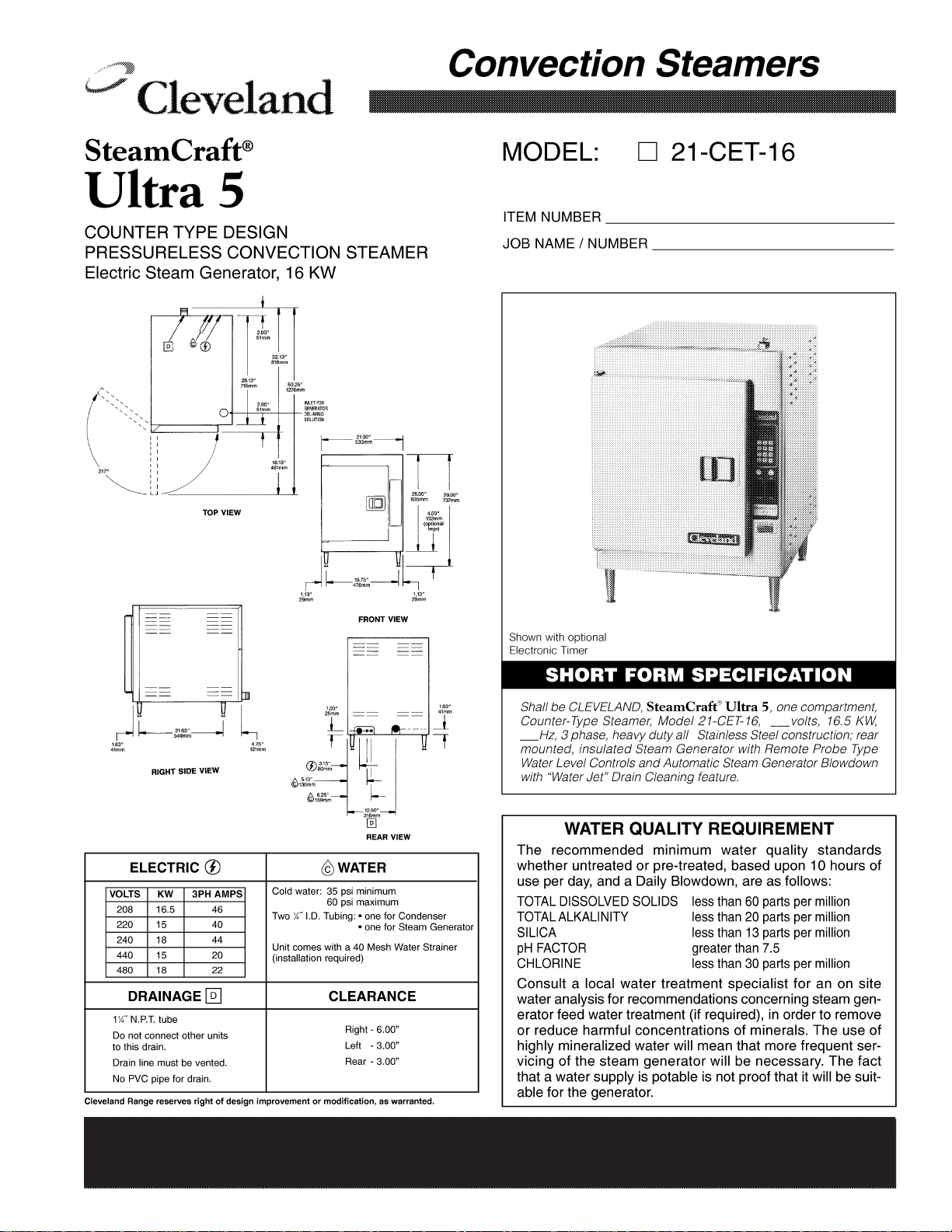

Cleveland 21-CET-16 Service Manual

Statement of Responsibilities

This document is for use by experienced and trained Qualified Cleveland Range, LLC Authorized Service

Representatives who are familiar with both the safety procedures, and equipment they service.

Cleveland Range, LLC assumes no liability for any death, injury, equipment damage, or property damage

resulting from use of, improper use of, or failure to use the information contained in this document.

Cleveland Range, LLC has made every effort to provide accurate information in this document, but

cannot guarantee that this document does not contain unintentional errors and omissions.

The information in this document may be subject to technical and technological changes, revisions, or

updates.

Cleveland Range, LLC assumes no liability or responsibility regarding errata, changes, revisions, or

updates.

Qualified Cleveland Range, LLC Authorized Service Representatives are obligated to follow industry

standard safety procedures, including, but not limited to, OSHA regulations, and disconnect / lock out /

tag out procedures for all utilities including steam, and disconnect / lock out / tag out procedures for gas,

electric, and steam powered equipment and / or appliances

All utilities (gas, electric, water and steam) should be turned OFF to the equipment and locked out of

operation according to OSHA approved practices during any servicing of Cleveland Ran ge equipment

Qualified Cleveland Range, LLC Authorized Service Representatives are obligated to maintain up-to-date

knowledge, skills, materials and equipment.

Cleveland Range, LLC

1333 East 179th St., Cleveland, Ohio, U.S.A. 44110

Ph: 1-216-481-4900 Fx: 1-216-481-3782 Visit our Web Site at www.clevelandrange.com

CLEVELAND RANGE 21CET16

SEQUENCE OF OPERATIONS

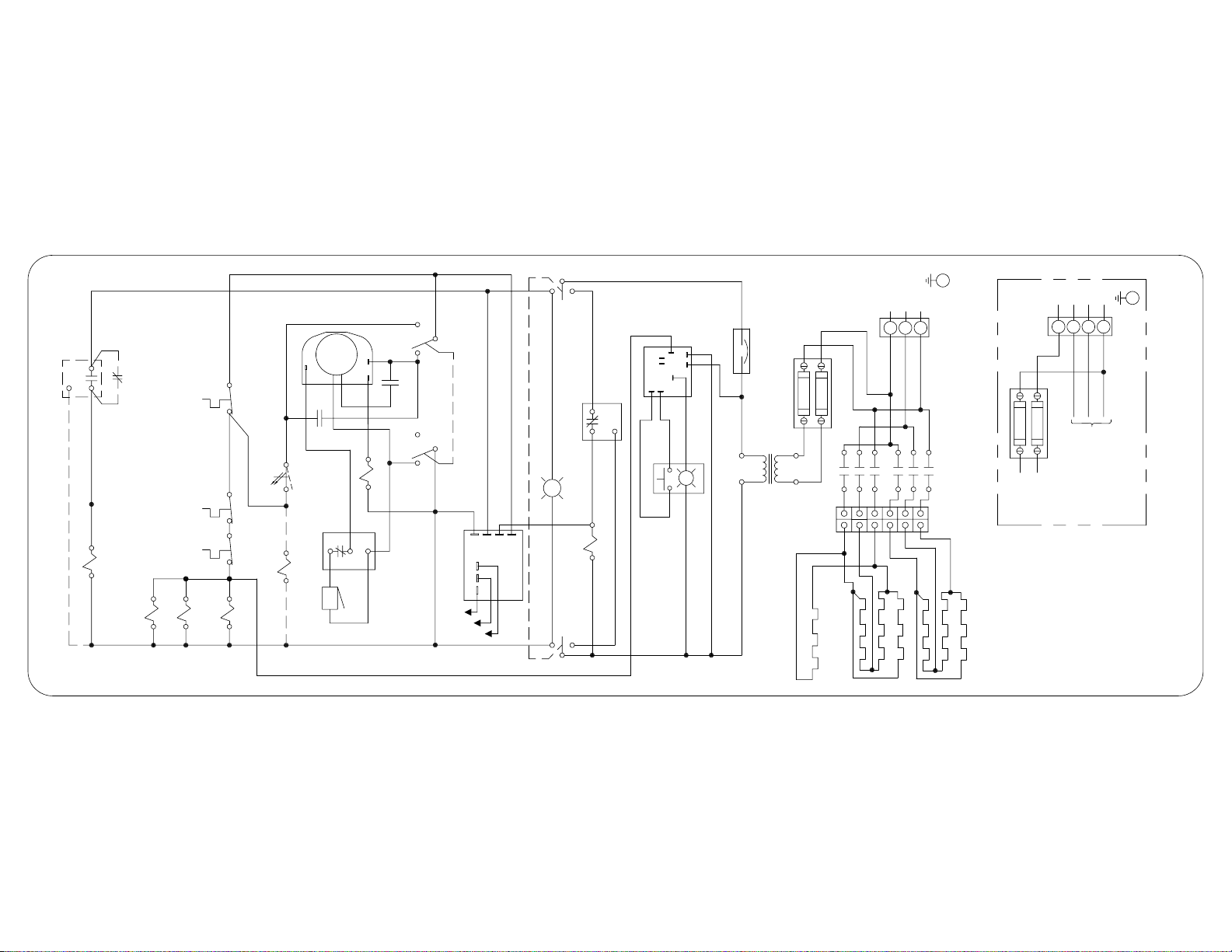

Mechanical Timer

1. Supply power is sent to the primary of the main transformer.

• 115 VAC is sent from the secondary of the main transformer to the on/off rocker,

1. To turn the unit on, depress the red on/off rocker switch.

• 115 VAC is sent to the red indicator light.

• 115 VAC is sent to the normally open drain valve closing it.

• 115 VAC is sent to H and N of the water level board

2. With the water level board energized and no water in the generator

• After a 5 second delay, 115 VAC is sent from the FILL terminal to the fill solenoid.

• The fill solenoid opens and the generator fills through the drain valve.

• The water fills to the low probe shorting it to ground

• 115 VAC is sent from the HEAT terminal to the timed manual switch.

• 115 VAC is sent to the preheat thermostat.

• 115 VAC is then sent through the high limits to the coil of condensate solenoid.

• The condensate solenoid opens sending cold water down the compartment

drain.

• 115 VAC is also sent through the high limits to the coil of the contactor.

• When the contactor is energized supply voltage is sent to both of the elements.

• The heat circuit will stay energized until the preheat thermostat opens at 185

degrees.

3. When the timed/manual switch is in the timed position and time is on the timer

• 115 VAC is sent from the timer to the coil of the R2 relay

• The R2 relay energizes

• R2B contacts close and 115 VAC is sent to the motor of the timer

• R2A contacts close and 115 VAC is through the optional door switch to the normally

closed contacts of the high limits

• 115 VAC is then sent through the high limit to the coil of condensate solenoid and the

coil of the mercury contactor.

• 115 VAC is sent to the clean light timer.

• When the clean light timer times down 115 VAC is sent to the clean light switch.

• When the clean light switch is depressed the clean light timer is reset.

4. When the contactor is energized supply voltage is sent to both of the elements.

5. When the timer times out 115 VAC is sent to the 3 second timer and then to the buzzer for 3

seconds.

6. When the water level reaches the high probe then 115 VAC is removed form the FILL

terminal and the fill solenoid is turned off.

7. After the water level drops below the high probe for 5 seconds 115 VAC is sent to the FILL

terminal again.

8. The red on/off rocker switch is depressed and the unit is turned off.

• 115 VAC is removed from the timer and heat circuits.

• 115 VAC is removed from the normally open drain valve allowing the steamer to drain.

• 115 VAC is sent to the 3-minute timer and the fill solenoid is energized for 3 minutes

flushing the drain.

L106380 G

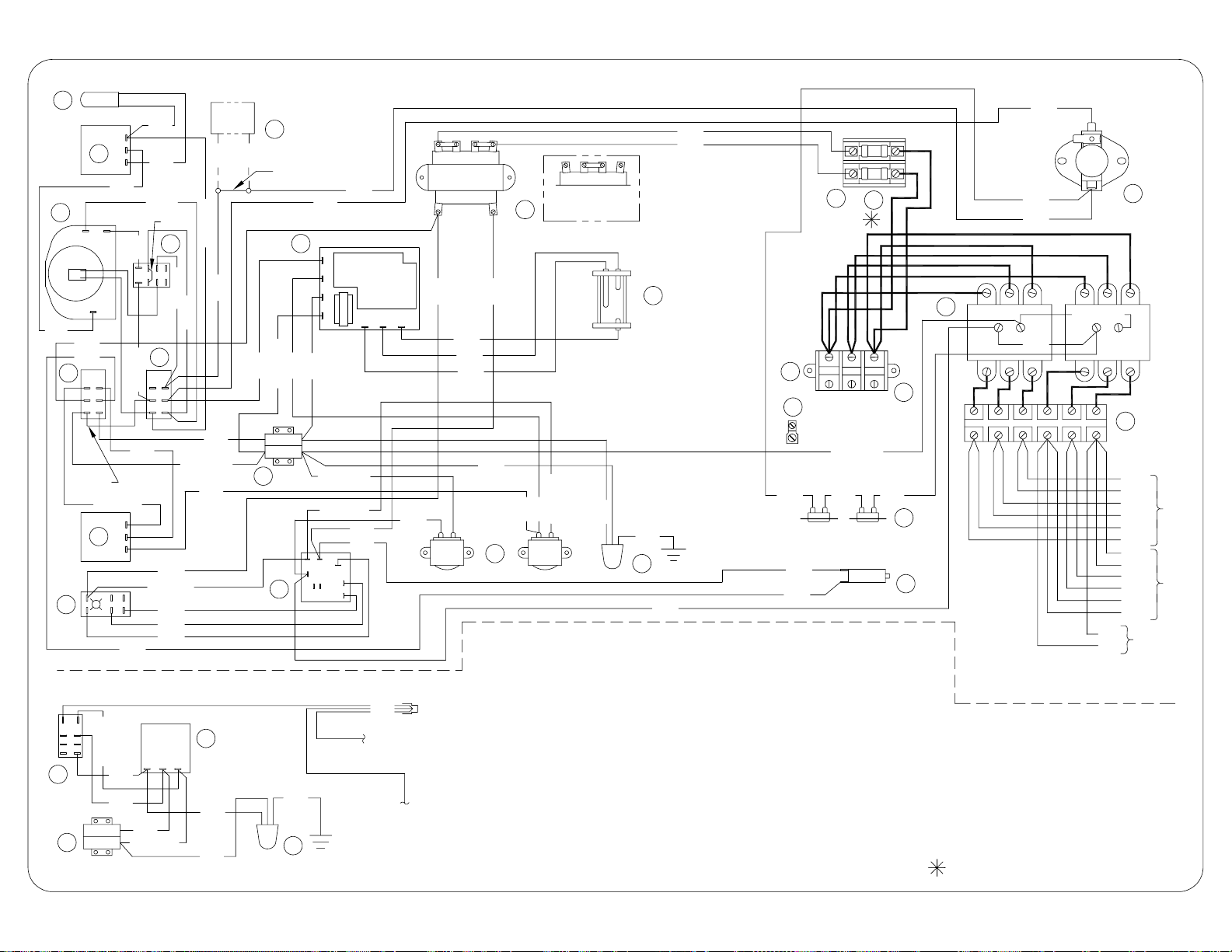

CONNECTION

BLK

DESCALE

POWER SWITCH

BLOWDOWN OPTION

INTERMITTENT

( HEAT STANDBY )

C NC

2

3

R1

1

DRAIN VALVE

CONDENSER

VALVE

THERMAL SWITCH

SWITCHES

HI LIMIT

CONTACTOR

ELECTRO-MECHANICAL

TIMER

CONTACTOR

MOTOR

R2A

C

DOOR

1

C

NO

R2B

NOC

MANUALTIMEDMANUAL

R2

3

2

BUZZER

TIMED

H

N

FILL

HEAT

3 SEC TIMER

PROBES

TO

WATER

BOARD

HIXL C

3 MIN TIMER

2 1

3

POWER ON

R

FILL VALVE

NC

NO

(SCS OPT)

SWITCH

( OPT )

R1

TIMER

RESET CIRCUIT

BREAKER

3

4

7

8

2

1

5

6

NO

NO

& RESET SWITCH

L

A

L

DESCALE INDICATOR

X1

120V

X2 SECONDARY

WHT

FU

FU

H4

H1 PRIMARY

TRANSFORMER

CUSTOMER

3Ø

FUSEBLOCK

L2

L1

L3

TB

FU

CONTACTORS

TO H4

TB

DRYING ELEMENT

HEATING ELEMENTS

FU

L3

L2

L1

N

TB

FUSEBLOCK

TO H1

380/415V 3Ø W / NEUTRAL

CONTACTORS

TO

STEAMCRAFT 5.1 MECHANICAL TIMER

CUSTOMER CONNECTION

19

BLK

3

2

17

1

BLK

PNK

18

NOC

LT BLU

ORN

LT BLU

27

BLU

WHT/BLU

6

RED

REMOVED W / OPTIONAL

DOOR SWITCH ( SCS )

YEL

10

ORN

HEATFILL H N

STEAMCRAFT 5.1 MECHANICAL TIMER

BLK

H1 H2 H4

H3

120

208/240

X2

X1

14

H3H1 H2 H4

JUMPER POSITION

FOR 480 V

OPERATION

BLK

YEL

FU

FU

25

26

BLK

ORN

7

ORN/BLK

LT BLU

WHT/RED

ORN

RED

BLU

PNK

NC

WHT

BLK

1

WHT/BLK

4

WHT/GRA

3

3

2

1

BLK

WHT/BLK

GRA

R2

2

WHT

WHT/RED

TAN

TAN

RED

INTERMITTENT BLOWDOWN OPTION

20

WHT/RED

27

8 N

RED

PRP

1 32

PRP

WHT/RED

RED

RED

RED

GRN

11

9

L1 L2 L3

22

CUSTOMER CONNECTION

21

WHT/RED

BLK

PRP

BLK

BLK

PRP

BLK

PARTS LIST

22218 - WATER SOLENOIDS

12

103731 - HI LIMIT SWITCHES

13

20535 - TRANSFORMER

14

15 103905 - CONTACTORS

108331 - RESET CIRCUIT BREAKER

16

20477 - 3 SEC TIMER

17

110198 - MOTORIZED TIMER

18

41350 - BUZZER

19

106541 - INTMT BLOWDOWN TIMER

20

20304 - GROUND LUG

21

101540 - END SEGMENT

22

15

BLK

WHT/BLK

23

21 34

13

16

NOTE:

HEAVY WIRE LINES INDICATES

12 AWG HI - TEMP WIRE

23

101541 - TERMINAL BLOCK SECTIONAL

24

109240 - 6 POLE TERMINAL BLOCK

25

109374 - FUSEBLOCK

26

109380 - FUSE, 3.5 A ( FOR 208 V &

65

WHT

WHT

24

HEATER

ELEMENTS

RED

WHT

BLK

WHT

BLK

RED

RED

WHT

BLK

WHT

BLK

RED

DRYING

ELEMENT

TOP

BOTTOM

240 V UNITS )

109381 - FUSE, 1.5 A ( FOR 480 V

UNITS )

27

105966 - RELAY

( SEE RATING PLATE )

P106380 G

WHT

C

XL

HI

YEL

BLU

RED

WHT/RED

N

8

5

WHT/RED

WHT/BLU

3

2

1

4

6

87 5

THERMAL SWITCH ( HSB )

GRN

11

BLK

BLK

ORN

TO

TIMED/MANUAL

SWITCH

( THRU SCS )

PRP

COND

TO

BLK

GRN

RED

BLK

RED

BLU

BLU

WHT/BLU

12

1

2

3

FILL

19993 - POWER SWITCH

104224 - TIMED/MANUAL SWITCH

20478 - 3 MIN TIMER

4 19994 - DESCALE INDICATOR RESET SW

5

106911 - DESCALE TIMER

6

108880 - DOOR SW (MAGNETIC)

7

105789 - THERMAL SWITCH ( HSB )

8

44168 - TERMINAL BLOCK

9

107239 - PROBE

10

107241 - WATER BOARD

11

22221 - DRAIN VALVE

Loading...

Loading...