Page 1

R-Series Data Center Products

User’s Guide

Rev G

Page 2

Technical Support

Please refer to our support website for technical updates, additional warranty

information and documentation, and software revisions:

Web: http://www.clearcube.com/support/

Email: support@clearcube.com

Phone: (512) 652-3400 or call toll free (866) 652-3400 (United States)

ClearCube Technology Corporate Headquarters

Mailing and Shipping Address:

ClearCube Technology, Inc.

3700 W Parmer Lane

Austin, TX 78727

Email: info@clearcube.com

Main Phone: (512) 652-3500 or call toll free (866) 652-3500 (United States)

Main Fax: (512) 652-3501

Or your local ClearCube Reseller or Authorized Service Provider

Copyrights

©2005 – 2012 by ClearCube Technology, Inc. All rights reserved. Under copyright

laws, this publication may not be reproduced or transmitted in any form, electronic or

mechanical, including photocopying, recording, storing in an information retrieval

system, or translating, in whole or in part, without the prior written consent of

ClearCube Technology, Inc.

This information is subject to change without notice and ClearCube shall not be liable

for any direct, indirect, special, incidental or consequential damages in connection

with the use of this material.

Trademarks

ClearCube™, Sentral™, Blade Switching BackPack™, PC Blade™, C/Port™, and

I/Port™, PC-over-Ethernet™, PCoE™, and the PCoE™ logo are trademarks of

ClearCube Technology Inc. Product and company names mentioned herein are

trademarks or trade names of their respective companies.

Patents

The ClearCube Architecture and its components described in this user manual are

protected by numerous granted and pending U.S. and international patents.

Granted patents include: US05926172, US05966056, US05994952, US06012101,

US06020839, US06037884, US06038616, US06119146, US06148182,

US06167241, US06385666, US06421393, US06426970, US06633934,

US06708247, US06735658, and US06886055.

Patents pending include: US S/N 09/755378, US S/N 10/279475, US S/N 10/19 871 9,

US S/N 10/198650, US S/N 10/409219, US S/N 09/728667, US S/N 09/728669, US

S/N 10/411804, US S/N 10/411908, US S/N 10/458853, US S/N 10/364584, US S/N

10/301536, US S/N 60/411066, US S/N 10/662933, US S/N 10/662889, US S/N

10/662932, US S/N 10/662968, US S/N 10/301563, US S/N 10/662936, US S/N

10/301518, US S/N 10/662955 and US S/N 10/662954.

Inquiries regarding patented technology should be directed to ClearCube Corporate

Headquarters.

Page 3

Contents

How to Use this Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

FCC Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

California Proposition 65 Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

WEEE Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .x

Warning Regarding Medical and Clinical Use of ClearCube Products. . . . . . . . . . . . . . . . . . .x

Avertissement concernant l'usage médical et clinique des produits ClearCube . . . . . . . . . . . .x

Warnung zum medizinischen oder klinischen Einsatz von ClearCube-Produkten . . . . . . . . . xi

El Cuidado con Respecto al Uso Médico y Clínico de los Productos de ClearCube. . . . . . . . xi

Symbols – English . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

Symboles – Français. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Guide de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Symbole – Deutsche. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Sicherheitsrichtlinien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

Símbolos – Español . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

Directrices de seguridad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

Chapter 1. ClearCube Architecture and Product Overview . . . . . . . . . . . . . . . . . . . . 1

R-Series PC Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

R-Series Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

C/Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Multi-Video Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Fiber Optic Extension System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Fiber Transceiver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

C7420 Fiber C/Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Zero Clients and Thin Clients. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Chapter 2. Network Planning and Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . 11

Rack and Cabinet Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Space and Floor Support Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Power and Cooling Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Additional Power Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Additional Cooling and HVAC Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Free IP Address Requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

R-Series Data Center Products User’s Guide Contents • iii

Page 4

Chapter 3. Chassis and Blade Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Tools for Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Shipment Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Chassis Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Unpacking the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installing the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Standard Chassis Mounting Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chassis Rapid Mount Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Chassis Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chassis Power Receptacles, Redundant Power, and Power Cords . . . . . . . . . . . . . . . . . 24

Chassis Configuration and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

R4300 Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Power Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Connecting Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Spare Allocation Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

R4300 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Mixed-Mode Chassis Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

R3040S Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

NICs When Using a Traditional Video Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

NICs When Using a V52x0 PCoIP Host Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

How OS Network Connections Are Mapped to NICs on Chassis Backpack. . . . . . . . . . 41

MAC Address Label on R-Series Blades. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

R3040S Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

R3080D Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

R1350 Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

C/Port Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

R3080D Cabling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

How OS Network Connections Are Mapped to NICs on Chassis Backpack. . . . . . . . . . 44

C/Port Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

RMM Firmware Update Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Updating RMM Firmware Using Telnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Updating RMM Firmware with Sentral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Remote Management Card Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Control Chain Auto-Negotiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Configuring the RMM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Resetting the RMM Settings to the Factory Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Configuring the RMC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Changing the IP Address of the RMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Resetting the RMC IP Settings to the Factory Defaults . . . . . . . . . . . . . . . . . . . . . . 55

iv • Contents R-Series Data Center Products User’s Guide

Page 5

R4300 Chassis Upgrade Kit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Fiber Transceiver and Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

PC Blade Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Unpacking the PC Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Installing PC Blades. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Connecting Ethernet Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

R3040S Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

R3080D Video Options and Ethernet Port Behavior . . . . . . . . . . . . . . . . . . . . . . . . .61

R1350 Video Options and Ethernet Port Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Using USB 2.0 Capability on the R3040S and R1350 . . . . . . . . . . . . . . . . . . . . . . . . . . .61

R1350 Monitor Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

R3080D and R3040S Display Support and Configuration . . . . . . . . . . . . . . . . . . . . . . . .62

Graphics Options and Number of Displays Supported . . . . . . . . . . . . . . . . . . . . . . . .62

Configuring Multiple DVI-I Displays with V52x0 PCoIP Host Cards. . . . . . . . . . . .62

Video Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Changing CMOS Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Resetting an R1350 CMOS Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Clearing All R3080D and 3040S CMOS Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Configuring RAID on an R3040S Blade. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Prerequisites and Overview of Required RAID Tasks . . . . . . . . . . . . . . . . . . . . . . . .66

Enable RAID in BIOS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Creating a RAID Volume Using Software RAID. . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Installing a Windows OS on a RAID Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Removing a PC Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Mass Storage Lockout: Disabling Access to USB Mass Storage Devices . . . . . . . . . . . .71

Re-installing System Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Flashing the Blade BIOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Chapter 4. Hardware Upgrade and Replacement Procedures. . . . . . . . . . . . . . . . . 77

Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Upgrading Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Model R3040S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Model R3080D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Important Installation Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Installing 2 DIMMs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Installing 3 DIMMs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Installing 4 DIMMs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Model R1350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Replacing and Upgrading Hard Disks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

R3040S Hard Disks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

R-Series Data Center Products User’s Guide Contents • v

Page 6

R3040S Hard Disk Tray, Drive Layout, and SATA Headers on Motherboard. . . . . 85

Replacing an R3040S Hard Disk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

R3080D Hard Disk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

R1350 Hard Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Replacing CPU Fans. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

R3040S Fans. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

R3080D Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Replacing a Front LCD Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Replacing the CMOS Memory Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Replacing Blade Interposer Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

R3040S Interposer Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

R3080D and R1350 Interposer Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Replacing R4300 Management, Connect and Network Modules. . . . . . . . . . . . . . . . . . . . . 105

Replacing the R4300 Fan Pack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Replacing an R4300 Power Supply Unit (PSU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Chapter 5. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

PCoIP Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

PCoIP Host on Different Subnet Than PCoIP Client Is Unable to Wake Up from Various

Power States. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Power Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

No power to PC blade. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

No video or link lights at desktops and no power to blades. . . . . . . . . . . . . . . . . . . . . . 108

Chassis power does not come on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Video Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Digital link shows red at blade but green on C/Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Fiber Optic Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

No video and/or digital link present. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

The monitor’s Auto-Adjust does not give a clear, sharp image. . . . . . . . . . . . . . . . . . . 109

Network and PXE Booting Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Unable to network or PXE boot using an R3040S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Appendix A. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

R-Series Blades. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

R4300 Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

F6150–160 Fiber Transceiver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Appendix B. Regulatory Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Appendix C. Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Product Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

vi • Contents R-Series Data Center Products User’s Guide

Page 7

Return Merchandise Authorization (RMA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

Fuse and Power Cord Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

Appendix D. Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Appendix E. Waste Electrical and Electronic Equipment Directive (WEEE) . . . . 125

WEEE Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

Informations sur la DEEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

Informationen über WEEE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

La información de REEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

R-Series Data Center Products User’s Guide Contents • vii

Page 8

viii • Contents R-Series Data Center Products User’s Guide

Page 9

Introduction

How to Use this Guide

Thank you for purchasing your quality ClearCube products. The ClearCube

Architecture was developed to bring you unprecedented levels of manageability,

security, reliability, and space savings. The ease of use of ClearCube’s products will

make installation straightforward.

This manual provides all the product and installation information needed to set up and

run ClearCube Technology’s R-Series architecture for managed desktop

environments. We recommend that you familiarize yourself with the ClearCube

Architecture and product descriptions and read through the entire installation and

setup procedures before beginning installation.

If you encounter any problems, please contact our Technical Support using the contact

information provided on the inside front cover of this manual and in Appendix C on

page 117.

FCC Warning

This equipment generates and uses radio frequency energy and, if not installed and

used in strict accordance with the instructions in this manual, may cause interference

to radio and television reception. Changes or modifications not expressly approved by

ClearCube Technology could void the user's authority to operate the equipment under

the FCC Rules.

California Proposition 65 Statement

WARNING: ClearCube products contain chemicals, including lead,

known to the State of California to cause cancer, birth defects, or

other reproductive harm. Wash hands after handling.

ClearCube products should be disposed of in accordance with local laws governing

computer equipment disposal.

R-Series Data Center Products User’s Guide Introduction • ix

Page 10

WEEE Information

See “Appendix E.Waste Electrical and Electronic Equipment Directive (WEEE)” on

page 125 for detailed information about the Waste Electrical and Electronic

Equipment Directive.

Warning Regarding Medical and Clinical Use of

ClearCube Products

ClearCube products are not designed with components and testing for a level of

reliability suitable for use in or in connection with surgical implants or as critical

components in any life support systems whose failure to perform can reasonably be

expected to cause significant injury to a human. Applications of ClearCube products

involving medical or clinical treatment can create a potential for death or bodily injury

caused by product failure, or by errors on the part of the user. Because each end-user

system environment is customized and differs from ClearCube testing platforms and

because a user may use ClearCube products in combination with other products in a

manner not evaluated or contemplated by ClearCube, the user is ultimately responsible

for verifying and validating the suitability of ClearCube products whenever ClearCube

products are incorporated in a system, including, without limitation, the appropriate

design, process and safety level of such system or application.

Avertissement concernant l'usage médical et clinique

des produits ClearCube

Les produits ClearCube ne sont pas conçus pour être utilisés avec une efficacité adéquate dans ou avec des implants chirurgicaux ou dans des appareils de maintien de vie

pour lesquels toute panne causerait de sérieux problèmes de santé ou blessures à l'être

humain. Les applications des produits de ClearCube dans des traitements médicaux ou

cliniques peuvent être dangereuses et toute panne du produit ou erreur de l'utilisateur

peuvent provoquer la mort ou des blessures. Du fait que l'environnement de chaque utilisateur final est unique et diffère de celui des plate-formes de tests de ClearCube, et que

l'utilisateur peut employer les produits ClearCube avec d'autres appareils d'une manière

qui n'a pas été évaluée ou envisagée par ClearCube, l'utilisateur est entièrement responsable de la vérification et de la confirmation de la compatibilité des produits ClearCube

lorsqu'ils sont incorporés dans un système, incluant, sans limitations, le concept approprié, le procédé et le niveau de sécurité des dits systèmes ou applications.

x • Introduction R-Series Data Center Products User’s Guide

Page 11

Warnung zum medizinischen oder klinischen Einsatz

von ClearCube-Produkten

ClearCube-Produkte sind nicht für Komponenten oder zum Testen geeignet, bei denen

eine Betriebssicherheit gewährleistet sein muss, die bei der Verwendung mit oder im

Zusammenhang mit chirurgischen Implantaten oder als kritische Komponenten in jeglicher Art von Lebenserhaltungssystemen einher geht, bei denen ein Funktionsausfall

eine ernstzunehmende Verletzung eines Menschen zur Folge haben kann. Die

Anwendung von ClearCube-Produkten bei medizinischen oder klinischen Behandlungen kann potentiell zum Tode oder zu Verletzungen bei Funk t ionsausfällen des Produkts oder bei Bedienungsfehlern durch den Benutzer führen. Da jede

Endbenutzerumgebung speziell angepasst ist und sich von ClearCube-Testplattformen

unterscheidet, und da ein Benutzer ClearCube-Produkte zusammen mit anderen Produkten auf eine nicht von ClearCube in Betracht gezogene Art verwenden kann, liegt die

endgültige Verantwortung über die Prüfung und Validierung der Eignung von ClearCube-Produkten beim Benutzer, wenn ClearCube-Produkte in ein System eingebunden

sind, einschließlich und ohne Einschränkung, das geeignete Design, der Prozess und die

Sicherheitsebene eines solchen Systems oder einer solchen Anwendung.

El Cuidado con Respecto al Uso Médico y Clínico de los

Productos de ClearCube

Productos de ClearCube no son diseñados con componentes aprobados para un nivel

de certeza adecuada para el uso en o con respecto a injertos quirúrgicos o

componentes críticos en ningún sistema de apoyo de vida, cuyo fracaso para actuar, se

puede esperar razonablemente causar una herida significativa a un humano. Las

aplicaciones de productos de ClearCube, el tratamiento médico, o clínico, que

implica, puede crear un potencial para la muerte o en herida personal causada por el

fracaso del producto, o por errores por parte del usuario. Porque cada ambiente de

sistema de usuario es construido al gusto del comprador y difiere en plataformas de

prueba de ClearCube y porque un usuario puede usar los productos de ClearCube en la

combinación con otros productos en una manera no evaluada ni contemplada por

ClearCube, el usuario es últimamente responsable de verificar y validar lo apropiado

de los productos de ClearCube cuando los productos de ClearCube se incorporan en

un sistema, incluyendo, sin limitación, el diseño apropiado, el nivel del proceso, y la

seguridad de tal sistema o la aplicación.

Symbols – English

Symbols are used on the equipment to convey specific information to the operator and

service person. It is important to understand the intended meaning of these symbols.

R-Series Data Center Products User’s Guide Introduction • xi

Page 12

Below are the graphical symbols that are used on ClearCube Technology, Inc.

Products and their meaning.

Refer to Manual

Used on the equipment’s rating label to direct the operator or service

person to the manual for additional information.

Shock Hazard

This symbol indicates the presence of electric shock hazards. Enclosures

marked with these symbols should only be opened by qualified service

personnel. Refer to the manual for additional information.

Power

Identifies the soft-start switch located on front of the blade, used to power

the blade on and off.

Fuse

Located on equipment rating label. Symbol is accompanied with the

specifications needed for replacement. Only qualified technicians should

perform this operation.

Protective Earth Terminal

This symbol identifies the location of the protective earth terminal on the

equipment. This terminal is used to connect the protective earth conductor

of the power cord to the building's electrical distribution system's ground.

Ground Bond Terminal

This symbol identifies the location ground bond terminal. This terminal is

used to connect the ground bonding conductor, or the combination of

conductive parts to earth ground for safety purposes.

Equipment Protection Class II

May be located on the power adapter’s rating label. Indicates that

equipment is double insulated from hazardous voltages. Not to be

confused with “Class 2” that is a US National Electrical Code (NEC) circuit

classification.

These same symbols are used within this document where appropriate to indicate

situations that merit checking this or another manual, or situations that could result in

damage to equipment or physical injury.

CAUTION: A Caution notice in this manual indicates that equipment

damage or minor injury may result if proper procedures are not followed.

xii • Introduction R-Series Data Center Products User’s Guide

Page 13

WARNING: A Warning notice in this manual indicates that catastrophic

equipment damage, or serious injury including death may result if

proper procedures are not followed.

Safety Guidelines

Before undertaking any troubleshooting or maintenance procedure, read carefully all

WARNING and CAUTION notices. This equipment contains voltage hazardous to

human life and is capable of inflicting personal injury.

• Installations – ClearCube equipment is required to be installed in accordance

with the local electrical codes and may be subject to inspection by the authority

having jurisdiction.

• Chassis Grounding – ClearCube’s chassis and Fiber Transceiver have been

designed with a three-conductor IEC 60320 appliance inlet that – with the proper

power cord – connects the building’s external protective earthing conductor to all

accessible metal parts of the enclosure. To minimize shock hazard, make sure

your electrical power outlet has an appropriate earth safety ground that is

connected each time you power on the equipment.

Swedish safety regulations require the following statement:

—Apparaten skall anslutas till jordat uttag när den anslutas till ett nätuerk.—

Finnish safety regulations require the following statement:

— Laite on liitettävä suojamaadoituskoskettimilla varustettuun pistorasiaan.—

• Power Cord Selection – ClearCube or ClearCube’s Distributors provides power

cords that are specifically designed for use with that particular piece of equipment

and are approved for use by the local authority having jurisdiction in the country

where the equipment is put into service. Please refer to the installation sections of

this manual for specific power cord requirements. For replacement of power

cords, refer to Appendix C – Technical Support.

• Power Adapters – ClearCube or ClearCube’s Distributors provides power

adapters that are specifically designed for use with that particular piece of

equipment and are approved for use by the local authority having jurisdiction in

the country where the equipment is put into service. Please refer to the installation

sections of this manual for specific power cord requirements. For replacement of

power cords, refer to Appendix C – Technical Support.

• IT Power Systems – ClearCube equipment has been evaluated and found to be

compatible with IT power distribution systems with a phase-to-phase voltage not

to exceed 240 V.

R-Series Data Center Products User’s Guide Introduction • xiii

Page 14

•Live Circuits – Operating personnel and service personnel must not remove

protective covers when operating the ClearCube chassis. Adjustments and service

to internal components must be undertaken by qualified service technicians.

During any service of this product other than replacing a PC blade or externally

accessible modules on the chassis, the main connector to the premise wiring must

be disconnected. Dangerous voltages may be present under certain conditions.

Use extreme caution.

• Explosive Atmosphere – Do not operate the chassis in conditions where

flammable gases are present. Under such conditions this equipment is unsafe and

may ignite the gases or gas fumes.

• Part Replacement – Only service equipment with parts that are exact

replacements, both electrically and mechanically. Contact ClearCube Technology

for replacement part information. Installation of parts that are not direct

replacements will void the warranty and may cause harm to personnel operating

the chassis. Furthermore, damage or fire may occur if replacement parts are

unsuitable.

• Modification – Do not modify any part of the C/Port, chassis, or PC blade from

its original condition. Modifications may result in hazards.

• Laser Safety – The Fiber Transceiver and the Fiber C/Port have been evaluated

and certified to an EN 60825-1 – Safety of laser products. Refer to Appendix B

for more details.

CAUTION: Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

ClearCube Technology products that use lasers display the following graphic on the

rating label:

Marked devices comply with the FDA code of Federal 21 CFR 1040 per Notice 50

and/or the Canadian Radiation Emitting Devices Act REDR C1370.

Symboles – Français

Les symboles sur l'appareil indiquent des informations spécifiques à l'intention de

l'utilisateur ou d'un technicien de mainte nance. Il est important de bien comprendre la

xiv • Introduction R-Series Data Center Products User’s Guide

Page 15

signification de ces symboles. Les symboles graphiques et leur signification,

ci-dessous, sont utilisés sur les produits de ClearCube Technology, Inc.

Se reporter au manuel

Ce symbole sur l'étiquette d'identification de l'appareil est destiné à

attirer l'attention de l'utilisateur ou du technic i en de main te na nc e su r

les renseignements supplémentaires portés sur le manuel.

Risque de choc

Ce symbole indique la présence des risques de décharge électrique.

Des clôtures identifiées par ces symboles devraient seulement être

ouvertes par le personnel de service qualifié. Se référer au manuel

pour l'information additionnelle.

Attente

Un symbole correspondant à chaque lame se trouve sur le devant du

châssis. Le bouton pour démarrage Soft Start active chaque lame

particulière.

Fusible

Voir l'étiquette d'identification de l'appareil. Le symbole est

accompagné des spécifications nécessaires au remplacement du

fusible. Seul un technicien qualifié devrait effectuer cette opé ra tio n.

Protection à la terre

Ce symbole identifie la borne utilisée pour connecter toutes les pièces

métalliques de la boîte par un conducteur externe vers la masse, afin

de protéger l'appareil contre les chocs électriques en cas de panne.

Borne en esclavage au sol

Ce symbole identifie la borne de lien d'au sol d'endroit. Cette borne

est utilisée pour relier le conducteur moulu de liaison, ou la

combinaison des pièces conductrices pour mettre à la terre la terre

pour la sûreté.

Protection d'équipement Classe II

L'information est souvent située sur l'étiquette d'identification de

l'alimentation. Elle indique que l'appareil est doublement isolé contre

les surtensions dangereuses. Ne pas confondre avec la mention

“Class 2” qui est une classification de circuit du NEC américain

(National Electrical Code).

Tous ces symboles sont utilisés dans ce document aux chapitres appropriés, afin

d'indiquer les situations qui demandent une vérification ou la consultation d'un autre

manuel, ou dans des situations qui risqueraient d'endommager l'appareil ou de

provoquer des blessures à l'utilisateur.

R-Series Data Center Products User’s Guide Introduction • xv

Page 16

PRÉCAUTION : une note de précaution indique que l'appareil peut être

endommagé ou que l'utilisateur risque d'être légèrement blessé si les

procédures correctes ne sont pas suivies.

ATTENTION : ce message indique que l'appareil pourrait être sérieusement

endommagé ou que de graves blessures ou la mort peuvent résulter au cas

où les procédures correctes ne seraient pas suivies.

Guide de sécurité

Avant de dépanner ou de commencer des opérations de main tenance, veuillez lire

attentivement tous les messages sous les rubriques ATTENTION et PRÉCAUTION.

La tension de cet équipement est dangereuse pour l'être humain et peut provoquer des

blessures.

• Installations – L'équipement de ClearCube doit être installé en conformité avec

les codes électriques locaux et est sujet à une inspection par les autorités

compétentes.

• Mise à la masse du châssis – Le châssis et le transceiver fibre de ClearCube ont

été conçus avec un socle de connecteur trois conducteurs IEC 60320 qui, avec le

cordon d'alimentation adéquat, connecte la masse protectrice externe du bâtiment

à toutes les parties métalliques du châssis. Afin de réduire les risques

d'électrocution, assurez-vous que votre prise électrique est bien connectée à la

masse chaque fois que vous branchez l'appareil.

Les règlements de sûreté de la Suède exigent le rapport suivant :

—Apparaten skall anslutas till jordat uttag när den anslutas till ett nätuerk.—

Les règlements de sûreté de la Finlande exigent le rapport suivant :

— Laite on liitettävä suojamaadoituskoskettimilla varustettuun pistorasiaan.—

• Choix du câble d'alimentation – ClearCube ou ses distributeurs fournissent des

câbles d'alimentation conçus spécialement pour ce type d'équipement et qui ont

été approuvés par les autorités locales compétentes du pays de mise en service.

Veuillez vous référer au chapitre sur l'installation pour en savoir plus sur le type de

câble d'alimentation spécifique requis. Pour le remplacement des cordons

d'alimentation, consulter Annexe C – Support Technique (Appendix C – Technical

Support).

• Adaptateurs – ClearCube ou ses distributeurs fournissent des adaptateurs conçus

spécialement pour ce type d'équipement et qui ont été approuvés par les autorités

locales compétentes du pays de mise en service. Veuillez vous référer au chapitre

sur l'installation pour en savoir plus sur le type de câble d'alimentation spécifique

xvi • Introduction R-Series Data Center Products User’s Guide

Page 17

requis. Pour le remplacement des cordons d'alimentation, consulter Annexe C –

Support Technique (Appendix C – Technical Support).

• Système d'alimentation IT – L'équipement ClearCube a été évalué et déclaré

compatible avec les systèmes de distribution d'alimentation IT d'une tension

composée d'un réseau triphasé ne devant pas dépasser 240 V.

• Circuits sous tension – Les agents installateurs et de maintenance ne doivent pas

enlever les caches protecteurs lorsqu'ils travaillent sur le châssis ClearCube. Les

ajustements ou réparations sur les composants internes doivent être effectués par

des techniciens qualifiés. Pour tout service sur cet appareil, à l'exception du

remplacement d'une lame PC ou du module de ventilati on, le connecteur princip al

doit être débranché. Sous certaines conditions, les tensions présentes peuvent être

dangereuses. Soyez extrêmement prudent.

• Atmosphère explosive – Ne pas faire fonctionner le châssis si des gaz

inflammables sont présents. Dans ces conditions, cet équipement est dangereux et

risque d'enflammer les gaz ou vapeurs gazeuses.

• Remplacement des pièces – Utiliser uniquement des pièces parfaitement

conformes, tant au niveau électrique que mécanique. Contacter ClearCube

Technology pour tout renseignement sur les pièces détachées. L'installation de

pièces qui ne sont pas parfaitement semblables annulera la garantie et risque de

causer des blessures au personnel travaillant sur le châssis. De plus, les pièces non

conformes peuvent provoquer des dégâts ou un incendie.

• Modification – Ne modifier aucun élément d'origine du C/Port, du châssis ou du

PC lame. Toute modification peut constituer un danger.

• Sécurité du laser – Le transceiver fibre et le C/Port ont été évalués et certifiés

conformes à la norme EN 60825-1 – Sécurité des appareils à laser. Consulter

l'Annexe B pour plus de renseignements.

PRÉCAUTION : Une utilisation de commandes, un ajustement ou

fonctionnement par des procédures différentes de celles spécifiées dans

ce document peuvent provoquer une irradiation dangereuse.

L'étiquette ci-dessous est apposée sur les appareils de ClearCube Technology qui

utilisent un affichage laser :

Les appareils ainsi identifiés sont en conformité avec le code FDA "Federal 21 CFR

1040, Notice 50" et/ou le "Canadian Radiation Emitting Devices Act REDR C1370".

R-Series Data Center Products User’s Guide Introduction • xvii

Page 18

Symbole – Deutsche

Symbole auf den Geräten geben dem Benutzer und dem Wartungspersonal bestimmte

wichtige Informationen. Es ist wichtig, die beabsichtigte Bedeutung dieser Symbole

zu verstehen. Die nachstehend angezeigten Symbole verweisen auf die durch

ClearCube Technology, Inc. verwendeten Symbole und ihre Bedeutungen.

Nähere Angaben im Handbuch

Wird auf dem Gerätebewertungsetikett verwendet, um den Benutzer

oder das Wartungspersonal auf weitere Informationen im Handbuch

aufmerksam zu machen.

Schlag-Gefahr

Dieses Symbol zeigt das Vorhandensein der Gefahren des

elektrischen Schlages an. Die Einschließungen, die mit diesen

Symbolen gekennzeichnet werden, sollten von qualifiziertem

Service-Personal nur geöffnet werden. Auf das Handbuch zu

zusätzlicher Information sich beziehen.

Bereitstehen

Ein Symbol wird für jedes an der Vorderseite des Käfigs angebrachte

Blade verwendet. Der Soft Start-Schalter, der das jeweilige Blade

einschaltet.

Sicherung

Befindet sich auf dem Gerätebewertungsetikett. Das Symbol wird von

den Spezifikationen zum Austausch begleitet. Dieser Vorgang sollte

nur durch qualifiziertes Fachpersonal ausgeführt werden.

Schützender Masse Anschluß

Kennzeichnet die Klemme, die alle Metallteile des Gehäuses durch

einen externen Leiter mit der Masse verbindet, um so eine Erdung

zum Schutz gegen elektrische Stromschläge bei einer Fehlersituation

herzustellen.

Grundbondanschluß

Dieses Symbol kennzeichnet die Position des

Grundbondanschlusses. Dieser Anschluß wird benutzt, um den

Grundabbindenleiter oder die Kombination der leitenden Teile

anzuschließen, um Boden zu den Sicherheit Zwecken mit Erde zu

bedecken.

Geräteschutzklasse II

Befindet sich auf dem Gerätebewertungsetikett. Gibt an, dass das

Gerät doppelt gegen gefährliche Spannungen isoliert ist. Die ist nicht

mit der “Class 2”-Schaltkreisklassifizierung des US National Electrical

Code (NEC) zu verwechseln.

Diese Symbole werden im Dokument verwendet, um auf Situationen hinzuweisen, in

denen dieses oder ein weiteres Handbuch zu Rate gezogen werden sollten, oder falls

die Möglichkeit von Schäden oder Verletzungen besteht.

xviii • Introduction R-Series Data Center Products User’s Guide

Page 19

VORSICHT: Ein Vorsichtshinweis weist darauf hin, das Geräteschäden

oder geringe Verletzungen bei unsachgemäßer Bedienung erfolgen

können.

WARNUNG: Ein Warnhinweis weist darauf hin, das vollständige

Geräteschäden oder schwere Verletzungen einschließlich des Todes bei

unsachgemäßer Bedienung erfolgen können.

Sicherheitsrichtlinien

Vor der Durchführung von Fehlerbehebungs- oder Wartungsarbeiten sollten Sie alle

WARNUNGS- und VORSICHTSHINWEISE genau durchlesen. Dieses Gerät weist

Spannungen auf, die zu Todesfällen und persönlichen Verletzungen führen können.

• Installationen – ClearCube-Geräte müssen in Übereinstimmung mit den

örtlichen elektrischen Richtlinien installiert werden und unterliegen unter

Umständen der Überwachung durch die jeweiligen Behörden.

• Gehäuseerdung – ClearCubes Chassis und Glasfaser-Transceiver wurden mit

einem Dreifachleiter-IEC 60320-Gerätesteckeingang entwickelt, welches anhand

eines geeigneten Netzkabels den externen Schutzmasseleiter des Gebäudes mit

allen zugänglichen Metallteilen des Gehäuses verbindet. Um die Gefahr eines

elektrischen Schlags zu minimieren, stellen Sie sicher, dass der Netzausgang eine

geeignete Sicherheitserdungsmasse aufweist, die bei jedem Einschalten des

Gerätes damit verbunden ist.

Sicherheit Regelungen von Schweden erfordern die folgende Aussage:

—Apparaten skall anslutas till jordat uttag när den anslutas till ett nätuerk.—

Sicherheit Regelungen von Finnland erfordern die folgende Au ssage:

— Laite on liitettävä suojamaadoituskoskettimilla varustettuun pistorasiaan.—

• Netzkabelauswahl – ClearCube oder der ClearCube Vertrieb bieten Netzkabel

an, die jeweils für das bestimmte Gerät entwickelt wurden und deren Verwendung

durch die örtlichen Behörden des jeweiligen Landes, in dem das Gerät betrieben

wird, genehmigt ist. Genaue Netzkabelanforderungen entnehmen Sie bitte den

Installationsabschnitten in diesem Handbuch. Nähere Angaben zur Auswechslung

von Netzkabeln finden Sie im Anhang C – Technischer Support (Appendix C –

Technical Support).

• Netzadapter – ClearCube oder der ClearCube Vertrieb bieten Netzadapter an, die

jeweils für das bestimmte Gerät entwickelt wurden und deren Verwendung durch

die örtlichen Behörden des jeweiligen Landes, in dem das Gerät betrieben wird,

genehmigt ist. Genaue Netzkabelanforderungen entnehmen Sie bitte den

Installationsabschnitten in diesem Handbuch. Nähere Angaben zur Auswechslung

R-Series Data Center Products User’s Guide Introduction • xix

Page 20

von Netzkabeln finden Sie im Anhang C – Technischer Support (Appendix C –

Technical Support).

• IT-Leistungssysteme – ClearCube-Geräte wurden ausgewertet und kompatibel

zu IT -Leistungsv erteilungssystemen mit einer Phasenspannung von ni cht mehr als

240 V befunden.

• Angeschlossene Stromkreise – Betriebs- und Wartungspersonal sollten die

Schutzabdeckungen nicht entfernen, wenn der ClearCube Chassis in Betrieb ist.

Justierungen und Wartungsarbeiten an internen Komponenten sollten nur durch

qualifiziertes Fachpersonal vorgenommen werden. Der Hauptanschluss muss

während allen Wartungsarbeiten an diesem Produkt, außer dem Austausch eines

PC-Blades oder des Lüftereinsatzes, vom Netz getrennt werden. Unter

bestimmten Bedingungen können gefährliche Spannungen vorhanden sein.

Vorsicht ist angezeigt.

• Explosive Umgebung – Betreiben Sie den Chassis nicht in Umgebungen, in

denen entflammbare Gase vorhanden sind. Der Betrieb des Gerätes in solch en

Umgebungen ist unsicher und kann die Gase entzünden.

• Teileersatz – Geräte sollten nur mit elektrischen und mechanischen Teilen, die

exakte Ersatzteile sind, gewartet werden. Wende n Sie sich an Cle arCube

Technology, um Ersatzteilinformationen zu erhalten. Die Installation von Teilen,

die nicht direkte Ersatzteile sind, hat ein Erlöschen des Garantieanspruches zur

Folge und kann dem Benutzungspersonal des Gehäuses Schaden zufügen.

Weiterhin können ungeeignete Ersatzteile Schäden sowie Brandschäden

hervorrufen.

• Modifizierungen – Das C/Port, Chassis oder PC Blade darf in keiner Weise vom

Originalzustand geändert werden. Modifizierungen können Risiken hervorrufen.

• Lasersicherheit – Der Glasfaser-Transceiver und das Glasfaser-C/Port wurden

ausgewertet und entsprechen der Richtlinie EN 60825-1 – Sicherheit von

Laserprodukten. Nähere Angaben finden Sie im Anhang B.

VORSICHT: Die Bedienung oder das Vornehmen von Justierungen oder

Vorgängen entgegen der hier aufgeführten können eine gefährliche

Laserstrahlungsbelastung zur Folge haben.

ClearCube Technology-Produkte, die Laser verwenden, weisen das folgende Symbol

auf dem Gerätebewertungsetikett auf:

Gekennzeichnete Geräte entsprechen dem FDA Code of Federal 21 CFR 1040 per

Notice 50 und/oder dem Canadian Radiation Emitting Devices Act REDR C1370.

xx • Introduction R-Series Data Center Products User’s Guide

Page 21

Símbolos – Español

Los símbolos se usan en el aparato para comunicar información específica a el

operador y a la persona de servicio. Es importante entender la intención del

significado de estos símbolos. Abajo se muestran los símbolos gráficos que se usan en

los productos ClearCube Technology, Inc., así como su significado.

Consultar el manual

Se usa en la etiqueta de especificaciones del aparato para dirigir al

operador o persona de servicio a que consulte el manual para

información adicional.

Peligro de choque

Este símbolo indica la presencia de los peligros de la descarga

eléctrica. Los recintos marcados con estos símbolos se deb en abrir

solamente por el personal de servicio cualificado. Referi r al man ual

para la información adicional.

Hacer una pausa

Un símbolo que se usa para cada blade o bandeja instalada,

localizado enfrente de el chassis. Switch de inicio suave usado para

encender cada blade en particular.

Fusible

Localizado en la etiqueta de especificaciones del aparato. El

símbolo está acompañado de las especificaciones necesarias para

su reemplazo. Solamente técnicos calificados deben de realizar

esta operación.

Terminal a tierra protectiva

Identifica a la terminal que se usa para conectar todas las partes

metálicas del gabinete a través de un conductor externo para

conectar a tierra y proteger contra descarga eléctrica en caso de

una condición de falla.

Terminal en enlace de tierra

Este símbolo identifica la localización del terminal en enlace de

tierra. Este terminal se utiliza para conectar el conductor de tierra

de la vinculación, o la combinación de piezas conductoras para

conectar a tierra la tierra para los propósitos de seguridad.

Protección del aparato Clase II

Puede estar localizado en la etiqueta de especificaciones en el

adaptador de corriente. Indica que el aparato tien e aislamiento

doble para voltajes peligrosos. No confundirlo con la "Clase 2" que

es una clasificación de circuito NEC de E.U. (National Electrical

Code).

R-Series Data Center Products User’s Guide Introduction • xxi

Page 22

Estos mismos símbolos se usan en este documento cuando es apropiado para indicar

situaciones que ameritan revisar este u otro manual, o que pudieran resultar en daño al

aparato o lesión física.

PRECAUCIÓN: Un aviso de Precaución indica que puede ocurrir daño al

aparato o lesiones menores si no se siguen los procedimientos

adecuados.

ADVERTENCIA: Un aviso de Advertencia indica que puede ocurrir daño

fatal al aparato, o lesiones serias incluyendo la muerte si no se siguen

los procedimientos adecuados.

Directrices de seguridad

Antes de llevar a cabo cualquier procedimiento de diagnostico de fallas o

mantenimiento, lea cuidadosamente todas los avisos de ADVERTENCIA y

PRECAUCIÓN. Este aparato contiene voltaje peligroso para el cuerpo humanos y

tiene la capacidad de infligir lesiones personales.

• Instalaciones – Se requiere que los aparatos de ClearCube se instalen de acuerdo

con los códigos eléctricos locales y pueden estar sujetos a inspección por las

autoridades en jurisdicción.

• Conexión a tierra del chasis – El chassis de ClearCube y el Transceptor de Fibra

han sido diseñados con una entrada de aparato con tres conductores IEC 60320

que (con el cable de alimentación apropiado) conecta al conductor aterrizado

externo protectivo de construcción a todas las partes accesibles de metal del

gabinete. Para minimizar el peligro de descarga eléctrica, asegure que su toma de

corriente eléctrica tiene una conexión a tierra de seguridad apropiada cada vez que

usted enciende el aparato.

Las regulaciones de seguridad de Suecia requieren la declaración siguiente:

—Apparaten skall anslutas till jordat uttag när den anslutas till ett nätuerk.—

Las regulaciones de seguridad de Finlandia requieren la declaración siguiente:

— Laite on liitettävä suojamaadoituskoskettimilla varustettuun pistorasiaan.—

• Selección del cable de alimentación – ClearCube o distribuidores de ClearCube

proveen de cables de alimentación que están específicamente diseñados para

usarse con la pieza del aparato en particular y están aprobados para su uso por las

autoridades en jurisdicción en el país donde el aparato se pone en servicio. Por

favor consulte las secciones de instalación de este manual para los requerimientos

específicos de los cables de alimentación. Para el reemplazo de los cables de

alimentación, consulte el Apéndice C – Soporte Técnico (Appendix C – Technical

Support).

xxii • Introduction R-Series Data Center Products User’s Guide

Page 23

• Adaptadores de alimentación – ClearCube o distribuidores de ClearCube

proveen de adaptadores de alimentación que están específicamente diseñados para

usarse con la pieza del aparato en particular y están aprobados para su uso por las

autoridades en jurisdicción en el país donde el aparato se pone en servicio. Por

favor consulte las secciones de instalación de este manual para los requerimientos

específicos de los cables de alimentación. Para el reemplazo de los cables de

alimentación, consulte el Apéndice C – Soporte Técnico (Appendix C – Technical

Support).

• Sistemas de alimentación eléctricos IT – El equipo ClearCube ha sido evaluado

y es compatible con sistemas de alimentación eléctricos de distribución IT con un

voltaje "fase a fase" que no exceda 240 V.

• Circuitos vivos – Personal de operación y de servicio no deben de remover las

cubiertas protectivas cuando estén operando el ClearCube chassis. Ajustes y

servicio a componentes internos deben de realizarse por técnicos de servicio

calificados. Durante cualquier servicio a los productos excluyendo el reemplazo

de la PC blade y la bandeja del ventilador, el conector principal al cableado local

se debe de desconectar. Voltajes peligrosos pueden estar presentes bajo ciertas

circunstancias. Use extrema precaución.

• Atmósfera explosiva – No opere el chassis en condiciones donde gases

inflamables estén presentes. Bajo tales condiciones este aparato no es seguro y

puede encender los gases o vapores de gases.

• Reemplazo de partes – El servicio al aparato debe de ser con partes que son de

reemplazo exacto, mecánica y eléctricamente. Comuníquese con ClearCube

T echnology para información sobre partes de reemplazo. Instalación de partes que

no son reemplazos directos cancelarán la garantía y pueden causar daño al

personal que opera el chasis. Además, puede ocurrir daño o fuego si las partes de

reemplazo son inapropiadas.

• Modificación – No modifique de su condición original ninguna parte de el

C/Port, chassis, o PC Blade. Las modificaciones pueden resultar peligrosas.

• Seguridad del láser – El Transceptor de Fibra y el C/Port han sido evaluados y

certificados a un EN 60825-1 – seguridad de productos láser. Consulte el

Apéndice B para más detalles.

PRECAUCIÓN: El uso de controles, ajustes o rendimiento de los

procedimientos, diferentes a los especificados en este documento

puede resultar en exposición a radiación peligrosa.

Productos de ClearCube Technology que usan láser muestran el siguiente gráfico en la

etiqueta de especificaciones.

R-Series Data Center Products User’s Guide Introduction • xxiii

Page 24

Los dispositivos marcados cumplen con el código federal FDA 21 CFR 1040 por

notificación 50 y/o el acta canadiense REDR C1370 para dispositivos con emisión de

radiación.

xxiv • Introduction R-Series Data Center Products User’s Guide

Page 25

Chapter 1. ClearCube Architecture

and Product Overview

The ClearCube architecture delivers Intel®-based PC functionality to the desktop

from a secure, centralized location. This architecture provides significant increases in

manageability and security while providing mission-critical reliability, performance,

and uptime improvements with lowered costs. Replacing a traditional PC box with a

ClearCube C/Port or client in an office or cubicle saves space, eliminates fan noise,

and simplifies cabling resulting in a clear cube. The key components of the ClearCube

Architecture are:

•PC Blade—a remotely located, Intel-based computer in a dense form factor.

•Chassis—a centralized chassis that houses multiple PC blades and accepts a

variety of plug-in module options that allow connecting all of the external cables

to the blades. Previously known as the chassis and BackPack.

• Client—a remote desktop unit (C/Port, PCoIP zero client, or thin client) to which

standard peripherals are connected.

• System Management Software—ClearCube Management Suite software and

monitoring hardware that is built into ClearCube blades, chassis, and user ports.

The ClearCube management suite software, Sentral, is an optional component.

™

• PC-over-Ethernet

ClearCube PCoE to access remote devices (such as traditional computers or

virtual machines) from your local computer, client, or thin client. PCoE provides

bidirectional audio, USB redirection, and user experience settings you can adjust

to accommodate a variety of usage and network scenarios. PCoE is an optional

component in your ClearCube environment.

This guide is one of a series of manuals that describe the ClearCube architecture.

Other manuals include:

(PCoE™) remote protocol software—You can use

• PCoIP User’s Guide

• I/Port User’s Guide

• C/Port and Multi Video Extender User’s Guide

• PCoE User’s Guide

• A-Series Data Center Products User’s Guide

R-Series Data Center Products User’s Guide ClearCube Architecture and Product Overview • 1

Page 26

R-Series PC Blade

Single-Slot R3080D

Single-Slot R1350Dual-Slot R3040S

The ClearCube PC blade is a dedicated computer that delivers full PC function ality

(including USB) to the desktop from a centralized location. Each R-series PC blade

contains all the industry-standard components of a desktop PC: processor, memory,

hard disk, video support, and Ethernet. You can easily connect peripherals to the PC

blade through USB ports on the User Port that is connected to the blade over a

network. Additionally, a single USB port is located on the front of the blade. You can

load application software on to your PC blade through peripherals connected to the

USB ports, or via the Ethernet connection on each blade.

Each blade has its own systems management circuitry powered independently from

the main components. This system illuminates the front panel status indicators and

monitors blade parameters even when the blade is powered off. The front panel LCD

shows the last three digits of the blade serial number as a default. ClearCube Sentral

software can be used to program as many as 10 alphanumeric characters into the

display. Figure 1 shows several R-series PC blades.

Figure 1 R-series PC Blades: Dual-Slot R3040S, Single-Slot R3080D, and Single-Slot R1350

2 • ClearCube Architecture and Product Overview R-Series Data Center Products User’s Guide

Page 27

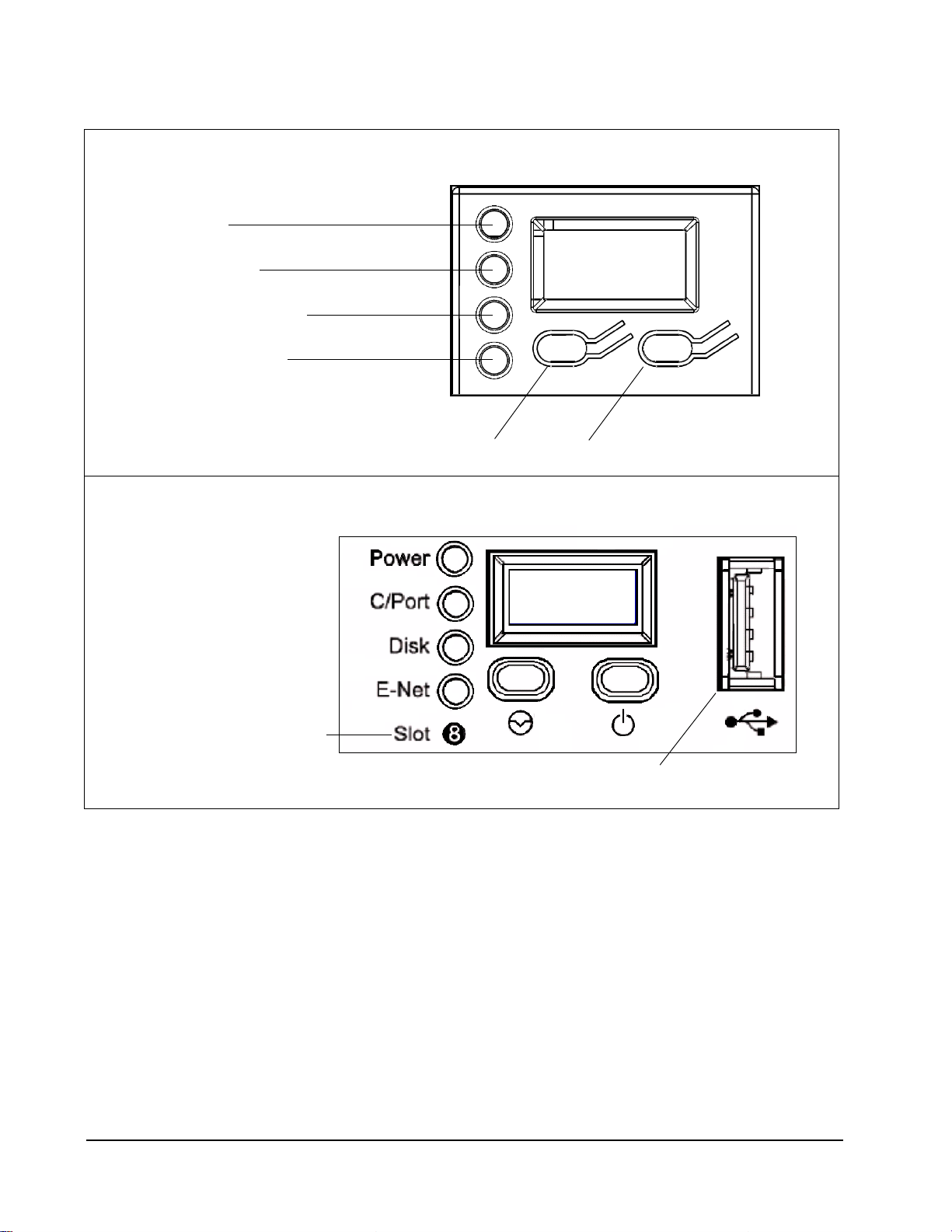

A display area at the front of each blade provides active status indicators. The four

LEDs on the front panel of the blade are described in Table 1 on this page and shown

in Figure 2 on page 4.

Table 1 Blade LED Functions

LED Color Description

Power

C/Port

Disk

E-Net

Green

Off

Green

Red

NOTE: The C/Port LED does not provide any information about PCoIP link

Green

Off

Green

Yellow/

Amber

Blade is powered on.

Blade is powered off.

C/Port is connected, and link is good.

C/Port is not connected, or link is bad.

status. If you are using a PCoIP client, see the LED on the PCoIP client

for link status information.

If you are connecting to a blade using a PCoIP zero client and a C/Port

is not connected to the blade, the C/Port LED is not applicable and is

always red.

Flashing indicates hard disk activity.

No hard disk activity.

Model R3040S: 10/100/1000 Mb/s link — flashing indicates activity.

Model R3080D: 10/100/1000 Mb/s link — flashing indicates activity.

Model R1350: 1000 Mb/s link — flashing indicates activity.

Model R3040S: Not applicable.

Model R3080D: Not applicable.

Model R1350: 10/100 Mb/s link — flashing indicates activity.

Off

No link.

The following figure shows the blade font panel as it appears on the blade, and also as

it appears inside a chassis with the chassis door closed. Labels on the chassis door

identify the front panel LEDs, buttons, and port.

R-Series Data Center Products User’s Guide ClearCube Architecture and Product Overview • 3

Page 28

138

Chassis Slot Designation (1 to 8)

USB Port

Reset Button Power Button

Network Activity Indicator

Power Indicator

C/Port Link Indicator

‡

Hard Disk Activity Indicator

138

Front Panel Display inside Chassis (Including Labels on Chassis Door)

Front Panel Display outside of Chassis

Figure 2 ClearCube R-Series Blade Front Panel Display outside of Chassis and inside Chassis (the Chassis Door

Provides LED and Button Labels)

‡

The C/Port LED is only applicable if a C/Port is connected to a blade. If you are

using a PCoIP zero client to connect to a blade and a C/Port is not connected to the

blade, the C/Port LED is not applicable and is always red.

4 • ClearCube Architecture and Product Overview R-Series Data Center Products User’s Guide

Page 29

R-Series Chassis

The ClearCube R-series chassis is a centralized chassis that houses up to eight

single-slot PC blades and up to four dual-slot PC blades. A standard 42U 19-inch rack

can hold as many as 14 chassis, for a total of 112 single-slot PC blades, 56 dual-slot

blades, or a combination of both.

Each chassis is a self-contained unit providing all of the Ethernet connections, C/Port

connections, airflow management, and power connections for PC blades. The R4300

chassis features interchangeable modules for maximum flexibility. Each chassis provides

system management connections through network and RS-485 links that you can daisy

chain from chassis to chassis. Figure 3 shows a chassis with PC blades installed.

The R4300 chassis, shown in Figure 4, provides a wide range of options for C/Port

and client connections to blades and to the ClearCube network.

The R4300 chassis provides advanced monitoring and switching functionality, with

software support for these modules provided by Sentral. The R4300 chassis and

Sentral are fully compatible with all R-series blades. The R4300 also provides full

backwards compatibility with all features implemented in Switch Manager 4.5, and is

compatible with ClearCube R4200 chassis systems utilizing Blade Switching

BackPacks (BSBPs) and Direct Connect BackPacks (DCBPs). The R4300 also

features dual redundant power supplies and dual AC power inputs.

Sentral communicates with the chassis through an Ethernet connection on the

management controller housed in each R4300. The management controller is installed

inside the R4300 and does not take up a blade slot.

Figure 3 ClearCube R-Series Chassis Front View

R-Series Data Center Products User’s Guide ClearCube Architecture and Product Overview • 5

Page 30

C/Port

Figure 4 R4300 Chassis Rear View

The C/Port, shown in the following figure, is a desktop unit to which a user’s standard

peripherals are connected. The C/Port supports a 200-meter (660-foot) connection

distance from the blade and has two USB 1.1 ports, PS/2 mouse and keyboard ports,

speaker and microphone ports, and SVGA video output port. Other C/Port options

such as the Multi-Video Expander (MVX) are also available from ClearCube. For

more information, see the C/Port and Multi Video Expander User’s Guide.

Figure 5 ClearCube C/Port

6 • ClearCube Architecture and Product Overview R-Series Data Center Products User’s Guide

Page 31

Multi-Video Solution

The ClearCube multi-video solution provides a revolutionary way to multi-task and

process information. While the C/Port provides all the peripheral and USB

connections, the multiplexed video signal can be passed through to the Multi-Video

Expander (MVX) via a noise-limiting VGA connector cable.

Shown in Figure 6, the MVX is physically the same size as the standard C/Port and

can be stacked on top of a C/Port. The MVX distributes the individual video frames to

the appropriate output connectors. The two video outputs on the MVX are special,

high-density connectors that can each drive two monitors.

The MVX can be used with either the standard C/Port or the Fiber C/Port for

connection over copper or fiber optic cable (the MVX does not function with other

clients). The MVX requires that the PC blade have a multi-monitor graphics card

installed. The centralized ClearCube architecture combined with multi-video

capabilities results in the ideal solution for space-constrained trading floors and other

applications requiring multiple displays. For more information, see the C/Port and

Multi Video Expander User’s Guide.

Figure 6 ClearCube MVX Back View

Fiber Optic Extension System

The Fiber Optic Extension System adds fiber optic connectivity to the ClearCube

architecture via a pair of multi-mode fiber optic cables.

The system is compatible with ClearCube R4300 chassis, backpacks, and blades. It

securely extends user desktops from centralized PC blades to a distance as great as

2000 meters (6562 feet) over a pair of 62.5 micron multi-mode fibers. The system

consists of two components, the Fiber Transceiver and the Digital Fiber C/Port.

R-Series Data Center Products User’s Guide ClearCube Architecture and Product Overview • 7

Page 32

Fiber Transceiver

Front Rear

The Fiber Transceiver, shown in Figure 7, is a 1U high, rack-mounted device

designed to work specifically with the ClearCube architecture.

Figure 7 ClearCube F6150-160 Fiber Transceiver

The F6150-160 Fiber Transceiver converts signals sent between C740 Fiber C/Ports

(shown below) and ClearCube blades. A single 16-port Transceiver supports two

R4300 chassis or 16 PC blades. Each blade in a chassis is connected to the transceiver

by an Ethernet cable (≤ 10 meters).

C7420 Fiber C/Port

Figure 8 shows the C7420 Digital Fiber C/Port. In a standard installation, the Digital

Fiber C/Port resides on the user's desktop and provides standard peripheral

connections including USB, PS/2, audio, and video. The Fiber C/Port is compatible

with the Multi-Video Expander (MVX).

Figure 8 ClearCube C7420 Digital Fiber C/Port

For more information about the Fiber C/Port, see the C/Port and Multi Video

Expander User’s Guide.

8 • ClearCube Architecture and Product Overview R-Series Data Center Products User’s Guide

Page 33

Zero Clients and Thin Clients

ClearCube I9424

PCoIP Zero Client

ClearCube I9440

PCoIP Zero Client

ClearCube I8520

Thin Client

ClearCube PCoIP® zero clients and thin clients connect to PC blades over a standard

Ethernet network. The Clients deliver video and peripheral signals to a local user from

a centralized PC blade, just like the C/Port. However, the key difference is that the

client connection (depending on the model) uses PCoIP protocol, Ethernet p rotocol, or

both, allowing it to work over standard switched networks. Therefore, ClearCube

clients do not require a point-to-point connection to a blade (no homerun cabling

needed).

ClearCube clients enable IT managers to use their existing IP network and cabling

infrastructure regardless of the distance between users' desktops and their centralized

PC blades.

• I9440—No operating system. Quad monitor using PCoIP technology

• I9424—No operating system. Dual monitor using PCoIP tech nology with internal

smart card reader

• I9422—No operating system. Dual monitor using PCoIP technology

• I9420—No operating system. Dual monitor using PCoIP technology

• I8520—Windows Embedded Standard with optional internal smart card reader

• I8442—Windows XP Embedded or Embedded Linux

• I8440—Windows XP Embedded or Embedded Linux

®

Figure 9 shows several ClearCube clients. For more information, see the I/Port User’s Guide.

Figure 9 Various ClearCube Clients

R-Series Data Center Products User’s Guide ClearCube Architecture and Product Overview • 9

Page 34

10 • ClearCube Architecture and Product Overview R-Series Data Center Products User’s Guide

Page 35

Chapter 2. Network Planning and

Site Preparation

Rack and Cabinet Requirements

Before installing the components of the ClearCube Architecture it is very important to

properly prepare the site where you will install the chassis and PC blades. This chapter

provides important information on how to plan for installation.

Figure 10 Standard 19-Inch Rack and Standard 19-Inch Cabinet

Figure 10 shows two frequently-used structures for holding ClearCube chassis. A

standard 42U rack or cabinet can hold as many as 14 chassis.

CAUTION: Equipment racks and cabinets can become highly unstable if not

adequately secured. Please read and follow the manufacturer's

specifications and recommendations for mounting instructions. Addition al

ClearCube guidelines are provided throughout this section that—with the

manufacturer's requirements—will ensure a safe installation.

R-Series Data Center Products User’s Guide Network Planning and Site Preparation • 11

Page 36

Fully enclosed electrical cabinets are the preferred option for mounting your

ClearCube chassis. When using cabinets, make sure that both front and back panels

and doors are vented to provide sufficient airflow for intake and exhaust. If you plan

to use a cabinet enclosure, ensure that you have at least 34 inches (86cm) of interior

depth measured from the front of the unit, to accommodate the cabling that exits from

the back of the chassis. Provide adequate space on the back of the rack or cabinet to

allow servicing the cables and equipment. Cabinets may be fitted with casters for

easier mobility or service access.

WARNING: When installing a chassis in a cabinet enclosure, never us e only

one set of mounting brackets at the front. Select a cabinet with an

adjustable center rail or back rail in addition to the front rail. ClearCube's

adjustable mounting kit will then be required to attach the chassis to both

the front and center/back rails.

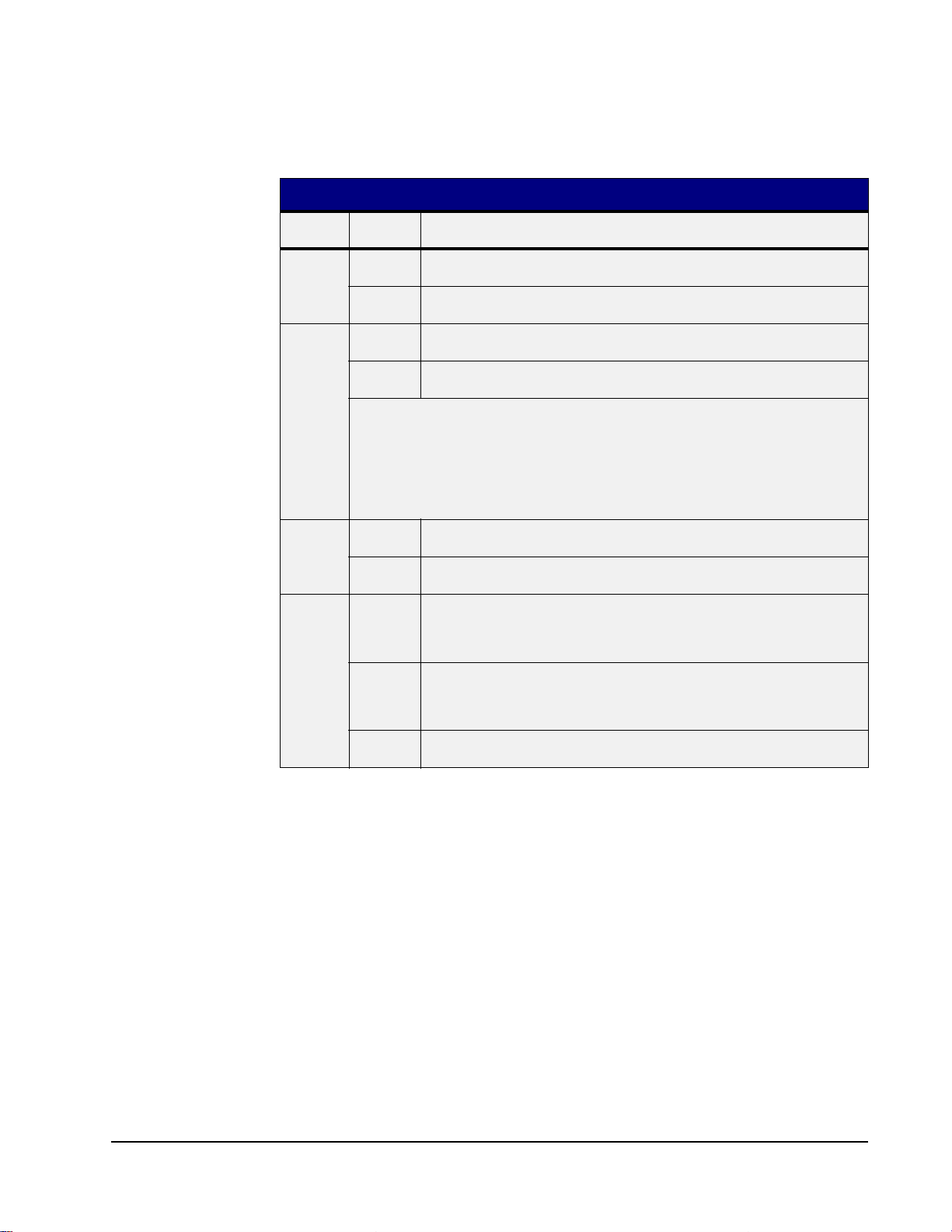

Space and Floor Support Requirements

The following table details the weight of a 42U rack or cabinet with 14 fully-loaded

chassis (not including the weight of the cabling or the rack).

Blade and chassis weights can vary depending on the

components each device contains. Blade and chassis weights

NOTE

shown in the following table are the maximum weights for each

device, where all possible components are populate d in th e

device.

Blade

R3040S

(4 per Chassis)

R3080D

(8 per Chassis)

R1350

(8 per Chassis)

Table 2. Maximum total weight and load in fully-loaded 42U rack

Blade Weight Chassis Weight

13 lbs (5.8 kg) 42 lbs (19 kg) 1316 lbs (597 kg) 219 lbs (99 kg)

5.2 lbs (2.4 kg) 42 lbs (19 kg) 1170.4 lbs (531 kg) 195 lbs (88 kg)

6 lbs (2.7 kg) 42 lbs (19 kg) 1260 lbs (572 kg) 210 lbs (95 kg)

Total Weight of 14 Fully-Loaded

Chassis

(Not Including Cables or Rack)

Load per Square Foot

(Square Meter)

Verify that the rack and floor will support this weight, even if initial installation does

not include 14 chassis units. This allows for future expansion at the location. If other

equipment is to be installed in the rack or cabinet, take this additional weight into

consideration.

WARNING: Improper structural support could cause the rack or cabinet to

lean and the floor to buckle, possibly to the point of structural damage.

12 • Network Planning and Site Preparation R-Series Data Center Products User’s Guide

Page 37

Power and Cooling Requirements

The ClearCube Support site provides

Spreadsheets

ClearCube blade and chassis deployments. Documentation and tools provide:

• Tables describing chassis power requirements

• Data center branch circuit requirements for various chassis and blade deployment

scenarios

• Power requirements for uninterruptible power supply (UPS) sizing

• Maximum and minimum British thermal unit (BTU) values

• BTU calculator with features enabling you to adjust the percentage of users and

application intensity

To download

1. See the following URL: http://www.clearcube.com/support/

2. In the Product Support section, find your blade model in the PC Blades

drop-down list.

3. Click the Manuals link below the product description.

4. Click the Power & Cooling Requirements link to download an archive file. The

archive file contains spreadsheets for various product configurations. Choose the

appropriate spreadsheet and read the included instructions about how to calculate

cooling requirements.

that you can use to determine power and cooling requirements for

ClearCube Power and Cooling Requirements Spreadsheets

ClearCube Power and Cooling Requirements

:

The following sections discuss additional items to consider when planning and

designing data centers.

Additional Power Considerations

As described in the previous section, obtain

Requirements Spreadsheets

deployment.