Page 1

C/Port and Multi Video Expander

User’s Guide

Page 2

Technical Support

Please refer to our support website for technical updates, additional warranty

information and documentation, and software revisions:

Web: http://support.clearcube.com

Email: support@clearcube.com

Phone: (512) 652-3400 or call toll free (866) 652-3400 (United States)

ClearCube Technology Corporate Headquarters

Mailing and Shipping Address:

The ClearCube Building

8834 Capital of Texas Hwy N.

Austin, Texas 78759

Email: info@clearcube.com

Main Phone: (512) 652-3500 or call toll free (866) 652-3500 (United States)

Main Fax: (512) 652-3501

Or your local ClearCube Reseller or Authorized Service Provider

Copyrights

©2005–2008 by ClearCube Technology Inc. All rights reserved. Under copyright laws,

this publication may not be reproduced or transmitted in any form, electronic or

mechanical, including photocopying, recording, storing in an information retrieval

system, or translating, in whole or in part, without the prior written consent of

ClearCube Technology, Inc.

This information is subject to change without notice and ClearCube shall not be liable

for any direct, indirect, special, incidental or consequential damages in connection

with the use of this material.

Trademarks

ClearCube™, Blade Switching BackPack™, PC Blade™, C/Port™, and I/Port™ are

trademarks of ClearCube Technology Inc. Product and company names mentioned

herein are trademarks or trade names of their respective companies.

Patents

The ClearCube Architecture and its components described in this user manual are

protected by numerous granted and pending U.S. and international patents.

Granted patents include: US05926172, US05966056, US05994952, US06012101,

US06020839, US06037884, US06038616, US06119146, US06148182,

US06167241, US06385666, US06421393, US06426970, US06633934,

US06708247, US06735658, and US06886055.

Patents pending include: US S/N 09/755378, US S/N 10/279475, US S/N 10/198719,

US S/N 10/198650, US S/N 10/409219, US S/N 09/728667, US S/N 09/728669, US

S/N 10/411804, US S/N 10/411908, US S/N 10/458853, US S/N 10/364584, US S/N

10/301536, US S/N 60/411066, US S/N 10/662933, US S/N 10/662889, US S/N

10/662932, US S/N 10/662968, US S/N 10/301563, US S/N 10/662936, US S/N

10/301518, US S/N 10/662955 and US S/N 10/662954.

Inquiries regarding patented technology should be directed to ClearCube Corporate

Headquarters.

Page 3

Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

How to Use this Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

FCC Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

California Proposition 65 Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

WEEE Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Warning Regarding Medical and Clinical Use of ClearCube Products . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Chapter 1. ClearCube C/Port Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

C/Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Fiber Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

C7420 Fiber C/Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

F6150–160 Fiber Transceiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Multi-Video Expander . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Chapter 2. C/Port Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Caution Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Orientation and Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Power Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

C7130 and C7120 C/Port Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Following Best Practices for Cabling and Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Identifying Your C/Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Identifying your Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Unpacking the C/Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Installing the C/Port on the Desktop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Tuning the C/Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Before Tuning a C/Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Tuning a C7130 Connected to an R4300 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Tuning a C7130 Connected to an R4200 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Tuning a C7120 or Earlier Model Connected to an R4300 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Tuning a C7120 or Earlier Model Connected to an R4200 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Fine-Tuning Model C7130 C/Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Tuning Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Using the C7130 Blade Reset Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Using the Blade Reset Button on Earlier C/Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Locking out Mass Storage Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

iii

Page 4

C7420 Fiber C/Port Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Setting up the C7420 Fiber C/Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Understanding C7420 LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Configuring the C7420 Fiber C/Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Understanding Default Network Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Setting up Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Direct Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

DHCP Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Sentral Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Chapter 3. MVX Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Hardware Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Installing the Video Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Installing the MVX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Software Installation and Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Removing Outdated NVIDIA Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installing the NVIDIA Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Important Notes about MVX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Appendix A. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

C/Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Red link status indicator on PC blade and C/Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

No link status indicator light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Poor video quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Loss of peripheral devices (USB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

No video or link lights at desktops and no power to blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

MVX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

No video is present . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

The monitor’s Auto-Adjust does not give a clear, sharp image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

The video signal is lost after changing display settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Fiber Optic Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

No video and/or digital link present . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

The monitor’s Auto-Adjust does not give a clear, sharp image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Appendix B. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

C/Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

C7420 Fiber C/Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

MVX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Appendix C. Regulatory Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

ElectroMagnetic Compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Emissions (Radio Frequency Interference) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Electro-Magnetic Interference (EMI) Immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Power Harmonics and Flicker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Safety Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

CE Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

iv

Page 5

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

C7420 Fiber C/Port and F6150–160 Fiber Transceiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

ElectroMagnetic Compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Emissions (Radio Frequency Interference) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Electro-Magnetic Interference (EMI) Immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Power Harmonics and Flicker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Safety Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

CE Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

v

Page 6

vi

Page 7

Preface

How to Use this Guide

Thank you for purchasing your quality ClearCube products. The ClearCube Architecture was

developed to bring you unprecedented levels of manageability, security, reliability, and space

savings. The ease of use of ClearCube’s products makes installation straightforward.

This manual provides all the product and installation information needed to set up and run

ClearCube Technology’s C/Port Architecture for managed desktop environments. We

recommend that you familiarize yourself with the ClearCube Architecture and product

descriptions and read through the entire installation and setup procedures before beginning

installation.

If you encounter any problems, please contact our Technical Support using the contact

information provided on the inside front cover of this manual.

FCC Warning

This equipment generates and uses radio frequency energy and, if not installed and used in

strict accordance with the instructions in this manual, may cause interference to radio and

television reception. Changes or modifications not expressly approved by ClearCube

Technology could void the user's authority to operate the equipment under the FCC Rules.

California Proposition 65 Statement

WARNING: ClearCube products contain chemicals, including lead, known to the State of

California to cause cancer, birth defects, or other reproductive harm. Wash hands after

handling.

ClearCube products should be disposed of in accordance with local laws governing computer

equipment disposal.

WEEE Information

The products described in this document are subject to regulation under the European Union

Directive 2002/96/EC, that mandates separate waste collection, treatment, and recycling of

electronic products. This directive is commonly known as WEEE, for Waste from Electrical

and Electronic Equipment, and its intent is to promote the safe and sensible disposal of

products that have outlived their usefulness.

The “crossed-out” trash bin symbol, shown to the left, identifies products that should be

recycled, not simply discarded. ClearCube Technology supports the reuse, recycling,

recovery, and responsible disposal of all products, not just our systems.

Preface • vii

Page 8

ClearCube Technology is committed to meeting the requirements of the European Union

WEEE Directive and is currently developing country-specific implementation plans that

comply with the WEEE legislation. The goal of the directive is to reduce the environmental

impact due to the disposal of electrical and electronic equipment that has reached the end of its

useful service life. This directive goes into enforcement on August 13, 2005.

ClearCube products are sold exclusively to commercial and industrial customers and not to

private households. Under the WEEE legislation terms, commercial and industrial customers

have the responsibility to ensure that all electrical and electronic equipment is disposed of

properly and in accordance with all applicable laws and local regulations. For more

information, visit the ClearCube Technology web site at www.clearcube.com

recycle@clearcube.com

, or call at (866) 652-3400 or +1 (512) 652-3400.

, email at

Materials used in this product, if not disposed of properly, could have adverse effects on the

environment and human health. Do not dispose of these products in unsorted municipal waste

containers. Deliver electronic waste only to an approved recycling, and/or treatment facility. If

one is not available, contact ClearCube for assistance.

Warning Regarding Medical and Clinical Use of ClearCube

Products

ClearCube products are not designed with components and testing for a level of reliability

suitable for use in or in connection with surgical implants or as critical components in any life

support systems whose failure to perform can reasonably be expected to cause significant

injury to a human. Applications of ClearCube products involving medical or clinical treatment

can create a potential for death or bodily injury caused by product failure, or by errors on the

part of the user. Because each end-user system environment is customized and differs from

ClearCube testing platforms and because a user may use ClearCube products in combination

with other products in a manner not evaluated or contemplated by ClearCube, the user is

ultimately responsible for verifying and validating the suitability of ClearCube products

whenever ClearCube products are incorporated in a system, including, without limitation, the

appropriate design, process and safety level of such system or application.

viii • Preface

Symbols

Symbols are used on the equipment to convey specific information to the operator and service

person. It is important to understand the intended meaning of these symbols. Below are the

graphical symbols that are used on ClearCube Technology, Inc. Products and their meaning.

Refer to Manual

Used on the equipment’s rating label to direct the operator or service person to the manual for additional information.

Stand By

One symbol used for each blade installed located on front of the

chassis. Soft Start switch used to power on that particular blade.

Page 9

Fuse

Located on equipment rating label. Symbol is accompanied with

the specifications needed for replacement. Only qualified technicians should perform this operation.

Protective Earth Terminal

Identifies the terminal that is used to connect all metal parts of the

enclosure through an external conductor to ground for the protection against electrical shock in a fault condition.

Equipment Protection Class II

May be located on the power adapter’s rating label. Indicates that

equipment is double insulated from hazardous voltages. Not to be

confused with “Class 2” that is a US National Electrical Code (NEC)

circuit classification.

These same symbols are used within this document where appropriate to indicate situations

that merit checking this or another manual, or situations that could result in damage to

equipment or physical injury.

CAUTION: A Caution notice in this manual indicates that equipment damage

or minor injury may result if proper procedures are not followed.

WARNING – A Warning notice

equipment damage, or serious injury including death may result if proper

procedures are not followed.

in this manual indicates that catastrophic

Safety Guidelines

Before undertaking any troubleshooting or maintenance procedure, read carefully all

WARNING and CAUTION notices. This equipment contains voltage hazardous to human

life and is capable of inflicting personal injury.

• Installations – ClearCube equipment is required to be installed in accordance with the

local electrical codes and may be subject to inspection by the authority having jurisdiction.

• Chassis Grounding – ClearCube’s chassis and Fiber Transceiver has been designed with

a three-conductor IEC 60320 appliance inlet that – with the proper power cord – connects

the building’s external protective earthing conductor to all accessible metal parts of the

enclosure. To minimize shock hazard, make sure your electrical power outlet has an

appropriate earth safety ground that is connected each time you power on the equipment.

—Apparaten skall anslutas till jordat uttag när den anslutas till ett nätuerk.—

• Power Cord Selection – ClearCube or ClearCube’s Distributors provides power cords

that are specifically designed for use with that particular piece of equipment and are

approved for use by the local authority having jurisdiction in the country where the

Preface • ix

Page 10

equipment is put into service. Please refer to the installation sections of this manual for

specific power cord requirements. For replacement of power cords, refer to Appendix C –

Technical Support.

• Power Adapters – ClearCube or ClearCube’s Distributors provides power adapters that

are specifically designed for use with that particular piece of equipment and are approved

for use by the local authority having jurisdiction in the country where the equipment is put

into service. Please refer to the installation sections of this manual for specific power cord

requirements. For replacement of power cords, refer to Appendix C – Technical Support.

• IT Power Systems – ClearCube equipment has been evaluated and found to be

compatible with IT power distribution systems with a phase-to-phase voltage not to

exceed 240 V.

• Live Circuits – Operating personnel and service personnel must not remove protective

covers when operating the ClearCube chassis. Adjustments and service to internal

components must be undertaken by qualified service technicians. During any service of

this product other than replacing a PC blade or the fan tray, the main connector to the

premise wiring must be disconnected. Dangerous voltages may be present under certain

conditions. Use extreme caution.

• Explosive Atmosphere – Do not operate the chassis in conditions where flammable gases

are present. Under such conditions this equipment is unsafe and may ignite the gases or

gas fumes.

• Part Replacement – Only service equipment with parts that are exact replacements, both

electrically and mechanically. Contact ClearCube Technology for replacement part

information. Installation of parts that are not direct replacements will void the warranty

and may cause harm to personnel operating the chassis. Furthermore, damage or fire may

occur if replacement parts are unsuitable.

• Modification – Do not modify any part of the C/Port, chassis, or PC blade from its

original condition. Modifications may result in hazards.

• Laser Safety – The Fiber Transceiver and the Fiber C/Port have been evaluated and

certified to an EN 60825-1 – Safety of laser products.

x • Preface

ClearCube Technology products that use lasers display the following graphic on the rating

label:

Marked devices comply with the FDA code of Federal 21 CFR 1040 per Notice 50 and/or the

Canadian Radiation Emitting Devices Act REDR C1370.

CAUTION: Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

Page 11

Chapter 1. ClearCube C/Port Overview

The ClearCube architecture delivers Intel-based PC functionality to the desktop from a secure,

centralized location. This results in dramatic increases in manageability and security while

providing mission-critical reliability, performance, and uptime improvements with lowered

costs. Replacing a traditional PC box with a ClearCube C/Port or I/Port in an office or cubicle

also saves space, eliminates fan noise and simplifies cabling resulting in a clear cube. The key

components of the ClearCube Architecture are:

• PC Blade – a remotely-located, Intel-based computer in a dense form factor.

• Chassis – a centralized PC blade housing that provides the power for each PC blade and

accepts a wide variety of chassis modules.

• Chassis Module – a modular interface card that plugs into a chassis and provides user

port, management, and network connections.

• User Port – a remote desktop unit (C/Port or I/Port) to which standard peripherals are

connected.

• System Management – ClearCube Management Suite software and monitoring hardware

that is built into the blades, chassis, and user ports.

C/Port

This guide is devoted to the following C/Ports:

• C/Port – Copper-connected user port

• Fiber C/Port – Optical fiber-connected user port

• Multi-Video Expander (MVX) – Optional accessory that connects to a C/Port or Fiber

C/Port and allows using as many as four monitors at the desktop (optional video card may

be required).

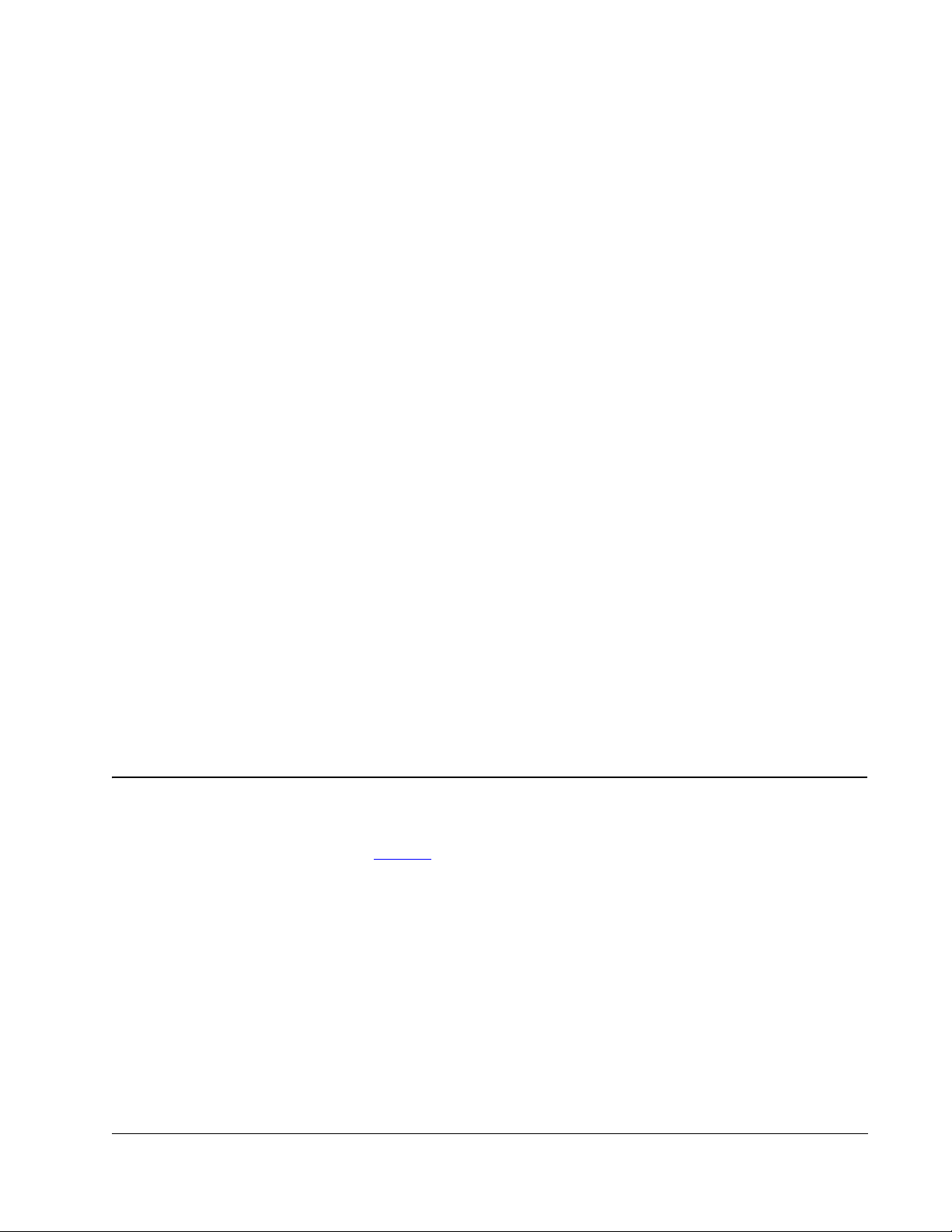

The C/Port, shown in Figure 1 on page 2, is a desktop unit to which a user’s standard

peripherals are connected. The C/Port supports a 200–meter (660–foot) maximum connection

distance from the blade and has two USB ports, PS/2 mouse and keyboard ports, speaker and

microphone ports and video output port. Other C/Port options such as the Multi-Video

Expander (MVX) are also available from ClearCube.

C/Port • 1

Page 12

Figure 1. ClearCube C/Port

C/Ports are connected via standard twisted-pair copper networking cables: CAT5, CAT5e,

CAT6, or CAT6e. Table 1

Cable Type Distance

CAT5 660 feet (200 meters)

CAT5e 660 feet (200 meters)

CAT6 * C7130: 330 feet (100 meters)

lists the distance limits for C/Port installations.

Table 1. C/Port Connection Limits

CAT6, CAT6e *

Cable certified for 45 nS / 100 meters delay skew or less.

*

Cable certified for 25 nS / 100 meters delay skew or less.

* *

Note: C/Port connections use all four twisted pairs in a straight-through connection.

Note: When configuring an Admin Daisy Chain connecting 9 or more R4300 chassis, the

Admin C/Port must be located within 100 meters of the equipment rack if using CAT5

or CAT5e cable, or within 50 meters of the equipment rack if using CAT6e. When the

Admin Daisy Chain has 8 R4300 chassis or fewer, or is composed entirely of R4200

chassis, the standard distance lengths for C/Port cabling apply.

C7120 or earlier: 330 feet (100 meters)

*

C7130: 660 feet (200 meters)

2 • ClearCube C/Port Overview

Page 13

Fiber Solution

This section describes:

• C7420 Fiber C/Port

• F6150–160 fiber transceiver

C7420 Fiber C/Port

The C7420 is connected to an F6150–160 fiber transceiver, and the fiber transceiver is

connected to ClearCube PC blades. When deployed using a secure point-to-point fiber

connection, data displayed to the desktop does not commingle with any network traffic, and

users cannot disconnect the fiber desktop for use with a PC or notebook. C7420 does not

require special OS drivers.

The C7420 securely extends user desktops from centralized PC blades. This point-to-point

fiber optic solution supports existing fiber cabling infrastructures that employ a pair of

multi-mode fibers for each user. On the back-end, the C7420 connects to a F6150 fiber

transceiver chassis using a pair of 62.5µm or 50µm, multi-mode fibers through an LC connector.

ClearCube’s digital fiber optic extension technology leverages PCoIP™ technology to deliver:

• High-end PC experience for up to two monitors. You can configure each monitor

independently, specifying resolution and portrait or landscape orientation.

• Transparent USB redirection from the C7420 back to the PC blade. Standard peripheral

connections include:

– USB (including isochronous USB devices)

– HD audio input and output

– Digital and analog video

• Standard PC blade connection up 2,000 meters or greater

• Small form factor pluggable (SFP) single or multimode fiber optic modules

Fiber Solution • 3

Page 14

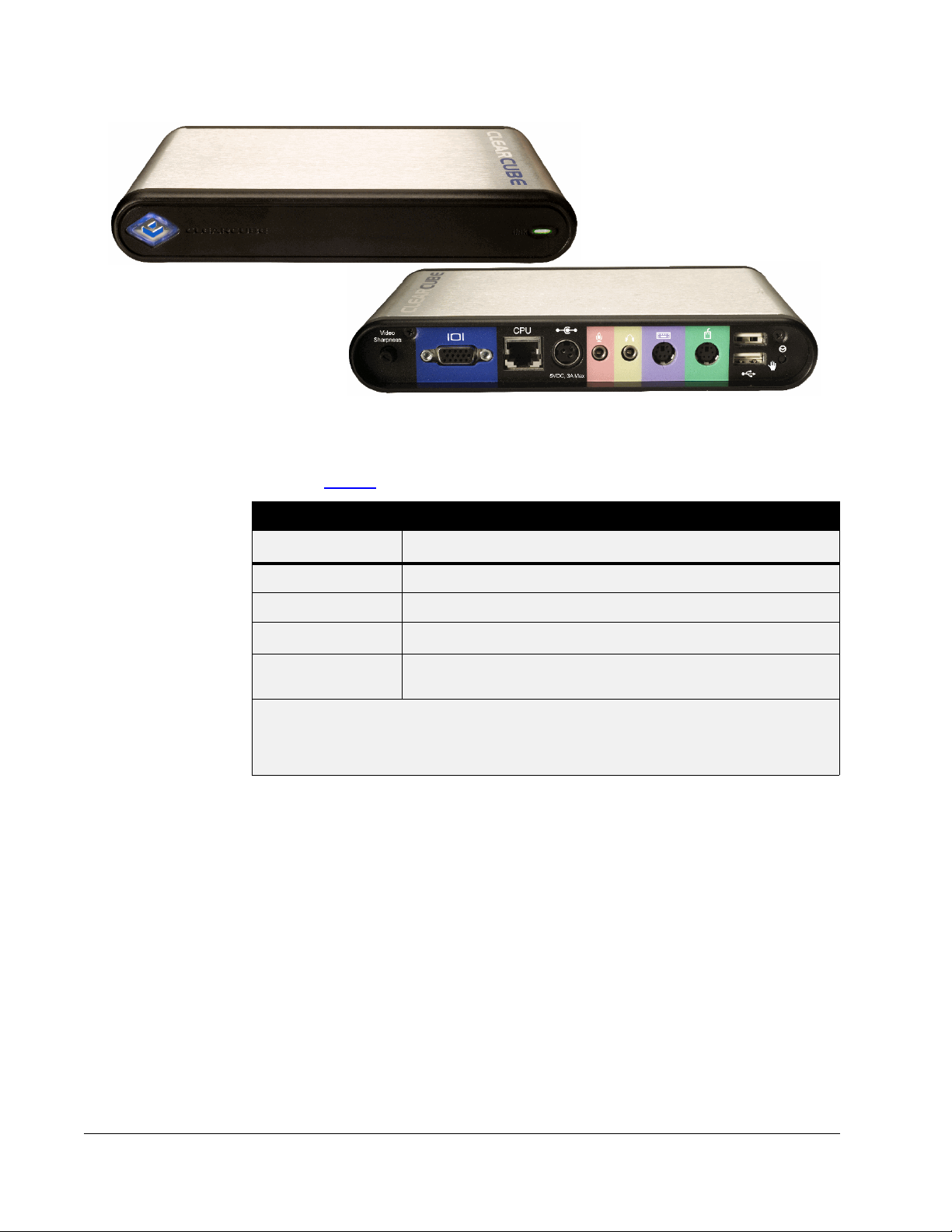

Front

Power Indicator LED

Power

Connector

For more information about setting up your C7420, about connecting devices to the C7420,

and about understanding the indicator LEDs, see "C7420 Fiber C/Port Installation

page 20.

F6150–160 Fiber Transceiver

Fiber

Activity

Link Indicator

USB 1.1 Ports

Rear

LC Fiber

Figure 2. C7420 Fiber C/Port

Power Button

Audio In Audio OutDVI–I Port 1 DVI–I Port 2

USB 1.1

Ports

Remote Blade

Power Button

" on

The F6150–160 fiber transceiver converts signals sent between C7420 Fiber C/Ports and PC

blades. The F6150–160 provides the following features:

• 2U–chassis compatible with standard, 19–inch racks

• Sixteen F6151 media converters that convert 10/100BASE–TX to 100BASE–FX

• Front–panel LEDs indicating power status, link status, connection speed, connection

mode, activity status, and collision status

• Hot–swappable media converters

• Hot–swappable, redundant, load–sharing power supplies

For more information about the F6150–160 fiber transceiver, see the Quick Start Guide and

the User’s Guide included with the transceiver.

4 • ClearCube C/Port Overview

Page 15

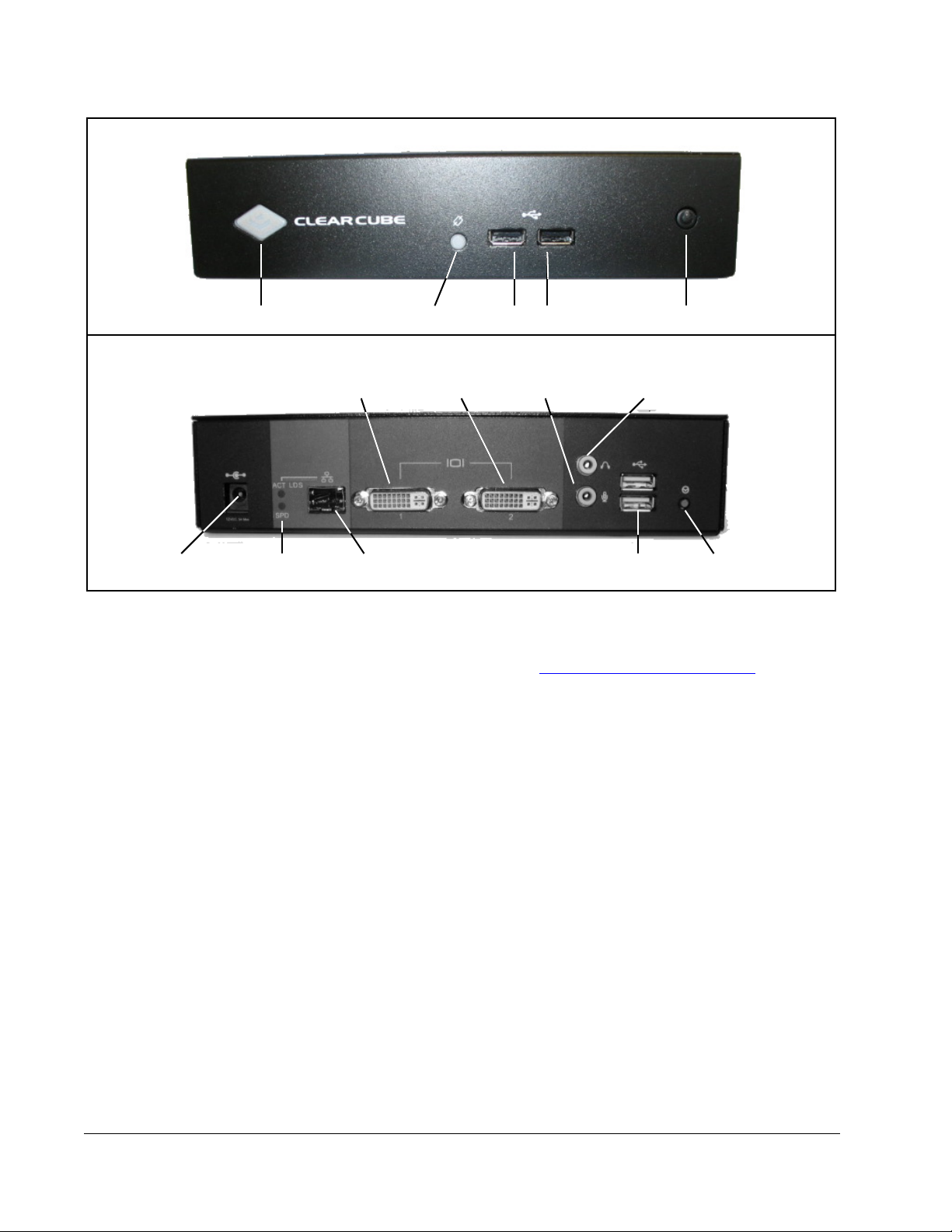

Multi-Video Expander

The ClearCube Multi-Video Expander (MVX) provides a revolutionary way to multi-task and

process information.

While the C/Port provides all the peripheral and USB connections, the multiplexed video

signal can be passed through to the MVX via a noise-limiting VGA connector cable. The

MVX distributes the individual video frames to the appropriate output connectors. The two

video outputs on the MVX are special, high-density connectors that can each drive two

monitors.

The MVX can be used with either the standard C/Port or the Fiber C/Port for connection over

copper or fiber optic cable (the MVX does not function with I/Ports). The MVX requires that

the PC blade have a multi-monitor graphics card and ClearCube-customized NVIDIA video

drivers installed. The centralized ClearCube architecture combined with multi-video

capabilities results in the ideal solution for space-constrained trading floors and other

applications requiring multiple displays.

Figure 3. ClearCube MVX Rear View

Shown in Figure 3

and can be stacked on top of a C/Port.

The ClearCube multi-video solution offers these features:

• Support for as many as four displays over a single C/Port cable or 62.5 micron,

multi-mode fiber

• NVIDIA-based graphics adapter for PC blade

• ClearView™ video driver/GUI based on NVIDIA’s award-winning nView video driver

• Analog and digital output (DVI) that provides resolution as high as 1280 x 1024 on each

monitor

on this page, the MVX is physically the same size as the standard C/Port

Multi-Video Expander • 5

Page 16

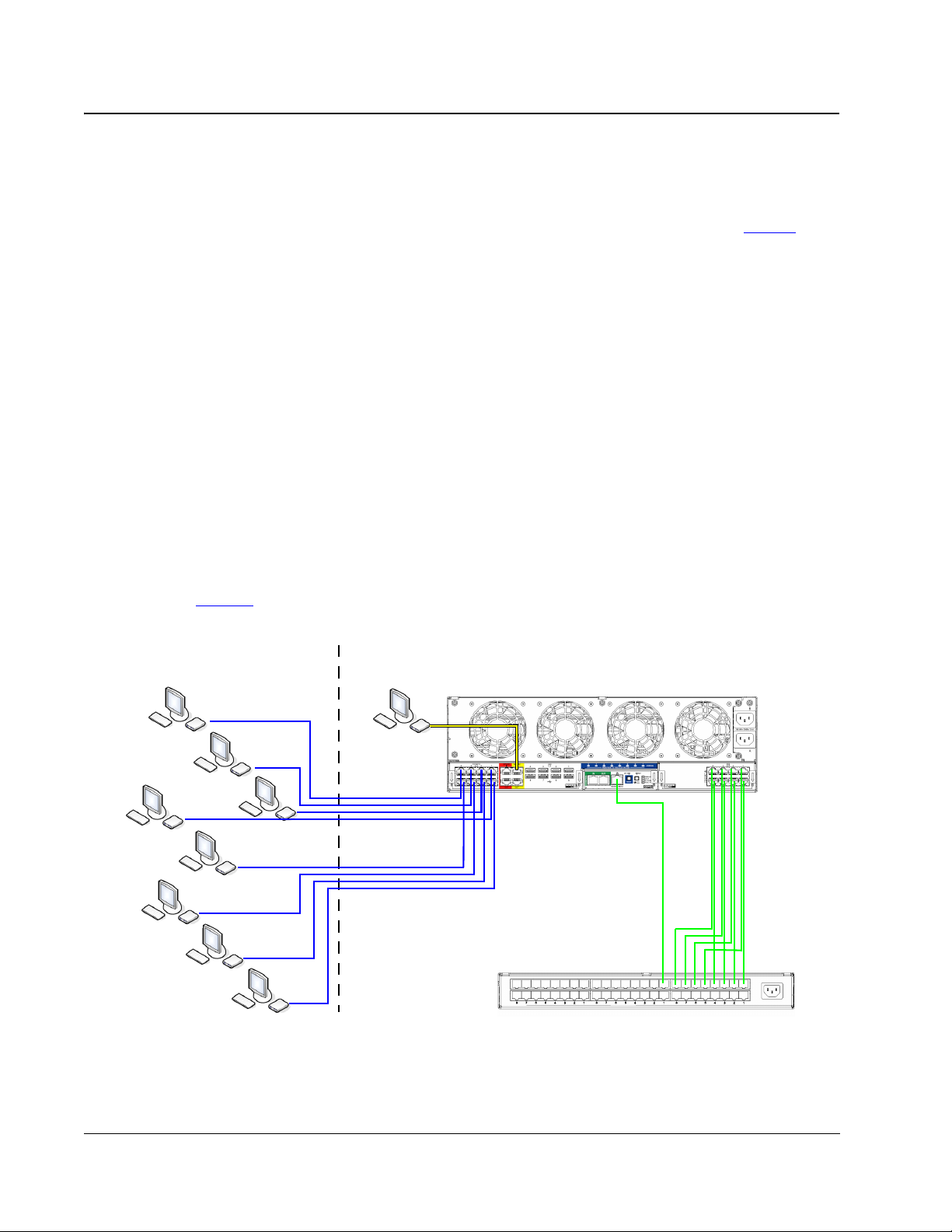

Cable Requirements

The ClearCube chassis uses standard network cables with RJ45 connectors to connect to

C/Ports and to an Ethernet network. These can be CAT5, CAT5e, CAT6, or CAT6e cables.

C/Ports require straight-through cables with all four twisted pairs available. See Table 1

page 2 for a maximum distance chart for these cables for C/Ports. Network connections follow

standard Ethernet guidelines. In practice, identical copper media can be used for C/Ports and

for network connections, although ClearCube recommends using different cable colors for

C/Port and network connections to simplify installation and maintenance. Throughout this

guide, “C/Port cable” and “network cable” refer interchangeably to copper-media cable such

as CAT5, CAT5e, CAT6, or CAT6e.

Note: Obtaining the maximum cable distance requires the use of cables with a delay skew

specification of < 25 nS / 100m. CAT6e cables generally meet this requirement, but a

majority of CAT6 cables do not.

Each fully loaded chassis requires eight C/Port cables with RJ-45 connectors for connections

to C/Ports at the desktop and eight network cables for blade connections to the Ethernet

network hub or switch. Additionally, short color-coded C/Port cables (Green for Chassis

Management & Control, Red for Sparing, and Yellow for Admin Port) are provided to

configure and daisy-chain your chassis.

Note: The C/Port cable connections use all four-wire pairs for the connection from the PC

blade to the C/Port. If your installation currently splits out wire pairs for multiple uses,

you must ensure that all four twisted pairs are available for each blade to C/Port

connection.

on

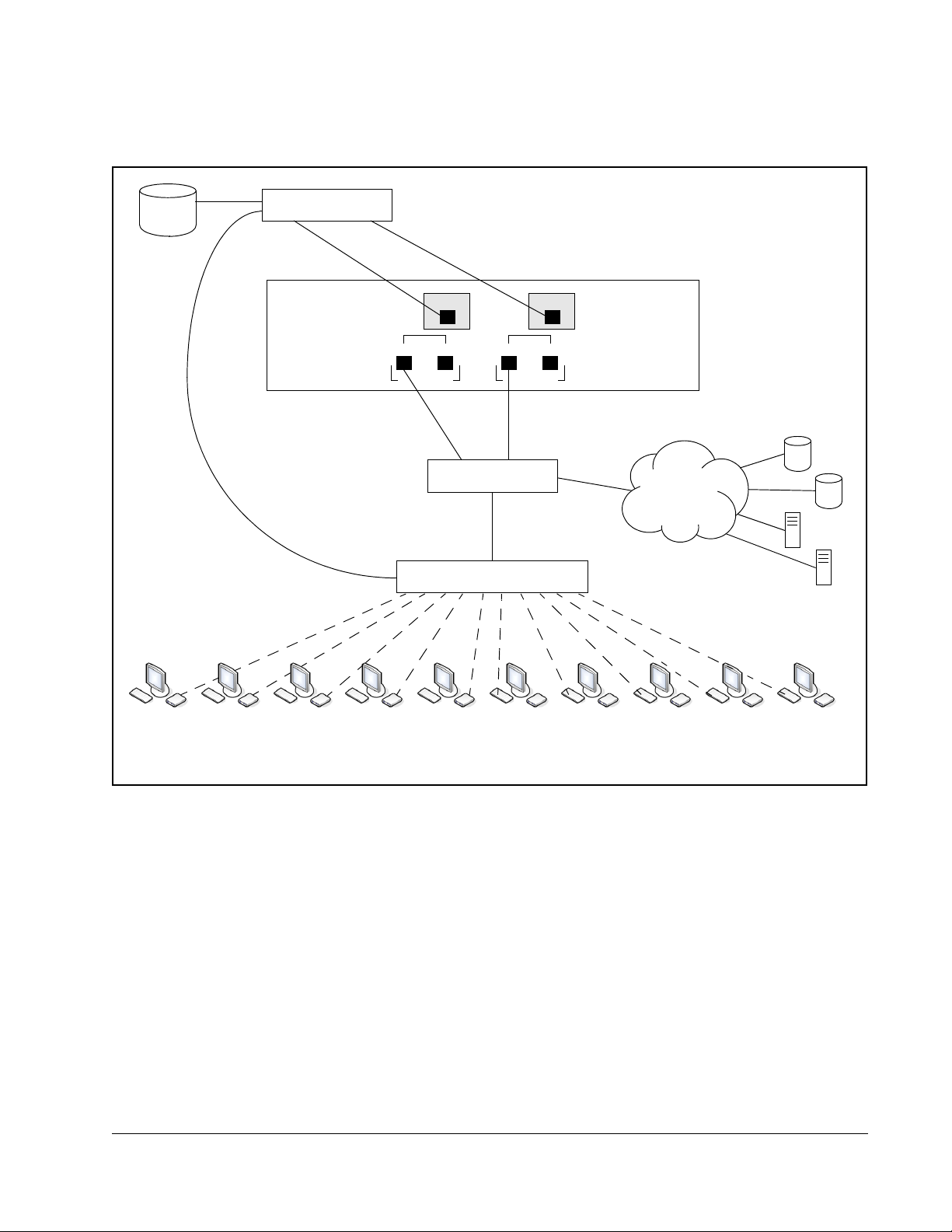

Figure 4 on this page provides schematics of the cabling required to connect your chassis to

user ports and your Ethernet network.

Data CenterUser Desktops

with C/Ports

Admin C/Port

and Terminal

Homerun

C/Port Cables

Figure 4. C/Port Architecture Cabling Diagram

Chassis

Network

Switch

Ethernet

Cables

6 • ClearCube C/Port Overview

Page 17

The following figure shows a typical cabling configuration to connect C7420 Fiber C/Ports to

an A3100 chassis. Note the recommended configuration, where the data network is separated

from the PCoIP network.

Sentral

Server

Sentral Switch

. . . .

PCoIP

PRI

SEC

BLADE 5

Network Switch

Fiber Transceiver

Fiber Connections

A3100 Chassis with 10 A1410 Blades

PCoIP

. . . .

PRI

SEC

BLADE 6

External Data Sources

Data

Network

and Entities

C7420 Fiber C/Ports and Peripherals

Figure 5. C7420 Cabling Diagram

Cable Requirements • 7

Page 18

8 • ClearCube C/Port Overview

Page 19

Chapter 2. C/Port Installation

Caution Statements

Improper connection, mounting, or use of this product could result in component failure or

undesired interference. Read the following caution statements before setting up and operating

your C/Port.

Setup

• Do not connect to AC power until all other connections are made, including the power

adapter. Connecting or disconnecting components or equipment on the back panel when

the C/Port is receiving AC power can cause power surges and damage the device.

• Do not force a connector into its socket. If any undue resistance is encountered, ensure that

the connector is correctly oriented to the receptacle.

• Do not attach the C/Port to a telephone jack or other powered network connection. This

will permanently damage the C/Port. This damage is not covered under the ClearCube

Technology limited warranty.

• Do not connect or disconnect USB devices or other peripherals during either the C/Port or

the blade start-up sequence. Unpredictable results will occur.

Orientation and Venting

Allow sufficient space around the C/Port for ventilation. Do not place the device in any

enclosure that restricts airflow around the device. Do not place any objects on the device.

Product environmental specifications are listed on page Appendix B. "Specifications"

page 41.

on

Power Sources

• To ensure regulatory compliance, use only the power supply included in the shipping

carton with the C/Port, or a ClearCube-approved equivalent.

• Surge protectors for electrical devices are recommended in areas of frequent lightning.

However, when lightning is occurring, your equipment should be properly shut down and

unplugged from AC power until the storm has passed.

Caution Statements • 9

Page 20

C7130 and C7120 C/Port Installation

The model C7130 C/Port provides automatic sharpness tuning that simplifies installation.

When connected to an R4300 chassis, the C7130 also provides a color Auto-tune feature that

greatly simplifies initial video configuration on the desktop.

Previous C/Ports require manual sharpness and color configuration on all chassis models.

C7130 C/Ports also require manual color configuration when connected to R4200 chassis

models, but provide automatic sharpness tuning. Any model of C/Port can always be manually

tuned.

Key elements in installing a C/Port include:

• Following best practices in monitor selection and cable layout

• Knowing which C/Port you are installing

• Knowing whether you are connecting to an R4300 chassis.

Understanding these elements will simplify and speed your installation.

Following Best Practices for Cabling and Monitors

C/Port cables should be routed from the data center to the desktop in as straight a line as is

reasonable, and should be separated from noise sources such as fluorescent lights, power

cables, and other signal cables whenever possible. Do not place power cables in the same

cable tray with C/Port cables, and follow applicable building and electrical codes when

installing cables. Use high-quality cables. See Table 1

cable specifications and maximum recommended cable lengths.

on page 2 for more information on

Before adjusting your C/Port for sharpness and color, set your monitor resolution and refresh

rate on the PC blade by using the controls provided with your operating system. To access

these controls for Windows operating systems, right-click in an open space on your desktop,

choose Properties, and then click on the Settings tab.

Video quality may be subjective, based on user preferences and the limitations of the monitor.

A higher quality monitor usually provides better video results. For best results with an LCD

monitor, set the monitor to its native resolution and press its Auto-Adjust button after video is

displayed.

Identifying Your C/Port

C/Ports are labeled on the bottom, and have their color switches set to the factory default

setting for easiest installation. See Figure 8

information. The procedures for installing all C/Ports are essentially the same. The differences

are in video tuning, and are described later in this section.

10 • C/Port Installation

on page 13 and Figure 9 on page 13 for more

Page 21

Identifying your Chassis

R4300 and R4200 chassis can easily be identified in your data center. Figure 6 on this page

shows R4300 and R4200 chassis. Note the difference in the connectors on the lower apron.

Figure 6. R4300 Chassis (L) and R4200 Chassis (R)

Unpacking the C/Port

The C/Port package contains one of each of the following items:

• C/Port unit

• C/Port power supply and power cord

A special tuning tool for adjustments is included with the documentation and software

package in your shipment. A mounting adapter is available as an option from ClearCube to

conveniently mount a C/Port underneath a desktop. Figure 7

features on the front and back panels of the C/Port.

on page 12 shows the major

C7130 and C7120 C/Port Installation • 11

Page 22

Power Indicator

(Blue Light

Around Badge)

C/Port Link Status

(Green = link, Red = no link)

DC Power Input

Microphone

Input

Audio

Output

Keyboard Port

Mouse Port

USB (2 Ports)

Blade

Reset/Power

Button

Video Sharpness

Adjustment Dial

Blade Connection (RJ-45)

Video Output

Figure 7. C/Port Front and Back Panels

Installing the C/Port on the Desktop

If you do not have easy access to the data center to determine whether you are connecting to an

R4300 or R4200 chassis, use the simple matrix shown in Table 2

procedure. If you are unsure of the chassis type to which the C/Port connects, use the manual

tuning procedures.

Table 2. C/Port Tuning Procedure

R4300 Chassis R4200 Chassis

to choose your tuning

To install a C/Port, do the following:

1. Verify the type of C/Port you are installing by reading the label on the bottom of the

C/Port.

a. If you are installing a C7130, verify that the three color switches on the bottom of the

b. If you are installing an earlier model, verify that the three color switches on the bottom

12 • C/Port Installation

C7130 C/Port Auto-Tune

Sharpness and Color

C7120 or earlier

C/Port

Manual Tune

Sharpness and Color

Auto-Tune Sharpness,

Manual Tune Color

Manual Tune

Sharpness and Color

C7130 are set to the positions marked F. This switch setting enables Auto-tuning on

the C7130. Use the C/Port tuning tool or a small flat-blade screwdriver to change the

switches, if necessary. See Figure 8

on page 13.

of the C/Port are set to the positions marked 1. This switch setting enables manual

tuning on all C/Ports. Adjust the switches if necessary. See Figure 9

on page 13.

Page 23

C

A

E

8

6

0

2

4

C

A

E

8

6

0

2

4

C7130

C7130 Auto-Tune

Default Setting

(F, not marked)

Figure 8. C7130 C/Port Color Switches

Universal C/Port II

C7110

C7130 Manual Tune

Setting

(1, not marked)

4

6

2

C7110 / C7120 C/Port

8

0

Default Setting

(1, not marked)

Figure 9. C/Port Color Switches, Earlier Versions

2. Locate your C/Port in a ventilated area away from any heat sources. Do not stack your

C/Port on top of monitor ventilation vents or on top of other significant heat generating

devices.

If you ordered the C/Port mounting kit, attach it to the desktop surface with screws or with

double-sided tape. The C/Port mounts onto the bracket with the keyhole-shaped holes on

the bottom, and can be easily removed if necessary.

3. Connect the mouse, monitor, keyboard and any audio devices to the respective connectors

on the C/Port.

4. Connect USB devices first to the C/Port and then plug in the power cord for the USB

device (if applicable).

5. Connect the twisted-pair link cable (CAT5 or similar) from the chassis to the CPU jack on

the C/Port. For dual-processor blades, the link cable must be connected to the secondary

C/Port jack on the chassis (e.g., if the blade is placed in slots 3 and 4, the link cable should

be plugged into C/Port jack #4 on the chassis).

C7130 and C7120 C/Port Installation • 13

Page 24

Do not attach the C/Port to a telephone jack or other powered network

connection. This will permanently damage the C/Port. This damage is not

covered under the ClearCube Technology limited warranty.

6. Connect the C/Port power supply module to the C/Port power input, and then plug the

power supply into the AC power socket. Make sure you have the properly rated power

supply module for your local power outlet. The blue power indicator on the left side of the

C/Port will light.

7. Examine the Link Status Indicator LED on the front of the C/Port. It should be green if

connected to a blade that is powered on. The link status should also be green if the blade is

not currently powered on, but has been powered on at least once since the C/Port

connection was made. If the LED is not green, verify that the C/Port is connected to the

proper cable and that the chassis has power.

8. The Link Status Indicator LED on the PC blade should now also be green. If not, check the

following:

• Verify that the chassis has power and the blade is turned on.

• Verify that the link cable plugged into the PC blade is the same one that is plugged

into the respective C/Port.

• Verify that the C/Port cable and RJ-45 connectors have been wired correctly.

• Green LEDs at both ends indicate that the installation is correct.

Tuning the C/Port

When connected to an R4300 chassis in the data center, the C7130 provides an Auto-tune

function that delivers superior video performance with simplified tuning. Manual sharpness or

color tuning is not required, but fine-tuning may be performed to enhance the final video

experience.

When connected to an R4200 chassis, the C7130 provides automatic sharpness tuning, but

manual color tuning is required. Mis-aligned colors on the display indicate that automatic

color tuning is not available (in other words, the C7130 is not connected to an R4300 chassis),

or the switches are set incorrectly.

Previous C/Ports require both manual sharpness and color tuning, regardless of their

connection in the data center. Figure 10

Guide, which provides an easy way to adjust sharpness and color on C/Ports. This file is

downloadable from the ClearCube Technology Support Web site.

on page 15 shows the ClearCube C/Port Tuning

14 • C/Port Installation

Page 25

Figure 10. ClearCube C/Port Tuning Guide

Before Tuning a C/Port

Download the ClearCube C/Port Tuning Guide,

Tuning a C7130 Connected to an R4300 Chassis

A C7130 connected to an R4300 performs Auto-tuning for both sharpness and color. In most

cases, no further adjustment is required. However, a small amount of fine-tuning is possible.

Do the following:

1. Open the ClearCube C/Port Tuning Guide (downloadable from the ClearCube Technology

Support Web site and shown in Figure 10

on page 15). If the picture is sharp, you are

finished.

2. If desired, fine-tune the C/Port. See “Fine-Tuning Model C7130 C/Ports

” on page 16.

If the colors on the screen are noticeably mis-aligned, verify that the three color tuning

switches are set to position F. If resetting the color switches to position F has no effect, use the

procedures in “Tuning a C7130 Connected to an R4200 Chassis

” on page 15.

Tuning a C7130 Connected to an R4200 Chassis

Do the following:

1. Open the ClearCube C/Port Tuning Guide (downloadable from the ClearCube Technology

Support Web site and shown in Figure 10

on page 15). The colors on the screen should be

noticeably mis-aligned.

C7130 and C7120 C/Port Installation • 15

Page 26

2. Change the three color tuning switches from position F to position 1. The colors should be

in better alignment.

3. View the black-and-white test patterns. Adjust the Video Sharpness control for the

clearest picture.

4. View the color bar patterns. Beginning with the color bar that is the farthest to the left, turn

the color switches one click at a time until the vertical color bars are in the best alignment.

5. If desired, fine-tune the C/Port. See “Fine-Tuning Model C7130 C/Ports

” on page 16.

Tuning a C7120 or Earlier Model Connected to an R4300 Chassis

Do the following:

1. Verify that the three color tuning switches are set to position 1. Adjust the switches if

necessary. See Figure 9

2. Open the ClearCube C/Port Tuning Guide (downloadable from the ClearCube Technology

Support Web site and shown in Figure 10

3. View the black-and-white test patterns. Adjust the Video Sharpness control for the

clearest picture.

4. View the color bar patterns. Beginning with the color bar that is the farthest to the left, turn

the color switches one click at a time until the vertical color bars are in the best alignment.

Note: The screen may go black momentarily during tuning. If it remains black, verify that you

have not set a color tuning switch between switch positions, or that you have not set it

to position 0, which turns off that color.

on page 13.

on page 15).

Tuning a C7120 or Earlier Model Connected to an R4200 Chassis

Do the following:

1. Verify that the three color tuning switches are set to position 1. Adjust the switches if

necessary. See Figure 9

on page 13.

2. Open the ClearCube C/Port Tuning Guide (downloadable from the ClearCube Technology

Support Web site and shown in Figure 10

on page 15).

3. View the black-and-white test patterns. Adjust the Video Sharpness control for the

clearest picture.

4. View the color bar patterns. Turn the switches one click at a time until the vertical color

bars are in the best alignment, beginning with the color bar that is the farthest to the left.

Note: The screen may go black momentarily during tuning. If it remains black, verify that you

have not set a color tuning switch between switch positions, or that you have not set it

to position 0, which turns off that color.

Fine-Tuning Model C7130 C/Ports

Use these instructions if more tuning is needed:

Following manual or Auto-tune completion, any color switch set to its original positions (1 for

manual, F for Auto-tune) may be fine-tuned one position counter-clockwise (1 to 0 for

manual, F to E for Auto-tune). If a turn results in better vertical alignment of the color bars on

the tuning guide, alignment is complete. If not, the fine-tune switches should be returned to

their original position, and alignment is complete.

16 • C/Port Installation

Page 27

On the C7130, when color alignment is complete on a fine-tuned automatic alignment, all

three switches must be in position E or F. For a manually tuned system, at least one switch

must be in position 0 or 1. If these conditions are violated, the colors will be mis-aligned until

the switch positions are corrected.

Tuning Notes

Fiber C/Ports do not require any tuning.

Any C/Port, whether Auto-tunable or not, can be tuned manually by starting at switch

positions 1-1-1.

On normal restart, an Auto-tuned C7130 performs an Auto-tune cycle, then applies any

previously set fine-tuning. If the original blade or connecting cable is changed, the previous

fine tuning may not be optimal. Therefore, when blade or cabling changes are made, reset the

color switches to F-F-F to remove previous fine tuning adjustments, and retune if desired.

When a C7130 set to an improper manual or Auto-tune state is restarted, it comes up in the

manual tuning mode regardless of switch settings, and will not Auto-tune. To correct this,

reset the color switches to F-F-F for Auto-tune, or to 1-1-1 for manual tuning.

Automatic color tuning is normally superior to manual tuning. One reason is that manual

alignment allows the possibility of visual error. Another reason is that manual tuning may

conflict with the automatic adjustment built into some monitors. However, manual tuning may

give a better picture in some cases, such as with a poorly aligned display. When an Auto-tuned

system does not deliver satisfactory video performance, use manual tuning.

Using the C7130 Blade Reset Button

To restart the blade from a C7130, press and hold the Blade Reset Button for at least two

seconds to send a Reset signal to the blade. When the Blade Reset Button is pressed for less

than two seconds, a Reset signal is not sent. Instead, if the C7130 is connected to an R4300

chassis, the C/Port flashes its Link light to indicate connection to an R4300. If connected to an

R4200, nothing happens when the Blade Reset Button is pressed for less than two seconds. If

you are resetting a blade, allow the reset sequence to finish before pressing the Blade Reset

Button again.

Using the Blade Reset Button on Earlier C/Ports

The C7120 does not provide any circuitry to detect the chassis type. To restart the blade from

a C7120 or earlier C/Port, press the Blade Reset Button momentarily and then release it. Your

monitor will go black for several seconds while the blade resets. Allow the reset sequence to

finish before pressing the Blade Reset Button again.

C7130 and C7120 C/Port Installation • 17

Page 28

Locking out Mass Storage Devices

An additional feature provides increased levels of security with C/Ports. The R Series PC

blades offer a unique Mass Storage Lockout (MSL) security feature that disables the use of

any USB mass storage device at the desktop (e.g., key drives, floppy drives, CD-ROM drives,

etc.). The default factory setting does not enable this security feature – thus in the default

mode, any USB device, including mass storage devices connected to the C/Port, will be

recognized by the operating system. However, Switch Manager allows setting MSL in

software to lock out the use of storage devices.

To enable MSL in hardware, a jumper on the PC blade needs to be moved from the default

position to the adjacent position. You will need a set of needle-nose pliers to access the MSL

jumper. See Figure 11

blade model number. The default position for the jumper connects pins 2 and 3, and USB mass

storage devices function normally.

When the jumper is in the default position, you can also use a software setting to disable mass

storage devices. This software setting is accessible through the Switch Manager software.

Note: When the MSL jumper is physically set to lock out mass storage devices, the software

cannot override this.

on page 18 through Figure 14 on page 19 for the jumper locations by

3

1

JP6

Default Setting:

USB Mass Storage

devices function

normally

3

1

JP6

Security Setting:

USB Mass Storage

devices will not

function

JP6

Figure 11. Model R1200 MSL Jumper Location and Settings

18 • C/Port Installation

Page 29

3

1

JP6

Default Setting:

USB Mass Storage

devices function

normally

3

1

JP6

Security Setting:

USB Mass Storage

devices will not

function

JP6

Figure 12. Model R1300 MSL Jumper Location and Settings

JP6

JP6

JP6

1

3

Figure 13. Model R2100 MSL Jumper Location and Settings

13

Default Setting:

USB Mass Storage

devices function

normally

Default Setting:

Default Setting: Security Setting:

USB Mass Storage

devices function

normally

1

3

JP6

Security Setting:

USB Mass Storage

devices will not

function

JP6

13

USB Mass Storage

devices will not

function

JP6

Figure 14. Model R2200 MSL Jumper Location and Settings

C7130 and C7120 C/Port Installation • 19

Page 30

C7420 Fiber C/Port Installation

ClearCube C7420 Fiber C/Ports connect to ClearCube A1410 and R1350 PC blades to provide

the following features:

• LC fiber optic connector

• Support for one or two independently–configurable monitors

• PC–over–IP™ (PCoIP™), delivering PC video and audio over your IP network

• Four USB 1.1 ports

• HD audio in and audio out

Setting up the C7420 Fiber C/Port

1. Place your C7420 on a desk or use the included mounting bracket to mount the C7420.

2. Connect the following to the

– A USB keyboard and pointing device using the front or rear USB ports.

– An LC–SC fiber cable to the LC jack on the rear of the C7420.

– A monitor cable to each DVI-I port on the rear of the

– The power adapter supplied with the

3. Connect the SC connector end of the LC–SC fiber cable to the F6150–160 fiber

transceiver. Ensure that the F6150–160 is set up correctly (see F6150 User Guide and

Quick Start Guide for more information).

4. Ensure that you have connected the power cable and AC adaptor provided with your

C7420

. Connect the AC adapter to the

outlet. Briefly press and hold the power button to power on the

C7420

:

C7420

.

C7420.

C7420

, and then connect the power cable to a power

C7420

.

Power Indicator LED

Power

Connector

Fiber

Activity

Link Indicator

LC Fiber

Front

Rear

USB 1.1 Ports

Audio In Audio OutDVI–I Port 1 DVI–I Port 2

Power Button

USB 1.1

Ports

Remote Blade

Power Button

20 • C/Port Installation

Page 31

Understanding C7420 LED Indicators

The following lists detail the LED indicators on the front and rear of the C7420.

Front Panel

• Blue power indicator—Illuminated when the

• Link LED—Shows when a connection, or link, is established between the

blade.

– Green LED—C/Port and blade are connected.

– Red LED—C/Port and blade are not connected (for example, the

optic cable is disconnected).

Rear Panel

• ACT/LOS—This LED indicates fiber activity and a loss of signal.

– Blinking green—Signal activity

– Orange—Loss of fiber signal

• SPD—This LED indicates connection speed. When illuminated, a 100–megabit

connection is established.

C7420

is powered on.

C7420

C7420

and a

LC fiber

Configuring the C7420 Fiber C/Port

ClearCube A1410 and R1350 PC blades contain V5120 Dual Host cards connected to the

blade’s PCI Express® connector. V5120 cards and C7420 Fiber C/Ports contain PCoIP

processors that manage video and audio data. When configuring and working with a C7420

user port connected to a blade with a V5120 Dual Host card, remember that:

• There are two PCoIP processors:

– C7420 Fiber C/Port processor

– V5120 Dual Host card processor

• Each PCoIP processor has an IP address, for a total of two IP addresses

You must provision PCoIP processors on blades and on user ports when deploying C7420

Fiber C/Ports. To provision a C7420, you must:

1. Determine the IP address structure for your environment and determine the IP addresses of

the blade, the V5120 Dual Host card, and the C7420 Fiber C/Port.

2. Provision the PCoIP processors on the C7420 and on the blade that connects to the user

port.

3. Establish a network connection between the C7420 and a blade using any of the following

options:

– Direct cable connection or connection through local Ethernet switch

– DHCP connection

– ClearCube Sentral®

The following section describes the default network address settings that the C7420 Fiber

C/Port and V5120 Dual Host use.

C7420 Fiber C/Port Installation • 21

Page 32

Understanding Default Network Addresses

The C7420 Fiber C/Port and V5120 Dual Host are initially configured for DHCP connections.

If a DHCP server does not provide an IP address within 20 seconds of startup, the C7420 and

the V5120 use the default network addresses detailed in the following table.

Table 3. Default Static Addresses

C7420 Fiber C/Port V5120 Dual Host

IP Address

Subnet Mask 255.255.255.0 255.255.255.0

Gateway Address 192.168.1.1 192.168.1.1

Peer Address 192.168.1.101 192.168.1.100

192.168.1.100

192.168.1.101

Setting up Connections

The following sections describe how to configure your C7420 Fiber C/Port and dual–monitor

blade. Connect the devices using the any of the following methods as appropriate for your

environment.

Sentral

Server

Fiber Connection

Fiber Transceiver

C7420 Fiber C/Port

Sentral Switch

F6150–160

Data Center

Keyboard

Figure 15. ClearCube architecture with C7420 Fiber C/Port and F6150–160 fiber transceiver

Mouse

Network Switch

Chassis and Blades

Direct Connection

To perform the following steps, you must have the IP and MAC address of the V5120 Dual

Host card in the blade to which you are connecting. Default IP and MAC addresses are

provided in the following steps.

Note: The C7420 Fiber C/Port and V5120 Dual Host are initially configured for DHCP

22 • C/Port Installation

connections. If a DHCP server does not provide an IP address within 20 seconds of

startup, the C7420 and V5120 use the defaults detailed in “Understanding Default

Network Addresses” on page 22.

Page 33

1. Ensure that you have connected devices as described in “Setting up the C7420 Fiber

C/Port” on page 20.

2. Connect the chassis and C7420 Fiber C/Port.

a. Connect one end of a CAT5 or CAT6 Ethernet cable to the appropriate port on your

chassis.

• R4300 chassis—Insert the cable in the Secondary Network port.

• A3100 chassis—Insert the cable to the PCoIP port.

b. Connect the other end of the cable to the TX port on the F6150–160 fiber transceiver

(for more information, see the Quick Start Guide and User’s Guide with the

F6150–160 fiber transceiver).

c. Connect one end of a CAT5 or CAT6 Ethernet cable to the appropriate port on your

chassis.

3. Provision the C7420.

a. Briefly press and hold the power button on the front of the C7420 to power it on. The

C7420 displays a dialog box.

b. In the upper–left corner of the screen, click Options > Configuration to open the

Configuration window. Click Unlock on the lower–left portion of the window to

display the Unlock dialog box. Click OK to unlock the window (you should not need

to type a password).

c. In the Network tab, ensure that the Enable DHCP option is cleared. Specify the

following for the C7420 to which you are connecting:

• IP addresses

• Subnet mask

• Gateway

These values can be any value appropriate for your environment. Click Apply and

then click OK in the Attention dialog box.

d. From the Session tab, select IP address in the Identify Peer by line. Specify the

following in the appropriate fields:

• Identify Peer by—The V5120 IP address that you specified in the previous step

• Peer MAC Address—The V5120 MAC addresses (printed on a label on the side

of the blade)

e. Click Apply and then click OK to close the Configuration window.

f. You can now continue to provision your blade.

4. Provision the V5120 Dual Host on the blade.

a. Open a Web browser on a computer with a static IP address on the same subnet as the

blade (that is, the V5120 Dual Host card) you are provisioning.

b. In your browser, type the default IP address of the V5120 to open the PCoIP Web

interface.

c. From the Log In page, click Log In (you should not have to type a password).

d. From the Network page, ensure that the Enable DHCP option is cleared. Specify the

following values for the V5120:

• IP Address

• Subnet Mask

• Gateway

e. Click Apply and then click Continue.

C7420 Fiber C/Port Installation • 23

Page 34

f. Click Configuration > Session. Ensure that the Accept Any Peer option is clear. In

the Peer MAC Address line, type the MAC address of the C7420 (the MAC address

is on a label on the bottom of the C7420).

g. Click Apply and then click Continue.

h. Click Configuration > Monitor Emulation. Select the monitor emulation option for

both monitors (DVI 1 and DVI 2).

i. Click Apply and then click Reset. The V5120 displays a power state message. Click

OK.

5. Briefly press and hold the reset button on your blade to reset it. You can now start your

C7420 and click Connect to connect to your blade.

DHCP Connection

When connecting a blade and a C7420 on a network with a DHCP server, you can enable both

devices to accept a dynamic IP addresses.

Note: The C7420 Fiber C/Port and V5120 Dual Host are initially configured for DHCP

Note: Ensure that your chassis is connected to switch on a network with a DHCP server.

connections. If a DHCP server does not provide an IP address within 20 seconds of

startup, the C7420 and V5120 use the defaults detailed in “Understanding Default

Network Addresses” on page 22.

1. Ensure that you have connected devices as described in “Setting up the C7420 Fiber

C/Port” on page 20.

2. Connect the chassis and C7420 Fiber C/Port.

a. Connect one end of a CAT5 or CAT6 Ethernet cable to the appropriate port on your

chassis.

• R4300 chassis—Insert the cable in the Secondary Network port.

• A3100 chassis—Insert the cable in the PCoIP port.

b. Connect the other end of the cable to the TX port on the F6150–160 fiber transceiver

(for more information, see the Quick Start Guide and User’s Guide with the

F6150–160 fiber transceiver).

3. Provision the C7420.

a. Briefly press and hold the power button on the front of the C7420 to start it.

b. In the upper–left corner of the screen, click Options > Configuration to open the

Configuration window. From the Network tab, select the Enable DHCP option. Click

Apply and then click OK.

c. From the Discovery tab, select the Enable Discovery and Enable Host Discovery

options. Click Apply and then click OK.

Your C7420 Fiber C/Port is now configured to discover blades automatically.

4. Provision the V5120 Dual Host card on the blade.

a. From the C7420 desktop, click the Connect button to display the Discovered Hosts

b. Open a Web browser on a computer with a static IP address on the same subnet as the

24 • C/Port Installation

dialog box. Record the IP address and MAC address of the blade’s V5120 Dual Host

card, or host, and then click Cancel to close the dialog box.

blade with the V5120 Dual Host card you are provisioning. To open the PCoIP Web

interface on the V5120, type the IP address that you recorded in the previous step in

the browser.

Page 35

c. From the Tera1200 PCoIP Processor menu, click Configuration > Monitor

Emulation. Select the monitor emulation option for both monitors (DVI 1 and DVI 2).

d. Click Apply and then click Continue.

e. Click Configuration > Discovery and select the Enable Discovery option.

f. Click Apply to save your changes and a success message is displayed. Click Reset

and then click OK to reset your blade and apply your changes.

g. Close the browser.

5. Return to the C7420 Fiber C/Port and click Connect to display the Discovered Hosts

dialog box.

6. Click OK to connect your configured C7420 Fiber C/Port and blade.

Sentral Connection

When you use Sentral to manage C7420 Fiber C/Ports and blades, Sentral sets IP addresses

and session controls according to device MAC addresses and the assignments that the

administrator specifies. See Sentral Administrator’s Guide for information about using Sentral

to manage blades and user ports.

C7420 Fiber C/Port Installation • 25

Page 36

26 • C/Port Installation

Page 37

Chapter 3. MVX Installation

Hardware Installation

Installing the Video Adapter

If you ordered your multi-video system pre-configured, see “Software Installation and

Configuration” on page 29. If you are updating a single-monitor blade to add multi-video

functionality, follow the procedure on the installation sheet that accompanies your Quadro4

video card.

After installing the card, power up the blade and click Cancel when prompted by the New

Hardware Wizard to install software. “Software Installation and Configuration

describes installing the appropriate video driver.

Note: ClearCube is not responsible for damage caused to either video card adapters or PC

blades due to improper customer installation. Both the video adapter cards and PC

blades contain parts sensitive to electrostatic discharge. The customer must use

industry-accepted practices to ensure the person(s) handling the equipment is

properly grounded during the installation. ClearCube can provide custom Professional

Services upgrade packages. Please contact your Account Manager for details.

” on page 29

Installing the MVX

Install the MVX at the user’s desktop. The MVX and the C/Port share the same footprint and

case styling, and can be placed one on top of the other. The MVX has its own power supply

separate from the C/Port. Figure 16

the output of the C/Port and to the monitors.

The actual monitor connections are accomplished by video splitter cables that have an LFH-60

connector on one end and two monitor connectors on the other. Note that each splitter cable

has either two DB-15 or two DVI-I connectors. The DVI-I cable is an integrated connector

that works with both analog input and digital input monitors.

on page 28 shows how the MVX should be connected to

Hardware Installation • 27

Page 38

Figure 16. MVX Connection Diagram

Note: The monitor connector ends of each splitter cable are stamped with either a 1 or a 2 to

indicate the output sequence order.

The Multi-Video Solution supports several different resolutions and refresh rates. Table 4 lists

the supported combinations. These combinations apply per monitor, with all monitors set to

identical resolutions and refresh rates.

Table 4. Supported MVX Resolution and Refresh Rates

Screen Resolution * Refresh Rates

640 x 480 (DOS mode only) 60 Hz

720 x 400 (DOS mode only) 60 Hz

800 x 600 60/75/85 Hz

1024 x 768 60/70/75/85 Hz

1152 x 864 75 Hz

1280 x 768 60/75/85 Hz

1280 x 960 60 Hz

1280x 1024 60/75 Hz

The ClearCube Multi-Video solution was designed and engineered to work with the Quadro4

video adapter on the PC blade. No tuning features are provided on the MVX. All tuning is

accomplished via the C/Port. Color tuning on the C/Port may be required for cable runs longer

than 100 meters.

Note: Fiber C/Ports do not require any tuning.

28 • MVX Installation

* When changing screen settings, the number of pixels is multiplied based on screen

orientation. For example, in 2x1 mode, at 1280 x 1024, the resolution is shown as 2560 x 1024.

Page 39

Once the C/Port has been installed and the blade has been powered up, the user needs to fine

tune the video image by choosing the desired resolution, selecting the refresh rate that looks

best, and using the tuning dial on the rear of the C/Port to sharpen the video image

appropriately. In addition, color tuning may be required using the color switches on the bottom

of the C/Port, as described in the C/Port Installation chapter.

The Video Sharpness knob on the rear of the C/Port affects all the monitors connected to the

MVX equally. Therefore, for the best video performance and consistency, monitors connected

to an individual MVX should be of the same make and model.

The following table shows the list of supported configurations for various blade-C/Port

combinations.

Table 5. Supported Blade, C/Port, and MVX Configurations

Multi-Video

C/Port Fiber C/Port

Solution

(C/Port & MVX)

Single Monitor Blade

(integrated graphics)

Multi-Video Blade

(Quadro4 adapter)

Supported Supported Supported

Supported

(Monitor 1 only)

(Monitor 1 only)

Software Installation and Configuration

The ClearView video driver is based on NVIDIA’s award-winning nView software. It

provides the user with a graphical interface for setting up and configuring the displays.

ClearView is seamlessly integrated within the Microsoft Windows environment, helping users

to maximize productivity through advanced desktop and application management. This

customized driver, available only from ClearCube, is required for using the MVX. Other

drivers do not support the full multi-monitor capabilities.

Removing Outdated NVIDIA Drivers

To remove outdated drivers, do the following:

1. Open the Control Panel and double click the System icon.

2. Select the Hardware tab and click the Device Manager button.

3. In the Device Manager window, expand the Display Adapters section,

4. Right-click on the NVIDIA line item matching the video adapter installed on the blade and

select Properties. Verify that the NVIDIA driver installed on the blade is the same

version available on the ClearCube web site at support.clearcube.com

5. If you have the most current version, go to “Installing the NVIDIA Driver

6. Click Add or Remove Programs and select NVIDIA Windows 2000/XP Display

Drivers. See Figure 17

on page 30.

Supported

(Monitor 1 only)

Supported

.

” on page 30.

Software Installation and Configuration • 29

Page 40

Figure 17. Removing the Old NVIDIA Drivers

7. Click Change/Remove and Yes at the next prompt to remove the currently installed

NVIDIA drivers.

8. Click OK to restart the computer. A default video driver in Windows provides video

support for your monitor.

Installing the NVIDIA Driver

Download and install the latest NVIDIA-supplied driver from the ClearCube web site at

support.clearcube.com

Note: DO NOT install any driver obtained directly from the NVIDIA web site, as this driver

does not support the ClearCube Multi-Video Solution.

1. Run the driver installer application.

2. Answer Yes when you are prompted to overwrite existing files.

3. Restart the computer.

4. After restarting the computer, right-click on the desktop, select Properties to bring up the

Display Properties dialog box, and click on the Settings tab, shown in Figure 18

page 31.

.

on

30 • MVX Installation

Page 41

Figure 18. Display Settings Tab

5. Set the resolution to 1280 x 1024 (not all flat panel monitors support resolutions greater

than 1024 x 768) pixels and click Apply. Click OK if prompted.

6. Click the Advanced button and then select the Monitor tab, shown in Figure 19

.

ClearCube recommends that the screen refresh rate be set to 60 Hz for flat-panel monitor

use, or 75 Hz for CRT use. Certain monitor models may work optimally at different

refresh rates, so these refresh rates should be used as guidelines, not requirements.