Clarion 39100-SVA-A11, PH-2761C-H, 39100-SVA-A1, PH-2761C-G, 39100-SVA-C11 Service Manual

...Page 1

Clarion Co., Ltd.

50 Kamitoda, Toda-shi, Saitama 335-8511 Japan

Service Dept.: 5-66 Azuma , Kitamoto-shi, Saitama 364-0007 Japan

Tel: +81-48-541-2335 / 2432 FAX: +81-48-541-2703

Service Manual

HONDA Automobile Genuine

AM/FM Radio CD Stereo

(Pre-AMP Type)

Published by Service Dept.

298-6423-00

Printed in Japan

Jan.2007

PH-2761C-F

Model

PH-2761C-F

( Genuine No. 39100-SVA-A11 )

( ID No. 4PC0 / ID Label: HM-B )

Model

PH-2761C-G

( Genuine No. 39100-SVA-A11 )

( ID No. 4PC0 / ID Label: HM-H )

Model

PH-2761C-H

( Genuine No. 39100-SVA-C11 )

( ID No. 4PC1 / ID Label: HN-B )

Model

PH-2761C-I

( Genuine No. 39100-SVB-A11 )

( ID No. 4TC0 / ID Label: HP )

Model

PH-2761C-J

( Genuine No. 39100-SVB-C11)

( ID No. 4TC1 / ID Label: HQ )

Model PH-2761C-K

( Genuine No. 39100-SNA-K51 )

( ID No. 4TC6 / ID Label: TL-B )

ORIGINAL SERVICE MANUAL

This additional service manual is designed to be used together with the original manual.

Original model Manual No.

PH-2761C-F PH-2761C-A 298-6303-00

PH-2761C-G PH-2761C-B

PH-2761C-H PH-2761C-C

PH-2761C-I PH-2761C-D

PH-2761C-J PH-2761C-E

PH-2761C-K PH-2761C-D

- 1 -

DIFFERENT POINT

CD mechanism and some parts were changed from the

original model(PH-2761C-A/B/C/D/E).

PH-2761C-A/B/C/D/E PH-2761C-F/G/H/I/J/K

CD mechanism 929-0292-80 929-5000-80

PH-2761C

Page 2

To engineers in charge of repair or inspection of our products.

Before repair or inspection, make sure to follow the

instructions so that customers and Engineers in charge

of repair or inspection can avoid suffering any risk or

injury.

1. Use specified parts.

The system uses parts with special safety features against fire

and voltage. Use only parts with equivalent characteristics

when replacing them.

The use of unspecified parts shall be regarded as remodeling

for which we shall not be liable. The onus of product liability

(PL) shall not be our responsibility in cases where an accident

or failure is as a result of unspecified parts being used.

2. Place the parts and wiring back in their original positions after

replacement or re-wiring.

For proper circuit construction, use of insulation tubes, bonding, gaps to PWB, etc, is involved. The wiring connection and

routing to the PWB are specially planned using clamps to keep

away from heated and high voltage parts. Ensure that they are

placed back in their original positions after repair or inspection.

If extended damage is caused due to negligence during repair, the legal responsibility shall be with the repairing company.

3. Check for safety after repair.

Check that the screws, parts and wires are put back securely

in their original position after repair. Ensure for safety reasons

there is no possibility of secondary ploblems around the repaired spots.

If extended damage is caused due to negligence of repair, the

legal responsibility shall be with the repairing company.

4. Caution in removal and making wiring connection to the parts

for the automobile.

Disconnect the battery terminal after turning the ignition key

off. If wrong wiring connections are made with the battery connected, a short circuit and/or fire may occur. If extensive damage is caused due to negligence of repair, the legal responsibility shall be with the repairing company.

5. Cautions in soldering

Please do not spread liquid flux in soldering.

Please do not wash the soldering point after soldering.

6. Cautions in soldering for chip capacitors

Please solder the chip capacitors after pre-heating for replacement because they are very weak to heat.

Please do not heat the chip capacitors with a soldering iron

directly.

7. Cautions in handling for chip parts.

Do not reuse removed chips even when no abnormality is observed in their appearance. Always replace them with new

ones. (The chip parts include resistors, capacitors, diodes, transistors, etc).

Please make an operation test after replacement.

8. Cautions in handling flexible PWB

Before working with a soldering iron, make sure that the iron

tip temperature is around 270 . Take care not to apply the

iron tip repeatedly(more than three times)to the same patterns.

Also take care not to apply the tip with force.

9. Turn the unit OFF during disassembly and parts replacement.

Recheck all work before you apply power to the unit.

10.Cautions in checking that the optical pickup lights up.

The laser is focused on the disc reflection surface through the

lens of the optical pickup. When checking that the laser optical diode lights up, keep your eyes more than 30cms away

from the lens. Prolonged viewing of the laser within 30cms

may damage your eyesight.

11.Cautions in handling the optical pickup

The laser diode of the optical pickup can be damaged by electrostatic charge caused by your clothes and body. Make sure

to avoid electrostatic charges on your clothes or body, or discharge static electricity before handling the optical pickup.

11-1. Laser diode

The laser diode terminals are shorted for transportation in order to prevent electrostatic damage. After replacement, open

the shorted circuit. When removing the pickup from the mechanism, short the terminals by soldering them to prevent this

damage.

11-2. Actuator

The actuator has a powerful magnetic circuit. If a magnetic

material is put close to it. Its characteristics will change. Ensure that no foreign substances enter through the ventilation

slots in the cover.

11-3. Cleaning the lens

Dust on the optical lens affects performance.

To clean the lens, apply a small amount of isopropyl alcohol to

lens paper and wipe the lens gently.

ADJUSTMENT

Clock accuracy

1.Connect the frequency counter with CLK-TP directly by

using 10:1 probes.

2.Set the frequency counter to not "FREQUENCY" but "PERIOD".

3.Set GATE TIME to 10S.

4.Adjust TC701 so that the reading is 30.5184 to 30.5186

micro seconds.

PH-2761C

- 2 -

Page 3

EXPLANATION OF IC

052-3197-21 uPD703272YGC324-8EAA System Contoller

Terminal Description

pin 1: A Vref 0 : - : Reference voltage for the internal ADC.

pin 2 : A VSS : - : Negative voltage supply for analog section.

pin 3: ANC CHK : O : This pin outputs H on testing.

pin 4: ANC OFF : O : This pin outputs H without ANC-connec-

pin 5: A Vref 1 : - : Reference voltage for the internal DAC.

pin 6: DSP RESET : O : Reset signal output to the DSP IC.

pin 7: DSP INIT : IN : The initial finished signal input from the

pin 8: FLMDO : O : Connect to the ground to standard motion.

pin 9: VDD : - : Positive voltage supply.

pin 10: REG C : - : The capacitor connection.

pin 11: VSS : - : Negative voltage supply.

pin 12: X 1 : - : The crystal connection.

pin 13: X 2 : - : The crystal connection.

pin 14: RESET :I N : Reset signal input.

pin 15: XT 1 : - : Crystal connection.

pin 16: XT 2 : - : Crystal connection.

pin 17: RDBS DATA : IN: RDBS data input.

pin 18: BU DET : IN : Backup detection signal input.

pin 19: ACC DET : IN : ACC detection signal input.

pin 20: RDBS CLCK : IN: RDBS clock input.

pin 21: SPEED PULSE : IN : The speed pulse input.

pin 22: TUNE DATA : O : I2C data output for BUS Tuner.

pin 23: TUNE CLK : O : I2C clock output for BUS Tuner.

pin 24: CATS KEY : IN: The treasure key signal input for CATS.

pin 25: FLASH TX : O : The serial data output for the flash mem-

pin 26: FLASH RX : IN : The serial data input for the flash memo-

pin 27: ILL PWM : IN: The illumination PWM input.

pin 28: CMS 1 : IN : The keyless entry setting terminal.

pin 29: CMS 2 : IN : The keyless entry setting terminal.

pin 30: LCD Bk Light : O : LCD back light ON signal output.

pin 31: GA-NET TX : O : The serial data output for GA-NET.

pin 32: GA-NET RX : IN : The serial data input for GA-NET.

pin 33: E VSS : - : Ground.

pin 34: E VDD : - : Positive voltage supply.

pin 35: K-LINE TX : O : K-LINE data output.

pin 36: K-LINE RX : IN : K-LINE data input.

pin 37: LCD BL PULSE : O : LCD back light control-pulse output.

pin 38: ILL PWM : O : The brightness control signal output for

pin 39: LCD CE 1 : O : Chip enable signal output to LCD driver.

pin 40: LCD DI : IN: The srial data input from the LCD driver.

pin 41: LCD DO : O : The srial data output to the LCD driver.

pin 42: LCD CLK : O : The clock pulse output to the LCD driver.

pin 43: DSP DATA : O : Serial data output to the digital signal pro-

pin 44: DSP CLK : O : The clock pulse output to DSP.

pin 45: LCD CE 2 : O : Chip enable signal output to LCD driver.

pin 46: LCD RESET : O : Reset pulse output to LCD.

pin 47: VR A IN :IN: The pulse signal input from the rotary

pin 48: VR B IN :IN: The pulse signal input from the rotary

pin 49: TN A IN :IN: The pulse signal input from the rotary

pin 50: TN B IN :IN: The pulse signal input from the rotary

pin 51: CATS IND : O : CATS indicator control signal output.

pin 52: CD 1.5V : O : 1.5V power supply control signal output.

pin 53 : MP3 DI : IN : MP3 serial data input.

pin 54: MP3 DO : O : MP3 serial data output.

pin 55: MP3 CLCK : O : MP3 clock output.

pin 56: ILL DET :IN : Illumination ON signal input.

tion.

Radio-Audio-DSP.

ory.

ry.

the illumination.

cessor.

encoder.

encoder.

encoder.

encoder.

pin 57: EJECT SW : IN : Eject switch signal input.

pin 58: SBSY : IN : Sub code block synchronous signal detec-

pin 59: LD MUTE : O : Muting signal output to the CD mecha-

pin 60: LD CONT : O : Loading control signal output.

pin 61: TR A :IN: Photo sensor signal input from the CD

pin 62: TR B :IN: Photo sensor signal input from the CD

pin 63: CHU SW : IN : CD disc chucking signal input.

pin 64 : S STOP :IN : Inside limit signal input from the CD mech-

pin 65 : BUS 0 :I/O: CD IC Data input / output.

pin 66 : BUS 1 :I/O: CD IC Data input / output.

pin 67 : BUS 2 :I/O: CD IC Data input / output.

pin 68 : BUS 3 :I/O: CD IC Data input / output.

pin 69: B VSS : - : Ground for the bus interface section.

pin 70 : B VDD : - : Positive voltage supply for the bus inter-

pin 71: CD RESET : O : The reset pulse output to the CD IC.

pin 72: CCE : O : The chip enable signal output.

pin 73: BUC CLOCK : O : CD IC clock pulse output.

pin 74: MP3 RAM STB : O : MP3 RAM standby output.

pin 75: MP3 REQ : IN : MP3 request input.

pin 76 : NU : - : Not in use.

pin 77: MP3 RESET : O : MP3 reset output.

pin 78: MP3 STB : O : MP3 standby output.

pin 79 : MP3 CS : O : MP3 chip selection signal output.

pin 80: MP3 LP : O : MP3 latch pulse output.

pin 81: MP3 ACK : IN : MP3 acknowledge input.

pin 82 : EEP ROM CE : O : The chip enable signal output to the EEP-

pin 83: EEP ROM CLK : O : The clock pulse output to the EEP-ROM.

pin 84 : EEP ROM DI : IN: The serial data input from the EEP-ROM.

pin 85: EEP ROM DO : O : The serial data output to the EEP-ROM.

pin 86: CD 8V : O : 8V power supply control signal output.

pin 87: CD 3.3V : O : 3.3V power supply control signal output.

pin 88: DSP 3.3V : O : 3.3V power supply control signal output.

pin 89: SYS ON : O : System ON signal output.

pin 90: TUNER ON : O : The tuner ON signal output.

pin 91 : REM 5V : O : Power ON signal output to the 5V and

pin 92: POWER STB : O : The standby signal output to Power IC.

pin 93: POWER MUTE : O : The mute signal output to Power IC.

pin 94: POWER DIAGI : IN : The diagnosis signal input from Power IC.

pin 95: AUX DET : IN : AUX detection signal input.

pin 96: ANC DET : IN : ANC detection signal input.

pin 97: HFT MUTE : IN : HFT level-detection for mute.

pin 98: PAS MUTE : IN : PAS level-detection for mute.

pin 99: TEL MUTE : IN : Telephone mute command input.

pin100: ST REMO :IN : Steering wheel remote control detection.

tion input.

nism.

mechanism.

mechanism.

anism.

face section.

ROM.

3.3V supply circuit.

- 3 -

PH-2761C

Page 4

EXPLODED VIEW / PARTS LIST

Escutcheon section

Other parts are the same as the original model. Please refer to page 10 of the original service manual.

*

NO. PART NO. DESCRIPTION Q'TY

1 940-8109-14 ES-ASSY (PH2761CF) 1

5 379-1373-43 LCD (PH2761CF/G/H) 1

29 347-7841-51 PROTECTOR 1

30 290-0016-01 LABE (HM-B) (PH2761CF) 1

940-8109-54 ES-ASSY (PH2761CG)

940-8109-64 ES-ASSY (PH2761CH)

940-8109-74 ES-ASSY (PH2761CI)

940-8109-84 ES-ASSY (PH2761CJ)

940-8152-40 ES-ASSY (PH2761CK)

379-1339-42 LCD (PH2761CI/J/K)

290-0016-08 LABEL(HM-H) (PH2761CG)

290-0016-02 LABEL(HN-B) (PH2761CH)

290-0016-03 LABEL(HP) (PH2761CI)

290-0016-04 LABEL(HQ) (PH2761CJ)

290-0016-19 LABEL(TL-B) (PH2761CK)

30

1

Main section

Other parts are the same as the original model. Plaease refer to page 11 of the original service manual.

*

NO. PART NO. DESCRIPTION Q'TY

4 310-1817-02 UPPER CASE 1

8 345-8581-03 GASKET 2

10 816-4028-50 FLAT WIRE 1

16 345-8720-00 GASKET 2

17 714-2603-8B MACHINE SCREW(M2.6x3) 2

19 929-5000-80 CD-MECH-MODULE 1

21 286-6685-11 SETPLATE (PH2761CF) 1

22 ----------- SOCKET CVR(Unused) 1

31 074-1237-79 OUTLET SOCKET(MECH) 1

286-6685-13 SETPLATE (PH2761CG)

286-6685-14 SETPLATE (PH2761CH)

286-6685-17 SETPLATE (PH2761CI)

286-6685-18 SETPLATE (PH2761CJ)

286-6685-28 SETPLATE (PH2761CK)

1

8

16

NOTE)

ES color code LCD color

PH-2761C-F(M-B) NH608L BLUE

PH-2761C-G(HM-H) YR334L BLUE

PH-2761C-H(HN-B) NH608L BLUE

PH-2761C-I(HP) NH608L AMBER

PH-2761C-J(HQ) NH608L AMBER

PH-2761C-K(TL-B) NH608L AMBER

PH-2761C

- 4 -

Page 5

C

24

25

26

27

28

29

30

31

32

33343536373839404142434445464748

49

50

51

52

53

54

55

56

57

C

C

C

C208

C210

IC201

IC201

: Changed point

*

Please refer to ELECTRICAL PARTS LIST about the changed parts.

*

Other circuits are the same as the original model.

Please refer to the original service manual [page21-25].

0.1

0.1

C232

0.1

C231

0.1

IC205

MSM51V17400D

-60TS-K

TC94A34FG

MP3

-RSTBY

MP3

-REQ

DQ1

DQ2

DQ3

DQ4

N.C.

18

19

20

21

22

SBSY

17DATA

DSP-CD

SFSY

SPDIF

VDD

CLCK

N.C.

N.C.

N.C.

/WE

DQ1

DQ2

DQ3

DQ4

/WE

/RAS

/CAS

/0E

/RAS

/CAS

/0E

REQ

N.C.

16151413

LRCKIA

BCKIA

SDIO

LRCKO

1211

BCKO

SDOO

GS-1-DA

TA

GS-1-CL

GS-1-W

N.C.

N.C.

VDDM

SRM

STB

VDDT

AD10

AD9

AD8

AD7

AD6

AD5

A10R

A9

A8

A7

A6

A5

AD4

AD3

AD2

AD1

A4

A3

A2

A1

AD0

A0

VSS

VDD

CKO/PO13/AD16

123456

VCC

DQ1

DQ2

/WE

/RAS

N.C.

789101112

242322212019181716151413

A10R

A0

A1

A2

A3

VCC

< CD+3.3V >

< GND >

< GND >

< REM+5V >

VSS

DQ4

DQ3

/CAS

/OE

A9

A8

A7

A6

A5

A4

VSS

VDDX

MP3/WMA DECODER

AUDIO-CPU

81

82

80

IC703

uPD70F3273YGC-8EA

R806

33K

R811 10K

(ASSY CODE ID)

PH-2761CF

PH-2761CG

PH-2761CH

PH-2761CI

PH-2761CJ

PH-2761CK

R811

Used

Used

Used

Used

Unused

Unused

R812

Used

Used

Unused

Unused

Used

Used

R813

Unused

Unused

Used

Unused

Used

Unused

R814

Unused

Unused

Unused

Used

Unused

Used

A

B

C

D

MP3-ACK

MP3-LP

E2P-CE

C

C

C

12 13 14 15 16

C712

X701

TC701

C711

X702

R729

18p

C736

4p

18p

160K

X-IN

X-OUT

RESET

XT1-IN

XT2-OUT

C

1

8

D714

R794

D712

IC705

R791

R795

R796

MA111

82

1/4W

MA111

NJM2903V

0.1

C722

1K

1K

10K

< GND >

VCC

C

C

C

C463

L416

R455

C462

C464

C465

C466

330

6.3V

10

0.1

0.1

220

10V

0.1

DSP3.3V-OUT

C

C400

1000p

J201

(To CD mech)

1

MBOV

SFSY

CLCK

CD-VDD

IPF

DATA

SFSY

CLCK

DATA

SFSY

GS1-SBSY

CLCK

DATA

BCK

LRCK

AOUT

R812 10K

R813 10K

R814 10K

CLK-TP

ELECTRICAL PARTS LIST

Main PWB section(B1)

Other parts are the same as the original model. Please refer to page 14 of the original service manual.

*

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

C212 043-0554-90 25V 10uF

C215 163-1073-15 6.3V 100uF

C217 119-3331-15 1/10W 33k ohm

C221 163-4763-15 6.3V 47uF

C222 163-4763-15 6.3V 47uF

C226 043-0554-90 25V 10uF

C227 043-0554-90 25V 10uF

C228 163-1073-15 6.3V 100uF

C231 168-1042-78 16V 0.1uF

C232 168-1042-78 16V 0.1uF

C400 168-1022-55 1000pF K

C467 ----------- (Unused)

C502 163-2263-15 6.3V 22uF

C564 163-1073-35 16V 100uF

Switch PWB section(B2)

Other parts are the same as the original model. Please refer to page 16 of the original service manual.

*

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

C112 ----------- (Unused)

C113 ----------- (Unused)

D101 001-7100-90 NESB017-EE2-

001-7100-92 NESB017-ED2-

KLP7*17.5

(PH2761CF/G/H)

KLP2LP3*17

(PH2761CI/J/K)

D102 001-7100-90 NESB017-EE2-

001-7100-92 NESB017-ED2-

D103 001-7100-90 NESB017-EE2-

001-7100-92 NESB017-ED2-

KLP7*17.5

(PH2761CF/G/H)

KLP2LP3*17

(PH2761CI/J/K)

KLP7*17.5

(PH2761CF/G/H)

KLP2LP3*17

(PH2761CI/J/K)

D104 001-7100-90 NESB017-EE2-

KLP7*17.5

(PH2761CF/G/H)

001-7100-92 NESB017-ED2-

KLP2LP3*17

(PH2761CI/J/K)

D105 001-7100-90 NESB017-EE2-

KLP7*17.5

001-7100-92 NESB017-ED2-

(PH2761CF/G/H)

KLP2LP3*17

(PH2761CI/J/K)

D106 001-7100-90 NESB017-EE2-

KLP7*17.5

(PH2761CF/G/H)

001-7100-92 NESB017-ED2-

KLP2LP3*17

C714 ----------- (Unused)

C722 168-1042-78 16V 0.1uF

C734 ----------- (Unused)

C736 166-4096-50 4pF CH

IC201 051-6711-20 TC94A34FG-004

IC205 051-9318-00 MSM51V17400D-

60TS-K

IC506 051-3057-90 BA4558RFV

IC701 051-5423-38 BD6329G-TR

IC703 052-3197-21 uPD703272YGC324-

IC705 051-3408-90 BA2903FV

J201 074-1237-79 SOCKET(29P)

R745 ----------- (Unused)

8EAA

(PH2761CI/J/K)

D107 001-7100-90 NESB017-EE2-

KLP7*17.5

(PH2761CF/G/H)

001-7100-92 NESB017-ED2-

KLP2LP3*17

(PH2761CI/J/K)

D108 001-7100-90 NESB017-EE2-

KLP7*17.5

(PH2761CF/G/H)

001-7100-92 NESB017-ED2-

KLP2LP3*17

(PH2761CI/J/K)

D109 001-7100-90 NESB017-EE2-

KLP7*17.5

(PH2761CF/G/H)

001-7100-92 NESB017-ED2-

KLP2LP3*17

D110 001-7100-90 NESB017-EE2-

(PH2761CI/J/K)

KLP7*17.5

(PH2761CF/G/H)

001-7100-92 NESB017-ED2-

KLP2LP3*17

(PH2761CI/J/K)

D111 001-7100-90 NESB017-EE2-

KLP7*17.5

(PH2761CF/G/H)

001-7100-92 NESB017-ED2-

D112 001-7100-90 NESB017-EE2-

KLP2LP3*17

(PH2761CI/J/K)

KLP7*17.5

(PH2761CF/G/H)

001-7100-92 NESB017-ED2-

KLP2LP3*17

(PH2761CI/J/K)

R806 119-3331-15 1/10W 33k ohm

R811 119-1031-15 1/10W 10k ohm

(PH2761CF/G/H/I)

R812 119-1031-15 1/10W 10k ohm

(PH2761CF/G/J/K)

R813 119-1031-15 1/10W 10k ohm

(PH2761CH/J)

R814 119-1031-15 1/10W 10k ohm

(PH2761CI/K)

TC701 004-1583-51 10pF WHT

X702 061-3506-80 32.768MHz

PWB 039-2882-00 PWB(WITHOUT

COMPONENTS)

D220 ----------- (Unused)

D221 ----------- (Unused)

LCD101 379-1373-43 LCD(INDICATOR)

Q205 ----------- (Unused)

379-1339-42 LCD(INDICATOR)

(PH2761CF/G/H)

(PH2761CI/J/K)

Q206 ----------- (Unused)

R105 116-2711-15 1/4W 270 ohm

(PH2761CF/G/H)

116-2211-15 1/4W 220 ohm

R106 116-2711-15 1/4W 270 ohm

(PH2761CI/J/K)

(PH2761CF/G/H)

116-2211-15 1/4W 220 ohm

(PH2761CI/J/K)

R107 116-2711-15 1/4W 270 ohm

116-2211-15 1/4W 220 ohm

R108 116-2711-15 1/4W 270 ohm

(PH2761CF/G/H)

(PH2761CI/J/K)

(PH2761CF/G/H)

116-2211-15 1/4W 220 ohm

(PH2761CI/J/K)

R109 116-2711-15 1/4W 270 ohm

(PH2761CF/G/H)

116-2211-15 1/4W 220 ohm

(PH2761CI/J/K)

R110 116-2711-15 1/4W 270 ohm

(PH2761CF/G/H)

116-2211-15 1/4W 220 ohm

(PH2761CI/J/K)

R111 ----------- (Unused)

PWB 039-2973-00 PWB(WITHOUT

COMPONENTS)

CIRCUIT DIAGRAM

Main PWB section(B1) 2/5

Main PWB section(B1) 3/5

Main PWB section(B1) 4/5

- 5 -

PH-2761C

Page 6

PRINTED WIRING BOARD

Main PWB section(B1) 1/2

Caution:

COMPONENT SIDE: Parts on the component side seen

from the component side are indicated.

SOLDER SIDE: Parts on the solder side seen

from the solder side are indicated.

IC Q

Q101

Q301

Q105

Q109

IC704

Q108

IC705

Q110

Q107

IC902

Q916

Q915

Q104

Q103

Q403

C302

C301

R793

R772

R783

R709

R797

R708

R762

IC902

5

Q91

D503

D504

1

6

Q91

R917

R918

R919

R920

R910

C905

11121314151617181920

12345678910

C910

A

C

Q101

R114

105

C105

C103

Q103

D105

R105

R106

D104

R108

L102

C107

R110

R111

Q104

R109

C109

C108

Q

C110

R112

C111

R113

109

Q

Q110

D106

Q107

R120

R118

Q108

R119

R769

IC704

1

456

C563

R779

R778

C560

C552

C720

C559

1617

131415

C448

C551

R449

C550

C498

C558

C408

C499

C549

C409

L404

C557

L401

C451

L405

C447

C449

789101112

123

L412

C491

C446

C433

R421

C436

C494

C437

4

2

13

R486

C381

R429

C416

5

R403

R406

C440

L409

R706

R302

R789

R785

R487

C382

C415

R427

R707

R303

6

R790

R788

L408

7

R786

R787

C384

R404

R405

C417

L407

R705

R704

R304

R482

D303

D302

14

12

10

891113

1

Q30

R301

D301

C723

D711

D718

1

IC705

R798

C721

R483

R488

R489

C383

R484

R485

C418

R425

R426

R407

R408

3

L416

Q40

1

D904

D713

D714

L706

R402

C466

C464

R455

D903

D712

C716

R401

C462

R796

R795

R775

R792

R791

IC601

IC602

IC603

IC604

IC701

IC205

IC403

IC506

Q702

Q701

IC506

- 6 -

R638

1

C621

R643

1

R646

IC604

R639

R641

C622

R640

C619

1

R637

R644

R645

IC603

R636

C620

R642

R635

R616

R476

R477

R625

C612

1

C486

R462

C487

R480

R481

R465

C488

C485

R626

R622

IC602

R615

R620

C599

C483

14 8

IC403

17

C484

C597

C614

R618

C596

C478

R210

C611

1

C598

R464

C216

R623

R624

IC601

R619

C477

C218

R617

R463

L201

R621

C613

R211

C481

C479

C480

C482

R466

R470

R467

R471

C232

C231

C214

C208

13

24

C226

IC205

C212

L413

C458

12

1

C224

C210

PH-2761C

L414

C459

Main PWB(B1)

SOLDER SIDE

C454

C453

C227

C209

C217

R722

R721

C450

R205

R204

R213

R720

C452

R719

R726

R724

R741

R728

R727

R800

R742

R731

R740

R701

R717

R703

R738

R743

R801

R736

R813(CH/CJ)

R814(CI/CK)

R799

R802

G/CJ/CK)

R812(CF/C

)

I

R811(CF/CG/CH/C

R805

R760

CLK TP

R758

R759

C703

R702

R718

R757

C702

1

R755

C708

IC701

J702(NC)

R753

R754

R737

R735

R750

R752

C701

C707

C706

R751

R732

1

Q70

R776

2

Q70

R739

R763

D702

R723

R725

R715

R716

R777

R765

CLK TP

Page 7

Main PWB section(B1) 2/2

1

NC

(TELM SH GND)

2

NC(TELM SIG-)

3

NC(HFT ICON1)

4

REMOTE

5

REMOTE GND

6

AUX GND

7

AUX SH GND

8

8

AUX SIG GND

9

NC

(NAVI SH GND)

10

NC(NAVI GND)

11

NC(HFT MUTE)

12

NC(TELM SIG+)

13

NC(HFT ICON2)

14

NC(PAS MUTE)

15

SW +B

16

AUX DET

17

AUX R-CH

18

AUX L-CH

19

NC(NAVI R-CH)

20

NC(NAVI L-CH)

1

+B

2

+B

3

SYSTEM ACC

4

ILL

5

BUS+

6

BUS-

7

MAIN GND

BUS GND

9

GND-SHIELD

10

ILL-C

11

R+

12

R-

13

L+

14

L-

1

MAIN GND

2

RR-

3

FR-

4

FL-

5

RL-

6

ILL-

7

+B

8

RR+

9

FR+

10

FL+

11

RL+

12

ILL+

13

K-LINE

14

NC(TEL-MUTE)

External Device Connector(20P) GA-NET Connector(14P) Main Connector(17P)

11 12 13 14 15 16 17 18 19 20

1

2345678910

Q516

11 12 13 14 15 16 17 18 19 20

12345678 910

TM701

R912

R913

C914

R915

C913

R914

C911

R916

R214

R215

Q913

C912

C496

Q914

C495

R451

C220

D201

Q904

204

Q205

Q

C735

C902

D902

D901

R903

Q912

R935

R936

R924

R923

R925

Q901

R901

R905

R921

Q902

R907

Q203

C901

R928

C906

R929

C907

C909

TM901

R577

R794

C432

D708

J302

TH501

R572

D501

Q517

C722

D806

D805

D804

C803

R305

Q803

R764

R311

R761

R804

R803

L702

IC404

C410

C403 C404 C405

IC706

C726

C727

L704

C729

C223

C904

VCC

Q921

Q922

1

C493

L703

D701

C710

C736

C705

TC701

R729

R927

R926

Q905

R911

Q907

Q909

Q908

R904

R902

C903

R909

C713

X702

Q906

124

P701

R306

R808

C465

C725

C712

101214 56247

101214 56247

85

IC301

14

C724

C402C411

C406

C463

L705

C711

R744

R746

R307

X701

R747

J301

R308

C303

C401

C709

R748

R749

1

25

D719

789 101112

1

D502

C439

3891113

13891113

T501

C421

C407

C419

C431

C438

123

789 101112

123

TM501

C423

C424

C420

C422

1

C435

C500

C442

C461

C444

C497

36

L411

R441

R442

C445

85

C704

R806

R712

14

IC702

100 76

L415

C400

75

IC703

26 50

712

711

Q

Q

29 1

51

R733

R730

16 17

13 14 15

J101

16 17

13 14 15

C548

C414

C425

C426

X401

R413

C429

C430

144 109

IC401

37 72

R445

R454

TP404

TP403

R713

R711

R710

R714

C205

R203

C206

C207

64

1

16

17

R446

R444

IC201

C412

C201

X201

C211

15

SECURITY

16

ACC

17

VSP

456

C504

R501

456

D505

C715

R766

C718

C547

C413

L402

L403

C428

C427

108

L406

73

R448

C460

R201

R202

C202

C204

C203

49

48

33

32

R209

TM201

R734

C719

L701

R412

R415

R416

L410

R440

R439

R784

C434

C441

C443

1

C112

R117

R115

IC204

A

ANT IN

B

GND

C

SWD +B

ANT Connector

B

A

C

ICQ

ANT101

A

C

C113

Q102

D103

R101

R102

Q106

R116

R107

C104 C106

L101

D101

D102

TH101

C101

C102

SUP101

TM101

C115

1

1

2

Q52

Q52

C221C222

C219

C225

L202

1

R122

R121

R459

C473 C475 C472

R460

C474

R212

L203

R461

C213

R458

1

C503

R578

R579

BL101

C564

C502

17

TM102

IC203

IC202

C215

C228

Q517

Q516

Q102

Q106

Q803

Q913

Q914

Q204

Q205

Q904

Q921

Q922

Q521

Q522

Q912

Q909

Q908

Q902

Q901

Q905

Q907

Q203

Q906

Q711

Q712

IC301

IC404

IC706

IC401

IC702

IC703

IC201

IC202

IC203

IC204

- 7 -

C

To J201 of SW PWB-B(page 8)

PH-2761C

Flat Wire

(816-4028-50)

Main PWB(B1)

COMPONENT SIDE

D

To J101 of CD PWB(page M6)

Page 8

Switch PWB-A(B2) section Switch PWB-B(B2) section

COMPONENT SIDE

Switch PWB-B(B2)

SOLDER SIDE

IC

Q

114

1

112

23

224

To P701 of

Main PWB

(page 7)

C

To J205 of

SW PWB-A

B

To J204 of

SW PWB-A

A

R203

R204

IC203

J203

J202

D201

J201

R201

PL111

PL112

C109

D214

D202

C121

D119

D118

C122

D209

PL103

PL104

D213

S119

S102

D206

S103

S104

S111

D211

S109

S106

D207

S107

S108

S112

S116

S114

S115

S117

S113

PL109

PL105

PL110

PL108

S101

S118

PL101

S105

C110

PL107

PL102

S110

D212

PL106

D210

D204

D216

D208

D222

D215

D203

D303

D205

1

IC

Q

TM102

D110 D111 D112

D109

D108

D107

LCD101

Q201

Q202

112

J205

Flat wire

(816-4013-51)

B

To J202 of SW PWB-B

R202

R110

120

IC201

6041

80

R123

R122

R121

61

21

40

C104

R104

C103

C102

C101

R109

R108

D105 D106

D104

21

40

D103D102

D101

TM101

COMPONENT SIDE SOLDER SIDE

Switch PWB-A(B2)

- 8 -

IC2

02

R208

R207

120

6041

114

J204

80

R114

R113

R112

61

C111

R107

C105

R106

R105

C108

R116

C107

C106

Flat wire

(816-4014-51)

A

To J203 of SW PWB-B

PH-2761C

Page 9

Clarion Co., Ltd.

50 Kamitoda, Toda-shi, Saitama 335-8511 Japan

Service Dept.: 5-66 Azuma , Kitamoto-shi, Saitama 364-0007 Japan

Tel: +81-48-541-2335 / 2432 FAX: +81-48-541-2703

Service Manual

CD mechanism

Published by Service Dept.

Printed in Japan

BLOCK DIAGRAM

PICK UP UNIT

LASER

DETECTOR

A,B,C,E,F

FOCUS

TRACKING COIL

SLED / LOADING

MOTOR

SPINDLE MOTOR

LIMIT

S2

SWITCH

CHUCKING

S1

SWITCH

PHOTO

Q1,2

TR A,B

LED A,B

D1,2

TC94A15FG

RF-AMP

SERVO PROCESSOR

3.3V

BA5825FP

MOTOR DRIVER

Model

IC2

IC1

929-5000-80

J101

5.0V

IF-VDD

AOUT

SFSY

SBSY

/RST

BUS0

BUS1

BUS2

BUS3

BUCK

/CCE

DATA

CLCK

BCK

LRCK

MBOV

IPF

LDMUT

LDCONT

SW /

DET

3.3V

CD-VDD

8.0V

8V

- M1 -

929-5000-80

Page 10

EXPLODED VIEW / PARTS LIST

B1

71

H1

46

H2

22

B2

29

H3

23

73

A1

34

63

1

72

48

H4

H5

44

68

G6

A4

65

69

D1

H6

G13

A4

H7

52

H3

H1

70

I1

H2

31

65

9

42

6

E2

27

58

8

A5

1

67

10

E1

25

41

26

B1

G12

D2

64

35

21

75

G13

A1

62

29

A8

B2

22

H6

3

H5

H4

A3

60

G2

47

G6

61

66

G3

C3

K2

K1

7

E2

G12

M1

C2

G5

C1

24

37

G4

G5

57

56

20

G1

A3

G11

G8

G9

G4

G11

G8

G3

E1

M1

32

54

G9

C5

33

55

53

K3

C5

K4

51

66

38

39

40

30

I2

74

G1

11

G14

G2

G14

50

A2

K3

K4

43

17

18

D1

59

12

929-5000-80

A2

46

A5

5

13

76

45

A8

36

H6

49

59

D2

I2

49

16

H6

48

69

H7

I1

4

2

K1

C3

K2

28

C1

14

15

19

C2

- M2 -

Page 11

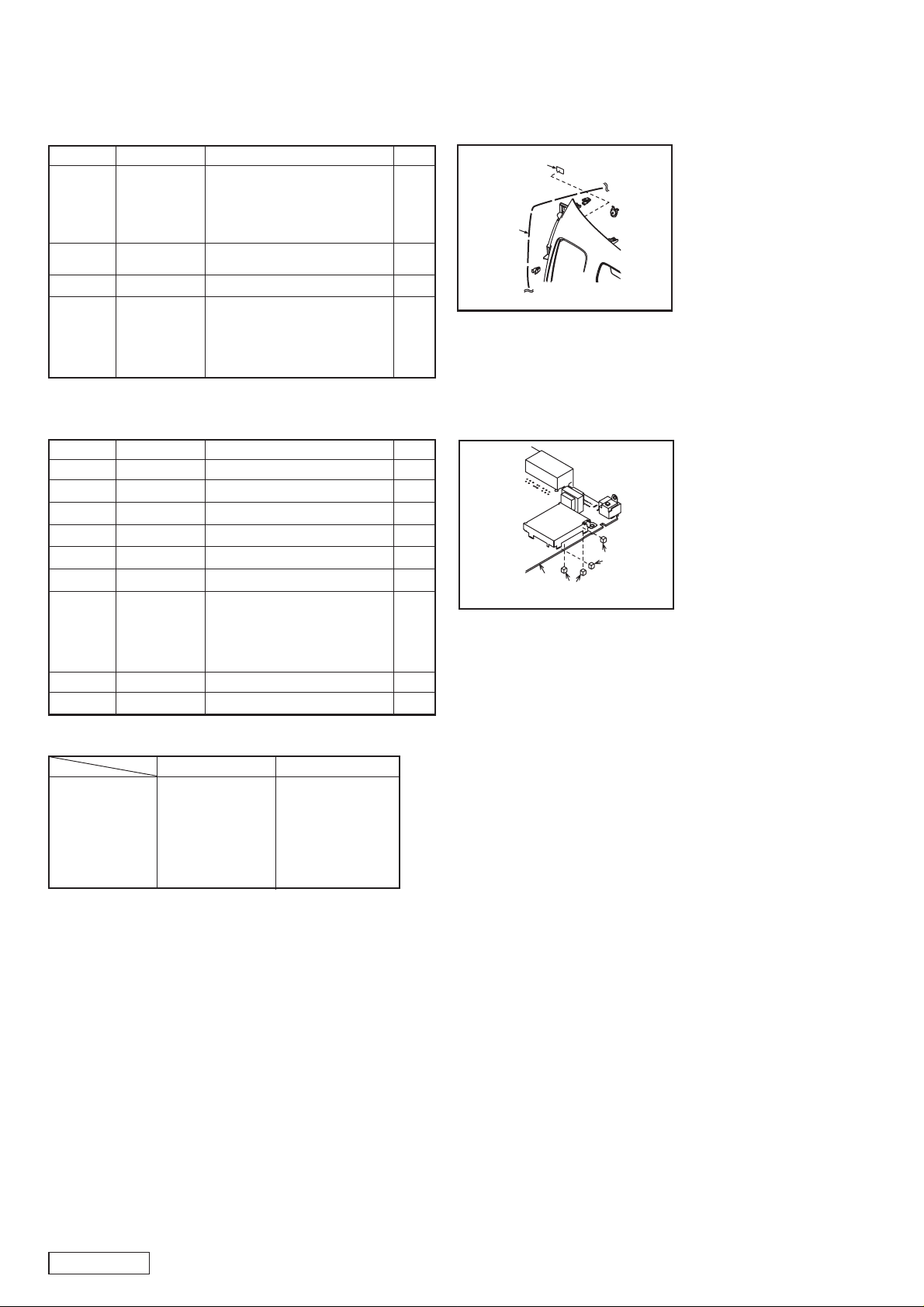

1 ----------- SENSOR PWB 1

2 ----------- MAIN PWB 1

3 SMA-182-100 SPINDLE MOTOR-ASSY 1

4 SMA-183-100 SLED MOTOR-ASSY 1

5 345-5476-20 CUSHION RUBBER 1

6 620-1023-23 CLAMPER PLATE 1

7 620-1026-21 SPRING PLATE 1

8 620-1596-23 CLAMPER LINK 1

9 620-1598-22 UPPER CHASSIS 1

10 620-1752-20 SENSOR ARM 1

11 620-1753-20 ID-LOCK PLATE 1

12 620-1754-20 LOWER CHASSIS 1

13 621-0608-21 SECOND GEAR 1

14 621-0609-20 BASE GEAR 1

15 621-0610-20 IDLE GEAR A 1

16 621-0611-20 IDLE GEAR B 1

17 621-0612-21 ROLLER GEAR A 1

18 621-0620-20 THREAD GEAR A 1

19 621-0621-20 THREAD GEAR B 1

20 621-0623-23 LS-HOLDER 1

21 621-0624-22 GUIDE RAIL 1

22 621-0711-20 LOADING ROLLER 2

23 621-0718-21 ROLLER GUIDE 1

24 621-0719-20 ROLLER GEAR B 1

25 621-0720-20 ROLLER GEAR C 1

26 621-0721-20 ROLLER GEAR D 1

27 621-0728-20 STOPPER LINK 1

28 621-1719-20 IDLE CASE 1

29 621-1726-20 ROLLER SLEEVE 2

30 621-1729-20 SH-BASE 1

31 621-1742-20 UPPER GUIDE 1

32 621-1743-20 SHIFT LEVER 1

33 621-1744-20 RACK 1

34 621-1745-20 LOCK ARM L 1

35 621-1746-20 LOCK ARM R 1

36 621-1747-20 GEAR COVER 1

37 621-1748-20 POWER GEAR A 1

38 621-1749-20 POWER GEAR B 1

NO. PART NO. DESCRIPTION Q'TYNO. PART NO. DESCRIPTION Q'TY

39 621-1750-20 POWER GEAR C 1

40 621-1751-20 POWER GEAR D 1

41 621-1752-20 DISC STOPPER 1

42 621-1753-20 CLAMPER RING 1

43 621-1754-20 GEAR BASE 1

44 622-1571-21 ROLLER SHAFT 1

45 624-0020-00 LEAD SCREW 1

46 629-0086-20 DAMPER F 2

47 629-0087-20 DAMPER R 1

48 716-1507-01 SCREW(M2x3) 3

49 716-1670-01 SCREW(M2x4) 4

50 716-1733-01 SCREW(M1.7x2.3) 2

51 716-3469-01 SCREW(1.7x4) 2

52 716-3473-01 SCREW(M2x3) 1

53 716-3551-00 SCREW(M1.4x2.5) 2

54 750-3467-21 SHIFT SPRING 1

55 750-3468-20 RACK SPRING 1

56 750-3469-20 CLAMPER SPRING 1

57 750-3470-20 ID-LOCK SPRING 1

58 750-3471-20 SENSOR SPRING 1

59 750-3472-21 DR-SPRING F 2

60 750-3473-20 DR-SPRING RA 1

61 750-3474-20 DR-SPRING RB 1

62 750-3475-21 DR-SPRING C 1

63 750-6797-20 ROLLER SPRING L 1

64 750-6798-20 ROLLER SPRING R 1

65 714-2003-8B SCREW(M2x3) 2

66 780-2025-00 SCREW(M2x2.5) 3

67 781-1730-00 SCREW(M1.7x3) 1

68 803-4906-60 VINYL-COAT-WIRE(ORG) 1

69 816-2542-01 FLAT WIRE 1

70 816-2590-00 VINYL-COAT-WIRE(GRN) 1

71 816-2591-00 VINYL-COAT-WIRE(YEL) 1

72 816-2592-00 VINYL-COAT-WIRE(BLUE) 1

73 816-2593-00 VINYL-COAT-WIRE(PUR) 1

74 966-1722-20 SH-RACK-ASSY 1

75 966-1743-21 DRIVE-PLT-ASSY 1

76 969-0071-30 PICKUP-ASSY 1

- M3 -

929-5000-80

Page 12

ELECTRICAL PARTS LIST

CD PWB(BM1) section

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

C1 168-1042-78 16V 0.1uF

C2 163-1073-35 16V 100uF

C4 178-1052-78 1uF

C5 042-0560-85 6.3V 100uF

C6 178-1052-78 1uF

C8 178-1052-78 1uF

C10 168-1042-78 16V 0.1uF

C11 168-1042-78 16V 0.1uF

C12 045-4701-50 47pF

C13 046-1532-78 0.015uF

C14 168-1042-78 16V 0.1uF

C15 046-1032-78 0.015uF

C17 046-4722-58 4700pF

C18 046-1522-58 1500pF

C19 168-1042-78 16V 0.1uF

C20 168-1042-78 16V 0.1uF

C21 046-6812-58 680pF

C22 168-1042-78 16V 0.1uF

C23 046-1532-78 0.015uF

C24 168-1042-78 16V 0.1uF

C25 045-6801-50 68pF

C26 168-1042-78 16V 0.1uF

Sensor PWB(BM2) section

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

D1 001-7058-90 AN1105W-RR

D2 001-7058-90 AN1105W-RR

J1 074-1138-60 10P

C27 046-3332-78 0.033uF

C29 046-6822-58 6800pF

C30 168-1042-78 16V 0.1uF

C31 046-4712-58 470pF

C32 046-4712-58 470pF

C33 168-1042-78 16V 0.1uF

C34 168-4732-78 16V 0.047uF

C35 168-4732-78 16V 0.047uF

C36 045-1007-50 10pF

C37 045-1007-50 10pF

C38 168-1042-78 16V 0.1uF

C39 046-5622-58 5600pF

C40 168-1042-78 16V 0.1uF

CCT1 050-0140-63 1/32W 47k ohm x4J

D1 001-0367-91 1SS226

IC1 051-6079-90 BA5830FPG

IC2 051-6399-00 TC94A15F

J101 074-1228-79 29P

J201 074-1138-65 15P

J301 074-1138-60 10P

Q1 131-1188-50 2SB1188PQR

R1 117-6811-15 1/8W 680 ohm

Q1 060-4015-91 PS1192HB

Q2 060-4015-91 PS1192HB

S1 013-7414-50 CHUCKING

R2 117-1001-15 1/8W 10 ohm

R3 033-2211-15 1/10W 220 ohm

R5 033-0000-05 1/10W 0 ohm

R6 033-5621-15 1/10W 5.6k ohm

R7 033-4731-15 1/10W 47k ohm

R8 033-3341-15 1/10W 330k ohm

R9 033-2231-15 1/10W 22k ohm

R10 033-2231-15 1/10W 22k ohm

R11 033-2731-15 1/10W 27k ohm

R12 033-4731-15 1/10W 47k ohm

R13 033-2731-15 1/10W 27k ohm

R14 033-1531-15 1/10W 15k ohm

R15 033-2731-15 1/10W 27k ohm

R16 033-8231-15 1/10W 82k ohm

R17 033-2731-15 1/10W 27k ohm

R18 033-8231-15 1/10W 82k ohm

R19 033-1051-15 1/10W 1M ohm

R20 119-2221-15 1/10W 2.2k ohm

X2 061-3534-90 16.92MHz

PWB 039-2741-20 PWB(WITHOUT

COMPONENT)

S2 013-7413-50 LIMIT

PWB 039-2675-20 PWB(WITHOUT

COMPONENT)

929-5000-80

- M4 -

Page 13

CIRCUIT DIAGRAM

CD PWB(BM1) section

Sensor PWB(BM2) section

٨

SENSOR-B

SENSOR-A

D2

AN1105W-RR

٨

8V

Q1

PS1192HB

D1

ITH

DRIVER W

GND

-RR

AN1105W

ER

REG. CONTROLL

R1

٨٨

J1

J301

680

٨

٨

Q2

PS1192HB

S1

SPVG22

10

LED+

LED+

10

٨

٨

X2

٨

C

٨

C38

0.1

٨

٨

٨

C40

0.1

9

GND

GND

9

TR-A

C36

C

16.92M

C

٨

٨

٨

C39

C

C37

8

PHOTO-A

TR-A

8

٨

R19

٨

٨

٨

CCT1

47KX4

٨

٨

7

TR-B

TR-B

D-3.3V

10p

10p

5600p

C

IF-VDD

S2

SPVG12

6

PHOTO-B

CHUCK-SW

CHU

7

6

CHU

1M

R20

2.2K

SSTOP

٨

٨

5

LIMIT-SW

SSTOP

5

٨

BUS0

٨

BUS1

٨

BUS2

٨

BUS3

BUCK

/CCE

٨

/RST

BCK

AOUT

LRCK

SL-

SL+

SP-

SP+

IC1

BA5830FP

VO3+

3.6V

15

470p

1.7V

3.3V

C32

8V

0V

C

C

٨

VREF

PDO

5.6K

R6

1.7V

1.7V

٨

VO3-

16

VO4+

17

VO4-

18

PwVCC2

19

PwGND

20

CNT

21

LDIN

22

OPOUTSL

23

OPINSL-

24

OPOUT3

25

OPIN3

26

BIAS

27

PrVCC

28

C31

٨

TRO

1.7V

TMAXS

47K

R7

C12

VO2+

VO2VO1+

PwVCC

PwGND

MUTE

PrGND

REG-B

OPOUT1

OPIN1

OPOUT2

OPIN2

470p

٨

FOO

1.7V

1.7V

TMAX

330K

R8

٨

٨٨

SP-

4

3

2

1

SL+

SP-

SP+

SL-

SL-

SP+

SP-

SL+

4

3

2

1

SP-

SL-

SL+

SP+

٨٨

٨

C

C1

16V

0.1

٨

٨

C2

100

3.3V

XVDD3

XO

XI

76

DVSS3

0V

77

RO

78

DVDD3

3.3V

79

DVR

1.7V

80

LO

81

DVSS3

0V

82

ZDET

0/IF-VDD

83

VSS5

0V

84

BUS0

85

BUS1

86

BUS2

87

0/IF-VDD

BUS3

88

BUCK

89

/CCE

90

/RST

91

3.3V or 5V

VDD5

92

IO0B

93

IO1B

94

IO2B

95

IO3B

0/IF-VDD

96

EMPH

97

BCK

98

AOUT

99

LRCK

CLCK

SBOK

100 26

DOUT

IPF

1 2 3 4 5 6 7 8 9101112131415161718192021222324

IPF

CLCK

MBOV

C

0.1

C10

٨

3.3V or 5V

SP+

SL+

SL-

٨

٨

٨

TESIN

XVSS3

0V

0V

٨

٨

٨

VSS3

FGIN

MONIT

VDD3

0V

3.3V

CLV:L

DIGITAL SERVO PROCESSOR

0/IF-VDD

0V

3.3V

VSS3

VDD3

٨

٨

٨

DATA

DATA

٨

SFSY

SFSY

SBSY

SBSY

٨

IO0A

A-3.3V

4.0V

3.6V

4.0V

0/IF-VDD 3.3V

0/IF-VDD

R16

82K

1.8V

1.7V

٨

R18

82K

1.6V

1.7V

٨

7.9V

C35

٨

0.047

27K

27K

٨٨

C

C34

R15

R17

0.047

٨

٨

C

6566676869707172737475

FMO

DMO

IO3A

IO2A

1.8V

RF-AMP AND

IC2

TC94A15FG

PVDD3

ARSEL

IO1A

AWRC

٨

C

0.1

C11

٨

٨

REG

F-

4.0V

14

F+

3.8V

13

T-

3.8V

12

T+

3.8V

11

VO-

8V

10

0V

9

٨

8

0V

7

3.3V

6

R14

5

15K

1.8V

4

AVDD3

3.3V

C33

TEZI

3

2

1

R13

C

٨

1.7V

1.7V

1.8V1.7V

1.7V

0.1

٨

TEI

1.7V

R11

27K

27K

٨

R12

47K

٨

٨

0.1

C30

C

٨

565758596061626364

SBAD

FEI

RFDC

RFRP

1.7V

1.7 TO 2.0V

0.2V

2.4V

3.3V

0.6 TO 1.8V

0.6 TO 1.8V

1.1 TO 2.4V

1.6V

1.5V

1.7V

1.5V

3.3V

0.8V

VCOREF

1.0 TO 2.3V

1.7V

1.4V

1.7V

PVREF

VCOF

LPFN

LPFO

CCC

22K

R9

47p

0.015

C13

٨

0.01

C15

٨

1.7V

٨

DTCN

DTCP

0

R5

C14

0.1

C

TP18

LD-

TP19

LD+

2.0 TO 2.8V

0V

J201

٨

AVSS3

PVSS3

0V

٨

٨

15

TRK(-)

T-

C

5152535455

RFZI

0V

FPI1

FPI2

FNI1

FNI2

RVSS3

MDI

LDO

RVDD3

EQSET

PNSEL

RFO

RFDCI

AGCI

INVSEL

TESTR

VMDIR

VRO

RESIN

AVDD3

RFEQO

RFRPI

SLCO

TO 2.3V

25

F+

٨

٨

٨

٨

٨

1.3

TNI

TPI

RFI

1.0

1.7V

14

FCS(+)

T+

Q1

2SB1188

10

R2

C5

100

6.3V

C

C4

C27

0.033

50

TO 2.2V

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

13

12

11

VR

TRK(+)

FCS(-)

F-

0.15V

٨

٨

٨

٨

1

C

C29

6800p

FTE

٨

3.3V

٨

٨

٨

C

C24

0V

C

C23

0.6 TO 1.8V

C19 C20

C

C

C18

1500p

fc=13.5KHz

C

C17

4700p

To pick up

9

8

7

10

PD

0.19V

220

R3

٨

٨

٨

٨

0.1

0.015

0.1 0.1

٨

6

VC

LD

VCC

GND

0V

3.3V

1.7V

D1

1SS226TE85L

1

٨

C6

C

٨

٨

1.8 TO 2.2V

C8

1

C

٨

٨

C

C26

0.1

C

C25

68p

٨

C22

0.1

C

C21

٨

C

٨

R10

٨٨

C

5

4

3

2

1

F

C

E

A

B

1.8 TO 2.2V

٨

٨

٨

٨

٨

680p

٨

٨

22K

٨

J101

٨

٨

0V

8V

29

28

27

26

25

8V

8V

P-GND

P-GND

LDMUT

CHU

TR-B

TR-A

SSTOP

24

23

22

21

SSTOP

CHU-SW

TR-B

TR-A

LCONT

BUCK

20

19

18

17

16

15

14

13

12

SBSY

/CCE

/RESET

BUCK

BUS0

BUS1

BUS2

BUS3

BUS0

BUS1

BUS2

BUS3

/CCE

/RST

SBSY

IPF

0V

11

MBOV

3.3V

9

8

10

IF-VDD

GND

IPF

CD-VDD

7

MBOV

CLCK

DATA

6

CLCK

SFSY

5

DATA

BCK

AOUT

LRCK

4

3

2

1

AOUT

LRCK

BCK

SFSY

To J201 of Main PWB

- M5 -

929-5000-80

Page 14

PRINTED WIRING BOARD

CD PWB(BM1) section

Sensor PWB(BM2) section

SLED MOTOR-ASSY

(SMA-183-100)

Q

SPINDLE MOTOR-ASSY

With LEAD

(SMA-182-100)

+

BLK(-)

RED(+)

MARKING

+

ORG(+)

GRN(-)

CD PWB (BM1)

COMPONENT SIDE

Sensor PWB-B

(BM2)

IC Q

Sensor PWB-A

(BM2)

GRN

FLAT WIRE

(816-2542-01)

ORG

BLK

RED

BLU

PUR

PUR

YEL

BLU

YEL

PICK UP-ASSY

(969-0071-30)

Caution:

COMPONENT SIDE: Parts on the component side seen

from the component side are indicated.

SOLDER SIDE: Parts on the solder side seen

from the solder side are indicated.

929-5000-80

CD PWB (BM1)

SOLDER SIDE

To J201 of Main PWB

- M6 -

Loading...

Loading...