Cleveland 24-CET-1 Service Manual

Cleveland Range

SERVICE

Printed

5/93

®

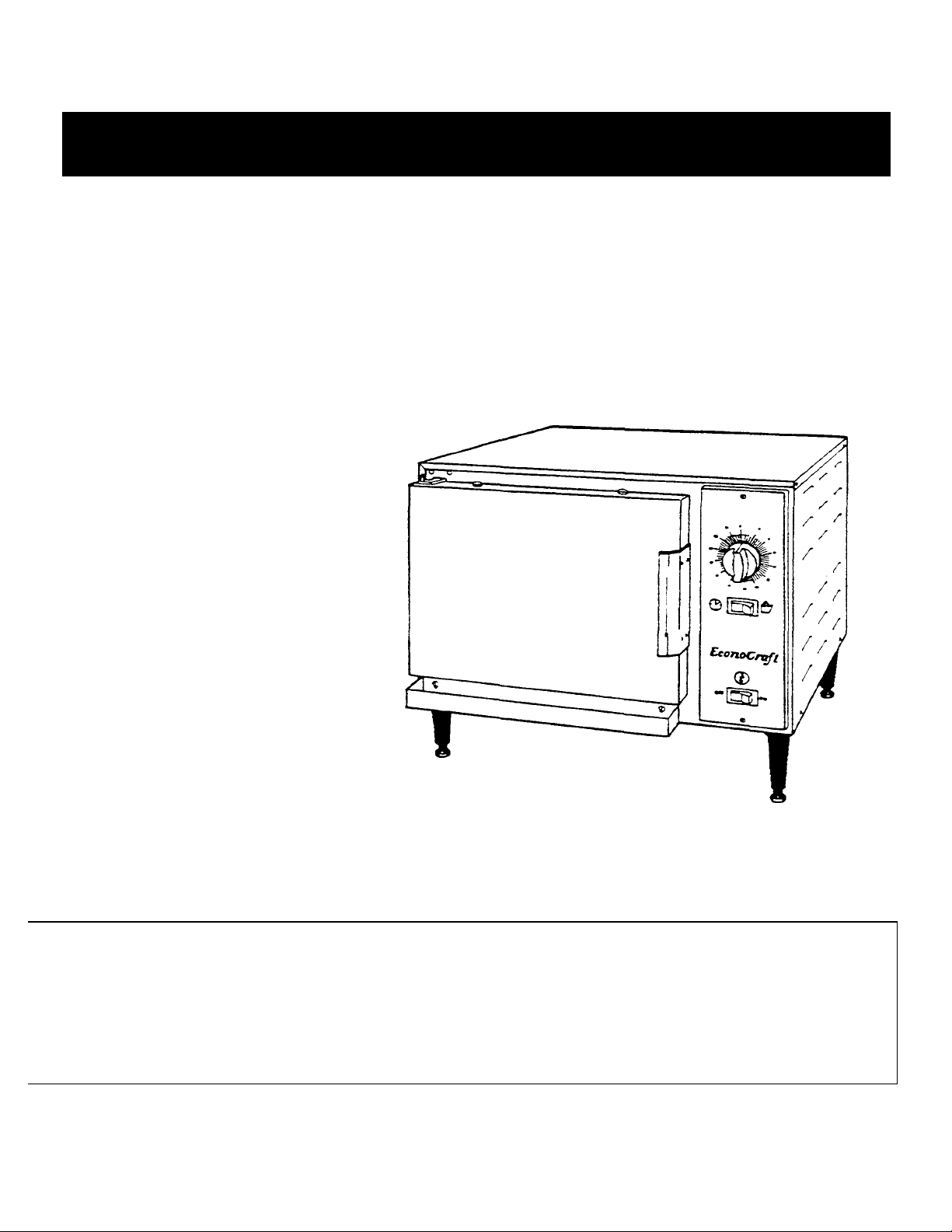

EconoCraft

Counter Type

Convection Steamer

MANUAL

MODEL 24-CET-1

Cleveland Range, Inc.

UNITED STATES CANADA

1333 East 179

Phone: (216) 481-4900 Telex: 98-0546 1177 Kamzto Road

FAX: (216) 481-3782 Mississaugha, Ontario, Canada L4W1X4

Phone: (416) 624-0260 FAX: (416) 624-0623

th

St. Cleveland, Ohio 44110 Garland commercial Ranges

CTS-06

PROTECTING WARRANTY COVERAGE

REFERENCE

Water Quality Requirements and Analysis

.,

7

Steam Generator Maintenance and Maintenance Records

31

Daily Draining and Washout

31

Descaling Frequency and Procedure

32

Approved Chemical Cleaners

32-33

Authorized Maintenance and Repair

35 Unvented Drain

11

Blocked Drain

33

Wate

r Pressure

16

The warranty printed to the left specifies the owner/user's responsibility for proper

installation, operation, and maintenance of the EconoCraft - If these responsibilities arc

not met, the Limited Warranty and/or Extended Limited Warranty coverage may be

adversely affected. The following table is provided to assist the owner/user in meeting

these responsibilities. In addition, the warranty advantages of installing a SteamerGard

water treatment system are explained after the table.

The Warranty Protection Table lists installation, operation, and maintenance factors

that have in the past adversely affected warranty coverage. The owner/user of an

EconoCraft should pay particular attention to these factors to protect his warranty

coverage. This table is not a comprehensive list of the owner/user's responsibilities.

Cleveland Range steam products are intended for use only by professionally trained

personnel- To meet his responsibilities, the owner/user must supplement this guide

with any additional actions consistent with the operation of steam generating food

preparation equipment by a trained professional.

Warranty Protection Table

PAGE

SUBJECT

Electric Power Requirements 7

SteamerGard Water Treatment System

A SteamerGard water treatment system protects the EconoCraft from impurities contained in regular tap water, especially Total Dissolved Solids (TDS) which cause lime

and scale deposits in steamer equipment. "The protection is so effective that

Cleveland Range increases the warranty coverage on an EconoCraft installed in

conjunction with a SteamerGard system to five years for pans and three years for

labor on water related components, elements, valves, generators, piping, etc.

However, even with a SteamerGard system installed, me owner/user should follow the

guidance of me Warranty Protection Table.

Table of Contents

Chapter Page

CHAPTER 1. PRODUCT IDENTIFICATION 1

MODELNUMBER 1

SERIAL NUMBER 1

PRODUCT INFORMATION PLATE. 1

CHAPTER 2. INSTALLATION INSTRUCTIONS 3

INTRODUCTION. 3

INSTALLATION POLICIES 3

INSTALLATION OVERVIEW 4

PREPARATION ATION FOR INSTALLATION 5

Unpacking and Inspection 5

Shipping Damage Instructions 6

Electric Power Requirements 7

Water Quality Requirements 7

Softened, Treated, or Filtered Water 8

Select the Operating Location 8

INSTALLATION INSTRUCTIONS 10

Assembly 10

Install Four Legs 11

Position and Level EconoCraft 11

InstalI and Connect the Free Air Vented Drain Lines

Install Electric Power Lines

Connect Electrical Line 14

Canadian Wiling Considerations 15

Install Water Supply Lines 15

Connect Water Supply Lines 17

Single Untreated Water Connection 17

Double Water Connection With Preheater 17

Double Water Connection With SteamerGard 18

Testing Water Supply Lines 18

Final Setup And Checkout 19

Setup 19

MANUAL Test 19

TIMED Test 20

Condenser Flow Adjustment 21

CHAPTER 3. OPERATION 23

INTRODUCTION 23

OPERATIONAL SAFETY 23

CONTROL PANEL

DRAIN PLUG 24

MANUAL MODE 25

11

13

24

Page i

Page ii

Table of Contents (continued)

Chapter Page

TIMED MODE 25

STARTUP AND PREHEAT 26

COOKING 26

TIMED Cooking 27

MANUAL Cooking 27

DRAIN STEAM GENERATOR (Every 4 hours) 28

SHUT DOWN (At end of day or shift) 28

CHAPTER 4. PREVENTATTVE MAINTENANCE AND TROUBLESHOOTING 31

INTRODUCTION 31

MAINTENANCE RECORDS 31

DAILY MAINTENANCE 31

Clean EconoCraft 31

WEEKLY MAINTENANCE 31

Descale Steam Generator 32

YEARLY MAINTENANCE 33

TROUBLESHOOTING GUIDE 34

TROUBLESHOOTING NOTES 35

TROUBLESHOOTING QUICK TEST 36

CHAPTER 5. ELECTRICAL SYSTEM 37

INTRODUCTION 37

Figures and Illustrations 37

ECONOCRAFT ELECTRICAL CIRCUITS 37

High Voltage Circuit 37

120 VAC Circuit 37

Low Voltage Control Circuit 39

Timer Circuits 39

CIRCUIT OPERATION 39

MANUAL Mode Circuit Operation 39

TIMED Mode. Circuit Operation 40

ELECTRICAL, CIRCUIT COMPONENTS 41

Terminal Block 41

Heater Element 41

ON/OFF Switch 42

TIMED/MANUAL Switch 42

Fill Solenoid Valve 42

Condenser Solenoid Valve 43

Mechanical Timer 43

3-Second Timer and Buzzer 44

High Temperature Limit Switch 44

Page ii

Chapter

Table of Contents (continued)

Page

Water Level Control Unit 44

Water Level Probe Assembly

Low Level Probe 45

High Level Probe 45

COMPONENT TESTING GUIDE INTRODUCTION 46

Nominal Voltage 46

FUNDAMENTAL COMPONENT TESTING 46

Visual Check 47

Connection Points and Wiring 47

Solenoid Valves 47

Timers 48

Thermostatic Snap 48

Terminal Block 48

Heater Element 49

Resistance Measurements 49

Insulation Resistance Measurements 49

Voltage Measurements 50

COMPONENT TEST PROCEDURES 50

Initial conditions for all testing 50

CT:1 ON/OFF Switch 50

CT:2 Fill Solenoid Valve 51

CT:3 Condenser Solenoid Valve 52

CT -4 TIMED/MANUAL Switch 53

CT5 High Temperarure Limit Switch 54

CT:6 Mechanical Dial Tuner 55

CT -7 Heater Contactor 55

45

CT-8 Heater Elements 56

CT-9 Water Level Control Unit 5S

CT-10 3-Second Timer and Buzzer 59

CT:11 Low Level Probe

CT:12 High Level Probe

CT:13 Transformer

CHAPTER 6. ILLUSTRATED PARTS LISTS 63

INTRODUCTION

Parts Differences Among Econocraft Steamers

Electrical Wiring and Schematic Ladder Diagrams

Ordering Parts 63

60

60

61

63

63

63

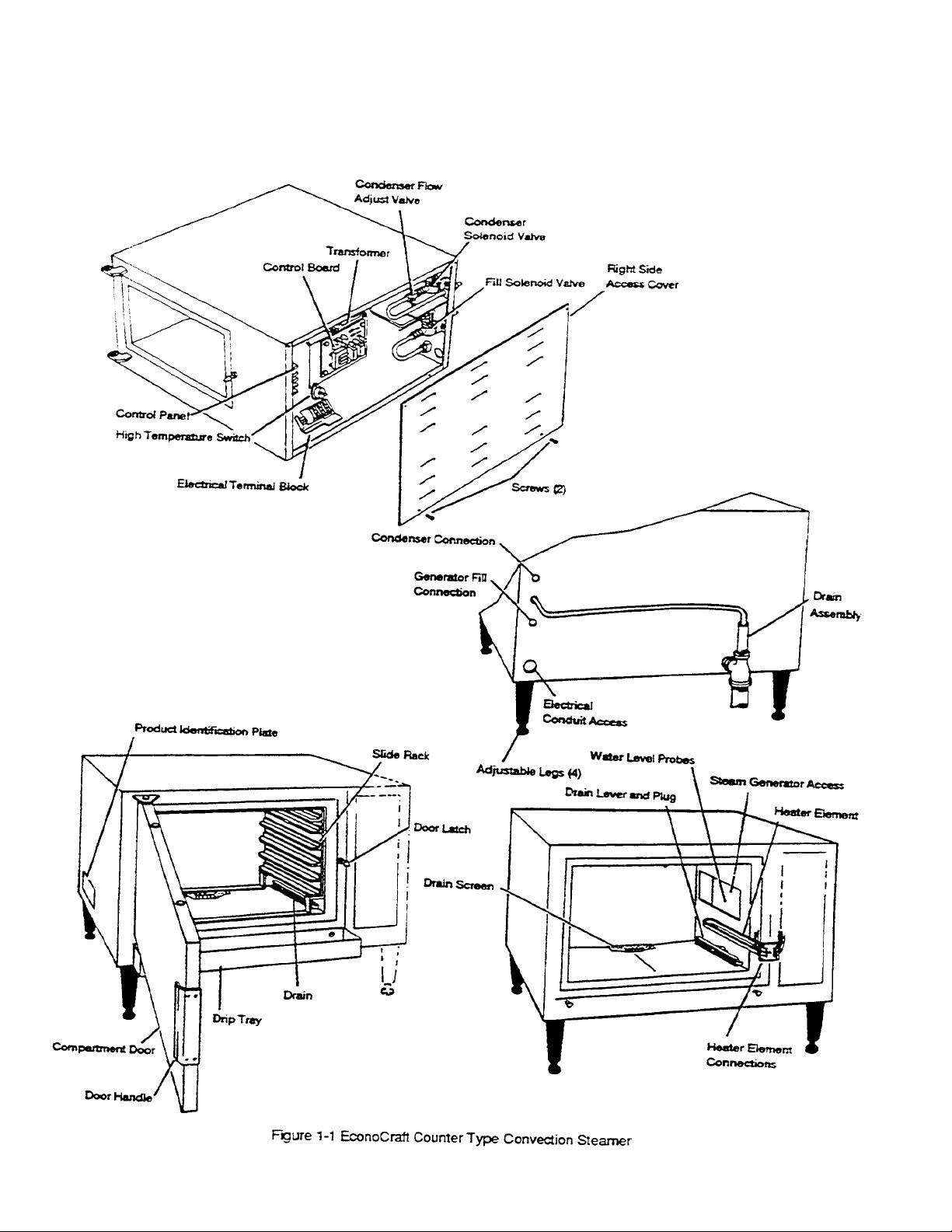

EconoCraft Service Manual, Chapter 1

Page 0

MODEL NUMBER

SERIAL NUMBER

Page 1

CHAPTER 1. PRODUCT IDENTIFICATION

Cleveland Range, Inc. identifies products by two numbers: a model number and a

serial number. The model number identifies the product characteristics. The serial

number identifies the individual unit.

EconoCraft steamers are identified by model number 24-CET-l. Each character of

the model number identifies a characteristic of the steamer. The EconoCraft is a

Convection steamer, .Electric powered,and Table-mounted with an input energy

rating of 8 kW. This manual covers all standard features of model 24-CET-l

EconoCraft steamers. Figure 1-1 illustrates the Econo-Craft and identifies the

major components.

During manufacture, EconoCrafts are assigned serial numbers. A typical

EconoCraft serial number is WC -7350-90G-02. The left half of the number carries

design information- The right half of the number contains the manufacturing date

and the unit of the manufacturing lot. The date of our sample number is 90G -02:

90=1990, G=July. 02=the second unit of the manufacturing lot. Serial numbers are

used when explaining differences in design, parts, or operation among units with

the same model number. For example: a particular part may be used on all 24CET-l steamers with serial numbers before WC -7350-90G-02, and a different pan

used on 24-CET-l steamer WC-7350-90G-02 and all those manufactured after it.

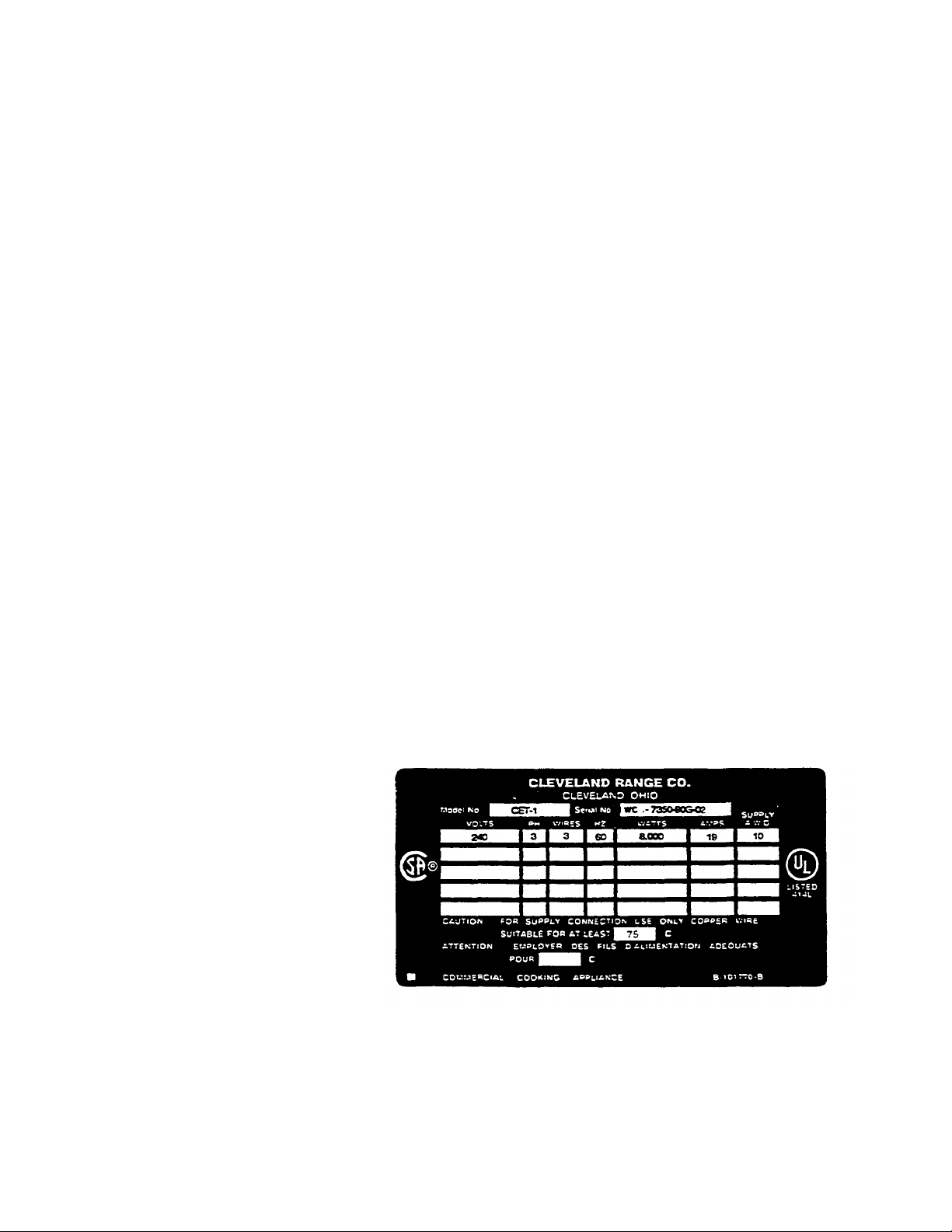

PRODUCT INFORMATION PLATE

Presently, there are no significant design, parts, or operating differences among

model 24-CET-l EconoCraft steamers.

The Product Information Plate on the left side of me unit lists me model number

and serial number for the steamer. Refer to Figure 1-1 for the location of the plate.

Figure 1-2 illustrates a typical EconoCraft product information plate. The plate

also lists power and wiring requirements.

Figure 1-2. EconoCraft Product Information Plate

Cleveland Range, Inc. Printed 5/93

Page 2 EconoCraft Service Manual, Chapter 1 Model 24-CET-1

WARNING

DEATH, INJURY, AND EQUIPMENT DAMAGE

could result from improper installation of the

EconoCraft, or from installation of a unit damaged

during shipment or storage. Either of these conditions could also void the equipment warranty.

DO NOT INSTALL an EconoCraft suspected of

damage.

Install the EconoCraft according to the policies and

procedures outlined in this manual.

Printed 5/93 Cleveland Range. Inc.

Model 24-CET-1 EconoCraft Service Manual, Chapter 2 Page 3

CHAPTER 2. INSTALLATION INSTRUCTIONS

INTRODUCTION

This chapter is a guide for qualified, professional plumbers and electricians

installing the EconoCraft steamer. This guide does not include procedures and

precautions in the common domain of licensed plumbers and electricians, or

experienced food service equipment installers. The instructions in this chapter

must be used in conjunction with a thorough understanding of the Basic Plumbing

Code of the Building Officials and Code Administrators International, Inc.

(BOCA) and the Food Service Sanitation Manual of the Food and Drug

Administration (FDA).

Before starting installation, the owner and the installer should read through this

chapter and thoroughl y understand and agree upon:

• The installation policies of Cleveland Range, Inc. as stated in Installation

Policies-

• An installation plan based on Installation Overview and Preparation For

Installation.

• Responsibility for feed water quality and its testing as described in

Preparation For Installation, Water Quality.

INSTALLATION POLICIES

• The EconoCraft must be installed by qualified plumbing and electrical

personnel, working to an applicable national and local codes. Equipment

installation must compl y with the Basic Plumbing Code of me Building

Officials and Code Administrators International, Inc. (BOCA) and the Food

Service Sanitation Manual of the Food and Drug Administration (FDA).

• Cleveland Range designs and manufactures equipment to comply with

applicable standards for manufacturers. Included among those certification

agencies which have approved the safety of the equipment design and

construction are: UL, A.G.A., ASME/N.Bd-, NSF, CSA, CGA, ETL. and

others.

• This equipment is designed and certi fied for safe operation only when

permanently installed in accordance with local and/or national codes. Many

local codes exist, and it is the responsibility of the owner and installer to

comply with these codes.

• In no event shall the manufacturer assume any liability for damage or injury

resulting from installations which are not in strict compliance with the

installation instructions and the codes cited above. Specifically, the

manufacturer will not assume any liability for damage or injury resulting from

improper installation of equipment, including, but not limited to, temporary or

mobile installations.

Cleveland Range, tnc. Printed 5/93

Page 4 EconoCraft Service Manual, Chapter 2 Model 24-CET-1

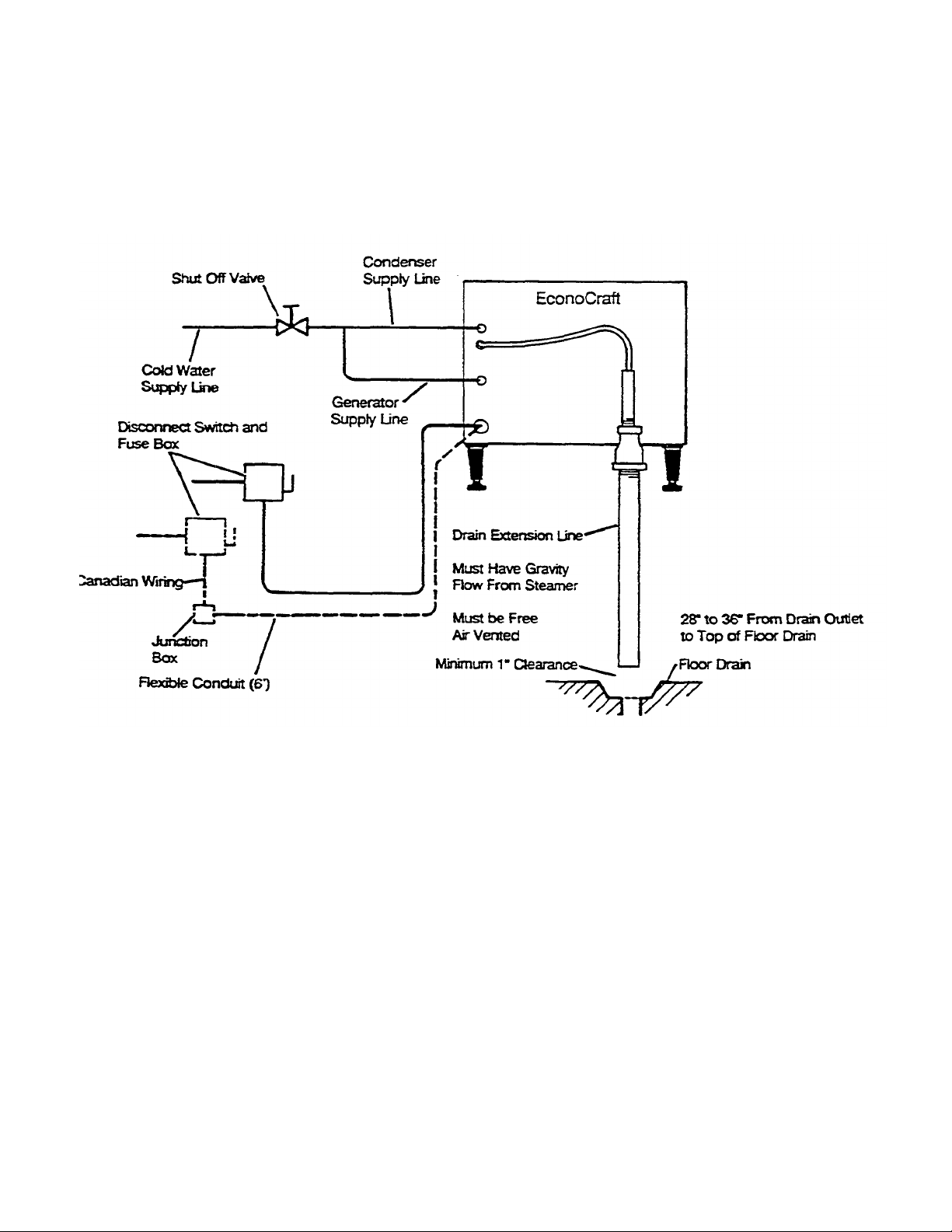

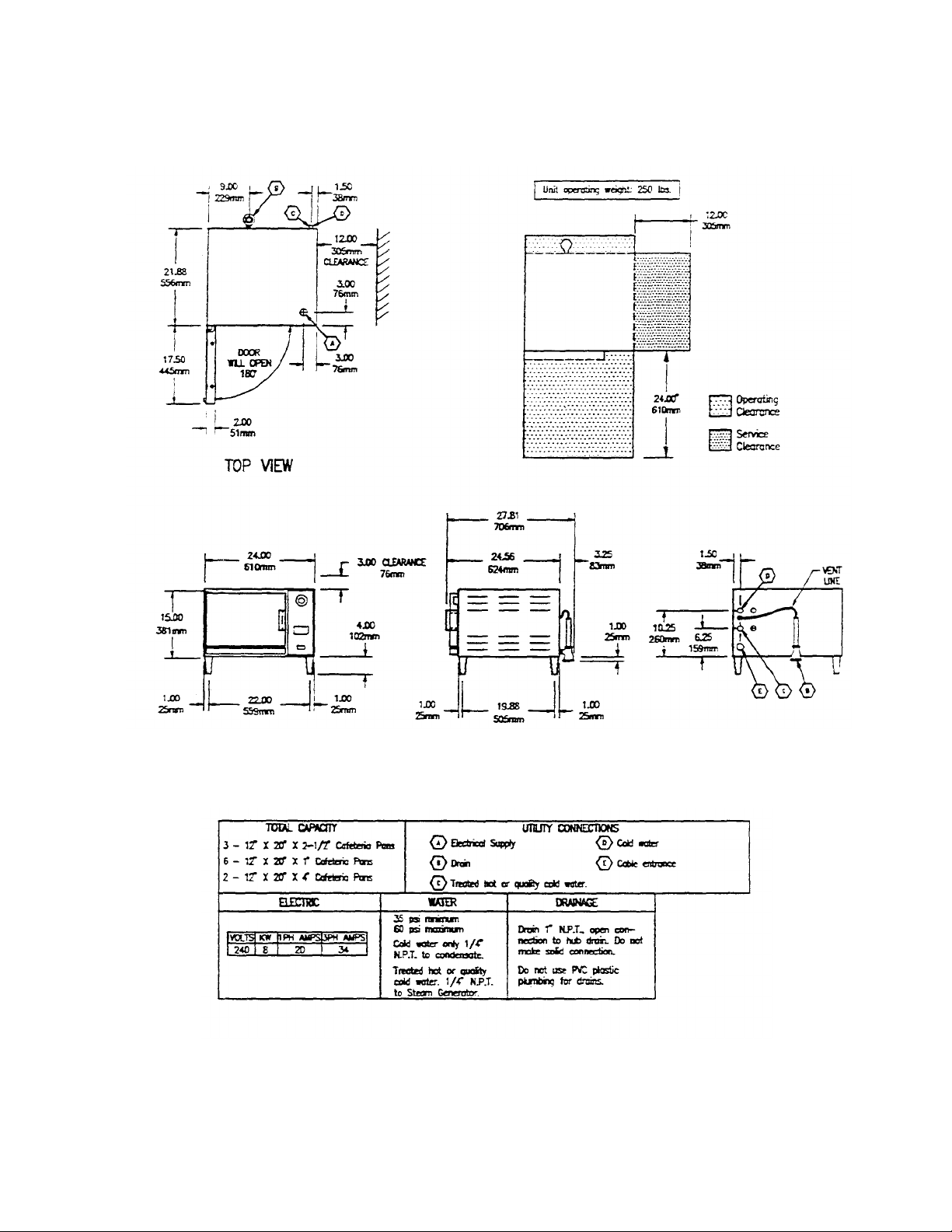

Figure 2-1. Schematic Installation Diagram

INSTALLATION OVERVIEW

Schematic Installation Diagram, Figure 2-1, illustrates the various electrical,

water, and drain lines that must be connected to the EconoCraft. These lines

can be constructed and connected to the EconoCraft easily and without

delays, if the various construction and installation tasks are performed in a

planned sequence. Table 2-1 summarizes these tasks and lists them in a

recommended sequence. The Installation Check List outlines the overall

installation process; the instructions referenced in Table 2-1 provide details.

Installation requirements may vary from site to site; adapt the check list

accordingly.

Printed 5/93. Cleveland Range, Inc.

Model 24-CET-1 EconoCraft Service Manual, Chapter 2 Page 5

Test EconoCraft water supply.

6

Assemble parts shipped loose.

6

Table 2-1. Installation Check List

TASK PAGE REFERENCE

Preparation

Select water supply system. 6

Install water treatment system. 6

Select EconoCraft location. 8

Installation

Unpack and inspect EconoCrafi. 5

Position and level EconoCraft. 11

Install drain line. 11

Connect drain line. 11

Install electric power line. 13

Connect electrical line. 14

Install water supply lines. 15

Connect water lines. 17

Perform final setup and checkout 19

PREPARATION FOR INSTALLATION

Select and prepare the EconoCraft operating location before permanently

positioning the unit Protect the unit and packaged components during site.

preparation. Do not select me operating location or start installation before

checking the electric power, gas, and water quality requirements to assure proper

drainage, ventilation, and safety.

COMPLETED

Unpacking and Inspection

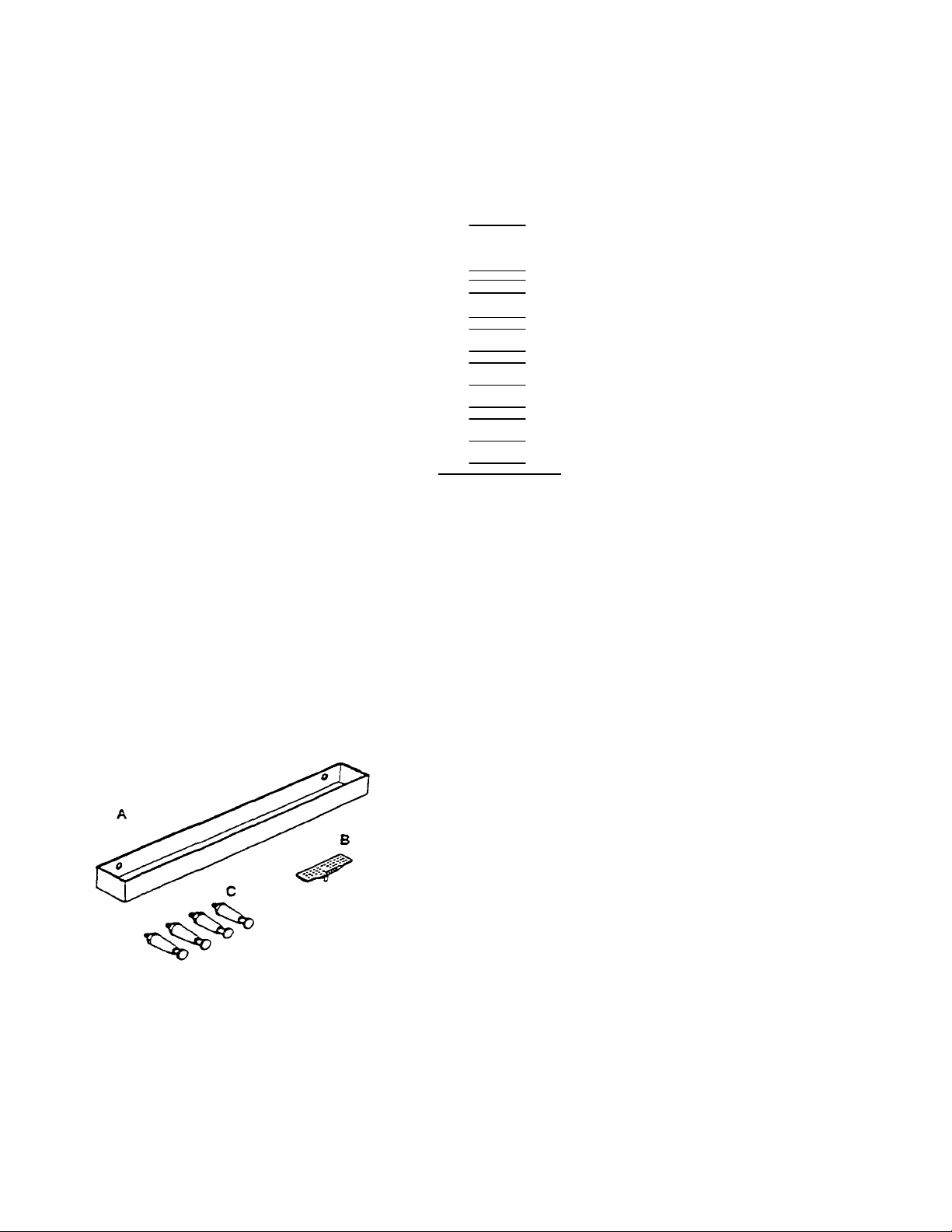

Figure 2-2- Parts Package Components

Cleveland Range, Inc- Pnnted5/93

1. Before unpacking the shipping canon, visually inspect it for damage.

• If the shipping canon appears damaged, do not open the carton- Refer to the

Shipping Damage Instructions below.

• If the sh ipping carton is undamaged, open it and remove the EconoCraft-

2. Slit the four comers of the canon and peel canon sides away from the

EconoCraft.

3. Open me door of the EconoCraft, and remove the package of pans. The

package contains six pans as illustrated in Figure 2-2. Check that all pans

nave been included in the package.

A Drip Tray B Drain

Screen C 4 Legs

Page 6 EconoCraft Service Manual, Chapter 2 Model 24-CET-1

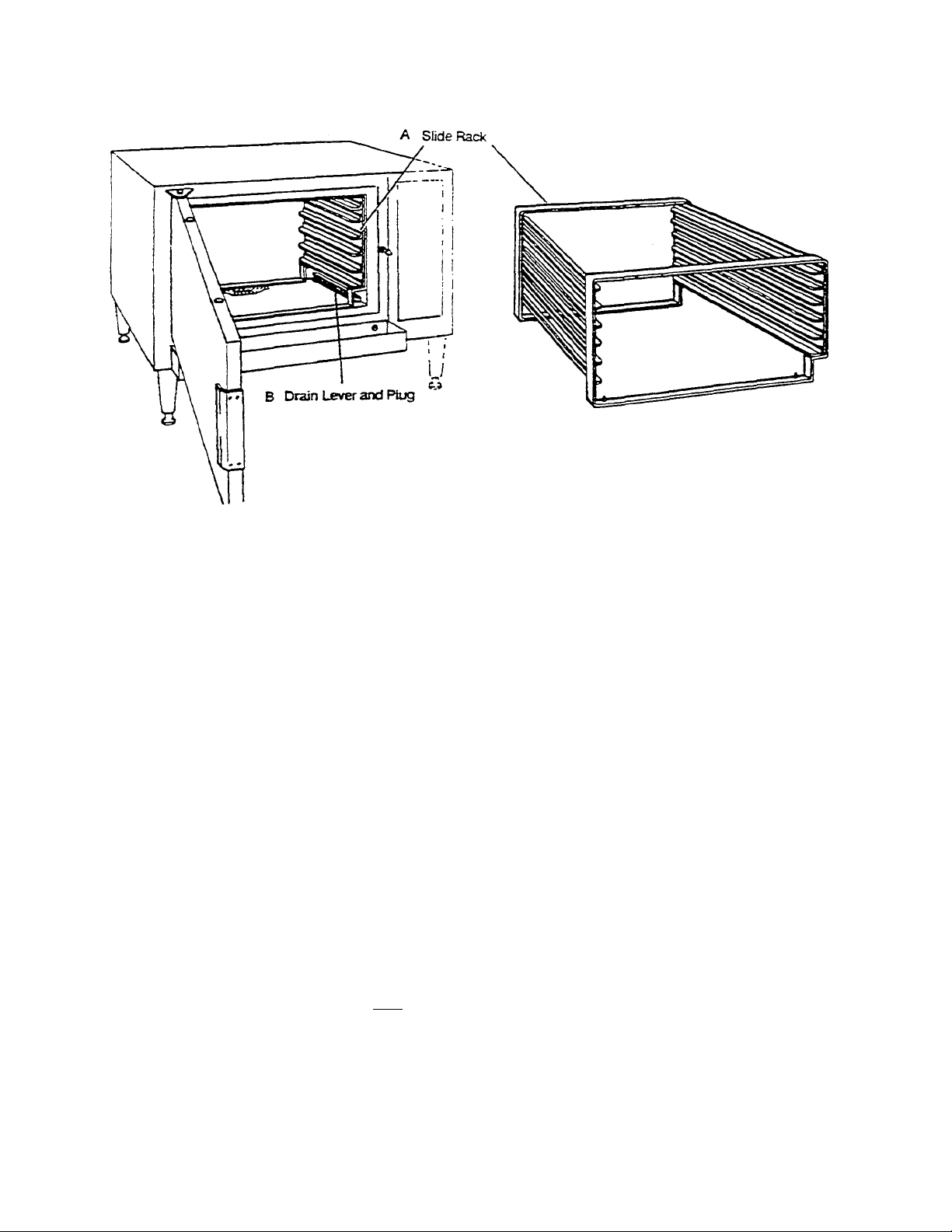

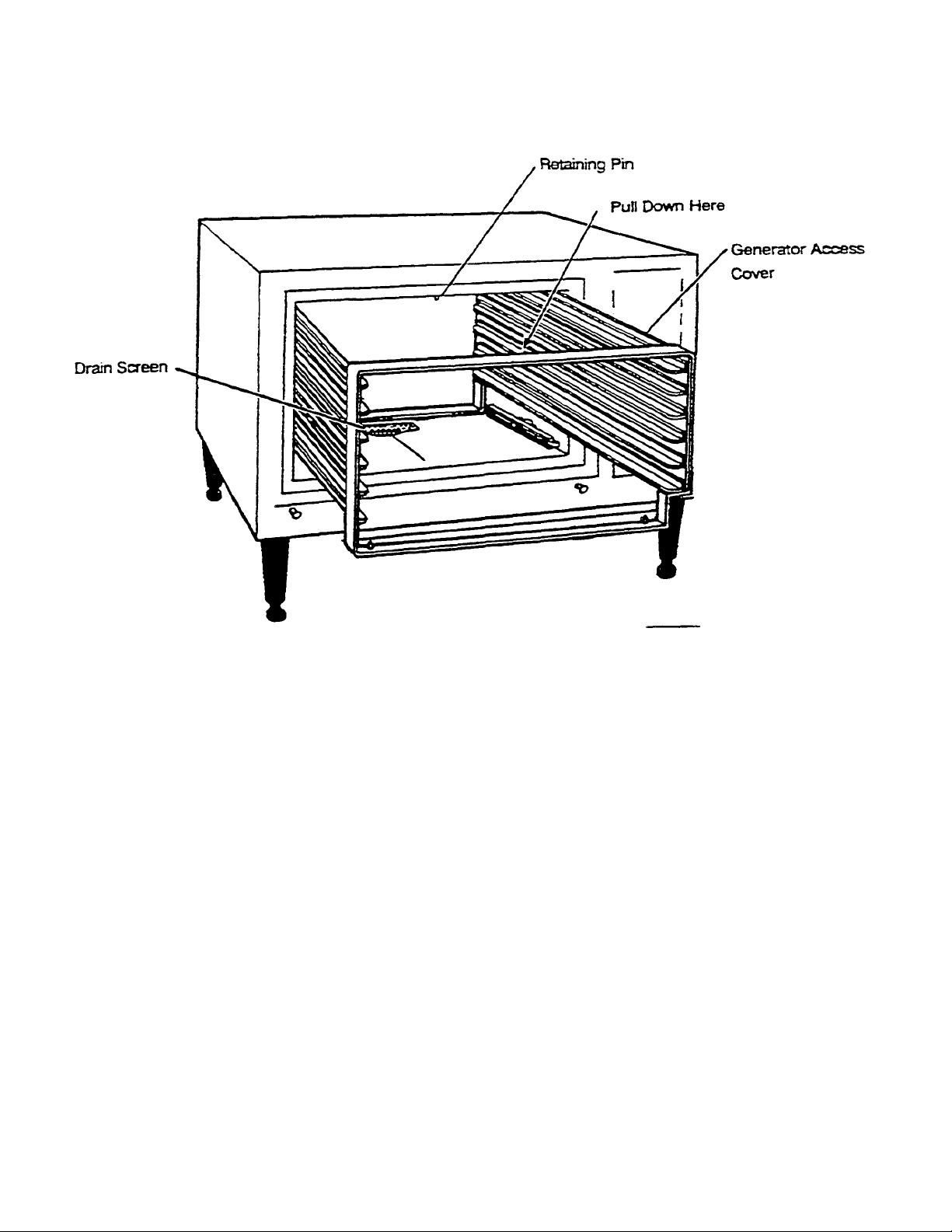

Figure 2-3. Pre-assembled Parts

4. When the parts package is removed, several pre-assembled pans can be

seen inside the unit Refer to Figure 2-3. Do not remove or try to operate

these parts at this time.

A Pan Rack

B Drain Plug and Lever

5. Inspect the EconoCraft and pans for damage or loss.

• If you discover or suspect shipping damage or loss, refer to the Shipping

Damage Instructions below.

• If all items are accounted for and undamaged, proceed to Assembly and

install the unassembled pans listed in step 3-

Shipping Damage Instructions

If shipping damage to the EconoCraft is discovered or suspected, observe the

following guidelines in preparing a shipping damage claim.

• Write down a descript ion of the damage or the reason for suspecting

damage as soon as it is discovered. This will help in filling out the claim

forms later.

• As soon as damage is discovered or suspected, notify the carrier that

delivered the shipment.

• Arrange for carrier representative to examine damage.

• Fill out all appropriate claim forms and have the examining carrier sign and

date each form.

Printed 5/93 Cleveland Range, Inc.

Model24-CET-1 EconoCraft Service Manual, Chapter 2 Page 7

Electric Power Requirements

The characteristics of the electric power supply must match the power

requirements specified on the EconoCraft Product Information Plate. The plate is

located on the left side of the unit.

Water Quality Requirements

As with any steam generating equipment, poor water quality degrades EconoCraft

performance. If feed water is low in Total Dissolved Solids (TDS) and free of

paniculate matter, the steam generator, hearing element, and valves of the

EconoCraft will give years of trouble-free service with a minimum of

maintenance.

In some areas, even potable tap water contains a variety of impurities that can

cause costly problems in steam generating equipment. Of primary concern are

mineral salts and other impurities which remain behind as lime or scale deposits

during the steam generating process. These deposits have caused many

components to fail. including heating elements, probes, and solenoid valves. Of

equal importance, lime and scale deposits decrease the efficiency of heat transfer

which causes increased water and power consumption. EconoCraft use in areas

with poor water quality requires installation of a SteamerGard water treatment

system or increased frequency of maintenance, cleaning, and descaling.

Check the quality of feed water before starting construction of the water supply

lines. If a SteamerGard water treatment system must be installed 10 achieve

acceptable water quality, install it before running the water supply lines to the

EconoCraft.

Contact a local water treatment specialist for an on-the-premises water analysis.

The recommended minimum feed water quality requirements for the EconoCraft

are listed in Table 2-2.

• If analysis shows that the supply water is within me required limits, a single

water connection can be installed as illustrated in Figure 2-13.

• If analysis shows the supply water within required limits and a hot water heater

is desired for preheating water to the steamer, install as illustrated in Figure 2-

14. DO NOT install with hot water to the condenser inlet. The condenser

supply must be cold water for proper operation of the steamer.

• If analysis shows that the supply water is NOT within the required limits, a

SteamerGard water treatment syst em and two water supply lines must be

installed as illustrated in Figure 2-15.

• If analysis shows that the supply water is NOT within the required limits, and it

is not possible to install a SteamerGard water treatment; plan on increasing the

frequency of maintenance, cleaning, and descaling beyond that recommended

in the maintenance schedule (Chapter 4, page 31).

• Always connect a cold water supply to the EconoCraft water supply lines. DO

NOT USE HOT WATER. The steamer will not function properly or withi n

design safety limits if hot or warm water is supplied to either the condenser

connection or the steam generator fill connection.

Cleveland Range, Inc- Printed5/93

Page 8 EconoCraft Service Manual, Chapter 2 Model 24-CET-1

Table

2-2.

Minimum Feed Water Quality Requirements

Total Dissolved Solids less than 60 parts per million

Silica less than 13 parts per million

Alkalinity less than 20 parts per million

ph factor greater than 7-5

Softened, Treated, or Filtered Water

Do not use softened or chlorinated water in the EconoCraft steam generator.

If the water supply is treated or softened either by the water company or on

the premises, it may contain chlorine or various salts. These additives are

damaging to the EconoCraft steam generator. Salts used to soften water

cause rapid scale buildup, and increased corrosion.

Some water treatment plants kill bacteria in the water by adding chlorine.

Chlorinated water is actually dilute hydrochloric acid. It is very damaging to

the EconoCraft. When healed in the steam generator, chlorinated water

rapidly dissolves generator walls and heater elements. In extreme cases,

poisonous and highly corrosive chlorine gas is released in the steam generator.

Installing a high volume, charcoal or reverse osmosis, water filtering system

removes most of me salts and chlorides introduced by water treatment and

softening. Contact a local water treatment specialist or the local water

company for assistance with chlorinated water.

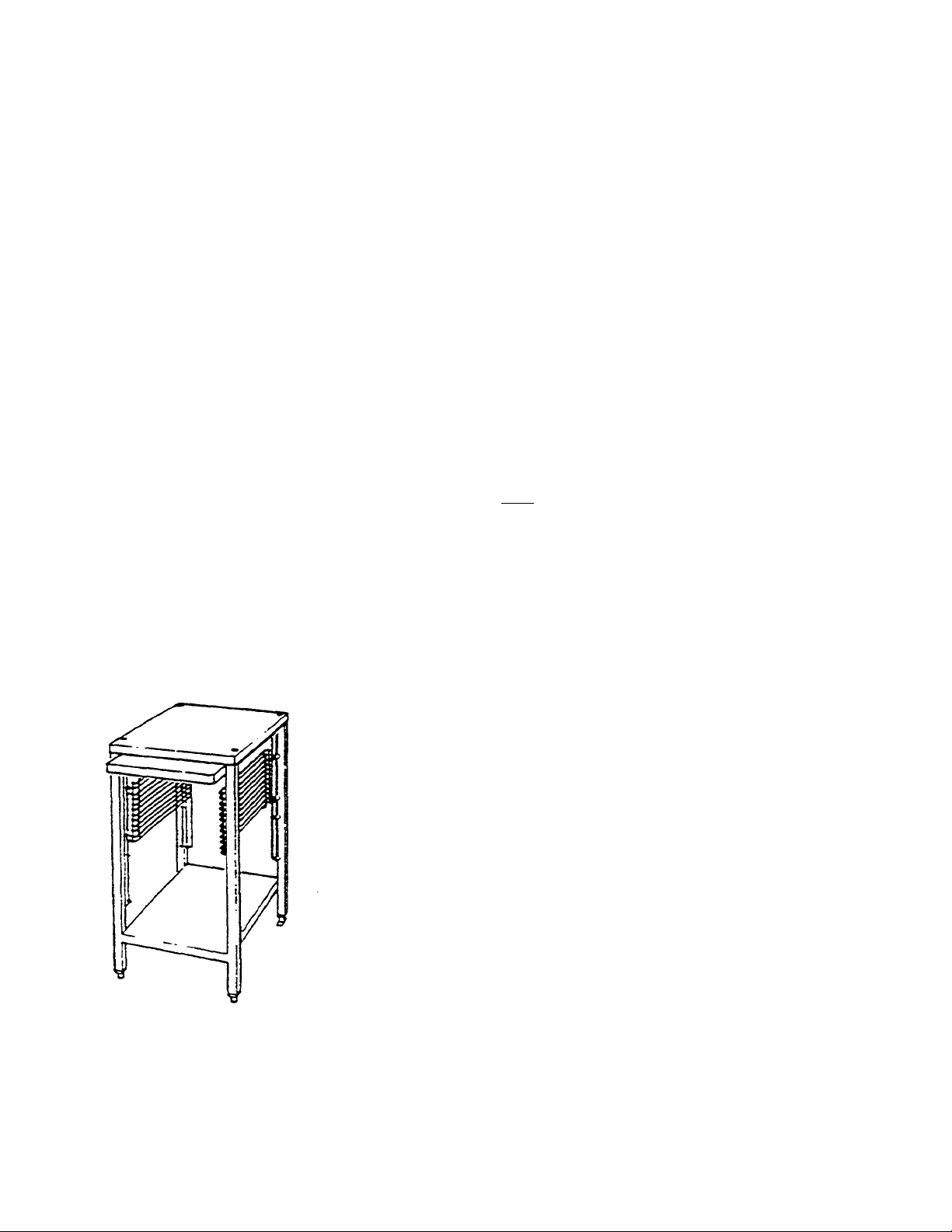

Figure 2-4. Equipment Stand

When selecting an operating location for the EconoCraft, observe me following criteria.

• The EconoCraft uses a minimum of counter space. Figure 2-5 illustrates

the dimensions and clearances required. The 3-inch clearance at the rear

includes spacing for the water inlet and fittings, and the maximum size (11/4-inch NPT) drain fittings.

• Note in Figure 2-5 that a 3-inch clearance is required above the

EconoCraft. Do not store articles on top of the unit.

• The EconoCraft weighs approximately 100 pounds. The counter area

selected must be capable of supporting an operational weight of

approximately 120 pounds to include the weight of wat er and food.

• The EconoCraft has capacity for one 12"x20" x25" Cafeteria Pan (model #

SP-2.5 or PP-2.5). Convenient storage for pans should be considered

when selecting the operating location.

If a satisfactory counter location is not available, consider using a model ES2424 Equipment Stand. This stand, illustrated in Figure 2-4, is designed to

support the EconoCraft, and meets the above criteria-

Printed 5/93 Cleveland Range, Inc.

Model 24-CET-1

Printed

5/93 Cleveland Range, Inc.

EconoCraft Service Manual, Chapter 2 Page 9

FRONT VIEW SIDE VIEW REAR VIEW

Figure 2-5- EconoCraft Dimensions and Clearances

Page 10 EconoCraft Service Manual, Chapter 2 Model 24-CET-1

Figure 2-6. Pan Rack and Drain Screen Removal

INSTALLATION INSTRUCTIONS

After selecting and preparing the EconoCraft operating location, the steamer can be unpacked, positioned, and installed.

This section of Chapter 2 details inspecting and positioning the EconoCraft. Installation and connection of the power, water,

and drain lines are also detailed. After final setup and testing, the EconoCraft will provide years of reliable operation.

Assembly

Install the Drain Screen

1. Slide the pan rack out of the steamer. See Figure 2-6. Pull down on the

center of the top front bar of the rack so it clears the retaining pin as the

rack is slid out.

2. Install the drain screen over the drain hole at the rear of the compartment.

The pin on the drain screen must face downward. The small flanged edge

faces toward the front of the unit.

3. Slide the pan rack into the steamer compartment. Pull down on the top front

bar of the rack so that it clears the retaining pin.

Printed 5/93 Cleveland Range. Inc.

Model 24-CET-1 EconoCraft Service Manual. Chapter 2 Page 11

Install Four Legs

Do not install the EconoCraft without legs.

1. Place the EconoCraft on its left side.

2. Check that the feet are fully retracted into the legs. Do not overtighten, the feet

should easily screw in and out by using fingers only.

3. Install all four (4) legs in the bottom of the EconoCraft

4. Turn the steamer upright.

Position and Level EconoCraft

For efficient operation, the steamer should be level both front to back and side to

side. The legs of the EconoCraft are four inches long when the adjustable feet are

fully retracted. The adjustable feet can be extended approximately two inches,

providing adjustment for leveling the steamer.

1- Refer to the Installation Check List, Table 2-1. Check that all Preparation

Tasks arc complete. Check that all Unpacking and Assembly tasks are

complete.

2- Place the EconoCraft at the location where it will be used.

3- Adjust the retractable feet of the Econocraft to level the unit.

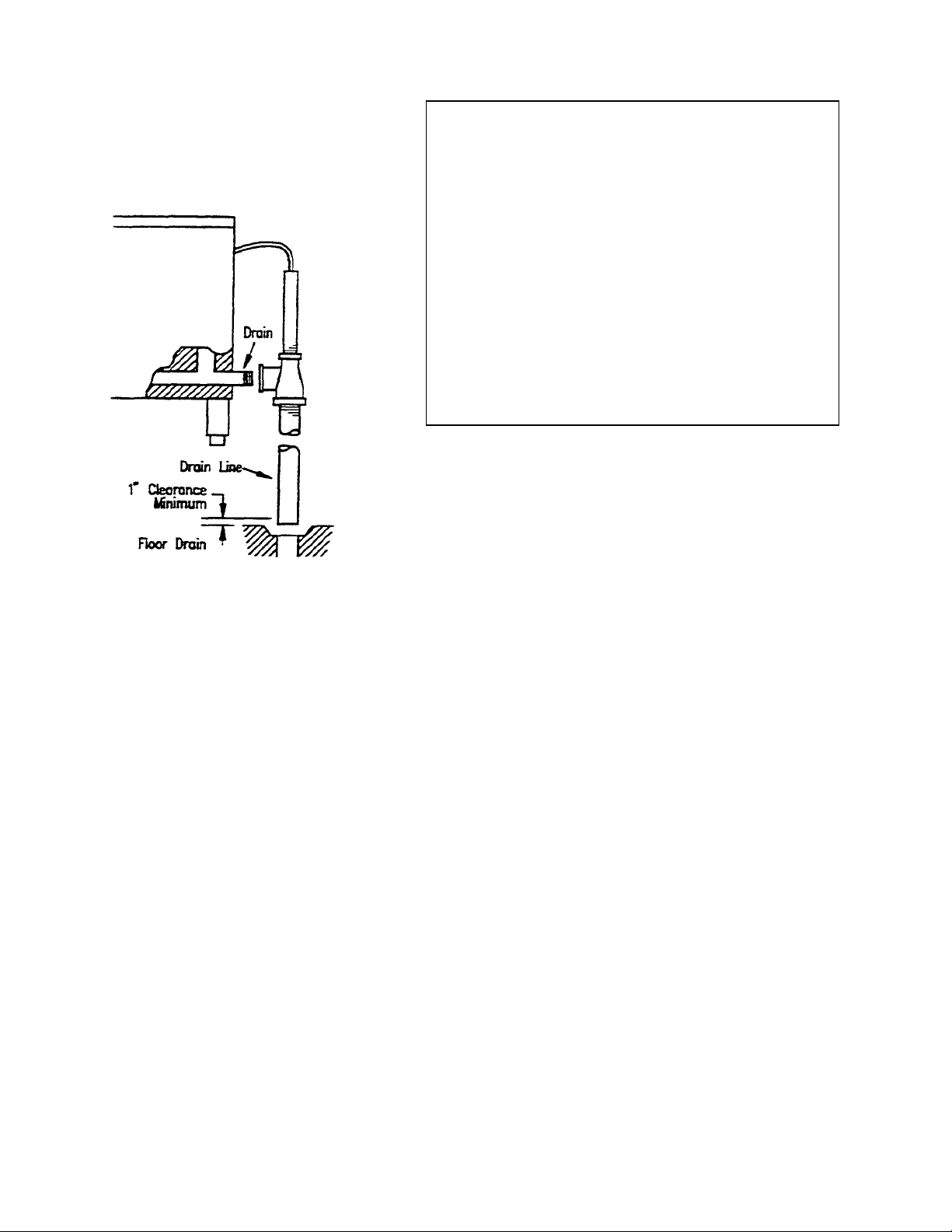

Install and Conne ct the Free Air Vented

Drain Lines

The drain outlet discharges exhaust steam and hot condensate from the steamer.

The drain outlet MUST be free air vented to equalize the pressure in the

EconoCraft with me atmosphere. Generating steam causes pressure to increase in

the unit: cold water flow into the condenser creates a vacuum (low pressure) in the

condenser. Without a free air vent, either high or low pressure in the compartment

will cause malfunction or damage. The openings at me top of the vent pipe and

drain outlet provide the EconoCraft with free air venting.

• Pressure build up in the steamer will cause steam and hot water leakage around

the door.

• A vacuum WILL implode the steamer and cause permanent physical damage.

Furnishing and installing the fittings and drain line is the responsibility of the

owner and/or installer. Figure 2-7 illustrates a drain layout recommended by

Cleveland Range. Observe the following instructions 10 determine the pipe size,

the number of fittings required, and the layout of the drain line path.

Page 12 EconoCraft Service Manual, Chapter 2 Model 24-CET-1

1.

The drain lines must be installed in compl

iance with the Basic Plumbing

WARNING

DEATH, INJURY, AND EQUIPMENT DAMAGE could

result from improper installation of the drain outlet lines.

THE DRAIN MUST BE FREE AIR VENTED.

Improper installation of these lines could void the

EconoCraft warranty. The following restrictions are

critical to the safety of personnel and equipment, and

must not be violated under any circumstances.

Do not connect the drain line into PVC pipe, or any other

drain material that cannot sustain 180° F.

Do not connect drains from any other equipment to the

EconoCraft drain line.

Do not connect the drain outlet extension line directly to

a floor drain or sewer line.

Figure 2-7. Drain Layout and Connections

Code of the Building Officials and Code Administrators International, Inc.

(BOCA), and the Food Service Sanitation Manual of the Food and Drug

Administration (FDA).

2. The pipe size used to extend the drain outlet to an open drain is

determined by me total length of pipe and number of bend finings

required to reach the open drain.

• If the drain outlet extension requires six feet or less of pipe, and no more than

two elbows are required, use 1-inch pipe and fittings.

• If the drain outlet extension requires six to twelve feet of pipe, or

requires three or more elbows, use 1-1/4-inch pipe and fittings.

3. The drain line must have a gravity flow from the EconoCraft drain outlet to

the floor drain. Do not install a p-trap in the drain line.

4. Free air venting requires a minimum of one inch clearance between the end of the

drain line and the top of the floor drain.

5. When assembling the pipe and fittings of the drain line, apply a hardening

type pipe sealant to the threads, and tighten them together FINGER

TIGHT ONLY. DO NOT USE A WRENCH.

6. Do not connect the steamer drain to drains or plumbing of any other equipment If

drains of two or more units are connected together, low pressure can develop,

causing an implosion and physical collapse of the steamer.

7. The EconoCraft is supplied with the drain assembly attached to the unit (Figure 2-

7). The overflow tube functions in free air venting and must extend upward from

the tee.

Printed 5/93 Cleveland Range, Inc.

Model 24-CET-1 EconoCraft Service Manual, Chapter 2 Page 13

Cleveland Range. Inc.

Printed

5/93

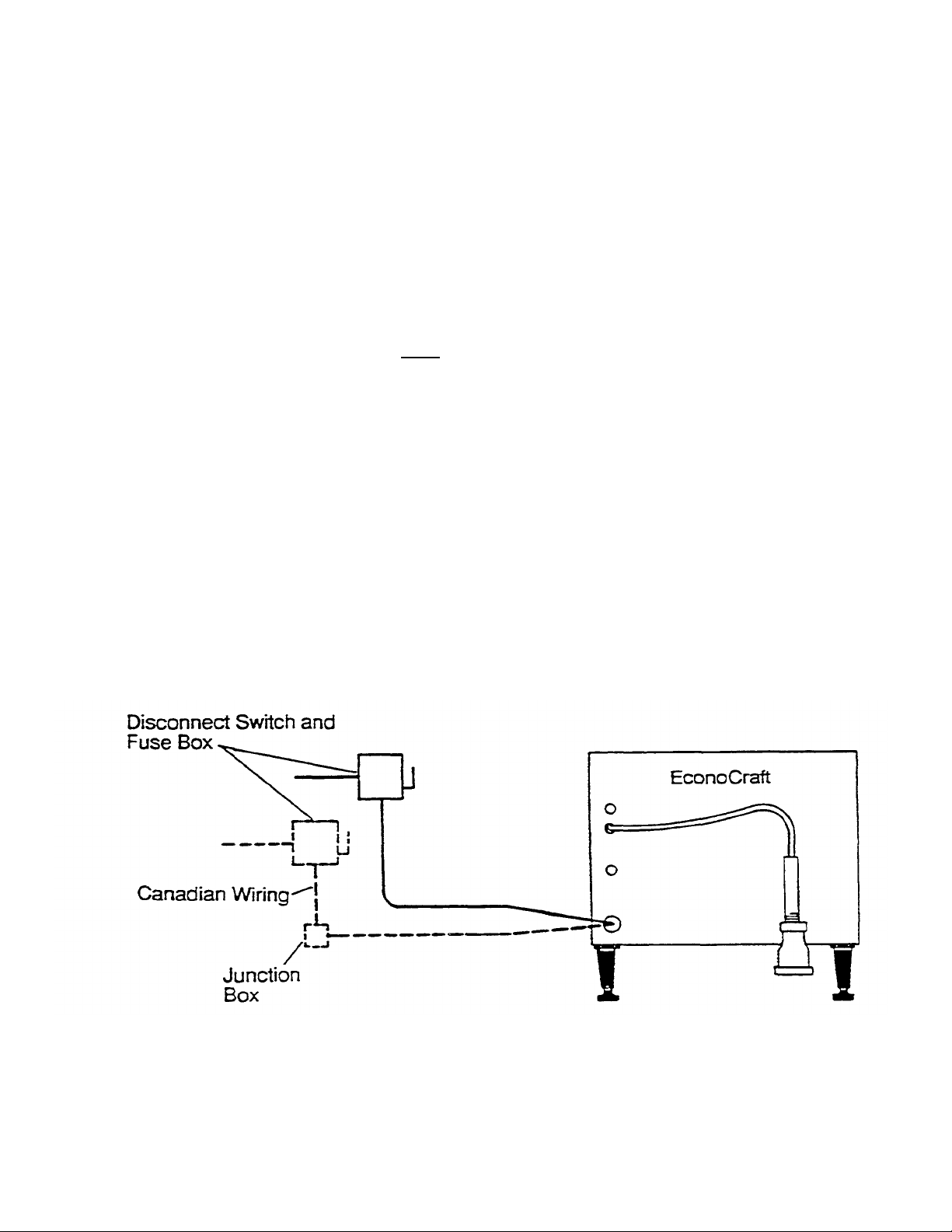

Install Electric Power Lines

Furnishing and installing the electrical power lines, switches, fuse boxes,

connectors and their accessories is the responsibility of the owner and/or installer.

Figure 2-8 illustrates an electrical layout recommended by Cleveland Range.

When installing the electrical power lines and accessories, observe the following

instructions.

1. In the United States, install the electrical power lines in accordance with local

codes and/or the National Electric Code, ANSI/NFPA No. 70-1990 (USA).

2. In Canada, install the electrical power lines in accordance with local codes

and/or the Canadian Electrical Code, CSA Standard C22.1 (Canada).

3. Install the proper size disconnect switch, circuit breaker or fuses, and wire and

conduit to conform to all local codes and the national codes cited above. See

Table 2-3 for wire requirements.

Figure 2-8. Electrical Layout

Page 14 EconoCraft Service Manual, Chapter 2 Model 24-CET-1

Figure

2-9.

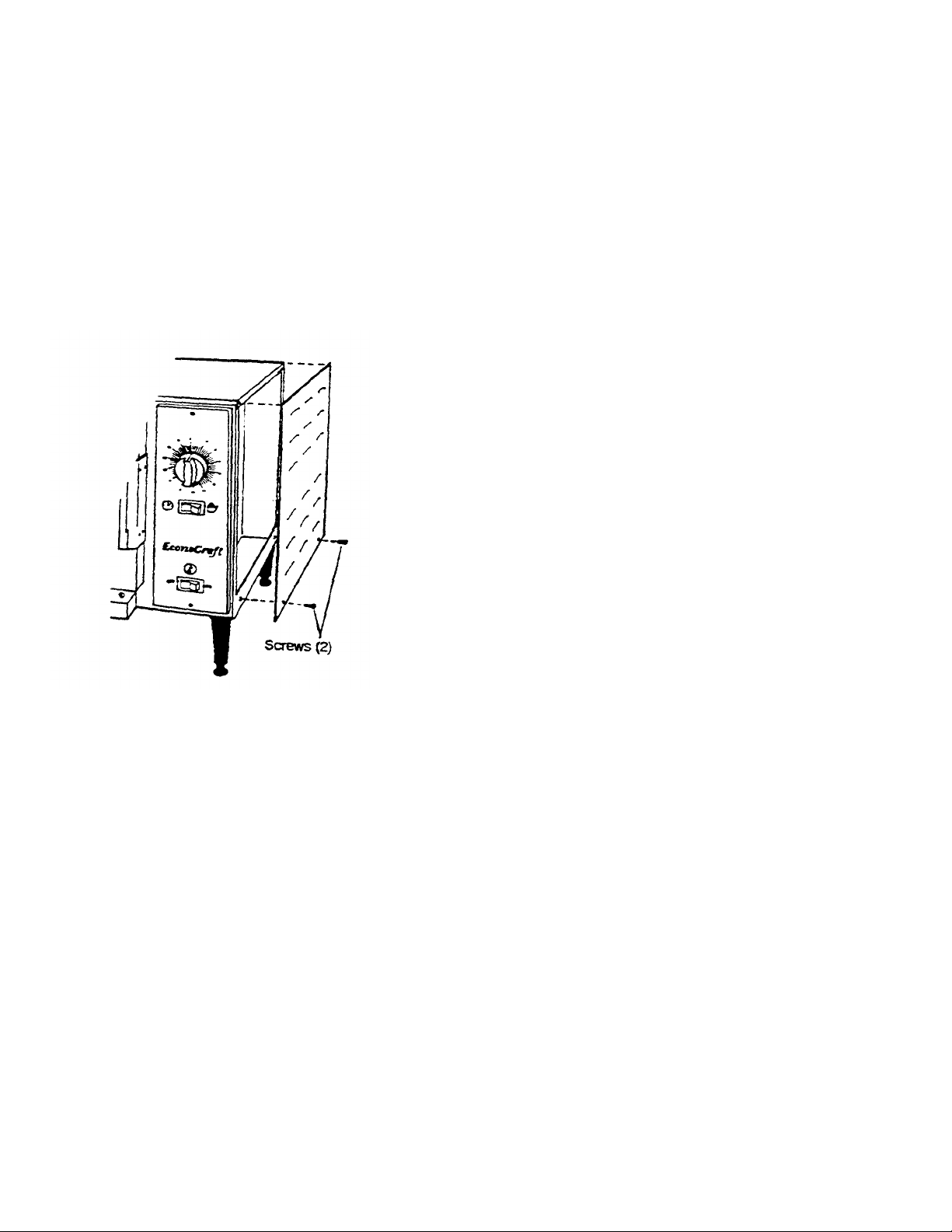

Access Panel Removal

4. Install a separate disconnect switch and fuses sized to line amps (see

8 20 10

8 11 10

8 10 10

Table 2-3. Minimum Wire Requirements

LINE VOLTAGE KILOWATTS LINE

AMPS*

208 8 23 10

220 8 21 10

240

380/220 8 13 10

415/240 8 12 10

440

480

*All 3 Phase

**Use solidcopper wire rated for 75°C.

Table 2-3). The fuses may be an integral pan of the disconnect switch or

in a separate fuse box.

5. There should be a sufficient length of flexible conduit between the

EconoCraft connector and the wall so the unit can be moved for service.

• Canadian steamers are supplied wife six feet of flexible conduit for

compliance with Canadian Standards Association. The electrical supply

line must end in a junction box behind the steamer for connection of

the flexible cable from the steamer.

6. Each steamer MUST be electrically grounded by the installer.

7. The characteristics of the electric power supply must match the power

requirements specified on the EconoCraft product information plate. The

plate is located on the left side of the unit (refer to Figure 1-1 and 1-2).

8. EconoCrafts arc wired for 3 phase, but can be converted to single phase.

Contact an authorized service agency for more information.

WIRE

GAUGE**

Verify that the electric power lines have been properly extended from me

external disconnect to the EconoCraft location. Connect the electrical lines

to the terminal block inside the right side access panel as described below.

1. Move the EconoCraft so the access panel can be easily reached.

2. Remove the access panel by removing the two screws (Figure 2-9) that

hold it in place. Save the screws.

3. Mechanically secure the flexible conduit to the electrical conduit access

hole (Figure 2-10). (See Canadian Wiring Considerations.)

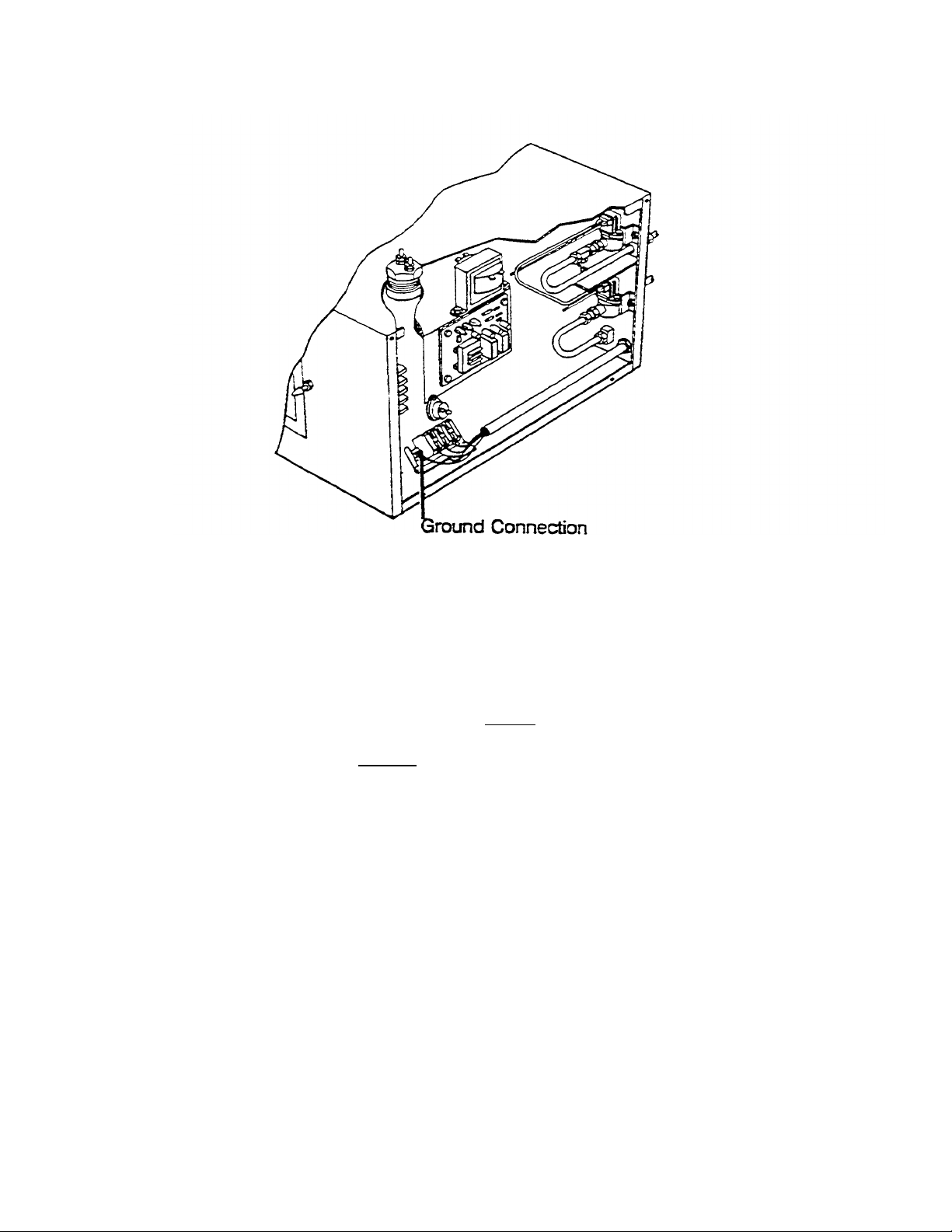

4. The terminal block and ground connection are near the front of the side

opening. The unit has a terminal block for 3-wire DELTA connection.

5. Refer to the connection diagram. Figure 2-10, and connect the wires to the

terminal block and ground connector accordingly.

6. The steamer MUST be electrically grounded by the installer.

Primed 5/93 Cleveland Range, Inc.

Model 24-CET-1 EconoCraft Service Manual, Chapter 2 Page 15

I

nstall Water Supply Lines

Figure 2-10. Connection Diagram

7. EconoCrafts are wired for 3 phase, but are convertible to single phase. Contact

an authorized service agency for information on single phase connections.

8. If no further work is required inside the access panel, such as plumbing and leak

checks, secure the access panel with the two mounting screws (Figure 2-9).

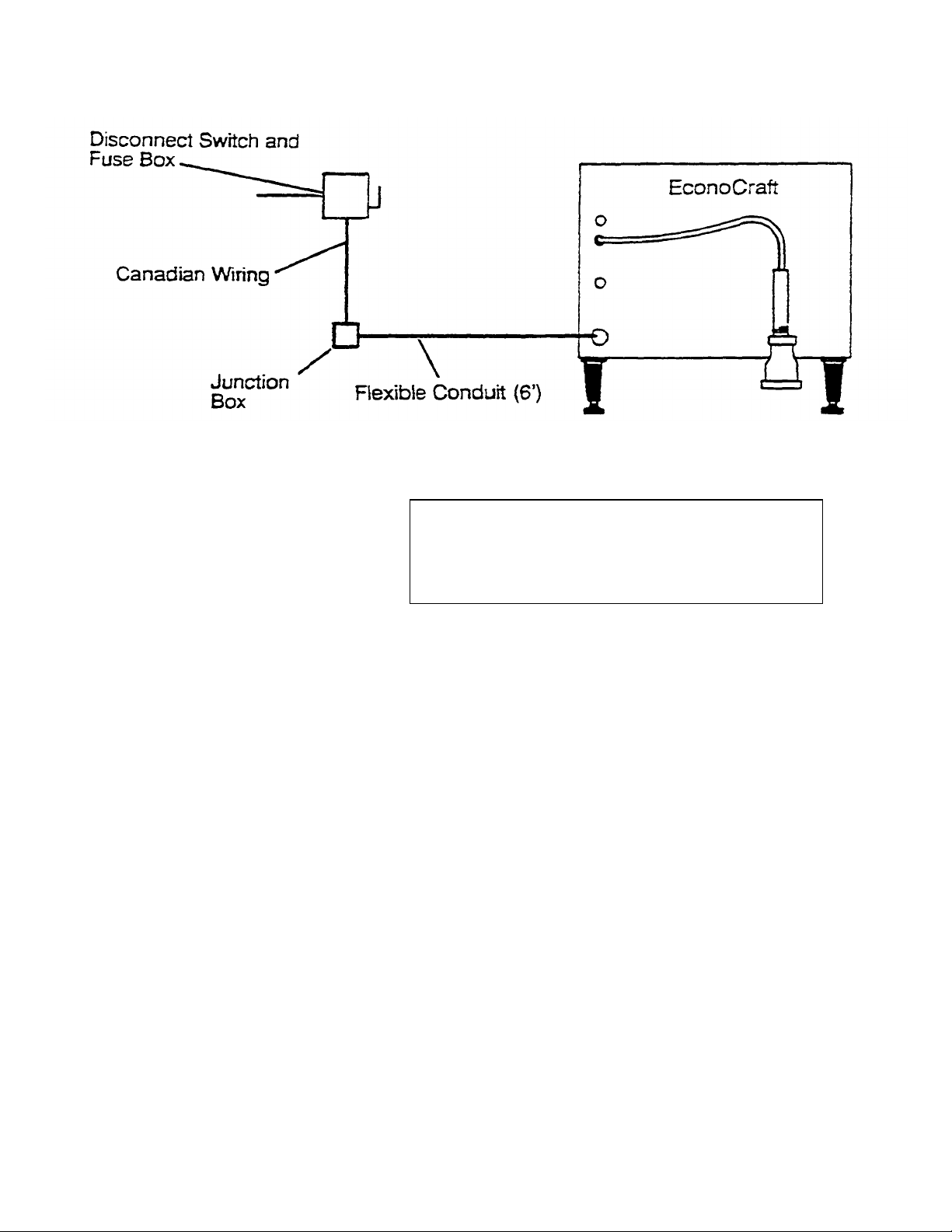

Canadian Wiring Considerations.

For all applications in Canada, install the electrical power lines in accordance with

local codes and/or the Canadian Electrical Code, CSA Standard C22.1 (Canada)

• Canadian steamers are supplied with six feet of flexible conduit connected to the

steamer and wired to the terminal block at the factory.

• The electrical supply line ends in a junction box behind the steamer for

connection of the EconoCraft flexible cable.

• Connect the wires from the EconoCraft flexible cable to those in the junction box

according to Figure 2-11.

• The steamer MUST be electrically grounded by the installer.

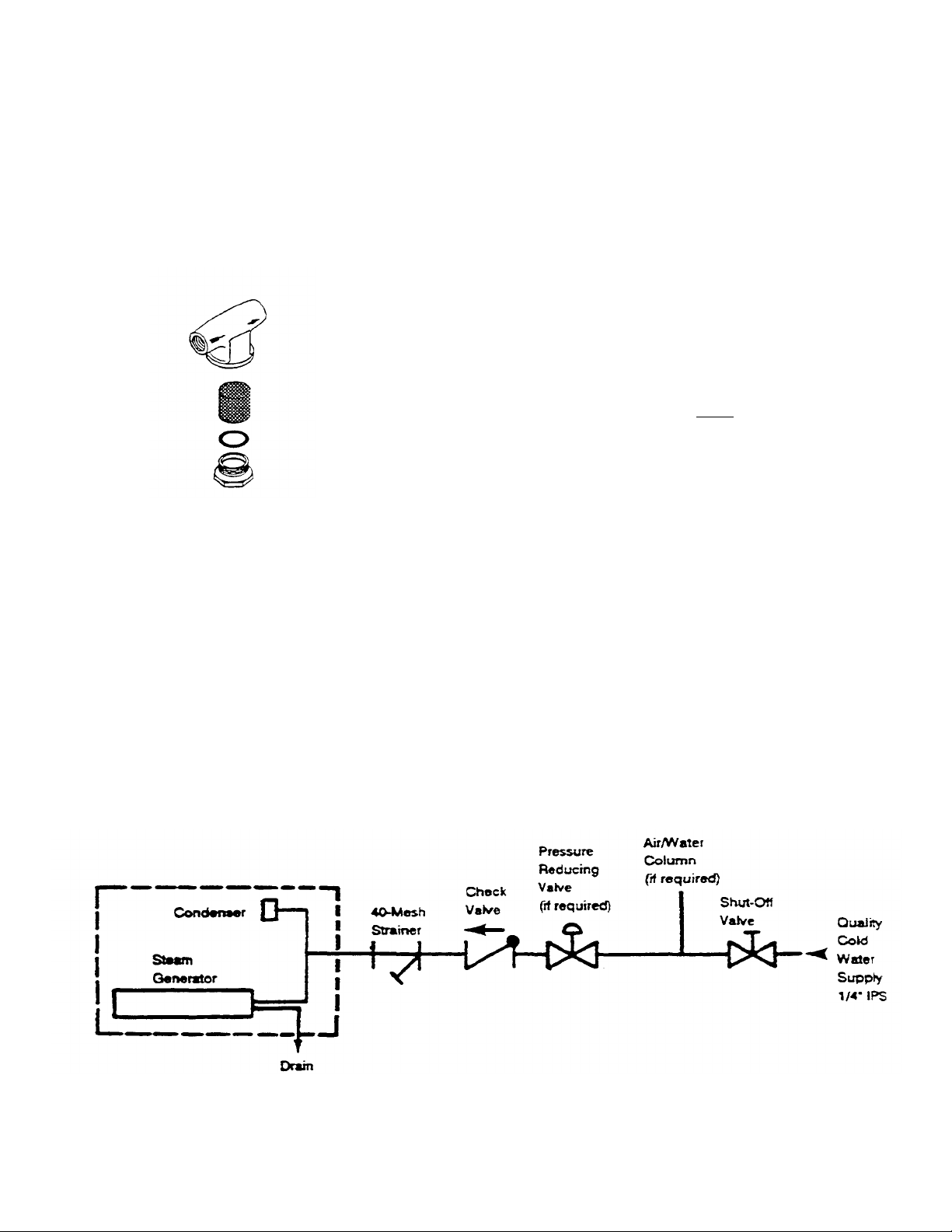

Furnishing and plumbing the water supply lines is the responsibility of the owner

and/or installer. Figures 2-13, 2-14, and 2-15 illustrate plumbing layouts

recommended by Cleveland Range. When installing water supply lines, observe

the following instructions.

Cleveland Range. Inc. Printed 5/93

Page 16 EconoCraft Service Manual, Chapter 2 Mode! 24-CET-1

Figure 2-11 - Canadian Connection Diagram

CAUTION

Do not connect warm or hot water supply to condensor

connection. If hot or warm water is supplied to this

connection, the steam condenser in the EconoCraft will

not work.

1. Connect a COLD water supply to the condenser connection (Figure 2-1).

2. Supply water pressure must have a minimum dynamic pressure of 35 psi (2.4

kg/cm2) and a maximum static pressure of 60 psi (4.1 kg/cm2).

3. The recommended size for the water supply lines is 1/4-inch IPS. This is

the size of generator and condenser connections on the rear of the

EconoCraft. If larger lines are used, a pressure reducer must be installed

in the supply line to maintain the pressure specified in ^2, above.

4. The National Sanitation Foundation (NSF) requires installation of a

check-valve in all supply lines in accordance with and as required by

local plumbing codes.

5. When a water treatment system is not installed, Cleveland Range recommends

the plumbing layout illustrated in Figure 2-13.

6. When installing a water treatment system, Cleveland Range recommends the

plumbing layout illustrated in Figure 2-15.

• The water supply to the condenser connection (Figure 2-1) can be

untreated-

• The treated water supply connects to the steam generator connection

(Figure 2-1).

7. When installing a hot water heater, Cleveland Range recommends the

plumbing layout illustrated in Figure 2-14.

Printed 5/93 Cleveland Range. Inc.

Model 24-CET-1 EconoCraft Service Manual, Chapter 2 Page 17

Figure

2-12.

Water Strainer

Connect Water Supply Lines

Connect the water supply lines paying particular attention 10 the following. Refer

10 the appropiate section below for information on the desired connection:

untreated, preheater, or SteamerGard.

1. Apply pipe dope or teflon tape to any threaded connection.

2. Rush the water supply lines before connecting the strainer.

3. When installing the water strainer(s), refer to Figure 2-12.

• Use a strainer with a 40 mesh screen.

• Make sure the arrow on the strainer body points in the direction of flow into

the steamer.

• Install the strainer so the access nut points down.

4. If water supply lines are larger than 1/4 -inch IPS, install a pressure reducer to

maintain the EconoCraft pressure requirements specified in Install Water

Supply Lines (page 15).

Single Untreated Water Connection

1. Refer to Figure 2-13-

2. Verify mat all components are installed in the single line before the tee that

divides the water flow between the steam generator and condenser.

Double Water Connection With Preheater

1. Refer to Figure 2-14.

2. Verify that each line connected to the steamer has a check valve and strainer

installed.

3. Verify that the hot water healer connects to the steam generator connection. The

condenser must have a cold water input to operate properly.

Figure 2-13. Single Water Connection

Cleveland Range, Inc. Printed 5/93

Loading...

Loading...