Page 1

15 DEGREE COIL NAILER

Model CON15

Part No: 3110295

OPERATING & MAINTENANCE

INSTRUCTIONS

GC0817

Page 2

INTRODUCTION

Thank you for purchasing this CLARKE Coil Nailer

Before attempting to operate the machine, it is essential that you read this

manual thoroughly and carefully follow all instructions given. In doing so you

will ensure the safety of yourself and that of others around you, and you can

also look forward to the product giving you long and satisfactory service.

GUARANTEE

This CLARKE product is guaranteed against faulty manufacture for a period of

12 months from the date of purchase. Please keep your receipt as proof of

purchase.

This guarantee is invalid if the product is found to have been abused or

tampered with in any way, or not used for the purpose for which it was

intended.

Faulty goods should be returned to their place of purchase, no product can

be returned to us without prior permission.

This guarantee does not effect your statutory rights.

ENVIRONMENTAL PROTECTION

Do not dispose of this product with general household waste. All tools,

accessories and packaging should be sorted, taken to a recycling

centre and disposed of appropriately.

PARTS & SERVICE

For parts & Servicing, please contact your nearest dealer, or

CLARKE International, on one of the following numbers.

PARTS & SERVICE TEL: 020 8988 7400

PARTS & SERVICE FAX: 020 8558 3622

or e-mail as follows:

PARTS: Parts@clarkeinternational.com

SERVICE: Service@clarkeinternational.com

2

Page 3

OVERVIEW

The CON15 Coil Nailer is suitable for use on softwood, hardwood, plywood,

hardboard, fibreboard or MDF, and will penetrate flexible plastics, leather,

fabrics, PVC & rubber sheet materials. It is not suitable for piercing hard

laminates, brittle plastics or metals (other than light foil).

Unpack and lay out the components, checking against the following list. Any

damage or deficiency should be reported to your Clarke dealer immediately.

• Coil Nailer

• Oil Bottle

• 4 x Hexagonal Keys (3, 4, 5 & 6 mm)

• 1 x Nail Roll

• Black Moulded Case

• Operators Manual (this document)

Your Coil Nailer has been designed to give long and trouble free service. If,

however, having followed the instructions in this booklet carefully, you

encounter problems, take the unit to your local Clarke dealer.

TECHNICAL SPECIFICATION

Feature Specification

Weight 4 kg

Dimensions (lxwxh) 330 x 130 x 355 mm

Operating Air Pressure 70-100 psi (4.8-6.9bar)

Max Air Pressure 120 psi (8.2 bar)

Drive Speed 300 nails/min

Compressed Air Consumption 6.5 cfm

Airline Connection 1/4" BSP male

Magazine Capacity 300 nails

Max Sound Pressure 99.5dB(A)

Sound Power Measured 112.5dB(A)

Please note that the details and specifications contained herein, are correct at the

time of going to print. However, CLARKE International reserve the right to change

specifications at any time without prior notice.

3

Page 4

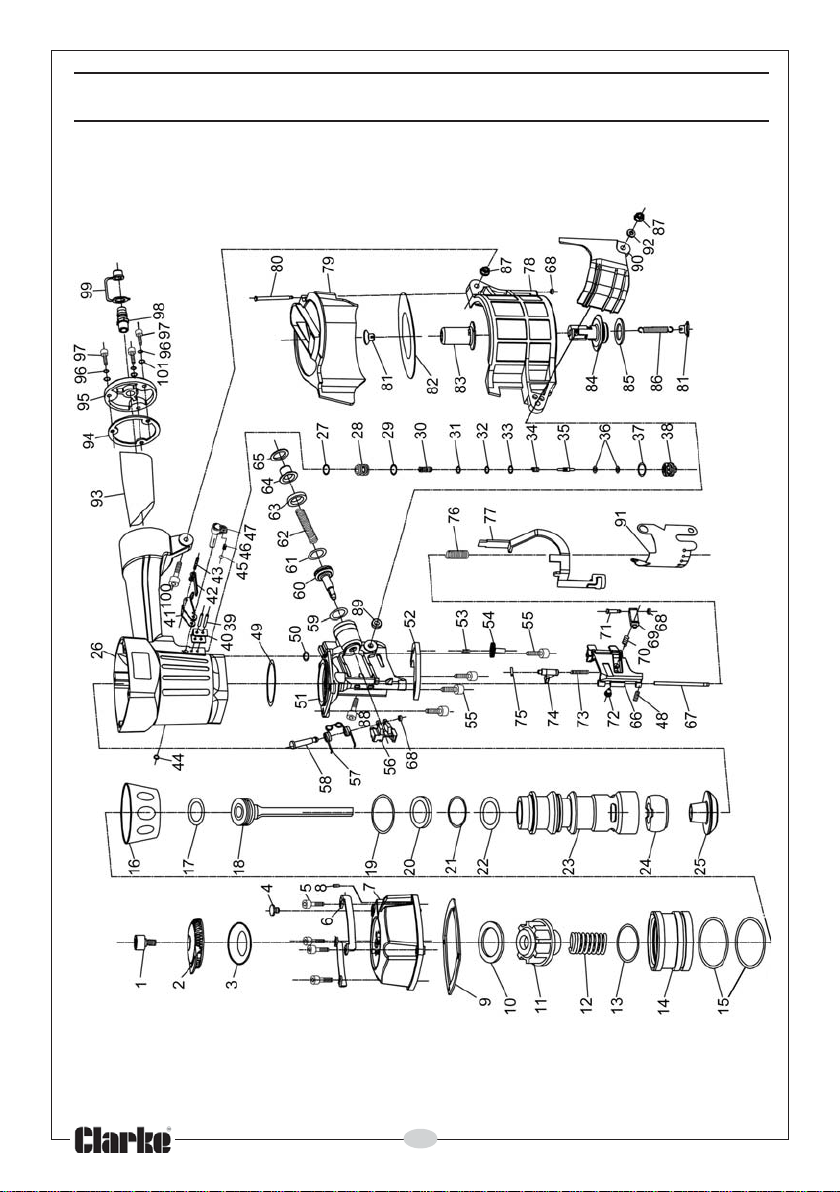

COMPONENTS

9

5

7

4

3

1. Nail Magazine

2. Drive Pawl

3. Protective Screen

4. Safety Yoke (muzzle)

5. Mode Switch (single/full contact sequential actuation)

6. Trigger

7. Pressure Adjuster

8. Compressed Air Hose Connector

9. Exhaust Deflector

2

1

6

8

4

Page 5

GENERAL SAFETY PRECAUTIONS

WORK AREA

1. ALWAYS Keep the work area clean and well lit. Floors should always be

kept clear. Cluttered or dark areas invite accidents.

2. ALWAYS keep children and bystanders away while operating a power tool.

Distractions can cause loss of control.

PERSONAL SAFETY

1. ALWAYS stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use a power tool while you are tired

or under the influence of medication, drugs or alcohol. A moment of

inattention can result in personal injury.

2. ALWAYS use safety equipment when operating this tool. Always wear

suitable protective clothing and eye protection including industrial gloves,

ear defenders and approved impact resistant safety glasses. (Eye glasses

are NOT safety glasses)

3. NEVER over-reach. Keep your proper footing and balance at all times to

enable better control of the machine in unexpected situations.

4. NEVER point the tool at anyone or any part of your own body. Keep all

parts of your limbs behind the safety guard at all times.

5. ALWAYS keep a safe distance between yourself and others when using

the tool.

6. NEVER attempt any repairs yourself. If you have a problem with the

machine contact your local Clarke dealer.

7. ALWAYS store power tools out of reach of children.

8. ALWAYS dress properly. Never wear loose clothing or jewellery which could

be caught on moving parts.

GENERAL POWER TOOL USE AND CARE

1. NEVER force or misuse the tool. It will do a better and safer job at the rate

for which it was designed.

2. ALWAYS maintain the tool with care and keep it clean for best / safest

performance.

3. NEVER use this tool if any part is damaged. Have it inspected and repaired

by a competent technician.

4. NEVER modify this tool in any way. Use it ONLY for the purpose for which it

is designed.

5. NEVER carry the tool with your finger on the trigger. The nailer is fitted with

a safety yoke mechanism to prevent accidental firing.

5

Page 6

6. ALWAYS disconnect the tool from the air supply when not in use, and

before carrying out any maintenance or re-loading with fresh nails.

7. ALWAYS Store the tool out of reach of children.

8. NEVER allow persons unfamiliar with these instructions to operate this tool.

SERVICING

1. ALWAYS have power tools serviced by your Clarke dealer, using only

identical replacement parts. This will ensure the safety of the power tool is

maintained.

COIL NAILER SAFETY INSTRUCTIONS

1. Although this tool is water resistant and may be used outdoors, DO NOT

leave it exposed to the elements. Avoid direct sunlight, direct heat, rain/

moisture etc.

2. ALWAYS keep the air hose away from the nailer and ensure that the

operator is not restricted by the length of the hose.

3. ALWAYS take care when a long air hose is required in the work area as it

presents a trip hazard. Coil the hose away as soon as the job is finished.

4. NEVER abuse hoses or connectors. NEVER carry a tool by the hose, or yank

it to disconnect from the air supply. Keep hoses away from heat, oil and

sharp edges. Check hoses for leaks or worn condition before use, and

ensure that all connections are secure.

5. NEVER use with an air supply greater than 8.2 bar (120 PSI).

6. NEVER use any other type of gas such as bottled oxygen or other bottled

gas as a power source to operate this tool. Use compressed air ONLY.

7. NEVER load the tool with the trigger depressed in case of accidental firing.

8. NEVER fire tool at an incline. It must be perpendicular to the work surface.

9. NEVER drive in nails at the edge of a work surface, as the edge could fail

and fly off, endangering yourself or others in the vicinity.

10. ALWAYS take care not to fire a nail into an existing metal fastening in case

the nail should ricochet causing personal injury.

11. NEVER operate the tool unless the safety nose is in contact with the

workpiece, or without any nails or damage to the tool could result.

12. ALWAYS keep hands away from the nose of the tool when connecting to

the compressed air supply.

13. ALWAYS ensure only the correct nails are used as specified.

6

Page 7

THE COMPRESSED AIR SUPPLY

WARNING: COMPRESSED AIR CAN BE DANGEROUS. ENSURE THAT YOU

ARE THOROUGHLY FAMILIAR WITH SAFETY PROCEDURES RELATING TO

THE USE OF COMPRESSORS AND COMPRESSED AIR SUPPLIES.

A filtered, lubricated and regulated air supply will be required as shown in the

layout below.

Ensure the pressure available is within the range of 70-100 psi. Higher pressure

or contaminated air will shorten the tool’s life because of increased wear,

and could be a safety hazard. Higher pressure will also increase the noise

level.

The air inlet used for connecting the air supply has a standard ¼” BSP thread.

For best performance, a quick-fit connector can be used at each end of the

line.

Line pressure, or hose internal diameter should be increased to compensate

for unusually long air hoses (over 10m). Minimum hose diameter should be

6mm (¼”) ID, and fittings should have the same internal dimensions.

Check the quality of the compressed air supply before starting work. Water in

the air line will cause damage to the tool, and a dirty filter will reduce the

available air pressure.

Ensure there are no leaks in any of the connections.

7

Page 8

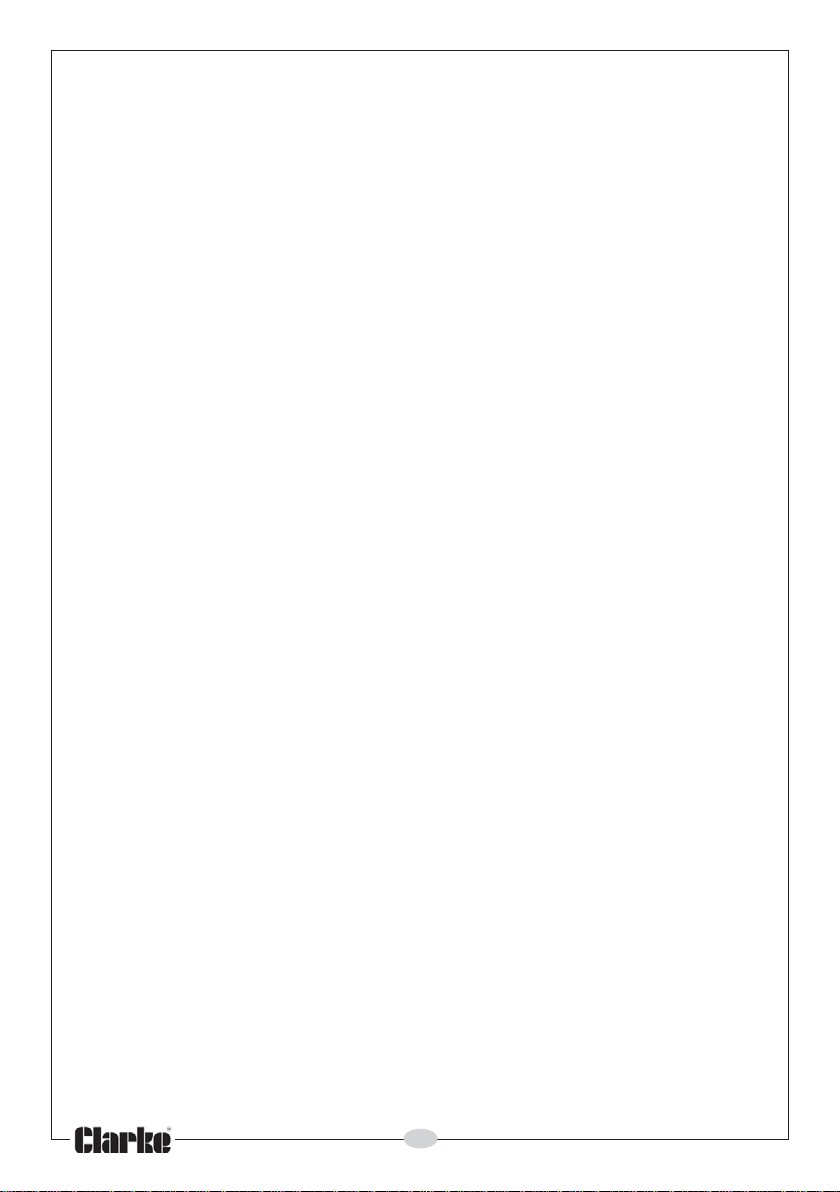

LOADING THE COIL NAILER

WARNING: ENSURE THE COMPRESSED AIR SUPPLY IS DISCONNECTED

BEFORE ATTEMPTING TO LOAD THE COIL NAILER. DO NOT HOLD THE

TRIGGER WHILE LOADING THE NAILER.

The machine is loaded with nails as follows:

1. Press the latch (1) open

and pull the magazine

cover (2) back.

2. Knowing the nail size to be

used, raise and twist the

adjuster 90 degrees for the

chosen nail size as required.

3. Insert a strip of nails into the

magazine, (pointed end

downwards), taking care

that the strip is wound

evenly around the centre

spigot (3) of the height

adjuster (4). Note that 3

different nail sizes can be

used, as indicated by the

markings on the inside of

the magazine. The sizes

available are listed on

page 12.

3 4

4. Take care when handling

the nails, that they do not become bound together.

1 2

8

Page 9

5. Offer the end of the strip of

nails into the gun, taking

care that the nail heads lay

flat in the groove (5) closest

to the machine body and

that the first nail in the strip is

resting in the drive pawl (6).

6. Close the magazine cover

and close the latch.

• This will not be possible if the

nails are not positioned

correctly. The machine is now ready to use.

6 5

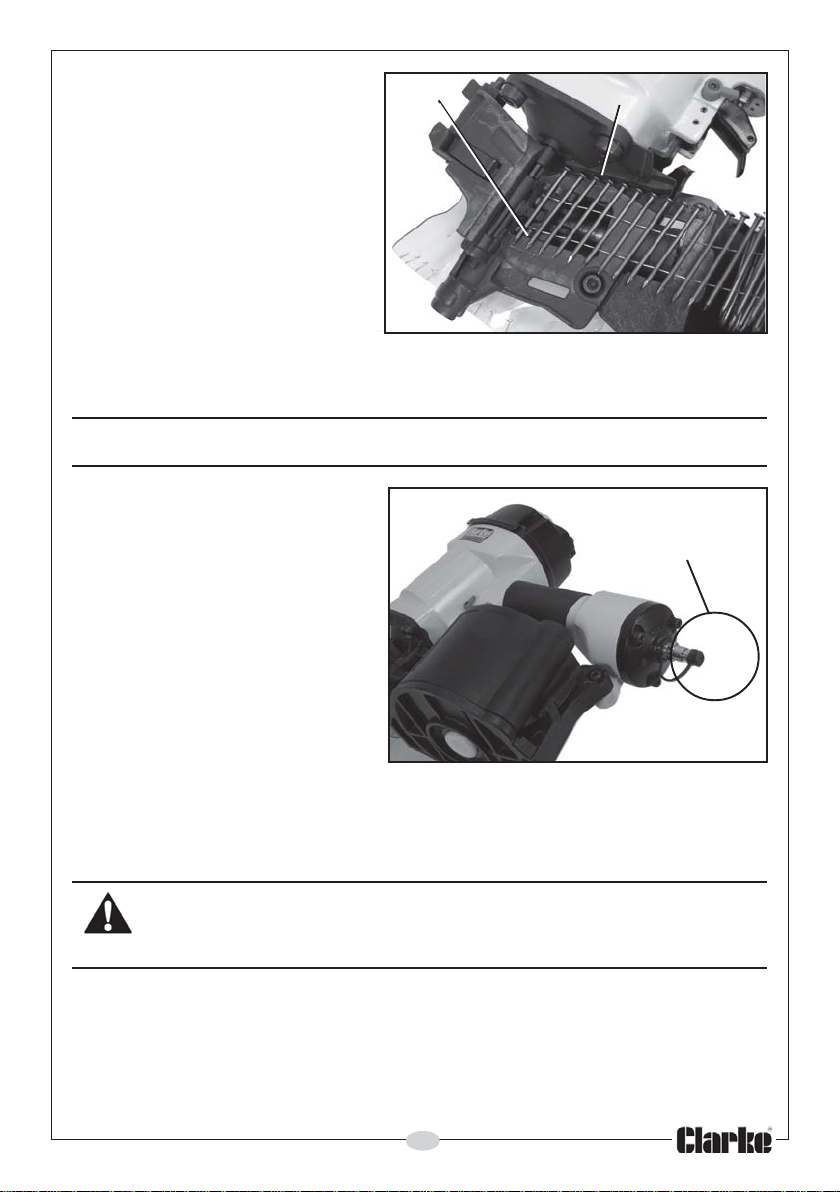

OPERATION

1. Connect the nailer to the air

supply. With the air supply

turned off, connect the air

line to the ¼” BSP connector.

(A whip hose with quick-fit

coupling is available from

your Clarke dealer).

2. Turn on the air supply.

• Check for air leaks. If any are

apparent, rectify before

proceeding.

3. Ensure the operating pressure

is set to between 70 -100 psi .

This may be adjusted, dependant upon the density of the workpiece. The

harder the target material, the higher the air pressure required. e.g. When

nailing into softwoods, a pressure of only 70 psi may be all that is required.

Quick release Airline

Connection

NEVER OPERATE THE TOOL UNLESS THE SAFETY YOKE IS IN CONTACT

WITH THE WORKPIECE, OR WITHOUT ANY NAILS OR DAMAGE TO THE

TOOL COULD RESULT.

9

Page 10

4. Before starting work, test the

nailer on a piece of scrap wood

to check that the driving depth

is correct. If the nails are being

driven too far or not deep

enough into the timber, adjust

the air pressure adjuster located

on the side of the nose section

accordingly. (Remember,

whatever pressure adjustment is

to be carried out on the tool is

dependant upon the pressure

received from the airline).

5. Hold the tool so that it is at right

angles to the workpiece. Lower

it so that the yoke contacts the

work surface and with a slight

downwards pressure, pull the

trigger to drive in the nail.

6. The machine is equipped with

a switch that can change the

operating mode from single

shot to sequential shots. When

the red switch is pointing

towards the operator, the coil

nailer will fire a single nail only.

To fire the next nail the trigger

must be released. When the

switch is pointing away from the

operator, the nailer can fire

sequentially.

7. An adjustable exhaust deflector

is fitted. Turn the deflector into

any chosen position to avoid

the blast from the exhaust.

Pressure

adjuster

Trigger Mode Switch

Deflector

CLEARING A JAM

Should the coil nailer jam, for example, with the last nail of a batch,

disconnect the air supply and pull the trigger to ensure the air line is not under

pressure. Open the magazine and latch and clear the jam before re-loading.

10

Page 11

MAINTENANCE

WARNING: ENSURE THE COMPRESSED AIR SUPPLY IS DISCONNECTED

BEFORE ATTEMPTING ANY MAINTENANCE ON THE COIL NAILER.

DAILY BEFORE USE

1. Check and clean, if necessary, the air inlet gauze filter located inside the

air hose connection point.

2. A bottle of Clarke airline oil is supplied with the coil nailer. Unscrew the cap

& withdraw the nozzle which is reversed within the neck of the bottle.

Screw the cap and nozzle correctly into place and squirt a few drops of

oil, into the air inlet. This should be carried out regardless of whether or not

an air line lubricator is used.

3. Inspect the tool for worn or damaged parts, or for any loose screws or

bolts.

4. Examine the trigger mechanism for free movement.

5. Keep the magazine and yoke free of grime or abrasive particles.

6. If working conditions are below freezing it is advisable to store air tools in a

warmer place.

DURING USE

For lubricating the internal components when in operation, an airline

lubricator should be used with Clarke Airline Oil, and adjusted to 2 drops per

minute.

If an airline lubricator is NOT used, this procedure should be repeated after

every two to three hours of use.

Make a regular inspection of the trigger, spring and safety mechanism for free

movement.

AIRLINE WORKING CONDITIONS

Be aware that factors other than the tool’s condition may effect it’s

operation and efficiency. Anything which will reduce the air supply, such as

reduced compressor output, excessive demand on the airline, moisture or

restrictions in the line, or the use of connectors of improper size or poor

condition will all reduce tool performance.

11

Page 12

Grit or gum deposits in the unit may also reduce efficiency. This condition can

be corrected by cleaning the air strainer and flushing out the tool with gum

solvent oil, or failing this, the tool should be dismantled, thoroughly cleaned,

dried and reassembled. This is a task for your Clarke dealer.

If the nailer runs erratically or becomes inefficient, and the air supply is sound,

it will be necessary to dismantle the piston assembly and replace worn or

damaged parts, which is best carried out by your Clarke dealer.

STORAGE

If the coil nailer is to be stored, or is idle for longer than 24 hours, run a few

drops of Clarke airline oil into the air inlet before storing.

Ensure the protective cap is replaced on the airline connector, once the

airline is disconnected.

ACCESSORIES & CONSUMABLES

A wide range of airline accessories is available, including Filter/Regulators.

Lubricators, High Pressure Hoses from 5 to 100 metres, Whip Hoses etc.

Contact your Clarke dealer for further information, or Clarke International

Sales Department on 01992 565333.

Wire-collated nails are available for the CON15 in three sizes:

Part No Nail Size

1800462 2.3 x 45mm Nails (300pcs)

1800464 2.5 x 50mm Nails (300pcs)

Clarke airline oil (1 litre) is available from your Clarke dealer; Part No 3050825

IMPORTANT: The use of parts other than genuine Clarke replacement parts

may result in safety hazards, decreased tool performance and will invalidate

your warranty.

12

Page 13

TROUBLESHOOTING

SYMPTOM PROBLEM SOLUTION

Air leak near top of

tool or in the trigger

area.

Air leak near bottom of

tool.

Air leak between body

and cylinder cap.

Nails are being driven

in too deep.

Tool does not drive nail

well or is operating

sluggishly.

In the event that any of the above situations occurs, requiring the dismantling

and overhaul of the tool, contact your Clarke International Service

Department on 020-8988-7400.

Tool fails to fire all the

nails in turn.

1. O-ring in trigger valve

area damaged.

2. Trigger valve head is

damaged.

3. Trigger valve stem, seal

or O-ring are damaged.

1. Loose screws.

2. Worn or damaged O-ring

or bumper.

1. Loose screws..

2. Worn or damaged O rings or seals..

1. Worn bumper.

2. Air pressure set too high.

1. Inadequate air supply.

2. Inadequate lubrication.

3. Worn or damaged O-ring

or seal.

4. Exhaust port in cylinder

head is blocked.

1. Worn bumper or

damaged spring.

2. Dirt in front plate.

1. Examine & replace O-ring

2. Examine & replace.

3. Examine and replace trigger

valve stem, seal or O-ring.

1. Tighten screws

2. Examine & replace O-ring

or bumper.

1. Tighten screws.

2. Examine & replace O-ring

or bumper.

1. Replace bumper.

2. Adjust air pressure.

1. Confirm adequate air supply

2. Insert 2-6 drops of oil into

air inlet.

3. Examine & replace O-ring

or seal.

4. Replace damaged

internal parts.

1. Replace bumper or

13

pusher spring.

2. Clean drive channel on

front

plate.

Page 14

PARTS LIST

14

Page 15

PARTS LIST

Description

No

Driver Guide HTCON15051 76 Compression Spring HTCON15076

51

Adjusting KNob HTCON15052 77 Safety Yoke HTCON15077

52

Compression Spring HTCON15053 78 Magazine HTCON15078

53

Adjusting Bolt HTCON15054 79 Magazine Cover HTCON15079

54

Bolt M8 x 25 HTCON15055 80 Anvil HTCON15080

55

Pawl HTCON15056 81 2 Spring Hook HTCON15081

56

Pawl Spring HTCON15057 82 Adjusting Plate HTC ON15082

57

Pin HTCON15058 83 Adjusting Sleeve HTCON15083

58

O - Ring 9.9 x 2.4 HTCON15059 84 Nail Depth A djusting Base HTCON15084

59

Piston HTCON15060 85 Rubber Washer HTCON15085

60

O - Ring 20.3 x 2.3 HTCON15061 86 Spring HTCON15086

61

Spring HTCON15062 87 Bolt M6 HTCON15087

62

Piston B ump Washer HTCON15063 88 Bolt M6 x 40 HTCON15088

63

Spring Base HTCON15064 89 Fixed Ring HTCON15089

64

Snap Retainer HTCON15065 90 Nail Head Cover HTCON15090

65

Part No

No Description

15

Part No

Page 16

PARTS DIAGRAM

16

Page 17

VIBRATION EMISSIONS

HAND-ARM VIBRATION

Employers are advised to refer to the HSE publication “Guide for Employers”.

All hand held power tools vibrate to some extent, and this vibration is

transmitted to the operator via the handle, or hand used to steady the tool.

Vibration from about 2 to 1500 hertz is potentially damaging and is most

hazardous in the range from about 5 to 20 hertz.

Operators who are regularly exposed to vibration may suffer from Hand Arm

Vibration Syndrome (HAVS), which includes ‘dead hand’, ‘dead finger’, and

‘white finger’. These are painful conditions and are widespread in industries

where vibrating tools are used.

The health risk depends upon the vibration level and the length of time of

exposure to it……in effect, a daily vibration dose.

Tools are tested using specialised equipment, to approximate the vibration

level generated under normal, acceptable operating conditions for the tool

in question. For example, a grinder used at 45° on mild steel plate, or a

sander on softwood in a horizontal plane etc.

’

These tests produce a value ‘a

which represents the average vibration level of all tests taken, in three axes

where necessary, and a second figure ‘K’, which represents the uncertainty

factor, i.e. a value in excess of ‘a’, to which the tool could vibrate under

normal conditions. These values appear in the specification panel below.

, expressed in metres per second per second,

MODEL No: CON15

DESCRIPTION: COIL NAILER

Declared vibration emission value in accordance

with EN12096

Measured vibration emission value -

Uncertainty value -

K:

3.5m/s

2

a:

3.3m/s

2

Values determined according to EN28622-1

17

Page 18

You will note that a third value is given in the specification - the highest

measured reading in a single plane. This is the maximum level of vibration

measured during testing in one of the axes, and this should also be taken into

account when making a risk assessment.

a

’ values in excess of 2.5 m/s2 are considered hazardous when used for

‘

prolonged periods. A tool with a vibration value of 2.8 m/s2 may be used for

up to 8 hours (cumulative) per day, whereas a tool with a value of 11.2 m/s

2

may be used for ½ hour per day only.

The graph below shows the vibration value against the maximum time the

respective tool may be used, per day.

The uncertainty factor should also be taken into account when assessing a

risk. The two figures ‘

a

’ and ‘K’may be added together and the resultant

value used to assess the risk.

It should be noted that if a tool is used under abnormal, or unusual conditions,

then the vibration level could possibly increase significantly. Users must always

take this into account and make their own risk assessment, using the graph

above as a reference.

Some tools with a high vibration value, such as impact wrenches, are

generally used for a few seconds at a time, therefore the cumulative time

may only be in the order of a few minutes per day. Nevertheless, the

cumulative effect, particularly when added to that of other hand held power

tools that may be used, must always be taken into account when the total

daily dose rate is determined.

18

Page 19

DECLARATION OF CONFORMITY

19

Page 20

Loading...

Loading...