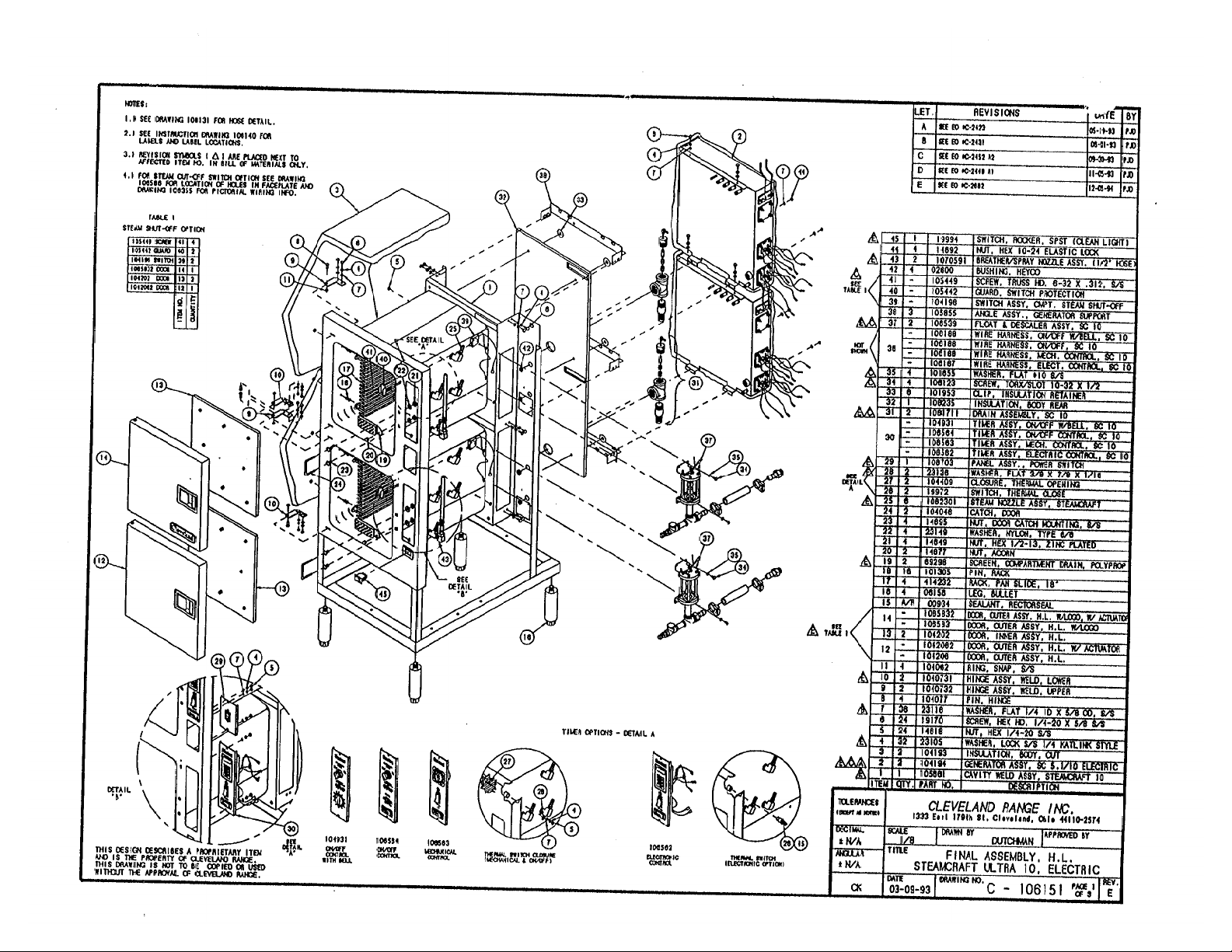

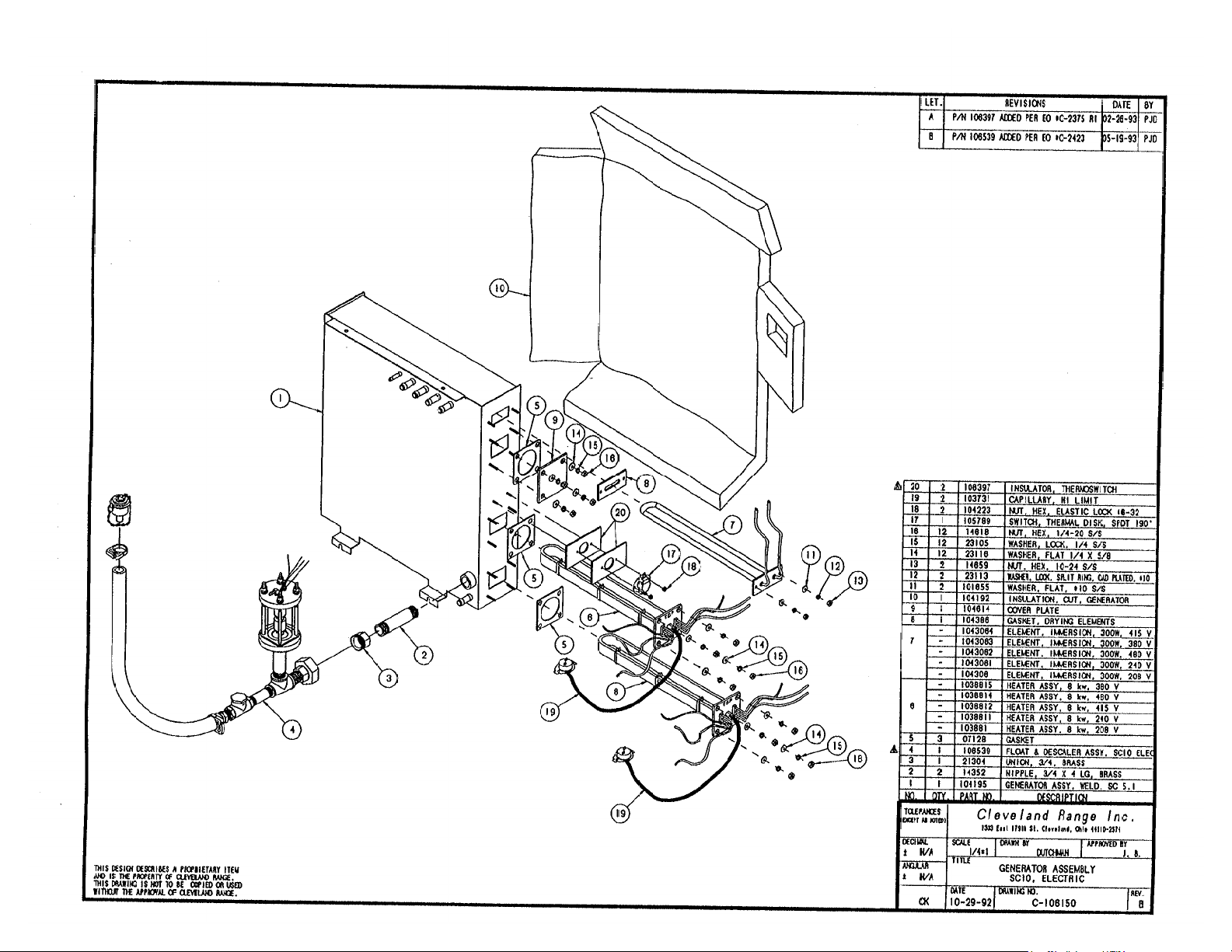

Page 1

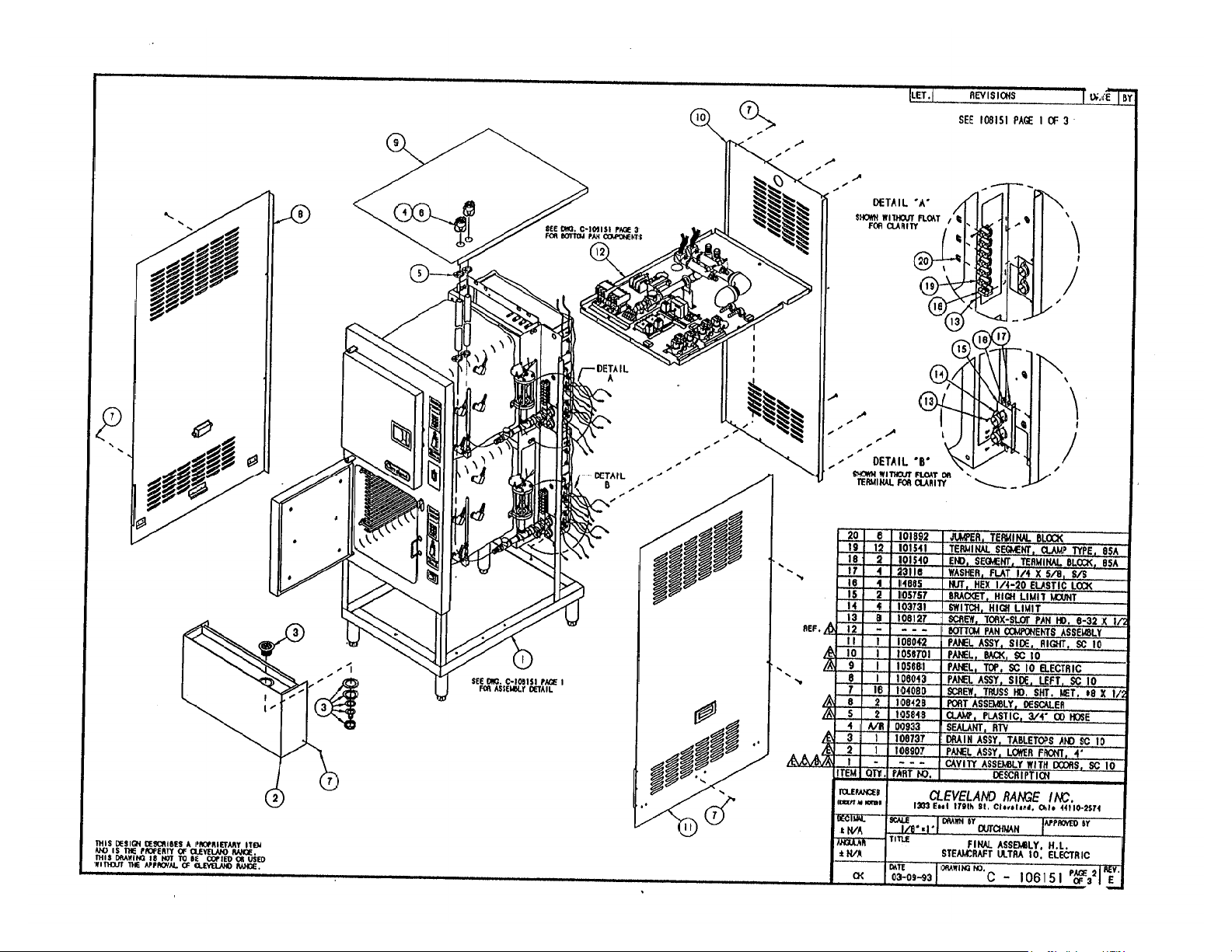

Page 2

107314 Door Bumper Kit

107313 Bumper only

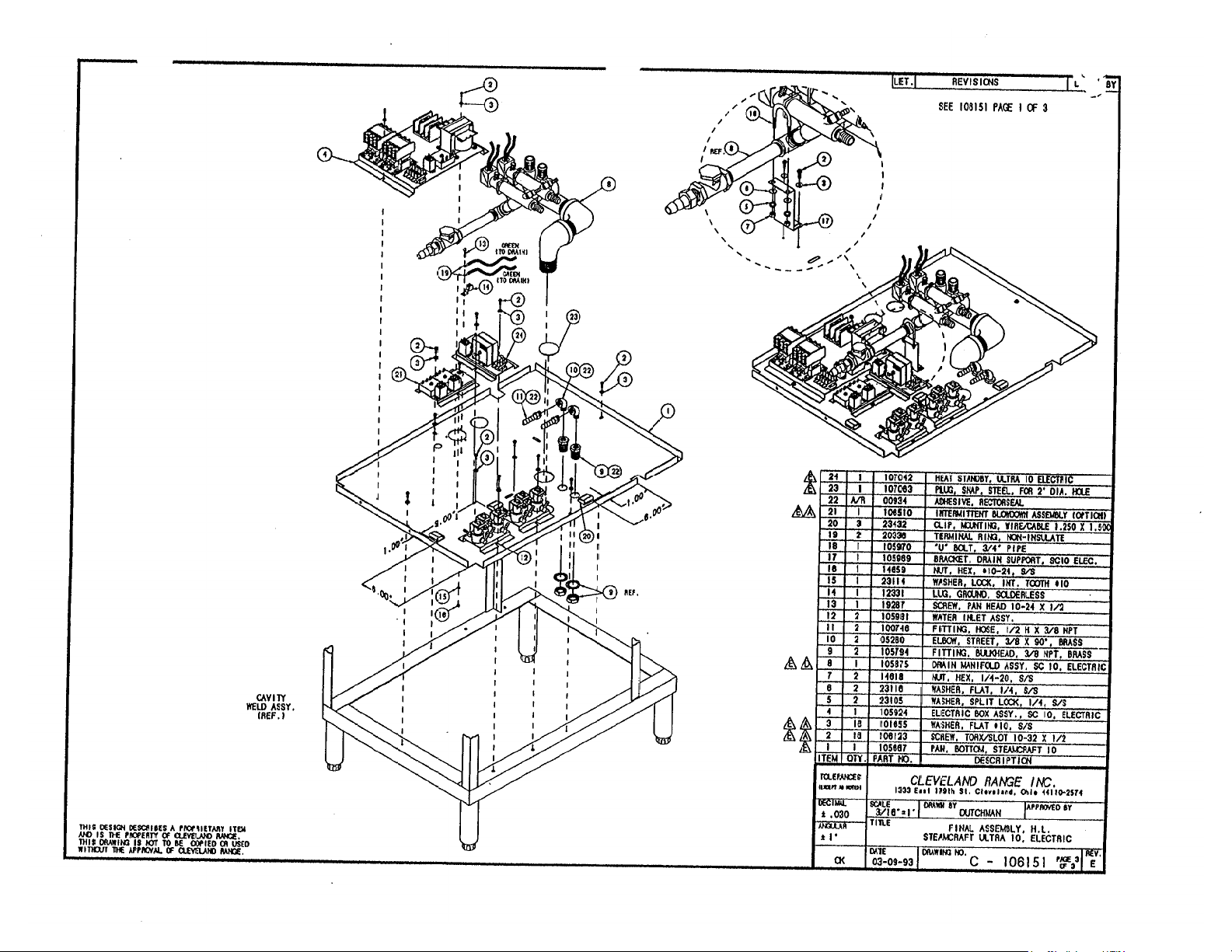

Page 3

Page 4

Page 5

Page 6

Page 7

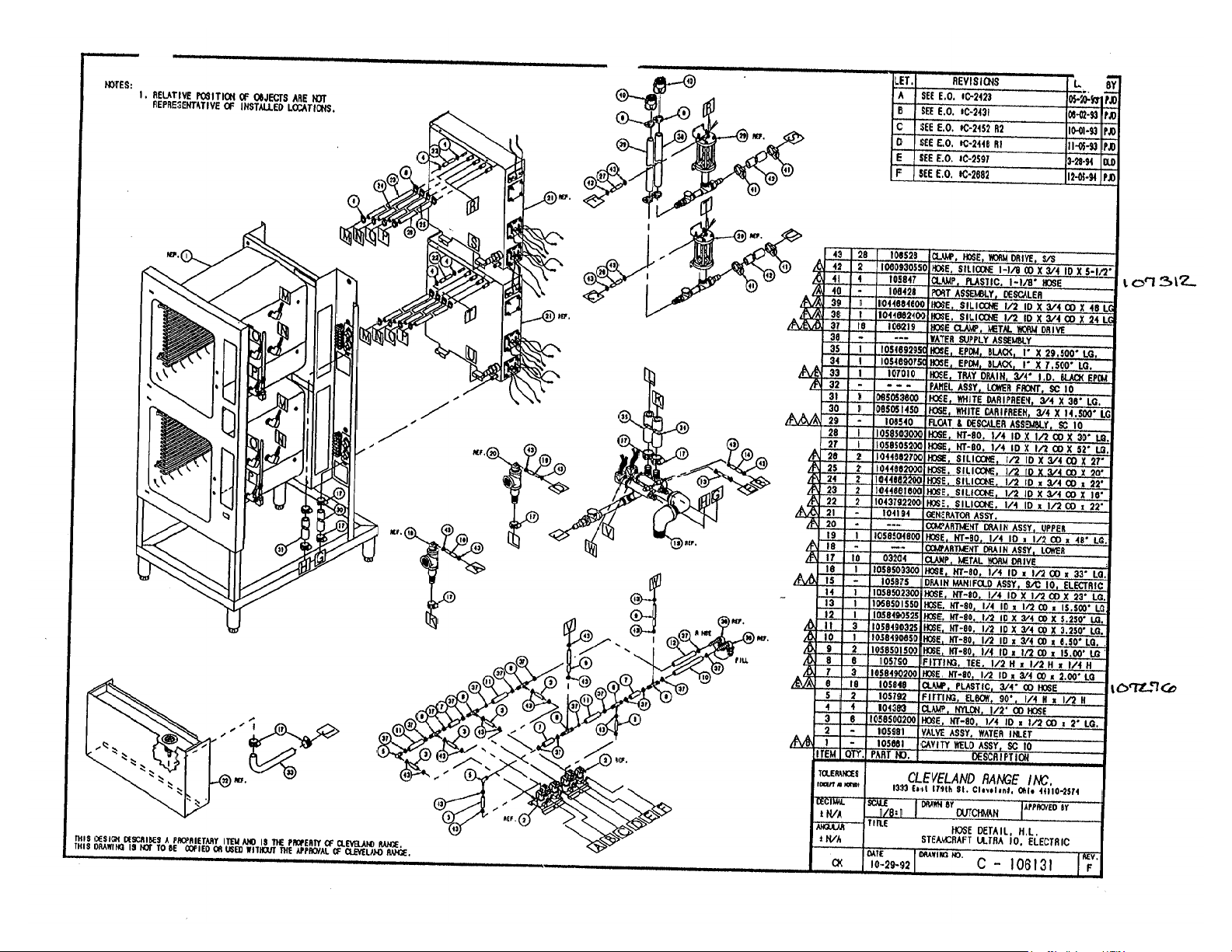

Page 8

Page 9

Page 10

Page 11

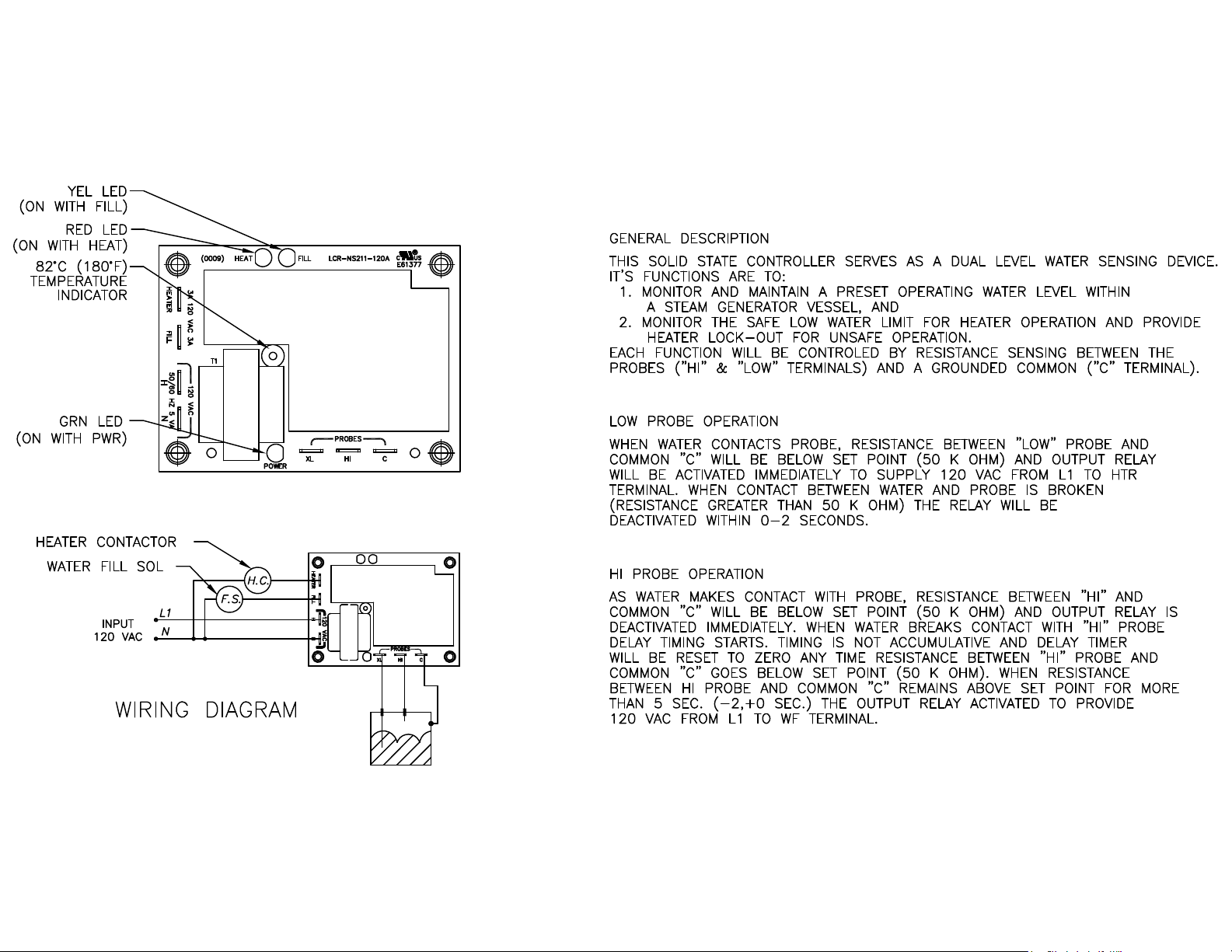

107241 Water Level Board

Page 12

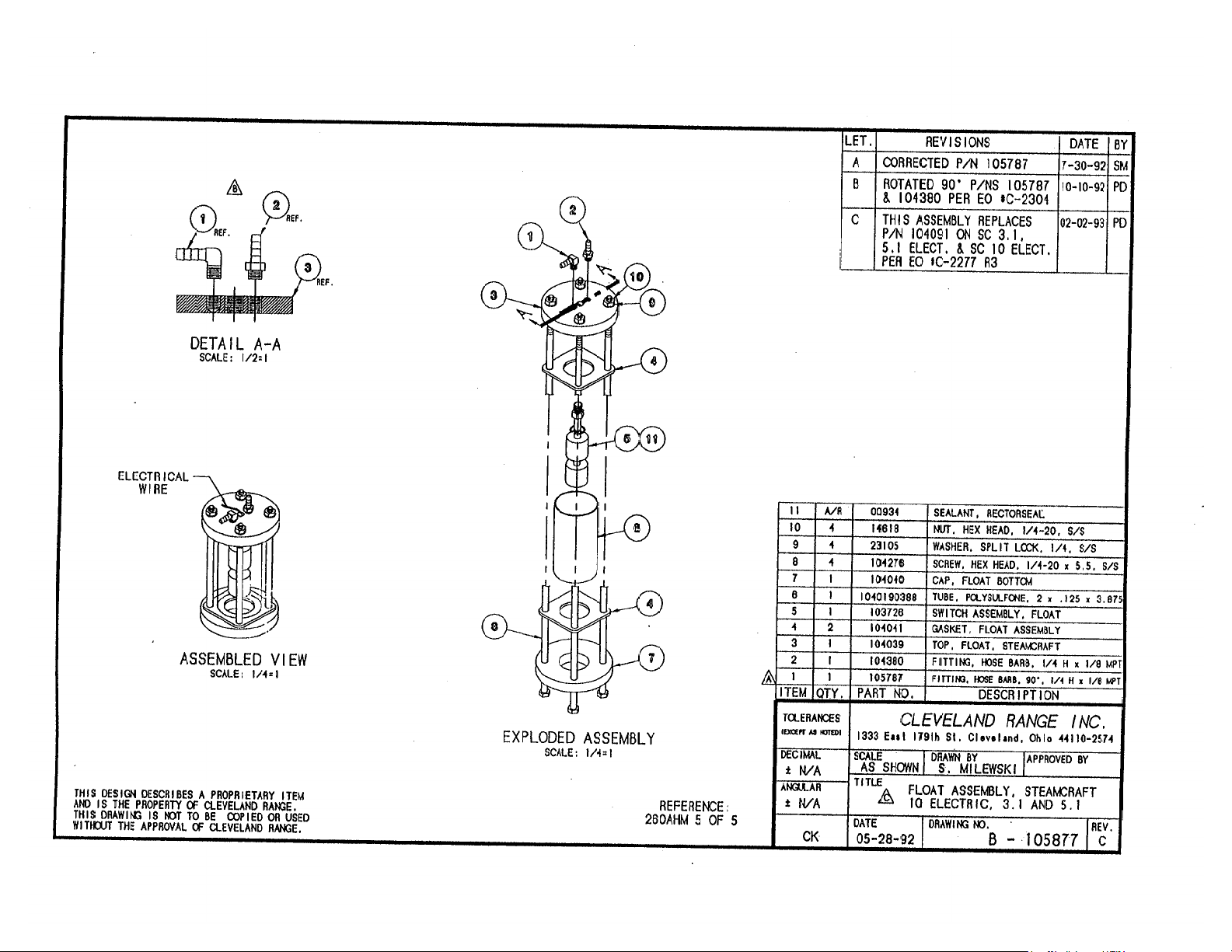

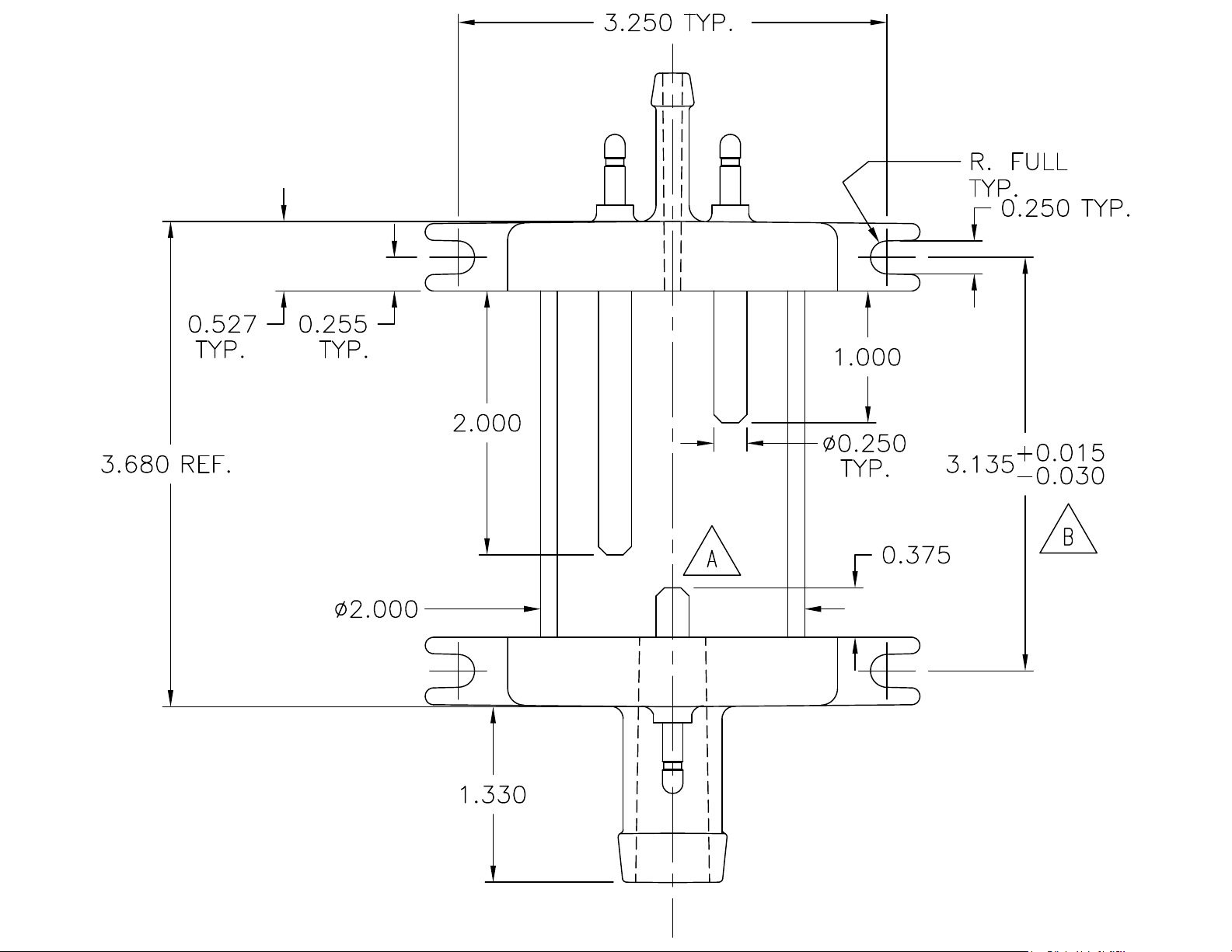

107239 Water Level

Probe Assembly

Page 13

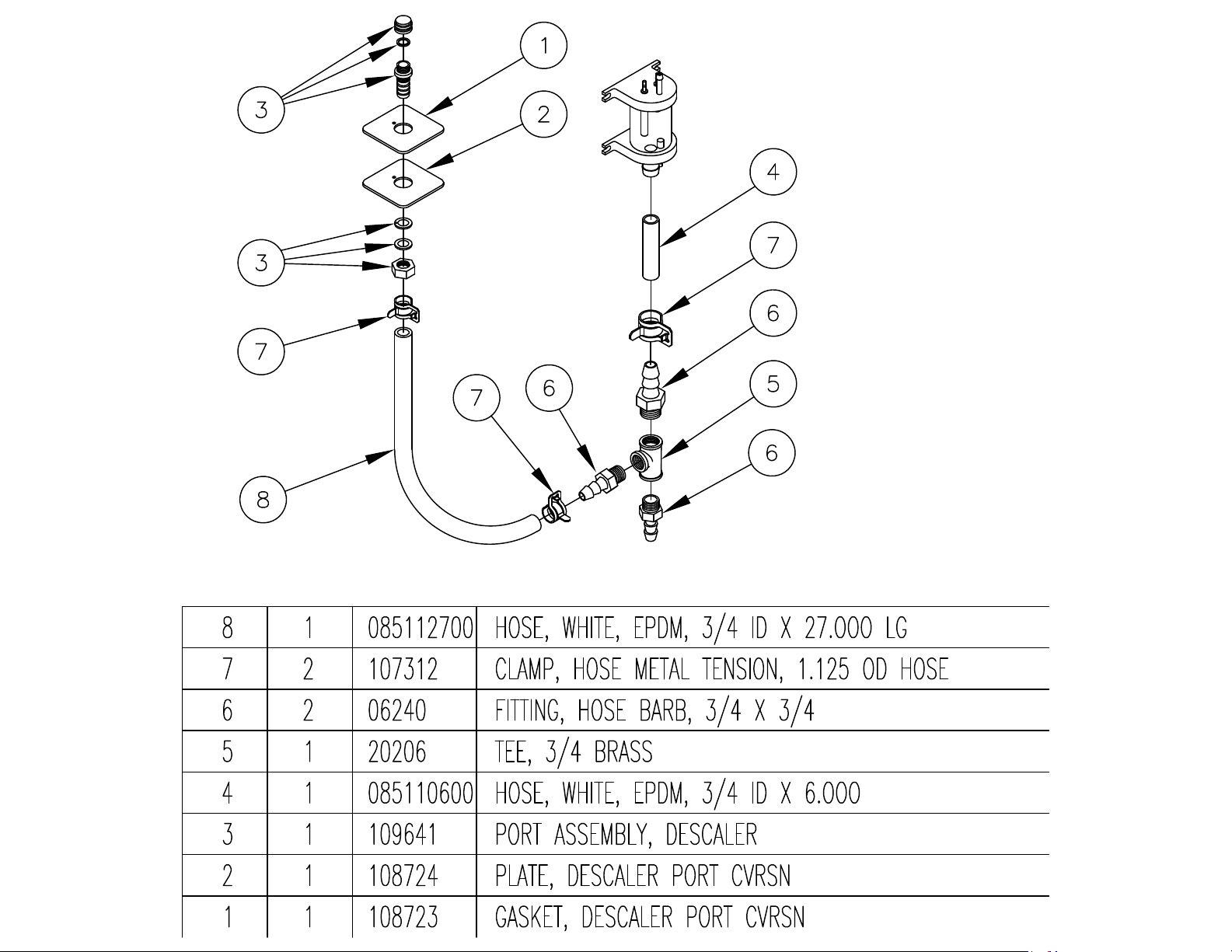

108727

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

108728 - CLEANING

PORT KIT.

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Statement of Responsibilities

This document is for use by experienced and trained Qualified Cleveland Range, LLC Authorized Service

Representatives who are familiar with both the safety procedures, and equipment they service.

Cleveland Range, LLC assumes no liability for any death, injury, equipment damage, or property damage

resulting from use of, improper use of, or failure to use the information contained in this document.

Cleveland Range, LLC has made every effort to provide accurate information in this document, but

cannot guarantee that this document does not contain unintentional errors and omissions.

The information in this document may be subject to technical and technological changes, revisions, or

updates.

Cleveland Range, LLC assumes no liability or responsibility regarding errata, changes, revisions, or

updates.

Qualified Cleveland Range, LLC Authorized Service Representatives are obligated to follow industry

standard safety procedures, including, but not limited to, OSHA regulations, and disconnect / lock out /

tag out procedures for all utilities including steam, and disconnect / lock out / tag out procedures for gas,

electric, and steam powered equipment and / or appliances

All utilities (gas, electric, water and steam) should be turned OFF to the equipment and locked out of

operation according to OSHA approved practices during any servicing of Cleveland Ran ge equipment

Qualified Cleveland Range, LLC Authorized Service Representatives are obligated to maintain up-to-date

knowledge, skills, materials and equipment.

Page 39

Cleveland Range, LLC

1333 East 179th St., Cleveland, Ohio, U.S.A. 44110

Ph: 1-216-481-4900 Fx: 1-216-481-3782 Visit our Web Site at www.clevelandrange.com

Page 40

CLEVELAND RANGE 24CEA10

SEQUENCE OF OPERATIONS

Mechanical Timer

1. Supply power is sent to the primary of the main transformer.

• 115 VAC is sent from the secondary of the main transformer to the on/off rocker,

2. To turn the unit on, depress the red on/off rocker switch.

• 115 VAC is sent to the red indicator light.

• 115 VAC is sent to both coils of the normally open drain valves closing them.

• 115 VAC is sent to the H and N terminals of both water level boards.

3. With the water level board energized and no water in the generators

• After a 5 second delay, 115 VAC is sent from the FILL terminals to the fill solenoids.

• The fill solenoids open and the generators fill through the drain valves until the high

probe is grounded (see step 4).

• The water fills to the low probe in each probe assembly shorting it to ground

• 115 VAC is sent from the HEAT terminals of the water level board to the timed

manual switches.

• 115 VAC is sent to the heat standby timer which will energize the R2 relay coil 3

seconds every 4 minutes

• The normally open contacts of the R2 relay close bypassing the timed/manual switch to

maintain heat while unit is idle

4. For each compartment, when the timed/manual switch is in the manual position or timed

position with time on the timer

• 115 VAC is sent from the timer to the coil of the R5 relay for the top compartment

• The R5 relay energizes

• R5B contacts close sending 115 VAC to the motor timer

• R5A contacts close sending 115 VAC through the optional door switch to the

normally closed contacts of the high limits

• 115 VAC is then sent through the high limits to the coil of condensate solenoid and the

coil of the contactor.

• 115 VAC is sent to the clean light timer.

• When the clean light timer times down 115 VAC is sent to the clean light switch.

• When the clean light switch is depressed the timer is reset.

• When the contactor is energized supply voltage is sent to both of the elements.

• 115 VAC is sent from the timer to the coil of the R6 relay for the bottom compartment

• The R6 relay energizes

• R6B contacts close sending 115 VAC to the motor timer

• R6A contacts close sending 115 VAC through the optional door switch to the

normally closed contacts of the high limits

• 115 VAC is then sent through the high limits to the coil of condensate solenoid and the

coil of the contactor.

Page 41

• 115 VAC is sent to the clean light timer.

• When the clean light timer times down 115 VAC is sent to the clean light switch.

• When the clean light switch is depressed the timer is reset.

• When the contactor is energized supply voltage is sent to both of the elements.

• When the mechanical timer times out 115 VAC is sent to the 3-second timer and then to

the buzzer for 3 seconds.

5. When the water level reaches the high probe then 115 VAC is removed from the FILL

terminal and the fill solenoid is turned off.

6. After the water level drops below the high probe for 5 seconds 115 VAC is sent to the FILL

terminal again.

7. The red 115 VAC switch is depressed and the unit is turned off.

• 115 VAC is removed from the timer and heat circuits.

• 115 VAC is removed from the normally open drain valves allowing the steamer to drain.

• 115 VAC is sent to the 3-minute timer and the R1 relay coil is energized.

• The normally open contacts of the R1 relay will close

• The fill solenoids are then energized for 3 minutes flushing the drains.

Page 42

DRYING ELEMENT

STEAMCRAFT-10 ELECTRIC

MECHANICAL TIMER

DRYING ELEMENT

HEATING

ELEMENTS

NOT USED ON

" LOW " WATTAGE MODEL

CUSTOMER

CONNECTION

Ø

3

BLK

DESCALER

TIMERS

3

2

4

1

6

7

8

5

3 MIN TIMER

POWER SWITCH

TIMEDMANUAL

R5B

C

C

NO

MOTOR

NC

UPPER MOTORIZED TIMER

NC

C

MOTOR

NC

C

1

3

TIMEDMANUAL

C

1

3

2

R6B

CNO

NO

NC

2

R3

BLOWDOWN

TIMER

OPTION

LOWER MOTORIZED TIMER

R4

BLOWDOWN

TIMER

OPTION

CONTACTORS

L1

L2

L3

TB

3 2

4

1

7 8

3

2

1

POWER ON

R

MANUAL

NO

C

R5A

NO

R2

MANUAL

C

R6A

NO

R2

1

2

3

HEAT STANDBY TIMER

6

5

R1 COIL

TIMED

R5

DOOR

SWITCH

(SCS OPT)

TIMED

R6

DOOR

SWITCH

(SCS OPT)

R2 COIL

L L

A

NO NO

HEAT

FILL

H

N

XL HI

3 SEC TIMER

3

1

HI LIMIT

SWITCHES

UPPER DRAIN VALVE

HEAT

FILL

H

N

XL HI

3 SEC TIMER

3

1

HI LIMIT

SWITCHES

LOWER DRAIN VALVE

HEATING

ELEMENTS

NOT USED ON

" LOW " WATTAGE MODEL

120V

VALVES

H4

X2

WHT

TO

TO

H1

X1

DESCALE INDICATOR

& RESET SWITCH

R1

WATER FILL

R1

WATER

BOARD

C

BUZZER

2

R3 (TDS OPTION)

COND. VALVE

HEATER CONT.

WATER

BOARD

C

BUZZER

2

R4 (TDS OPTION)

COND. VALVE

HEATER CONT.

PRIMARY

TRANSFORMER

SECONDARY

PROBES

PROBES

L105972 K

Page 43

RED

03509

BLK

LT BLU

NO

9

C

24

R5

ORN/BLK

LT BLU

LT BLU

ORN

BLK

BLK

BLU

LT BLU

BLK

PNK

7

W/BLU

WHT/BLK

W/BLU

WHT/BLK

NC

20

22

321

2

RED

BLK

9

PNK

7

W/BLU

BLK

GRA

WHT/BLK

W/BLU

6

NOC

NC

20

ORN/BLK

WHT

WHT/GRA

WHT

WHT/RED

RED

LT BLU

R6

LT BLU

LT BLU

WHT/BLK

BRN

ORN

BLK

BLK

LT BLU

BRN

BRN

WHT

22

1322

BLK

BLU

RED

REMOVED W / OPTIONAL

RED

DOOR SWITCH ( SCS )

WHT

BRN

24

RED

BLU

REMOVED W / OPTIONAL

DOOR SWITCH ( SCS )

GRA

BRN

YEL

4

YEL

BRN

YEL

WHT/GRA

CUSTOMER CONNECTION

GRA

25

26

15

( TOP ) ( BOT )

BRN

WHT/BRN

WHT

WHT/RED

BLK

BLU

3

BLACK

RED

BLACK

WHITE

RED

WHITE

BLACK

RED

BLACK

WHITE

RED

WHITE

JUMPER SET

FOR 480 VOLTS

H4

1

H2

H3

H1

ALTERNATE TRANSFORMER

CONFIGURATION

JUMPER SET

FOR 208/240 V

H4

H2

H3

H1

FU

FU

20

ORN

R1

BLU

15

WHT

YEL

YEL

WHT/YEL

DRYING

ELEMENT

HEATER

ELEMENT

HEATER

ELEMENT

STEAMCRAFT 10 - ELECTRIC

MECHANICAL TIMER

RED

YEL

BLU

RED

BLU

BLK

WHT

BRN

WHT/GRA

BLK

BLK

BLK

BLK

WHT

BLK

BLACK

RED

BLACK

WHITE

RED

WHITE

BLACK

RED

BLACK

WHITE

RED

WHITE

X1

X2

YEL

RED

WHT/RED

PNK

BLK

X1

X2

WHT

3

WHT/GRA

2

1

GRA

N

RED

WHT/GRA

BLK

RED

5

WHT/YEL

RED

YEL

BRN

WHT/BRN

WHT

WHT/YEL

WHT/YEL

1

10

BRN

RED

4

BLK

YEL

ORN

HEAT

FILL

HN

BLK

17

11

21

XL

YEL

3

2

1

WHT

23

WHT

HEAT

FILL

H N

RED

DRYING

ELEMENT

HEATER

ELEMENT

HEATER

ELEMENT

RED

CHI

RED

WHT/RED

YEL

WHT/YEL

WHT/YEL

YEL

21

XL

YEL

CHI

RED

GRN

BLU

WHT/BRN

ORN

GRN

WHT/RED

8

BRN

18

R3

RED

BLK

R2

20

RED

ORN

BLU

BLU

WHT/BRN

( TOP )

FILL

14

( BOT )

WHT/ORN

WHT/RED

FILL

( TOP )

BRN

COND

BRN

20

R4

YEL

BRN

19

BRN

BRN

WHT/BRN

RED

BRN

RED

18

BLK

BLK

RED

17

YEL

RED

12

RED

RED

WHT

BLK

2

3

4

78

TAN

TAN

12

1

6

5

YEL

YEL

WHT/YEL

WHT/YEL

WHT

2

3

4

87

( BOT )

COND

( TOP )

16

( BOT )

16

BLK

1

6

5

TAN

TAN

NOTE :

THIS ELEMENT NOT

INSTALLED FOR

" LOW " WATTAGE UNIT

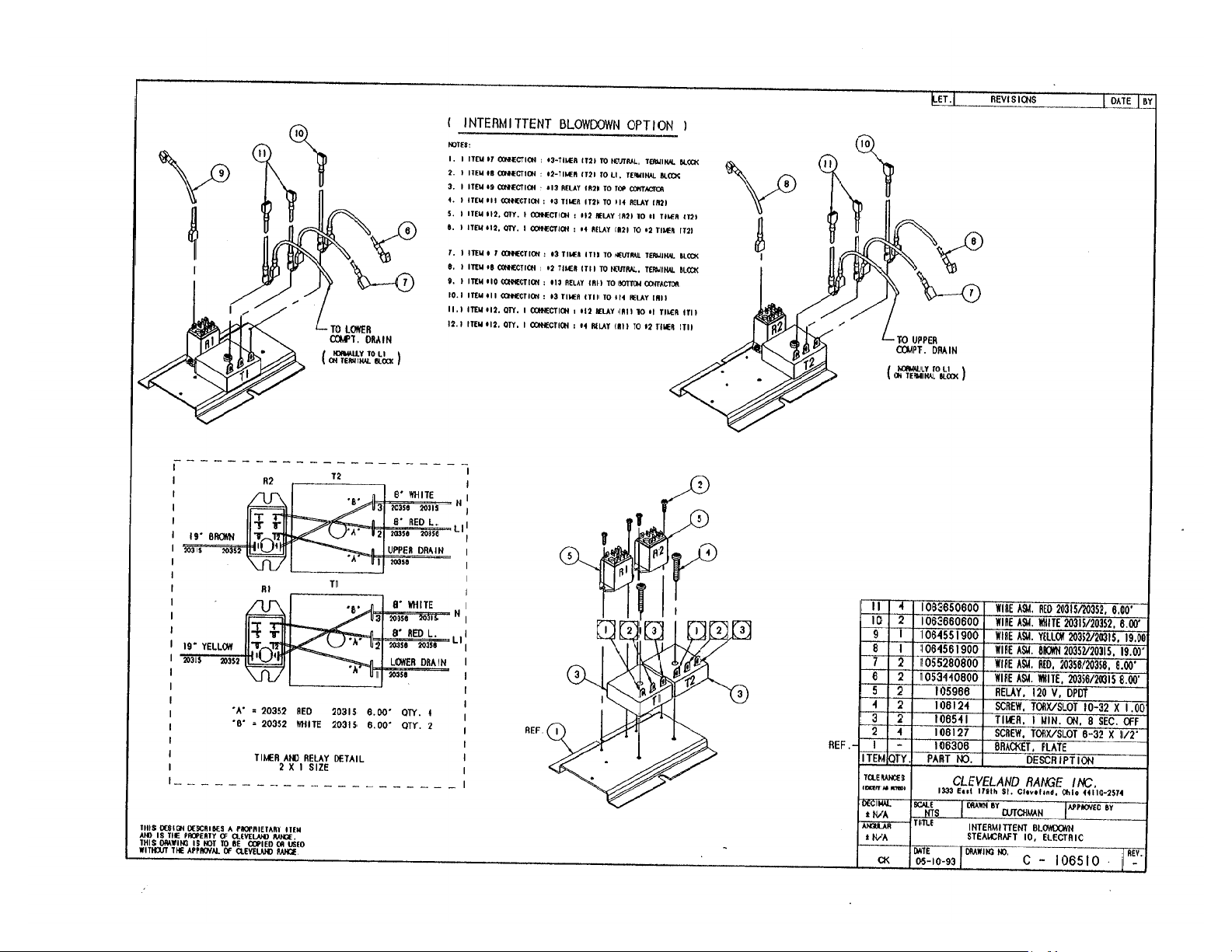

INTERMITTENT

BLOWDOWN OPTION

20535 - TRANSFORMER - POWER

1

2

20477 - 3 SEC TIMER

02193 - TERMINAL BLOCK

3

101541 - TERMINAL SEGMENT

4

106175 - TERMINAL BLOCK 4 POLE

5

19993 - POWER SWITCH

6

104224 - TIMED / MANUAL SWITCH

7

19994 - DESCALE IND RESET SW

8

110198 - MOTORIZED TIMER

9

20478 - 3 MIN TIMER

10

11

109239 - HEAT STANDBY TIMER

12

106911 - DESCALE TIMER

13

106541 - INTMT BLOWDOWN TIMER

14

222231 - FILL VALVE

03459 - CONTACTOR ASSY

15

16

22221 - DRAIN VALVE

103731 - HI LIMIT SWITCH

17

18

107239 - PROBE

19

22218 - WATER SOLENOIDS

20

105966 - RELAY

21

107241 - WATER BOARD

22

41350 - BUZZER

23

44168 - TERMINAL BLOCK 2 POLE

24

108880 - DOOR SW ( SCS ) MAG

25

109380 - FUSE 3.5A 600V

26

109374 - FUSE BLOCK

3

13

2

1

3

13

2

1

YEL

2

3

4

1

867

5

PARTS LIST

12

2

3

4

1

87

RED

P105972 K

RED

RED

RED

WHT

RED

6

5

RED

RED

WHT

5

RED

16

16

RED

RED

WHT

RED

RED

RED

WHT

WHT

RED

RED

Page 44

Page 45

Page 46

Page 47

Page 48

PROBLEM:

21CET8

21CET16

21CEA10

Steamer won't

steam.

Steamer won't

steam

Is the red light

on?

Yes

No

Is there supply

voltage to the

primary of the

transformer?

Yes

Supply power to

No

the s t eam er.

Replac e the

water boar d

Replace the wire

from the water

board to the long

probe.

See

STEAMER

WON'T FIL L

Replace the wi r es

to the water

board.

jumper between XL and

C on the water board, i s

No

there 120 VAC between

N and Heat?

No

there debris on

With a

Yes

Is

the Long

probe?

No

No

Is there water

in the sight

Is there 120 VAC

between termi nal s H

and N on th e water

Is there 120 VAC

between ter m i nals

No

N and Heat on t he

water board ?

115 VAC t o th e

common termi n al of

the timed/manual

glass?

Yes

board?

Yes

Yes

Is there

switch?

Replace the wi r es

No

to the switch.

Is there 115 VAC at

the secondary of

the transformer?

Yes

Replace the on/ off

rocker switch

No

Replac e the

transformer.

Yes

Clean or r ep lace

the probe assy.

Yes

Does

the unit steam

in Manual

mode?

Yes

Replac e the

timer.

Does t he

No

st eam er have

the opt i onal

door switch?

steamer steam w i t h

door swit ch

bypassed?

Adjust or replac e

the door switch.

Yes

Does

Yes

Is there

115 VAC t o th e

No

No

high limit?

Is there 115

VAC l eaving

the high limit?

Is there 115

VAC to the coil

of the

contactor?

Is th ere an

amp draw at

the elem en t ?

Wait longer for t h e

steam. Heat fr om t h e

element will heat the

water to steam.

Yes

Yes

Yes

Yes

No

No

No

No

Replac e the

wires to the

high limit.

Replac e the

high limit.

Replac e the

wires to the

contactor coil.

Replac e the

element.

Page 49

PROBLEM:

21CET8

21CET16

24CEA10

Steamer wont

fill

Steamer wont fill.

Yes

Is there supply

voltage to the

steamer?

Yes

No

Supply power to

the s t eam er.

Replace wiri n g t o

the fill solenoid.

Is there water

steamer?

Is there 120 VAC

between the H and N

on the water b oard?

Is there

120 VAC

between Fill and

N on the water

Is there

No

120 VAC across

the coil of the f il l

solenoid?

to the

Yes

Yes

board?

Yes

Yes

Supply cold water

No

Replace the on/ off

No

No

to the s t eamer.

rocker switch.

Remove

the wire from th e H I

terminal on the water

board. Is there 120 VAC

between F i l l

and N?

Yes

Is there

debris on t h e

HI probe in the

probe as sy?

No

Replace the water

No

Replace the wire

to the Hi p r ob e.

board

Replace wiri n g t o

drain valve.

Replace the wir in g

to the intermittent

blowdown timer.

No

No

Replace the f il l

solenoid

Does

the s t eam er have

the opt i onal

intermittent

blowdown timer?

Yes

Is

there 120 VAC

between ter m i nals

2&3 on the timer?

Yes

Replac e the

intermittent

blowdown timer.

No

No

Is

water leaving

the fill

solenoid?

Yes

Is there

120 VAC across

the coil of the

drain valve?

Yes

Is water

draining from

the generator?

Yes

Replace the drain

valve.

If water is l eaving

No

and not draining

from the generator

where is it goin g ?

check for leaks..

Yes

Clean the pr ob es

or replace the

probe as sy.

the fill solenoid

Page 50

PROBLEM:

21CET8, 21CET16, 24CEA10

Electronic timer displays "PAUS" and won't count down

Timer displays "paus"

and won't count down

Is steam heating

Replac e the

thermo-switch

cabinet above 192

degrees (the set

thermo-switch)?

Does the timer

count down when

Yes

the thermo-switch

is bypassed?

the cook i n g

No

temp of the

Yes

No

See

Steamer

won't steam

Replac e the

electronic ti m er

Steam leaks

around the

door

Is COLD water

supplied to both

water lines t o t h e

steamer?

Yes

Is the door gasket

physically

damaged?

Yes

Turn over the

gasket or

replace it.

water(35-60 psi) to

No

Is the door ou t of

No

Supply cold

the s t eam er.

alignment?

Yes

Replac e the

door bearings

and pins.

PROBLEM:

21CET8, 21CET16, 24CEA10

Steam leaks around the door.

Is there 120 VAC

No

Is the drain

obstructed?

Yes

Remove the

obstruction

across the coil of

No

the condensate

Is the solenoid

solenoid?

Yes

opening?

No

No

Replac e the

wiring to the

condensate

solenoid.

Replac e the

condensate

solenoid.

Yes

Replac e the

condensate spray

nozzle

Page 51

PROBLEM:

21CET8

21CET16

24CEA10

Steamer overfills.

(Water sprays into cooking

cabinet)

Steamer overfills

(Water sprays into the

cooking cabinet)

Start

There is an

obstruction in th e

drain. Remove the

obstruction.

Yes

Does

the rise in t h e water

level in the sig h t g l as s

stop when the cooking

cabinet door is

opened?

No

There is an

obstruction in th e

generat or c au sing

it to pressurize.

Delim e the s t eam

generator

thoroughly.

Replace the three

minute timer.

Yes

Yes

Does

the water ri se in the

sight glass when steam

is gener ated an d 0 VAC

to the fill s olenoid?

No

Replace the f il l

solenoid

There is an obstruction in

the plumbing t o and from

the sight glass . Remove

the debris (delime

thoroughly).

Remove the

wire from the Fill

terminal on the water

board. Is there 120 VAC

across the coil of th e

fill

solenoid?

Yes

Yes

Yes

Does

the water level in th e

sight glass stop at th e

HI (short) probe on the

initial fill?

No

Does

water spray in t he

cabinet before t he

water reaches th e H I

(short) probe?

No

Is

there 120 VAC

across the coil of ;t h e

fill solenoid when the

HI (short) probe is

submerged?

Replace the water

level boar d.

Clean or r ep lace

the pr obe

assembly.

Yes

Yes

No

With HI and C

terminals on the

water board ju m ped ,

Is there 120 VAC

between termi nal s N

and Fill?

No

Is

there debris on

the HI (short)

probe?

No

Replace the wire

to the probe

assembly

No

Replace the f il l

solenoid

Page 52

Steamer won't

stop steaming

Is the

timed/manual switch

in the timed posit i on

with no time on the

timer?

Yes

Steamer will steam

constantly in th e

manual position. P u t

No

the timed/manual

switch in the timed

position with no tim e on

PROBLEM:

21CET8

21CET16

24CEA10

Steamer won't stop steaming with

door open

the timer.

Does th e steam er

have the op t ional

door switch?

Yes

Adjust or replac e

the door s w it ch .

No

Does steamer

continue to steam with

both wires removed

from terminal 1 on t h e

heat standby

timer?

No

Replac e the heat

standby timer.

21CET8, 24CEA10

Steamer won't preheat

Yes

120 VAC t o th e

Replace the timer.

Problem:

Steamer

won't

preheat

Is there

coil of the

contacter?

Yes

No

Is

there an am p

draw at t h e

element?

Yes

Replac e the

contactor

voltag e i s rem oved

from t he elemen t

steam is sti l l mad e

No

for approxim ately

10 seconds . This

When supply

is normal.

Is the

timed/manual

switch in t h e t i med p ostion

with time on it or i n t he

manual

postion?

Yes

See Problem:

steamer won't

steam.

This steamer is

not equiped with a

thermostat. The

No

timed manual

switch must be in

manual or time

must be on the

preheat

timer.

Page 53

Page 54

Page 55

Descaling Procedure-SteamCraft Ultra and Gemini Series

How Much DISSOLVE to Use

Model Dissolve

Ultra 3 1/2 Gallon

Ultra 5 1 Gallon

Ultra 10 (Elec.) 1 Gallon (ea.)

Ultra 10 (Gas) 1½ Gallon

Gemini 6 & 10 1 Gallon (ea.)

1. Turn the unit OFF and open the

doors:

This will drain and rinse the generator for about

3 minutes.

2. Turn the unit power back On:

The generator will begin to refill with water.

3. Select Timed with the Timed/Manual

switch:

DO NOT start the timer, since you do not want

to heat the water during descaling. Leave the

doors open.

6. Let the descaler soak in generator for

approximately one hour:

7. After one hour, turn the unit power

This will drain and rinse the generator

Off:

for about 3 minutes.

4.

Remove descaling port cap and add

with the specified amount of

DISSLOVE:

Do this while the unit is refilling. The generators

can take-up to 8 minutes to refill.

After refill has stopped, add extra tap

5.

(See chart above)

water into the descaling port until

liquid is seen entering the cooking

cabinet.

coming out of the drain,

Adding extra water when descaling will raise the

descaling solution higher than the normal fill level,

allowing the DISSOLVE to work on sensors and

surfaces above the water line

Note: Some SteamCraft Ultra models (the

electric powered Ultra 10 and Gemini 6 and 10,

for example) have two generators and two

descaling ports. Both units should be descaled

at the same time, using this procedure

Note: Ultra 10 gas will have liquid

8. After the 3-minute drain cycle

completes, turn the unit back ON. After

the filling has stopped, add water until

liquid enters the cooking compartment (or

drain for the ultra 10 gas), and then turn

the unit OFF. This will drain and flush any

residue from the water level control

assembly. Replace descaling cap.

After the 3 minute drain cycle

9.

completes, Turn the unit ON and set

the Timer for 20 minutes:

Time/Manual switch is in the timed setting

and the doors are closed.

Make sure the

10. When the timer times out (after 20

minutes) turn the power Off:

This will drain and rinse the generator for

about 3 minutes.

This ends the descaling procedure. You can

now turn the unit back on and resume normal

startup and cooking operations.

Loading...

Loading...