Page 1

Operators Manual

Use and Care Instructions

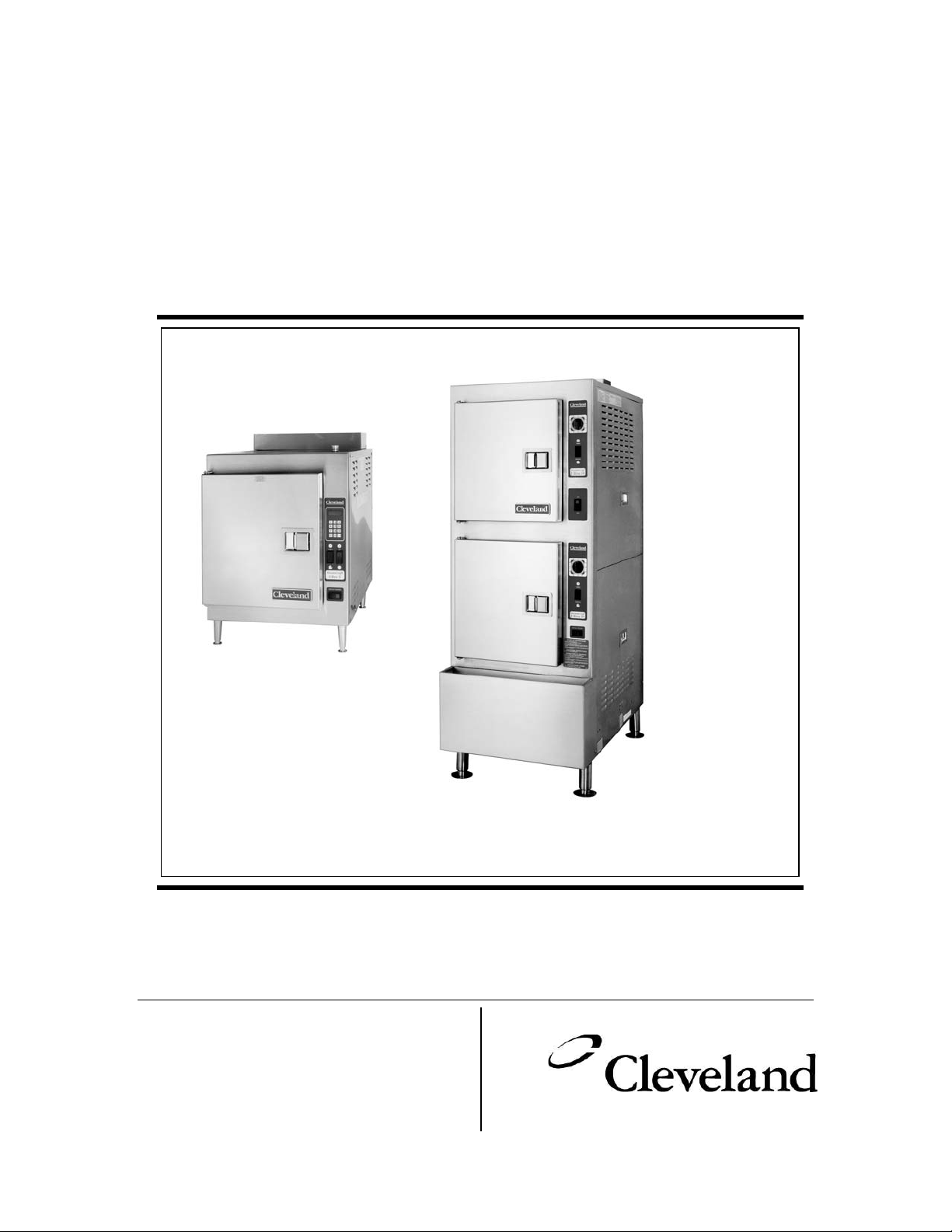

Gas Models, SteamCraft® Ultra 5, Ultra 10

Series: SteamCraft® Model Nos. 21CGA5,

24CGA10

1333 East 179th Street

Cleveland, Ohio 44110

Phone: (216) 481-4900

Fax: (216) 481 3782

Part No. CGA-OPM Rev. A 10/04

Page 2

FOR THE USER

r

r

r

A

FOR YOUR SAFETY

Do not store or use gasoline o

other flammable vapors o

liquids in the vicinity of this o

any other appliance.

WARNING

Disconnect power before servicing!

WARNING

If door is stuck shut: DO NOT force door open.

Door stuck shut may indicate a blocked drain.

Hot water will spill out if door is forced open.

• Turn OFF unit

• Call qualified Cleveland Range authorized

service technician

• Wait for unit to cool before servicing

WARNING

Improper installation, adjustment, alterations,

services or maintenance can cause DEATH,

INJURY, or PROPERTY DAMAGE.

Read installation, operating, and maintenance

instructions thoroughly before installing or

servicing this equipment.

DANGER

Wait for unit to cool before

servicing!

IMPORTANT

IT IS IMPORTANT TO POST INSTRUCTIONS WHICH ARE TO BE

FOLLOWED IN THE EVENT THE USER SMELLS GAS. THESE

INSTRUCTIONS SHOULD BE DISPLAYED IN A PROMINENT LOCATION,

ND BE FULLY UNDERSTOOD BY ALL USERS OF THIS EQUIPMENT.

OBTAIN THIS INFORMATION FROM YOUR LOCAL GAS SUPPLIER.

ALL SERVICE MUST BE PERFORMED BY A QUALIFIED CLEVELAND

RANGE AUTHORIZED TECHNICIAN.

Cleveland Range, LLC, strongly recommends the use of non-slip draining antifatigue mats (not included) rated for use in wet, greasy, or dry work areas to help

prevent slipping and / or falling injuries. Obtain the best mats for your needs from

your local supplier.

Wiring diagram is located on the back of the right side panel on left door hinge models.

Wiring diagram is located on the back of the left side panel on right door hinge models.

RETAIN THIS MANUAL FOR REFERENCE

KEEP IT WHERE YOU CAN USE IT

Page 3

Cleveland STATEMENT OF POLICIES

L I M I T E D W A R R A N T Y

CLEVELAND RANGE products are warranted to the original purchaser to be free from defects in materi als and workmanship

under normal use and service for the standard warranty period of one year from date of installation or 18 months from date of

shipment, which ever comes first.

CLEVELAND RANGE agrees to repair or replace, at its option, f.o.b. factory, any part which proves to be defective due to

defects in material or workmanship during the warranty period, providing the equipment has been unaltered, and has been

PROPERLY INSTALLED, MAINTAINED, AND OPERATED IN ACCORDANCE WITH THE CLEVELAND RANGE OWNER’S

MANUAL.

CLEVELAND RANGE agrees to pay any FACTORY AUTHORIZED EQUIPMENT SERVICE AGENCY (within the continental

United States, and Hawaii) for reasonable labor required to repair or replace, at our option, f.o.b. factory, any part which proves

to be defective due to defects in material or workmanship, during the labor warranty period. T his warranty includes travel time

not to exceed two hours and mileage not to exceed 50 miles (100 miles round-trip), BUT DOES NOT INCLUDE POST STARTUP, TIGHTENING LOOSE FITTINGS, MINOR ADJUSTMENTS, MAINTENANCE, CLEANING OR DESCALING.

The standard labor warranty allows factory payment of reas onable labor required to repair or replace such defective parts.

Cleveland Range will not reimburse the expense of labor required for the repair or replacement of parts after the standard

warranty period, unless an Extended Labor Warranty Contract has been purchased to cover the equipment for the balance of the

warranty period from the date of equipment installation, start-up, or demonstration.

PROPER INSTALLATION IS THE RESPONSIBILITY OF THE DEALER, THE OWNER-USER, OR INSTALLING

CONTRACTOR, AND IS NOT COVERED BY THIS WARRANTY. Many local codes exist, and it is the responsibility of the

owner and installer to comply with these codes. Cleveland Range equipment is built to comply with applicable standar ds for

manufacturers, including UL, ANSI, NSF, ASME/Ntl. Bd., CSA, and others.

BOILER (Steam Generator) MAINTENANCE IS THE RESPONSIBILITY OF THE OWNER-USER AND IS NOT COVERED BY

THIS WARRANTY. The use of good quality feed water is the responsibility of the Owner-User (see Water Quality

Recommendations below). THE USE OF POOR QUALITY FEED WATER WILL VOID EQUIPMENT WARRANTIES. Boiler

maintenance supplies, including boiler hand hole gaskets, are not warranted beyond the first 90 days after the date the

equipment is placed into service. Preventive maintenance records must be available showing descaling per applicable

Cleveland Operator Manual for Boiler Proration Program considerations.

WATER QUALITY RECOMMENDATIONS

TOTAL DISSOLVED SOLIDS less than 60 parts per million

TOTAL ALKALINITY less than 20 parts per million

SILICA less than 13 parts per million

CHLORIDE less than 30 parts per million

pH FACTOR greater than 7.5

The foregoing shall constitute the sole and exclusive remedy of origin al purchaser and the full liabilit y of Cleveland Range for

any breach of warranty. THE FOREGOING IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, WHETHER

WRITTEN, ORAL, OR IMPLIED, INCLUDING ANY WARRANTY OF PERFORMANCE, MERCHANTABILITY, OR FITNESS

FOR PURPOSE, AND SUPERSEDES AND EXCLUDES ANY ORAL WARRANTIES OR REPRESENTATIONS, OR WRITTEN

WARRANTIES OR REPRESENTATIONS, NOT EXPRESSLY DESIGNATED IN WRITING AS A “WARRANTY” OR

“GUARANTEE” OF CLEVELAND RANGE MADE OR IMPLIED IN ANY MANUAL, LITERATURE, ADVERTISING BROCHURE

OR OTHER MATERIALS.

CLEVELAND RANGE’S liability on any claim of any kind, including negligence, with respect to the goods or services covered

hereunder, shall in no case exceed the price of the goods or services, or part thereof, which gives rise to the claim. IN NO

EVENT SHALL CLEVELAND RANGE BE LIABLE FOR SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, OR ANY

DAMAGES IN THE NATURE OF PENALTIES.

LIMITED EXTENDED WARRANTY COVERAGE

The purchase of a Limited Extended Warranty Contract extends th e standard warranty coverage to the purchased period of

time (one to two years) from the date of installation, start-up, or demonstration, whichever is sooner.

*An additional two years Parts and Labor Warranty can be purchased with each piece of Clevelan d equ ipment for an

additional 2% of the List Price per year. The 2% of list price charge will be the net invoice amount for each year of

extended warranty purchased.

- Extended warranty must be purchased at the same time the equipment is purchased.

- Extended Warranty has the same exclusions as stated in our standard warranty.

Second year limited extended warranty coverage on Cleveland Steamers when purchased with a water filter applies to water

related components only

Page 4

Page 5

OPERATORS MANUAL

SteamCraft 21CGA5

Table of Contents

Chapter Page

CHAPTER 1 INTRODUCTION …………………………………………………………………………… 1

A. Free Start-Up Program………………………………………………………………………………… 1

B. Gas Leak Instructions...………………………………………………………………………………..

C. Operational Safety……………………………………………………………………………………...

D. Product Information………..…………………………………………………………………………...

1

2

4

CHAPTER 2 GENERAL OPERATION …………………………………………………………………..

A. MAIN EXTERNAL POWER SWITCH………………………………………………………………...

B. DOOR INTERLOCK SWITCH (OPTIONAL)…………………………………………………………

C. POWER ON (AUTOMATIC FILL)…………………………………………………………………….

D. LIGHTING AND SHUTDOWN INSTRUCTIONS……………………………………………………

E. INSPECTING THE COOKING COMPARTMENT…………………………………………………..

F. PREHEATING THE STEAMER……………………………………………………………………….

G. DESCALING REQUIRED LIGHT FEATURE………………………………………………………..

H. HEAT STANDBY FEATURE…………………………………………………………………………..

I. MINERAL PURGE FEATURE (OPTIONAL)………………………………………………………….

CHAPTER 3 CONTROL PANELS ……………………………………………………………………….

A. DIAL TIMER CONTROL PANEL……………………………………………………………………...

1. Cooking Operations – Dial Timer Control Panel………………………………………………...

2. Manual and Timed Modes…………………………………………………………………………

a. Manual Mode…………………………………………………………………………………….

b. Timed Mode………………………………………………………………………………………

B. KEYPAD TIMER CONTROL PANEL…………………………………………………………………

1. Cooking Operations – Keypad Timer Control Panel.…………………………………………...

2. Manual and Timed Modes…………………………………………………………………………

3. Timed Mode and Use of the Timer….……………………………………………………………

a. Timer Use and Temperature Compensation …………………………………………………

b. Timer Operation ……………………………………………………………………..…………

5

5

5

5

6

8

8

9

9

9

10

10

10

10

10

10

12

12

12

12

12

13

CHAPTER 4 COOKING WITH THE STEAMER ………………………………………………………..

A. OPERATING AND COOKING PROCEDURE – TIMED MODE…………………………………..

B. OPERATING AND COOKING PROCEDURE – MANUAL MODE………………………………..

1. Using Timer in Manual Mode……...……………………………………………………………...

2. Manual Cooking Procedure..………………………………………………………………………

CONTINUED ON NEXT PAGE

15

16

16

17

17

Page 6

Table of Contents

CONTINUED

Chapter Page

CHAPTER 5 SHUTDOWN AND CLEANING PROCEDURES ………………………………………. 18

A. STEAM GENERATOR BLOWDOWN……………………………………………………………….. 18

1. Power OFF (Automatic Blowdown) …………………………….……………………………….. 18

2. Blowdown Frequency…………………………….………………………………………………... 18

3. Blowdown Procedure.…………………………….……………………………………………….. 18

B. SHUTDOWN AND CLEANING……………………………………………………………………….. 19

CHAPTER 6 PREVENTATIVE MAINTENANCE AND TROUBLESHOOTING …………………….. 21

A. MAINTENANCE………………………………………………………………………………………... 21

1. Maintenance Records…………………………….……………………………………………….. 21

2. Daily Maintenance….…………………………….………………………………………………... 21

3. Weekly Maintenance………………………………………………………………………………. 21

Clean Drain ………………………………………………………………………………………… 21

4. Monthly Maintenance……………………………………………………………………………… 22

a. Descale Generator …………………………………………………………………………….. 22

b. Descaling Procedure……………………………………………………………………………. 23

B. OPERATORS TROUBLESHOOTING GUIDE……………………………………………………… 25

0

CHAPTER 7 STEAM COOKING GUIDE ……………………………………………………………….. 29

A. INTRODUCTION……………………………………………………………………………………….. 29

B. SIZING UP PAN CAPACITY………………………………………………………………………….. 30

1. Serving Sizes – How Much? How Many?............................................................................. 30

2. Reference Charts for Typical Pan Capacities....................................................................... 30

C. CONVECTION STEAMER SUGGESTED TIMER SETTING GUIDELINES……………………. 31

D. STEAMING TIPS FOR LOBSTER AND CRAB…………………………………………………….. 33

1. Live Lobster and Crab..………………................................................................................... 33

2. Lobster Tail………………………………………………………………………………………… 33

3. King Crab Legs…………………………………………………………………………………….. 33

Page 7

CHAPTER 1 INTRODUCTION

®

To use a SteamCraft® gas steamer safely and effectively, each operator must read and understand this

Chapter completely before starting operation. Owner(s) and operator(s) of steamer(s) must keep these

instructions in an easily accessible location for reference and training.

Owner(s) and operator(s) of steamer(s) must be aware that steam can cause serious injuries and

equipment damage. Pay particular attention to the Operational Safety section of this chapter, and

DANGERS, WARNINGS and CAUTIONS displayed in this manual and on equipment.

DANGER

DO NOT ATTEMPT TO START OR OPERATE a SteamCraft

steamer during a power outage.

DEATH, INJURY, AND/OR EQUIPMENT DAMAGE could result from

the improper installation of a steamer.

Before starting a recently installed or repaired steamer, be sure it has

been installed by qualified personnel according to the instructions

found in the separate Installation and Maintenance Manual.

A. Free Start-Up Program

Cleveland Range’s “Free Start-Up” is designed to help owners and operators get the most from their

Cleveland Range equipment.

Performance Check-Out: Contact your Cleveland Range maintenance and repair center for your

Performance Check-Out. This includes inspection of installation, reviewing cleaning and

maintenance instructions, and starting warranty protection.

Equipment Demonstration: After your Performance Check-Out, contact your Cleveland Range

sales representative for your free demonstration of proper operation, use, and care of your new

equipment.

Use and Care Video: After your Equipment Demonstration, your sales representative will present

and explain your free copy of the Cleveland Range Use and Care Video.

Consult your Customer Service Directory or call Cleveland Range at 216-481-4900 to begin your

free Start-Up Program

B. GAS LEAK INSTRUCTIONS

If operator(s) smell gas or suspects there is a gas leak: immediately refer to posted gas leak

instructions. Posted instructions are provided by local gas suppliers and supersede any other

instructions.

Common precautions in the event of a gas leak include:

1

Page 8

•

Do not light or start any appliance

•

Do not touch any electrical switch

•

Do not use any phone in building

•

Immediately call gas supplier from a phone away from building

•

Follow gas supplier’s instructions

•

If gas supplier cannot be reached: call fire department

C. OPERATIONAL SAFETY

Safe and effective operation of steamer(s) depends upon proper installation, use, maintenance, and

repair. Operational safety must include all of these. The Operational Safety section outlines minimum

safety policies and practices that must be used when operating one or more SteamCraft

®

steamers.

Any operational safety program must be tailored to the specific site and use of equipment.

Burn hazards are present in any professional food service operation.

When using steamer(s), observe the following precautions:

•

Remember at all times that steam can cause severe burns

•

When checking inside steamer: stand on hinge side and back from steamer

•

Open door slowly

•

Water leaking from door gasket can mean a blocked drain

•

If drain is blocked, hot water can fill the compartment and spill out when door is opened

•

Open door slightly to allow steam to vent before looking or reaching into cooking compartment

•

Do not reach into cooking compartment until steam has cleared

•

Do not reach into steamer or handle hot items without wearing DRY heatproof gloves

•

Wet or damp gloves conduct heat, and may cause burns when touching hot items

•

Do not use anything but hands to operate switches or any other control on steamer(s)

•

Do not block vents on sides or rear of steamer

•

Do not block combustion and ventilation air flow to steamer

•

Do not store articles on top of steamer

•

Do not block gas flue exhaust

Steamer(s) require minimum service if properly operated and maintained by trained personnel

The following steps will help keep the steamer in a safe, efficient operating condition

1. Do not store or leave combustible materials near steamer(s)

2. Keep the area around and under the steamer(s) free of combustible materials

3. Use non-slip draining anti-fatigue mats rated for use in wet, greasy, or dry work areas to help

prevent slipping and / or falling injuries. Obtain the best mats for your needs from your local

supplier

4. Train all personnel who will use the steamer

5. Personnel must know how to:

2

Page 9

• operate steamer(s)

• clean interior(s) and exterior(s)

• drain steamer(s)

• descale steam generator(s)

6. Steamer(s) may be equipped with a three-prong (grounding) plug for protection against shock

hazard

7. Grounding plugs must be plugged directly into a properly grounded three-prong receptacle

8. Do NOT cut off or remove or alter the grounding prong

9. Insp e ct gas flue exhaust per i od i c al l y fo r si g n s o f s o ot i n g o r bl o c ka g e

10. Contact a qualified Cleve land Range authorized service representative to service steamer(s) if any

improper operation of the burner system is suspected

11. Operating personnel must be able to recognize problems and report them so that corrective actions

can be taken by trained personnel as outlined in the troubleshooting charts found in the back of this

manual and in the separate Installation Manual

12. Conduct regular steamer inspections. Check for:

• water line leaks

• door seal leaks

• drain leaks

• clogged drain(s)

• steam generator scale buildup

• steamer control malfunctions

13. Follow the instructions for steamer maintenance found in this manual and the Installation Manual

14. Before each use of the steamer:

• inspect compartments for drain and screen blockage

• inspect door gasket assemblies for proper installation and cleanliness

• inspect slide racks for proper installation and cleanliness

15. Allow only qualified Cleveland Range authorized service representatives to service the steamer

16. Use only factory authorized repair parts

17. Maintain written records of steamer maintenance and service. Each record should include at least:

•

date of the maintenance or service

•

description of the maintenance or service performed

•

include part numbers if applicable

•

copies of purchase order(s) and invoice(s) for service and parts

•

name and signature of person performing the maintenance or service

3

Page 10

D. Product Information

Gas Flue Exhaust

Descaling Port

Descaling Port

Timer Controls

ON / OFF Switch

TIMED / MANUAL Switch

Descaling Required Light

4” Adjustable Legs

Descaling Port

Gas Flue Exhaust

Note: SteamCraft® Ultra 10 has a threaded 2½” tall

steam relief valve (“pop valve”) at the back of the

steamer behind the gas flue exhaust.

DO NOT attach anything to this relief valve.

Timer Controls

Timed / Manual Switch

ON / OFF Switch

Descaling Required Light

Drain Trough

6” Adjustable Flanged Feet

4

Page 11

CHAPTER 2 GENERAL OPERATION

S

t

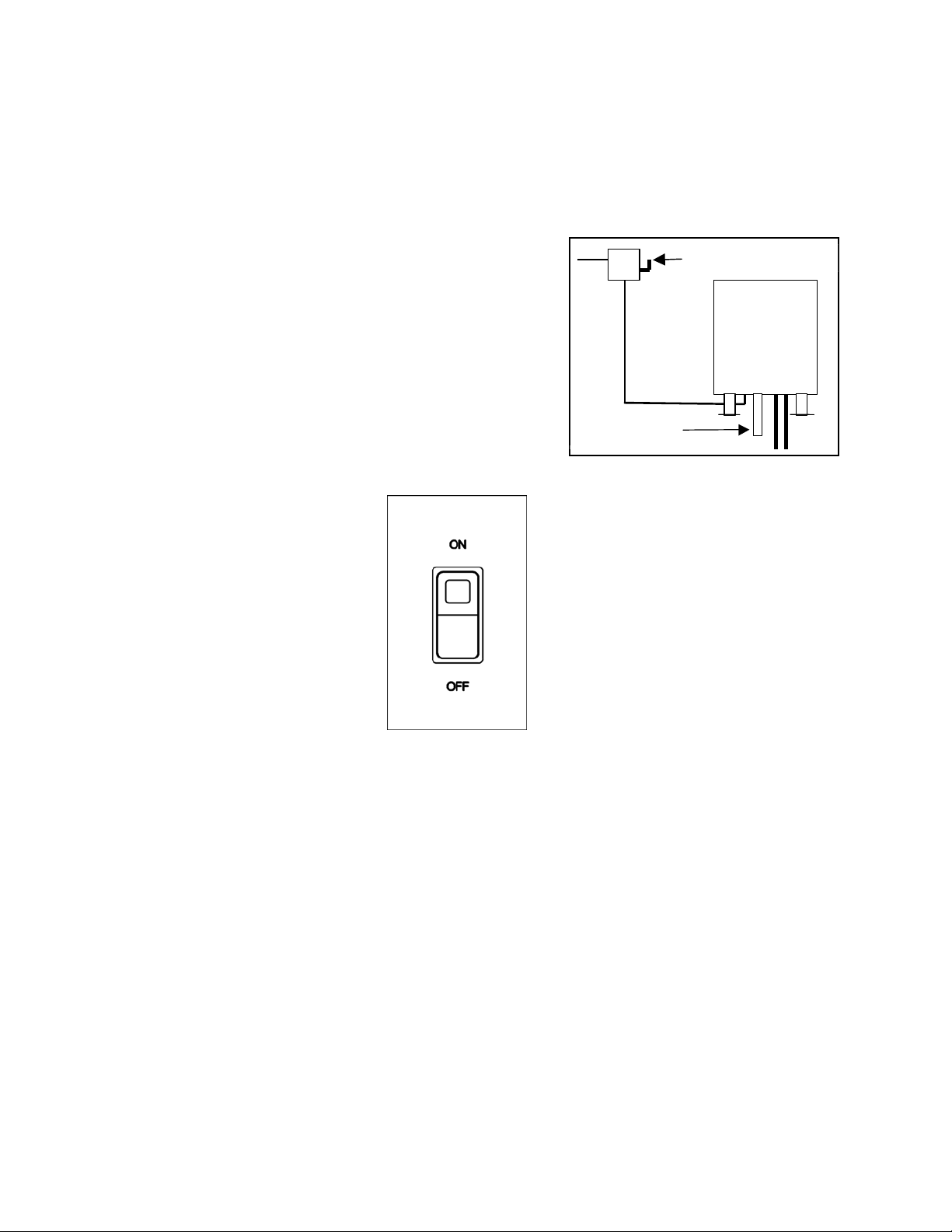

A. MAIN EXTERNAL POWER SWITCH

Usually the steamers main external power switch is left ON.

If the main external power switch is OFF, turn it ON as

follows:

1. OPEN water supply valves

2. Turn ON/OFF switch to OFF (Figure 2-2)

3. TIMED/MANUAL switch and timer settings are not

important in this procedure. Control panel circuits are

not powered while ON/OFF switch is OFF

MAIN EXTERNAL

POWER SWITCH

teamCraf

4. Refer to Figure 2-1. Use main external power switch to

turn on electric power to steamer. Steam generators will

DRAIN LINE

immediately start blowdown cycles. Blowdown cycle

lasts 3 minutes.

Figure 2-1 Main External Power Switch

Figure 2-2 Compartment POWER

ON/OFF Control

B. DOOR INTERLOCK SWITCH (OPTIONAL)

The steamer compartments of the SteamCraft

®

Steamer can be equipped with automatic steam cutoff

switches, which turn OFF the production of steam to a cooking compartmen t whenever the door to that

compartment is opened.

NOTE: Even though the continued production of steam ends as soon as a door is opened, it may take

up to a minute for residual steam in the system to clear from the steam lines and the cooking

compartment. To avoid possible injury always wait until this residual steam has cleared before reaching

into the cooking compartment.

C. POWER ON (AUTOMATIC FILL)

Use this procedure at the start of a shift to prepare the steamer for operation without starting steam

generation.

When the steamer is turned ON, the steam generator automatically fills with water.

5

Page 12

1. Press TIMED (top end) of the TIMED/MANUAL switch (for ON/OFF models set the compar tment(s)

ON/OFF switch(es) to OFF)

2. Turn the steamer ON/OFF power switch to the ON position (Figure 2-2)

• Steamer compartment control panel(s) energizes

• Steam generator fills to the operating level

• Steamer heat standby operation starts (see Chapter 2, Section H for details)

3. When ready to start cooking, begin either Timed or Manual operating procedures in Chapter 4

D. LIGHTING AND SHUTDOWN INSTRUCTIONS

DO NOT TRY TO LIGHT BURNERS WITH A FLAME

BURNERS ARE SELF-IGNITING

SteamCraft

• automatically light burners

• sense flame

• control gas flow.

Electronic ignition systems provide:

• safe ignition

• precise burner control

• safe shutdown.

®

Steamers have electronic ignition systems that:

DANGER

DEATH, INJURY AND/OR EQUIPMENT DAMAGE will result from an

improperly adjusted gas control and ignition system.

Do not alter or make adjustments on the gas control and ignition system.

If adjustment is required: contact an authorized service center.

If adjustment is required, contact a Cleveland Range authorized service

center. Cleveland Range is in no way responsible for the operation or safety

of this equipment if the controller, valve, igniter probe or any other gas system

component is adjusted by anyone other than a qualified Cleveland Range

authorized service representative

START-UP and SHUT-DOWN SUMMARY

For quick reference ONLY.

For safe operation and use of this equipment: operators must comply with all safety and operating

instructions

Note: Standby heat timer maintains steam generator water temperature by igniting burner for 20

seconds every six minutes. (See Section H) This is normal.

6

Page 13

Model 21CGA5 Gas Fired Table Top Steam Generator and Cooker

Lighting Instructions – 21CGA5

1. Turn the ON/OFF SWITCH to the ON position

• Steam Generator will fill with water (about 5 minutes)

2. Turn ON the COOKING COMPARTMENT

• Spark will initiate and main gas valve will open for 4 seconds

• If the burner fails to light in 4 seconds then the gas valve will close and lock out

3. Turn ON the COOKING COMPARTMENT

4. System may be reset manually

• Wait 5 minutes

• Turn the ON/OFF SWITCH to OFF and back to ON

Shutdown Instructions – 21CGA5

1. Turn POWER ON/OFF Switch to OFF.

• Burners turn OFF

• Drain opens

• Steamer starts 3 minute blow down cycle

• Control panels de-energize

Model 21CGA10 Gas Fired Floor Mounted Steam Generator and Cooker

Lighting Instructions – 21CGA10

1. Turn the ON/OFF SWITCH to the ON position

• Steam Generator will fill with water (about 5 minutes)

2. Turn on a COOKING COMPARTMENT

• Blower will start and pilot will attempt to light for 90 seconds

• If no ignition occurs the system will automatically reset in 6-7 minutes

3. System may be reset manually

• Turn the ON/OFF SWITCH to OFF for 5 minutes

• Turn the ON/OFF Switch back ON

Shutdown Instructions – 21CGA10

1. Turn POWER ON/OFF CONTROL to OFF.

• Burners turn OFF

• Drain opens

• Steamer starts 3 minute blow down cycle

• Control panels de-energize

DANGER

Steam leaks around the door, cooking compartment flooding,

reduced cooking performance, and compartment implosion

can be caused by a blocked drain or drain screen.

Inspect and clean the drain and drain screen before each use.

7

Page 14

E. INSPECTING COOKING COMPARTMENT

Drain and Drain Screen

Inspect and clean drain and drain screen before each use

Drain screen covers drain at back of cooking

compartment (Figure 2-4)

Screen prevents large food particles from entering and

blocking drain line

Any blockage of drain line or screen reduces drainage

from cooking compartment(s)

• reducing cooking performance

DRAIN SCREEN

• causing equipment damage

• creating hazards to operators

Figure 2-4 Compartment

Drain Screen

A blocked or slow drain causes:

•

Hot water to collect in the compartment and spill out when the compartment door opens

•

Pressure fluctuations in the compartment, resulting in steam leaks around the door gasket, or

compartment implosion

•

Reduced convection in the compartment, reducing cooking performance

Before every steaming operation: inspect the cooking compartment and remove any food scraps or

debris from the racks, walls, and floor of the compartment. Pay particular attention to the drain and drain

screen.

1. DO NOT use steamer(s) if water stands in the drain opening

2. Clean the drain in accordance with the instructions found in Chapter 5, SHUTDOWN AND

CLEANING PROCEDURES and / or Chapter 6 PREVENTATIVE MAINTENANCE AND

TROUBLESHOOTING

3. REMOVE any food or debris blocking drain or drain screen

4. DO NOT push food or debris down the drain

5. Make sure screen covers drain. Screen prevents large pieces of food from entering and blocking

drain

F. PREHEATING STEAMER

BEFORE PREHEATING, inspect and clean compartment. After preheating, compartment will be too

hot to inspect and clean safely.

Preheating steamers helps productivity and consistency

To preheat: run a cooking cycle of approximately 15 minutes with no food in the cooking compartments.

If using a steamer with a keypad (electronic) timer: set a 1 minute cooking time for preheating.

The keypad (electronic) timer will only begin to countdown once the steamer has reached cooking

temperature.

8

Page 15

G. DESCALING REQUIRED LIGHT FEATURE

These steamers have a reminder light to let the operator know when descaling procedure is required.

1. When the pre-set number of hours passes

• “DESCALE REQUIRED” light turns on (Figure 2-5)

• Switch does NOT descale steamer – it is only a REMINDER to perform the descaling

operation

2. Descale steam generator as soon as possible

according to the instructions in Chapter 6 Section

A4

3. Press “DESCALE REQUIRED” switch after

descaling to turn off light and reset timer

Note: If the steamer is new or power has been OFF

for a prolonged period of time, the Descale

Required light timer will reset and the light will turn

ON even if it is not time for scheduled descaling.

Reset the light and verify the next scheduled

descaling from the maintenance records to ensure

the steamer remains on its proper descaling

schedule.

H. HEAT STANDBY FEATURE

The steamer has a Heat Standby Feature to keep the Steam Generator near steaming temperature

between cooking operations. When timed models have the timer set to zero or ON/OFF models are

set to OFF, the Heat Standby Feature will turn the burners on every 6 minutes for 20 seconds as long

as the steamer is ON and has water in it.

Figure 2-5 Descale Required Light

NOTE: Orientation of

switches may vary

depending on model.

• Do not work near or above the exhaust flue whenever power is on.

• There is no warning to Heat Standby burner ignition.

I. MINERAL PURGE CYCLE (OPTIONAL)

The steamer can be equipped with a mineral purge cycle designed to help remove solid particles from

the steamer before they form scale. Once every minute the drain valve will open for 1 second to allow

mineral laden water to exit the drain. The Mineral Purge Cycle will operate whenever the steamer is

ON whether or not it is in cook mode.

9

Page 16

CHAPTER 3 CONTROL PANELS

Standard steamer control panels have mechanical timers (Figure 3-1)

Optional electronic keypad timers are available (Figure 3-2)

• Electronic timers count down only when compartments are at cooking temperature

Optional ON/OFF control panels are available (Not Shown)

• ON/OFF control panels use selectors to turn steam ON and OFF

• Operation is identical to the MANUAL mode of timer equipped models

A. DIAL TIMER CONTROL PANEL

1. Cooking Operations – Dial Timer Control Panel

For safe, efficient operation Dial Timer Control Panel steamer(s), operators must at minimum:

• follow all cautions, warnings and instructions

• be familiar with control panel shown in Figure 3-1

• be familiar with all operating features before attempting to operate steamer(s)

2. Manual and Timed Modes

• Steamer has two operating modes: manual and timed

• TIMED/MANUAL rocker switch selects operating mode

• Pressing MANUAL end of switch selects manual operating mode

• Pressing TIMED end of switch selects timed operating mode

• Cooking procedures are slightly different for each mode

a. Manual Mode

• Manual mode provides continuous steaming

• Operator starts and stops steaming operations

• See the Operating and Cooking Procedure – Manual mode in Chapter 4, Section B for

more information.

b. Timed Mode

•

Timer provides timed control of steaming operations

•

Timer starts and stops steaming operations

•

To use timer: set timer to desired time

•

Steamer will begin cooking as soon as timer is set

•

When timer reaches zero:

Steaming functions will automatically end

Buzzer will sound for 3 seconds to alert operator(s)

10

Page 17

1). DIAL TIMER

Dial timer sets the operating time from 0 to 60

minutes Turn dial clockwise until it points to the

required number of minutes. When timer reaches 0,

a buzzer sounds for 3 seconds

2). TIMED/MANUAL Sw itch.

TIMED/MANUAL switch selects the manual or

timed operating mode. Pressing MANUAL (bottom)

end of switch selects manual mode. Pressing

TIMED (top) end of the switch selects timed mode.

3). POWER ON Indicator Switch and Light.

When red indicator light is ON Power is ON to

control panel.

SteamCraft® Ultra 10

Located below top

compartment control

Figure 3-1 Dial Timer Control Panel

11

Power ON Control

panel

Page 18

B. KEYPAD TIMER CONTROL PANEL

CAUTION

Press switches and keys with fingertips only.

Do not use kitchen utensils or anything sharp.

1. Cooking Operations – Keypad Control Panel

For safe, efficient operation of the steamer, the operator must, at a minimum:

• Comply with all cautions, warnings and instructions in detailed operating procedures

• Be familiar with the control panel shown in Figure 3-2

• Operator must be familiar with all operating fe atures e xplained in this manual before attempting

to operate the steamer.

2. Manual and Timed Modes

• Steamer has two operating modes: MANUAL and TIMED

• TIMED/MANUAL rocker switch selects operating mode

– Pressing MANUAL end of switch selects manual operating mode

– Pressing TIMED end of switch selects timed operating mode

• Cooking procedures are slightly different for each mode

• Manual mode provides continuous steaming

– Operator starts and stops steaming operations

3. Timed Mode and Use of the Timer

a. Timer Use and Temperature Compensation

Keypad timer control starts and stops steaming operation, and monitors cooking time and

compartment temperature for accurate, efficient, uniform steam cooking.

•

Keypad control uses a temperature compensation circuit

•

Timer automatically adjusts for food defrosting and/or compartment heat up time

•

Timer ONLY COUNTS DOWN WHILE THE COOKING COMPARTMENT IS AT COOKING

TEMPERATURE.

•

This provides automatic control of the steaming operation and assures uniform cooking

•

When steamer is below cooking temperature: timer pauses and displays “PAUS”

•

When temperature is reached: remaining time is displayed

•

When the timer counts down to zero

– buzzer sounds (Press the START/STOP key to silence the buzzer)

– steam generator shuts down

•

Timer will countdown when steamer is being operated in manual mode only when steamer

is at cooking temperature BUT timer does not start or stop steaming cycle

12

Page 19

b. Timer Operation

1). Setting the Timer

• Timer must be zeroed (Press the CLEAR key to zero the timer)

• Timer can be set only when cooking time display is clear (00:00)

• Cooking time display contains four digits

– Left two digits are minutes

– Right two digits are seconds.

• The display 12:34 is set for 12 minutes and 34 seconds.

2). To set cooking time:

a) Calculate required cooking time in minutes and seconds.

b) Press number keys for minutes and then for seconds.

c) If the cooking time is 99 seconds or less only press the number keys for seconds.

3). Starting/Stopping Timer

Press START/STOP key to start or stop timer

When START/STOP key is pressed steam generator begins heating water

Steam fills the cooking compartment.

a) Timer display reads “PAUS”

until the cooking compartment reaches proper cooking temperature

when timer cycle is paused by pressing the START/STOP key again after timer

has started

b) When cooking compartment reaches proper cooking temperature timer display shows

count down

Example: A timer setting of 10 minutes may take 11 or 12 minutes for timer to countdown and

alarm to sound. This is normal. Heating compartment and food to cooking temperature

uses additional time.

4). Shutting Off Alarm

(a) When timer counts down to zero:

• alarm sounds continuously

• generator stops steaming

• steam flow to cooking compartment gradually stops

(b) Press the START/STOP key to silence the alarm

(c) Cooking time display returns to last time set

(d) Either run same setting again or clear and reset timer

13

Page 20

TIMER Display

• Four digit display indicates minutes and seconds

remaining in countdown

• Display shows from zero (00:00) to 99 minutes and

99 seconds (99:99)

• Display shows PAUS when countdown is halted

either by the START/STOP key or by the

Temperature compensating circuit.

Number Pad Keys

• Keys set number of minutes and seconds in timer

countdown

• Pressing 1 2 3 4 sets timer for 12 minutes and 34

seconds (12:34)

START/STOP Key

• START/STOP Key starts and stops the timer

• In TIMED mode steaming functions are linked to

timer

• In MANUAL mode steaming functions are

independent of timer.

CLEAR Key

• Clear Key resets the timer to zero (00:00) after

timer has been stopped

• Clear Key must be pressed before a new time can

be set

TIMED / MANUAL Switch

• TIMED/MANUAL switch selects the manual or

timed operating mode.

• Pressing MANUAL (bottom) end of switch selects

manual mode

• Pressing TIMED (top) end of switch selects timed

mode

POWER ON Indicator Switch and Light

• When red indicator light is ON, power is ON to

control panel

SteamCraft Ultra 10

Power ON Control

Located below top

compartment

control panel

Figure 3-2 Keypad Control Panel

14

Page 21

CHAPTER 4 COOKING WITH THE STEAMER

g

t

r

Y

DANGER

When checking inside the steamer: Turn OFF the compartment

before opening the door and always open the door slowly and

stand to the hinge side and away from the steamer. Water leaking

from the door gasket can be a sign of a blocked drain. If the drain

is blocked, hot water can accumulate inside the compartment and

spill out when the door is opened.

DANGER

FOR STEAMERS WITH OPTIONAL DOOR

INTERLOCK: Even though the production of steam ends

as soon as a door is opened, it may take up to a minu te

for residual steam in the system to clear from the steam

lines and the cooking compartment. To help prevent

injury: always wait until this residual steam has cleared

before reachin

into the cooking compartment.

DANGER

SEVERE BURNS will result from exposure to steam.

Do not open the steamer door before steam flow stops. Stand to

hinge side and away from steamer when opening the compartmen

door. Open door slightly to allow steam to vent before looking o

reaching into cooking compartment. Do not reach into cooking

compartment until steam has cleared.

Do not reach into steamer or handle hot items without wearing DR

heatproof gloves. Wet or damp gloves conduct heat, and may cause

burns when touching hot items.

CAUTION

Some foods drip juices. Use a solid catch pan under

perforated pans when steaming food that will drip juices.

Failure to use a catch pan can cause a clogged drain.

15

Page 22

A. OPERATING AND COOKING PROCEDURE – TIMED MODE

In timed mode, timer starts and stops steaming operation

1. Inspect and clean drain and cooking compartment as required. Refer to INSPECTING

COOKING COMPARTMENT in Chapter 2, Section E

2. If necessary, preheat cooking compartment. Refer to PREHEATING STEAMER in Chapter 2,

Section F

3. Slide pans of food into slide racks inside steamer

4. Do not place pans or anything else on bottom of compartment

•

For best cooking results, use 2-1/2 inch deep, perforated pans without covers

•

These give best heat transfer and shortest cooking time

5. Close steamer door

6. Check control settings. Settings should be:

•

ON/OFF switch is ON

•

TIMED/MANUAL switch is TIMED

7. Set required cooking time. For KEYPAD MODELS press START/STOP key to start cooking

cycle

8. Shortly after the door is closed, steam fills the cooking compartment

9. When timer reaches zero cooking cycle is complete

10. Buzzer sounds, steam generator stops and steam flow to cooking compartment gradually stops

•

For DIAL timers the buzzer will stop after 3 seconds

•

For KEYPAD timers, press START/STOP key to silence alarm

11. Carefully open the cooking compartment door, and remove the pans from the slide racks

•

If steamer will be used again in a few minutes shut door to maintain cooking compartment

temperature

•

If another use is not planned for more than half an hour leave the cooking compartment

door slightly open to reduce internal pressure while steam condenses and compartment

cools

•

If steamer is not being used again during this shift, perform Power OFF and Shut Down and

Cleaning Procedures found in Chapter 5

B. OPERATING AND COOKING PROCEDURE – MANUAL MODE

• Operator controls cooking functions

• Operator starts and stops steaming operations

• Operator sets cooking time including heat-up time for steam generator, compartment, and food

• Use manual-cooking mode for:

– Maintaining compartment temperature between cooking batches

– Continuous supply of steam

16

Page 23

1. Using Timer in Manual Mode

• Keypad timer may be used when steamer is operating in manual mode

• BUT keypad timer will not start or stop the steaming cycle

2. Manual Cooking Procedure

Follow this procedure when cooking in manual mode.

a. Inspect and clean drain and cooking compartment. Refer to INSPECT THE COOKING

COMPARTMENT in Chapter 2, Section E

b. Operator can bring compartment to cooking temperature by either preheating or increasing

the cooking time. If the operator chooses to preheat the cooking compartment manually,

refer to PREHEATING THE STEAMER in Chapter 2, Section F

c. Slide pans of food into racks inside steamer. Do not place pans or anything else on bottom

of compartment.

1) For best cooking results, use 2-1/2 inch deep, perforated pans without covers.

2) These give best heat transfer and shortest cooking time.

d. Close steamer door

e. Select manual mode by pressing MANUAL end of TIMED/MANUAL rocker switch

f. Steaming cycle starts as soon as switch is pressed

g. Shortly after door is closed, steam fills cooking compartment

h. If KEYPAD timer is used to monitor cooking:

1) Set and start timer

2) KEYPAD timer only counts down time when steamer is at cooking temperature

3) buzzer sounds when timer reaches zero

4) Press START/STOP key to turn OFF buzzer

5) In manual mode timer does NOT stop steaming functions

i. To stop manual mode steaming

1) Turn timer OFF, or set to ZERO, or for ON/OFF Models turn ON/OFF switch OFF

2) Press TIMED end of TIMED/MANUAL rocker switch for timer models

3) Generator stops

4) Steam flow to cooking compartment gradually stops

j. Carefully open cooking compartment door, wait for steam to clear, and remove pans from

slide racks.

1) If steamer will be used again in a few minutes: shut door to maintain temperature.

2) If another use is not planned for more than half an hour: leave cooking compartment

door slightly open to reduce internal pressure while steam is condensing and cooling.

3) If steamer is not being used again during this shift, perform POWER OFF, SHUT

DOWN, and CLEANING PROCEDURES in Chapter 5

17

Page 24

CHAPTER 5 SHUTDOWN AND CLEANING PROCEDURES

A. STEAM GENERATOR BLOWDOWN

1. Power Off (Automatic Blowdown)

• Blowdown occurs automatically when steamer is turned OFF at its ON/OFF switch

• Steam generator drain valve is rinsed with fresh water and drained

• Blowdown at frequent intervals helps decrease scale buildup in steam generators

• Blowdown at frequent intervals reduces frequency of descaling and other maintenance

2. Blowdown Frequency

Supply water quality determines how often blowdown must be performed

More frequent use and higher content of total dissolved solids and particulates in feed water require

more frequent blowdown

A determination should be made before installation if additional blowdowns will be required as part

of daily maintenance based on water quality analysis done before installation

This information should be noted in the daily maintenance program developed for the equipment

After it has been determined whether or not the local water supply meets the minimum supply water

quality standards, observe the following guidelines to establish proper blowdown scheduling:

•

When using a supply water system that does not meet the minimum supply water quality

standards, blowdown must be performed after every 4 hours of operation, or more frequently as

required, and at the end of each shift

•

For steamers using water that meets the minimum supply water quality standard, either

naturally or by using a water treatment system, blowdown must be performed at the end of

each shift

3. Blowdown Procedure

When each steamer is turned OFF, its blowdown cycle starts and runs automatically

A complete cycle takes about 3 minutes.

Do NOT turn power OFF at the main external power switch during blowdown

a. Turn ON/OFF switch to OFF.

b. Red indicator light turns OFF

c. Drain valve opens

d. Drain valve draws water from steam generator

e. Fill valve operates for 3 minutes to help flush debris through the drain valve as generator

drains

f. At end of 3-minute blowdown cycle: fill valve closes

g. When blowdown is complete steamer can be restarted, or shutdown procedure completed

•

To restart steamer, refer to POWER ON in Chapter 2, Section C

•

To shut down steamer, refer to SHUT DOWN and CLEANING in Chapter 5

18

Page 25

B. SHUT DOWN AND CLEANING

Do not use a hose or water jet

Wait for steamer to cool before cleaning!

Let rinse water drain through compartment drain opening. If water does

not drain freely: drain lines must be cleaned before cooking again.

Clogged or slow drains are dangerous because hot water can collect in

compartment and spill out when door is opened.

WARNING

to clean steamer!

DANGER

WARNING

DANGER

DANGER!!

Steam leaks around the door, cooking compartment flooding,

reduced cooking performance, and compartment implosion

can be caused by a blocked drain or drain screen.

Inspect and clean the drain and drain screen before each use.

This procedure should be performed at the end of each shift

1. Refer to Power OFF (Automatic Blowdown), and turn OFF steamer

2. Allow 3 minutes for automatic blowdown cycle

3. Open steamer door and allow steamer to cool

4. Remove slide racks

5. Wash and rinse racks separately or clean them in a dishwasher according to health requirements

6. Do not remove drain screen

7. Remove spilled food from inside compartment

8. Clear residue from drain screen

9. Clean interior of compartment thoroughly

10. Use soft bristle brush to remove stubborn food particles

11. Do not use abrasive cleaning compounds or steel wool

12. Rinse inside of steamer compartment with clean water

19

Page 26

13. Clean door assembly

a. Remove door gasket assembly (see Figure 5-1)

b. Grasp gasket assembly at sides and lift up and towards

you to remove assembly

c. Note keyhole slots on the door and retaining pins on

gasket assembly

d. Wipe gasket assembly with damp cloth

e. Wipe inside of door with damp cloth

f. Rotate gasket assembly 180°

g. Replace by sliding the retaining pins into the keyhole slots

h. Either long edge of gasket assembly fits at top

i. Periodic rotating of door gasket assembly will increase

door gasket life

14. Replace cleaned slide racks

15. Wipe exterior with damp cloth

16. NEVER HOSE DOWN STEAMER

• Electrical components inside steamer will not function correctly if wet or damp

17. Leave steamer door(s) open until next steamer operation

• This prevents compartment odor buildup and increases gasket life

Figure 5-1

Door Gasket Assembly

20

Page 27

CHAPTER 6 PREVENTATIVE MAINTENANCE AND

TROUBLESHOOTING

A. MAINTENANCE

Maintenance on steamers must be performed on a regular basis to keep steamers operating properly.

By following the maintenance instructions in this chapter and in the separate Installation Manual,

problems with steamers will be kept to a minimum. Frequency of steamer maintenance may need to be

increased, depending on equipment usage and water quality. If problems occur, refer to the

Troubleshooting Guide in this chapter. For more information on products and services, contact your

sales representative.

1. Maintenance Records

Make a file for maintenance records

Keep a written record of daily, weekly, monthly, and yearly maintenance

These records will:

• Help protect warranty coverage

• Help personnel know when to perform maintenance

• Assist service personnel

2. Daily Maintenance

a. Blowdown Steam Generator

Blowdown each steam generator according to steam generator blowdown instructions in

Chapter 5.

b. Clean the Steamer

Clean interior and exterior of the steamer according to the shutdown instructions in Chapter 5.

3. Weekly Maintenance

Clean Drain

• Each cooking compartment is equipped with a drain screen

• Always operate steamer with screen(s) in place

• Screen(s) prevents large food particles from entering and blocking drain line

• Blockage of drain line can cause pressure buildup in compartment(s) resulting in steam leaks

around door gasket(s)

• Drain line blockage reduces convection action of steam in compartment(s) and reduces

performance

a) Inspect drain screen and drain line for blockage

b) Rotate drain screen 90 degrees to inspect drain opening

c) Clean opening and restore screen to its operating position

d) Clean drain with a USDA approved drain cleaner

e) Follow the instructions of the drain cleaner manufacturer

f) Flush drain with clean water

21

Page 28

4. Monthly Maintenance

a. Descale Steam Generator

• Steam generators should be descaled at least once a month, depending on scale buildup.

– For serious steam generator scale buildup: install a water treatment system for

steamer(s) generator water supply

– If this is not possible: Frequency of descaling must be increased

• Steamer has a descaling reminder light to assist in scheduling maintenance

– Descaling light has been factory set for an operating time of about 1 month

– If a different descaling frequency is required: have timer reset by a qualified Cleveland

Range authorized service technician

• When descaling light comes on: descale the steam generator as soon as possible

• Cleveland Range recommends the use of DISSOLVE® Descaler Solution, Cleveland

Range Part No. 106174 or 1061741

• Use no other system of steamer descaling

NOTE: Part No. 106174 is the Part No. for a case (6 1-gallon containers) of DISSOLVE

descaler. It is also available in 5-gallon containers as Part No. 1061741.

THESE INSTRUCTIONS ARE FOR USE WITH DISSOLVE

Cleveland Range Part Nos. 106174 or 1061741 ONLY.

•

Health Hazard Data, Effects of Overexposure

®

DESCALER SOLUTION

®

– This product may cause a burning sensation to eyes or skin.

•

Emergency and First Aid Procedures

– In case of eye contact, immediately flush eyes with plenty of water.

– If irritation persists seek medical attention. In case of skin contact wash with soap and

water.

– If inhaled, remove to fresh air and if burning persists, call a physician.

– If swallowed, drink 1 or 2 glasses of water and call a physician.

•

Spill or Leak Procedures

– Rinse with plenty of water to dilute.

– Sodium carbonate or calcium carbonate may be used to soak up liquid.

– Considered non-hazardous, spent material may be disposed of in a sewer system with

water flush.

CAUTION

Do not use any other product or method of descaling other than the

DISSOLVE

®

Descaler method using Part Nos. 106174 or 1061741.

22

Page 29

WARNING

Descaling procedure is slightly different depending on model. This

entire procedure should be read and fully understood as it applies to

the model being descaled, before beginning descaling operations.

DANGER

The liquid solution in Cleveland Range Descaler Solution Part No. 106174 or 1061741

can be harmful if not handled properly. Follow these basic safety rules for handling and

using this product. Instructions and warnings on container labels supercede all other

warnings and instructions.

Wear protective clothing when mixing or applying chemical cleaners

Wear rubber gloves, and OSHA approved eye protection when descaling

Avoid breathing fumes

If liquid contacts skin: wash with soap and water and seek medical attention.

If chemical contacts eyes: flush with water and seek medical attention

If chemical is swallowed or ingested: drink 1 or 2 glasses of water and seek medical

attention

Descaling Procedure for SteamCraft® Ultra 5 and Ultra 10

Cleveland Range recommends DISSOLVE® Descaler Solution, Part No. 106174 or 1061741

Use no other system of steamer descaling

Appropriate warnings and safe handling procedures must be provided to handlers and users

Instructions and warnings on Dissolve® containers and Material Safety Data Sheets supercede

and replace instructions and warnings in this manual

General precautions: wear rubber gloves, splash goggles and other protective clothing and

equipment as necessary. Refer to Dissolve® container labels and Material Safety Data Sheets for

information regarding eyewash, first aid, medical treatment, and spill control.

b. Descaling Procedure

1) Turn steamer OFF and open door(s)

• 3 minute Automatic Blowdown cycle runs

2) Turn steamer ON

• Generator begins to refill

23

Page 30

3) Press TIMED end of TIMED/MANUAL switch (or for

ON/OFF Models put the ON/OFF selector Switch in

the OFF Position)

4) DO NOT start timer

• Water must be cold for descaling

• Open cooking compartment door(s)

• Leave cooking compartment door(s) open

5) Remove descaling port cap (see Figure 6-1)

6) Add required amount of Dissolve® through the

descale port while generator refills

• Pour slowly to avoid overflow

• Refill can take up to 8 minutes

• Use 1 gallon Dissolve® for Ultra 5 gas

• Use 1 ½ gallons Dissolve® for Ultra 10 gas

7) Add 1-2 gallons of cold tap water to descaling port a fter refill stops, cont inue to fil l with c old

water until descaling solution enters cooking compartment(s) through steam nozzles

• Note: Some descaling solution will flow from drain of Ultra 10 gas steamers

• Adding extra water to generator(s) raises descaling solution to higher than normal

water fill level, allowing descaling solution to clean sensors and surfaces above

normal water fill level

8) Let descaling solution soak in generator(s) for 1 hour

9) After 1 hour, turn ON/OFF switch OFF to start 3 minute Automatic Blowdown

• This drains and rinses generator(s)

10) After Automatic Blowdown ends, turn ON/OFF switch to ON

11) Add cold tap water through descaling port after generator refills, until wa ter enters cooking

compartment(s) through steam nozzles

• This raises the water level to rinse the surfaces cleaned in Step 8

12) Turn ON/OFF switch OFF to start 3 minute Automatic Blowdown to rinse generator

13) Replace descaling cap and close cooking compartment door(s)

14) Turn TIMED/MANUAL switch to TIMED

Figure 6-1

Descale Port

15) Turn steamer ON/OFF switch to ON and set TIMER for 20 minutes

• For Keypad Timer models: Press START/STOP key to begin the cook cycle

• For ON/OFF models: Turn the steamer ON for twenty minutes

16) After the timer counts down, turn ON/OFF switch to OFF to start Automatic Blowdown

17) After Automatic Blowdown cycle ends, reset DESCALE REQUIRED light

18) Descaling is complete, resume normal startup, cooking, and shutdown procedures

24

Page 31

B. TROUBLESHOOTING GUIDE

The Troubleshooting Guide is a list of symptoms that may occur during routine operation.

• “Problem” (left column) lists common operating problems.

• “Possible Cause” (center column) lists causes of problems in order they should be checked.

• “Remedy / Reference” (right column) lists fixes for problems from easiest to hardest.

• “Notes” in “Remedy / Reference column are at end of Table 6-1 Troubleshooting Guide.

ATTEMPTING TO REPAIR OR CORRECT PROBLEMS REQUIRING A QUALIFIED CLEVELAND

RANGE AUTHORIZED SERVICE REPRESENTATIVE VOIDS WARRANTY

Trouble Shooting Guide

Table 6-1

PROBLEM POSSIBLE CAUSE REMEDY/REFERENCE

Power indicator light

does not turn ON when

ON/OFF switch is in the

ON position

Power ON but steam

generator does not fill

Power turned OFF at main external

power switch or breaker

Inoperative controls or failed light See note #1

Water supply to steamer shut off Open water supply valves

Water line strainer and/or external

filter system is clogged

Inoperative solenoids or controls See note # 1

Turn ON power at main external power

switch or breaker

Clean water supply strainer and/or filter

system

Control panel POWER

indicator light ON and

steamer does not make

steam in MANUAL or

TIMED modes

Abnormal amount of

steam coming from drain

timer does not light

(Electronic Timer models

only)

Compartment bottom

dirty with food drippings

Water supply to steamer shut OFF Open water supply valves

Door interlock switch not engaged or

has failed (if unit has this option)

Water line strainer and/or external

filter is clogged

Gas supply valve is closed Open gas supply valve

Inoperative controls or solenoid See note # 1

Hot water instead of cold water

connected to condenser fitting

Water supply to condenser turned

OFF

Condenser water line strainer and/or

nozzle clogged

Water supply line to condenser

blocked, broken, or leaking

Inoperative controls, thermostat or

solenoids

Timer transformer has failed See note #1Power light is ON, but

Inoperative controls See note #1

Juices and/or food leaking from pans Put a solid pan under perforated pans to

Close door completely If problem

persists, see note #1

Clean water supply strainer and/or

external filter system

Make proper connections See section

on Water Supply

Open water supply valve

Clean out condenser water supply

strainer and/or nozzle

Repair or replace water supply line See

note # 1

Turn OFF electricity at main external

power switch See note # 1

catch drippings, or put less food in pans

(Continued On Next Page)

25

Page 32

PROBLEM POSSIBLE CAUSE REMEDY/REFERENCE

Reduced Steam flow into

cooking compartment

Water leaking from

bottom of cabinet

Steam and / or water

draining around

compartment door

See Warning under

Note #7

Water leaking from water

pipes or drain lines

Descale Required

indicator is lit

Note: Switch does not

descale steamer, it is

just a reminder that

steamer must be

descaled every 4-6

weeks

steamer does not make

steam in timed mode

Water is flowing out of

steam ports into cooking

compartment

Water coming from drain

even when not cooking

Trouble Shooting Guide

(Continued)

Steam generator scale buildup Descale steam generator with Cleveland

Range approved descaler

Gas inlet pressure low See note #2

Inoperative or improperly adjusted

controls

Broken or loose plumbing inside

steamer cabinet

A small amount of water condensing

around the door is normal

External drain not properly installed,

should be free-air vented and

pitched down.

External drain is blocked or

restricted

Door gasket or door parts worn See note # 1

Inoperative controls inside cabinet Turn OFF power at main external power

Plumbing needs repair See note # 3

If steamer is new, or has just been

descaled

Steamer needs descaling Descale steamer with Cleveland Range

Bad or improperly set descale timer See note #1

Timer fuse has blown (Electronic

timer models only)

Inoperative timer control or damaged

wiring

Water level floats are dirty and are

not moving properly or stuck

(21CGA5) or

Water probes are dirty (24CGA10)

Inoperative controls or solenoid See note #1

Unit is equipped with mineral purge

cycle option

Condenser valve is bad See note #1

Drain solenoid is stuck partway open Turn OFF power to blowdown steamer. If

See note #1

Turn OFF electricity at main external

power switch and close water supply

valve(s) See note # 1

No action necessary

See notes #2 and #3.

Clean external drain

See note #3

switch See note # 1

Press switch to reset descale timer

approved descaler After descaling is

completed, press switch to reset descale

timer

See note #1ON/OFF Indicator ON but

See note #1

Turn OFF water supply to steamer and

descale steamer manually with

Cleveland Range approved descaler

See Operators Manual for instructions

If condition persists see note #1

If only a small amount of water is coming

intermittently from drain. This is normal

operation see Chapter 2, Section I

problem persists, see note #1.

(Continued On Next Page)

26

Page 33

PROBLEM POSSIBLE CAUSE REMEDY/REFERENCE

Steam flow does not stop

when TIMER stops.

Food takes too long to

cook

To verify steamer’s

proper operation see

note #6

Water comes out of

descale port

Trouble Shooting Guide

(Continued)

Operating in manual mode. Switch to timed mode for timer to control

steam flow.

Inoperative controls inside cabinet. Turn OFF power to that compartment at

ON/OFF lever/switch. See note #1.

Pans too close to bottom of cabinet Put pans in racks near top of cabinet

Compartment overloaded with too

much food

Food is being cooked in covered

solid pans

Put less food into pan

Use fewer pans

Remove covering

Steam must have direct access to food

for cooking to take place

Food is frozen Increase cooking times for frozen food

Suggested cooking times are usually

listed for cooking at sea level

Hot water connected to condenser

line

Extend cooking times for altitudes above

2000 feet

Make proper connections See section on

Water Supply. See note # 3

Condenser water is turned OFF Turn ON water to condenser

Condenser water line strainer and/or

nozzle is clogged

Clean out condenser water supply

strainer and/or nozzle

Steam generator scale buildup Descale steam generator with Cleveland

Range approved descaler

Inoperative or improperly adjusted

See note #1

controls

Descale cap is missing Install descale cap. Descale port must

be closed tightly for steamer to operate

properly. If missing see note #8

Descale cap is loose Tighten descale cap. Descale port must

be closed tightly for steamer to operate

properly

Descale cap and/or gasket is

See note #8

damaged

TROUBLESHOOTING NOTES

1. If problem is inside the steamer, call a qualified Cleveland Range authorized service representative.

Cleveland Range will not pay for warranty repairs by unauthorized repair centers.

2. Proper installation of the steamer is the responsibility of the owner or installer. Call a qualified Cleveland

Range authorized service representative to correct the installation. Refer to Cleveland Range Warranty.

3. Repairs to external plumbing should be done by a Licensed Plumber.

4. Repairs to external wiring should be done by a Licensed Electrician.

5. For more information on products and services, contact your nearest Authorized Sales Representative.

Call factory for preventative maintenance programs, descaling kits, descaling information, and water

treatment systems: USA: (800) 338-2204, Canada: (800) 427-6668.

6. To evaluate whether a SteamCraft

®

steamer is producing normal cooking performance, conduct the

Egg Test as follows (NOTE: this test is not valid for pressure steamers). A properly operating steamer

will produce cooked eggs as follows.

27

Page 34

Place a perforated steam table pan in the middle rack position in the cooking compartment. Turn ON

the steamer, and set the selector switch to the manual mode (or for ON/OFF models set the selector

to the ON position) so that steam is being produced. When wisps of steam have begun to exit the

steam nozzles, preheat the steamer by closing the cooking compartment door and leaving it ON for

ten minutes. After the compartment is preheated follow the instructions as listed below.

• Place a fresh egg in pan

• Close the door and set the timer as directed by the size chart below

Egg Size SteamCraft Steamer

Medium 12 minutes

Large 14 minutes

Extra Large 14 minutes

• When time is complete, carefully remove the egg and place in a container

• Run cold water running over the egg for 5 minutes

• After cooling, crack eggshell and peel

• The result will be a perfect hard boiled egg

7. Whenever opening door, especially when water or steam leaks around gasket, heed warning below:

WARNING

When checking inside the steamer: always open the door slowly and stand to

the hinge side and away from the steamer. Water leaking from the door gasket

can be a sign of a blocked drain. If the drain is blocked, hot water can

accumulate inside the compartment and spill out when the door is opened.

8. Replacement descale caps and gaskets can be ordered from a Cleveland Range authorized

maintenance and repair center.

28

Page 35

A

CHAPTER 7 STEAM COOKING GUIDE

A. Introduction:

Steam cooking is an excellent way to prepare food. Steam provides an even, intense and penetrating

heat so steam cooking is fast and convenient for large or small quantities. Food never burns, pans never

boil over, and there is no lifting of water in pots or waiting for water to boil. Steam cooking saves money

and time while maintaining high quality and consistency.

Seafood:

Steamed fish is tender, succulent, flaky and table ready in minutes. Steam cooking gives you, the

operator, precise portion control of expensive seafood products.

Vegetables:

Steam cooking vegetables – fresh or frozen – on perforated pans provides colorful, flavorful, and vitamin

packed servings in minutes. Just follow the recommended timer settings.

Meat:

Steam cooked meat is tender, moist and flavorful and shrinkage is minimal. Stew meat, pot roasts, ham,

and corned beef are wonderful when steam cooked. Meat steam cooked for sandwiches is moist, savory,

and sliceable. Steam tenderizes poultry for stewing, barbecuing, frying, and other cooking methods.

Desserts:

Prepare pudding and custard without scalding or scorching by steam cooking. Steam “baked” apples are

ready in minutes, as are applesauce, and stewed fruit. Dried fruits rehydrate quickly and consistently.

Steam “Baked” Apples: Core apples and arrange in a shallow pan. Fill the apples with your favorite

mixture of cinnamon, sugar, raisins, butter, brandy, etc. Steam for 3 minutes. If desired, brown slightly

under a broiler to “finish.” Serve with cream or ice cream.

dditional Ideas:

There are many applications for steam cooking besides vegetables and seafood:

• Eggs can be soft cooked, coddled, hard cooked, poached, scrambled, and made into custard or pudding.

25 dozen eggs can be hard cooked in 12 minutes using three 12” x 20” x 2½” perf orated pans in one

compartment of the steamer.

• Momentary steam blanching of fruits simplifies skin removal.

• Dumplings, steamed breads, muffins, hot cereal, pasta, noodle and rice can be prepared or reheated in

the steamer.

• Beef and other meat, cooked by steaming, is moist, tender and flavorful. The meat drippings from the

catch pan can be used to make gravy soups or clear stock, or as a salt free broth.

• Turkey, chicken and other poultry are tender, juicy when steamed then combined into a casserole, added

to BBQ sauce, or browned under the broiler. Chicken pieces can be breaded, steamed, then finished in

the deep fryer. It is crisp, delicious, and juicy.

• Hot Dogs, sausages and other variety meats remain plump and juicy when steamed.

• Entrees such as lasagna, macaroni and cheese, or beef stew can be prepared from scratch. Froze n

institutional packs can be reheated in the steamer. It is not necessary to cover them.

29

Page 36

B. SIZING UP PAN CAPACITY:

1. Serving Sizes – How Much? How Many?

How to estimate portion size and number of servings from a standard steam table pan.

• A 12” x 20” x 2½” solid pan will hold 7½ quarts or 240 fluid ounces.

Table 7-1 Serving Size

240 Fluid Ounces Produces

Portion Size Number of Servings Type of Product

10 oz 24 Stew, Casserole, Lasagna

8 oz 30 Soup, Bisque

6 oz 40 Soup, Bisque

4 oz 60 Mashed Potatoes

2 oz 120 Sauce

1 oz 240 Sauce

• Number of servings of cooked vegetables from one 12” x 20” x 2½” perforated pan.

Frozen Vegetable Yields:

10.0 lbs Approx. 50-3 oz servings

7.5 lbs. Approx. 35-3 oz servings

5.0 lbs. Approx. 25-3 oz servings

2. Reference Chart for Typical Pan Capacities

Size in Inches Quarts Fluid Ounces Pounds

12 x 20 x 1 ¼ 3 ½ 112 2

12 x 20 x 2 ½ 7 ½ 240 8

12 x 20 x 4 14 ½ 464 10

30

Page 37

C. CONVECTION STEAMER – SUGGESTED TIMER SETTING GUIDELINES FOR

TIMER CONTROLS WITH THE COMPENSATING THERMOSTAT (see Note)

Timer settings are approximate due to the differences in food quality, age, shape and the degree of doneness

desired. Perforated pans are recommended. Starred items (*) must be cooked in solid pans. Items marked

with two stars (**) require handling in two steps: 1) steam for approximately ½ the time shown, 2) remove

from steamer, separate thawed portion, or stir, and return to steamer for the time remaining. The

compensating feature of the timer allows the cooking compartment to reach temperature before the preset

time starts to count down. Note: Times may need to be increased slightly when using external timers to track

cooking times.

VEGETABLES: Fresh Frozen Fresh Frozen

Artichoke 12

Asparagus, spears 6 6

Beans, green, 2” cut 6 5

French cut 4 5**

Whole 6 4

Broccoli, spears 4-6 3-4

Florettes 3 1-2

Chopped 6-8

Brussels sprouts 4-5 4

Cabbage, 4

whole to remove

leaves for cabbage rolls

Carrots-baby whole 7 6

Sliced, 4 3

Cauliflower,

Florettes 5 3-4

Whole 10

Corn, yellow, whole 2

On cob, 5 12**

Cobbettes 6 12**

Mixed Vegetables 3-6 3-4

Mushrooms,

Whole 1½” 3

Sliced 1

Onions, diced, sliced 2-3 1

Whole 4 2

Peas, green 3

Potatoes, whole 8 oz. 20-25

Peeled, quartered, 15-19

Fresh peeled, diced 8-10

Potatoes, sweet, whole 20-30

Spinach leaf, whole 2 15**

Chopped 15**

Squash, acorn halves 6

Butternut, quartered 6

Spagh etti squash

Halves 15-18

Tomatoes, sliced* 1

Turnips, whole 20-25

Zucchini, sliced 2-4

SEAFOODS: Steam all seafood on a perforated pan

with catch pan

Clams in shell 3-5

Cod fillets, 6 oz. 6 8

Portions

Crab legs, king 6-8

Snow crab 4-6

Crab, live, 4 oz.

3/4 - 1 lb. 12

Halibut, 6-8 oz. 4-6 6-8

Lobster, whole, 1 lb. 6

Lobster tails, frozen, 8 oz 12

Defrosted, butterflied 4-6

Mussels in shell 5

Oysters in shell 2-4

Red snapper, 8 oz. 4-5 4-5

Salmon steak, 8 oz. 6 7

Shrimp, 10 ct. per lb. IQF 3 4-6

EGGS (Medium Sized):

Hard cooked for egg

Salad, potato salad 11

Soft cooked 3

Coddled 6

Scrambled* 7-10**

FRUITS:

Blanch for peeling

Fresh: Avocado 1

Grapefruit 1

Orange 1

Apricot 1

Dried: add water to re-hydrate

Apple 10

Apricot 10

Peach 10

Pear 10

Prune 10

31

Page 38

MEATS & POULTRY:

Cook meats and poultry in nested pans. Juices can

be used for gravy, sauces, beef stock and soups.

Portion size, thickness, and grade should be

considered when selecting a timer setting for

doneness.

Filet Mignon

4 oz. 3 min.

6 oz. 3-4 min.

8 oz. 4 min.

10 oz. butterflied 5 min.

16 oz. butterflied 8.min

POULTRY: Fresh Frozen

Turkey, whole 6-8 min./lb. 6-8 min./lb.

Chicken halves, 1¼ -1½lb.

per half 20-24 min.

Breast, boneless,

skinless 10-12 min.

PORK, SAUSAGE,

HOT DOGS: Fresh Frozen

Pork, Chop, 4 count/lb. 10 min.

Italian sausage, 4 oz. 10 min.

Ribs, 3lb. and down 30 min.

Hot-dogs, 8 count/lb. 5 min. 10

BEEF: Fresh Frozen

Cubes, 1 1/2” 6-7 min./lb.** 6 min./lb.**

Ground chuck for chili 6 min./lb.** 4-6 min./lb.**

Pot-roast, choice 8-12 min./lb.

Rump roast, choice

Boned, rolled, tied 12 min./lb.

Meat loaf, 4lb. Loaf 5 min./lb.

Corned beef, 6-8lb.

cut, add 1/2” water

to pan 20-23 min./lb.*

STEAKS: : Fresh Frozen

Using a 3/4” to 1” steak, the steaming time listed

below produces a “rare” steak. A “well done” steak is

first steamed to the “rare” stage, then broiled or grilled

for 1 1/2 minutes on each side. This “well done”

steak shrinks less, is more tender and juicy; and,

when served, is the same size as the “rare” steak.

STEAKS: : Fresh

Sirloin Chopped 8 oz 4 min.

Ribeye, 8 oz. 4 min.

Sirloin steak 6 oz. 4 min

8 oz. 6 min.

Strip steak - 10-oz. 5 min.

12 oz. 7 min.

T-bone 12 oz. 5 min.

16 oz. 8 min.

18 oz. 8 min.

22 oz. 10 min.

PREPARED ENTREES: Fresh Frozen

Full Size Pans

Cabbage rolls, stuffed* 30 min. 30 min.

Cover with tomato

Sauce & serve

Casserole dishes*

Beef Stew 30min. 60 min.

Stroganoff 30 min. 60 min.

Lasagna* fresh 30 min. 60 min.

Reheat serving 6-8 min. 12 min.

RICE & BEANS:

Rice, long grain

4 cups cold water/lb. 17 min.

Beans, pre-soaked overnight,

1 lb. Beans = 1 ¼ qt. Water 45 min.

Beans* unsoaked,

1 lb. Beans x 1 ½ qt. water 2 ½ Hours

Refried beans, 2-#10 cans 15-17 min.

PASTA:

Steam in nested pans. Place pasta on 2 ½”

perforated pan inside a solid 2 ½” pan. Cover pasta

with cold water.

Egg noodles, 1 ½” wide 4-6 min. **

Lasagna noodles 10-12 min.**

Macaroni, shells, elbow 10-12 min.**

Penne 10 min**

Rigatoni 10 min. **

Spaghetti, vermicelli 8 min.**

Spaghetti, regular 8 min.**

32

Page 39

D. STEAMING TIPS - LOBSTER - CRAB

1. Live Lobster and Crabs

a. Live lobsters and crabs are steamed according to the time on the Suggested Timer Setting

Guide.

b. Steam them on a perforated pan with a catch pan (a solid pan) on a lower pan slide. Discard the

juices and non-edible matter collected during steaming.

2. Lobster Tail 8 oz.

a. To serve in a shell, cut the frozen lobster tail in half, lengthwise. Place the cut side up on a

perforated pan. Steam 5-6 minutes or until the meat turns opaque white. Season and garnish to

serve.

b. To serve a butterfly lobster tail, thaw tail, cut top shell length-wise all the way to the tail fins.

Spread shells apart and pull meat out. Close empty shell and lay meat on top of shell. Steam

according to Suggested Timer Setting Guide.

3. King Crab Legs

a. Pre-cooked, frozen: steam just long enough to heat through.

b. Serve either whole or cut into 3 sections.

33

Page 40

Loading...

Loading...