kW

T1

T2

T3

OVERLOAD

.4A - .63A

95

1

2

3

6

RINSE

THERMOSTAT

TANK

HEATER

3 kW

L2

T2

A

1

A

2

WIRE DIAGRAM FOR MODEL: EST-44

(230 VAC three-phase, dual floats.)

11/19/2014

Rev. 2.05

WASH HEATER

CONTACTOR

RINSE HEATER

CONTACTOR

RINSE PUMP

CONTACTOR

WASH PUMP

CONTACTOR

CONVEYOR

CONTACTOR

CONVEYOR

TIMER

WASH

THERMOSTAT

WASH

TANK

PRE-RINSE

TANK

3:

CONNECT ONLY TO PRIMARY OF LISTED CLASS 2 TRANSFORMER 208-230V 60Hz MAXIMUM 100VA.

1:

TABLE LIMIT SWITCH CONNECTION PRE-WIRED AT FACTORY.

NOTES:

2:

SANI/RINSE. SIGNAL IS ON WHEN FINAL RINSE IS ACTIVE.

4:

DETERGENT FEEDER SIGNAL AND FAN MOTOR CONTROL CONTACTOR COIL.

6: DISPENSER POWER BLOCK 208-240 VOLTS

CHEMICAL

DISPENSER

208-230V

NOTE 6

5: COMBINED LOAD OF USER DEVICES (CHEMICAL PUMPS, FAN CONTROLS, ETC.) MUST NOT EXCEED 1 AMP.

T1

T2

T3

OVERLOAD

1.6A - 2.5A

95

3. Electrical Diagram For 230V EST-44

MODEL EST-44 Installation and Operation Manual Rev. 2 .04 Page

Page 24

Operation

23

4. Electrical Diagram For E-Temp Heater Only

MODEL EST-44 Installation and Operation Manual Rev. 2 .04 Page

Page 25

Operation

24

T1

L1

L3

T3

T1

T2

L1

L2

L3

T3

PUMP

MOTOR

T1

T2

L1

L2

L3

T3

MAIN

CONTACTOR

T1

T2

T3

L1

L2

L3

L3

L2

L1

T3

T2

T1

1

1

A

2

A

A

2

CYCLE START

TRIP SWITCH

POWER

SWITCH

3

2

7

AUTO

MANUAL

FINAL RINSE

TRIP SWITCH

WATER

SOLENOID

VALVE

RINSE

WATER

SOLENOID

VALVE

DOOR

SAFETY

SWITCH

NOTE 1

NOTE 2, 3 & 5

NOTE 4, & 5

}

220V SIGNAL FOR USER SUPPLIED

FAN MOTOR CONTROL CONTACTOR

COIL.

GROUND

A

2

PUMP

MOTOR

A

A

T1

T2

L1

L2

L3

T3

1

CONV

MOTOR

TANK

HEATER

10kW

1

2

3

6

TANK

HEATER

3 kW

L2

T2

A

1

A

2

WIRE DIAGRAM FOR MODEL: EST-44

w/TRANSFORMER: 480/575/600, DUAL FLOATS.

11/19/2014

Rev. 2.01

3:

CONNECT ONLY TO PRIMARY OF LISTED CLASS 2 TRANSFORMER 208-230V 60Hz MAXIMUM 100VA.

1:

REMOVE JUMPER FOR OPTIONAL TABLE LIMIT SWITCH CONNECTION.

NOTES:

2:

SANI/RINSE. POWER IS ON WHEN FINAL RINSE IS ACTIVE.

4:

DETERGENT FEEDER CONNECTIONS AND SIGNAL FOR FAN MOTOR CONTROL CONTACTOR COIL.

5: COMBINED LOAD OF USER DEVICES (CHEMICAL PUMPS, FAN CONTROLS, ETC.) MUST NOT EXCEED 1.5 AMPS.

WASH HEATER

CONTACTOR

RINSE HEATER

CONTACTOR

RINSE PUMP

CONTACTOR

WASH PUMP

CONTACTOR

CONVEYOR

CONTACTOR

CONVEYOR

TIMER

TRANSFORMER

* AMP FUSE

SLOW BLOW

(x2)

1.25AMP

FUSE

SLOW BLOW

(2)

* 250 VA Transformer:

440 Volt application - 1.8 Amp

480 Volt application - 1.5 Amp

* 350 VA Transformer - 1.8 Amp

RINSE

THERMOSTAT

WASH

THERMOSTAT

WASH

TANK

PRE-RINSE

TANK

T1

T2

T3

OVERLOAD

.25A - .4A

95

T1

T2

T3

OVERLOAD

.63A - 1A

95

5. Electrical Diagram For 480V EST-44

MODEL EST-44 Installation and Operation Manual Rev. 2 .04 Page

Loading...

Loading...