20V CORDLESS JIGSAW

MODEL NO: CJS20Li

PART NO: 6487025

OPERATION & MAINTENANCE

INSTRUCTIONS

LS1013

INTRODUCTION

Thank you for purchasing this CLARKE 20V Cordless Jigsaw.

Before attempting to use this product, please read this manual thoroughly and

follow the instructions carefully. In doing so you will ensure the safety of yourself

and that of others around you, and you can look forward to your purchase

giving you long and satisfactory service.

GUARANTEE

This product is guaranteed against faulty manufacture for a period of 12

months from the date of purchase. Please keep your receipt which will be

required as proof of purchase.

This guarantee is invalid if the product is found to have been abused or

tampered with in any way, or not used for the purpose for which it was

intended.

Faulty goods should be returned to their place of purchase, no product can

be returned to us without prior permission.

This guarantee does not effect your statutory rights.

WHAT’S SUPPLIED

Unpack your tool and make sure that the following items are present. Should

there be any damage caused during transit contact your Clarke dealer

immediately.

1 x 20 Volt Cordless Jigsaw 1 x Wood Blade

1 x Parallel Fence 1 x Metal Blade

2

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

SAFETY PRECAUTIONS

WARNING: READ ALL INSTRUCTIONS. FAILURE TO FOLLOW ALL

INSTRUCTIONS LISTED BELOW MAY RESULT IN ELECTRIC SHOCK, FIRE AND/

OR SERIOUS INJURY. THE TERM “POWER TOOL” IN ALL WARNINGS LISTED

BELOW REFERS TO YOUR 20V CORDLESS JIGSAW.

1) WORK AREA SAFETY

a. Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b. Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the

dust or fumes.

c. Keep children and bystanders away while operating a power tool. Distractions

can cause you to lose control.

2) ELECTRICAL SAFETY

a. Power tool plugs must match the outlet. Never modify the plug in any way. Do

not use any adapter plugs with earthed (grounded) power tools. Unmodified

plugs and matching outlets will reduce risk of electric shock.

b. Avoid body contact with earthed or grounded surfaces, such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed or grounded.

c. Do not expose power tools to rain or wet conditions. Water entering a power tool

will increase the risk of electric shock.

d. Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

e. When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric

shock.

f. If operating a power tool in a damp location is unavoidable, use a residual

current device (RCD) protected supply. Use of an RCD reduces the risk of electric

shock.

3) PERSONAL SAFETY

a. Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while operating power

tools may result in serious personal injury.

b. Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce personal injuries.

3

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

c. Prevent unintentional starting. Ensure the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the

tool. Carrying power tools with your finger on the switch or energising power tools

that have the switch on invites accidents.

d. Remove any adjusting key or wrench before turning the power tool on. A wrench

or a key left attached to a rotating part o the power tool may result in personal

injury.

e. Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

f. Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing

and gloves away from moving parts. Loose clothes, jewellery or long hair can be

caught in moving parts.

g. If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection

can reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a. Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was

designed.

b. Do not use the power tool if the switch does not turn it on and off. Any power tool

that cannot be controlled with the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source and/or the battery pack from the

power tool before making any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce the risk of starting the

power tool accidentally.

d. Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e. Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool's

operation. If damaged, have the power tool repaired before use. Many

accidents are caused by poorly maintained power tools.

f. Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits etc. in accordance with these

instructions, taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended

could result in a hazardous situation.

4

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

5. BATTERY TOOL USE AND CARE

a. Recharge only with the charger specified by the manufacturer. A charger that is

suitable for one type of battery pack may create a risk of fire when used with

another battery pack.

b. Use power tools only with specifically designated battery packs. Use of any other

battery packs may create a risk of injury and fire.

c. When battery pack is not in use, keep it away from other metal objects, like

paper clips, coins, keys, nails, screws or other small metal objects, that can make

a connection from one terminal to another. Shorting the battery terminals

together may cause burns or a fire.

d. Under abusive conditions, liquid may be ejected from the battery; avoid

contact. If contact accidentally occurs, flush with water. If liquid contacts eyes,

additionally seek medical help. Liquid ejected from the battery may cause

irritation or burns.

6) SERVICE

a. Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is

maintained.

ENVIRONMENTAL PROTECTION

Recycle unwanted materials instead of disposing of them as waste.

All tools, accessories and packaging should be sorted, taken to a

recycling centre and disposed of in a manner which is compatible

with the environment.

SAFETY INSTRUCTIONS FOR ALL SAWS

a. Keep hands away from cutting area and the blade. Keep your second hand on

the auxiliary handle, or motor housing. If both hands are holding the saw, they

cannot be cut by the blade.

b. Do not reach underneath the workpiece. The guard cannot protect you from the

blade below the workpiece.

c. Never hold the piece being cut in your hands or across your leg. Secure the

workpiece to a stable platform. It is important to support the work properly to

minimise body exposure, blade binding, or loss of control.

d. Hold the power tool by insulated gripping surfaces when performing an

operation. Contact with a live wire will also make exposed metal parts of the

power tool live and shock the operator.

5

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

SYMBOLS & PICTOGRAPHS

Laser Radiation, Class 2 Laser: Do not stare

into the beam

Weee Symbol CE Mark

Read instruction manual before use

KICKBACK

Kickback is a sudden reaction to a pinched or misaligned saw blade which causes the

saw to lift up and out of the workpiece.

When the blade is pinched or bound tightly by the kerf closing down, the blade stalls

and the motor reaction moves the unit back quickly towards the operator.

If the blade becomes twisted or misaligned in the cut, the teeth at the back edge of the

blade can dig into the top of the workpiece causing the blade to climb out of the kerf

and jump back towards the operator. Kickback is the result of misuse or incorrect

operating procedures and can be prevented by taking the following precautions:

a. Hold the saw tightly and position your arms to resist kickback forces. Position your

body to one side of the blade.

b. If the blade starts to bind, or when interrupting a cut, release the trigger and hold

the saw still in the material until the blade comes to a full stop. Do not attempt to

remove the saw from the work or pull the saw backward while the blade is

moving or kickback can occur. Investigate and take corrective actions to

eliminate the cause of blade binding.

c. When restarting a saw in the workpiece, centre the saw blade in the kerf and

make sure that saw teeth do not touch the material. If the blade is binding, it

can kickback from the workpiece as the saw is restarted.

d. Support large panels to minimise the risk of blade pinching and kickback. Large

panels tend to sag under their own weight. Supports must be put below the

panel on both sides, near the line of cut and near the edge of the panel.

e. Bevel adjusting locking screws must be tight and secure before making a cut. If

blade adjustment shifts while cutting, it may cause binding and kickback.

6

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

FITTING THE BATTERY PACK (NOT SUPPLIED)

This 20V Jigsaw requires a 20V battery pack (6487040) and 1 Hour Charger

(6487050) to operate. Both are available separately from your local Clarke

dealer.

TO FIT THE BATTERY

1. Slide the battery pack on to the

jigsaw.

TO REMOVE THE BATTERY

1. Push and hold the release buttons

on the side of the battery pack.

2. Slide the battery pack away from

the jigsaw.

INSTALLING/CHANGING BLADES

CAUTION: MAKE SURE THAT THE BATTERY PACK IS REMOVED TO AVOID

RISK OF ACCIDENTAL STARTING.

This jigsaw is equipped with a tooless blade holder which allows fast and

convenient blade changing.

1. Push and hold the blade holder up.

2. Insert the blade as far as possible,

with the teeth facing forwards.

• Use only jigsaw blades with the

correct T-shank.

• Do not use blunt or damaged

blades.

3. Release the blade holder and gently

pull on the blade to make sure that it

is secure before refitting the battery.

7

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

ADJUSTMENTS

ADJUSTING THE PENDULUM

The pendulum moves the blade away from the cut on the down (non-cutting)

stroke and forward into the workpiece on the upward (cutting) stroke. The

pendulum can be particularly useful when cutting thicker, denser materials.

1. Adjust the pendulum control to

suit the material being cut using

the following suggested settings

as a starting point if required. Do

not use the pendulum action for

cutting ceramics or metals.

Material Pendulum Setting

Ceramics 0

Metal 0

Plywood, Plastics 1-2

Timber, Fiberglass & Chipboard 1-3

ADJUSTING THE SOLE PLATE

The sole-plate is adjustable so that bevels of up to 45° may be cut. Loosen the

two socket head screws under the sole-plate before adjusting it to the desired

angle and re-tightening the screws.

8

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

OPERATION

SWITCHING ON/OFF

• Ensure that the workpiece is securely held and the cutting line is

clearly marked.

1. Place the sole-plate on the workpiece taking care that the blade is not

touching the workpiece or striking on anything below.

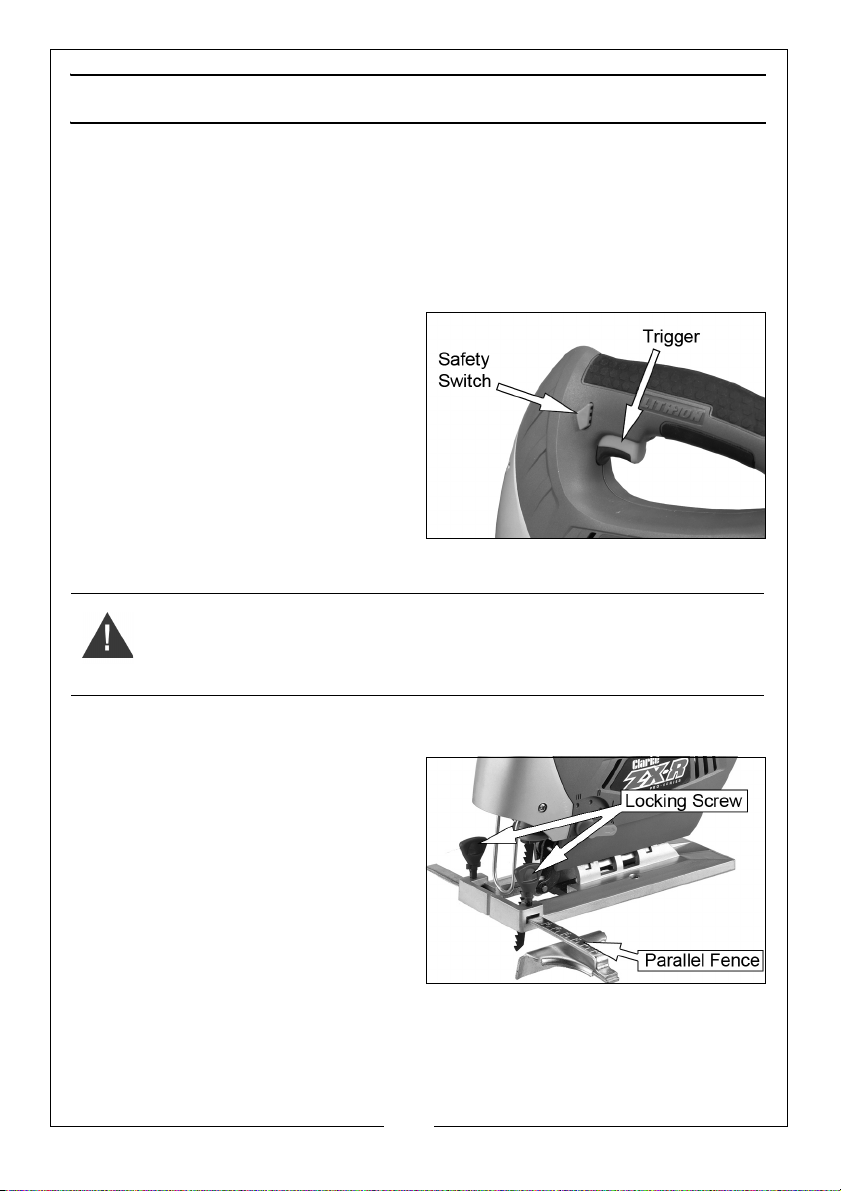

2. Press and hold the safety switch

and then squeeze the trigger.

• The jigsaw has a variable speed

trigger. For increased speed,

squeeze the trigger harder.

• Let the blade work through the

workpiece, ensuring the sole

plate is flush with the

workpiece.

3. Release the trigger to stop the

saw.

WARNING: THE BLADE WILL CONTINUE TO RUN FOR A SHORT PERIOD

AFTER THE TRIGGER HAS BEEN RELEASED. WAIT UNTIL IT STOPS BEFORE

REMOVING IT FROM THE WORKPIECE.

PARALLEL FENCE

1. Insert the parallel fence as shown.

2. Secure in place with the locking

screw.

9

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

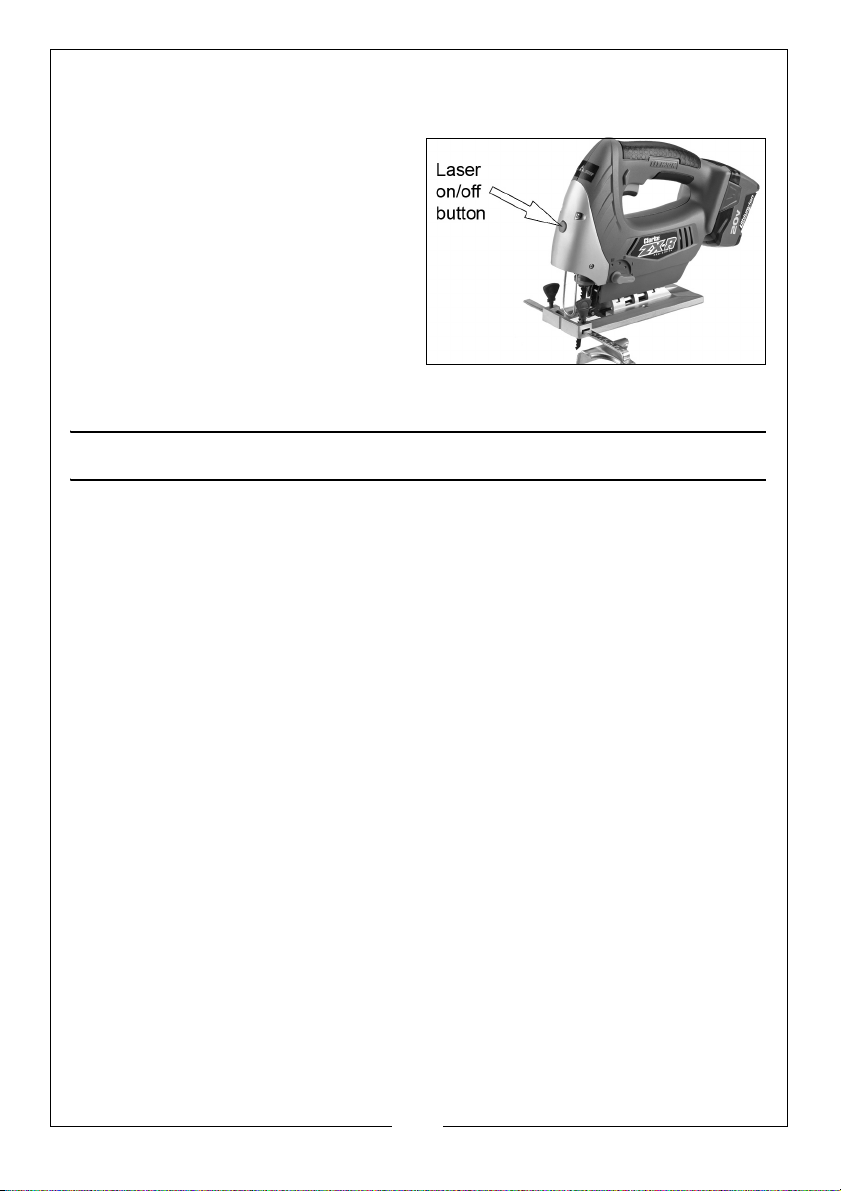

LASER GUIDE

The laser guide helps keep the blade aligned with the cutting line.

1. Press the Laser on/off button to

turn the laser on.

• Do not point the laser beam at

people.

• Keep the laser beam below

eye level.

• Only turn on laser beam when

the tool is on the work piece.

2. Press the Laser on/off button

again to turn the laser off.

CUTTING TIPS

• Wait until the blade is running at full speed before attempting to cut

the workpiece.

• Do not put unnecessary pressure on the blade and avoid applying

lateral pressure.

• Take extra care when cutting curves - move the blade slowly to

avoid stress on the blade.

WOOD

• Check that any previously used timber being sawn does not contain

any nails or other metal objects which would damage the blade.

METAL

• Choose a suitable blade for cutting metal

• Lubricate the material and blade with cutting oil to prevent

overheating.

HOLE CUTTING

• When starting a cut from the center of a work piece, drill a 12mm

diameter hole to ensure that there is clearance for the blade

• Remember that the blade should emerge from the workpiece at

every point of the cut.

• When cutting tight curves, reduce the forward speed of the saw.

10

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

MAINTENANCE

CLEANING

1. Keep air vents free of blockages, (use compressed air to clean the

machine if possible).

2. After use, clean all dust and wood chippings from the jigsaw.

3. Keep the blade locating clip and support roller clean, you should lightly oil

the support roller at regular intervals.

4. Keep the handle clean.

5. Regularly clean the sole plate to prevent scratches and scores on the

surface.

GENERAL MAINTENANCE

1. Make sure that the power cable it is sound and that there are no cracks or

bare wires.

2. Do not use solvents when cleaning plastic parts, most plastics are

vulnerable to damage from the different types of solvents.

• Make sure that all nuts, bolts and screws stay tight to keep the jigsaw

in a safe working condition.

• All bearings etc, in this tool are lubricated with a sufficient amount of

high grade lubricant for the tools lifetime in normal operating

conditions, therefore no further lubrication is necessary.

• Only use the replacement blades specified for this product (see your

Clarke dealer).

• Refer to your Clarke dealer if internal maintenance is necessary.

CONSUMABLE SPARE PARTS

Replacement saw blades for wood and metal are available from your Clarke

dealer.

Replacement Blades (10 per pack)

Wood: Part no. 6462188

Metal: Part no. 6462190

11

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

SPECIFICATIONS

No Load Blade Speed 0-2400 Strokes per minute

Operating Voltage 20 V DC

Stroke length 25.4 mm

Maximum Blade Length 76 mm

Pendulum settings 3

Weight (without battery pack) 1.7 kg

Dimensions (without battery pack) (L x W x H) 227 x 74 x 215 mm

Sound pressure Level (LPA) 87.3 dB(A)

Sound Power Level (LWA) 98.3 dB(A)

Sound Uncertainty Value (K) 3 dB(A)

Vibration 5.383 m/s²

Vibration Uncertainty Value (K) 1.5 m/s²

MAXIMUM CUTTING DEPTH

Wood 50 mm

Aluminium 8 mm

Mild Steel 6 mm

12

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

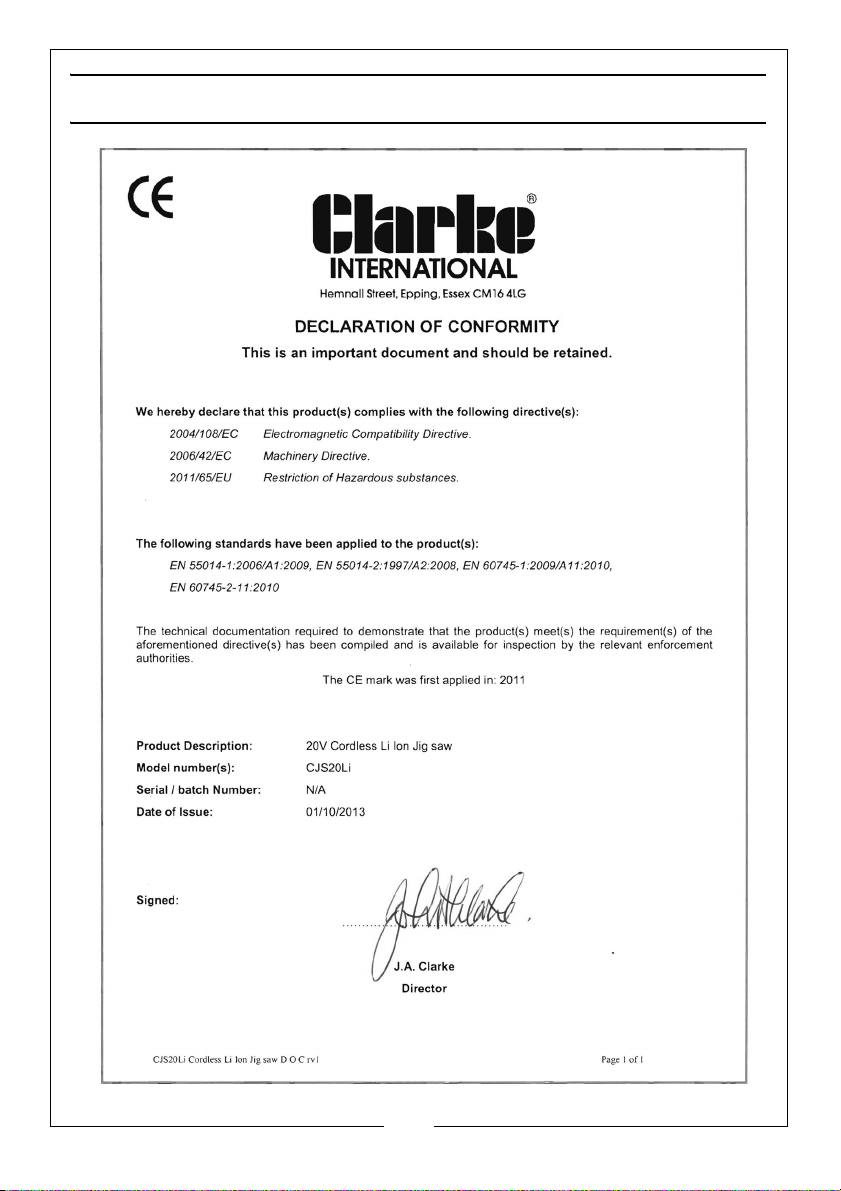

DECLARATION OF CONFORMITY

13

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

CLARKE ZX-R RANGE

The Clarke ZX-R 20V cordless power tools are designed as a high power and

quality solution for the tradesman that requires a number of different tool

types.

20v

Hammer Drill.

Model:

CDD20Li

Part Number:

6487010

20v

Circular Saw

Model:

CCS20Li

Part Number:

6487015

20v

Led Lamp

Model:

CFL20Li

Part Number:

6487035

20v

Jig Saw

Model:

CJS20Li

Part Number:

6487025

20v

Multifunction

Tool.

Model:

CMFT20Li

Part Number:

6487030

20v

Reciprocating

Saw

Model:

CRS20Li

Part Number:

6487020

20v

Impact Driver

Model:

CID20Li

Part Number:

6487000

20V Battery

Model

BL1500Li

Part Number

6487050

Also Available

20V Battery Charger

Part Number

r6487050

14

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

NOTES

15

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

Loading...

Loading...