Page 1

Parts Manual

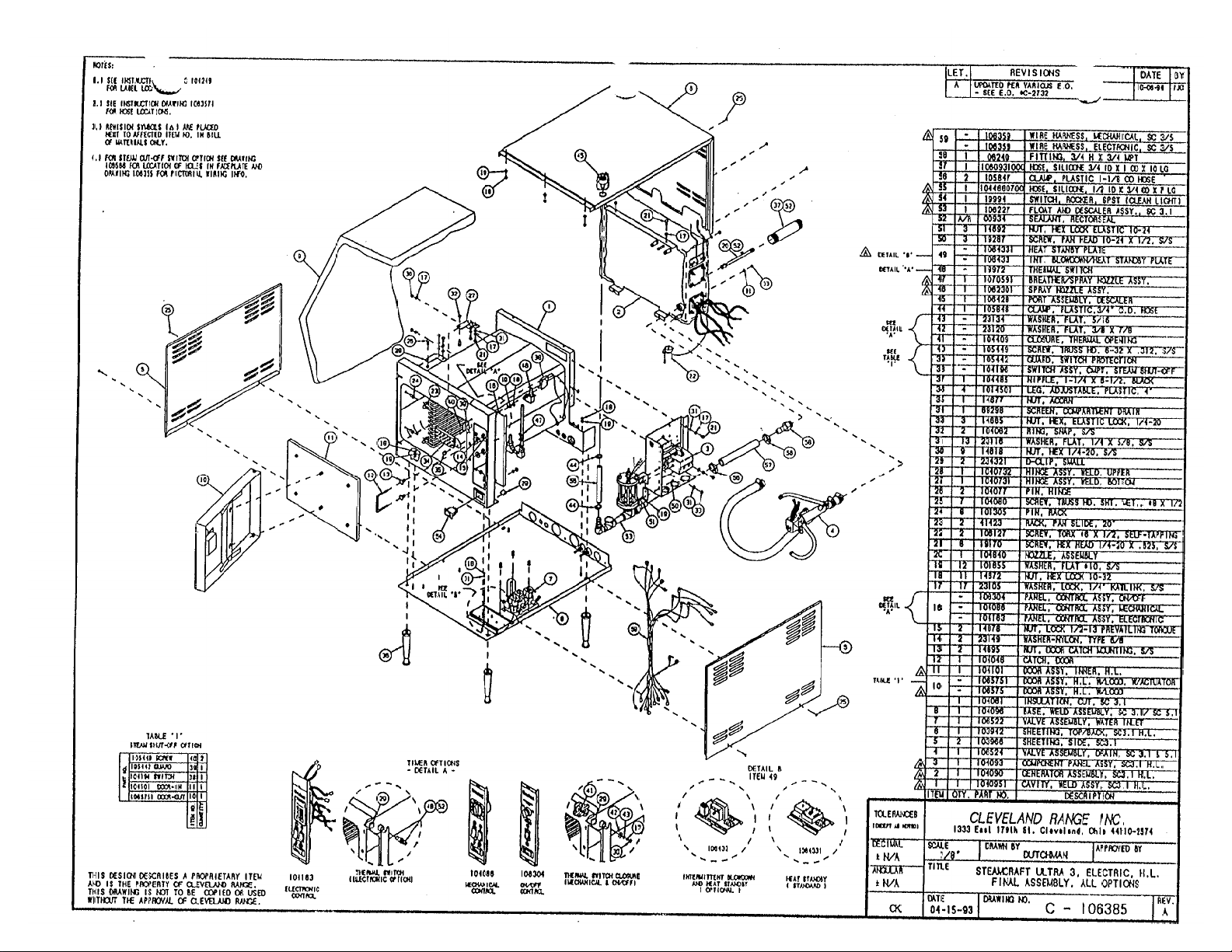

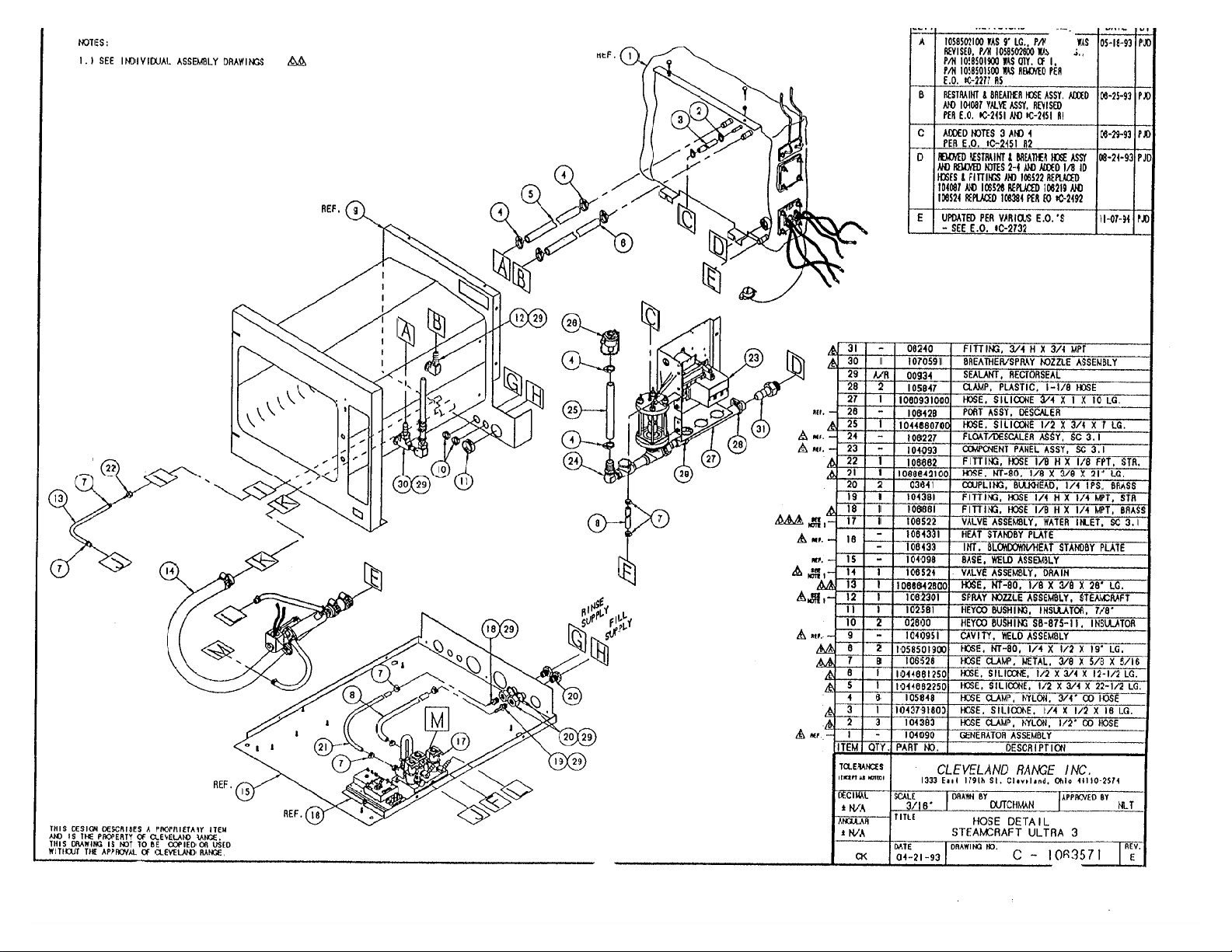

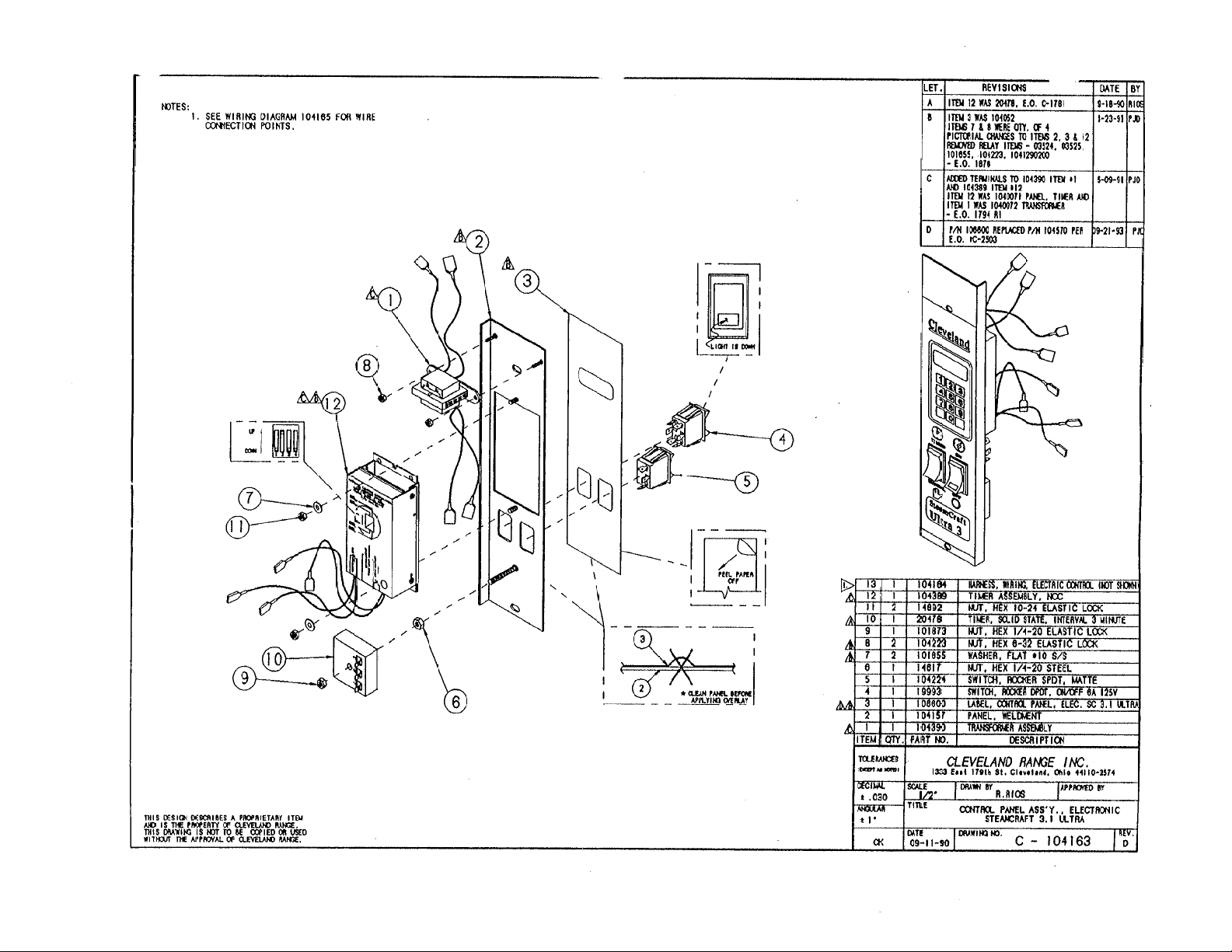

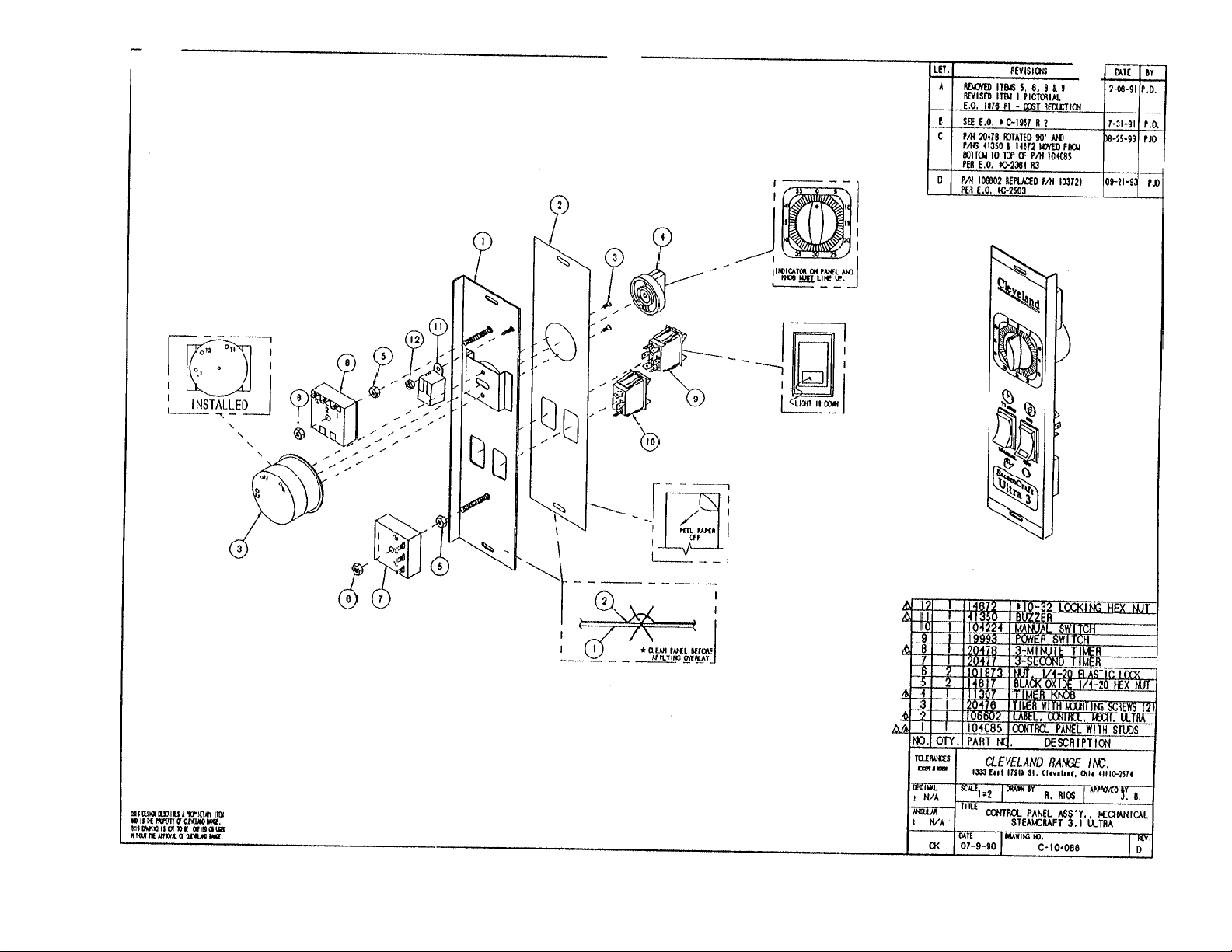

Counter Type Electric Convection Steamer

Series: SteamCraft Models 21CET8

1333 East 179

Cleveland, Ohio 44110

Phone: (216) 481-4900

1-800-338-2204

Fax: (216) 481-3782

www.clevelandrange.com

th

Street

Page 2

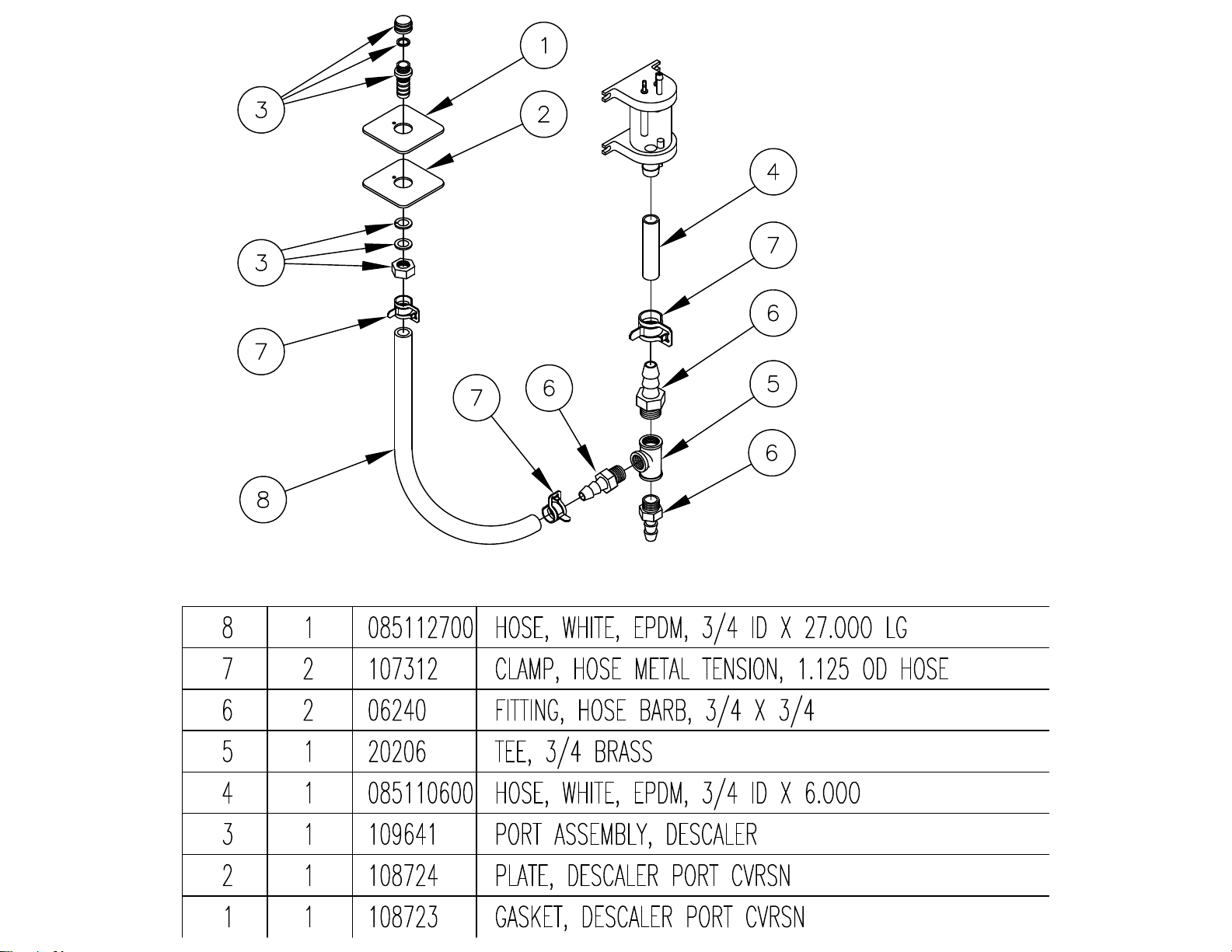

Stacking Blower Retro

Kit 110060

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

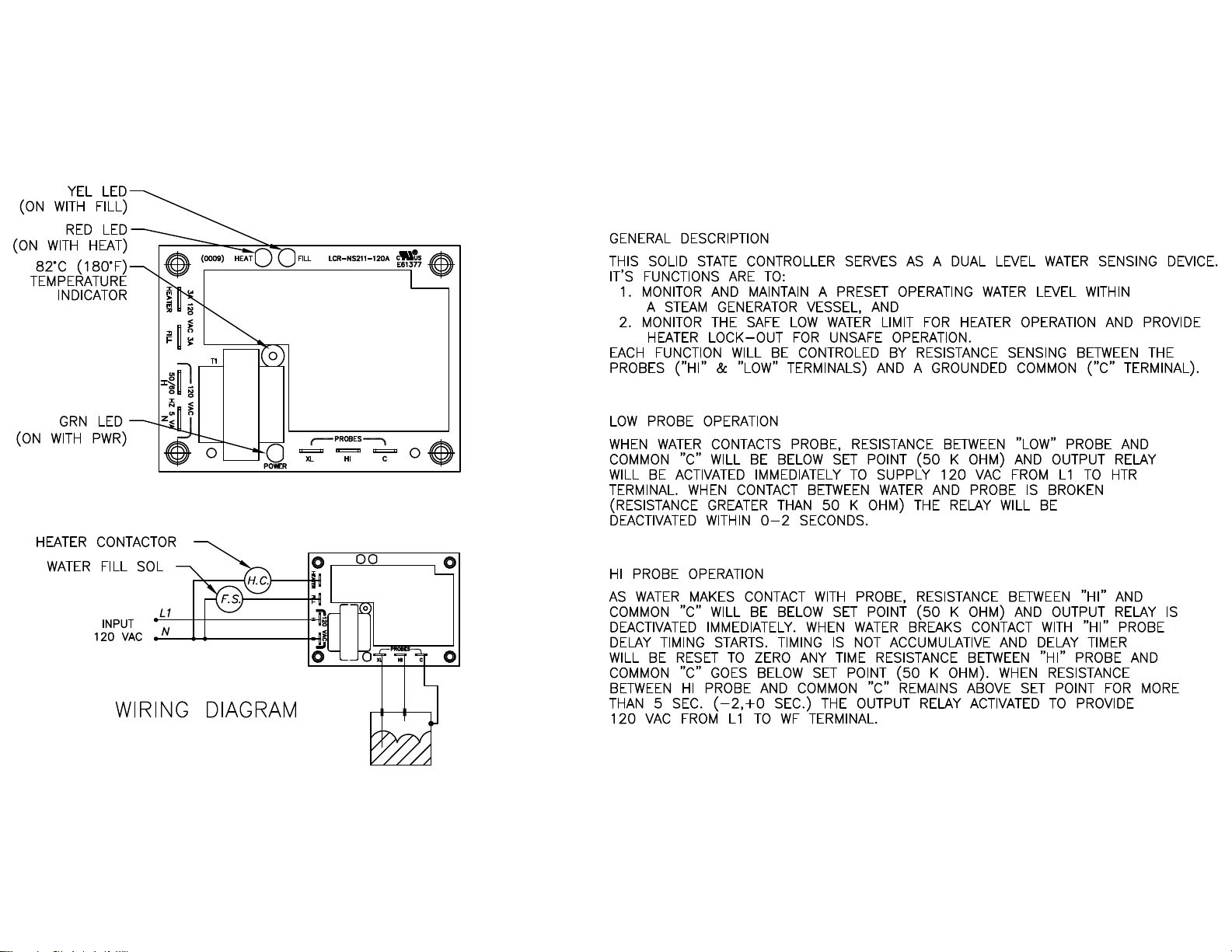

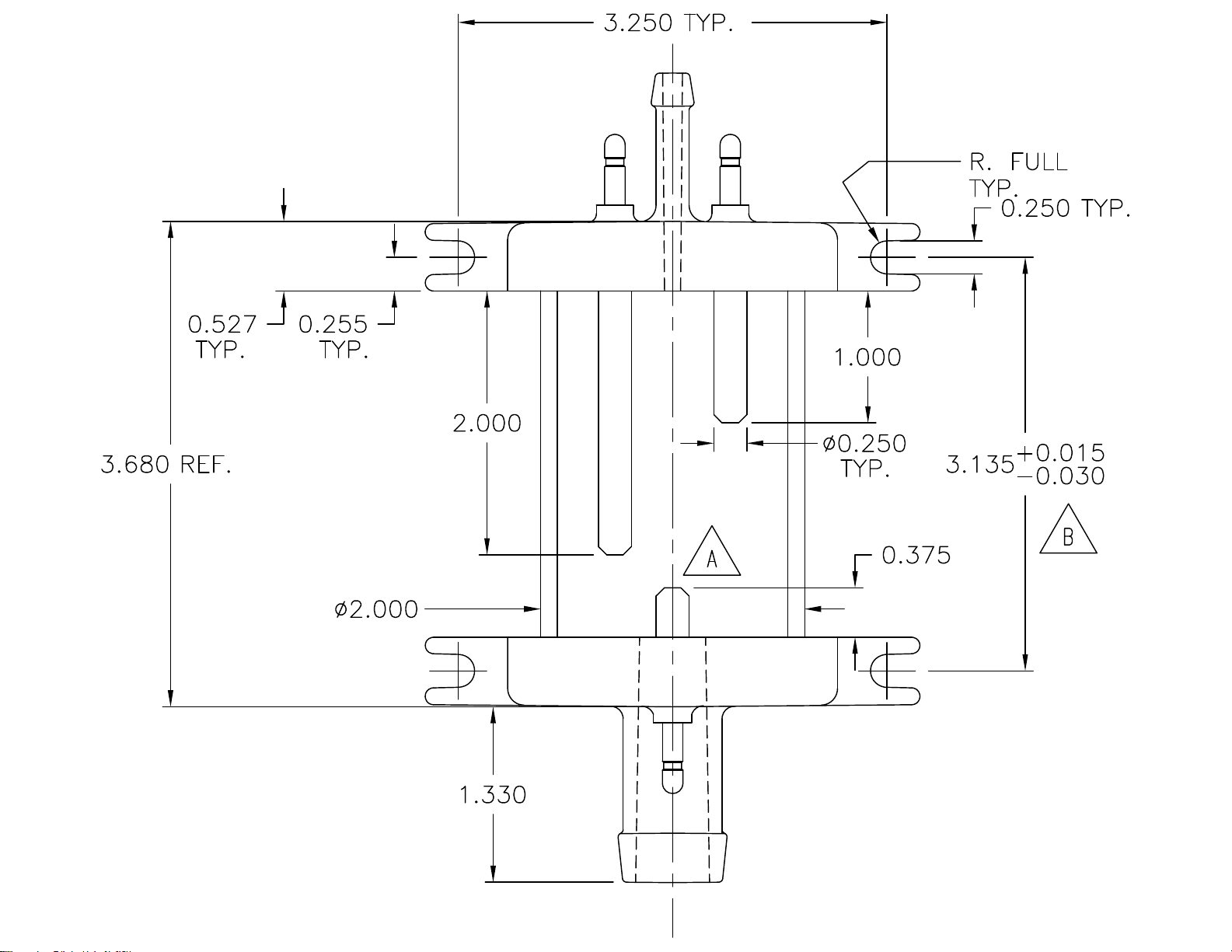

107241 Water Level Board

Page 14

107239 Water Level

Probe Assembly

Page 15

108727

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

CLEVELAND RANGE 21CET8

SEQUENCE OF OPERATIONS

Mechanical Timer

1. Supply power is sent to the primary of the main transformer.

• 115 VAC is sent from the secondary of the main transformer to the on/off rocker,

2. To turn the unit on, depress the red on/off rocker switch.

• 115 VAC is sent to the red power light.

• 115 VAC is sent to normally open drain valve closing it.

• 115 VAC is sent to H and N on the water level board

3. With the water level board energized and no water in the generator

• 5 seconds later 115 VAC is sent from the FILL terminal to the fill solenoid.

• The fill solenoid opens and the generator fills through the drain valve.

• The water fills to the low probe shorting it to ground

• 115 VAC is sent to the heat standby timer which will energize 3 seconds every 4

minutes to maintain heat while unit is idle

• 115 VAC is sent from the HEAT terminal to the timed manual switch.

4. When the timed/manual switch is in the timed position and time is on the timer

• 115 VAC is sent from the timer to the R2 relay coil

• R2 relay energizes closing the R2A and R2B contacts

• 115VAC is sent through the now closed R2B contacts to the timer motor

• 115 VAC is sent through the now closed R2A contacts through the door switch to the

normally closed contacts of the high limit switch.

• 115 VAC is then sent through the high limit to the coil of condensate solenoid

• The condensate solenoid opens spraying cold water down the compartment drain.

• 115 VAC is also sent through the high limit to the coil of the contactor.

• 115 VAC is sent to the clean light timer.

• When the clean light timer times down 115 VAC is sent to the clean light switch.

• When the clean light switch is depressed the clean light timer is reset.

5. When the contactor coil is energized supply voltage is sent to both of the elements.

• The elements are energized and the water is heated to steam.

• Steam is directed to the cooking compartment.

6. When the timer times out

• 115 VAC is sent to the 3 second timer and then to the buzzer for 3 seconds.

• 115 VAC is removed from the R2 relay.

• R2A contacts open de energizing the heat circuit

• R22B relay contacts open removing the 115 VAC from the timer motor

Page 32

7. When the water level reaches the high probe then 115 VAC is removed from the FILL

terminal and the fill solenoid is turned off.

8. After the water level drops below the high probe for 5 seconds 115 VAC is sent to the FILL

terminal again.

9. The red on/off switch is depressed and the unit is turned off.

• 115 VAC is removed from the heat and timer circuit.

• 115 VAC is removed from the normally open drain valve allowing the steamer to drain.

• 115 VAC is sent to the 3-minute timer and the fill solenoid is energized for 3 minutes

flushing the drain.

Page 33

STEAMCRAFT 3.1 MECHANICAL TIMER (PROBE)

CUSTOMER

CONNECTION

380/415V

3Ø

W/ NEUTRAL

L1

L2

L3

N

TB

FU

FU

FIELD CONVERSION FROM 3Ø

TO 1Ø IS NOT PERMITTED

DRYING ELEMENT

HEATING ELEMENTS

CUSTOMER

CONNECTION

1Ø

CUSTOMER

CONNECTION

3Ø

BLK

DESCALE

TIMER

L1

L2

L3

RESET CIRCUIT

BREAKER

POWER

SWITCH

L1

L2

3Ø

TB

4

1Ø

TB

23

1

6

87

5

3

1

3 MIN TIMER

2

CONTACTOR

FU

FU

CONTACTOR

FU

FU

L

NO

POWER ON

R

H4

X1

A

FILL VALVE

120V

L

NO

DRYING ELEMENT

HEATING ELEMENTS

H1 PRIMARY

X2 SECONDARY

DESCALE INDICATOR

& RESET SWITCH

WHT

MANUAL

MOTOR

ELECTRO-MECHANICAL

BLOWDOWN OPTION

TIMED TIMEDMANUAL

R2B

C NO

C

NO

C

R2A

NC

NO

TIMER

1

3

HEAT STANDBY

TIMER

R1

C NC

INTERMITTENT

BLOWDOWN

1

2

3

SWITCH

(SCS OPT)

R1

NO C

2

TIMER

HEAT

FILL

H

N

R2

DOOR

( STACKED UNITS OPTION )

WATER

BOARD

XL

C

HI

3 SEC TIMER

3

2

1

R1

( OPT )

HI LIMIT

SWITCH

COOLING FAN

DRAIN VALVE

TO

PROBES

BUZZER

CONTACTOR

CONDENSER

VALVE

L106347 M

Page 34

BLK

3

20

2

1 BLK

LT BLU

19

PNK

WHT/BLK

3

4

NC

WHT

1

NOC

WHT/GRA

3

2

1

ORN

WHT/BLK

GRA

23

R2

ORN/BLK

BLK

2

WHT/RED

WHT

TAN

TAN

RED

BLU

LT BLU

18

WHT/BLU

LT BLU

SINGLE PHASE WIRING CONFIGURATION

TO

FUSE BLOCK

L1 L2 L3

TERMINAL BLOCK

CUSTOMER

CONNECTION

WHT/BLK

WHT/BRN

17

BLU

BLK

REMOVED W / OPT

DOOR SWITCH ( SCS )

YEL

YEL

TAN

WHT/BLK

WHT

BLK

5

3

2

1

4

6

7

58

BRN

21

BRN

BLK

DRYING ELEMENT

BLK

HEATER

RED

ELEMENT

WHT

DRYING ELEMENT

BLK

HEATER

RED

ELEMENT

WHT

STEAMCRAFT 3.1 MECHANICAL TIMER (PROBE)

WHT

BLK

WHT

BLK

BLK

RED

GRN

16

RED

BLK

15

HEAT FILL

YEL

C

HI

XL

NH

TAN

RED

WHT

JUMPER POSITION

FOR 480 V

OPERATION

H2

H4 H3 H1

WHT/BLU

26

BLK

YEL

TIMED/MANUAL SWITCH

6

22

7

N

6

3

WHT

2

1

INTERMITTENT BL OWDOWN OPTION

3

WHT

2

YEL

BLK1

WHT

3

RED

2

RED

1 RED

TAN

RED

9

N

( TO HIGH LIMIT )

BLK

WHT

RED

BLU

WHT/BLK

8

7

23

RED

GRN

COND

BLK

BRN

TIMED/MANUAL SWITCH

( THRU SCS )

BLK

( TO COND SOL )

BRN

RED

BLU

RED

WHT/BRN

10

GRN

8

WHT/BLU

FILL

19993 - POWER SWITCH

1

104224 - TIMED / MANUAL SW

2

20478 - 3 MIN TIMER

3

4

19994 - DESCALE IND RESET SWITCH

106911 - DESCALE TIMER

5

109239 - HEAT STANDBY TIMER

6

44168 - TERMINAL BLOC K

7

22221 - DRAIN VALVE

8

107211 - COOLING FAN ( OPT )

9

22218 - WATER SOLENOI DS

10

11

103731 - HI LIMIT SWITCH

300022 - CONTACTOR

12

108331 - RESET CIRCUIT BRKR

13

20535 - TRANSFORM ER

14

15

107241 - WATER BOARD

107239 - PROBE

16

WHT

WHT

BLK

14

H4 H2

208/240

VOLT

BLK

X2X1

H1

H3

BLK

24

L2

L1

L3

CUSTOMER CONNECTION

WHT/BRN

BRN

BLK

11

BLK

PARTS LIST:

BLK

BLK

BLK

BLK

FU

FU

27

28

13

BLK

WHT

WHT

WHT

25

12

BRN

17

18

19

20

21

22

23

24

25

26

27

28

BLK

HEATER

ELEMENT

RED

DRYING ELEMENT

BLK

WHT

HEATER

ELEMENT

RED

WHT

DRYING ELEMENT

108880 - DOOR SW ( MAGNETIC )

41350 - BUZZER

110198 - MOTORIZED TIMER

20477 - 3 SEC TIMER

104234 - CONTACTOR

106541 - INTMT BLOWDOWN TIMER

105966 - RELAY

101540 - END SEGMENT

101541 - TERM BLOCK SECTIONAL

20304 - GROUND LUG

109380- 3.5 AMP, 600V FUSE

109374 - FUSE BLOCK

P106347 M

Page 35

Page 36

Page 37

STEAMCRAFT 3.1 ELECTRONIC TIMER (PROBE)

CUSTOMER

CONNECTION

380/415V

3Ø

W/ NEUTRAL

L1

L2

L3

N

TB

FU

FIELD CONVERSION FROM 3•

TO 1• IS NOT PERMITTED

DRYING ELEMENT

HEATING ELEMENTS

CONNECTION

CUSTOMER

CONNECTION

3•

BLK

DESCALE

POWER SWITCH

CUSTOMER

1•

RESET CIRCUIT

TIMER

L1

L2

L3

BREAKER

TB

3

4

7

L1

L2

2

1

8

3 MIN TIMER

CONTACTOR

TB

FU

FU FU

DRYING ELEMENT

CONTACTOR

FU

FU

H4

X1

120V

L

6

5

NO

L

A

NO

HEATING ELEMENTS

H1 PRIMARY

X2 SECONDARY

DESCALE INDICATOR

& RESET SWITCH

WHT

3

2

1

POWER ON

FILL VALVE

R

COMPARTMENT

THERMAL SWITCH

TIMED

MANUAL

HEAT STANDBY

TIMER

BLOWDOWN OPTION

( SCS OPT )

R1

C

1

FU

DOOR

SWITCH

MAGNETIC

3

NC

TRANSFORMER

ELECTRONIC

1

2

INTERMITTENT

BLOWDOWN

TIMER

24 VAC

TIMER

R1

CNO

WATER

HEAT

BOARD

FILL

H

N

HIXL C

COIL R1

( OPT )

HI LIMIT

SWITCH

( STACKED UNITS OPTION )

COOLING FAN

DRAIN VALVE

PROBES

CONTACTOR

CONDENSER

VALVE

TO

2

3

L106346 M

Page 38

Page 39

PROBLEM:

21CET8

21CET16

21CEA10

Steamer won't

steam.

Steamer won't

steam

Is the red light

on?

Yes

No

Is there supply

voltage to the

primary of the

transformer?

Yes

Supply power to

No

the s t eam er.

Replac e the

water boar d

Replace the wire

from the water

board to the long

probe.

See

STEAMER

WON'T FIL L

Replace the wires

to the water

board.

jumper between XL and

No

C on the water b oard , i s

there 120 VA C between

N and Heat?

No

there d ebr i s on

With a

Yes

Is

the Long

probe?

No

No

Is there water

in the sight

Is there 120 VAC

between t erm i n als H

and N on the wat er

Is there 120 VAC

between ter m i nals

No

N and Heat on t he

water board ?

115 V AC t o th e

common term i n al of

the timed/manual

glass?

Yes

board?

Yes

Yes

Is there

switch?

Replace the wires

No

to the switch.

Is there 115 VAC at

the secondary of

the transformer?

Yes

Replace the on/ of f

rocker switch

No

Replac e the

transformer.

Yes

Clean or r ep lace

the probe ass y.

Yes

Does

the unit st eam

in Manual

mode?

Yes

Replac e the

timer.

Does t he

No

st eam er have

the opt i onal

door switch?

steamer steam w i th

door swit c h

bypass ed?

Adjust or replac e

the door switch.

Yes

Does

Yes

Is there

115 V AC t o th e

No

No

high limit?

Is there 115

VAC l eaving

the high limit?

Is there 115

VAC to the coil

of the

contactor?

Is th ere an

amp draw at

the elem en t ?

Wait longer for t h e

steam. Heat fr om t h e

element will heat the

water to steam.

Yes

Yes

Yes

Yes

No

No

No

No

Replac e the

wires to the

high limit.

Replac e the

high limit.

Replac e the

wires to the

contactor coil.

Replac e the

element.

Page 40

PROBLEM:

21CET8

21CET16

24CEA10

Steamer wont

fill

Steamer wont fill.

Yes

Is there supply

voltage to the

steamer?

Yes

No

Supply power to

the s t eam er.

Replace wiri n g t o

the fill solenoid.

Is there water

to the

steamer?

Is there 120 VAC

between th e H and N

on the water b oard?

Is there

120 VAC

between Fill and

N on the water

board?

Is there

No

120 VAC across

the coil of t h e fill

solenoid?

Yes

Yes

Yes

Yes

Supply cold water

No

Replace the on/ of f

No

No

to the s t eamer.

rocker switch.

Remove

the wire f r om t h e H I

terminal on the water

board. Is there 120 VAC

between F i l l

and N?

Yes

Is there

debr i s on th e

HI probe in the

probe as sy?

No

Replace the water

No

Replace the wire

to the Hi p r ob e.

board

Replace wiri n g t o

drain valve.

Replace t h e wi r i ng

to the intermittent

blowdown timer.

No

No

Replace t h e fill

solenoid

Does

the s t eam er have

the opt i onal

intermittent

blowdown timer?

Yes

Is

there 120 VAC

between ter m i nals

2&3 on the timer?

Yes

Replac e the

intermittent

blowdown timer.

No

No

Is

water leaving

the fill

solenoid?

Yes

Is there

120 VAC across

the coil of the

drain valve?

Yes

Is water

draining from

the generator?

Yes

Replace the drain

valve.

If water i s leaving

No

and not draining

from the generator

where is it g oi ng ?

check for leaks..

Yes

Clean t h e probes

or replace the

probe as sy.

the fill solenoid

Page 41

PROBLEM:

21CET8, 21CET16, 24CEA10

Electronic timer displays "PAUS" and won't count down

Timer displays "paus"

and won't count down

Is steam heati ng

Replac e the

thermo-switch

cabinet above 192

degrees (the set

thermo-switch)?

Does the timer

count down when

Yes

the thermo-switch

is bypassed?

the cook i n g

No

temp of the

Yes

No

See

Steamer

won't steam

Replac e the

electronic ti m er

Steam leaks

around the

door

Is COLD water

supplied to both

water li n es t o t h e

steamer?

Yes

Is the door gasket

phys ic ally

damaged?

Yes

Turn over the

gasket or

replace it.

water(35-60 p si) t o

No

Is the door ou t of

No

Supply cold

the s t eam er.

alignment ?

Yes

Replac e the

door bearings

and pins.

PROBLEM:

21CET8, 21CET16, 24CEA10

Steam leaks around the door.

Is there 120 VAC

No

Is the drain

obstructed?

Yes

Remove the

obstruction

across the coil of

No

the condensate

solenoid?

Is the solenoid

Yes

opening?

No

No

Replac e the

wiring to the

condensate

solenoid.

Replac e the

condensate

solenoid.

Yes

Replac e the

condensate spray

nozzle

Page 42

PROBLEM:

21CET8

21CET16

24CEA10

Steamer overfills.

(Water sprays into cooking

cabinet)

Steamer overfills

(Water sprays into the

cooking cabinet)

Start

There is an

obstruction in th e

drain. Remove the

obstruction.

Yes

Does

the rise in t he wat er

level in the sig h t gl as s

stop when the cooking

cabinet door is

opened?

No

There is an

obstruction in th e

generator caus i ng

it to pressurize.

Delim e the steam

generator

thor oughly.

Replace the three

minute timer.

Yes

Yes

Does

the water rise in t h e

sight glass when steam

is generat ed and 0 V A C

to the fill solenoid?

No

Replace t h e fill

solenoid

There is an obstruction in

the plumb in g t o and from

the sight glass . Remove

the debris (delime

thoroughly).

Remove the

wire from the Fill

terminal on the water

board. Is there 120 VAC

across the coil of th e

fill

solenoid?

Yes

Yes

Yes

Does

the water l evel in th e

sight glas s st op at t h e

HI (short) probe on the

initial fill?

No

Does

water s p r ay in t h e

cabinet before t he

water reach es the H I

(short) probe?

No

Is

there 120 VAC

across the coil of ;t h e

fill solenoid when the

HI (short) probe is

submerged?

Replace the water

level boar d.

Clean or r ep lace

the pr obe

assembly.

Yes

water boar d ju m p ed,

between t erm i n als N

Yes

No

With HI and C

terminals on the

Is there 120 VAC

and Fill?

No

Is

there d ebr i s on

the HI (short)

probe?

No

Replace the wire

to the probe

assembly

No

Replace t h e fill

solenoid

Page 43

Steamer won't

stop steaming

Is the

timed/manual switch

in the timed posit i on

with no time on the

timer?

Yes

Steamer will steam

constantly in th e

manual p os i t i on. P u t

No

the timed/manual

switch in the timed

position with no tim e on

PROBLEM:

21CET8

21CET16

24CEA10

Steamer won't stop steaming with

door open

the timer.

Does th e st eam er

have the op t ional

door switch?

Yes

Adjust or replac e

the door s wi t ch .

No

Does steam er

continue to steam with

both wires removed

from terminal 1 on t h e

heat st andby

timer?

No

Replac e the h eat

standby timer.

21CET8, 24CEA10

Steamer won't preheat

Yes

Replace the timer.

Problem:

Steamer

won't

preheat

Is there

120 V AC t o th e

coil of the

contacter?

Yes

No

Is

there an am p

draw at t h e

element?

Yes

Replac e the

contactor

voltag e i s r em oved

from t he elem en t

steam is sti l l mad e

No

for approxi m ately

10 seconds . This

When supply

is normal.

Is the

timed/manual

switch in t h e ti m ed p os t i on

with tim e on it or i n t h e

manual

postion?

Yes

See Problem:

steamer won't

steam.

This steamer is

not equiped with a

thermostat. The

No

switch must be in

manual or time

must be on the

preheat

timed manual

timer.

Page 44

Problem:

21CET16

Steamer won't preheat

Steamer won't

preheat

Does th e st eam er

have a pr eheat

thermostat

Yes

Is there

continuity on the

normally closed

contacts of t h e

preheat

thermostat?

No

No

Yes

Is the

timed/manual

switch in t h e ti m ed p os t i on

with tim e on it or i n t h e

manual

postion?

Yes

See Problem:

steamer won't

steam.

This steamer is

not equiped with a

thermostat. The

No

timed manual

switch must be in

manual or time

must be on the

preheat

timer.

Replace t he pr eh eat

thermostat

Page 45

STEAMCRAFT 3.1 MECHANICAL TIMER ( FLOAT )

CUSTOMER

CONNECTION

380/415V

3Ø

W/ NEUTRAL

L1

L2

L3

N

TB

FU

FU

FIELD CONVERSION FROM 3

TO 1Ø IS NOT PERMITTED

DRYING ELEMENT

HEATING ELEMENTS

CUSTOMER

CONNECTION

1Ø

CUSTOMER

CONNECTION

3Ø

BLK

DESCALE

TIMER

POWER

SWITCH

L1

L2

3Ø

L1

L2

L3

TB

RESET CIRCUIT

BREAKER

32

4

78

3 MIN TIMER

1Ø

TB

CONTACTOR

FU

FU

DRYING ELEMENT

CONTACTOR

FU

FU

H4

X1

120V

L

1

6

5

3

NO NO

2

L

A

HEATING ELEMENTS

H1 PRIMARY

X2 SECONDARY

DESCALE INDICATOR

& RESET SWITCH

FILL VALVE

WHT

1

R1

POWER ON

NO C

R

R3B

NOC

C

NO

MOTOR

R3A

NC

ELECTRO-MECHANICAL

TIMER

R2

1

2

3

HEAT STANDBY

TIMER

BLOWDOWN OPTION

R2

NCC

1

2

3

MANUALTIMED

C

NO

CNO

LOW WATER

INTERMITTENT

BLOWDOWN

TIMER

TIMED

R3

DOOR

SWITCH

(SCS OPT)

CUT-OFF

R1

WATER LEVEL

3 SEC TIMER

3

BUZZER

2

1

COIL R2

( OPT )

CONTACTOR

CONDENSER

HI LIMIT

SWITCH

VALVE

( STACKED UNITS OPTION )

COOLING FAN

DRAIN VALVE

L300163 D

Page 46

3

20

2

1

19

LT BLU

ORN

NOC

23

BLK

BLK

LT BLU

18

R3

WHT/BLU

LT BLU

YEL

TAN

BLU

TAN

TAN

RED

PNK

WHT/BLK

WHT/GRA

3

4

NC

WHT

1

2

1

ORN/BLK

WHT/BLK

2

WHT/BLK

GRA

WHT/GRA3

BLU

WHT

WHT/RED

SINGLE PHASE WIRING CONFIGURATION

TO

FUSE BLOCK

21

L2L1 L3

TERMINAL BLOCK

CUSTOMER

CONNECTION

WHT/BLK

WHT/BRN

17

BLU

RED

BLK

BRN

5

1

6

587

BLK

BLK

HEATER

ELEMENT

HEATER

ELEMENT

BLK

REMOVED W / OPT

DOOR SWITCH ( SCS )

BLK

YEL

WHT

23

4

BRN

DRYING ELEMENT

BLK

RED

WHT

DRYING ELEMENT

BLK

RED

WHT

STEAMCRAFT 3.1 MECHANICAL TIMER ( FLOAT )

WHT

BLK

WHT

BLK

15

RED

RED

BLK

RED

WHT

BLU

BRN

BLK

BLU

WHT/BLK

BRN

WHT/BRN

COND

RINSE

BLK

23

WHT/GRA

BLU

R1

7

N

BLU

WHT

BLK

YEL

6

3

2

1

RED

GRN

8

9

BLK

INTERMITTENT BLOWDOWN OPTION

7

N

6

22

WHT

3

2

YEL

BLK1

WHT

RED

2

RED

1

( TO HIGH LIMIT )

BLK

R2

23

WHT3

RED

RED

TO TIMED/MANUAL

BLK

SWITCH

( THRU SCS )

( TO COND SOL )

RED

8

GRN

WHT/BLU

26

BLU

BLU

BLU

WHT/GRA

10

FILL

1

19993 - POWER SWITCH

2

104224 - TIMED / MANUAL SW

20478 - 3 MIN TIMER

3

4

19994 - DESCALE IND RESET SWITCH

106911 - DESCALE TIMER

5

109239 - HEAT STANDBY TIMER

6

44168 - TERMINAL BLOCK

7

22221 - DRAIN VALVE

8

107211 - COOLING FAN ( OPT )

9

22218 - WATER SOLENOIDS

10

103731 - HI LIMIT SWITCH

11

300022 - CONTACTOR

12

108331 - RESET CIRCUIT BRKR

13

14

20535 - TRANSFORMER

15

103726 - FLOAT

16

--

WHT

WHT

BLK

14

X1

X2

208/240

VOLT

H3

H2H4

H1

BLK

BLK

24

L2L1

L3

CUSTOMER CONNECTION

WHT/BRN

BRN

WHT/BLU

BLK

11

BLK

PARTS LIST:

BLK

BRN

BLK

25

WHT

WHT

WHT

BLK

BLK

BLK

FU

FU

2827

JUMPER POSITION

FOR 480 V

OPERATION

H3

H2H4

12

BLK

HEATER

ELEMENT

RED

DRYING ELEMENT

BLK

WHT

HEATER

ELEMENT

RED

WHT

DRYING ELEMENT

17

108880 - DOOR SW ( MAGNETIC )

41350 - BUZZER

18

110198 - MOTORIZED TIMER

19

20477 - 3 SEC TIMER

20

21

104234 - CONTACTOR

22

106541 - INTMT BLOWDOWN TIMER

105966 - RELAY

23

101540 - END SEGMENT

24

101541 - TERM BLOCK SECTIONAL

25

20304 - GROUND LUG

26

109374 - FUSE BLOCK

27

109380 - FUSE 3.5A 600V

28

P300163 D

H1

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Descaling Procedure-SteamCraft Ultra and Gemini Series

How Much DISSOLVE to Use

Model Dissolve

Ultra 3 1/2 Gallon

Ultra 5 1 Gallon

Ultra 10 (Elec.) 1 Gallon (ea.)

Ultra 10 (Gas) 1½ Gallon

Gemini 6 & 10 1 Gallon (ea.)

1. Turn the unit OFF and open the

doors:

This will drain and rinse the generator for about

3 minutes.

2. Turn the unit power back On:

The generator will begin to refill with water.

3. Select Timed with the Timed/Manual

switch:

DO NOT start the timer, since you do not want

to heat the water during descaling. Leave the

doors open.

6. Let the descaler soak in generator for

approximately one hour:

7. After one hour, turn the unit power

Off:

This will drain and rinse the generator

for about 3 minutes.

Remove descaling port cap and add

4.

with the specified amount of

DISSLOVE:

Do this while the unit is refilling. The generators

can take-up to 8 minutes to refill.

After refill has stopped, add extra tap

5.

(See chart above)

water into the descaling port until

liquid is seen entering the cooking

cabinet.

coming out of the drain,

Adding extra water when descaling will raise the

descaling solution higher than the normal fill level,

allowing the DISSOLVE to work on sensors and

surfaces above the water line

Note: Some SteamCraft Ultra models (the

electric powered Ultra 10 and Gemini 6 and 10,

for example) have two generators and two

descaling ports. Both units should be descaled

at the same time, using this procedure

Note: Ultra 10 gas will have liquid

8. After the 3-minute drain cycle

completes, turn the unit back ON. After

the filling has stopped, add water until

liquid enters the cooking compartment (or

drain for the ultra 10 gas), and then turn

the unit OFF. This will drain and flush any

residue from the water level control

assembly. Replace descaling cap.

After the 3 minute drain cycle

9.

completes, Turn the unit ON and set

the Timer for 20 minutes:

Time/Manual switch is in the timed setting

and the doors are closed.

Make sure the

10. When the timer times out (after 20

minutes) turn the power Off:

This will drain and rinse the generator for

about 3 minutes.

This ends the descaling procedure. You can

now turn the unit back on and resume normal

startup and cooking operations.

Page 56

Loading...

Loading...