Page 1

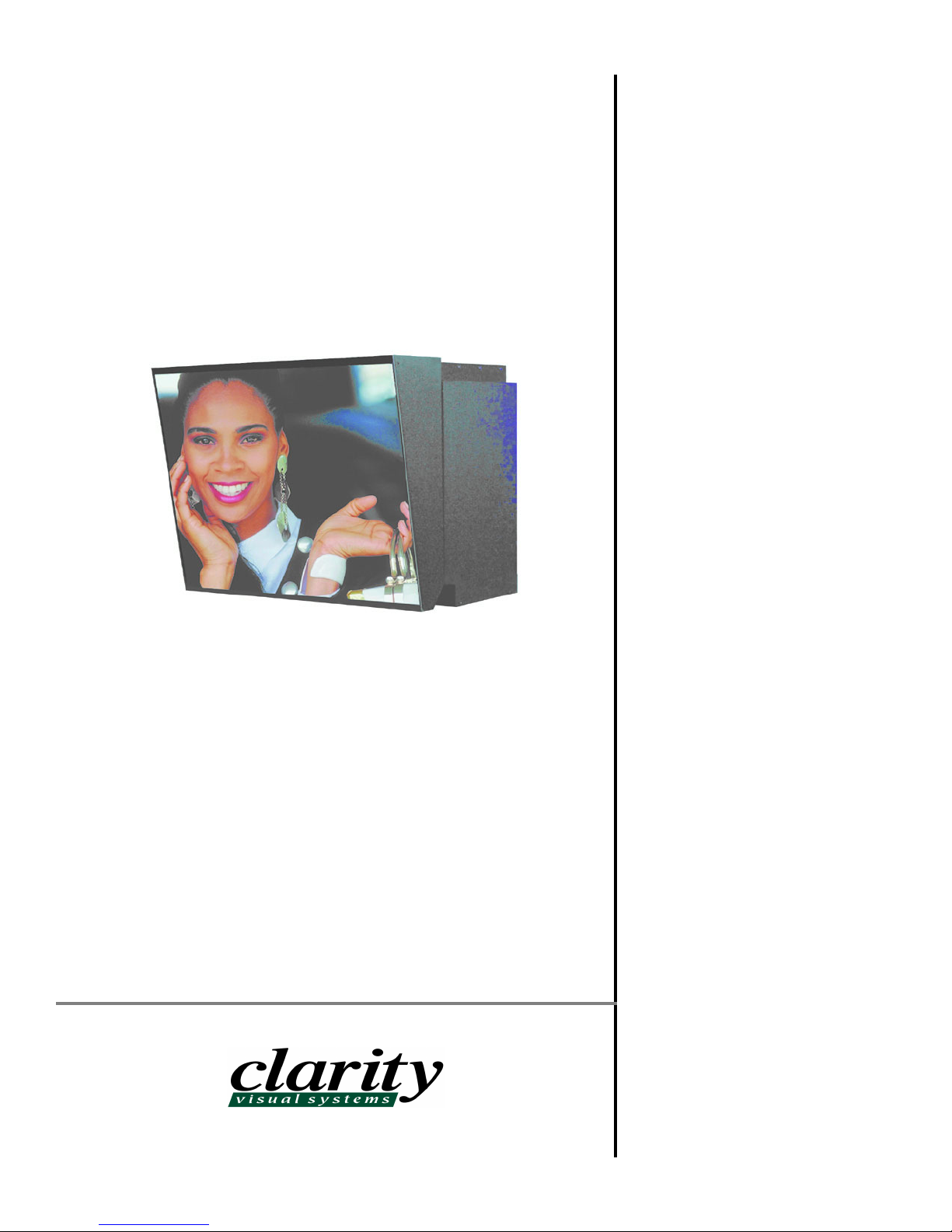

Leopard

VN-3820-VA

User Guide

Page 2

Page 3

VN-3820-VA

VN-3830-VA

User’s Guide

070-0032-06

7 October 2003

Page 4

© 2003 by Clarity Visual Systems™, Inc.

All Rights Reserved.

Contents of this publication may not be reproduced in any form without permission of Clarity Visual Systems,

Inc.

Trademark Credits

Macintosh is a registered trademark of Apple Computer Corp.

IBM is a registered trademark of International Business Machines, Inc.

Windows is a trademark of Microsoft Corp.

All other names are trademarks or registered trademarks of their respective companies.

Disclaimer

The information contained in this document is subject to change without notice.

Clarity Visual Systems Company makes no warranty of any kind with regard to this material. While every

precaution has been taken in the preparation of this manual, Clarity Visual Systems shall not be liable for

errors or omissions contained herein or for incidental or consequential damages in connection with the

furnishing, performance, or use of this material.

ii

Page 5

LIMITED WARRANTY. Clarity warrants to Buyer that the VN-3820-VA or the VN-3830-VA (the “Product”),

if properly used and serviced, will perform substantially in accordance with the product data sheet and users

manual, and will be free from defects in material and workmanship for 1 year following date of shipment.

This warranty does not apply to lamps (see following section for lamp warranty) and other consumable parts.

The main illumination lamp is considered a consumable and is warranted against failure for 30 days from the

date of installation or first day of rental. The replacement of other consumable parts are the Buyer's

responsibility.

If any Product fails to conform to the written warranty, Clarity's exclusive liability and Buyer's exclusive

remedy will be, at Clarity's option, to repair, replace or credit Buyer's account with an amount equal to the

price paid for any such defective Product returned by Buyer during the warranty period, provided that: (a)

Buyer promptly notifies Clarity in writing that such Product failed to conform, furnishes an explanation of any

alleged deficiency and obtains from Clarity a return authorization; and (b) Clarity is satisfied that claimed

deficiencies actually exist and were not caused by accident, misuse, neglect, alteration, improper installation,

repair or improper testing. Clarity will have a reasonable time to make repairs, to replace Products or to credit

Buyer's account.

LIMITATIONS. Any written warranty offered by clarity is in lieu of all other warranties, express or implied.

Clarity neither assumes nor authorizes any other person to assume any other liabilities in connection with the

sales or use of any product without limitation. Clarity disclaims all other warranties, express or implied,

including any warranty of merchantability or fitness for a particular.

In no event will clarity be liable to buyer or any other party for procurement costs, loss of profits, loss of use, or

for any other incidental, consequential, indirect or special damages or for contribution or indemnity claims,

however caused. Clarity's liability shall be limited to actual direct damages not in excess of the amounts paid

to clarity by buyer for the product. These limitations will apply to all claims, including, without limitation,

warranty, contract, indemnity, tort (including negligence), strict liability or otherwise.

iii

Page 6

Table of Contents

Information You Need to Know ................... 1-1

1.1 What is the VN-3820-VA (VN-3830-VA)? .................1-2

1.2 Your Safety Is Important .............................1-4

How to Install the Displays....................... 2-1

2.1 Before Your Start . . . ...............................2-2

2.2 Two Ways to Install the Displays .......................2-4

2.2.1 How to Remove and Replace the Screen ..........2-6

2.2.2 Installing: Hanger Method ......................2-8

2.2.3 Installing: Flush to Ceiling .....................2-10

2.3 After the Units Are Hung … ..........................2-12

Setup, Control, and Calibration ................... 3-1

3.1 About the Remote Control............................3-2

3.2 The Power Up Sequence.............................3-4

3.3 Adjusting for Optimum Picture Quality ..................3-6

3.3.1 Adjusting Black and White Levels ................3-8

3.3.2 Matching Frequency & Phase ..................3-10

3.3.3 Matching the Displays to Each Other ............3-12

3.3.3.1 About Color Balancing..................... 3-14

3.3.4 Changing the Position of the Image .............3-16

3.4 Saving and Recalling the Settings .....................3-18

3.5 Setting Additional Controls ..........................3-20

3.6 Controlling with RS232 Commands ...................3-22

Routine Maintenance Is Important................. 4-1

4.1 Replacing Lamp and Air Filter.........................4-2

4.2 Cleaning the Screen and Mirror .......................4-4

If You Have Trouble … .......................... 5-1

5.1 How to Fix Startup Problems..........................5-2

5.2 How to Fix Image Problems ..........................5-4

5.3 Common Questions (and Answers) ....................5-6

References ................................... 6-1

6.1 Menus ...........................................6-2

6.2 LEDs.............................................6-7

6.3 Connections, Interlocks and Lockout ...................6-8

6.4 RS232 Command List ..............................6-10

iv

Page 7

6.5 Installation Check List .............................. 6-13

6.6 Adjustment Check List ............................. 6-14

6.7 Technical Support Request ......................... 6-15

6.8 Regulatory Information ............................. 6-16

6.9 Specifications .................................... 6-17

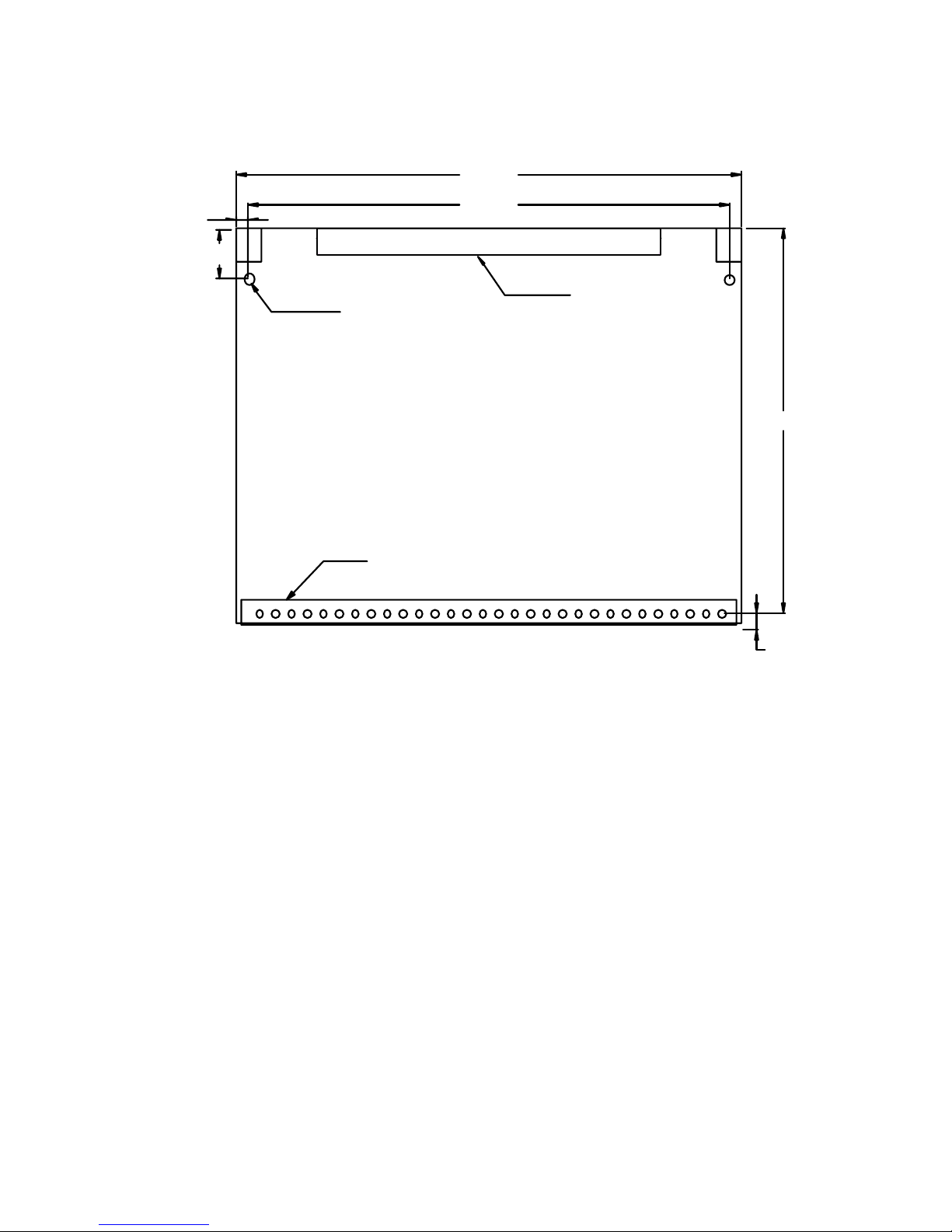

6.10 Measurements, millimeters.......................... 6-20

6.11 Measurements, inches ............................. 6-23

6.12 Dimensions for Banner Installations ................... 6-27

6.13 Making Test Patterns With “Paint” .................... 6-28

Index........................................6-31

v

Page 8

vivi

Page 9

1 Information You Need to Know

1.1 What is the VN-3820-VA (VN-3830-VA)?

1.2 Your Safety Is Important

1 - 1

Page 10

1.1 What is the VN-3820-VA (VN-3830-VA)?

The Clarity VN-3820-VA and VN-3830-VA were designed for overhead displays, where several units

are used side-by-side. They display analog VGA signals, just like a computer monitor, using bright

LCD projection technology. They can be controlled with RS-232 signals or with an IR remote control

(supplied). The 3830 model has a brighter lamp, but at the cost of a shorter lamp life. Otherwise, the

two models are the same.

These displays use LCD projection technology

for an image that is bright all the way to the

corners, even in well-lit environments such as

shops, restaurants and sports arenas. The 3800

series, with a 38" (965mm) screen, measured

diagonally, was designed for applications where

several units are lined up side-by-side in a

banner configuration. They are usually mounted

above the viewers. The screen tilts down at a

10° angle for optimum viewing in these

applications.

This manual covers both the VN-3820-VA

and the VN-3830-VA. The only difference

between them is that the 3830

but with half the average lamp life. In this

manual the term VN-3820-VA will mean either

model, unless specifically stated otherwise.

Model Average Life Brightness

VN-3820-VA 8,000 hours 125 fL

VN-3830-VA 4,000 hours 150 fL

!

Note: Average lamp life of 8,000 hours means that

after 8,000 hours of use half the lamps will

still be functioning (and half won’t).

The VN-3820-VA is shipped with the cable tray

removed for easier installation. Plastic buttons

are in place to cover the side-to-side mounting

holes. The batteries are already in the remote

control.

Standard accessories:

• One 3 m 10A IEC power cord

• One 3 m HD15 D-sub VGA patch cable

• One remote control with batteries

installed

• One upper mounting rail (hanger rail)

is 20% brighter

• One lower mounting bracket

• Three bolts, washers and nuts for bolting

the displays side-to-side

• Two end caps with screws for the lower

cable channel doors, left and right ends

• Two bolts for securing the unit to the

lower mounting bracket

• One cable channel door (not really an

“accessory,” but it comes in the

accessories box)

• One User’s Guide (this manual)

Optional accessories:

• A pair of strong magnets to remove

screens in the middle of a banner display

(SRT-200).

• Lock for channel cover (VN-38-LK)

• Power loop-thru cable (VN-38-PL)

• 1 m RS-232 daisy chain cable with RJ45

connections at each end (VN-38-RL)

• 10 m RS-232 host computer cable with

RJ45 connections (VN-38-S-232)

• 9-pin D-sub-to-RJ45 adapter (VN-38-RA)

• Service Manual (VN-38-SM; available

after 31 August 1999)

You will have to supply the hardware to install

the rails on the wall and the tools for this

hardware. For the display, you won’t need any

special tools. If the thumb screws and tight, you

can use a coin to loosen them.

About this manual: You will find some

information repeated in several places. This is

done on purpose. However, the explanation of

how to remove the screen is too long to repeat

every time it is needed; it is given once. The

serial number is located on the back panel and

again in the lower cable channel.

1 - 2

Page 11

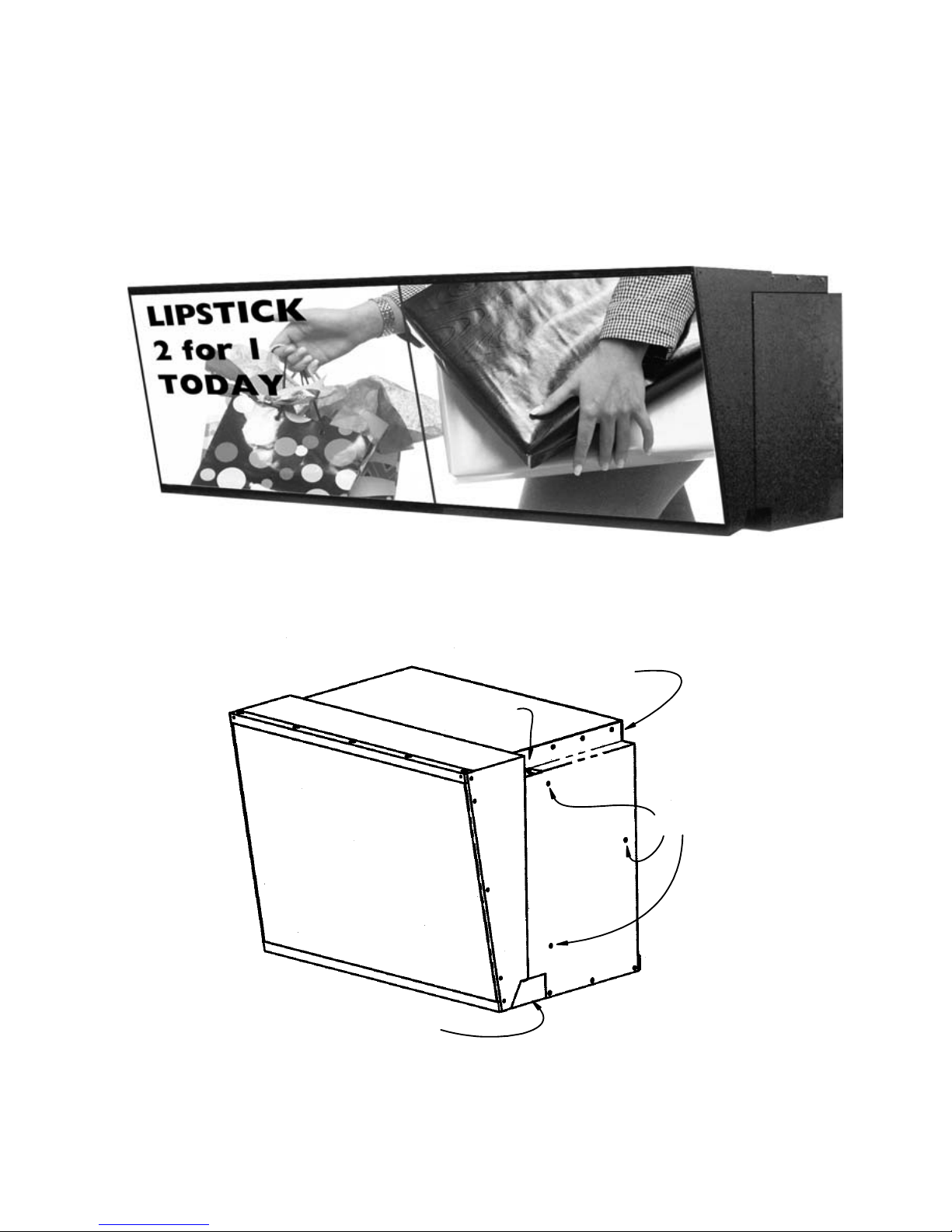

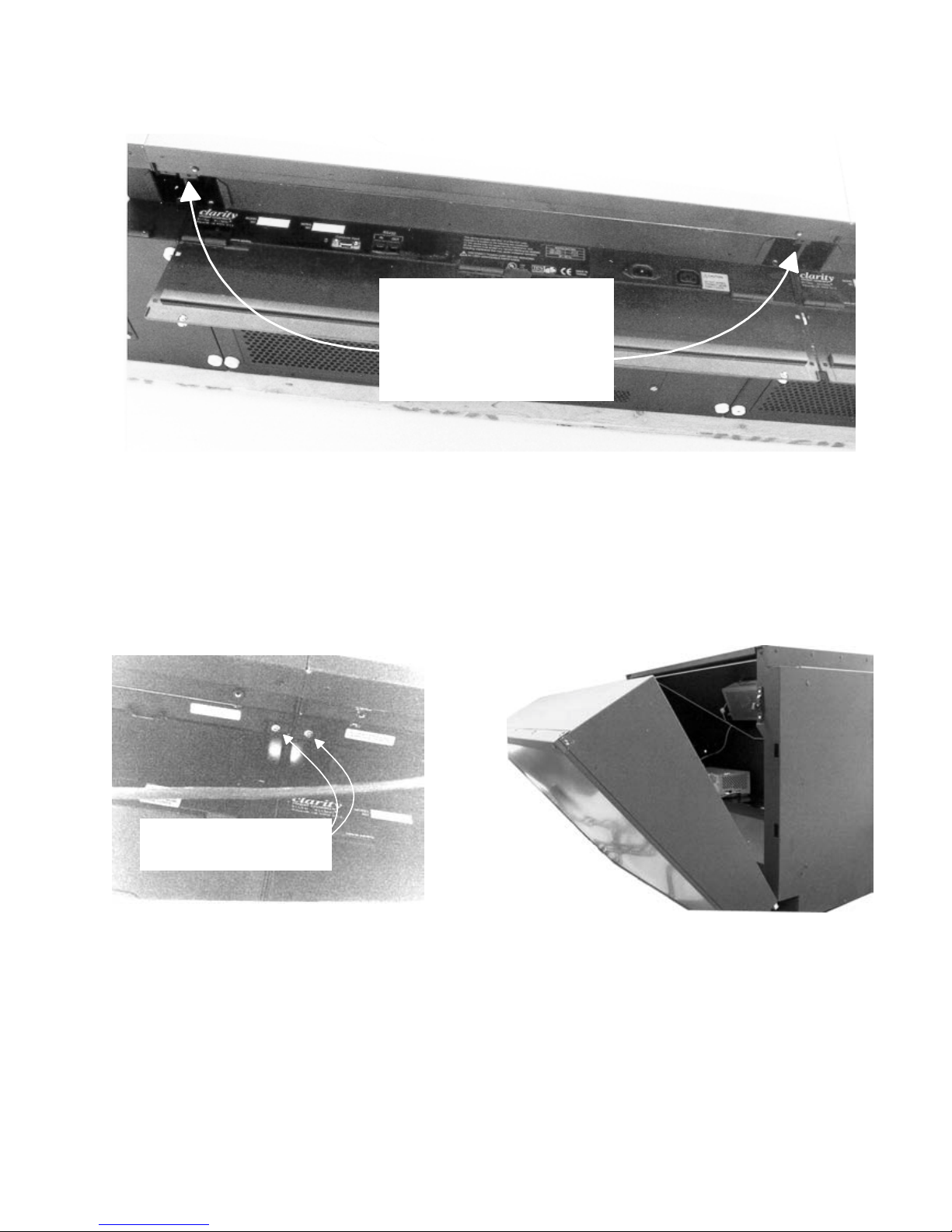

Two displays mounted side-by-side

Top cable channel

Vertical cable channel

Side bolt holes

Lower cable cha nnel

with end cap in place

Display unit, front top view

1 - 3

Page 12

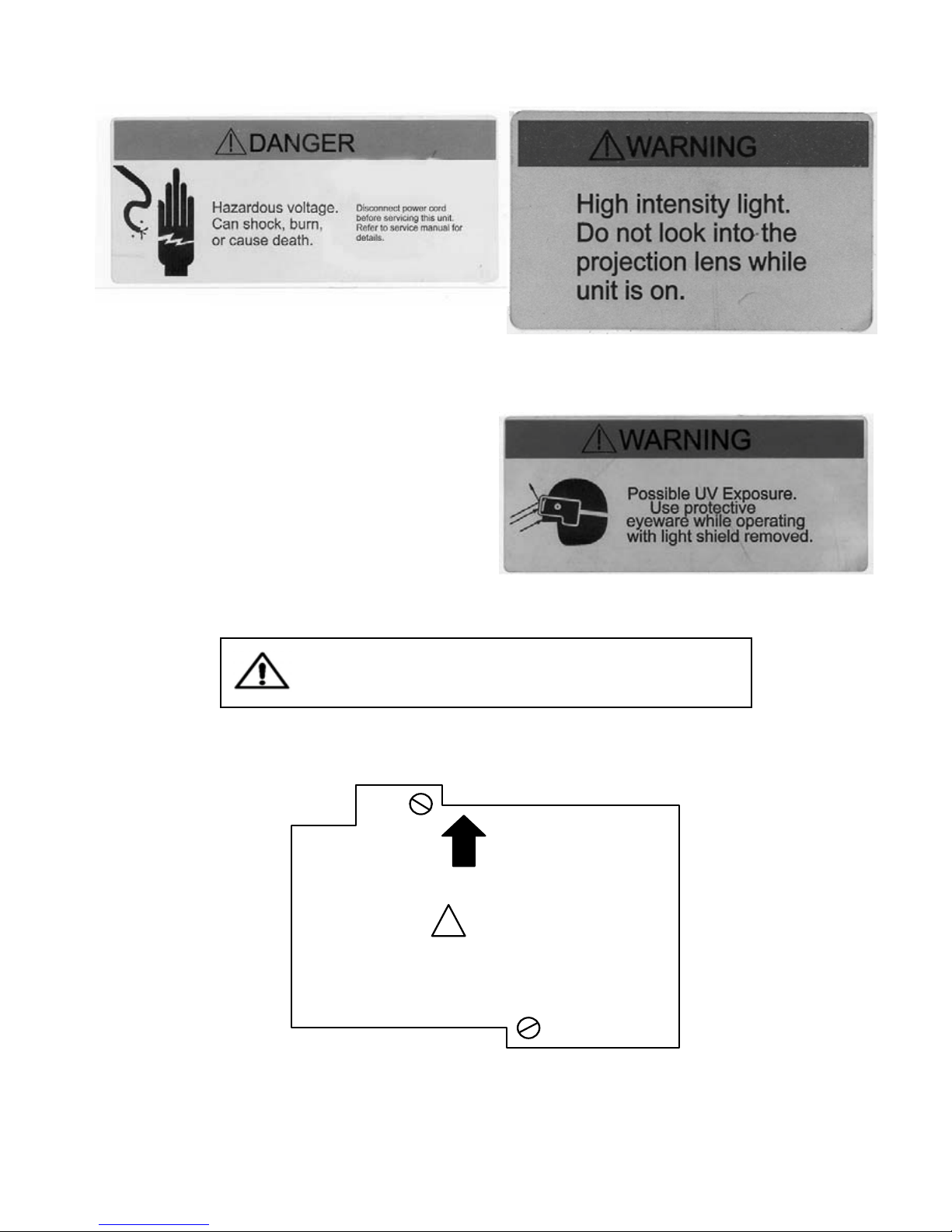

1.2 Your Safety Is Important

This list of safety warnings isn’t very long. Reading it could save you from getting an electric shock, a

UV radiation burn, or a heat burn.

These display units were designed with the

user’s safety in mind. However, if a user doesn’t

heed the safety warnings and cautions, there is

great potential for physical harm. The safety

warnings are on stickers in various places in and

on the display. They are reproduced on the

facing page so you can see them all at once.

There are some other items you should be

aware of that relate to safety, things to keep in

mind while installing and using the displays:

• The displays need at least 8" (200mm) of

clearance at the bottom. This is not just

for air circulation, which is important, but

also to allow the lamp and air filter doors

to open.

• There is no electrical interlock of the

screen. Opening the screen does not turn

off the power. The screen is held in place

by locks secured with screws. There are no

user-serviceable parts inside, so there is no

reason for a user, who is not a qualified

service person, to open the screen.

• The wall on which the displays will be

mounted must be strong enough to hold

them. Each units weighs about 68 lbs

(31kg). Simply mounting them into

wallboard won’t be adequate.

WARNING TURN OFF POWER SWITCH BEFORE OPENING COVER. HOT LAMP INSIDE. ALLOW AT

LEAST 15 MINUTES FOR LAMP TO COOL BEFORE REPLACING. RISK OF EXPLOSION.

HANDLE BULB WITH CARE. SEE USER’S MANUAL FOR LAMP REPLACEMENT.

AVERTISSMENT COUPER L’ALIMENTATION ELECTRIQUE AVANT OUVERTURE DE LA FACE AVANT.

ATTENTION, LA LAMPE EST CHAUDE. LAISSER REFROIDIR AU MOINS 15 MINUTES AVANT

SON REMPLACEMENT. RISQUE D’EXPLOSION. MANIPULER L’AMPOULE AVEC

PRECAUTION. SE REFERER AU MANUEL DE L’UTILISATEUR POUR TOUT

REMPLACEMENT DE LA LAMPE.

WARNUNG DEM ÖFFNEN DES DENKELS-STROM ABSCHALTEN. VORSICHT-EXPLOSIONS GEFAHR-

LAMPE IST HEIß. WARTE WENIGSTENS 15 MIN. FÜR DIE LAMPE ZUM ABKÜHLEN.

VORSICHT MIT DER LAMPE BEIM HANTIEREN. FOLGE ANWEISUNGEN FÜR DEN LAMPEN

WECHSEL IM REPARATUR MANUAL.

1 - 4

Page 13

DISCONNECT POWER CORD BEFORE SERVICING.

NO USER SERVICEABLE PARTS INSIDE.

FRON T

!

WARNING

HOT SURFACES NEAR

LAM P. SKIN B URN

HAZARD

Lamp housing as seen from the

bottom of the display

1 - 5

Page 14

1 - 6

Page 15

2 How to Install the Displays

2.1 Before You Start . . .

2.2 Two Ways to Install Display

2.2.1 How to Remove and Replace the Screen

2.2.2 Installing: Hanger Method

2.2.3 Installing: Flush to Ceiling

2.3 After the Units Are Hung …

2 - 1

Page 16

2.1 Before Your Start . . .

There are some important things to think about before you install the displays: How high should the

displays be? Will there be adequate ventilation? How will power and signal cables be routed? Is there

adequate AC power available?

Before you drill holes in the wall, plan ahead. It

won’t take long and could prevent you from

“doing it right the second time.” Here is a list of

the things you should think about:

Power: For every 4 units, you will need one

115V outlet rated at a minimum of 15 amps

(230V rated at a minimum of 8 amps). The

displays have auto-ranging power supplies, so

they work at 230 or 115 VAC without any

manual switching. (Specifications: p. 6-17)

Each unit has an IEC power loop-through

(not fused, not switched) to provide power to the

next units in a line. The limit for this string at

115V is 4 units. The limit on stringing together

the 230V lines is 8 units.

Power enters the unit at the bottom front,

inside the lower cable channel. See Cable

Routing on this page.

Clearance: There must be at least 8 inches

(200mm) of free space below the unit. This is

not just for air flow, although that is certainly

important. This 8" space provides access to the

lamp and air filter doors.

If the display will be mounted with the

hanger method, leave 1" (25mm) above the unit.

This is room enough to lift the unit off the

hanger and remove it.

The sides and back have no clearance

specification.

Stacking units: No stacking permitted! Each

unit needs space below it, as stated above. You

can install them side-by-side, right up against

each other; the units were designed specifically

for this. But no vertical stacking, please.

enclosed cable channel. This is open at

each end, so cables can run from one unit

to the next. End caps are supplied, so you

can close the ends of a row.

• Upper channel: Along each side of the top,

from front to back, there is an open

channel. With adjacent units, these

becomes an open-top tray connected to

the vertical channel.

• Vertical channel: Down the front of each

side is an enclosed cable channel which

connects the upper and lower cable

channels.

With these three channels you can route

cables from the top rear, along the top channel

between a pair of displays, down one of the

vertical channels, and horizontally in the lower

channel from unit to unit.

Wall strength: Each display unit weighs 65 lbs

(30 kg). Be sure to attach the hangers, or the

units themselves in flush mounting, to the wall

studs (interior vertical wall structures).

Mounting at an angle: When the display is

mounted with the back vertical, the screen has a

down angle of 10°. You can mount and use the

displays with the back tilted forward or

backward up to 20°, so the screen will tilt down

at 30° or up at 10°.

The displays can also be mounted with a left

or right tilt of up to 20°. (We don’t know why

you would want to do this, but you could do it.)

Mounting bolts: The upper and lower support

rails are supplied, but you will have to supply

your own hardware for installing these rails.

Cable routing: The units have three channels

for routing cables, both data and control:

• Lower channel: Beneath each unit, going

all the way across the bottom front, is an

2 - 2

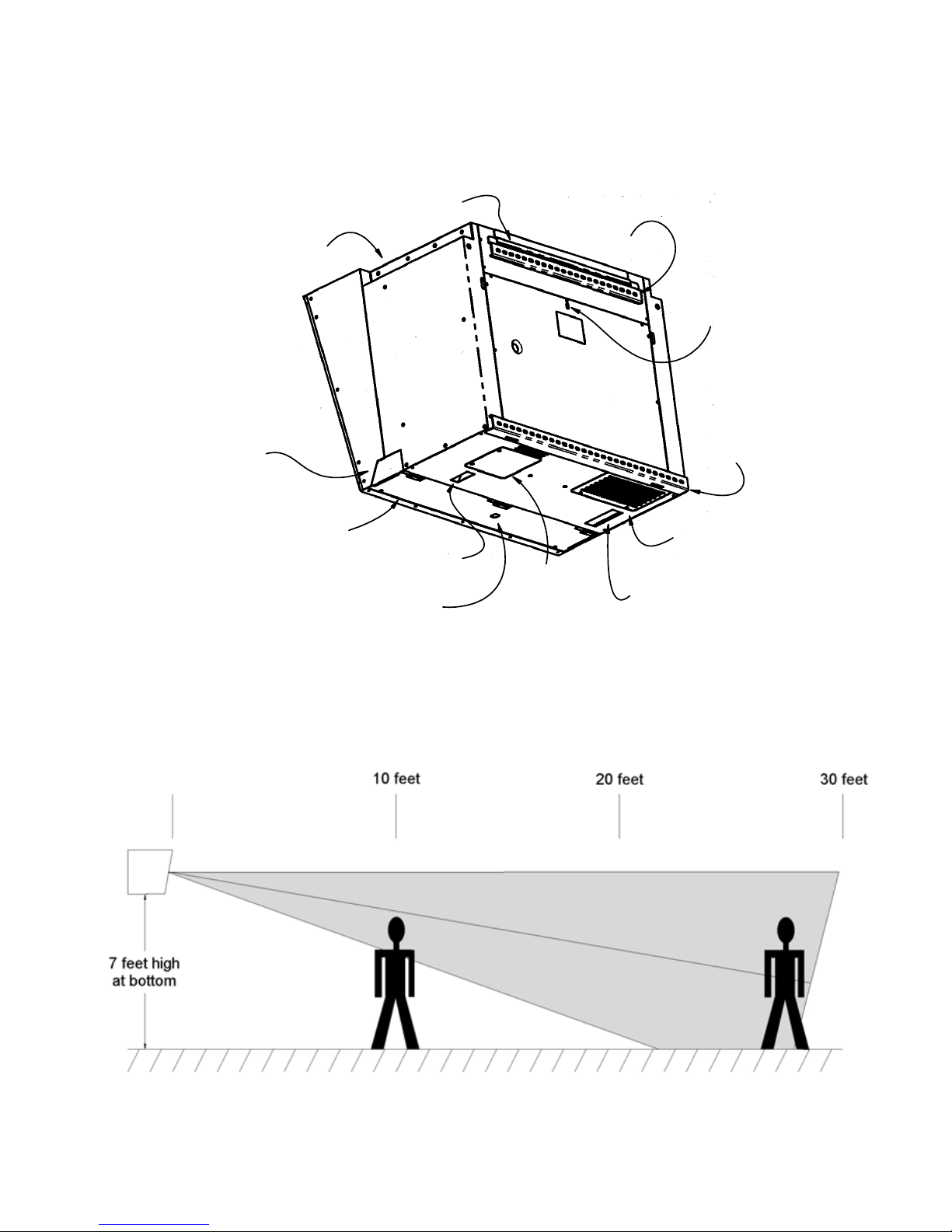

Page 17

Hanger flange

Top cable channel

End cap

Lower cable

channel, closed

Circuit

breaker

Hole for

optional

lock

Bottom rear view

Upper rail

Lamp access

door

Air filter

access door

LED panel

Mirror

adjustment

scr e w, r ear

Lower rail

Viewing cone is ±10° from normal. Display is shown 7 feet (2.1 m) high at bottom.

Back of display is vertical. Screen (normal) is angled down 10°. People shown are 6 feet (1.8 m) tall.

2 - 3

Page 18

2.2 Two Ways to Install the Displays

There are two standard methods to install the displays: on the supplied hanger or flush mounted. The

hanger method is preferred, because it makes servicing easier. Use the flush mount method only if

the top of the display must be flush with the ceiling. The bottom of the unit must have 8" (200 mm)

of space below it. Two physically capable people are needed to install the displays.

Of the two ways to install the displays—hanger

and flush mount—the hanger method is preferred. It is easier to remove it from the wall, if

you need to do this for servicing. This table

compares the two installation methods:

Hanger Flush to Ceiling

Easy to install and remove

from the wall

Sticks out ½" (13mm) from

the wall

Must be 1" (25mm) below

the ceiling

Unit is securely mounted

to the wall

Bottom of display needs

8" (200mm) clearance

Routine servicing (lamp

and filter replacement)

from below

As you can see, several items are the same

between the two methods. In either case, the

screen must be removed during the initial

installation, and that requires a qualified service

person.

The hanger and lower support bracket are

supplied, but with either method, you must

supply the mounting hardware.

The Flush Mount method can be done by

attaching the display directly to the wall or by

mounting the display on Unistrut™ or other

preformed metal support system.

The Flush Mount method must use the

Must remove screen to

remove from the wall

same

Can be flush against the

ceiling

Same

Same

Same

lower support rail for each display. This makes

the units more secure.

To give you a general idea of the process

involved in the two methods, here are the basic

steps. The details for each method are given in

the next two sections of the manual. Read those

sections. Don’t try to mount the units for the

first time with these brief instructions.

Hanger Method:

1. For all units, mount the upper hanger rails

to the wall, keeping it the proper distance

from the ceiling to allow the display unit

to be lifted onto the hanger.

2. Mount the lower support rails on the wall

the proper distance below the hanger rails.

3. Hang the display units on the hanger rail

and secure it to the lower support rail.

4. Remove the screen and bolt the units

together, side-to-side.

5. Replace the screen.

Flush Mount Method:

1. Measure and drill holes in the wall for the

mounting bolts which you have supplied.

2. Measure for and mount the lower support

rails.

3. Remove the screen.

4. Hold the display against the wall and

install the mounting bolts.

5. Install the bolts in the lower support rails.

6. Bolt the displays together, side-to-side.

7. Replace the screen.

2 - 4

Page 19

775 mm

19 mm

75 mm

Upper Support Rail

13 mm hole

for flush

mounting

Lower support rail

737 mm

68 mm

Hanger flange

524 mm

19 mm

Rear view, showing support rail dimensions

and holes for flush mounting

!

Note: Drawings in inches are in the Reference section on page 6-23

No more than 4

115 VAC

12 534

Do not connect more than 4 units in an AC series

2 - 5

Page 20

2.2 Two Ways to Install the Displays

2.2.1 How to Remove and Replace the

Screen

The screen should only be removed by a qualified service person. It can be removed even if the unit is

mounted flush to the ceiling. There are two captive screws at the bottom, inside the cable tray, that

must be loosened to open the screen locks. Then “pop” out the screen at the top.

The screen is removed or replaced in many of

the following procedures, so these instructions

are only given here.

The screen is held in place at the bottom by

tabs that make a sort of hinge and by springloaded latches at the top. It is locked by screen

locks at the bottom which are held by screws.

Only qualified service persons should remove

the screen. There are no user serviceable parts

inside.

To remove the screen:

1. Open the lower cable channel door, if it is

not already open. This is at the bottom of

the unit. Loosen the two captive thumb

screws at the left and right ends of the

access door.

2. Unscrew the two screws at the end of the

cable channel which hold the screen lock

levers.

3. Pull down the screen locks. They pull

straight down about an inch (25mm).

4. Pull the screen out sharply at the top. The

screen will “pop” out at the top.

• If the screen is not against the ceiling,

you can reach the back of the screen at

the top corners and pull out.

• If the screen is against the ceiling and it

is in the middle of a banner (row) of

displays, it can be nearly impossible to

grab the top of the screen to pull it. Use

the optional tool, SRT-200. This

accessory is two strong magnets, each

with about 90 lbs. of pulling strength.

Put the magnets at corners of the wide

mullion near the top. Pull out sharply.

To remove the magnets, tilt them so

one of the long sides comes off.

5. Rotate the screen down a little and lift it

up and off.

To replace the screen:

1. At the bottom of the screen, see that the

screen locks are pulled out.

2. Insert the tabs at the bottom of the screen

into the slots at the bottom of the display.

3. Rotate the screen up against the display

unit.

4. Press sharply with the palm of your hand

to “pop” the screen latches in place at

both top corners. Check that both sides

are properly latched.

5. In the lower cable channel, push the

screen locks up, one on each side.

6. Secure the screen locks with the screws.

CAUTION

requirement to install these screen locking screws.

!

Note: If you are going to transport the display,

7. Close the lower cable channel door and

The cable channel cover swings down on hinges,

but it can also be removed. To remove the door,

unscrew the thumb screws at each end of the

channel and let the door swing down. There are

three hinges, and the center one has a spring

clip to keep the door in place. With the door

open, lift the spring clip and slide the door to

the left. The hinge pins will come out and the

door can be set aside.

This is important! It is a safety

tighten all thumbscrews with a screwdriver. If

the display will not move, “finger tight” is

enough.

secure it with the thumb screws.

2 - 6

Page 21

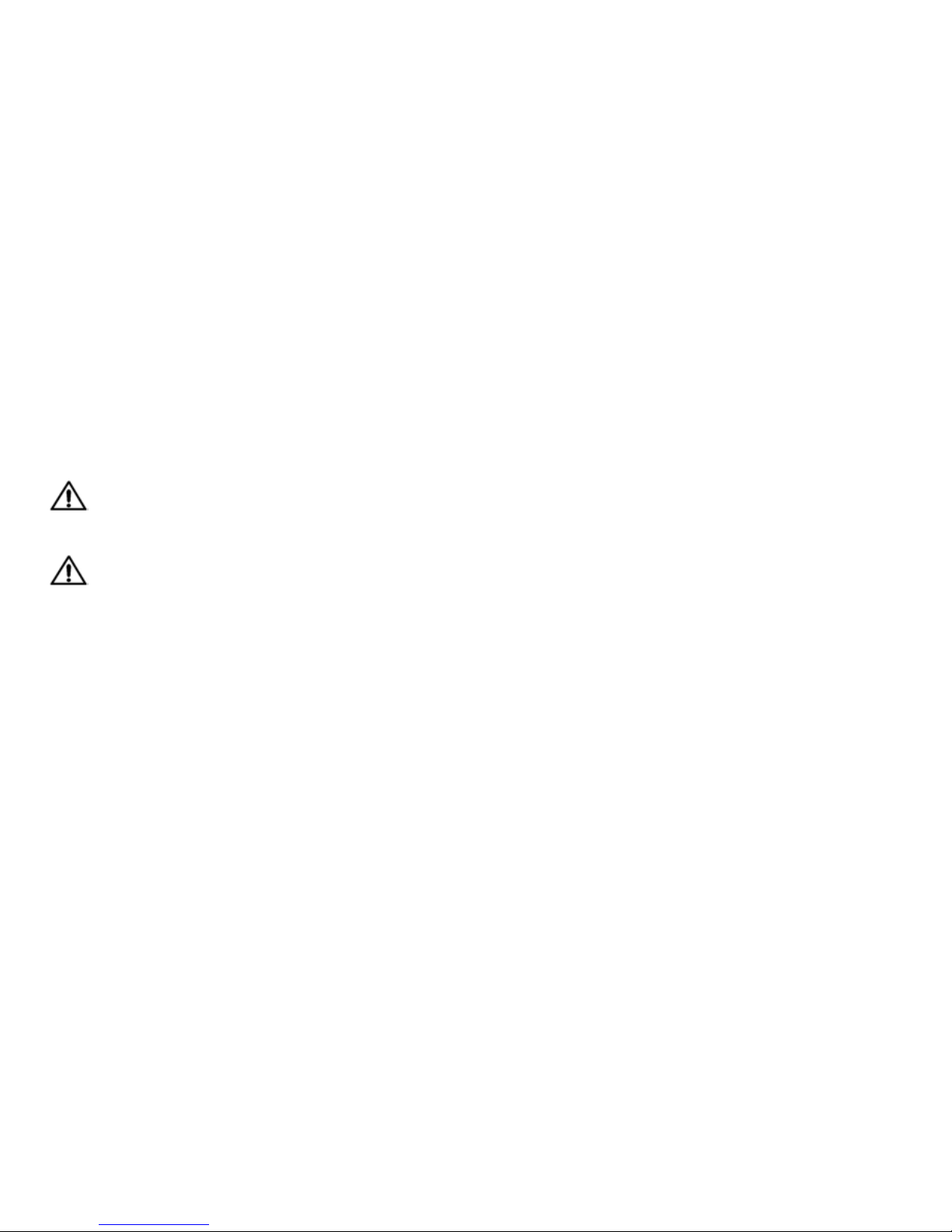

Location of

scree n lo cking

scre ws

Screen locking screws are in the cable channel at the sides of each unit.

Screen locking screws

in neighboring units

Screen lock screws of side-by-side units

Screen being removed

2 - 7

Page 22

2.2 Two Ways to Install the Displays

2.2.2 Installing: Hanger Method

This is the standard, and preferred, mounting method. When the display is mounted using the

hangers that are provided, it is easy to remove it from its position in the banner. Remember to leave a

one-inch clearance at the top.

With the Hanger Method, you need a one-inch

(25mm) space above the display so you can lift

the unit up and onto the hanger. And, of course,

you need an 8-inch (200mm) clearance at the

bottom (measured after the units are hung in

place) to be able to open the lamp and air filter

access doors.

Mounting hardware is not supplied, except

for the bolts that hold the unit to the lower

support rail. You will have to supply appropriate

bolts or screws to attach the rails to the walls.

CAUTION

persons only.

This is a procedure for qualified service

CAUTIONBe sure the mounting bolts go into the

structural member of the wall (wall stud). It is not

safe to mount the hanger rail or lower support rail on

wall board alone.

The center holes of the upper rail, on which

the unit hangs, should be at least 3 11/16 inches

(93mm) below the level of the ceiling. This will

leave at least one inch (25mm) of space to lift

the unit up and over the lip of the hanger rail.

Measuring from the center of the holes in the

upper and lower rails, the lower support rail

should be 20 11/16" (525mm) down from the

hanger rail. This will put it in the right place so

the bottom of the display will rest on the lower

rail when the unit is hung on the upper rail. It is

okay if the distance between the rails is slightly

less than this—it can be as little as 20 9/16"

(522mm)—but don’t make it more.

The hanger rail is 23" (584mm) long. They

should be spaced horizontally 7½" (190.5mm)

apart.

The lower support rails are 30" (762mm)

long. They should be spaced ½" (13mm) apart.

Larger drawings in millimeters and inches are

shown in sections 6.10 and 6.11.

Steps for installing the hanger rails:

1. Measure and mark the positions of the

upper hanger rail and the lower support

rail. Measurements are given in the

preceding paragraphs and in the drawings.

When hanging several units together in a

row, notice that the two rails are not as

wide as the unit itself.

2. Drill holes appropriate for your mounting

hardware.

3. Mount the upper and lower rails for each

unit. Be sure all the rails are even with

each other and properly spaced.

4. The units have three 1/4" holes on each

side for bolting the them together. The

displays are shipped with these holes filled

with plastic buttons. Remove all these

buttons except the ones on the outside

ends of the row. Do not use washers on

these bolts. They are designed to grip the

chassis.

5. Hang each display unit on its hanger rail

and position them so they rest on the

lower support rails.

6. Install the two bolts which hold each unit

to the lower rail. Use washers on these

bolts. (There may be an extra washer in

the accessories kit.)

!

Note: Drawings in inches are in the Reference

section on page 6-23.

Now go to section 2.3: After the Units Are

Hung, page 2-12.

2 - 8

Page 23

Rear view showing hanger flange

and upper cable channel

Lower support rail

582 mm

609 mm

Hanger

flange

121 mm 316 mm

68 mm

Upper

support

rail

13 mm

524 mm

13 mm

Lower

support

rail

Side view with dimensions to center of holes in support rails

2 - 9

Page 24

2.2 Two Ways to Install the Displays

2.2.3 Installing: Flush to Ceiling

The flush mounting method is not the preferred method, However, for those installations that

absolutely require the unit to be flush mounted to the ceiling, this is the way to do it. It is a little

more difficult to remove a unit from its position when mounted this way.

With this method, you do not need any space

between the ceiling and the top of the display.

Heat is not a problem. However, it is still

necessary to leave 8" (200mm) below the unit to

be able to open the lamp and air filter doors.

The units can be mounted directly to the

wall. The display will stick out from the wall the

thickness of the hanger flange. Or you can use

Unistrut™ or some other preformed metal

support system. These systems allow the units

to slide sideways for final positioning, but the

units will stick out from the wall by the thickness of the support system hardware.

CAUTION

Always secure the unit to structural members within

the wall, such as studs.

Do not mount directly to wallboard.

CAUTIONAlways use the lower support rail of

some type. If your planned installation will not use

the supplied lower support rail, use some other

structurally sound method of securing the bottom of

the units to the wall.

The lower support rail provides a vital

measure of safety. It is a rest for some of the

weight of the unit, and it secures the unit to the

wall. Always use the lower support rail in flush

mounting the displays. The lower support rails

are 30" (762mm) long. They should be spaced

½" (13mm) apart.

Steps for mounting flush to ceiling:

1. If you will use a preformed metal support

system, measure and mark the positions

for these and for the lower support rail.

— or —

1. If you will install the units directly to the

wall, measure and mark the positions of

the lower support rail and the two

mounting holes. Measurements are given

in the drawing on the facing page.

2. Drill holes appropriate for your mounting

hardware.

3. Mount the lower rail for each unit. Be sure

all these rails are even with each other.

4. Remove the screens from all units.

5. The units have three 1/4" holes on each

side for bolting the them together. The

displays are shipped with these holes filled

with plastic buttons. Remove all these

buttons except the ones on the outside

ends of the row.

6. With someone holding the unit in

position, install the two upper mounting

bolts.

7. Optionally, you may bolt the units together side-to-side. Do not use washers on

these bolts.

8. Install the two bolts which hold the unit

to the lower support rail. Use washers.

There may be an extra washer in the kit.

9. Replace the screens and secure their

latches. Tighten (only finger tight) the

screen latch screws.

Now go to section 2.3: After the Units Are

Hung, page 2-12.

2 - 10

Page 25

775 mm

19 mm

75 mm

13 mm holes (2)

for flush mounting

Lower support rail

737 mm

Hanger flange

592 mm

19 mm

Back view with flush mounting hole dimensions, no upper support rail

!

Note :

Drawings in inches are in the Reference section on page 6-23.

2 - 11

Page 26

2.3 After the Units Are Hung …

Bolt the units together side-to-side. Each unit has three channels for cables. After the cables are laid

out in these, all the video, control and power connections are accessible from the bottom cable

channel.

At this stage, the units are all mounted on the

wall. The next step is to bolt the units to each

other. Three 1/4" bolts with wingnuts are

provided for this purpose. With all the screens

removed, bolt the units together, removing the

plastic buttons if you have not already done this.

Lay out the cables in the channels, bringing

everything to the lower cable channel. The three

cable channels are:

• Along the top from front to back there is

an open channel made by two neighboring

units.

• There is a vertical channel down the front

of each side which connects the upper and

lower channels.

• There is a lower channel with a door

which can be removed. (The displays are

shipped with this door removed.) There is

an optional lock available for this door,

and there are end caps for the units on the

end of the row. The lower channel has

cable clamps for dressing cables so they

don’t fall down when the door is opened.

All cables should be routed in these channels:

video data, RS-232 control and power.

Power can be looped from one unit to the

next with the optional VN-38-PL Power

Loop-Thru cable.

CAUTION

at 240V) should be looped together for power.

RS-232 control cables can be looped together

to make one line. The only limit on number of

units is signal strength at the end of a long line.

Always use the best quality RS-232 cables

available. It saves time and headaches.

End caps should be installed on the two ends

No more than 4 units at 115V (or 8 units

of the lower cable channel for a neater

appearance and to keep curious hands out. Open

the cable channel door. Clip the end cap onto

the door with the slanted part toward the front

of the door. Secure the end cap with a screw

(supplied). Close the door. The doors can now

be opened and closed with the caps in place, and

they can’t be removed with the doors closed.

(Yes, you will have many extra end caps.)

When all the cables are connected, it’s time to

close the units. Here is a check list:

• Screens are in place, the screen locks are

closed (up), and the two Phillips head

screws are tightened on each lock.

• Video data cables and RS-232 control

cables are connected.

• Power cables are connected. If you used

power loop-thru, no more than 4 units at

115V (8 units at 240V) are looped

together.

• End caps are installed at each end of the

row and secured with screws.

• Plastic buttons are installed in the side

bolt holes on the end units.

• Lower cable trays are closed and secured

with the thumb screws at each end. If

these units have the optional lock

(VN-38-LK), they are locked.

• The air filter door is closed and the air

filter is installed in it.

• The lamp is installed and its access door

is closed.

One last thing: Stand in front exactly between

each pair of displays. Look straight at the point

where the sides of two units meet. Sometimes

there is a slight crack between them, and you

can see light coming from above the displays. If

this is going to be distracting, use black tape on

the top of this crack to block the light. The tape

won’t be visible from the front.

2 - 12

Page 27

Computer input; RS-232 input and output

AC power input and output

No more than 4

115 VAC

12 534

o not connect too many units in series for AC power.

Four (4) display units is the limit.

2 - 13

Page 28

2 - 14

Page 29

3 Setup, Control, and Calibration

3.1 About the Remote Control

3.2 The Power Up Sequence

3.3 Adjusting for Optimum Picture Quality

3.3.1 Adjusting Black and White Levels

3.3.2 Matching Frequency & Phase

3.3.3 Matching the Displays to Each Other

3.3.3.1 About Color Balancing

3.3.4 Changing the Position of the Image

3.4 Saving and Recalling the Settings

3.5 Setting Additional Controls

3.6 Controlling With RS-232 Commands

3 - 1

Page 30

3.1 About the Remote Control

The units can be controlled with the remote control and with RS-232 commands coming from a

“control” computer. It is generally faster and easier during initial setup to use the remote control.

This section is an overview of the remote control.

A remote control is provided with each unit,

although you will probably only need one of

them for the entire row of displays. If there are

lots of people around the displays, it is probably

a good idea to keep these out of sight to prevent

curious fingers from turning the units off,

changing the settings, and generally causing lots

of trouble.

The remote control operates like a TV or

VCR remote with IR (infra-red) signals. Aim the

remote at the screen. When there are several

displays in a row, you may have to get close to

the unit you want to control. Otherwise you

find yourself affecting two or three units. There

is a way around this, which is explained below

under How to control only one unit.

Many of the functions on the remote control

will seem obvious. Here is an explanation of the

main features:

•The

ON and OFF buttons turn the lamp on

and off. It takes a few seconds for the

lamp to light when you press the ON

button. OFF turns the lamp and fans off,

of course. The electronics remains on as

long as there is power and the circuit

breaker is on.

•The

MENU button opens the main menu

on the screen. From this menu you

highlight an item with the up-down

arrows. Then press

ENTER to activate the

highlighted selection.

•The

PREV MENU button closes the current

menu and keeps the “parent” menu, if

there is one. If there isn’t a parent menu,

this button removes the last menu.

•

ENTER selects the highlighted item and

opens that menu. Or, if the highlighted

item is like this:

[ ] Flip Vert

it turns on (or turns off) the feature.

• Seven of the main menu items have fast

access buttons that let you get to the

feature immediately. These are in the

upper right corner of the remote. (In this

display, the Source button has no

function; it is used in other Clarity

products, which use the same remote.)

• In general, the up-down arrow buttons

move through the menus, and the rightleft arrow buttons change the highlighted

value.

•The

ID and MON SEL buttons are different

because their functions are not available in

the main menu.

How to control only one unit: The IR signal

from the remote radiates over a fairly broad area,

and it is sometimes hard to control just one

unit, especially if you are more than 10 feet

(3m) back. To solve this, turn off the IR sensor

in the units you don’t want to control. Get close

to the units you want to “turn off” and press

MON SEL and press ENTER. Now that unit will not

respond to any commands except another

- ENTER, which will turn it back on.

SEL

MON

In this manual, buttons on the remote control

will be printed in a style like this:

LEVEL

and menu items will be printed like this:

Input Level

3 - 2

Page 31

This control is

not functio nal in

this display

These two controls

are not found in the

Main Menu

This opens the

Main Menu

Adjust a value

OFF

SOURCEON

CURTAIN

RESET

IDMON S EL

PREV MENUMENU ENTE R

LEVEL

PHASE

FREQ

COLO R

These controls are

also found in the

Main Menu

Select or

activate a feature

Back up one

menu le vel

Move through

the menu

The Remote Control

3 - 3

Page 32

3.2 The Power Up Sequence

The lamp doesn’t start immediately, because the turn-on sequence has a 15-second delay. The LEDs

will tell you a lot about what is going on and what, if anything, is wrong.

The main power switch is on the bottom of the

display in a recessed pocket. This is a lighted

circuit breaker, which is lit when unit power is

switched on and unlit when it is off.

Turning on the circuit breaker initiates the

start-up sequence. For the first 5 seconds it

seems like nothing is happening, but internally

the electronics module is going through an elaborate initialization routine. Then all the LEDs

turn on for a second. The fan starts and the

STANDBY LED blinks.

About 10 seconds later everything is settled

down, and the lamp turns on. It takes the lamp

another half minute to become fully illuminated. The

FAN and LAMP LEDs will be lit, which

you can see by looking at the bottom of the unit,

and the

STANDBY LED is out. Several other LEDs

will be on, indicating normal conditions:

STANDBY off

LAMP ON on

BALLAST POWER on

12 VOLTS on

5 VOLTS on

TEMPERATURE on

FAN on

INTERLOCK on

SOURCE on(if there is a valid VGA

signal coming from the

source computer)

RS232 GLOBAL off

RS232 LOCAL off

REMOTE off

About the circuit breaker

When the current through the breaker

exceeds its rating, the circuit breaker trips,

which shuts off all power to the display. Power

to the neighboring units via the loop-thru is not

interrupted, so one circuit breaker does not turn

off the whole row.

If the circuit breaker trips off, the rocker

switch moves to t again he off position. To

reset, push the switch on. If it continues to trip

off, leave it off and contact a qualified service

person.

Auto Lamp On

The normal (default) state of the unit is

Auto Lamp On, which is a menu item in the

Misc Control menu. When there is an in

this item (the default condition), the display

does not have a standby period. The lamp starts

immediately after the electronics module has

completed its startup routine after AC power is

applied.

However, if Auto Lamp On does not have

an x, thelamp will not turn on automatically at

the end of the startup period, and the

STANDBY

LED will be on steadily.

Auto Lamp On

in Misc

Standby LED will …

Control menu

Has x flash during startup, then

go out; lamp turns on

without an ON command

Does not have x flash during startup, then

stay on; unit waits for ON

command from remote or

RS232.

The LEDs provide lots of information about

what’s going on with the display. The table of

the facing page explains each LED. All the LEDs

are green. Some of them flash or blink to

indicate different states of the unit.

Lockout is indicated by a flashing

STANDBY LED.

During lockout, you cannot turn on the lamp. If

the lamp access door is opened,

flash for 30 seconds. After that,

STANDBY will

STANDBY stays

on without flashing, and the display waits for an

ON from the remote or an RS232 command.

3 - 4

Page 33

LED Meaning

STANDBY

LAMP ON

BALLAS T POWE R

12 VOLTS

5 VOLTS

TEMPER ATUR E

FAN

STANDBY

LAMP ON

BALLAST

POWER

12 VOLTS

5 VOLTS

TEMPERATURE

FAN

INTERLOCK

SOURCE

On if the unit is in the standby mode (waiting for an ON

command)

Blinking during the lock-out time

Off if the lamp is on

On if the lamp is illuminated

Off if the lamp is off

Flashes with TEMPERATURE if the lamp is over temperature

On if the 300V supply is working and providing power to the

lamp ballast

On if this voltage is available to the electronics module

On if this voltage is available to the electronics module

Shows the status of the temperature of the LCD and lamp:

On if all measured temperatures are OK

Flashes with LAMP ON if the lamp temperature is too high

Flashes alone if the LCD is over temperature.

On if the fan is operating properly

Off if the fan is off

Blinking if the fan has a “locked rotor”

On if all interlocks are “closed” (normal operation)

Flashes if any interlock opens, lamp door or thermal

On if a valid source is present at the VGA connector

INT ERL OC K

SOURCE

RS232 GLOBAL

RS232 LOCAL

REMOTE

RS232 GLOBAL

RS232 LOCAL

REMOTE

On very briefly if any RS232 activity is detected at the RS232

IN connector

Off if there is no activity here

On very briefly if a valid RS232 command for this unit is

received. This includes all global RS232 commands sent

without specific addressing and all commands addressed

to this specific unit or the group that this unit is in.

On very briefly when receiving IR (infra-red) commands, or

when unit sense stray IR.

3 - 5

Page 34

3.3 Adjusting for Optimum Picture Quality

Black Level, White Level, Frequency, and Phase must be adjusted every time the input is changed.

Black Level must be done before White Level. Color Balance should be checked whenever a lamp is

changed in any unit in a banner. This section presents an overview of the adjustment process, which

is then given in detail in the following sections.

All video sources are different, even separate

outputs on the same video card. Sometimes they

are different by a lot, but usually they aren’t

different by much, maybe just a few millivolts.

Still, these differences are important. The

Input Level adjustments—Black Level and

White Level—compensate for these small

differences and match the display to the specific

computer video output card.

The four adjustments described here and in

the next two sections match the display to a

particular computer video output card. If you

change computers, or if you change the video

card connected to a display, do these

adjustments again.

!

Note: Black and White Level adjustments cannot

be used to make color adjustments. Color

adjustments, getting the units to match in

color and brightness, is accomplished with

Color Balance controls, described in section

(page 3-12.)

What voltage is the video card using for

black? That is the question the Black Level

adjustment answers. What is the voltage

difference between black and white? That is the

question White Level answers. Fortunately,

these two adjustments are automatic. However,

the automatic sequence must be initiated

manually.

area around the upper left corner of the Black

Level menu. If the picture is absolutely black or

white in this area, it is enough.

Frequency and Phase are two other adjustments

that compensate for differences in video output

cards. Frequency matches the display’s internal

dot clock to the incoming signal’s frequency.

Phase does a similar job with the signal’s phase.

Frequency and Phase are not automatic, but

the adjustments are not difficult. You need an

external checkerboard signal to make these

adjustments.

Where do you get a checkerboard pattern?

One of the "fill" patterns in Windows 95 Paint

has this pattern. Section 6.13 on page 6-28

shows how to make the checkerboard pattern as

well as solid black and white patterns.

With MAC OS 8.0, look for a checkerboard

pattern in File, Control Panel, Desktop Patterns.

After the Black and White Levels and Frequency

and Phase adjustments are finished, make the

displays match each other using the Color

Balance controls. Lamps vary slightly from one

display to the next in their brightness and their

“color temperature.” The Color Balance process

reduces these differences to a minimum.

Use the internal test patterns, White and

50% Gray, to do this color balancing.

!

Note: Black Level and White Level must be

adjusted with external black and white

signals. You can’t use the display’s internal

test pattens for this. Also, you must use the

computer that will be used for the video

program. If this computer changes, do all

these adjustments again.

For the Black and White external test

patterns, it is not necessary for the whole screen

to be black or white. The electronics looks at the

3 - 6

Page 35

List of Picture Quality Adjustments

• Black Level and White Level: Black Level must be done before White Level. Both

of these must use a black (or white) image from the video source. Use the Auto

for Black and for White.

• Frequency: Use a checkerboard pattern from the video source. Adjust Frequency

to eliminate vertical bands in the picture.

• Phase: Use a checkerboard pattern from the video source. Adjust Phase for

minimum horizontal noise or streaking.

• Color Balance: Use the internal white and gray patterns to match the displays to

each other. (Section 3.3.3)

• Position: Center the image with the Position controls.

LED panel

Bottom of display unit

Circuit breaker

3 - 7

Page 36

3.3 Adjusting for Optimum Picture Quality

3.3.1 Adjusting Black and White Levels

Black and White Level adjustments compensate for differences in video output cards. These

adjustments cannot be used to adjust for color differences between display units. The electronics

must know that the input source means by “black” and “white” The level adjustment sequence,

which is automatic but started manually, does this job. You must use external signals.

Black Level must be done before White Level.

Both must use an external signal. The internal

test patterns cannot be used.

You should adjust the Black Level and White

Level with the actual computer and the actual

video card output that will be used for program

material. If you change computers, or if you

change the video card output connected to a

display, do these adjustments again. No two

video cards are alike. These adjustments are

quick and easy to do. Take a moment to get it

right.

!

Note: Do not use the Black Level or White Level

controls to adjust for color differences

between displays. Use the Color Balance

controls for this.

Here is the procedure for black and white

level adjustment:

1. On the remote, press

LEVEL. This opens

the Input Level menu. (This menu is also

available from the main menu.)

2. With the highlight on Black Level, press

ENTER. Black must be done before White.

3. Generate a black signal from the computer

source. Any picture that is completely

black around the upper left corner of the

menu will work. However, it must be

completely black, not just very dark gray.

When in doubt, make a black signal with

Windows Paint, as described on page 6-28.

4. Highlight Auto and press

ENTER. In less

than two seconds the electronics will

automatically find the incoming signal’s

black level and adjust to it.

5. Press

6. Highlight White Level and press

LEVEL again.

ENTER.

7. Generate a white signal from the

computer source.

8. Highlight Auto and press

ENTER. This

automatic process takes longer than the

black adjustment, but it is still only five

seconds or so. When the numbers stop

changing, it’s finished.

9. Press

PREV MENU to close the menu.

It is possible to adjust these levels manually, but

there is no reason to do this. The automatic

method is more accurate and much faster than

the manual method, so the manual method will

not even be described. Stick with automatic.

Everybody does.

3 - 8

Page 37

Input Level

[ ] Black Level

[ ] White Level

Input Level menu

Always do Black Level first.

Black Level

(Requires black field)

Auto [ ]

All

! #

Level Sample

Red 127 000

Green 123 001

Blue 131 000

Black Level menu

White Level

(Requires white field)

Auto [ ]

All

! #

Level Sample

Red 127 254

Green 123 255

Blue 131 255

White Level menu

3 - 9

Page 38

3.3 Adjusting for Optimum Picture Quality

3.3.2 Matching Frequency & Phase

These adjustments match the internal dot clock to the external signal. An external checkerboard

patterns is required. This pattern must come from the source computer.

These two adjustments require an external

checkerboard pattern. The instructions for

making this pattern in Windows 95 are in

Section 6-13, page 6-28.

In an emergency, you can get a pretty good

checkerboard pattern from the Windows shutdown screen. First, minimize all applications

and use a plain white background for the Desk

Top. Select Start, then Shut Down, but don’t go

any further. The window now has a pattern in

which every other pixel is black.

With MAC OS 8.0, look for a checkerboard

pattern in File, Control Panel, Desktop Patterns.

Always do Frequency before Phase, because the

phase adjustment is meaningless unless the

frequency is correct. Here is the procedure:

• Generate a checkerboard pattern on the

source computer.

• On the remote, press

MENU.

• Highlight Misc Control and press

ENTER.

• See that Sharpness has an x in it. If it

doesn’t, highlight it and press

• On the remote, press

FREQ.

ENTER.

• Adjust Frequency with the right-left arrow

keys. When the frequency is wrong, you

will see vertical bands of noise in the

picture. (If there is horizontal streaking as

well, ignore that for now.) As you change

frequency, the number of bands will

increase or decrease. At one frequency,

there will be no bands. That’s what you

want. All displays using the same

computer source, even with different video

cards, will have the same Frequency

number at the end of this process.

!

Note: It doesn’t matter what the Frequency number

is. This is just a reference number between

000 and 127. It is not the frequency.

• Press PHASE.

• Adjust Phase with the right-left arrows.

When the phase is wrong, you will see

horizontal streaks of noise. As you change

the Phase the noise will increase or

decrease.

!

Note: It doesn’t matter what the Phase number is.

This is just a reference number between 000

and 031.

• Try to adjust for no noise at all. It may

not be possible to eliminate all of it, in

which case reduce it to a minimum.

Sometimes within the 000–031 range of

the Phase number, there are two places

where noise is eliminated. Run the Phase

number up and down the scale. Find the

area where the horizontal noise is reduced

over the widest range of Phase numbers.

Set the Phase in the middle of this range.

3 - 10

Page 39

LEVEL

PHASE

FREQ

Frequency

and Phase

OFF

SOURCEON

CURTA IN

RESET

Menus

COLOR

IDMON SEL

PREV MENUMENU ENTER

Remote control with location of Frequency and Phase

buttons

Phase Select

016

Phase Select menu

Frequency Select

064

Frequency Select menu

3 - 11

Page 40

3.3 Adjusting for Optimum Picture Quality

3.3.3 Matching the Displays to Each Other

To get all the units in a row to look the same, you must balance their colors and their brightness. Use

the internal White and Gray patterns, and match all the units to the darkest one. Color balancing can

be done before or after the other adjustments in Chapter 3, because it does not interact with any

other adjustment. Some help with this procedure is given in the next section, too.

Color Balancing compensates for differences in

lamp brightness and color. Lamps are not all the

same, no matter how closely the manufacturing

process is controlled. You should check color

balance and adjust for any differences whenever:

• you change any lamp in the display group;

• you install a new display unit;

• you change the electronics module in any

display.

Each lamp has a fixed brightness level, and

there is nothing you can do to change it. Therefore, you will use the electronics to dim the

image slightly on the brighter units to make

them match the brightness (and color temperature) of the least bright unit.

Color balancing should always be done with

the internal white and gray patterns.

!

Note: Never attempt to color balance with the

White and Black Level controls.

How to Color Balance:

1. Turn on the internal white pattern in all

displays. (

ENTER > Test Patterns > ENTER >

MENU > Misc Control >

White )

2. Turn off the menus (

PREV MENU) but leave

the White pattern up.

3. On all displays, open the Color Balance

menu (

!

Note: In the Color Balance menu, the up-down

COLOR).

arrows move the cursor through all the

choices in both columns. It is a common

mistake to try to move between columns with

the right-left arrows. The right-left arrows

change the value. Highlighting the pair of

arrows above either column and pressing

right or left changes all three values in the

column together. Highlighting just the

number next to

Green changes the green

value only.

4. Adjust the Wht numbers so they are 031

for Red, Green and Blue in all displays.

This is important.

5. Adjust the Gry numbers so they are 007

for Red, Green and Blue in all displays.

This is just as important.

!

Note: The Gry numbers range from 000 to 015. Be

sure to start the whole color balancing

process at 007.

6. Choose the darkest display in the group.

We will call this the baseline display. It is

now as bright as it is ever going to be, so

we will adjust all other displays to this

baseline display.

7. Choose one of the displays next to the

baseline display. This will be called the

variable display.

8. Close the menus (

PREV MENU) on all

displays except the variable display.

9. On the variable display, adjust the Wht

level down for all three colors until the

brightness of the variable closely matches

the brightness of the baseline display.

10. Adjust the individual colors of the variable

until the “color” of the variable matches

the baseline unit. (The next section,

3.3.3.1, has some additional hints about

color matching.) If you need more Blue,

but Blue is already at 031, try subtracting

both of the other two colors, Red and

Green.

11. When this variable unit matches the

baseline unit, choose the display on the

other side of the baseline. This one now

becomes the variable display. And the

previous variable display is now another

baselines unit, because they are the same

color and brightness. Adjust the new

3 - 12

Page 41

variable display to match the baseline in

the same way.

12. Continue matching each display to its

neighbor until you have all displays

looking alike in white. It is not important

to make the displays project a pure white.

It is only important that they all look alike

when a white signal is received.

13. On each display, save the settings: Press

MENU > Save Config > ENTER > use left

arrow to highlight Yes >

ENTER. Now if

you accidentally change the White color

balance setting, you can recall these

values. (Saving is fully explained in

Section 3.4)

14. Go to the Test Pattern menu and choose

50% Gray (

ENTER > Test Patterns > ENTER > 50%

MENU > Misc Control >

Gray) for all displays.

15. Look for the display that has a gray level

somewhere in between all of the other

units. (You can use a middle brightness

value this time, because in gray, you can

adjust down and up from the 007 starting

point.) This is the new baseline display.

16. Using the Color Balance controls in the

Gry column, adjust all the displays to

match the baseline unit, starting with the

Color Balance

Wht Gry

units nearest to the baseline unit.

17. Continue adjusting variable units for Gray

until all displays match each other for

brightness and color.

18. On each display, save the settings again:

MENU > Save Config > ENTER > left

arrow to highlight Yes >

ENTER.

The first time you do it, color balancing will

take a while. Don’t be discouraged. It gets easier

with practice. And the results are worth the

effort.

!

Note: Do not try to color balance using the Red,

Green and Blue test patterns. Match the

Whites and Grays, and the rest will take care

of itself.

SOURCEON

CURTAIN

OFF

RESET

LEVEL

PHASE

FREQ

Color Balance

COLOR

IDMON SEL

PREV M ENUMENU ENTE R

Menu

All

! # ! #

Red 031 007

Green 031 007

Blue 031 007

Color Balance menu

Location of Color Balance menu button

3 - 13

Page 42

3.3 Adjusting for Optimum Picture Quality

3.3.3 Matching the Displays to Each Other

3.3.3.1 About Color Balancing

The previous section gave the steps to achieve color balancing. However, if you have not done a color

balance before, you may need the hints in this section to help you understand how to get all those

screens to look alike. Sometimes you get the color you want by reducing the colors you don’t want.

For our purposes, white light is made up of three

separate primary colors: Red, Green, and Blue.

These combine in various amounts to give us all

the other colors. Adding colors of light together

is not the same as mixing paint colors.

When you mix red, green, and blue paint

together, you will get black, or at least a dark,

muddy brown. When you mix red, green, and

blue light together, you get white.

Here is how the colors of light mix to get the

other colors:

• Red + Blue = Magenta (a kind of purple)

• Blue + Green = Cyan (a kind of sea green)

• Green + Red = Yellow (hard to imagine,

but true)

• Red + Green + Blue = White

In trying to color balance a group of displays,

you must always start with the darkest cube

first. This darkest one cannot ever get brighter

than it is right now (with its present lamp), so

you have to bring everything down to this

baseline unit.

You must also make the color of the other

cubes match the color of this darkest one. If you

do this accurately for white and for gray, all the

other color shades will match each other. An

image of a person walking from one display to

another will keep the same skin tones for the

entire trip.

You cannot adjust the saturation or the hue

of the three primary colors, red, blue and green.

Matching the displays for white and gray will

make all the other colors appear the same from

one display to the next. However, as the color of

an image approaches a pure red, green, or blue,

the less control you will have when trying to

match them. This is why color balancing in

done with whites and grays and not with

primary colors.

It takes practice to color balance several

displays quickly, but patience and practice will

go a long way to achieving good color balance,

even for a beginner.

!

Note: If you suffer from any degree of color

blindness, more common in men than in

women, it would be a good idea to give the

color balancing job to someone else.

In the color balancing process, focus your

attention on just two displays. At first this will

be the baseline display and one of the displays

next to it. Ignore all the others. Let’s call the one

you are changing the “variable” unit.

First, reduce the brightness of the variable

unit. Use the up/down arrow buttons to

highlight the two arrow symbols below the word

“Wht.” Then, click the left arrow button a few

times and watch the brightness of the variable

display go down. It may also change color as it

gets darker.

Using the left/right arrow buttons, get the

brightness of this cube to be as close as possible

to the brightness of the baseline cube. It is

sometimes difficult to judge when the two cubes

are the same “brightness” when they are

different in “color,” but get them as close as you

can.

Now comes the judgement part. How does

the color of the variable cube differ from the

baseline cube? Is it more blue, more green, more

yellow? Try to judge the color of the middle of

the cubes, because the edges sometimes are a

little darker. (This is only noticeable when both

cubes are very bright, as they are now.) Here is a

table to help you know what to change:

If the

variable is

…

… more green, reduce the green

then __ in the variable

3 - 14

Page 43

… more blue, reduce the blue

… more red, reduce the red

If the

baseline is

…

… more green, reduce blue and red

… more blue, reduce green and red

… more red, reduce blue and green

then __ in the variable

Here are some more hints:

• Stand in the center of the viewing area. If

you are off to one side or above or below

the centerline, the apparent brightness

will change.

• Stand well away from the units. If you are

very close, the viewing angles will vary

from one unit to the next, and the apparent brightness may be different among

units.

• Always adjust the “variable” cube, not the

baseline cube.

• “Rock” the setting. Go beyond the closest

setting and then come back. Sometimes

when you see what is on both sides of the

“almost right” spot, it is easier to determine what is the best setting.

• If adjusting one of the variable’s colors

won’t get it right, try adjusting one of the

other two colors.

• Try to judge the color by the middle of the

cubes, because the edges sometimes are a

little darker. (This is only noticeable when

both cubes are very bright, as they are

now.)

• When you have the whites matching, then

do the grays. The baseline cube for gray

may be different from the one for white.

• The white and gray adjustments interact

with each other. If you finish the whites

and start on the grays, don’t go back to

adjust the white levels. If you do, you will

have to do the grays again from the beginning.

• If the entire group has been matched for

white and gray, then check program

material. It should look fine without any

very noticeable change in color or

brightness from one cube to the next.

• Don’t try to match the primary colors.

When you turn all the cubes to one of the

internal test colors, such as red, the match

may not be absolutely perfect, even if color

balancing was done correctly. Do not try

to change the color balance settings to

compensate for this.

• Never try to color balance with the Black

and White Level settings. This is the path

to disastrous color results.

• If you think you are close to color

matching two cubes, Save the settings.

Then, if you try some further adjustments, you can always Recall what you

had before.

• If you Reset any settings, color balance

goes to the factory default values of 031

and 007, which is not correct. For color

balance values, factory default is not best;

it is simply where you start.

Color Balance

Wht Gry

All

Red 031 007

Green 031 007

Blue 031 007

! # ! #

Color Balance menu

3 - 15

Page 44

3.3 Adjusting for Optimum Picture Quality

3.3.4 Changing the Position of the Image

The Position control is used to move the electronic image slightly. If the display is black at any edge,

and Position doesn’t correct this, the unit needs optical adjusting.

The Position control will make minor adjust-

ments in the electronic position of the picture,

but it won’t change the optical position of the

picture. It is important to understand the

difference between these two types of position

control.

Optical position means moving the LCD (for

up-down, right-left, or tilt), the lens (for size) or

the mirror (for keystoning). These are

mechanical adjustments you make if the picture

is keystoned, or tilted, or if the one edge of the

picture image leaves a dark line at the edge of

the screen. Or if the image doesn’t fill the screen

or fills it too much. Optical positioning moves

the bright area of the screen. Of course, the

picture in the bright area moves, too.

Think of optical positioning as moving a

cinema projector. Moving the projector moves

the bright image around on the white screen. If

you move it too much, there will be a dark area

on one edge of the screen.

Before you adjust anything, you should know

the goal of alignment and understand the parts

of the Geometry test pattern. The goal is to have

a rectangular image with three pixels hidden

behind each mullion (each screen border).

The internal Geometry test pattern helps in

hiding three pixels. Here is the pattern:

2-pixel-wide magenta rectangle; the 1-pixel

magenta rectangle and the next two pixels of

white should be completely hidden. As with

most ideal situations, this is difficult to achieve

precisely. If you come within ±2 pixels of this

ideal, be satisfied.

To adjust LCD alignment, press

MENU.

Highlight Misc Control and press Enter. Choose

Test Patterns, then choose Geometry. Adjust

the LCD alignment with two screws at the

bottom of the display. These move the LCD up

and down and rotate it. Inside the air intake

door, you can find the horizontal adjustment

screw for the LCD.

If the image is too large or too small, rotate

the lens. You can reach the lens by opening the

air intake door and reaching up and back toward

the center of the unit. Rotating the lens changes

the image size, not the focus.

Electronic position means moving left-right or

up-down with the Position control. The

image moves within the bright area of the

screen, but the bright area does not move.

If your banner application will have pictures

that span across two or more display units, it is

important that adjacent parts of the picture

match correctly. Minor adjustments with the

Position control will do this.

2 pixels white (hide)

1 pixel magenta (hide)

Lower left corner of internal Geometry test pattern

showing size and position of magenta lines

Ideally, you should just see the outer edge of the

3 - 16

2-pixel -wid e

black grid

white background

2 pixels magenta (see)

To move or position the image electronically,

follow these steps:

1. Open the Position menu (

Position >

ENTER.)

2. Highlight Position and press

MENU >

ENTER.

3. In the Position menu, use the four

arrow buttons to move the image.

4. Press

PREV MENU twice to exit Position.

Position moves the image in increments of

one pixel each time an arrow is pressed. You

can press and hold an arrow key to move

Page 45

continuously in one direction. Position wraps,

so eventually the image will jump to the other

Position

$

% &

'

side and continue.

LCD adjustment screw locations: 2 up-down screws in holes shown by circles;

left-right screw inside air filter door indicated by arrow.

Front of

Display

Up

Left-right LCD adjustment screw

inside air filter door, indicated by

white arrow.

A screwdriver is inserted in the

adjustment screw.

3 - 17

Page 46

3.4 Saving and Recalling the Settings

It is important to save the settings. Saving the settings means that every time the unit turns on, it

knows what it needs to do to look right. It also means that if you change something experimentally,

you can go back to where you were before. And you can always Reset to the factory default settings.

The “settings” refers to everything you setup

through the menus: Frequency, Phase, Color

Balance, Position, Flip Horz, Buzzer on or off—

everything. After you save all this, you can

change anything, then easily recall the saved

settings. The display unit always turns on with

these saved values.

The menus for Save, Recall and Reset all

operate in basically in the same way. As the

diagram shows, there are three places where

settings are stored.

The first storage place is the Active Settings.

This is what the unit is actually doing when it is

on. If you change anything, this is where the

change occurs. (Actually, the Active Settings

isn’t really a memory. When the power goes off,

everything in this register is lost. However, on

power up, the Saved Memory is copied into

Active Settings.)

The second storage place is Saved Memory.

When you Save, a copy of the contents of Active

Settings is placed in Saved Memory. When you

Recall settings, a copy of Saved Memory is

placed in Active Settings, and the unit follows

these instructions. Saved Memory is not lost

when the power goes off, even if the AC power

is lost.

The third storage place is Factory Default

Values. You can’t change these, of course. If you

get things all tangled, you can always Reset to

the original factory settings. This will not

change the Saved Memory settings. It simply

puts the factory defaults into Active Settings.

This way you can compare what you saved with

what the factory settings were without

destroying any saved values.

To put Factory Default into Saved Memory,

Reset and then Save.

About Reset: The factory default values are not

the “best” values. If you Reset to the default

values, Black Level, White Level, Frequency and

Phase won’t be right, because the factory did not

have the particular computer you are using as a

source. Color Balance values won’t be right

either; they will all be 031 and 007 for white

and gray.

3 - 18

Page 47

When you choose

Save Config from the main

Save Config

[ ] Save

Save Configuration,

first screen

menu, the first box looks like the one on the left.

The

cursor is

in the

Save

brackets

.

Whe

Save Config

[ ] Save

n you

push

ENTER,

the box

Are you sure?

Yes No

changes

to

the one

on the

Save Configuration,

second screen

right,

and the cursor is on No.

To save the configuration, press the left arrow to

highlight Yes, then press

ENTER.

The Recall Config and Reset Config

menus operate in a similar way.

Recal l

Activ e

Settings

Save

Reset

Saved

Memory

Factory

Defau lt

Values

Relationship of the three memories to Saving, Recalling, and Resetting

3 - 19