Page 1

Cleveland Range

UNITED STATES

CANADA

SteamCraft 10®

Convection Steamer

SERVICE

MANUAL

Printed 3/93

Cleveland Range, Inc.

1333 East 179th St.. Cleveland, Ohio 44110 Phone: (216) 451-4900 •

Telex: 98-0546 • FAX: (216) 481-3782

MODELS: 24-CEA-10, & 24-CGA -10

Garland Commercial Ranges

1177 Kamato Road

Mississaugha, Ontario. Canada L4W1X4

Phone: (416) 624-0260 - FAX: (416) 624-0623

Page 2

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the vicinity of this

or any other appliance.

GAS LEAK INSTRUCTIONS

Post in a prominent location, instructions

to be followed in the event the user smells

gas. This information shall be obtained by

consulting the local gas supplier.

For safe and efficient operation of this equipment, this manual must be retained by the owner/user

for future reference.

PROTECTING WARRANTY COVERAGE

The warranty printed to the left specifies the owner/user's responsibility for proper installation, operation,

and maintenance of the SteamCraft 10. If these responsibilities are not met, toe Limited Warranty and/or

Extended Limited Warranty coverage may be adve rsely affected. The following table is provided to assist

the owner/user in meeting these responsibilities. In addition, the warranty advantages of installing a

SteamerGard water treatment system are explained after the table.

The Warranty Protection Table lists installation, operation, and maintenance factors that have in the past

adversely affected warranty coverage. The owner/user of a SteamCraft 10 should pay particular attention

to these factors to protect his warranty coverage. This table is not a comprehensive list of the owner/user's

responsibilities. Cleveland Range steam products are intended for use only by professionally trained

personnel To meet his responsibilities, the owner/user must supplement this guide with any additional

actions consistent with the operation of steam generating food preparation equipment by a trained

professional.

Warranty Protection Table

SUBJECT PAGE

REFERENCE

Electrical Power Requirements & Line Voltage 10

Water Quality Requirements & Analysis 11

Water Pressure 16

Vented Drain 20

Level Operation 19

Blowdown Frequency 55 & 63

Steam Generator Maintenance & Maintenance Records 67

Descaling Frequency & Procedure 68

Approved Chemical Cleaners 68

Authorized Maintenance & Repair 74

SteamerGard Water Treatment System

A SteamerGard water treatment system protects the SteamCraft 10 from impurities contained in regular

lap water, especially Total Dissolved Solids (TDS) which cause lime and scale deposits in steamer

equipment. The protection is so effective that Cleveland Range increases toe warranty coverage on a

Steam Craft 10 installed in conjunction with a SteamerGard system to five years for parts and three years

for labor on water related components, elements, valves, generators, piping, etc. However, even with a

SteamerGard system installed, the owner/user should follow toe guidance of the Warranty Protection

Table.

Page 3

Models 24-CGA-10 and 24-CEA-10 SteamCraft 10 Service Manual

Table of Contents

Chapter Page

CHAPTER 1. PRODUCT IDENTIFICATION 1

MODEL NUMBER 1

SERIAL NUMBER 1

PRODUCT INFORMATION PLATE 1

CHAPTER 2. INSTALLATION INSTRUCTIONS 7

INTRODUCTION 7

INSTALLATION POLICIES 7

INSTALLATION OVERVIEW 8

PREPARATION FOR INSTALLATION 10

Protecting The SteamCraft 10 10

Electric Power Requirements 10

Gas Supply Requirements 10

Exhaust Hood Requirements – All Models 10

Water Quality Requirement s 11

Softened, Treated, or Filtered Water 16

Water Supply System 16

Selecting The Operating Location 17

INSTALLATION INSTRUCTIONS 18

Unpacking & Inspection 18

Shipping Damage Instructions 19

Position & Level The SteamCraft 10 19

Adjustable Leveling Legs 19

Positioning & Leveling 19

Install Slide Racks 20

Install & Connect The Free Air Vented Drain Lines 20

Exhaust Hood Ventilation – All Models 22

Install Electric Power Lines 22

Connect Electrical Line 23

Install Water Supply Lines 24

Connect Water Supply Lines 26

General Connection Requirements 26

Untreated Water Connection (Without SteamGard) 27

Treated Water Connection (With SteamGard) 27

Testing Water Supply Lines 27

Install & Connect Gas Supply Lines 27

Leak-Testing Gas Supply Lines 28

Pressure Testing The Gas Supply Lines 29

Bleed Air From The Gas Supply Lines 30

Burner Ignition Test (Gas -Fired Models Only) 31

Final Setup & Checkout 33

Cleveland Range, Inc . Printed 3/93

Page 4

Page ii SteamCraft 10 Service Manual Models 24-CGA-10 0 and 24-CEA-10

Table of Contents (continued)

Chapter Page

Installation Checks 33

Operating Tests 34

Operating Test Preparation 34

Blowdown Inspection Procedure 35

Operating Test Procedures 35

Timer Test Procedures – Key Pad Control Panel 37

Timer Test Procedures – Dial Timer Control Panel 38

CHAPTER 3. OPERATION 41

INTRODUCTION 41

DIFFERENCES AMONG MODELS 41

Atmospheric Generator Models 41

Pressure Generator Models 41

OPERATIONAL SAFETY 41

BURNER LIGHTING 43

GAS LEAK INSTRUCTIONS 43

OPERATING MODES 43

Manual Operation 43

Timed Operation 43

Manual Timer 43

Steam Generator BlowDown 44

MAIN DISCONNECT SWITCH 44

CONTROL PANELS 44

COOKING OPERATIONS KEY PAD CONTROL PANEL 46

Summary Of Cooking Operations 46

Power ON (Automatic Fill) 47

Start Steam Supply 47

Inspect The Cooking Compartment 47

Preheat The Cooking Compartments 48

Place Food Into The Cooking Compartment(s) 49

Select The Operating Mode 49

Timed Cooking Procedure 50

Manual Cooking Procedure 51

Power OFF (Automatic Blowdown) 52

Blowdown Frequency 52

Blowdown Procedure 53

Shut Down And Cleaning (At End Of Day Or Shift) 53

DIAL TIMER CONTROL PANEL SUMMARY 55

COOKING OPERATIONS – DIAL TIMER CONTROL PANEL 56

Summary Of Cooking Operations 56

Power ON (Automatic Fill) 56

Printed 3/93 Cleveland Range, Inc.

Page 5

Models 24-CGA-10 and 24-CEA-10 SteamCraft 10 Service Manual Page iii

Table of Contents (continued)

Chapter Page

Start the Steam Supply 57

Inspect the Cooking Compartment 57

Preheat the Cooking Compartment(s) 57

Place Food into The Cooking Compartment(s) 58

Select the Operating Mode 58

Timed Cooking Procedure 58

Manual Cooking Procedure 59

Remove Food from The Cooking Compartment(s) 59

Power OFF (Automatic Blowdown) 60

Blowdown Frequency 60

Blowdown Procedure 60

Shut Down And Cleaning (At End Of Day Or Shift) 61

CHAPTER 4. PREVENTATIVE MAINTENANCE AND TROUBLESHOOTING 63

INTRODUCTION 63

MAINTENANCE RECORDS 63

DAILY MAINTENANCE 63

Blowdown Steam Generator 63

Clean SteamCraft 10 63

WEEKLY MAINTENANCE 63

Clean Drain 63

MONTHLY MAINTENANCE 64

Descale Steam Generator 64

YEARLY MAINTENANCE 67

Clean Water Line Strainer 67

TROUBLESHOOTING NOTES 70

CHAPTER 5. COMPONENT AND CIRCUIT FUNCTIONS 71

INTRODUCTION 71

Models Covered In This Chapter 71

Figures and Illustrations 71

SteamCraft 10 Variations 71

Steam Generator Power Source 71

Control Panel Type 72

THEORY OF OPERATION 72

Steam Generator Water Filling Cycle 72

Steam Generator Preheating 74

Steaming Functions For Model 24-CEA-10 75

Steaming Functions For Model 24-CGA-10 76

Gas Burner Ignition and Combustion Functions – Model 24-CGA-10 79

Burner Ignition and Control System 79

Cleveland Range, Inc. Printed 3/93

Page 6

Page iv SteamCraft 10 Service Manual Models 24-CGA-10 and 24-CEA-10

Table of Contents (continued)

Chapter Page

Condenser and Drain Functions 80

Condenser Operation 80

Drain Valve Functions 81

Shutdown, Steam Generator And Float Cylinder Rise Functions 82

STEAMCRAFT 10 ELECTRICAL CIRCUITS – Model 24-CEA-10 83

High Voltage Circuit 83

120 VAC Circuit 83

STEAMCRAFT 10 ELECTRICAL CIRCUITS – Model 24-CGA-10 83

STEAMCRAFT 10 TIMER CIRCUITS 84

ELECTRICAL CIRCUIT COMPONENTS 84

Terminal Bloc k 84

ON/OFF Switch 85

TIMED/MANUAL Switch 85

3-Minute Timer 85

Float Assembly 86

Rinse Solenoid Valve 87

Drain Solenoid Valves 87

Water Fill Solenoid Valves 87

Condenser Solenoid Valves 87

Preheat Thermostat 88

Key Pad and Dial Timers 88

Electronic Key Pad Timer 88

Compartment Thermostat (Electronic Key Pad Units Only) 89

Mechanical Timer 89

3-Second Timer And Buzzer (Mechanical Timer Units Only) 89

Heater Element – Model 24-CEA-10 89

Dryer Element – Model 24-CEA-10 89

High Temperature Limit Switch 89

Combustion Control Module – Model 24-CGA-10 90

Combustion Air Blower 90

Air Prover Pressure Switch 90

Pilot Spark Igniter 90

Automatic Gas Valve 90

Steam Relief Solenoid Valve – Model 24-CGA-10 90

Compartment Steam Solenoid Valves – Model-CGA-10 90

CHAPTER 6. COMPONENT TESTING GUIDE 91

INTRODUCTION 91

Models Covered In This Chapter 91

Figures And Illustrations 91

Nominal Voltage Reference 91

Printed 3/93 Cleveland Range, Inc.

Page 7

Models 24-CGA-10 and 24-CEA-10 SteamCraft 10 Service Manual Page v

Table of Contents (continued)

Chapter Page

COMPONENT TESTING FUNDAMENTALS 92

Visual Check 92

Connections and Wiring 92

Solenoid Valves 93

General Considerations 93

Normally Open And Normally Closed Valves And Contacts 93

Water Pressure and Control Valves 93

Measuring Resistance Through The Solenoid 93

Jammed or Blocked Valves 93

Thermostatic Snap Switches 95

Heater Element 95

Resistance Measurements 95

Insulation Resistance Measurements 96

Voltage Measurements 96

INITIAL TEST PROCEDURE – INTRODUCTION 96

Test Procedures Layout and Conventions 96

INITIAL TEST PROCEDURE – GENERAL PREPARATIONS 97

Model Numbers and Test Procedure Variations 97

INITIAL TEST PROCEDURE – MODEL 24-CGA-10 98

Set Up the Initial Test Conditions 98

COMPONENT TEST PROCEDURES 123

Initial Conditions for All Testing 123

CT:1 Drain (3-Way) Solenoid Valves 123

CT:2 3-Minute Timer 124

CT:3 Rinse Solenoid Valves 125

CT:4 Water Fill Solenoid Valves 126

CT:5 ON/OFF Switch 127

CT:6 Float Assembly 128

CT:7 Gas Control Transformer – 24 Volt Model 24-CGA-10 131

CT:8 Preheat Thermostat (Steam Generator) 131

CT:9 TIMED/MANUAL Switch 132

CT:10 Condenser Solenoid Valves 133

CT:11 Steam Relief Solenoid Valve – Model 24-CGA-10 135

CT:12 Compartment Steam Solenoid Valve – Model 24-CGA-10 136

CT:13 Mechanical Timer 137

CT:14 & CT:15 3-Second Timer And Buzzer (Mechanical Timer Units Only) 137

CT:16 Electronic Timer Transformer – 24 Volt 138

CT:17 Electronic Key Pad Timer 139

CT:18 Compartment Thermostat (Key Pad Timer Units Only) 141

CT:19 Transformer – Model 24-CEA-10 142

CT:20 & CT:21 Heater Contactor – Model 24-CEA-10 142

Cleveland Range, Inc. Printed 3/93

Page 8

Models 24

-

CGA

-10

and

24-CEA

-

10

Table of Contents (continued)

Chapter Page

CT:22 High Temperature Limit Switch – Model 24-CEA-10 144

Terminal Block 145

CT:23 & CT:24 Heater & Dryer Elements – Model 24-CEA-10 145

CT:25 Relay R-1 – Model 24-CEA-10 147

Burner Ignition & Control System Components – Model 24-CGA-10 147

CHAPTER 7. ILLUSTRATED PARTS LISTS 149

INTRODUCTION 149

Parts Differences Among SteamCraft 10 Steamers 149

Electrical Schematics And Wiring Diagrams 149

Ordering Parts 149

CHAPTER 8. IGNITION MODULE 199

INTRODUCTION 199

HONEYWELL & WHITE -RODGERS MANUALS 199

Printed 3/93 Cleveland Range, Inc.

Steam Craft 10 Service Manual

Page 9

Models 24-CGA-10, 24-CGP -10, 24-CEA-10, 24-CEP-10 SteamCraft 10 Service Manual, Chapter 1 Page 1

CHAPTER 1. PRODUCT IDENTIFICATION

Cleveland Range, Inc. assigns two product identification numbers to each

SteamCraft 10: a model number and a serial number. The model number

identifies the product characteristics. The serial number identifies the individual unit.

MODEL NUMBER

The operating section of this manual (Chapters 1 through 4) covers four

models of the Steam Craft 10 steamers:

• Gas fired atmospheric generator 24-CGA-10

• Gas fired pressure generator. 24-CGP-10

• Electric atmospheric generator. 24-CEA-10

• Electric pressure generator 24-CEP-10

The service section of this manual (Chapters 5 through 8) covers only the

atmospheric models:

• Gas fired atmospheric generator 24-CGA-10

• Electric atmospheric generator. 24-CEA-10

Each character of the model number identifies a characteristic of the

steamer. The Steam Craft 10 is 24 inches wide; a Convection steamer,

Electric or Gas powered, Atmospheric or Pres surized steam generator, and

has the capacity for 10 cooking pans.

SERIAL NUMBER

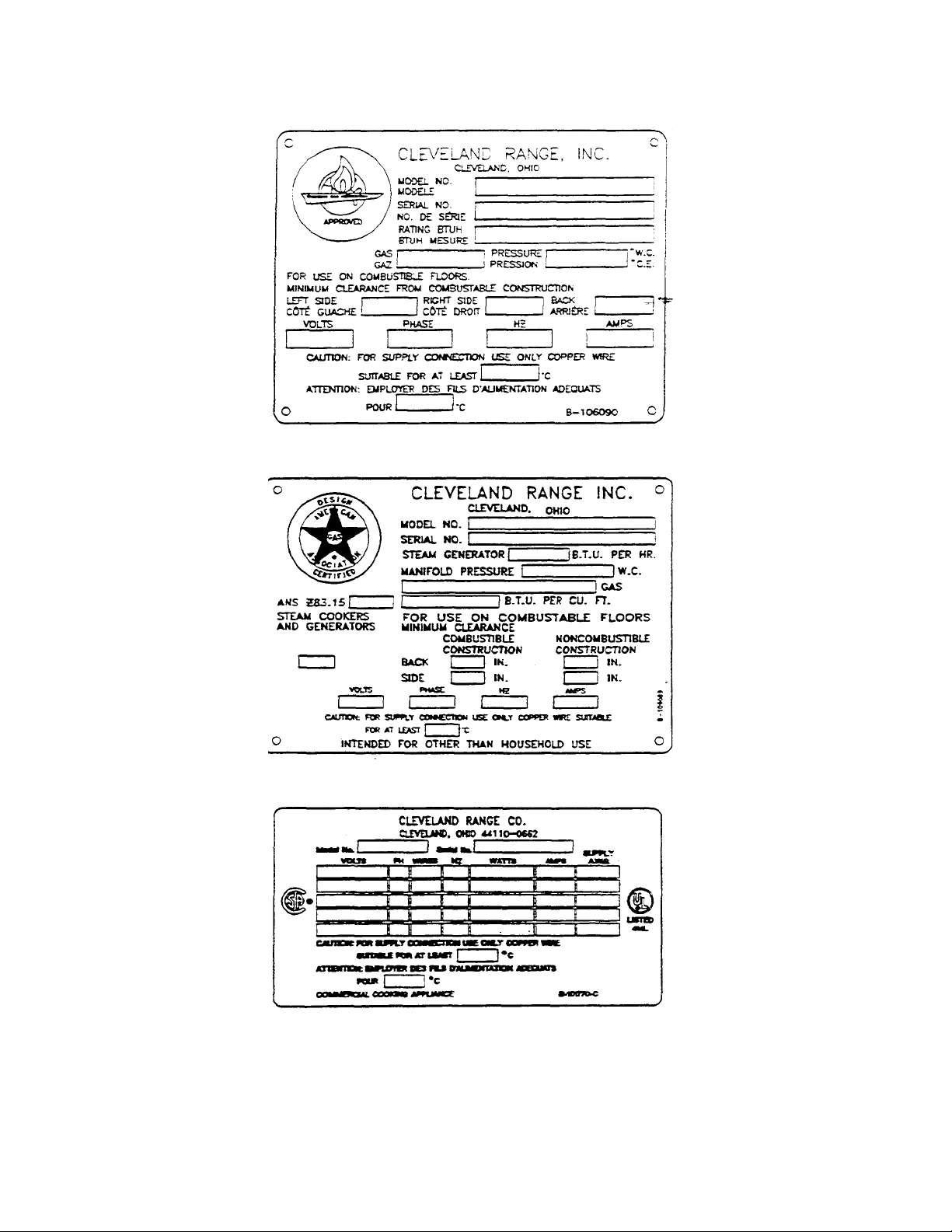

PRODUCT INFORMATION PLATE

This manual covers all standard features and options available on

SteamCraft 10 steamers. Other than selection of options, there are

presently no significant design, parts, or operating differences among

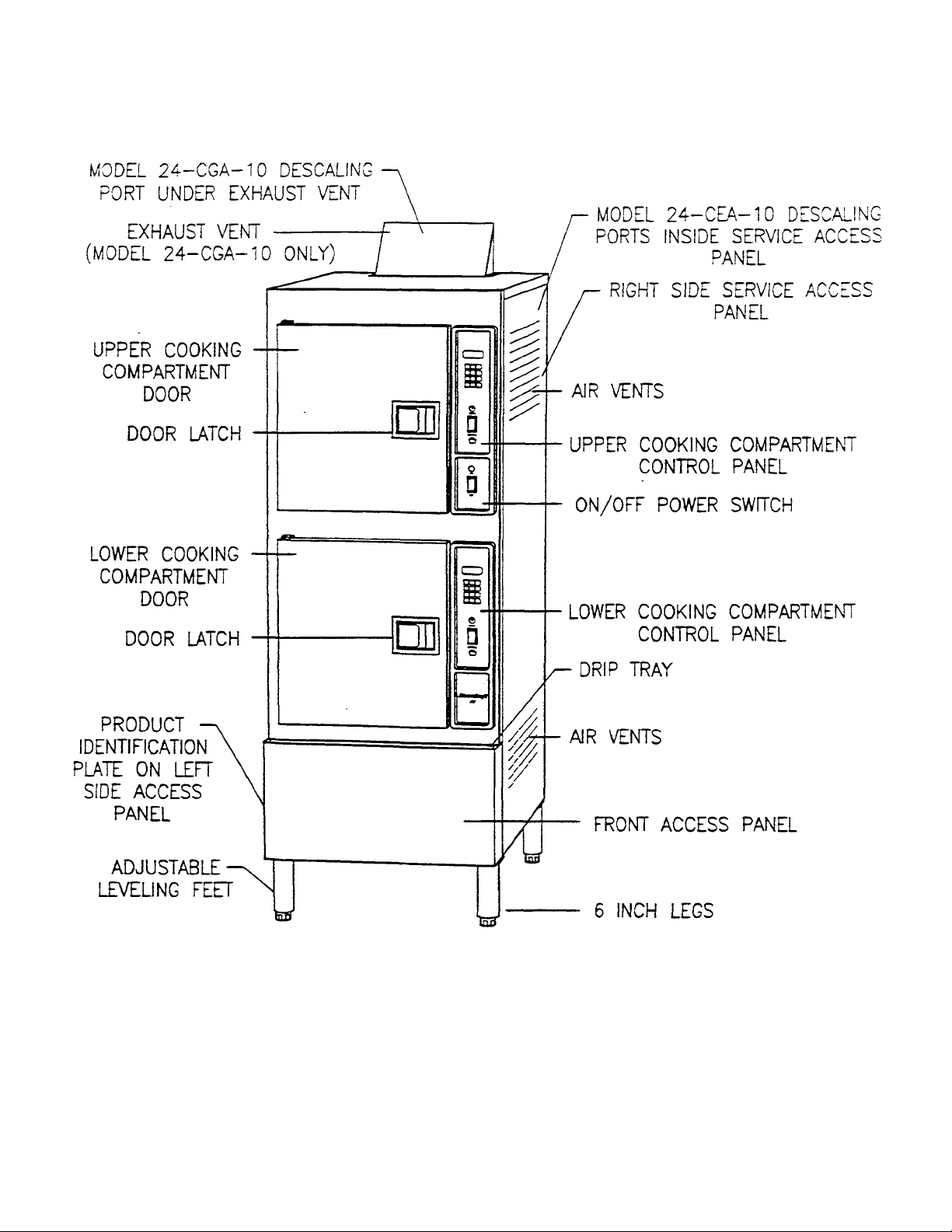

steamers with the same model number. Figure 1-2, Sheets 1 through 4

illustrate the four SteamCraft 10 models and identify the major components.

During manufacture, SteamCraft 10's are assigned individual serial num-

bers. A typical SteamCraft 10 serial number is: WC-7350-90G-02. The left

half of the number carries design information. The right half of the number

contains the manufacturing date and the unit of the manufacturing lot The

date of our sample number is 90G-02:90=1990, G=July. 02=the second unit

of the manufacturing lot Serial numbers arc used when explaining differ-

ences in design, parts, or operation among units with the same model

number. For example: a particular part may be used on SteamCraft 10's

with serial numbers before WC-7350-90G-02, and a different part used on

steamer WC-7350-90G-02 and those manufactured after it.

The Product Information Plates list the unit's model and serial numbers, and

power and wiring requirements. These plat es are located on the left side

panel, in the lower right corner. Figure 1-1 illustrates typical SteamCraft 10

Product Information Plates. Refer to me Figure 1-2 for the location of the

plates.

Page 10

Page 2 Chapter 1, SteamCraft 10 Service Manual Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10

Figure 1-1. SteamCraft 10 Product information Plates

Printed 3/93 Cleveland Range, Inc.

Page 11

Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10 SteamCraft 10 Service Manual, Chapter 1 Page 3

Figure 1-2. SteamCraft 10, Models 24-CGA-10 and 24-CEA-10

with Key Pad Control Panel (Sheet 1 of 4)

Cleveland Range, Inc. Printed 3/93

Page 12

1, SteamCraft 10 Service Manual Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10 Page 4

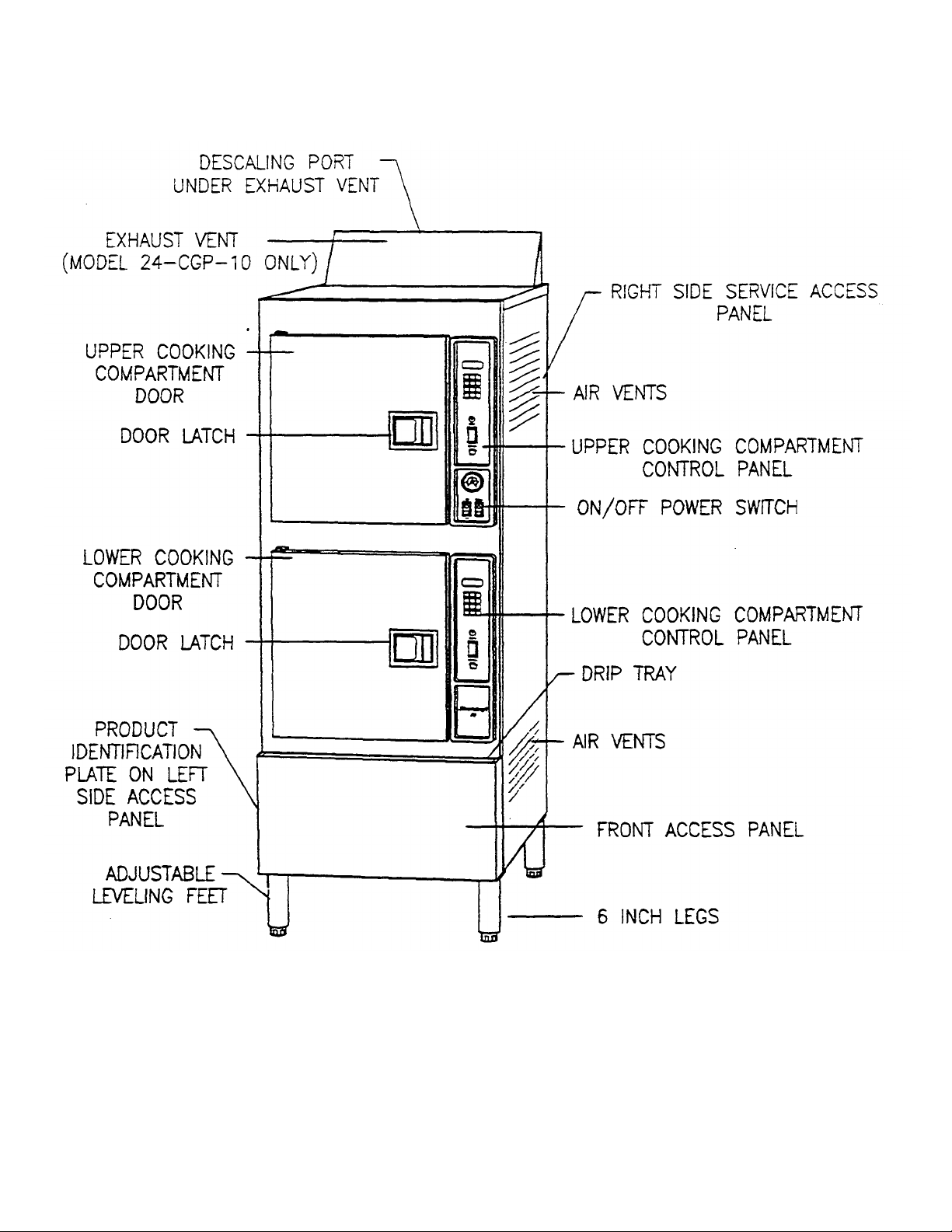

Figure 1-2. SteamCraft 10, Models 24-CGP-10 and 24-CEP-10

with Key Pad Control Panel (Sheet 2 of 4)

Printed 3/93 Cleveland Range, Inc.

Page 13

Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10 SteamCraft 10 Service Manual, Chapter 1 Page 5

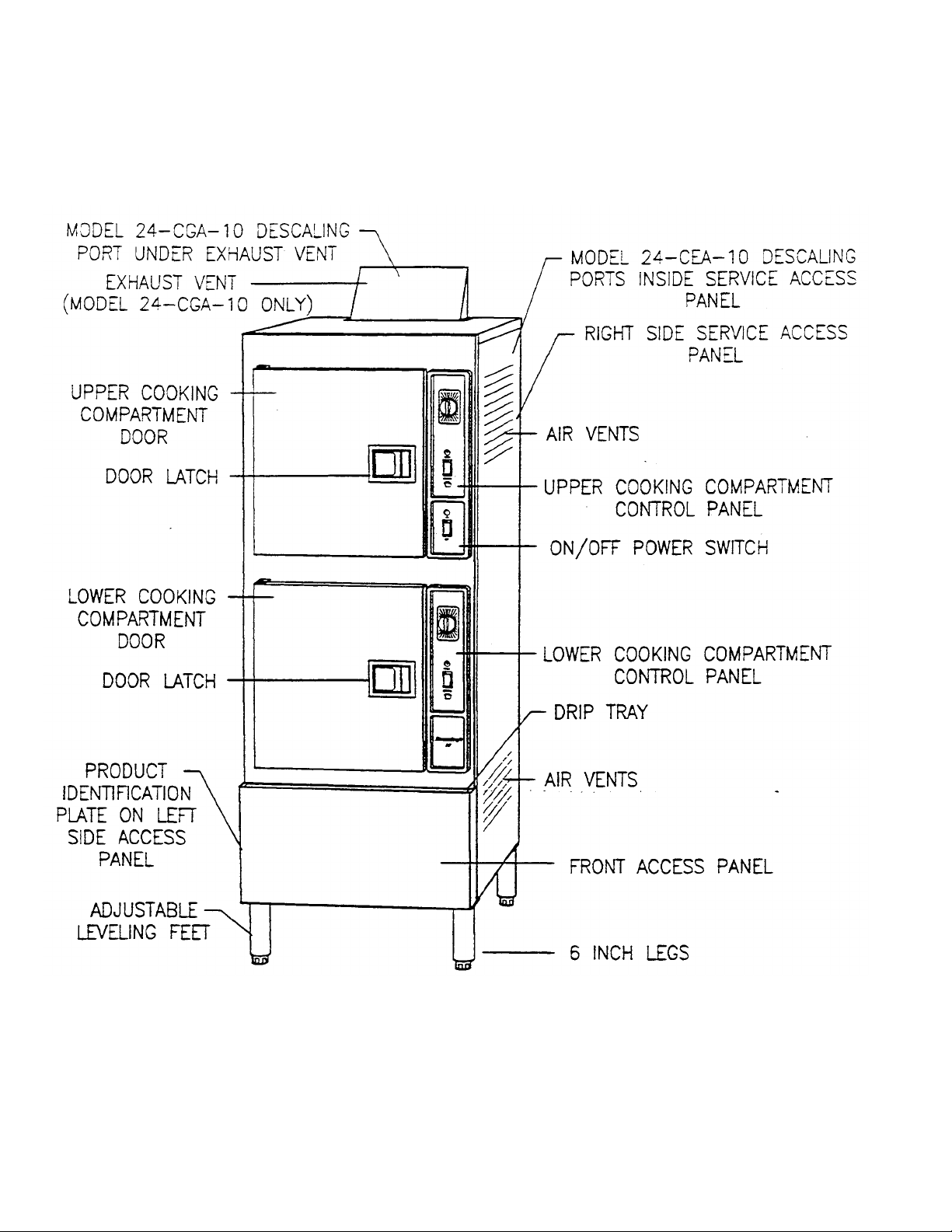

Figure 1-2- SteamCraft 10, Models 24-CGA-10 and 24-CEA-10

with Dial Timer Control Panel (Sheet 3 of 4)

Page 14

Page 6 Chapter 1, SteamCraft 10 Service Manual Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10

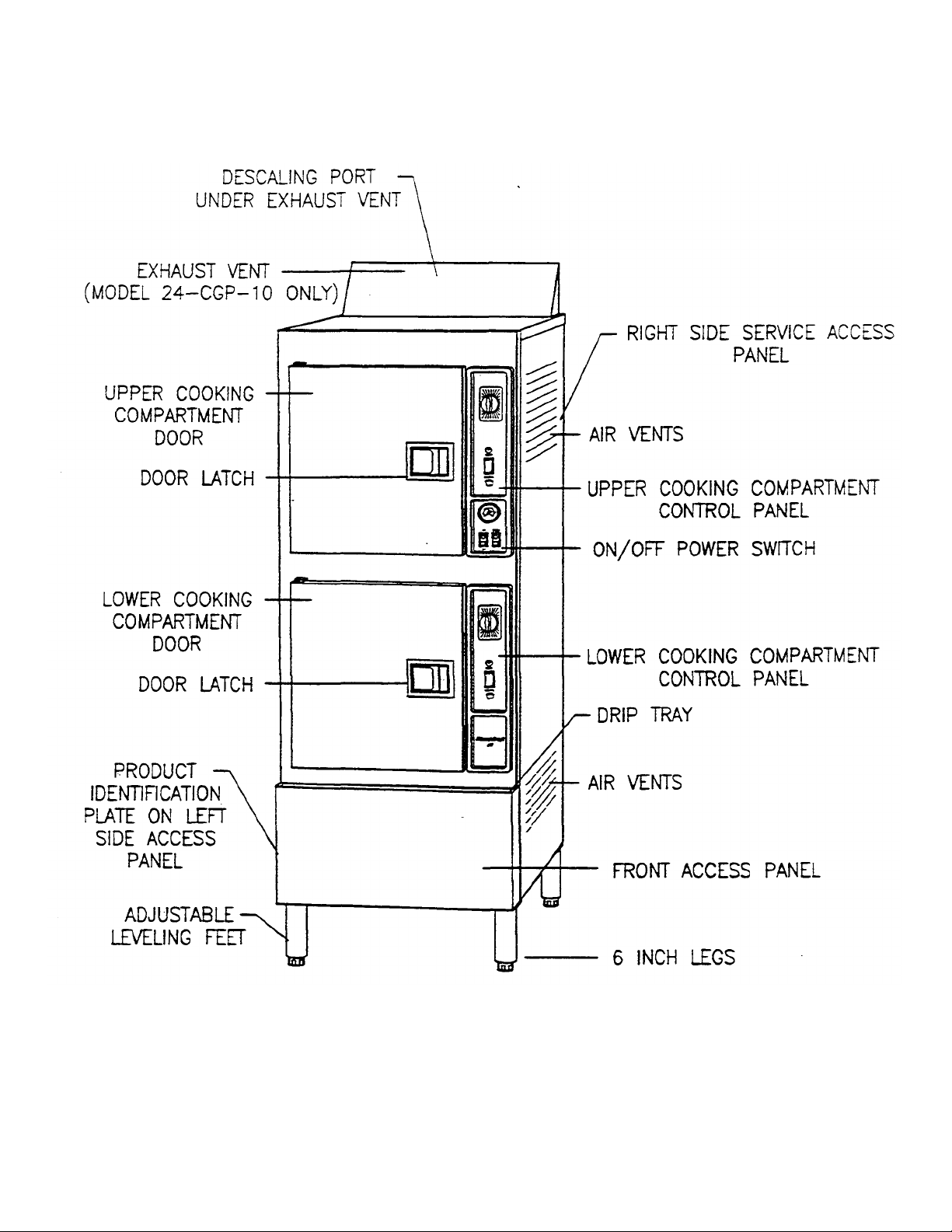

Figure 1-2. SteamCraft 10, Models 24-CGP-10 and 24-CEP-10

with Dial Timer Control Panel (Sheet 4 of 4)

Page 15

Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10 SteamCraft 10 Service Manual, Chapter 2 Page 7

CHAPTER 2. INSTALLATION INSTRUCTIONS

This manual and several components are packaged inside the Steam Craft 10

shipping carton. Only enough of the carton shoul d be opened to remove this

manual. Do not remove the Steam Craft 10 from the carton until just before

installation. If the shipping carton has already been removed and discarded, protect

the Steam Craft 10 from dirt and damage during storage, site preparation, and

installation as described in Protecting The Steam Craft 10, page 10.

WARNING

DEATH, INJURY, AND EQUIPMENT DAMAGE

could result from improper installation of the

SteamCraft 10, or from installation of a unit damaged during shipment or storage. Either of these

conditions could also void the equipment warranty.

DO NOT INSTALL a SteamCraft 10 suspected of

damage.

Install the SteamCraft 10 according to the policies

and procedures outlined in this manual.

INTRODUCTION

This chapter is a guide for installation of the SteamCraft 10, model numbers 24CGA-10,24-CGP-10,24-CEA-10 and 24-CEP-10. This guide is for use by qualified

professionals, and does not include all procedures and precautions in the common

domain of licensed plumbers, pipe fitters, and electricians, or experienced food

service equipment installers. This guide must be used in conjunction with

professional experience and a thorough under standing of the local, state, and

national utility, construction and sanitation codes; the most prominent of which are

listed in the Installation Policies section below.

Before starting installation, the owner and the installer should read through this

chapter and thoroughly understand and agree upon:

• The installation policies of Cleveland Range, Inc. as stated in Installation

Policies.

• An installation plan based on the Installation Overview and Installation Check

List

• Responsibility for feed water quality and its testing as described in Preparation

For Installation, Water Quality Requirements.

INSTALLATION POLICIES

The SteamCraft 10 must be installed by qualified plumbing and electrical

personnel, working to all applicable national and local codes.

• In the U.S.A., equipment installation must comply with the Basic Plumbing

Code of the Building Officials and Code Administrators International, Inc.

(BOCA), the National Fuel Gas Code, ANSI Z223.1-(latest edition), the

National Electric Code, ANSI/NFPA No. 70-(latest edition), and the Food

Service Sanitation Manual of the Food and Drug Administration (FDA).

• In Canada, equipment installation must comply with the CAN/CGA-B 149

Installation Code, the Canadian Electrical Code CSA C221and any other

applicable national and local codes.

Cleveland Range, Inc. Printed 3/93

Page 16

Previous Page

Page 8 Chapter 2, SteamCraft 10 Service Manual Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10

Chec

k electric power requirements.

1

,2

10

Check gas supply requirements (gas models only).

2,3,4 10

Test supply water quality.

5,6 11

Select water treatment system.

6 16

Select operating location

-

17

Installation

Position and level steamer.

11 19

Install exhaust hood.

12 22

24

6 26

Test water supply lines.

27

Install and connect gas supply lines (gas models only).

2,3,4 27

INSTALLATION OVERVIEW

• Cleveland Range designs and manufactures equipment ID comply with

applicable standards for manufacturers. Included among these certification

agencies are: UL, A.G.A., ASME/N.Bd., NSF, CSA, CGA, ETL, and

others.

• This equipment is designed and certified for safe operation only when

permanently installed in accordance with local and/or national codes. Many

local codes exist, and it is the responsibility of the owner and installer to

comply with these codes.

• In no event shall the manufacturer assume any liability for damage or injury

resulting from installations which are not in strict compliance wit h the

Installation Instructions and the codes cited above. Specifically, the

manufacturer will not assume any liability for damage or injury resulting

from improper installation of equipment, including, but not limited to,

temporary or mobile installations .

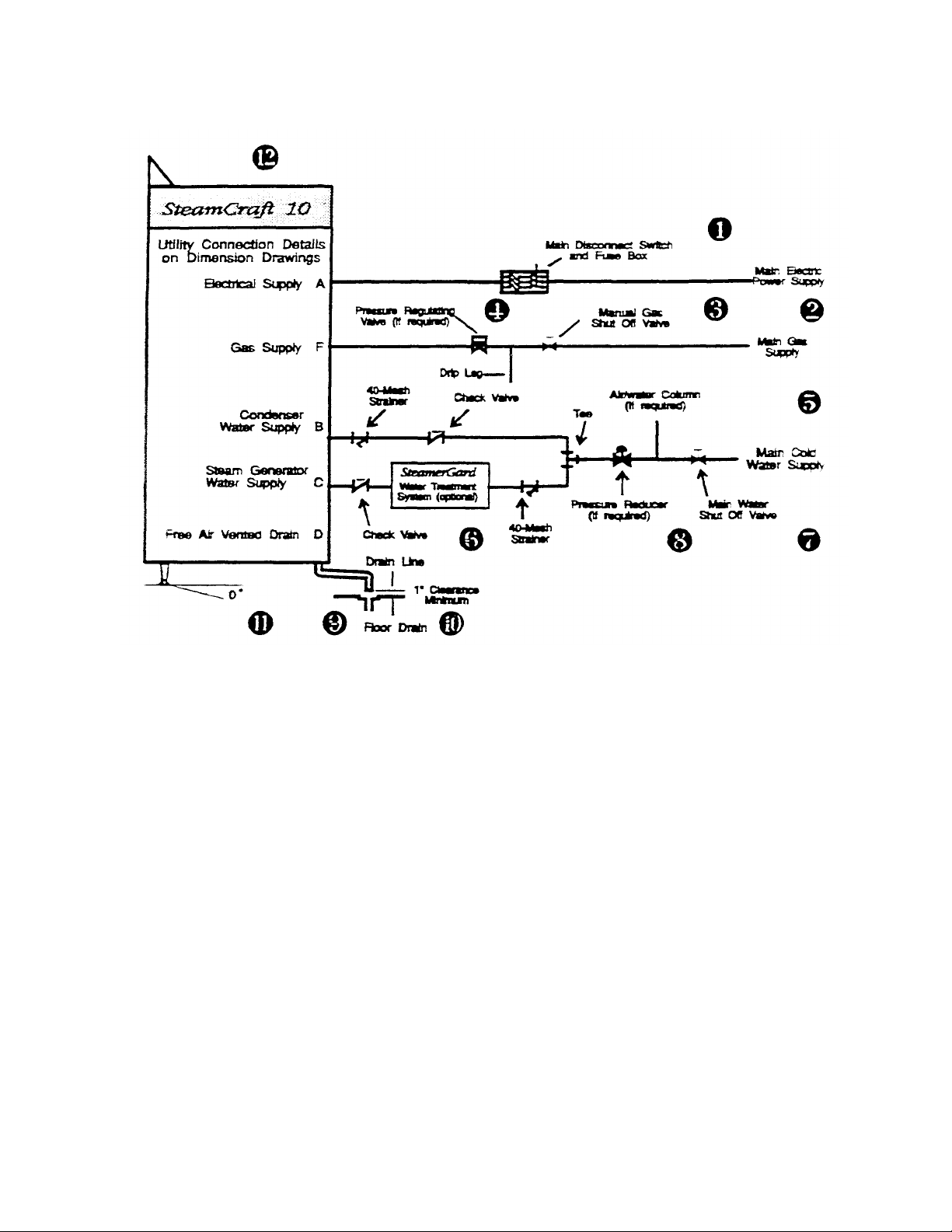

SteamCraft 10 installation is presented in two parts: preparation and installation. Table 2-1 and Figure 2-1 provide an overview of installation process.

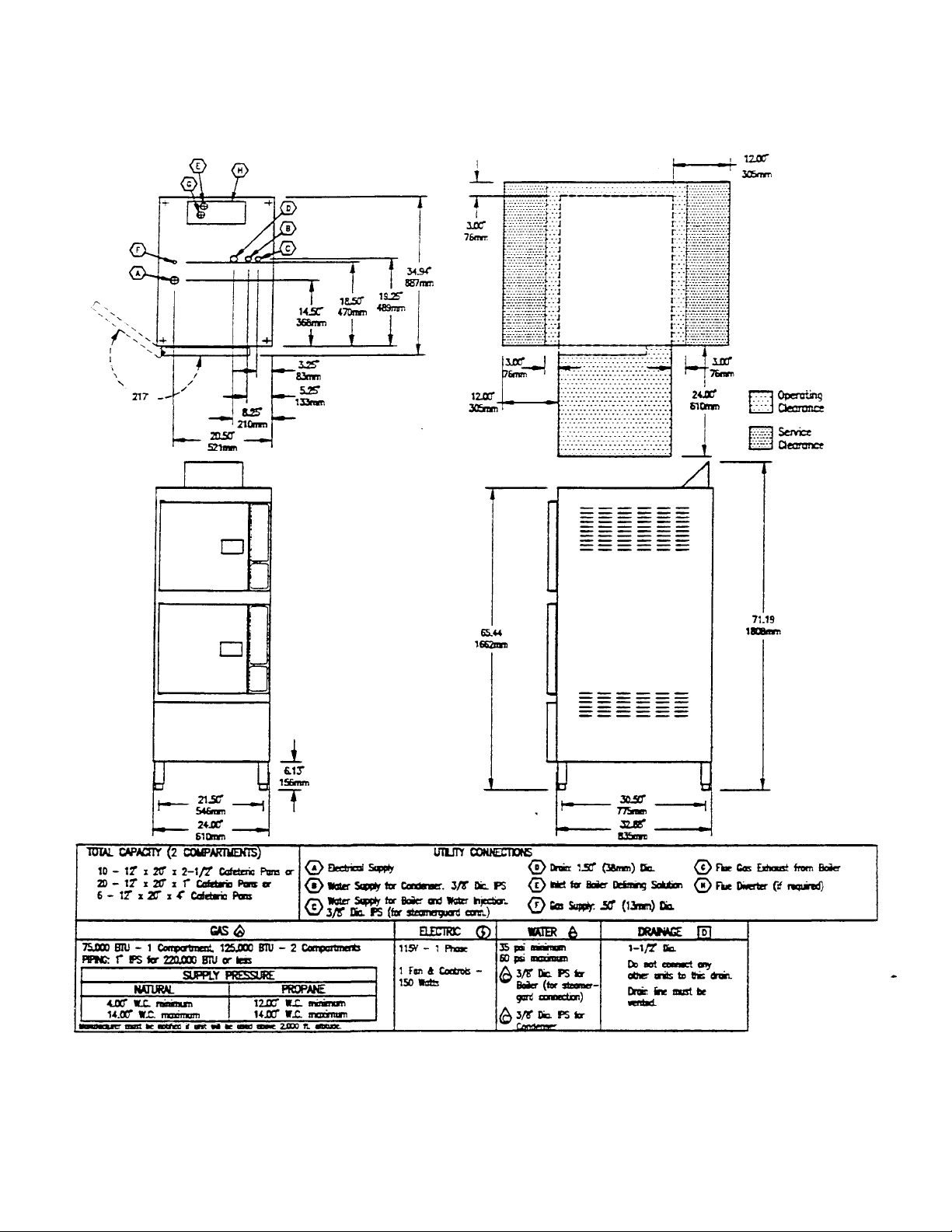

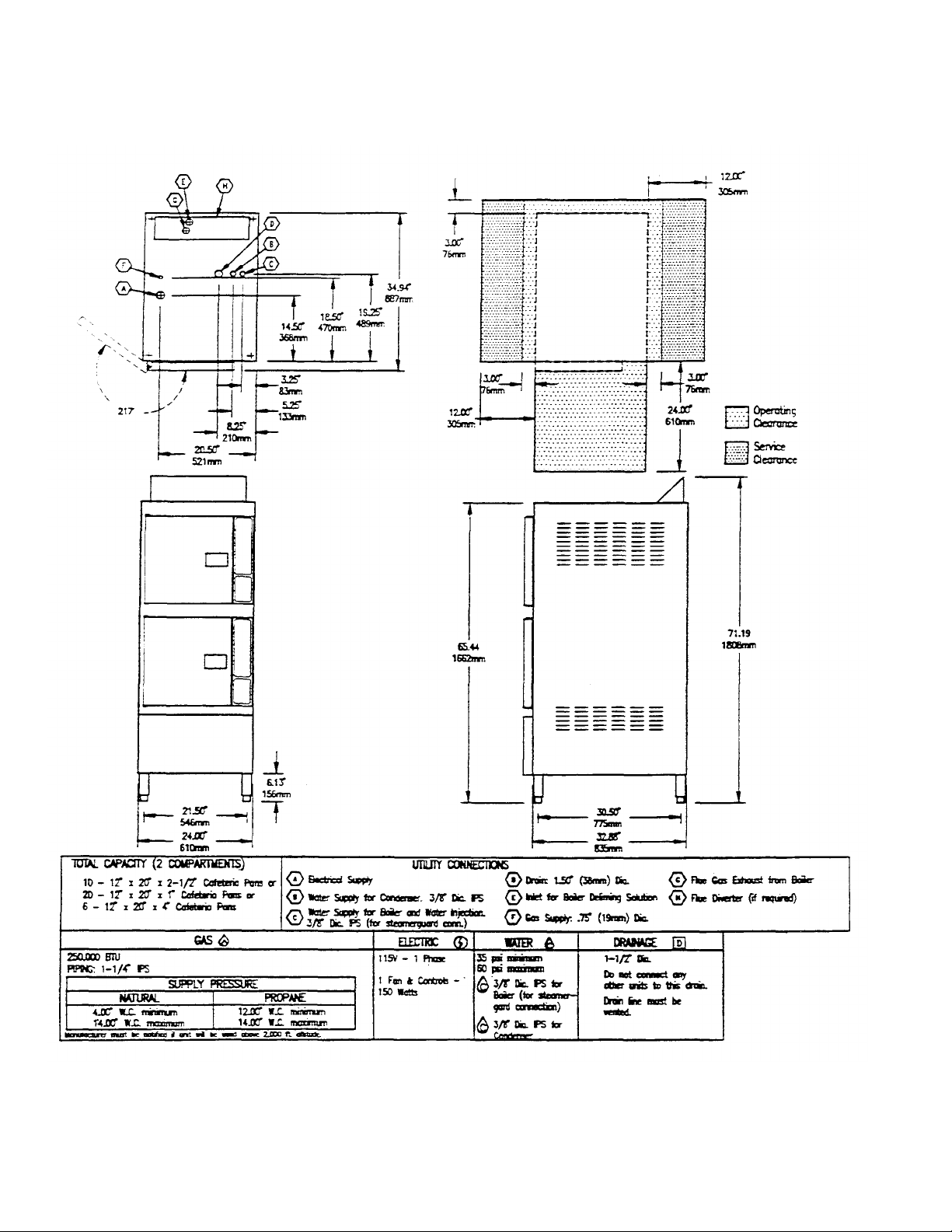

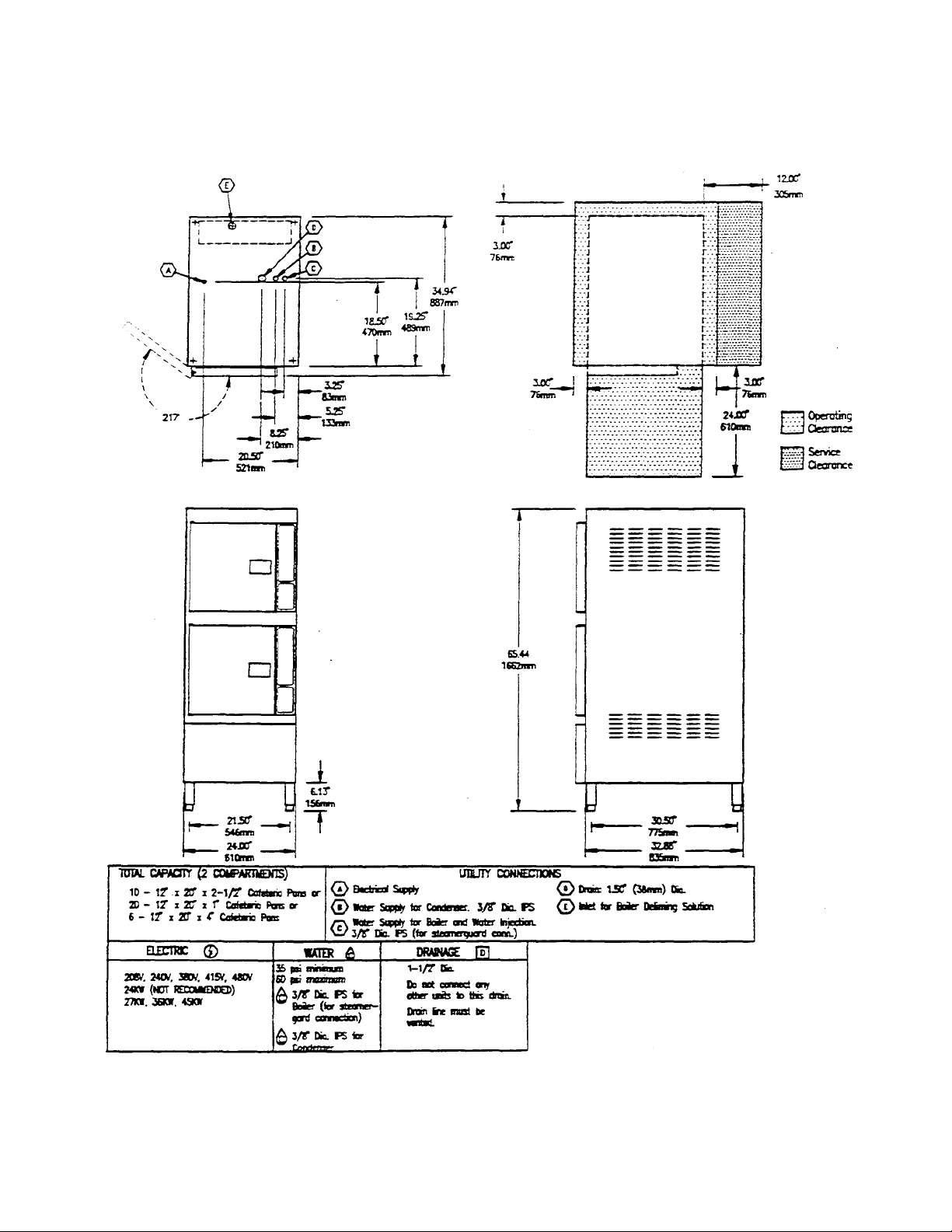

Figure 2-1, Schematic Installation Diagram, illustrates the utility lines and

connections required to install the SteamCraft 10. The Dimension Drawings,

Figure 2-2, show the required utility connection points, dimensions, and

clearances for each of the SteamCraft 10 models.

Table 2-1, Installation Check: List, outlines the overall installation process by

listing, in recommended sequence, the major tasks to be performed. For each

task the table references applicable notes from Figure 2-1 and the manual

pages on which the task instructions begin. Complete the preparation tasks in

sequence, and then the installation tasks. Installation requirements may vary

from site to site; adapt the check list accordingly.

Table 2-1. Installation Check List

(Refer to Figure 2-1)

TASK FIGURE 2-1

NOTES

Preparation

Check exhaust hood requirements. 12 10

Unpack, inspect, and protect me unit.

Install and connect drain line. 9,10 20

Install and connect electrical line. 1,2 22

Install and connect water supply lines.

Install water treatment system.

5,6,7,8

PAGE REFERENCE COMPLETED

18

Test gas supply lines (gas models only).

Bleed gas line at union upstream of gas valve (gas models only) 3 30

Test burner igniter control module (gas models only).

Perform final setup and checkout

28

31

33

Page 17

Models 24-CGA-10, 24-CGP -10. 24-CEA-10, 24-CEP-10 SteamCraft 10 Service Manual Chapter 2 Page 9

INSTALLATION DIAGRAM NOTES

1 . For each unit, the installer must provide a ground con-

nection and a separate fused disconnect switch.

2. The Product Identification Plate, located in the lower right

corner of the left side panel, specifies the electric power

and gas utility requirements.

3. A manual shut off valve and a drip leg must be installed

between the main gas supply and the steamer supply

lines- Bleed air from the gas line at the fitting closest to

the internal automatic gas valve. Refer to Figure 2-14 for

the recommended component arrangements.

4. Never exceed 14" water column (1/2 psi) gas pressure. If

the gas supply pressure exceeds 14" water column, a

pressure regulating valve must be installed in the gas

supply plumbing to reduce the gas pressure to less than

14" water column.

5. The unit must have a cold water supply, NOT HOT. The

water supply must meet the quality requirements of

Table 2-2, and the pressure requirements on page 16.

6. A SteamerGard filtering system is recommended when

water quality does not meet the Table 2-2 requirements,

Figure 2-1. Schematic Installation Diagram

7. Run a single water line between the main cold water supply

and the tee. The two separate steam generator and

condenser/blowdown supply lines are relatively short.

8. A manual shut off valve must be installed between the main

water supply and the steamer supply lines- Refer to Figure

2-10 or 2-11 for recommended component arrangements.

9. The drain line must have a gravity flow away from the

steamer, and must not be connected to the drain lines of any

other equipment.

10. The drain line must be free air vented. If the line empties

into a floor drain, there must be a one inch minimum

clearance between me drain line and the floor drain

openings- The floor drain must not be located under the

body of the unit.

11. To maintain proper operation and full warranty cover age,

the unit must be level from to back and side 10 side.

12. The flue at the back of the gas-fired units must be ventilated

as specified by local and national codes

Page 18

Page 10 Charter 2, SteamCraft 10 Service Manual Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10

PREPARATION FOR INSTALLATION

Select and prepare the SteamCraft 10 operating location before permanently

positioning the unit. Protect the unit and packaged components during site

preparation. Do not select the operating location or start installation before

checking the electric power, gas, and water quality requirements to assure

proper drainage, ventilation, and safety.

Protecting The SteamCraft 10

Do not remove the SteamCraft 10 from its shipping canon until just before

installation. If me shipping canon has already been removed and discarded,

refer to Unpacking and Inspection on page 18, and inspect me shipment.

Remove the SteamCraft 10 and components from the immediate work area

during storage, site preparation, and while running the utility supply lines to

the operating location. To protect the SteamCraft 10 from dirt, and prevent

loss or damage, take the following precautions as a minimum.

1. Leave pac kaged components inside the shipping canon or cooking com partment.

2. Keep the SteamCraft 10 dean by covering it with a plastic tarp or drop

cloth.

3. Do not store other items on top of the SteamCraft 10.

Electric Power Requirements

Gas Supply Requirements

Exhaust Hood Requirements

All Models

The characteristics of me electric power supply must match the power

requirements specified on the SteamCraft 10 product identification plate. The

plate is located on the left side panel, in the lower right comer, as detailed in

Figure 2-2.

NEVER EXC EED 14" WATER COLUMN (1/2 psi) GAS PRESSURE. If the

gas supply pressure exceeds 14" water column, a pressure-regulating valve

must be installed in the gas supply plumbing to reduce the gas pressure to

less than 14" water column.

• Natural gas pressure must be between 4" -14" water column.

• L.P. gas supply pressure must be between 12" -14" water column.

In addition to the required venting of gas -fired equipment, some state and

local codes require me venting of steam generating equipment. It is the

responsibility of me owner and/or installer to learn and comply with these

codes.

• Models 24-CGA-10 and 24-CGP-10 have gas -fired steam generators with

an exhaust vent on top of the unit These units MUST be installed under an

exhaust hood suitable for ventilation and operation of gas -fired appliances,

as specified by local and national codes.

• Models 24-CEA-10 and 24-CEP-10 have electric steam generators and do

not have an exhaust vent. In some areas, local codes require installation of

these units under an exhaust hood suitable for ventilation and operation of

steam generating appliances.

Page 19

Water Quality Requirements

CAUTION

less tha

n

13

parts per million

Alkalinity

less than

20

parts per million

Table

2-2.

Minimum Water Quality Requirements

Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10 SteamCraft 10 Service Manual, Chapter 2 Page 11

Using water not within the limits specified in this

manual could void or adversely affect Cleveland

Range's warranty coverage of the SteamCraft 10.

As with any steam generating equipment, poor water quality degrades

SteamCraft 10 performance. If feed water is low in Total Dissolved Solids

(TDS) and free of particulate matter, the steam generator, heating element,

and valv es of me Steam Craft 10 will give years of trouble -free service

with a minimum of maintenance.

In some areas, even potable tap water contains a variety of impurities that

can cause costly problems in steam generating equipment. Of primary

concern are mineral salts and other impurities, which remain behind as

lime or scale deposits during the steam generating process. These deposits

have caused components to fail, including nearing elements, probes, and

solenoid valves. Of equal importance is me decrease in heat transfer

efficiency caused by lime and scale deposits. Decreased heat transfer

increases water and power consumption. Use of the SteamCraft 10 in areas

with poor water quality requires installation of a SteamerGard water

treatment system or increased frequency of maintenance, cleaning, and

descaling.

Check the quality of supply water as described below before starting construction of the water supply lines. If a SteamerGard water treatment

system must be installed to achieve acceptable water quality, install it

before connecting the water supply lines to the SteamCraft 10. For more

information on water treatments, refer to Softened, Treated, or Filtered

Water on page 16.

Contact a local water treatment specialist for an on-the-premises water

analysis. The recommended minimum feed water quality requirements for

the SteamCraft 10 are listed in Table 2-2.

Total Dissolved Solids less than 60 parts per million

Silica

ph factor greater than 7.5

Page 20

Page 12 Chapter 2, SteamCraft 10 Service Manual Models 24-CGA-10, 24-CGP-10, 24-CEA -10, 24-CEP-10

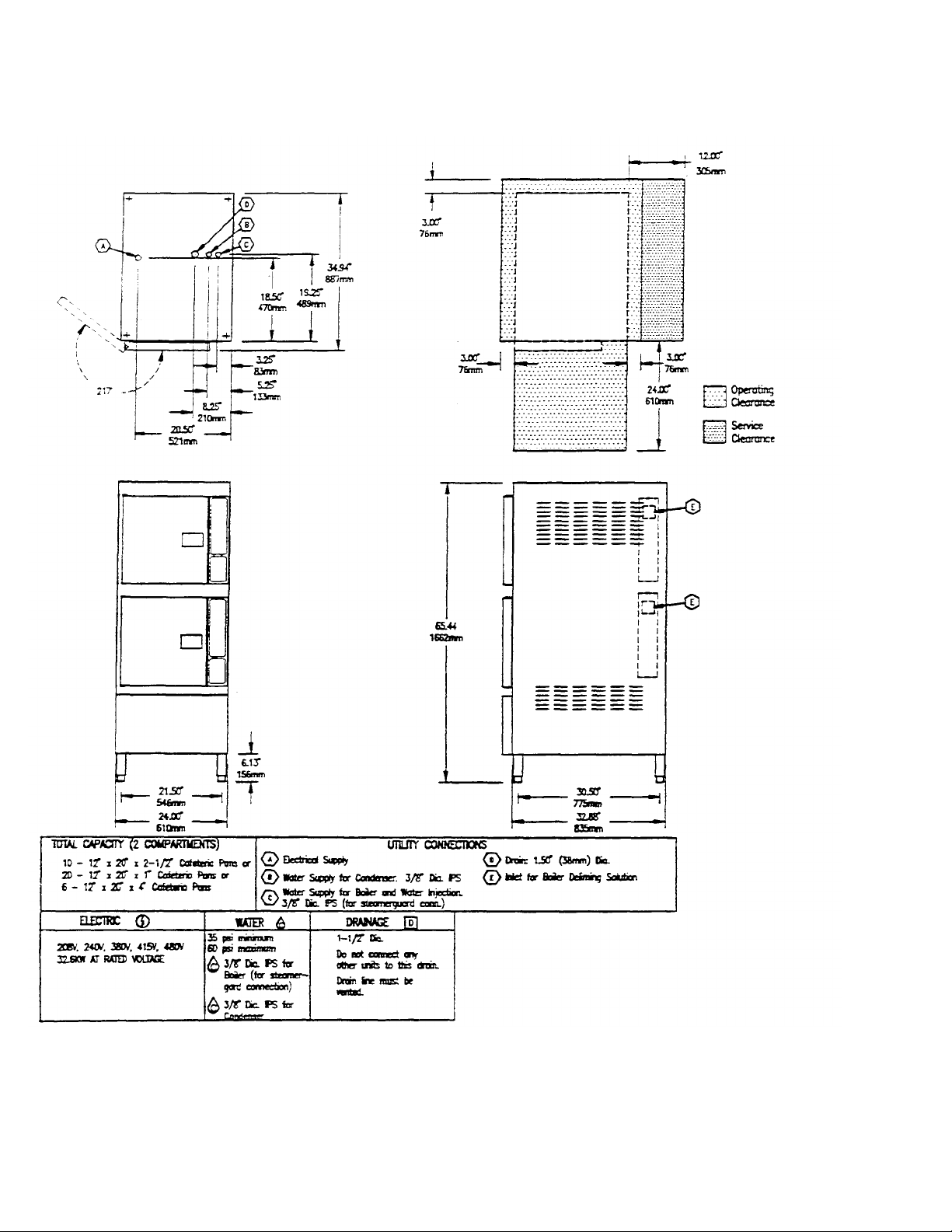

Figure 2-2- SteamCraft 10 Dimensions and Clearances

Model 24-CGA-10 (Sheet 1 of 4)

Printed 3/93 Cleveland Range, Inc.

Page 21

Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10 SteamCraft 10 Service Manual, Chapter 2 Page 13

Figure 2-2- SteamCrafi 10 Dimensions and Clearances

Model 24-CGP-10 (Sheet 2 of 4)

Cleveland Range, Inc. Printed 3/93

Page 22

Page 14 Chapter 2, SteamCraft 10 Service Manual Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10

Figure 2-2- SteamCraft 10 Dimensions and Clearances

Model 24-CEA-10 (Sheet 3 of 4)

Printed 3/93 Cleveland Range, Inc.

Page 23

Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10 SteamCraft 10 Service Manual, Chapter 2 Page 15

Figure 2-2. SteamCraft 10 Dimensions and Clearances

Model 24-CEP-10 (Sheet 4 of 4)

Cleveland Range, Inc. Printed 3/93

Page 24

Page 16 Chapter 2, SteamCraft 10 Service Manual Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10

Softened, Treated, or Filtered Water

Do not use softened or chlorinated water in the SteamCraft 10 steam

generator- If the water supply is treated or softened either by the

water company or on the premises, it may contain chlorine or various

salts. These additives are damaging to the SteamCraft 10 steam

generator. Salts used to soften water cause rapid scale buildup, and

increased corrosion.

Some water treatment plants kill bacteria in the water by adding

chlorine. Chlorinated water is actually dilute hydrochloric acid. It is

very damaging to the SteamCraft 10. When heated in the steam

generator, chlorinated water rapidly dissolves generator walls and

heater elements. In extreme cases, poisonous and highly corrosive

chlorine gas is released in the steam generator.

Installing a high volume water filtering system such as the

SteamerGard removes most of the salts used for water softening.

Contact a local water treatment specialist or the local water company

for assistance with chlorinated water.

Water Supply System

Select a water supply system that fulfills the requirements listed in

Table 2-2. The supply must provide a minimum dynamic pressure of

35 psi (2.4 kg/cm2) and a maximum static pressure of 60 psi (4.1

kg/cm2). Refer to page 24 for detailed pressure and fitting

requirements, and recommended plumbing layouts.

• Always connect a cold water supply to the SteamCraft 10 water

supply lines. DO NOT USE HOT WATER. The SteamCraft 10 will

not function properly or within design safety limits if hot or warm

water is supplied to the condenser water connection.

• If analysis shows that the supply water is within the required limits, a

single line water system can be installed. A single water line system

is illustrated in Figure 2-10 on page 25,

• If analysis shows that the supply water is NOT within the required

limits, install a SteamerGard water treatment system. Figure 2-11

on page 25 illustrates a treated water supply arrangement.

• If analysis shows that the supply water is NOT within the required

limits, and it is NOT possible to install a SteamerGard water

treatment system;

plan on increasing the frequency of maintenance, cleaning, and

descaling beyond that recomme nded in the maintenance schedule

(Chapter 4).

Page 25

Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10 SteamCraft 10 Service Manual, Chapter 2

Selecting The Operating Location

For safe and efficient operation, observe the following criteria when selecting an

operating location for the Steam Craft 10 Steamer.

1. Do not install these units in areas where combustibles are stored or may

accumulate. The surrounding area must be clear of combustibles, including the

space under the unit.

2. Do not locate the SteamCraft 10 directly over a floor drain used for:

draining hot condensate from this or any other appliance. The drain must be

outside the body of the unit.

3. A proper air supply for combustion and ventilation air is critical for safe,

efficient operation of SteamCraft 10 Steamers. The area around the steamer

must have adequate ventilation for gas-fired appliances.

4. The back panel and both side panels have vents for combustion and ventilation

air. Do not block these air vents. Do not install any heat producing equipment

near the air vents of the unit.

WARNING

All clearance requirements above, below, and

around the unit are the same for non-combustible

locations as for combustible locations.

5. The dimension drawings (Figure 2-2) specify all dimensions and clear ances

required for proper operation and service of each SteamCraft 10 Steamer

covered in this manual. Maintain at least a 3-inch operating clearance at the

sides of the unit, and at least a 3-inch clearance at the back. Do not store articles

on top of the unit.

6. The lower from and right side panels of the unit are the service access panels.

Select an operating location that allows a minimum 12-inch clearance for

service access through these panels.

7. Installation of an exhaust hood over the unit may be required by local, state,

and/or national codes. Refer for Exhaust Hood Requirements - All Models on

page 10. If the SteamCraft 10 cannot be installed under an existing hood, check

the exhaust hood venting requirements for a suitable hood over the operating

location.

8. The location selected must be capable of supporting the operational weight of

the SteamCraft 10, including the weight of water and food. The SreamCraft 10

Steamer operating weights are listed on the dimension drawings.

9. The Steam Craft 10 must be level both front for back and side to side. Select an

operating surface that is level enough for allow leveling the unit without

extreme adjustment of the legs.

Page 26

Page 18 Chapter 2, SteamCraft 10 Service Manual Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10

INSTALLATION INSTRUCTIONS

After selecting the operating location, the SteamCraft 10 can be unpacked,

positioned, and installed. After Final Setup and Checkout, the SteamCraft 10 will

provide years of reliable operation.

CAUTION

Malfunctions and equipment damage may result from improper

mounting. Malfunctions and/or damage resulting from

improper mounting are not covered by the equipment warranty.

The SteamCraft 10 MUST BE LEVEL BOTH FRONT TO

BACK AND SIDE TO SIDE in all mounting arrangements.

Equipment damage will result from shifting the SteamCraft 10

more than 10° out of level while power is turned on. The unit

must be level front to back and side to side.

U npacking and Inspection

1. Before unpacking the shipping carton, visually inspect it for damage.

• If the shipping carton appears damaged, do not open the carton. Refer to the

Shipping Damage Instructions on page 19.

• If the shipping carton is undamaged, proceed with step 2.

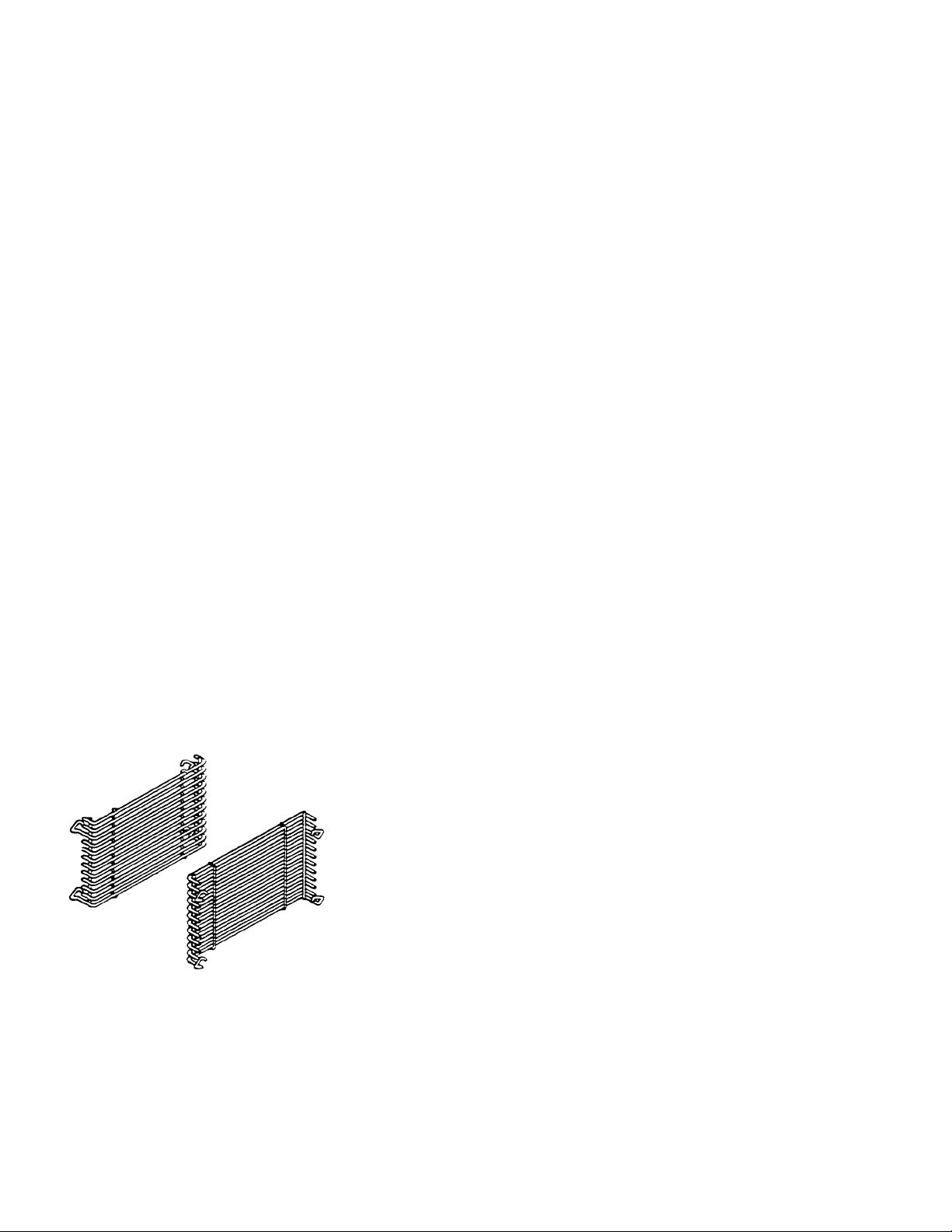

2. Slit the four corners of the carton and peel carton sides away from the SteamCraft

10. The slide racks are shipped in separate packing inside the cooking

compartment. Be careful not to damage or throw these racks away.

3. Remove the slide rack carton from the cooking compartment. The pack age

contains four slide racks (two for each cooking compartment) as illustrated in

Figure 2-3.

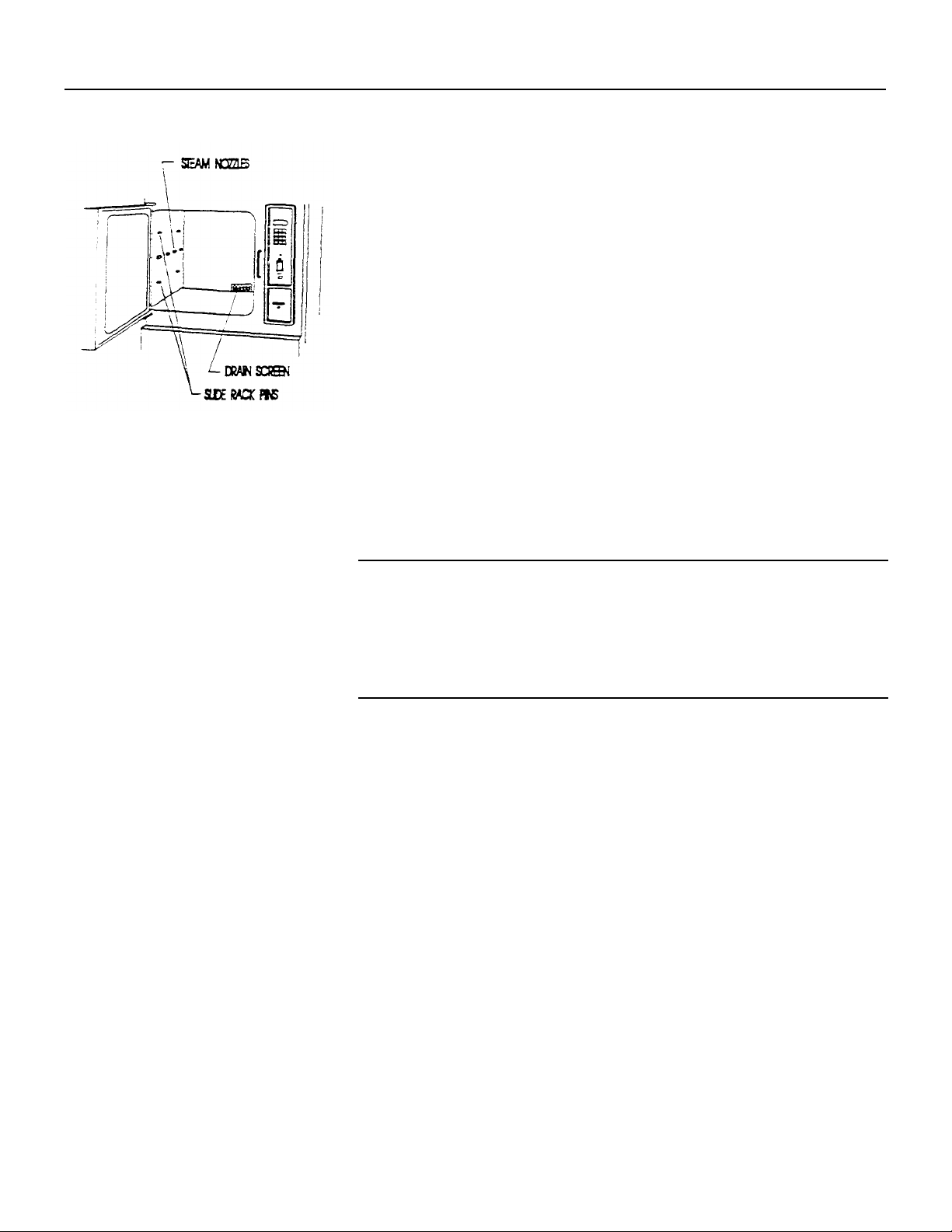

4. Open both cooking compartment doors. Several pre-assembled parts can be seen

inside each cooking compartment. Refer to Figure 2-4, and verify that the Drain

Screen, Steam Nozzles, and Slide Rack Mounting Pins are installed.

5. Inspect the SteamCraft 10 and parts for damage or loss.

• If you discover or suspect shipping damage or loss, refer to the Shi pping

Damage Instructions.

• If all items are accounted for and undamaged, place the packaged slide racks

inside the cooking compartments, and proceed to Position and Level the

SteamCraft 10.

Figure 2-3. Slide Racks

Page 27

Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10 SteamCraft 10 Service Manual, Chapter 2 Page 19

Shipping Damage Instructions

If shipping damage to the SteamCraft 10 is discovered or suspected, observe the

following guidelines in preparing a shippi ng damage claim.

• Write down a description of the damage or the reason for suspecting damage as

soon as it is discovered. This will help in filling out the claim forms later.

• As soon as damage is discovered or suspected, notify the carrier who delivered

the shipment.

• Arrange for a carrier representative to examine the damage.

• Fill out all appropriate claims forms and have the examining carrier sign and date

each form.

Figure 2-4. Pre-assembled Pans

Position and Level The

SteamCraft 10

NOTE: If ther e is not enough room to work on the drain, electrical. and water lines

with the SteamCraft 10 in place, skip this procedure until they are

completed. While preparing the utility lines, protect the SteamCraft 10

as described on page 10. After the lines are prepared, position and level

the SteamCraft 10, then connect the utility lines.

Adjustable Leveling Legs

The supporting legs of the SteamCraft 10 Steamer are 6-inches long when the

adjustable feet are fully retracted. This provides the minimum 6-inch space below

the unit required by NSF sanitary standards. The adjustable feet can be extended

approximately 2 inches to provide a means of leveling the SteamCraft 10.

Positioning and Leveling

1. Check that all Unpacking and Inspection tasks are complete.

2. Thoroughly clean the floor area that will support the SteamCraft 10.

3. Using a level, determine and mark the highest corner of the floor area that will

support the leveling legs.

WARNING

INJURY AND EQUIPMENT DAMAGE could result from

improper lifting. Refer to the appropriate di mension drawing

and check the weight of the unit being installed. Use enough

workers with experience lifting heavy equipment to place the

SteamCraft 10 on the supporting surface.

Page 28

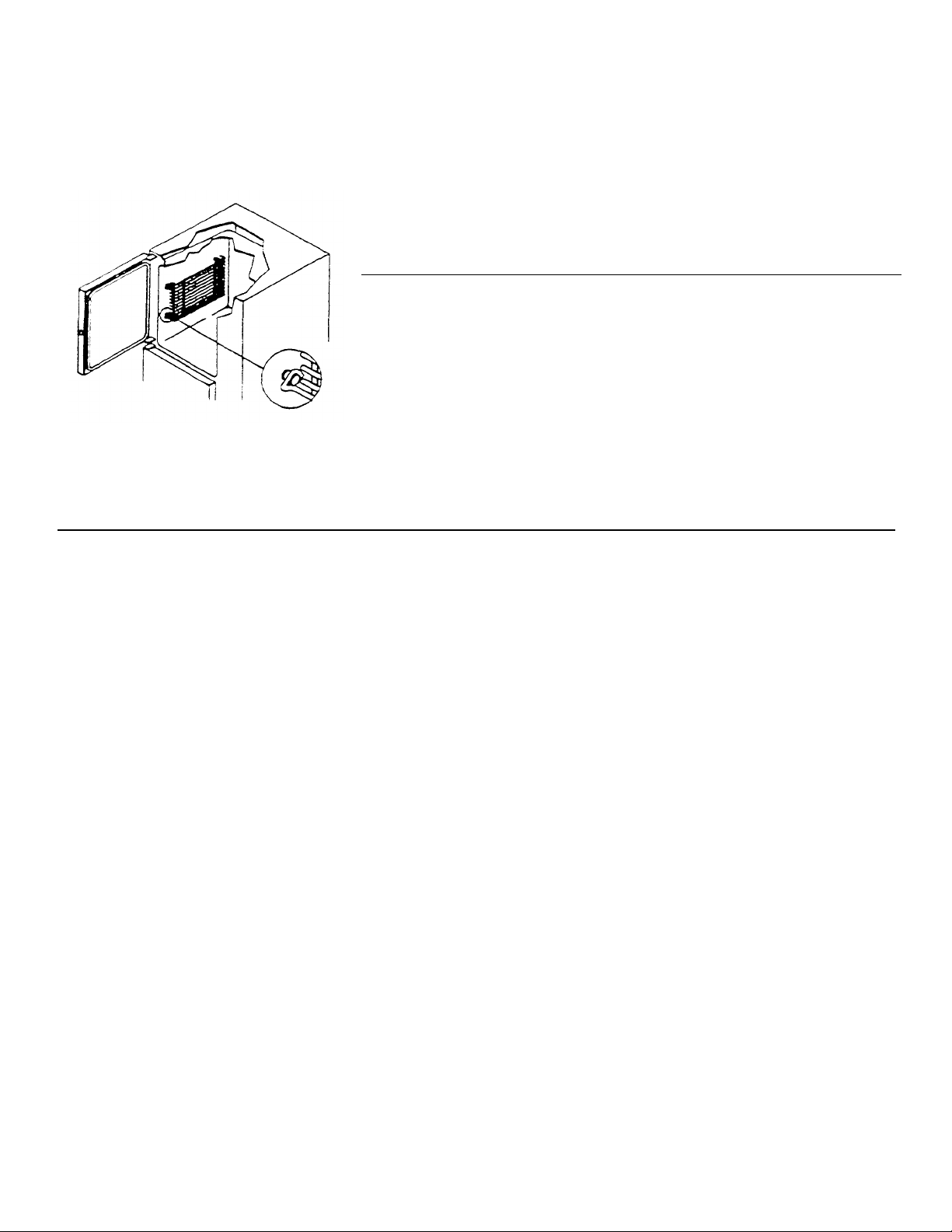

Figure

2-5.

Slide Rack Installation

I

nstall and Connect the Free Air

Page 20 Chapter 2, SteamCraft 10 Service Manual Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10

4. Move the SteamCraft 10 into position.

5. Check the adjusting foot of the leg in the highest corner (marked in step 3). The

foot should be fully retracted and provide a 6-inch clearance under the unit.

6. Using a level, adjust the other three legs until the Steam Craft 10 is level both front

to back and side to side.

7. After the Steam Craft 10 has been positioned and leveled, install the slide racks as

described below.

Install Slide Racks

1. Refer to Figure 2-5. There are two slide racks for each cooking compartment. Each

rack has four loops: two at the top and two at the bottom. Hold the slide rack so

the ends of the hanger loops point down, as shown in the figure.

2. Slide one rack into the compartment with loops toward the compartment wall and

mounting pins.

3. Hook the loops over the top and bottom pins.

4. Repeat steps 1 through 3 for each of the other racks.

Vented Drain Lines

The drain outlet must be free air vented to equalize the pressure in the Steam Craft 10

Steamer with the atmosphere. Generating steam causes pressure to increase in the

unit; cold water flow into the condenser creates a vacuum (low pressure) in the

condenser. Without a free air vent, either high or low pressure in the compartment

will cause malfunction or damage.

• Pressure build up in the steamer will cause steam and hot water leakage around the

door.

• A vacuum will implode the steamer and cause permanent physical damage.

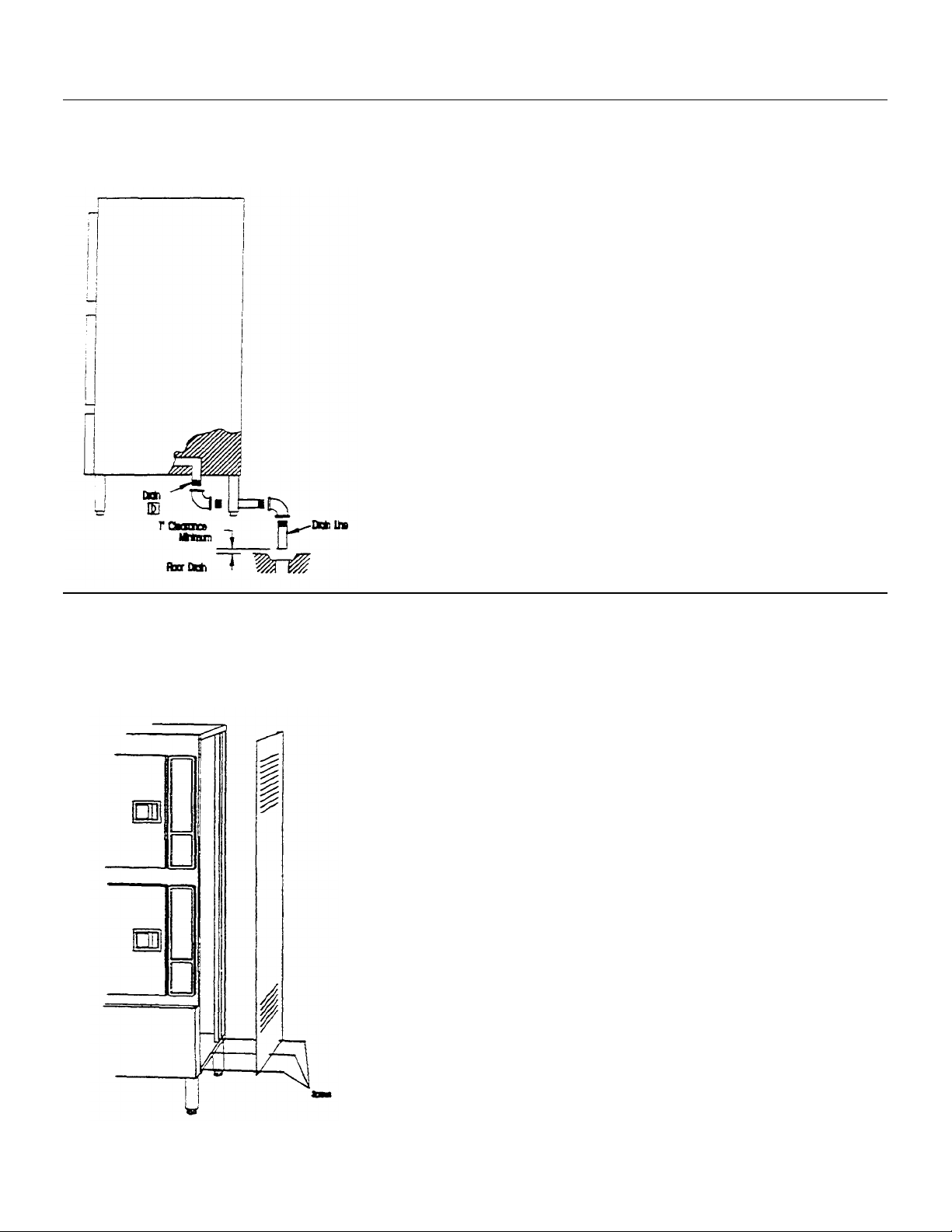

Refer to Figure 2-6, and the dimension drawings (Figure 2-2). The drain outlet (D)

discharges exhaust steam and hot condensate from the steamer. The drain exhaust

vent and a 1-inch minim um clearance between the drain opening and floor drain

provide the SteamCraft 10 Steamer with free air venting.

Furnishing and installing the drain lines and fittings is the responsibility of the owner

and/or installer. Figure 2-6 illustrates a drain layout recommended by Cleveland

Range. Observe the following instructions to determine the pipe size, the number of

fittings required, and the layout of the drain line.

Page 29

Figure

2-6.

Drain Layout and Connections

Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10 Page 21 SteamCraft 10 Service Manual, Chapter 2

WARNING

DEATH, INJURY, AND EQUIPMENT DAMAGE

could result from improper installation of the drain

outlet lines.

Improper installation of these lines could void the

SteamCraft 10 Steamer warranty. The following

restrictions are critical to the safety of personnel and

equipment, and must not be violated under any

circumstances.

Do not connect the drain line into PVC pipe, or any

other drain material that cannot sustain 180° F.

Do not connect drains from any other equipment to the

SteamCraft 10 Steamer drain line.

Do not connect the drain outlet extension line directly

to a floor drain or sewer line.

1. The drain lines must be installed in compliance with local, state, and national

utility, construction and sanitation codes; the most prominent of which are listed

in the Installation Policies section below

2. The floor drain receiving the hot condensate from the Steam Craft 10 must not be

located under the body of the unit. Steam rising from the drain up into the unit

body will adversely affect operation, cooling air ventilation. and may cause

corrosion on some of the electrical contacts. Improper location of this drain will

seriously reduce warranty coverage.

3. The total length of pipe and number of bend fittings required to reach the open

drain determines the pipe size used to extend the drain line to an open drain.

• If the drain outlet extension requires six feet or less of pipe, and no more than

two elbows are required, use 1.5-inch pipe and fittings.

• If the drain outlet extension requires six to twelve feet of pipe, or requires three

or more elbows, use 2-inch pipe and fittings.

4. The drain line must have a gravity flow from the Steam Craft 10 Steamer drain

outlet to the floor drain Do not install a trap in the drain line.

5. Free air venting requires a minimum of one inch clearance between the end of the

drain line and the top of the floor drain.

6. Do not connect the steamer drain to drains or plumbing of any other equipment. If

drains of two or more units are connected together.

• Low pressure can develop, causing an implosion and physical collapse of the

steamer.

• Drainage from another unit can flow back into a cooking compartment of the

steamer.

Figure 2-7. Access Panel Removal

Page 30

Figure 2

-

7

Exhaust Hood Ventilation All

SteamCraft 10's with gas

-

fired steam generators have a

n exhaust hood (H.

Figure 2

-

Furnishing and installing the electrical power lines, switches, fuse boxes, connectors

Page 22 Chapter 2, SteamCraft 10 Service Manual Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10

Models

7. Refer to

to the 1.5-inch drain pipe connection (D) inside the Steam Craft 10.

8. When assembling the drain pipes and fittings, apply a hardening type pipe sealant

to the threads, and thread them together FINGER TIGHT ONLY. DO NOT USE

A WRENCH.

2) which covers the Gas Flue port (G) on top of the unit. In addition to the required

venting of gas-fired equipment, some state and local codes require the venting of

steam generating equipment.

1. The SteamCraft 10 gas flue (G ) must be vented in compliance with all local, state,

and national codes for venting gas-fired appliances. Steam venting must comply

with the state and local codes where applicable.

2. The exhaust hood must be sized for the cumulative ventilation requirem ents of all

gas -fired appliances in the area, as well as to the SteamCraft 10.

3. Do not connect the gas flue directly to a forced draft exhaust system or canopy.

Excess draft through the flue reduces the oven's efficiency and may affect cooking

times.

4. If an existing exhaust hood cannot be used, a new one should be con-structed over

the SteamCraft 10. The Dimensions and Clearances Draw -ing (Figure 2-2)

contains the dimensions, gas flow, and BTU per hour data required to calculate

the minimum required hood dimensions and minimum ventilation capacity

(c.f.m).

. Remove the right side access panel and connect the drain line

Install Electric Power Lines

and accessories is the responsibility of the owner and/or installer. Figure 2-8

illustrates an electrical layout recommended by Cleveland Range. When installing the

electrical power lines and accessories, observe the following instructions.

1. In the United States, install the electrical power lines in accordance with local

codes and/or the National Electric Code, ANSI/NFPA No. 70-1990 (USA).

2. In Canada, install the electrical power lines in accordance with local codes and/or

the Canadian Electrical Code, CSA Standard C22.1 (Canada).

3. Install the proper size, disconnect switch, circui t breaker or fuses, and wire and

conduit to conform to all local codes and the national codes cited above. See

Table 2-3 for wire requirements.

4. Install a separate disconnect switch and fuses or breakers sized to meet the line

amps required by the Steam Craft 10 (see Table 2-3). The fuses or breakers may

be an integral part of the disconnect switch or in a separate fuse box. Install the

disconnect switch for easy access as needed for daily startup and shutdown.

Page 31

Connect Electrical Line

AMPS

AMPS

Refer to Table

4-1.

and identify th

e

electrical schematic diagram th

at applies

Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10 SteamCraft 10 Service Manual, Chapter 2 Page 23

Figure 2-8. Recommended Electrical Layout

5. There should be a sufficient length of flexible conduit between the SteamCraft 10

connector and the wall so the unit can be moved for service

6. Each steamer must be electrically grounded by the installer in accordance with the

National Electric Code, ANSI/NFPA No. 70-(latest edition).

7. The characteristics of the electric power supply must match the power

requirements specified on the SteamCraft 10 product identification plate. The

plate is located on the left side panel, in the lower right corner, as detailed in

Figure 2-2.

Table 2-3. Minimum Wire Requirements

VOLTS KILOWATTS

3 Phase

208 32.6 92 115 0

220 27.4 73 91 1

240 32.6 80 100 1

440 27.4 36 45 6

480 32.6 40 50 6

*Use solid copper wire rated for 75°C, wet location.

SERVICE

WIRE

SIZE*

to the SteamCraft 10 model being installed. Connect the electrical lines to the

terminal block inside the right side access panel as described below.

1. Verify that the main disconnect switch is in the OFF position.

2. Remove the right side access panel by removing the three screws

(Figure 2-7) that hold it in place. Save the screws.

3. Refer to the connection diagram in Figure 2-9, and connect the wires to the

terminal block and ground connector accordingly.

Page 32

Figure

2-9.

Electrical Connections

Install Water Supply Lines

Furnishing and plumbing the water supply lines is the responsibility of the

Page 24 Chapter 2, SteamCraft 10 Service Manual Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10

4. The steamer must be electrically grounded by the installer in accordance

with the National Electric Code, ANSI/NFPA No. 70-(latest edition).

5. If no further work inside the side panel is required at this time, such as

plumbing and leak checks, secure the side panel with the three mounting

screws (Figure 2-7). Do not turn power ON at the main disconnect switch

until power is required for component or operational testing

owner and/or installer. This section illustrates plumbing layouts recommended

by Cleveland Range. When installing water supply lines, observe the following

instructions.

1. The Steam Craft 10 has two 3/8-inch IPS fittings for connecting the steam

generator and condenser/blowdown water supply lines. These fittings are

detailed as C and B in Figure 2-2.

2. Always connect a cold water supply to both water supply lines. DO NOT

USE HOT WATER. The steamer will not function properly or within

design safety limits if hot or warm water is supplied to either the condenser

connection or the steam generator fill connection.

3. Do not connect the SteamCraft 10 to a softened or treated water supply

which adds chlorine or chloride salts to the water. Refer to Softened,

Treated, or Filtered Water on page 16 for details.

4. Supply water must have a minimum dynamic pressur e of 35 psi (2.4 kg/cm )

and a maximum static pressure of 60 psi (4.1 kg/cm2). Water pressure

greater than 60 psi will cause damage TO the solenoid valves. Local water

pressure can be 100 psi or more. If possible, check supply pressure at nonpeak demand time. A local water company can assist in this check. If static

pressure exceeds 60 psi, a pressure regulator must be installed in the supply

lines. For best results, set the regulator for 50 psi dynamic pressure.

Page 33

Models 24-CGA-10, 24-CGP -10, 24-CEA-10, 24-CEP-10 SteamCraft 10 Service Manual, Chapter 2 Page 25

5. Refer to the recommended plumbing layouts in Figures 2-10 and 2-11 and install

the water supply lines and fittings in accordance with all local and national

codes. Pay particular attention to the following requirements and

recommendations.

a. When installing a water supply system without a SteamerGard, Cleveland

Range recommends the plumbing layout illustrated in Figure 2-10. This is a

single water line from the main cold water supply to the tee just outside the

SteamCraft 10. The two separate lines from the tee to the steam generator and

condenser/blowdown connections are comparatively short.

b. When installing a water supply system with a SteamerGard. Cleveland Range

recommends the plumbing layout illustrated in Figure 2-11. Note the following

details:

• This is a single water line from the main cold water supply to the tee just

before the SteamerGard. The two separate and comparatively short lines

run from the tee to the SteamerGard intake connection and from the tee to

the SteamCraft 10 condenser/blowdown connec-tion.

• The water supply to the condenser connection can be untreated.

• The treated water supply connects to the steam generator fill connec -

tion.

Figure 2-11. Treated Water Supply Arrangement

Page 34

Connect Water Supply Lines

c. Whether installing a treated or untreated water supply system, use the

General Connection Requirements

Page 26 Chapter 2, SteamCraft 10 Service Manual Models 24-CGA-10, 24-CGP-10, 24-CEA -10, 24-CEP-10

following water line sizes.

• For the two lines between the Steam Craft 10 and the tee use 3/8-inch

IPS water supply lines to match the 3/8-inch compression fittings

mounted on the bottom panel of the SteamCraft 10.

• For the single line between the tee and the main cold water supply,

use 1/4-inch to 5/8-inch IPS water supply lines. If lines larger than

5/8-inch are used in this segment, a pressure regulator must be

installed before the tee, to maintain the pressure specified in step four.

d. Install a manual water valve between the main cold water supply line

and the SteamCraft 10 lines.

e. The National Sanitarian Foundation (NSF) requires installation of a

check-valve in all supply lines in accordance with and as required by

local plumbing codes.

f. At the points indicated in the recommended plumbing layouts, install a

40-mesh water strainer of the type and construction illustrated in Figure

2-12. A strainer is provided with the Steam Craft 10.

Figure 2-12. Water Strainer Assembly

Figure 2-13. Water Strainer Installation

4. Construct all supply lines up to the point of installing the strainer(s)

illustrated in the recommended plumbing layouts. Flush the water supply

lines before connecting the strainer(s).

• If the remaining water supply lines and/or SteamerGard are not

immediately installed and connected after flushing, temporarily cap the

water supply lines.

• If the final installation and connections are performed immediately, refer

to the connection instructions in the SteamerGard manual, and Connect

Water Supply Lines, following.

The water supply connections are located unde r the SteamCraft 10, as shown

in Figure 2-2. Connect the water supply lines to the Steam Craft 10 by

following both the general connection requirements and those requirements

specific to the type of supply system, either untreated water supply (Figure 2-

10) or water supply treatment system (Figure 2-11).

1. Apply pipe dope or teflon tape to any threaded connection.

2. Flush the water supply lines before connecting the strainers), and again

before connecting the lines. to the SteamCraft 10 connections.

3. When installing water strainer(s), use a strainer with a 40 mesh screen as

illustrated in Figure 2-13.

• Make sure the arrow on the strainer body points in the direction of flow

i nto the steamer.

• Install the strainer so the access nut points down.

4. If incoming line pressure exceeds 60 psi static pressure, install a pressure

regulator to maintain the SteamCraft 10 pressure requirements specified in

Install Water Supply Lines (pa ge 24).

Page 35

Testing Water Supply Lines

Treated Water Connection (With SteamerGard)

Install and Connect Gas

Untreated Water Connection (Without SteamerGard)

Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10 SteamCraft 10 Service Manual, Chapter 2 Page 27

1. Refer to Figure 2-10. Verify that a suitable check valve is installed according to

NSF and local codes.

2. Look at the flow indicating arrows on the strainer and check valve and verify that

flow is toward the steamer.

3. Install the tee and connecting lines- Flush these lines before connecting them to

the water supply fittings on the steamer.

1. Verify that the SteamerGard water treatment system has been installed according

to the SteamerGard installation manual. The 40-mesh strainer supplied with the

SteamerGard must be installed at the SteamerGard water inlet.

2. Refer to Figure 2-11. Verify that suitable check valves are installed according to

NSF and local codes. The condenser line check valve should be installed

between the tee and the steamer. The steam generator line check valve should be

installed between the SteamerGard and the steamer.

3. Look at the flow indicating arrows on the strainers and check valves. Verify that

flow is toward the steamer.

4. Install the connecting lines and flush them before connecting them to the water

supply fittings on the steamer. Be sure the line from the Steamer Gard water

treatment system connects to the steam generator fitting on the SteamCraft 10.

Supply Lines

1. Check all connections for proper tightness. Remove the side panel to inspect

water connections inside the steamer (Figure 2-7).

2. Open the water supply valves.

3. Check all lines and connections for leakage, both inside and outside the steamer.

4. If no other inspections are being made at this time, replace the right side access

panel.

Furnishing and installing the gas supply lines, valves, regulators, and accessories is

the responsibility of the owner and/or installer. When installing the gas supply lines

and accessories, observe the following instructions.

1. Install the gas supply lines in accordance with local codes and/or the National

Fuel Gas Code, ANSI Z223.1-(latest edition).

2. Refer to Figure 2-14 for Cleveland Range recommended layout of the gas supply

lines. Refer to Figure 2-2, Dimensions and Clearances for pressure data and

connection locations.

Page 36

Page 28 Chapter 2, SteamCraft 10 Service Manual Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10

Figure 2-14. Recommended Gas Supply Line Layout

Leak-Testing Gas

Supply Lines

• On Atmospheric models (24-CGA-10), use 1/2-inch IPS gas supply pipe

and fittings.

• On Pressure models (24-CGP-10), use 3/4-inch IPS gas supply pipe and

fittings.

3. Install a manual shut off valve between the gas supply line and the

SteamCraft 10 gas connection (F on Figure 2-2)

4. Install a sediment trap (drip leg) in the gas supply line, then connect the

gas supply piping to the steam generator gas valve piping. In order to

protect the automatic gas control valve from condensation, the drip leg

should be close to the SteamCraft 10 gas connection.

5. If natural gas pressure exceeds 14" water column, a pressure regulating valve must

be installed in the gas supply plumbing to reduce the pressure to within the limits

specified in Gas Supply Requirements, on page 10.

6. If LP gas is supplied, use a gas pipe joint compound which is resistant to

LP gas. Refer to Figure 2-2 and note the pressure limit specified for LP

gas.

The gas lines and burner control connections should be inspected for proper

installation, and tested for leaks and proper operation:

• At Initial Installation

• As pa rt of regular maintenance procedures.

• As the first step in troubleshooting.

• After service or repair, the components affected should be inspected and

tested for leaks and proper operation.

Page 37

Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10 SteamCraft 10 Service Manual, Chapter 2 Page 29

WARNING

FIRE OR EXPLOSION HAZARD

LEAKING GAS CAN CAUSE FIRE OR EXPLOSION

WITH PROPERTY DAMAGE, INJURY, OR LOSS OF

LIFE. If the installer smells gas, or suspects there is a gas

leak, immediately refer to the posted gas leak instructions.

The posted instructions are provided by the local gas supplier.

and supersede any other instructions. Until the leak is

stopped, observe the following precautions in addition to the

posted instructions.

• Do not light or start any appliance.

• Do not touch any electrical switch.

• Do not use any phone in the building.

• Immediately call the gas supplier from a phone away from the bui lding

Follow the gas supplier's instructions.

• If the gas supplier cannot be reached, call the fire department.

Pressure Testing The Gas Supply Lines

Do not permanently supply gas to these lines until they have been tested. When

testing these lines observe the following.

1. A gas lines and fittings assembled during installation are outside of the

SteamCraft 10. Check these connections for proper tightness.

2. Prepare the Steam Craft 10 valves and connections for the test pressure being

used. The same pressure criteria apply when testing lines prior to the manual

gas shut-off valve.

• The appliance and its individual shut-off valve must be disconnected from the

gas supply piping system during any pressure testing of that system at test

pressures in excess of 14" water column (1/2 psi or 3.45 kPa).

• The appliance must be isolated from the gas supply piping system by closing

its individual manual shut-off valve during any pressure testing of the gas

supply piping system at test pressures equal to or less than 14" water column

(1/2 psi or 3.45 kPa).

3. Refer to Figure 2-14, and open the main shut-off valve for the steamer gas supply

line.

4. Test the pipe joints for leaks with soap and water solution.

• Paint pipe joints with rich soap and water solution.

• Bubbles indicate a gas leak.

• Tighten joints and/or replace component to stop gas leak.

• If you smell gas, turn off the main gas shut-off valve, and refer to Gas Leak

Instructions on page 43.

5. Reassemble any connections or piping disassembled in step 2. Repeat steps 3

and 4 to test these reassembled connections.

6. Close the main shut-off valve for the steamer gas supply line.

Page 38

Page 30 Chapter 2, SteamCraft 10 Service Manual Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10

Figure 2-15. Automatic Gas Valve

Bleed Air from the Gas Supply Lines

After the gas supply line is assembled, connected to the SteamCraft 10, and

pressure tested satisfactorily; bleed the air from the line. The SteamCraft 10

gas control module uses an intermittent gas pilot. The module sparks the pilot

igniter and sends gas to the pilot simultaneously. If the pilot flame sensor does

not detect pilot ignition within a few seconds, the control module stops both

pilot spark and gas flow. Bleeding the entire supply gas line through this type of

gas control system may take quite a long time. To save time, bleed the air

through a loosened fitting. Bleed the gas supply line by the following

procedure.

1. Turn off electrical power to the SteamCraft 10 at both the panel ON/OFF

switch (Figure 2-16), and the main disconnect switch (Figure 2-8, Rec ommended Electrical Layout).

2. Remove the left side access panel by removing the three mounting screws.

Save the screws.

• Verify that the automatic gas valve wiring connections are clean and tight.

• Verify that the manual ON/OFF valve of the automatic gas valve is in the

ON position (Figure 2-15).

3. If the main gas valve is too far from the unit for one man to both bleed the

line and operate the valve, arrange for an assistant to operate the valve.

4. Use the union fitting located just ahead of the gas valve as the bleed point.

This will minimize the amount of air remaining between the bleed point and

the automatic gas valve after bleeding the line. If it is not possible or

convenient to use this union fitting, select another fitting close to the

SteamCraft 10 automatic gas valve. To minimize the amount of air

Page 39

Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10 SteamCraft 10 Service Manual, Chapter 2 Page 31

remaining between the bleed point and the automatic gas valve, select a fitting

as close as possible to the valve. If the drip leg is close enough to the Steam

Craft 10, it may be used as an alternate bleed point.

5. Loosen the fitting enough to allow gas to escape. Open the main gas valve and

bleed the trapped air out of the gas supply line. Retighten the fitting.

6. Test the pipe joint for leaks with soap and water solution.

• Paint pipe joint with rich soap and water solution.

• Bubbles indicate a gas leak.

• Tighten joints to stop gas leak.

7. Install the left side access panel on the Steam Craft 10.

8. Leave the electrical power OFF at both the main disconnect switch and the

control panel ON/OFF switch.

9. The SteamCraft 10 is now ready for operational testing.

• If this test is part of initial installation, perform the Burner Ignition Test

before performing the Operating Tests.

• If this is part of component repair, perform the Burner Ignition Tests next If

the unit passes, it is ready to resume normal cooking operations

WARNING

DO NOT TRY TO LIGHT THE BURNERS OR PILOT

WITH A FLAME. The SteamCraft 10 has an electronic

ignition system which automatically lights the pilot and burners, senses the flame, and controls gas flow. This provides

precise burner control, safety ignition, and shutdown features.

DEATH. INJURY OR EQUIPMENT DAMAGE may result

from an improperly adjusted gas control and ignition system.

Do not alter any adjust ments on this electronic control or

solenoid valve. If adjustment is required, contact an

authorized service center. Cleveland Range is in no way

responsible for the operation or safety of this equipment if the

controller, valve, or igniter probes are adjusted by anyone

other than a Cleveland Range authorized service

representative.

Burner Ignition Test

(Gas-Fired Models Only)

This is a functional test of the intermittent pilot ignition system. Pilot/burner

ignition is completely automatic. The test consists of starting the unit and setting

the controls for generating steam. The ignition system will either light the pilot and

burners, or fail.

1. If not already done during prior installation and testing:

Page 40

Page 32 Chapter 2, SteamCraft 10 Service Manual Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10

a. Pressure test the gas supply lines as described in Pressure Testing Gas

Supply Lines.

b. Bleed trapped air from the gas supply lines as described in Bleed Air

From The Gas Supply Lines, above.

c. Check that the manual ON/OFF valve of the automatic gas control

valve is in the ON position.

d. Turn the main manual gas shut-off valve to the ON position.

2. Turn ON the electrical power to the SteamCraft 10 at the main disconnect

switch.

NOTE: When initial power is supplied to the SteamCraft. 10 with the

ON/OFF switch in the OFF position, a 3-minute blowdown

cycle starts. This blowdown cycle stops when the ON/OFF

switch is changed to the ON position.

3. For Atmospheric Models Only (24-CGA-10 and 24-CEA-10): Turn

ON the electrical power to the SteamCraft 10 at the control panel ON/OFF

switch.

a. Water begins filling the steam generator. The preheating circuits are

energized but the burners do not light until water reaches the safety

level sensor.

b. After 5 to 7 minutes, water reaches the safety level sensor and the

burners light with a distinctive sound.

• If the burners light within 7 minutes of turning the unit ON, the igniter

control s are functioning. End this test procedure here.

• If the burners do not light within 9 minutes of turning the unit ON,

there may be air in the gas supply lines. Proceed to step 5.

4. For Pressure Models Only (24-CGP-10 and 24-CEP-10): Turn ON the

electrical power to the SteamCraft 10 at the control panel ON/OFF

switch.

a. The red indicator the switch lights and water fills the steam generator.

b. After about 5 minutes, the amber indicator the STEAM switch lights.

c. When the amber light turns on, pr ess the STEAM switch on the control

panel. The burners should light with a distinctive sound.

• If the burners light within one minute of pressing the Steam switch,

the igniter controls are functioning. End this test procedure here.

• If the burners do not light within one minute of pressing the Steam

switch, there may be air in the gas supply lines. Proceed to step 5.

5. Turn off electrical power to the SteamCraft 10, at both the panel ON/OFF

switch (Figure 2-16), and the main disconnect switch (Figure 2-8, Recommended Electrical Layout).

NOTE: When the burners fail to ignite, a safety circuit in the igniter

control de -energizes the system and closes the automatic gas

valve. The safety circuit resets when the SteamCraft 10 is

turned OFF and turned back ON.

6. Refer to Bleed Air from the Gas Supply Lines, and bleed any trapped air

from the gas supply lines.

Page 41

Final Setup and Checkout

Installation Checks

Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10 Page 33 SteamCraft 10 Service Manual, Chapter 2

7. Repeat steps 2 through 6 no more than three times. If the burners do not

light after the third attempt, call a Cleveland Range authorized service

representative to adjust the burner controls.

8. Turn off electrical power to the Steam Craft 10, at both the panel ON/OFF switch

(Figure 2-16), and the main disconnect switch (Figure 2-8, Recommended

Electrical Layout).

The Final Setup and Checkout procedures prepare a recently installed or repaired

SteamCraft 10 for operation. The procedures check proper electrical, gas, water,

and drain connections to the SteamCraft 10, and verify basic steamer operation.

Read through all pans of this procedure before starting.

CAUTION

Equipment damage and faulty operation will result if the

gas, water, or electrical supplies fall below requirements.

This may be caused by other equip ment on the same

supply lines. During all tests, adjustments, and inspection

of the SteamCraft 10, turn on all equipment drawing on

the same utility supply lines.

Proper operation of the SteamCraft 10 is dependent upon proper

installation.Performing the following checks after installation could avoid

unnecessary service calls.

1. Refer to the appropriate dimension drawing and verify that the specified

clearances are met

2. Verify that the unit is level front to back and side to side.

3. Check inside each cooking compartment for proper installation of the drain

screen, slide racks, and door gasket assembly. Be sure the drain is not blocked.

4. Clean the protective plastic film off the outside of the Steam Craft 10.

5. Refer to the Installation Check List on page 8, and verify that each task has been

completed in accordance with the referenced paragraphs. Pay particular attention

to:

• Voltage Requirements and Electrical Connections

• Water Quality and Pressure Requirements

• Free Air Drain Layout and Venting

• Gas Supply Pressure Requirements (if appl icable)

• Exhaust Hood Venting (if applicable)

6. Refer to Figure 2-8, and Table 2-3, and verify installation of proper size fuses or

breakers.

7. Check that the water supply valves are open.

Page 42

Operating Tests

Page 34 Chapter 2, SteamCraft 10 Service Manual Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10

8. If using a SteamerGard water treatment system, refer to the SteamerGard

manual and start the system. Check that all valves between the SteamerGard and the SteamCraft 10 are open.

9. For gas fired models (24-CGA-10 and 24-CGP-10), turn on the main gas

supply valve only after the gas supply lines and the burner controls are

tested.

Perform these operating tests only after completing the Ins tallation Checks

and correcting any deficiencies. These operating tests consist of observing

various steamer functions in the MANUAL and the TIMED operating

modes. Read through all of the procedures before starting.

• The SteamCraft 10 has two cooking compartments and each compartment

has a separate control panel. The compartments can operate separately or

simultaneously. Throughout these tests, reference is made to only one

compartment control panel. Except when the instructions specify upper or

lower compartments, the controls of either or both panels can be used.

• The SteamCraft 10 control panels have either a Key Pad Timer or a Dial

Timer. The operating difference between the Dial and Key Pad Control

Panels is significant only in timed mode. To avoid confusion, a separate

Timer Testing procedure is provided for the Dial and Key Pad Control

Panels. In addition, SteamCraft 10 models 24-CGP-10 and 24-CEP-10

with pressure steam generators have a steam generator control panel.

The Key Pad Control Panel is shown in Figure 2-16, page 37. The

Timer Test for the key pad control panel starts on page 37.

The Dial Timer Control Panel is shown in Figure 2-18, page 38. The

Timer Test for the dial timer control panel starts on page 38.

Steam Generator Control Panel is shown in Figure 2-17, page 37 and

Figure 2-19, page 39.

Operating Test Preparation

1. Verify that electrical power to the SteamCraft 10, is turned OFF at both

the panel ON/OFF switch, and the main disconnect switch.

WARNING

Death, severe electrical shock or equipment damage

can result from touching any component inside unit

when main disconnect switch is in the on position.

Use extreme caution during testing with the access

cover removed.

2. Refer to Figure 2-7, and remove the right side access panel so the upper

and lower float assemblies are clearly visible.

Page 43

Models 24-CGA-10, 24-CGP-10, 24-CEA-10, 24-CEP-10 SteamCraft 10 Service Manual, Chapter 2 Page 35

Blowdown Inspection Procedure

1. The TIMED/MANUAL switch and TIMER settings are not significant while

the ON/OFF switch is in the OFF position.

2. With the panel ON/OFF switch turned OFF, turn on electric power to the

SteamCraft 10 at the main disconnect switch. The steamer will immedi ately

start an automatic, 3-minute blowdown cycle. During the automatic blowdown

cycle, the condenser and drain valves are fully open, while the steam generator

and float assembly are flushed with fresh water.

3- Stop the blowdown cycle before it is complete by setting the ON/OFF switch to

the ON position. This energizes the operating control circuits, the red ON/OFF

indicator lights, blowdown stops, and the steam gener ator fills with water.

4. Restart the blowdown cycle by setting the ON/OFF switch to the OFF position.

Observe the following functions.

a. Look at the top of the float control. There should be a steady flow of water

entering the top of the float chamber through the spray nozzle.

b. Look at the one inch vent gap between the steamer drain pipe and the floor

drain. A steady stream of water should be draining from the steamer.

c. After about 3 minutes, the cycle is complete. Check the two points listed

above; there should be no water flow at either point

Operating Test Procedures

1. Verify that electrical power to the SteamCraft 10 is turned OFF at the panel

ON/OFF switch, and turned ON at the main disconnect switch.

2. Set both upper and lower compartment TIMED/MANUAL switches to the

TIMED position.

3. Set both upper and lower compartment timers to zero minutes.

• For Key Pad Control Panels: The timer display is blank while the ON/OFF

switch is set to OFF. If the timer is not zeroed (00:00) when power is turned

on in step 4, press and hold the CLEAR key on the key pad control panel