Page 1

Parts Manual

Floor Type Gas Convection Steamer

Series: SteamCraft Model 24CGP10

1333 East 179

Cleveland, Ohio 44110

Phone: (216) 481-4900

1-800-338-2204

Fax: (216) 481-3782

www.clevelandrange.com

th

Street

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

109967

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

CLEVELAND RANGE

SEQUENCE OF OPERATIONS

24CGP10

Mechanical Timer

1. To turn the unit on, depress the red on/off rocker switch.

• 115 VAC is sent to normally open blowdown valve closing it.

• 115 VAC is sent to the Timed/Manual switches for the cabinets.

• 115 VAC is sent to L1 and L2 of the water level board.

2. With the water level board energized and no water in the boiler

• 115 VAC is sent from the IND terminal to the low water indicator light on the console.

• 115 VAC is sent from the WF terminal to the fill solenoid after a 5-second delay.

• The fill solenoid opens and the boiler fills.

• The water fills to the secondary low water cutoff probe in the boiler, shorting it to

ground

• 115 VAC is removed from the IND terminal and the low water indicator light is

de-energized.

• 115 VAC is sent from the HTR terminal through the normally closed contact of

the high-pressure switch to the amber reset switch,

• 115 VAC is sent through the normally closed R1 contacts to energize the amber

light.

• If the low water cut off probe is not grounded for 20 seconds, 115 VAC is

removed from HTR and sent back to IND energizing the low water light.

3. When the momentary amber switch is depressed 115 VAC is sent to the R1 relay closing it.

• The normally closed R1 contacts open de-energizing the amber light.

• The relay latches through the normally closed contacts of R1

• If either the high-pressure switch (set at 15 PSI) or the low probe circuit on the

water level board opens, then the latch circuit opens.

• When the water level or pressure returns to a safe condition the amber light will

energize and the process may begin again.

4. The R1 relay contacts close sending 115 VAC through the normally closed operating

pressure switch to the 24 VAC transformer.

• 24VAC is sent through the low water cutoff float switch to the R2 relay coil.

• The normally open R2 contacts close and send 115 VAC to the fan.

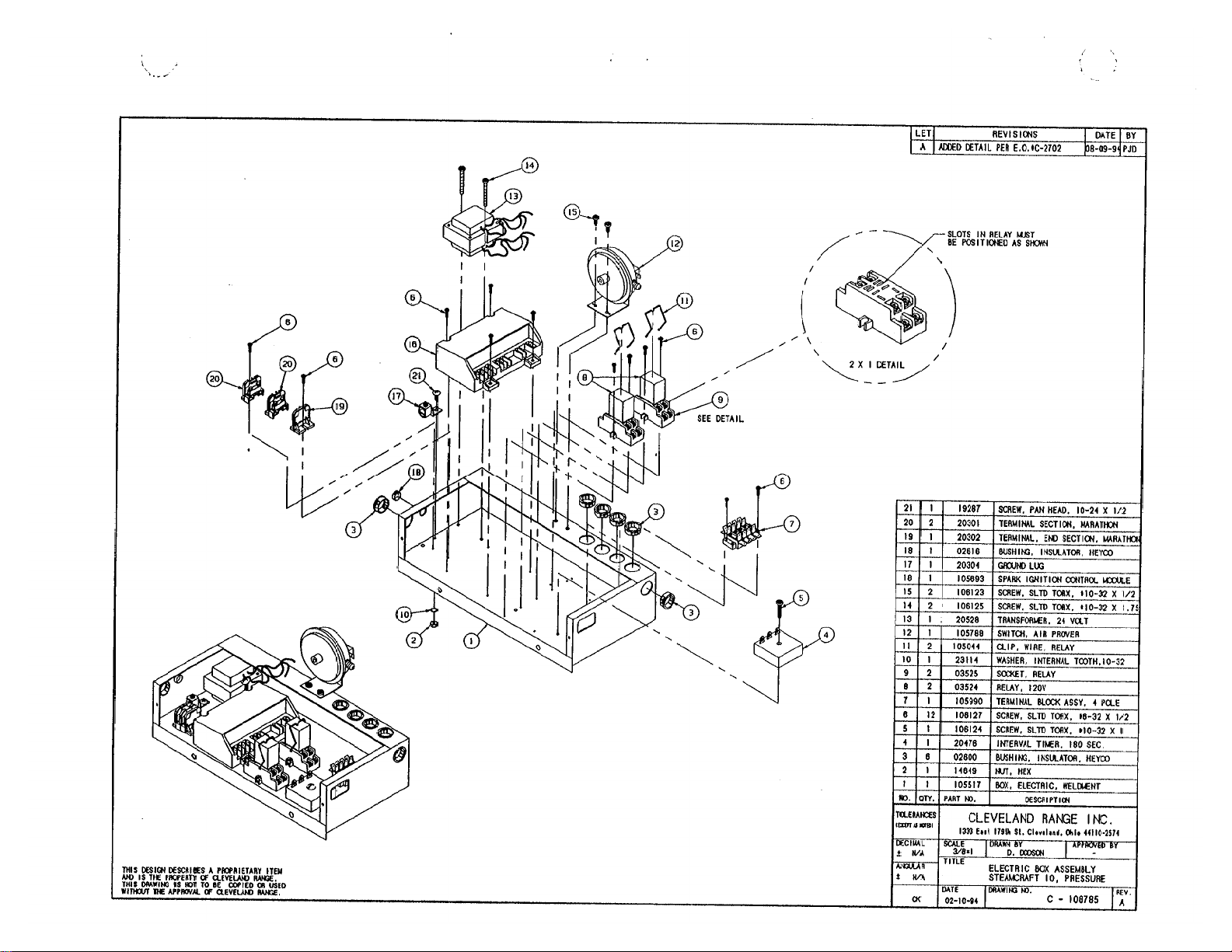

• The fan turns and the air prover switch is closed.

• 24 VAC is sent through the air prover switch to the ignition module.

• With 24 VAC to the ignition module 24VAC is sent to the pilot coil on the gas

valve.

• A spark is generated at the igniter.

• The pilot valve is energized and opens.

• Gas is sent to the pilot burner.

• The gas is ignited and the flame rectifies the AC current.

Page 38

• When the ignition module reads 1.0 micro amps DC current through the

ground wire the coil to the main gas valve is energized

• The pilot flame lights the main burner.

• If the module does not read 1.0 micro amps DC in 90 seconds it will shut

down the main burner and make one more try before locking out.

5. The water in the boiler is heated to steam.

• As steam is generated and pressure builds the air is pushed out through the steamtrap

on the lower steam manifold.

• Steam goes through the steam trap heating it to 192 degrees closing the steam trap.

6. Pressure builds in the boiler to the set point of 8-10 PSI.

• The operating pressure switch opens and the heat circuit is de-energized.

7. With the timed/manual switch in the timed position and time on the timer.

• 115 VAC is sent to the steam solenoid and steam is sent to the cooking cabinet. There

the steam is directed around the product.

• 115 VAC is sent to the “Pause” or “Sure Cook” light.

• 115 VAC is sent to the normally open contacts of the compartment thermostat.

• The normally open contacts of the compartment thermostat close when the

compartment temperature reaches 193 degrees

• 115 VAC is sent to the timer motor and the timer begins to count down.

• 115 VAC is sent to the condensate solenoid and cold water is sent to the condensate

spray nozzle pulling the steam down the drain.

• When the steam pressure drops below the operating set point the heat circuit is

energized and the heat process begins again.

8. Water continues to fill the boiler until the operational water float is lifted and closes, shorting

the HI terminal on the water level board to the C terminal. .

• When the HI terminal is shorted to the C terminal the WF terminal on the water level

board is de-energized.

• If the water level drops below the operational water float switch for more than 5

seconds the WF terminal is energized and the water fill circuit begins again.

9. When the mechanical timer counts down:

• 115 VAC is removed from the condensate circuit.

• 115 VAC is removed from the steam solenoid.

• 115 VAC is sent to the 3-second timer

• 115 VAC is sent from the 3-second timer to the buzzer for 3 seconds.

10. With the timed/manual switch in the Manual position

• 115 VAC is sent to the steam solenoid and steam is sent to the cooking cabinet. There

the steam is directed around the product.

• 115 VAC is sent to the “Pause” or “Sure Cook” light.

• 115 VAC is sent to the normally open contacts of the compartment thermostat.

• The normally open contacts of the compartment thermostat close when the

compartment temperature reaches 193 degrees

Page 39

• 115 VAC is sent to the condensate solenoid and cold water is sent to the condensate

spray nozzle pulling the steam down the drain.

• When the steam pressure drops below the operating set point the heat circuit is energized

and the heat process begins again.

11. The unit is turned off by depressing the red rocker switch.

• 115 VAC is removed from the timing and heat circuits.

• 115 VAC is removed from the normally open blowdown valve allowing the unit to

drain.

• 115 VAC is sent to the 3-minute timer.

• The three-minute timer will energize the fill and rinse solenoids for 3 minutes while

the steamer drains assisting and cooling the blowdown. .

Page 40

Page 41

Page 42

CLEVELAND RANGE

SEQUENCE OF OPERATIONS

24 CGP 10

Electronic Timer

1. To turn the unit on, depress the red on/off rocker switch.

• 115 VAC is sent to normally open blowdown valve closing it.

• 115 VAC is sent to the 24 VAC transformer to the timer.

• 24 VAC is sent to the timer.

• 115 VAC is sent to the Timed/Manual switches for the cabinets.

• 115 VAC is sent to L1 and L2 of the water level board.

2. With the water level board energized and no water in the boiler

• 115 VAC is sent from the IND terminal to the low water indicator light on the console.

• 115 VAC is sent from the WF terminal to the fill solenoid after a 5-second delay.

• The fill solenoid opens and the boiler fills.

• The water fills to the secondary low water cutoff probe in the boiler, shorting it to

ground

• 115 VAC is removed from the IND terminal and the low water indicator light is

de-energized.

• 115 VAC is sent from the HTR terminal through the normally closed contact of

the high-pressure switch to the amber reset switch,

• 115 VAC is sent through the normally closed R1 contacts to energize the amber

light.

• If the low water cut off probe is not grounded for 20 seconds, 115 VAC is

removed from HTR and sent back to IND energizing the low water light.

3. When the momentary amber switch is depressed 115 VAC is sent to the R1 relay closing it.

• The normally closed R1 contacts open de-energizing the amber light.

• The relay latches through the normally closed contacts of R1

• If either the high-pressure switch (set at 15 PSI) or the low probe circuit on the

water level board opens, then the latch circuit opens.

• When the water level or pressure returns to a safe condition the amber light will

energize and the process may begin again.

4. The R1 relay contacts close sending 115 VAC through the normally closed operating

pressure switch to the 24 VAC transformer.

• 24VAC is sent through the low water cutoff float switch to the R2 relay coil.

• The normally open R2 contacts close and send 115 VAC to the fan.

• The fan turns and the air prover switch is closed.

• 24 VAC is sent through the air prover switch to the ignition module.

• With 24 VAC to the ignition module 24VAC is sent to the pilot coil on the gas

valve.

• A spark is generated at the igniter.

• The pilot valve is energized and opens.

Page 43

• Gas is sent to the pilot burner.

• The gas is ignited and the flame rectifies the AC current.

• When the ignition module reads 1.0 micro amps DC current through the

ground wire the coil to the main gas valve is energized

• The pilot flame lights the main burner.

• If the module does not read 1.0 micro amps DC in 90 seconds it will shut

down the main burner and make one more try before locking out.

5. The water in the boiler is heated to steam.

• As steam is generated and pressure builds the air is pushed out through the steamtrap

on the lower steam manifold.

• Steam goes through the steam trap heating it to 192 degrees closing the steam trap.

6. Pressure builds in the boiler to the set point of 8-10 PSI.

• The operating pressure switch opens and the heat circuit is de-energized.

7. With the timed/manual switch in the timed position (with time on the timer) or in the manual

position:

• The timer display alternates between “PAUS” and the time set.

• 115 VAC is sent to the steam solenoid and steam is sent to the cooking cabinet.

There the steam is directed around the product and pulled down the drain by the

condensate spray.

• When the cooking compartment reaches 193 degrees internally the thermal switch

closes and the timer begins to count down.

• 115 VAC is sent to the condensate solenoid. The condensate solenoid sends cold

water to the condensate spray nozzle pulling the steam down the drain.

• When the pressure drops below the set point the heat circuit is energized and the heat

process begins again.

8. Water continues to fill until the operational water float is lifted and closes, shorting the HI

terminal on the water level board to the C terminal. .

• When the HI terminal is shorted to the C terminal the WF terminal on the water level

board is de-energized.

• If the water level drops below the operational water float switch for more than 5

seconds the WF terminal is energized and the water fill circuit begins again.

9. When the electronic timer counts down:

• 115 VAC is removed from the condensate circuit.

• 115 VAC is removed from the steam solenoid

10. With the timed/manual switch in the manual position

• 115 VAC is sent to the steam solenoid and steam is sent to the cooking cabinet and

around the product.

• 115 VAC is sent to the normally open contacts of the compartment thermostat.

Page 44

• The normally open contacts of the compartment thermostat close when the

compartment reaches 193 degrees.

• 115 VAC is sent to the condensate solenoid and cold water is sent to the condensate

spray nozzle pulling the steam down the drain.

11. The unit is turned off by depressing the red rocker switch.

• 115 VAC is removed from the timing and heat circuits.

• 115 VAC is removed from the normally open blowdown valve allowing the unit to

drain.

• 115 VAC is sent to the 3-minute timer.

• The three-minute timer will energize the fill and rinse solenoids for 3 minutes

while the steamer drains assisting and cooling the blowdown. .

Page 45

Page 46

Page 47

PROBLEM:

24CGP10 Boiler

won't build

pressure

Replac e the

water boar d .

Replac e the

water boar d

Repair

or Replace th e

probe circuit.

Replace R2

relay

Yes

No

Yes

See

Steamer won' t

fill.

Is the red "Low

Water" light on

with a j u mp er from

terminal s LO W

and C on the wat er

board?

No

Repair

or Replace th e

probe circuit.

Is there 120 VAC

between ter m i nals

L2 and HTR on t h e

water boar d wi t h a

jumper b etween

LOW and C?

Replace the R1

relay

Boiler won't build

Is the r ed l i g ht on

in the on/off

Is there water in

No

the sight glass?

Is the red "Low

Yes

Water" light on ?

Is the Amber ligh t

on in t h e r es et

Is there 120 VAC

terminals L2 and

No

HTR on the water

Is there 120 VAC

No

to the Reset

Replac e the

Reset switch

pressure

switch?

Yes

Yes

No

switch?

No

between

board?

Yes

switch?

Yes

Is there 115 VAC

No

to the s t eamer?

After depressing

the reset switch,

Yes

does th e A m ber

light go off?

Is there 120 VAC

to the pri m ary of

the 24 VAC

transformer?

Is there 2 4 V A C at

the secon dar y of

the transformer?

Yes

Replac e the

on/off rocker

switch

Yes

ignition

Yes

No

No

Is there 120 VAC

to the pri m ary of

transformer wit h

No

pressure switch

No

Connect 115

VAC to

steamer.

Replace

the high limit

pressure

switch

Yes

With the High

Limit pressu r e

switch

temporarily

bypassed , does

the Am b er li g h t g o

off when the reset

switch is

depressed?

the ignition

the operatin g

temporarily

bypass ed?

Yes

Replac e the

ignition

transformer

No

Replace the R1

No

the operating

Replace the R1

relay.

relay

Replace

pressure

switch

Yes

Is there 2 4 V A C to

coil of R2?

No

Replace float

switch

Is there 120 VAC

No

Replac e the

to blower ?

Yes

blower

No

Is the blower

turning?

Yes

Replace t he air

prover s w it ch

Is there 2 4 V A C at

No

ignit ion module?

Is there fl am e at

the burner?

Is there allot of

steam comi n g ou t

the drain?

Replac e the

steam t rap

Yes

Yes

Yes

Yes

No

No

See Boiler

won't ignite.

With

flame and water the

Boiler is makin g

steam. Chec k for

leaks.

Page 48

PROBLEM:

24CGP10

Gas boiler

won't fill

Boiler won't fill.

Yes

Is there 115 VAC

to the s t eamer?

Yes

No

Supply 115

VAC to the

steamer.

Replac e the

wiring to th e fill

solenoid.

Is there w at er to

Is there 120 VAC

between the L1

120 VAC between

L2 and WF on the

120 VAC across

No

the coil of t h e fill

the s t eam er?

Yes

and L2 on the

water board ?

Yes

Is there

water board ?

Yes

Is there

solenoid?

No

No

No

Supply cold

water to the

steamer.

Replac e the

on/off rocker

switch .

Remove

the wire f r om t h e H I

terminal on the water

board. I s t h er e 12 0

VAC between L2 and

Replace float

switch

WF?

Yes

No

Replac e the

water boar d

Replace wiri n g

to drain

solenoid.

Replac e the

wiring to the

intermittent

blowdown

timer .

No

the s t eam er have

blowdown timer?

No

there 120 VAC

between ter m i nals

2&3 on the timer?

Replace t h e fill

solenoid

Does

the opt i onal

intermittent

Yes

Is

Yes

Replac e the

intermittent

blowdown

timer.

No

No

Yes

Is

water leaving the

fill solenoid?

Yes

Is there

120 VAC across

the coil of the

drain valve?

Yes

Is water draining

from the

generator?

Yes

Replac e the

drain valve.

No

If water

is leaving the fill

solenoid and not

draining from th e

generator wh er e is it

going? check for

leaks..

Page 49

Replac e the

gas valve.

PROBLEM:

24CGP10

Gas boiler

won't ignite

Replace pilot

assy and ignition

wire

Boiler won't heat.

start

Is there 2 4 V A C to

the ignition

module?

Yes

Is there s p ark t o

the igni t er and 2 4

VAC to the pilot

coil of th e gas

val ve f or 9 0

seconds ?

No

No

See Boiler

won't build

pressure.

Replac e the

ignit ion module

Supply gas to

the Steamer .

Is there gas to th e

No

Yes

unit?

Is there gas to th e

No

pilot assy?

Replac e the

gas valve

Yes

Is there fl am e at

No

the pilot assy?

Is there at least

1.0 micro amp DC

ground terminal at

Is there 2 4 V A C to

the main valve coil

Yes

on gas valve?

Yes

Yes

to the burner

the ignition

module?

Yes

After replacing the

ground wire to the

burner ground

terminal , is th er e

No

1.0 micro amp DC

to the ignition

No

Replac e the

ignit ion module

module?

Yes

No

Replac e the

pilot as sy and

ignition wire

PROBLEM: 24CGP10 Gas Boiler Overfills

Boiler over fills

With a jumper

across termin als

HI and C on the

water boar d , is

there 120 VAC

between L2 and

WF?

No

Replace the float

switch.

Replace t h e fill

solenoid

With water in th e

sight glas s is t h er e

120 VAC between

No

terminals L2 and

WF on the water

Yes

board.?

Yes

Replac e ;th e

water boar d

Page 50

PROBLEM:

24CGP10

Gas Boiler Over

Pressurizes

(15# Safet y

valve opens)

Boiler over

pressurizes

Replace

operating

pressure

switch

Does operatin g

pressure switch

open at pr oper

No

setting (chec k

service manual f or

that st eam er)?

Replac e the

safety valve.

Yes

No

Does the burner

continue to burn

with operating

pressure switch

open?

No

Does the pressure

in the gauge

continue to ris e

with no burners

on?

PROBLEM: 24CGP10 Stops Producing Steam

Yes

Replac e g as

valve.

Descale boilerYes

Replac e the

operating p r es sur e

switch

Yes

Does th e s t eamer start t o

steam when the operatin g

pressure switch is

temporarily by-pass ed?

No

The

ignit ion module

has gone into

lockout. See

Boiler won't

ignite

Steamer stops

steaming

Does the Boiler

build pressure?

Does th e am ber

No

light in the reset

switch come on?

Is the temperature

sensitive dot

(surrounded by a

yellow ci r cle) on

the water board

white?

No

Yes

No

With the cabinet in

the ti m ed p os i t i on and

Yes

Yes

time on the timer is

the 120 VAC t o th e

steam s olenoid?

Is the low water

indicator on (120

terminals on the

Replace S t eam

Solenoid

Yes

VAC bewtween

the IND and L 2

waterboard )?

Replac e the

With the cabinet in

the manual

postion is ther e

No

120 VAC to the

steam s olenoid?

Replac e the

water boar d

Does th e low

water in d i cator

light go off with a

jumper btween the

Yes

LOW and C

terminals on the

waterboard?

timer

Yes

No

No

Yes

Replac e the

door swit c h

Yes

With the optional

door switch by

passed, is th er e

120 VAC to the

steam s olenoid?

No

Replac e the

timed/manual

switch

Clean or

replace the low

water probe

Replace

the water board. I t h as

reached a temperatur e of

over 180

degrees.

No

Is high pressure

switch opening

prematurely?

No

Delime the

boiler

Yes

Replace high

pressure switch

Page 51

PROBLEM:

24CGP10

Timer displays "PAUS" ("Sure Cook" light is on) and won't count down

START

Is steam heati ng

Replac e the

thermo-switch

cabinetabove 192

degrees (the set

thermo-switch)?

count down when

Yes

the thermo-switch

the cook i n g

No

temp of the

Yes

Does the timer

No

is bypassed?

See

24CGP10 Stop s

Producing

Steam

Replac e the

timer

Steam Leaks

Around Door

Is COLD water

supplied to th e

steamer?

Yes

Is the door gas k et

phys ic ally

damaged?

Yes

Turn over the

gasket or

replace it.

No

No

Supply

cold water (35-

60 PSI) to the

steamer.

Is the door ou t of

alignment ?

Yes

Replac e the

door bearings

and pins.

PROBLEM:

24CGP10

Steam leaks around the door.

Is there 120 VAC

No

Is the drain

obstructed?

Yes

Remove the

obstruction

across the coil of

No

the condensate

Is the solenoid

solenoid?

Yes

opening?

No

No

Replac e the

compartment

thermostat

Replac e the

condensate

solenoid.

Yes

Replac e the

condensate spray

nozzle

Page 52

1333 East 179th Street

Cleveland, Ohio 44110

Phone: (216) 481- 4900

Fax: (216) 481- 3782

Page 53

Page 54

Page 55

Page 56

Page 57

Loading...

Loading...