Page 1

INSTALLATION / OPERATION / MAINTENANCE

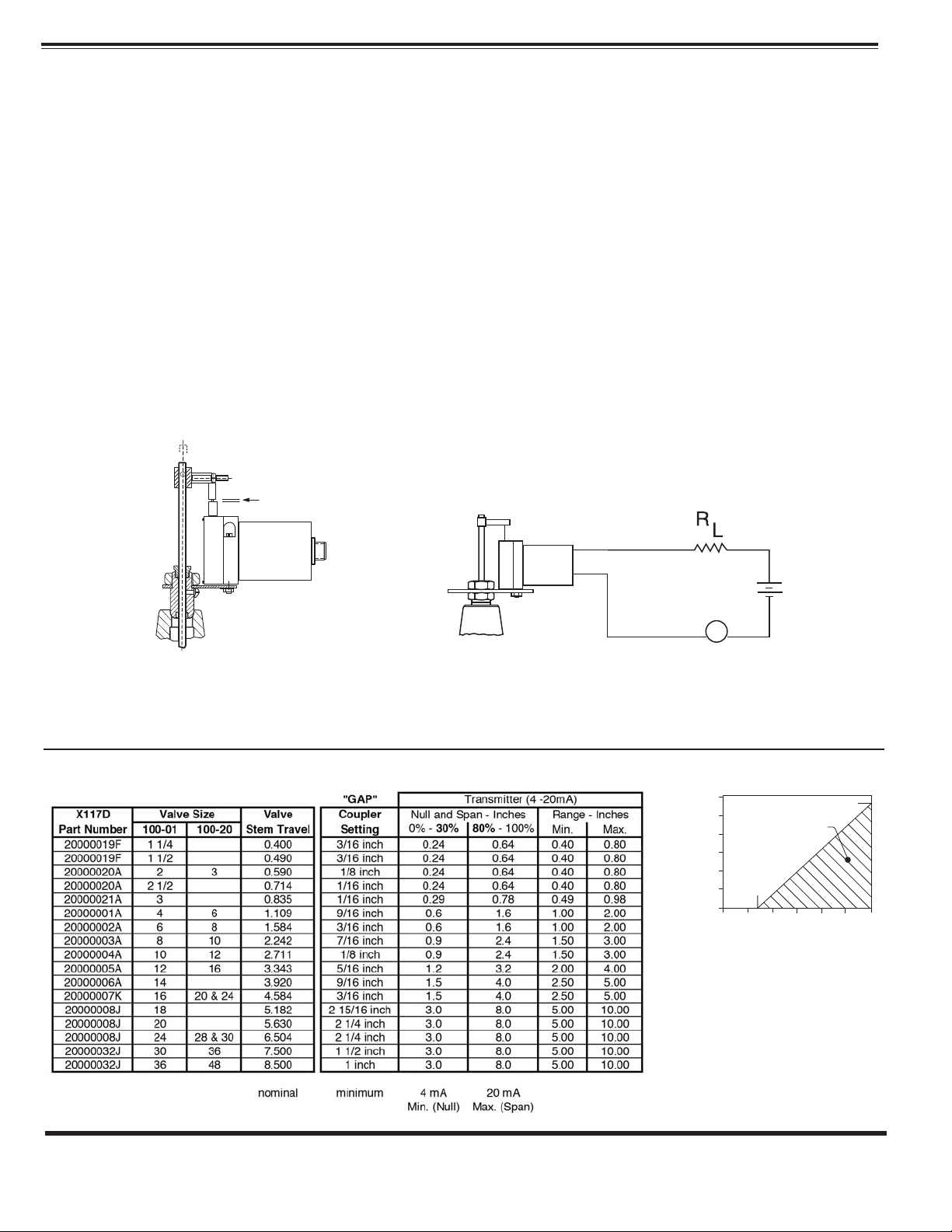

Valve Position Transmitter

DESCRIPTION

The Cla-Val Model X117D Valve Position Transmitter is designed to

provide analog signal (4 - 20 mA, 2 wire) output of valve position

for Cla-Val Main Valves. A stem extension is fitted to the main

valve stem with the position transmitter mechanically linked to it.

The valve stem is mechanically linked to the electronics for an output signal that is in direct proportion to valve position. Provisions

are made for bleeding air from valve cover through a small bleed

screw and washer located on adapter.

INSTALLATION

Normally, the X117D is supplied mounted on the Cla-Val main

valve. If X117D has not been installed at factory, then install stem,

adapter, mounting bracket with transmitter (in that order) as shown

on drawing No. 200000.

OPERATION

The signal from the position sensing linkage mechanism is converted

to a two-wire 4 to 20 mA current output appearing at the output terminals. The excitation voltage ranges from 12 to 35 Volts DC.

The minimum supply voltage is a function of total loop resistance.

It may be calculated using the formula:

V(min) = (0.02 x Load Resistance) + 12 VDC

WIRING

Loosen jam nut holding transmitter and bracket to adapter when

connecting transmitter to field wiring. Tighten jam nut after connections

and adjustments are made.

Use good field wiring practices for low voltage DC analog instrumentation wiring (suggest minimum of 18-gauge multistrand wire).

Avoid potential ground loops. Calibration of transmitter should be

done with a temporary hookup of test equipment before final wiring

connections are made.

Units with NEMA 6, IP-68 enclosures have permanently attached

8' shielded cable leads. Use Red wire for positive and Black wire

for negative.

Units before Feb. 2000 have NEMA 6 enclosure with MS3102E14S-6PAmphenol plug and socket for attaching leads. Use "A"

contact for positive and "B" contact for negative.

For best noise immunity, use twisted pair shielded cable to connect

field wiring to the transmitter. The shield of the cable should be

open at the transducer and grounded at the other end. Units with

permanently attached cable are supplied with shield open inside

transmitter.

CALIBRATION

1. When properly adjusted, the transmitter will have the valve

closed position within 0% to 30% of total transmitter range and the

valve open position within 80% to 100% of total transmitter range.

At valve closed position the transmitter will have a 4 mA output and

at fully open position the transmitter will have a 20 mA output.

IMPORTANT CAUTION

spring loaded to retract and can be damaged by a sudden release

: The transmitter wire rope mechanism is

MODEL

X117D

of the wire rope. Use care to insure that it is returned to the transmitter very slowly during start up and operation. This damage may

not be covered by warranty.

2. You will need the following tools to calibrate and align the X117D:

A.) A small flat blade screwdriver (.105 Max. width x .023”

max. thickness) with non-metallic handle to fit the span and

null potentiometer

B.) A 4-20 mA calibration/tester or multiamp-tester/meter or

some means of measuring the 4-20 mA transmitter output

C.) Hand tools to adjust and tighten X117D assembly during

calibration

3. Preliminary mechanical settings. (Refer to Drawing No. 200000)

Be sure that the valve is in the fully closed position. See Technical

Manual for the main valve for information on this. Check that line

isolation or block valves are closed.

Adjust Nut Coupler (9) up or down on stem until gap between wire

rope end and transmitter housing is according to table (below).

The Hex Coupler (10) is used to tighten nut coupler to stem. A

minimum gap is required, see Reference Table. (Refer to Drawing

No. 200000)

Long threaded end of Hex Coupler (10) has two hex nuts (11) for

adjusting position of end of wire rope directly over the opening in

the top of the transmitter. Use one hex nut on each side of the wire

rope end. Wire rope should go vertically up and down without

noticeable angle from vertical.

4. Temporarily connect calibration equipment (milliamp meter and

power supply or portable instrumentation tester) to transmitter

wiring. Calculate total loop resistance to determine minimum load

resistor. See OPERATION

screws found on housing end.

section. Remove two calibration cover

Page 2

Refer to calibration equipment and adjust transmitter potentiometer

M

+

Meter

12 to

35 VDC

–

+

Red

Black

_

marked “NULL” until the meter reads 4 mA. A clockwise turn

increases output. Use care in adjusting the potentiometer while

turning the screwdriver.

Refer to calibration equipment (see Step 4) and adjust potentiometer

marked “SPAN” until the meter reads 20 mA. A clockwise turn

increases output. Use care in adjusting the potentiometer while

turning the screwdriver.

5. For the most accurate calibration it is necessary to open valve

fully. CAUTION: This will either allow a high flow rate through the

valve, or the downstream pressure will quickly increase to the

inlet pressure. In some cases, this can be very harmful. Where

this is the case, and there are no block valves in the system to

protect the downstream piping, it should be realized that steps

should be taken to remedy this situation before proceeding further.

Normally, block valves are to be used to protect downstream piping

while the valve is in the open position. Close downstream block

valve. Vent cover chamber to atmosphere. Slightly open inlet

block valve. Allow valve to open while fluid is vented from cover

chamber. When flow stops valve is in the fully open position.

Note: continuous leakage from cover chamber could mean additional

troubleshooting of the main valve or pilot system must be done.

6. With valve in fully open position, inspect position of wire rope

and nut coupler. (See Step 3). Adjust if necessary.

GAP

7. There is some interplay between:

1.) the “span” and “null” settings,

2.) the 4 to 20 mA signal and,

3.) the actual valve open and closed positions.

Repeat steps 4-6 above. Cycle valve from open to closed positions and check settings as necessary to achieve desired valve

position signal accuracy.

8. Remove all calibration equipment and attach permanent

wiring. Recheck wiring and output signals at remote location.

See Wiring section. Reinstall two cover screws on housing.

Recheck and tighten all fasteners. Bleed air from main valve

cover through small bleed screw and washer located on one

wrench flat of adapter.

MAINTENANCE

The X117D is constructed of durable materials which normally

requiring no lubrication or periodic maintenance. The two ‘O’ rings

(2) (p/n 00951E) in the adapter (5) that seal against the stainless

steel actuating stem (1) will need replacement if signs of leakage

at the stem occur.

Coupler gap is set with valve in fully closed position. This establishes the minimum mechanical position for 4 mA output.

ADJUSTMENT: Zero and span adjustments allow setting the 4 mA position (valve closed) within 0% to 30% of total transmitter range

and setting the 20 mA position (valve fully open) within 80% to 100% of total transmitter range.

X117D Adjustment Parameters

MAX. LOAD, R (OHMS)

Operating Zone

1200

1000

800

600

400

200

0

0

OPERATING ZONE

12V

10

15

SUPPLY VOLTAGE, V

1150 OHMS

25

30

20 35

CLA-VAL

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

Copyright Cla-Val 2012 Printed in USA Specifications subject to change without notice.

N-X117D (R-8/2012)

Loading...

Loading...