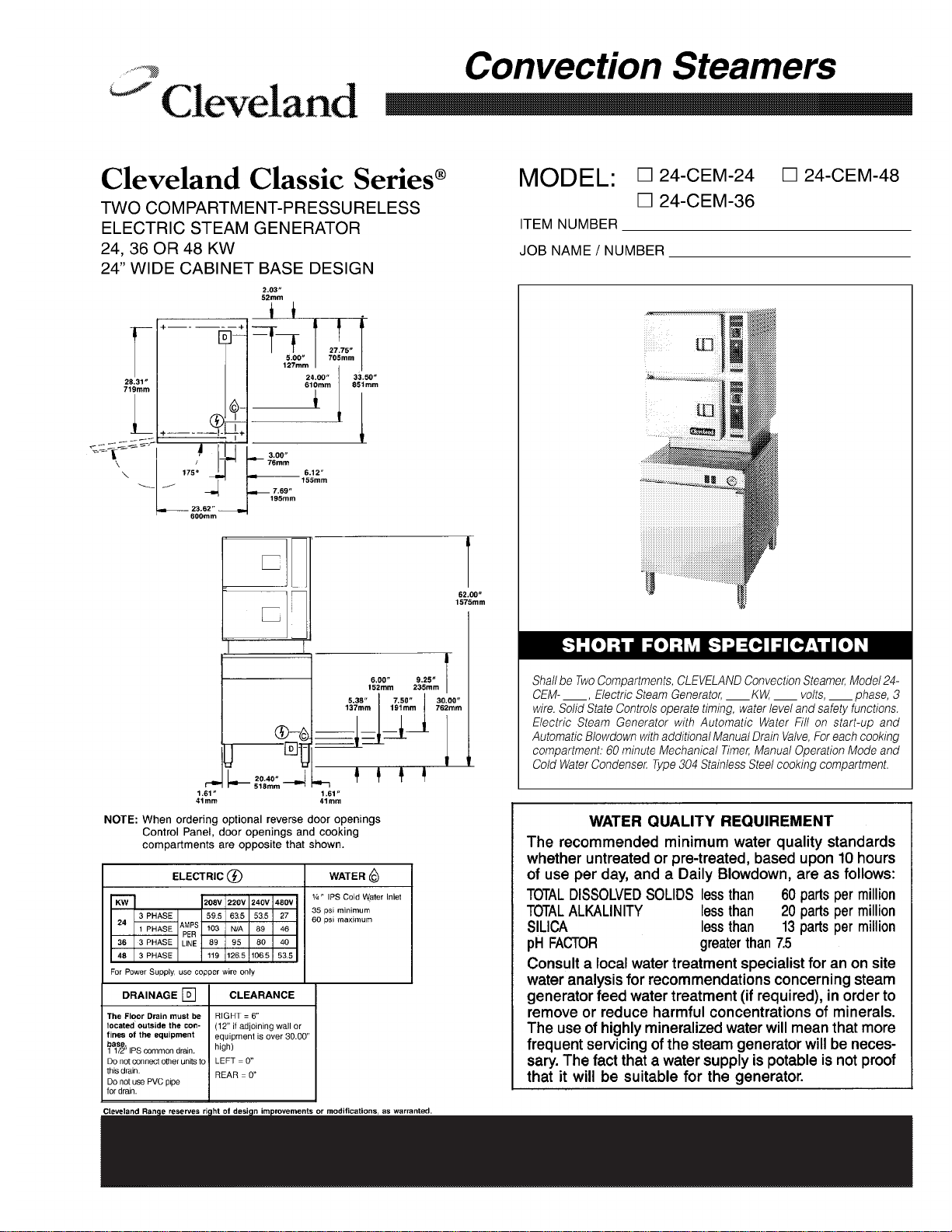

Page 1

Statement of Responsibilities

This document is for use by experienced and trained Qualified Cleveland Range, LLC Authorized Service

Representatives who are familiar with both the safety procedures, and equipment they service.

Cleveland Range, LLC assumes no liability for any death, injury, equipment damage, or property damage

resulting from use of, improper use of, or failure to use the information contained in this document.

Cleveland Range, LLC has made every effort to provide accurate information in this document, but

cannot guarantee that this document does not contain unintentional errors and omissions.

The information in this document may be subject to technical and technological changes, revisions, or

updates.

Cleveland Range, LLC assumes no liability or responsibility regarding errata, changes, revisions, or

updates.

Qualified Cleveland Range, LLC Authorized Service Representatives are obligated to follow industry

standard safety procedures, including, but not limited to, OSHA regulations, and disconnect / lock out /

tag out procedures for all utilities including steam, and disconnect / lock out / tag out procedures for gas,

electric, and steam powered equipment and / or appliances

All utilities (gas, electric, water and steam) should be turned OFF to the equipment and locked out of

operation according to OSHA approved practices during any servicing of Cleveland Ran ge equipment

Qualified Cleveland Range, LLC Authorized Service Representatives are obligated to maintain up-to-date

knowledge, skills, materials and equipment.

Page 2

Cleveland Range, LLC

1333 East 179th St., Cleveland, Ohio, U.S.A. 44110

Ph: 1-216-481-4900 Fx: 1-216-481-3782 Visit our Web Site at www.clevelandrange.com

Page 3

CLEVELAND RANGE

SEQUENCE OF OPERATIONS

Electric Boiler Base

1. Supply voltage is sent to the primary of the Control Transformer.

x 115 VAC is sent from the secondary of the Control Transformer to the on/off rocker

switch.

2. To turn the unit on, depress the red on/off rocker switch.

x 115 VAC is sent to the upper cabinets and terminal block in control box.

x 115 VAC is sent to normally open drain valve closing it.

x 115 VAC is sent to L1 and L2 of the water level board.

3. With the water level board energized and no water in the boiler

x 115 VAC is sent from the WF terminal to the fill solenoid.

x The fill solenoid opens and the boiler fills through the drain valve.

x The water fills to the low probe shorting it to ground

x 115 VAC is sent from the HTR terminal through the normally closed contacts of the

highlimit pressure switch to contacts of the ice cube relay and the amber reset switch,

energizing the amber light.

4. When the momentary amber switch is depressed 115 VAC is sent to the coil of the ice cube

relay closing it.

x The relay latches itself through a jumper to the coil.

x If either the high-pressure switch or the low water cut of switch opens, the latch

circuit opens.

x When the contacts close the amber light will energize and the process may begin

again.

x The relay contacts close sending 115 VAC through the normally closed contacts of the

operating pressure switch to the coil of the contactor(s). .

5. With 115 VAC to the coil of the contactor(s).

x The contactor closes.

x Supply power is sent to the elements.

6. The water in the boiler is heated to steam.

x As steam is generated and pressure builds the air is pushed out through the steamtrap.

x When steam goes through the steam trap and heats it to 192 degrees it closes.

7. Pressure builds in the boiler to the set point of 8-10 PSI (except 36CEM16 or pressure

steamers that are set at 5PSI).

x The operating pressure switch opens and the heat circuit is de-energized.

x When the pressure drops below the set point the heat circuit is energized and the heat

process begins again.

Page 4

8. Water continues to fill until the high probe is grounded.

x When the high probe is grounded the WF terminal on the water level board is de-

energized.

x The fill solenoid closes until the high probe is ungrounded for 05 seconds.

x If the water level drops below the low probe for more than 20 seconds the WF terminal

is energized and the water fill circuit begins again.

9. When the unit is turned off, by depressing the red rocker switch,

x 115 VAC is removed from the heat circuit.

x 115 VAC is removed from the drain circuit and the normally open drain valve opens

allowing the unit to drain.

x 115 VAC is sent to the 3-minute timer.

x The three-minute timer will energize the fill solenoid for 3 minutes while the steamer

drains.

Page 5

Page 6

Page 7

CLEVELAND RANGE

SEQUENCE OF OPERATIONS

Electric Boiler Base

With Secondary Low Water Cut Off Switch

1. Supply voltage is sent to the primary of the Control Transformer.

x 115 VAC is sent from the secondary of the Control Transformer to the on/off rocker

switch.

2. To turn the unit on, depress the red on/off rocker switch.

x 115 VAC is sent to the upper cabinets and terminal block in control box.

x 115 VAC is sent to normally open drain valve closing it.

x 115 VAC is sent to L1 and L2 of the water level board.

x 115 VAC is sent to the open contacts of the low water cut-off switch.

3. With the water level board energized and no water in the boiler

x 115 VAC is sent from the WF terminal to the fill solenoid.

x The fill solenoid opens and the boiler fills through the drain valve.

x The water fills to the low probe shorting it to ground

x 115 VAC is sent from the HTR terminal through the normally closed contacts of the

operating pressure switch to coil of the contactor(s).

x The rising water also raises the float on the low water cut-off switch closing it.

x 115 VAC is sent through the normally closed contact of the high-pressure switch to the

amber reset switch, energizing the amber light.

4. When the momentary amber switch is depressed 115 VAC is sent to the ice cube relay

closing it.

x The relay latches itself through a jumper to the coil.

x If either the high-pressure switch or the low water cut of switch opens, the latch

circuit opens.

x When the contact close the amber light will energize and the process may begin

again.

x The relay contacts close sending 115 VAC to the coil of the contactor.

5. With 115 VAC to the coil of the contactor(s).

x The contactor closes.

x Supply voltage is sent to the elements.

6. The water in the boiler is heated to steam.

x As steam is generated and pressure builds the air is pushed out through the steamtrap.

x When steam goes through the steam trap and heats it to 192 degrees it closes.

7. Pressure builds in the boiler to the set point of 8-10 PSI (except 36CEM16 or pressure

steamers that are set at 5PSI).

Page 8

x The operating pressure switch opens and the heat circuit is de-energized.

x When the pressure drops below the set point the heat circuit is energized and the heat

process begins again.

8. Water continues to fill until the high probe is grounded.

x When the high probe is grounded the WF terminal on the water level board is de-

energized.

x The fill solenoid closes until the high probe is ungrounded for 05 seconds.

x If the water level drops below the high probe for more than 20 seconds the WF

terminal is energized and the water fill circuit begins again.

9. When the unit is turned off, by depressing the red rocker switch,

x 115 VAC is removed from the heat circuit.

x 115 VAC is removed from the drain circuit and the normally open drain valve opens

allowing the unit to drain.

x 115 VAC is sent to the 3-minute timer.

x The three-minute timer will energize the fill solenoid for 3 minutes while the steamer

drains.

Page 9

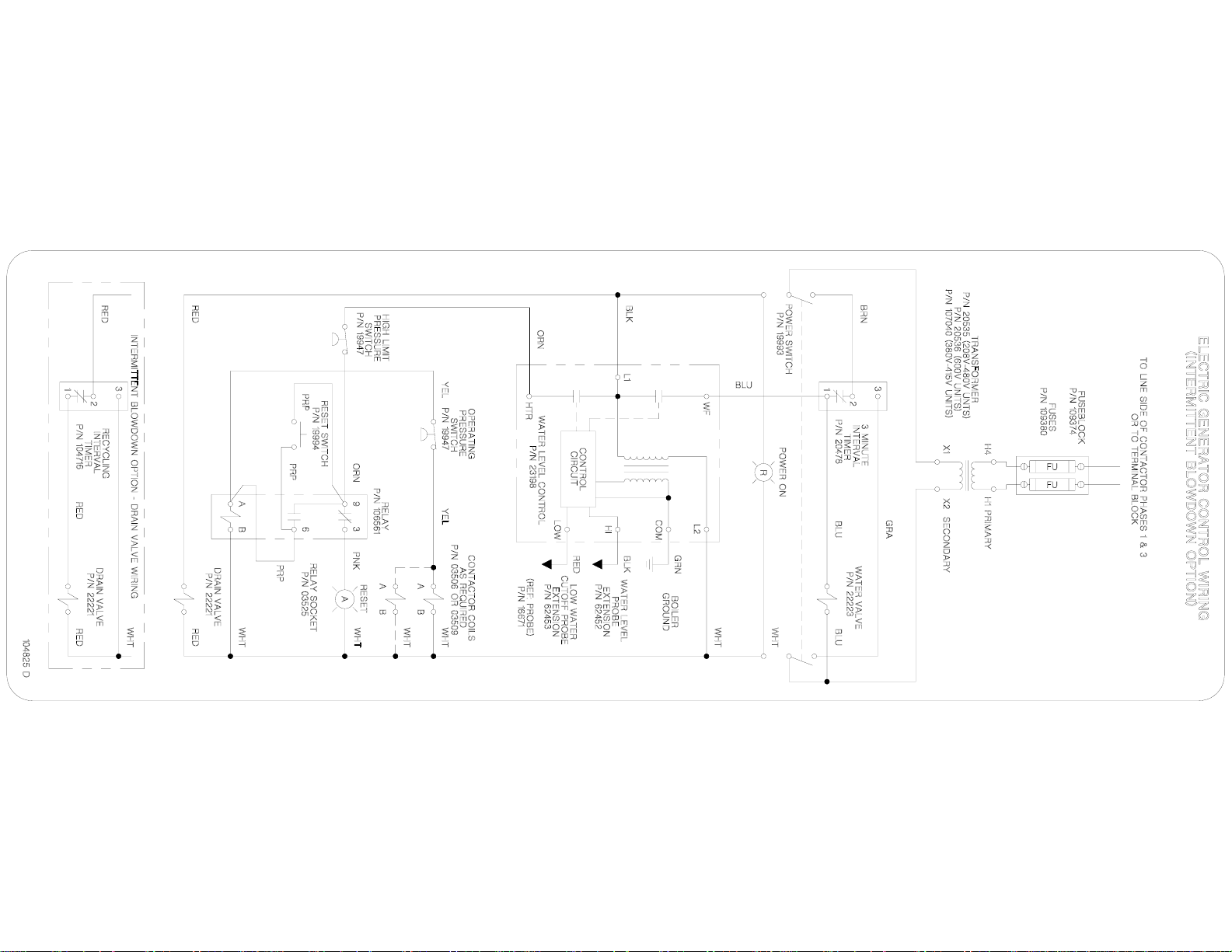

ELECTRIC GENERATOR CONTROL WIRING

CALIFORNIA CODE (ASME CSD-1)

(INTERMITTENT BLOWDOWN OPTION)

FUSEBLOCK

P/N 109374

FUSES

P/N 109380

FU

FU

TO LINE SIDE OF CONTACTOR

PHASES 1 & 3 OR

TO TERMINAL BLOCK

TRANSFORMER

P/N 20535 (208V-480V UNTS)

P/N 20536 (600V UNITS)

P/N 107040 (380V-415V UNITS)

BRN

POWER SWITCH

P/N 19993

BLK

BLK

LOW

WATER

SWITCH

P/N 19995

H4

X1

3

2

P/N 20478

1

BLU

WF

L1

WATER LEVEL CONTROL

HTR

OPERATING

PRESSURE

YEL

SWITCH

P/N 19947

HIGH LIMIT

PRESSURE

SWITCH

P/N 19947

ORNBLK

3 MINUTE

INTERVAL

TIMER

POWER ON

CONTROL

CIRCUIT

P/N 23198

H1 PRIMARY

X2 SECONDARY

R

YEL

RELAY

P/N 106561

74

93

ORN

GRA

L2

GRN

COM

BLK

HI

RED

LOW

CONTACTOR COILS

P/N 03506 OR 03509

CONTACTOR COILS

P/N 03506 OR 03509

RED

PNK

WATER VALVE

P/N 22223

BOILER

GROUND

WATER LEVEL

PROBE

EXTENSION

P/N 62452

LOW WATER

CUTOFF PROBE

EXTENSION

P/N 62453

(REF: PROBE)

P/N 16671

AS REQUIRED

A

BBA

AS REQUIRED

BA

AB

RESET

A

BLUBLU

WHT

WHT

WHT

WHT

WHT

WHT

WHT

PRP

RESET SWITCH

P/N 19994

INTERMITTENT BLOWDOWN OPTION - DRAIN VALVE WIRING

3

RED

RECYCLING

INTERVAL

2

TIMER

P/N 104716

1

PRP

AB

6

PRP

DRAIN VALVE

P/N 22221

DRAIN VALVE

P/N 22221

WHT

REDRED

WHT

REDRED

104870 E

Page 10

Page 11

PROBLEM:

Electric Boiler

won't build

pressure

Boiler won't build

pressure

Is the red ligh t on

in the power

switch?

No

Is there p ow er to

the s t eam er?

Yes

No

Connect power

to st eam er.

Replac e the

latching relay.

Repair

or Replace the

probe circuit.

Steamer won' t

Replac e the

water boar d

Is there 120 VAC

between ter m i nals

L2 and HTR on t h e

Yes

water board wit h a

jumper b etween

Low and C?

See

fill.

No

Is there water in

No

the sight glass?

Is the Amber ligh t

Is there 120 VAC

terminals L2 and

No

HTR on the water

Yes

Yes

on in the reset

switch?

No

between

board?

Yes

After depressing

the reset switch,

Yes

does th e A m ber

light go off?

Is there 120 VAC

to the coil(s) of the

contactor(s)?

Replac e the

on/off rocker

switch

Replace

the high limit

pressure

switch

Yes

Yes

No

Is there 120 VAC

to the coil(s) of the

contactor(s) with

No

pressure switch

With the High

Limit pressu r e

switch

temporarily

bypassed , does

the Amber li g h t go

off when the reset

switch is

depressed?

No

Does this boiler

have the op t ional

Secondary Low

Water Cut Out?

the operating

temporarily

bypassed?

No

No

from terminal 6 t o

9 on the latching

relay, does the

Amber light go out

No

switch depressed?

With the SLWCO

bypassed , does

the Amber li g h t go

Yes

off with the reset

switch depressed?

SLWCO switch

Yes

With a jumper

with the reset

No

switch

temporarily

Yes

Replac e the

Replac e the

latching r elay

Replac e the

latching r elay

Is there 120 VAC

No

to terminal 6 on

the latching relay?

Yes

Replac e the

Reset switch

Yes

Does the contactor

pull in?

Yes

Is ther e an amp

draw at t h e

element?

Yes

Is there allot of

steam comin g ou t

the drain?

Yes

Replac e the

steam t rap

No

No

No

Replac e the

contactor

Replac e the

element.

Elements heati ng

the water, the

Boiler is making

steam. Check for

Yes

Replace

the operating

pressure

switch

With

leaks.

Page 12

Boiler

won't fill.

Yes

PROBLEM:

Electric boiler

won't fill

Is there p ow er to

the s t eam er?

Yes

Is there w at er to

the s t eam er?

Yes

Is there 120 VAC

between the L1

and L2 on the

water board ?

Yes

Is there

120 VAC between

L2 and W F on t h e

water board ?

No

No

No

Supply power

to the s t eamer.

Supply cold

water to the

Replac e the

on/off rocker

No

steamer.

switch .

Remove

the wire from th e H I

terminal on the water

board. Is th er e 12 0

VAC between L2 and

WF?

No

Replac e the

water boar d

Replace wiri n g

to drain

solenoid.

Replac e the

wiring to the

intermittent

blowdown

timer .

No

the s t eam er have

blowdown timer?

No

between ter m i nals

2&3 on the timer?

Replac e the

wiring to the fi ll

solenoid.

Replace the f il l

solenoid

Does

the opt i onal

intermittent

Yes

Is

there 120 VAC

Yes

Replac e the

intermittent

blowdown

timer.

No

No

No

Yes

Is there

120 VAC across

the coil of the f il l

solenoid?

Yes

Is

water leaving the

fill solenoid?

Yes

Is there

120 VAC across

the coil of the

drain valve?

Yes

Is water draining

from the

generator?

Yes

Replac e the

drain valve.

No

Yes

Is there

debris on the HI

probe extension?

Yes

Clean or

replac e t he

probes

extension.

If water

is leaving the fill

solenoid and not

draining from th e

generator where is it

going? check for

leaks..

No

Replac e the

wire to the Hi

probe.

Page 13

PROBLEM:

Electric Boiler

Over

Pressurizes

(15# Safet y

valve opens)

Replace

operating

pressure

switch

Replac e the

safety valve.

No

service manual f or

Yes

Boiler over

pressurizes

Does operating

pressure switch

open at pr oper

setting (chec k

that st eam er)?

Does the 15#

safety valve op en

with little or no

pressure on the

gauge after i t h as

been repl aced?

No

Delime the

boiler.

Does the contactor

continue to pull in

Yes

Does the pressure

No

with no voltage to

with operating

pressure switch

open?

No

in the gauge

continue to ris e

contactor coil?

Yes

Yes

Replace

contacto.r

Replac e the

weeper val ve .

Replace

operating

pressure

switch.

PROBLEM:

Electric Boiler Stops Producing Steam

Boiler stops

steaming

Does th e am ber

light in the reset

No

switch come on?

Yes

Is the temperature

sensitive dot

(surrounded by a

yellow circ le) on

the water board

white?

No

Replace

the water board . I t h as

reached a temperatur e of

over 180

degrees.

Yes

Does boiler have

the opt i onal

Secondary Low

Water Cut Out?

Yes

Will Boiler stop

making steam

with SLWCO

temporarily

bypassed?

No

No

Yes

Delime boiler

Yes

Are the probes

covered with

scale?

No

Is high pressure

switch opening

prematurely?

No

Replac e the

water boar d

Yes

Replace high

pressure switch

Does SLWCO

open and c l ose as

float is moved up

and down?

No

Replace

Secondary Low

Water Cut Out

switch.

Yes

Install delay

timer for

SLWCO

Page 14

Replace the f il l

solenoid

With the HI probe

emersed in water

is there 120 VAC

No

between ter m i nals

L2 and WF on t h e

PROBLEM: Electric Boiler Overfills

Replac e 3

Boiler over fills

Yes

water board .?

minute timer

No

With the wire

removed from

terminal 1on the 3

minute timer, i s

there 120 VAC to

the fill solenoid?

With a jumper

across termin als

HI and C on the

Yes

water b oard , i s

there 120 VAC

between L2 and

The pr obe

circuit is open.

Check con t i n ui t y of t h e

probe wire and

WF?

No

probe.

Yes

Replac e ;the

water boar d

PROBLEM: Transformer continues to fail.

Transformer Fails

start

Leave

fuse in place.

Transformer

could have been

bad.

No

After a 2 am p

inline fuse is

placed on t h e

secondary, does

the fuse open?

Yes

the resistance of

all the solenoid coils.

Compare to chart.

allow for 10 %

Check

deviation.

Loading...

Loading...