Page 1

5

•

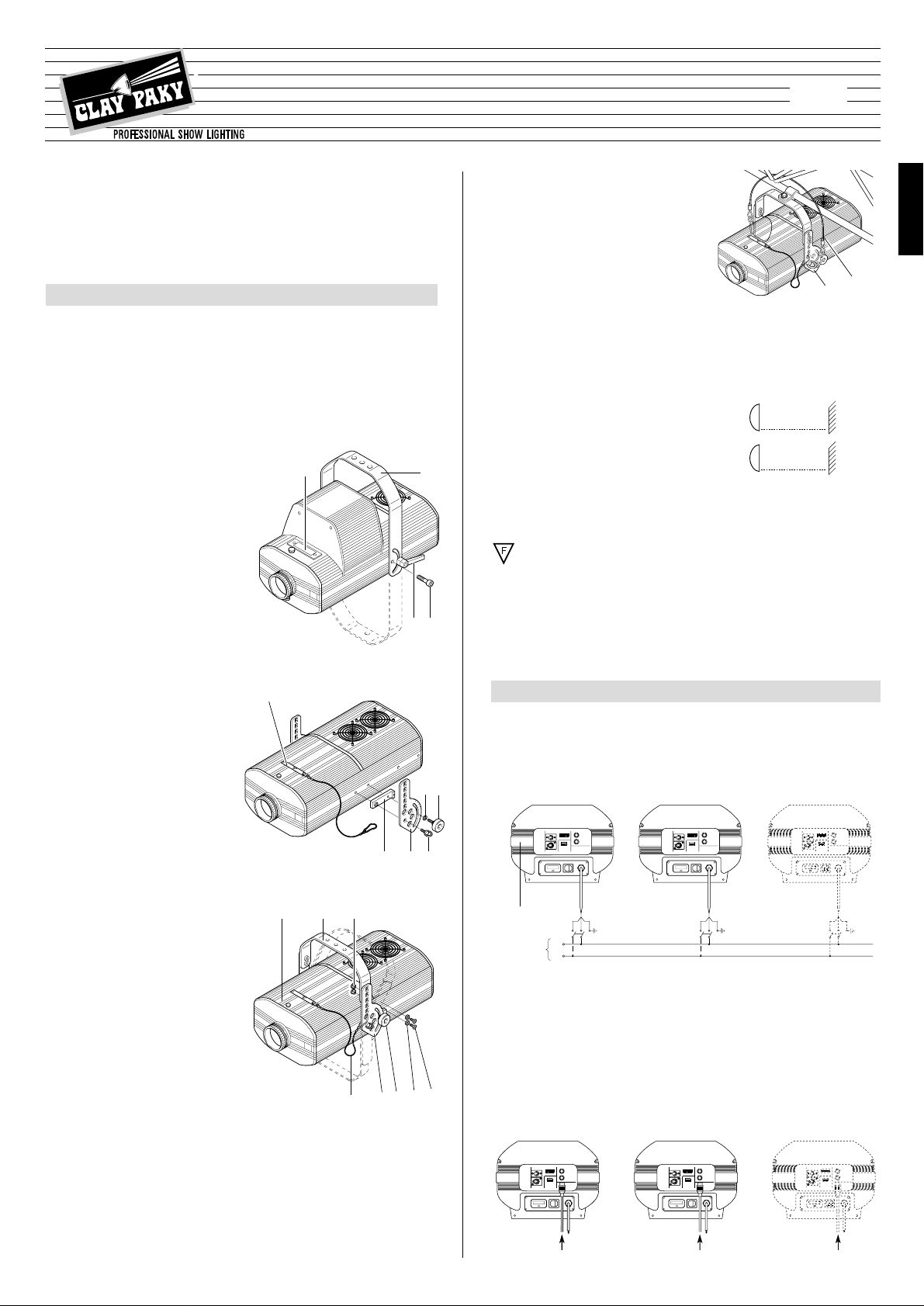

Installing the projector

The projector can be mounted in any position without its operating characteristics

being affected.

IMPORTANT: fix the projector in the desired position utilizing the holes in the

bracket ( 2).

Secure preferably using a ø10 bolt with nut and lock washer (version HMI 575) two ø12 bolts with nuts and lock washers (version HMI 1200).

Make certain that the anchorage is stable before positioning the projector.

IMPORTANT: the safety wire must be secured to the projector and to the support-

ing structure in such a way that if the bracket should f ail, the projector will f all as short

a distance as possible.Following any such failure, the safety wire must be replaced

with a genuine Clay Paky spare.

•

Minimum distance from target objects

The projector must be positioned in such a way that

objects struck by the beam are separated from the

lens at least by the distance indicated on the lamp

change label against the symbol shown alongside.

•

Minimum distance of inflammable materials from any part of the equip-

ment: 0.1 m (4”) for HMI 1200, 0.07 m (3”) for HMI 575.

The appliance may be mounted on surfaces rated normally inflammable.

IMPORTANT: For better and more reliable operation of the projector, the ambient

temperature must not exceed 35° C (95° F). Protection factor IP 20: the appliance is

protected against penetration of solid bodies more than 12mm (0.5”) in diameter

(first digit 2), but can be damaged by spray, jet, drip or rain water (second digit 0).

TIGER C.C.

ENGLISH

HMI 575

HMI 1200

2

4

8

765

1

3

3

1

POWER SUPPLY AND INTERFACE

2

•

Connecting to the electrical power supply

The operations described in this heading must be carried out by a licensed

electrician.

It is good policy to connect projectors to the power supply by wa y of dedicated switches, so that each can be turned on and off individually from a remote station.

The projector is designed to operate at the voltage and frequency indicated on the

electrical data plate (14) affixed to the rear end.

Check that these two values correspond to the mains voltage and frequency.

IMPORTANT: the projector must be connected to a power supply circuit having

a proper earth system (Class I appliance).

•

Connecting the control signals

0-10V CONNECTION

- Independent operation

INST ALLING THE PROJECTOR

1

•

Unpacking

Open the box, remove the projector from the packing and place it on a flat, horizontal surface.

Unpack the standard accessories supplied with the equipment. Inspect the lamp

change label (1) and replace it with one of the optional language versions if necessary.

Make certain that the label is never removed, as it displays important safety information.

•

Initial assembly operations (HMI

575 version)

Position the bracket (2) as required and

secure by tightening the knobs (3). The

bracket can also be fitted on the underside of the projector by removing screws

(4) and knobs (3).

•

Initial assembly operations (HMI

1200 version)

Position block (5) on the projector

body so that it is aligned with the

threaded holes; secure graduated

plate (6) with eyebolt (7) and then fit

knob (3) and washer (8).

Position bracket (2) on graduated plate

(6) at the desired height; inser t bushing

(9), chamfered washer (10) and screw

(11) in the selected hole and tighten

using the supplied Allen key.

The bracket can also be fitted on the

underside of the projector by inverting

the position of graduated plate (6).

If the projector has been shipped with

plate (6) already fitted, before removing the plate (if necessary) remove the

safety bolt located inside the fixture in

correspondence with eyebolt (7).

Set the projector support in the

desired position and secure by tightening knobs (3).

Fasten the safety wire (12) of lamp

change cover (13) to graduated plate (6).

•

Fitting the lamp

Refer to directions for replacement of

the lamp given under heading 6 MAINTENANCE.

9213

12 6 3 10 11

14

•

Fitting the safety wire

A safety wire (25) is supplied for use with

version HMI 1200.The wire must be secured

to the gantry or other structure and then

anchored to the eyebolts (7) on the projector

itself.

25

7

IMPORTANT: Read carefully It is essential for the correct and safe use of the

equipment that erectors and operators should be fully conversant with the

information and instructions given in this manual.

INSTRUCTION MANUAL

ENGLISH

®

(5’ 11”)

1.8 m

HMI 575

(8’ 2”)

2.5 m

HMI 1200

0.00

10

0.00

10

0.00

1 0

Alimentation

L

N

0.00

10

0 - 10V 0 - 10V 0 - 10V

0.00

10

0.00

1 0

Page 2

6

0.00

10

0.00

10

0.00

1 0

The connection between controller and projector must be made

using a multicore cable with 8 wires of 0.25mm

2

section and a

DIN 8 PIN 45° plug/socket connector.

RS 232/423(PMX) - DMX 512 CONNECTION

Projectors are wired up to the controller and one to the next using two-core screened

cable and Cannon 5 pin XLR type plug/socket connectors.

To connect a DMX line, a ter minating plug (15) with a 100Ω resistor wired between

pins 2 and 3 must be fitted to the last projector connected in series; the plug is not

required when using an RS232/423(PMX) signal.

The wires must not come into contact with each other or with the metal casing of the plug.

The casing of the plug/socket must be connected to the screen and to pin 1

of the connectors.

Having completed the operations described above, press the on/off switch (16).

Check that the lamp comes on and that the auto-reset sequence starts.

•

Projector address codes (for digital signals)

Each TIGER C.C. projector uses 3 control channels. To ensure that different projectors are addressed correctly by the controller, a code must be assigned to each one.

This operation is carried out on each TIGER C.C. by setting the microswitches as

indicated in the table below.

SIGNAL

SCREEN

SIGNAL

RS232/423 (PMX)

1

2

3

45

SIGNAL

SCREEN

SIGNAL

54

3

2

1

DMX 512

- Projectors operating simultaneously and identically

0 - 10V

0.00

10

0.00

10

0.00

1 0

15

TEST

256

128643216842

1

ON

10987654321

1112

PAN

TILT

Is

THE DIGITAL START

ADDRESS IS THE SUM

OF THE NUMBERS

PRODUCED BY THE

SELECTED SWITCHES

DIGITAL

START

ADDRESS

AND

OPTIONS

SELECT

EG.

RESPOND

C.1 - 4

EG.

RESPOND

C.17 - 20

RUN TEST

SEQUENCE

DMX 512

RS232/423

: 1 = ,2 = SIG - ,3 = SIG +

: 1 = ,2 = SIG ,3 = SIG

DIGITAL INPUT

ANALOGUE

INPUTS 0 - 10V

Projector

1-3

4-6

ON

OFF

ON

OFF

TEST

256

128

64

32

16

842

1

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

1

2

3

7-9

4 10-12

5 13-15

6 16-18

7 19-21

8 22-24

9 25-27

10 28-30

CODE

- Channels

Projector - Channels

Projector - Channels

Projector - Channels

Projector - Channels

Projector - Channels

Projector - Channels

Projector - Channels

Projector - Channels

Projector - Channels

Spotlight selection

Setting the TEST switch to the ON position for a few seconds with the projector powered-up, an auto-reset routine is carried out.Leaving the TEST switch at the ON position for a longer period, a full self-test program will be completed;once the operation

has terminated, return the switch to the OFF position.

POSITIONING THE PROJECTOR

3

•

Alignment procedure

Before positioning the projector, set the channels as shown in the following table:

CHANNEL FUNCTION

4

CHANNEL

1 COLOUR

2

DIMMER/STOPPER/STROBE

3 FROST

SLIDER POSITION

0% (white beam)

100% (maximum aperture)

0% (white beam)

CHANNEL FUNCTION

3

2

After setting up the channels loosen the

knobs (3), and manoeuvre the projector

on its bracket (2) until the beam is

directed at the centre of the scene, then

retighten the knobs (3).

•

Adjusting the lens

Move the lens (17) back and forward

until the projected image is satisfactorily

focused, then tighten knob (18).

1817

• DIMMER/STOPPER/STROBE - channel 2

0

1

3

5

7

8

9

WHITE

RED

YELLOW

VIOLET

GREEN

ORANGE

BLUE

PINK

6

4

2

10

The change of colour in response to

movement of the potentiometer is linear and continuous so that the slider

can be stopped in intermediate positions to obtain a two colour beam.

In the 0% to 50% range of adjustment,

the dimmer opens gradually to maximum aperture. Strobe effect is produced from 54.7% to 95%, with frequency increasing from 1 to 7 flashes

per second.

The aperture remains fixed between

95% and 100% of the range.

COLOUR WHEEL

DIMMER/STOP/STROBO

FROST

1

2

3

•

COLOUR WHEEL - channel 1

16

1 COL

3 FROST

TIGER C.C.

Is

STOP 2

10

9

8

7

6

5

4

3

2

1

0

Page 3

7

•

Changing the colour filters

Having opened the projector, identify the filter to be changed, grip firmly between

thumb and forefinger and push against the

spring clip (23) until free of the fixed clips

(24). Bend the filter outwards and remove.

Offer the new filter to the spring clip (23)

and anchor behind the two fixed clips (24).

•

Routine cleaning

To maintain the light output of the projector undiminished, parts that tend to accumulate dust and grease must be cleaned

periodically.

In most circumstances, the projector will

give long and trouble-free service if these

simple guidelines are followed.

To remove dirt from the lenses and filters,

use a soft cloth moistened with any liquid

detergent suitable for cleaning glass.

IMPORT ANT: do not use solvents or alcohol

Parts that need cleaning frequently.

Parts that need cleaning monthly.

Internal components should also be given

a general clean once a year, dislodging

dust and dirt with a brush and removing it

simultaneously with a vacuum cleaner.

TROUBLESHOOTING

7

0

1

2

3

4

5

6

7

8

9

10

•

FROST - channel 3

The frost filter is inserted gradually as

the slider is advanced.

LENS UNITS

5

GRAPHS SHOWING BEAM DATA AND ILLUMINATION VALUES

7

6

5

4

3

2

1

0

1

2

3

4

5

6

7

BEAM OPENING m

0 5 10 15 20 25 30 35 40 DISTANCE m

0 1,87 3,74 5,61 7,48 9,35 11,2 13,10 14,96 DIAMETER m

HMI 575

3.600

HMI 1200

8.600

900

2.150

400

955

225

537

144 100 73 56 LUX

344 238 175 135

Objective 1:1,8 / 170 - Standard

7

6

5

4

3

2

1

0

1

2

3

4

5

6

7

BEAM OPENING m

0 5 10 15 20 25 30 35 40 DISTANCE m

0 1,16 2,32 3,48 4,64 5,80 6,96 8,12 9,28 DIAMETER m

HMI 575

8.200

HMI 1200

19.800

2.050 911 512 328 227 167 128

Objective

1:2,5 / 250

LUX

4.950 2.200 1.237 792 550 404 309

13°

21°

0” 6’ 2” DIAMETER ft in

12’ 3”

18’ 5” 24’ 6” 30’ 8” 36’ 9” 43’ 49’ 1”

0” 16’ 5” DISTANCE ft in

32’ 10”

49’ 3” 65’ 7” 82’ 98’ 5” 114’ 10” 131’ 3”

0” 16’ 5” DISTANCE ft in

32’ 10”

49’ 3” 65’ 7” 82’ 98’ 5” 114’ 10” 131’ 3”

0” 3’ 10” DIAMETER ft in

7’ 7”

11’ 5” 15’ 3” 19’ 22’ 10” 26’ 8” 30’ 5”

MAINTENANCE

6

IMPORTANT: isolate the projector from the electrical power supply before commencing maintenance work of any description. The maximum temperature on the

outer surface of the projector under normal operating conditions is shown on the lamp

change label. After switching off, do not remove any part of the projector for at least

2 minutes, as indicated on the lamp change label (1).

Once this time has elapsed, the risk of a lamp exploding is practically zero.If the lamp

needs changing, wait a further 20 minutes to avoid the risk of burns.

In the event of a lamp exploding, the appliance is designed to prevent fragments of

glass from being scattered. The lenses supplied with the appliance must be fitted at

all times, and if visibly damaged, must be replaced with genuine spares.

•

Opening the projector

Loosen the knobs (19) and remove the lamp access cover (13).Once the necessary

work has been completed, refit the cover and tighten the knobs.

19 13

19 13

•

Changing the lamp

Open the projector, loosen the two side nuts (20) of the lamp to be changed and

remove it from the supports (21).

Remove the new lamp from its bo x, loosen the two side nuts (20) and locate the lamp

in the supports (21). Finally, retighten the nuts.

IMPORTANT: for uniform distribution of the light beam, the lamp must be positioned so that the glass pip (22) on the bulb does not coincide with the optical axis

of the projector.With this in mind, locate the pip as high up as possible.

CAUTION:The projector uses a high pressure lamp with external starter.

- When fitting a new lamp, read the manufacturer's instructions carefully.

- The lamp must always be changed without delay if damaged or deformed

by heat.

20

21

20 22

ENGLISH

No electrical power supply. Check that po wer is a vailab le at the mains

socket.

Signal transmission cable short-circuiting or disconnected.

Change cables.

PROJECTOR DOES NOT LIGHT UP

ELECTRONICS NOT WORKING

FAULTS

PROJECTION FAULTY

REDUCED BRIGHTNESS

POSSIBLE CAUSES

CHECKS AND REMEDIES

•

•

•

•

•

•

••

•

Lamp expended or faulty. Change lamp (see instructions).

Address codes incorrect.

Defect in electronic circuits.

Lenses broken.

See projector coding instructions.

Contact an authorized technician.

Contact an authorized technician.

Dust or grease deposit. Clean (see instruct ions).

24

23

Page 4

8

TECHNICAL DATA

CONSTRUCTION

FEATURES

Safety devices

•

Power supply shuts off automatically

in the event of overheating or cooling

system failure.

•

Power shuts off automatically when

lamp change cover is opened.

Cooling

Forced ventilation cooling system using

axial flow fans.

Housing

•

Extruded diecast aluminium.

•

Epoxy powder coated finish.

Mounting

•

Steel bracket with epoxy powder coated finish.

•

Six installation positions 25 mm (1”)

apart (HMI 1200 version only).

•

Bracket adjustable through 100°.

•

Anchorage for safety wire (HMI 1200

version only).

Operating position

Will function in any position.

Weights and dimensions

•

HMI 575: 21 kg. (46 lbs 3 ozs)

•

HMI 1200: 37 kg. (81 lbs 6 ozs)

ELECTRICAL

MECHANICAL SPECIFICATIONS

Power supply

•

220 - 240V 50Hz

•

200 - 220V 60Hz

Lamp

Metal halide with special built-in power

supply.

•

Type HMI 575W

- Cap SFc 10-4

- Colour temperature 6000 K

- Luminous flux 49000 lm

- Average life 750 h

•

Type HMI 1200W

- Cap SFc 15.5-6

- Colour temperature 6000 K

- Luminous flux 110000 lm

- Average life 750 h

Power consumption

•

Version HMI 1200

- 3000 VA at 220V 50Hz

•

Version HMI 575

- 1500 VA at 220V 50Hz

Motors

N. 3 microstepping motors with full

microprocessor control.

OPTICAL SYSTEM

Main optical unit

•

Base in diecast aluminium

•

Twin lens condenser

•

High luminous intensity spherical

reflector.

Lens units

•

Standard: 1:1,8/170 mm

•

Optional: 1:2,5/250 mm

CONTROL SYSTEM

Channels

N. 3 control channels.

Inputs

TIGER C.C. is designed to accept analog or digital control signals from controllers or computers.

•

RS232/423(PMX) or DMX 512 digital

serial input

•

0-10V analog input

8

WIRING DIAGRAM

9

(13-17.5”)

330 ÷ 445

(14.6”)

370

(25.6”)

650

(13”)

330

(16.9”)

430

(31.5”)

800

HMI 575

HMI 1200

HMI 575

HMI 1200

The products referred to in this manual comply with EC

Directives on:

• Low Voltage 73/23

• Electromagnetic Compatibility 89/336

The specifications published in this manual are not binding, and may be revised or updated

at any time by Clay Paky without notice in the interests of improving product quality.

Loading...

Loading...