Page 1

UNIWRAP

Technical Systems

Hydraulic System

Page 2

Page 3

TIC UNIWRAP Hydraulic System

Contents

1 Hydraulic circuit diagram................................................5

2 Pre-conditions for use ................................................... 27

3 Valve block .....................................................................31

4 Individual components .................................................. 41

11/04 UNI-h 3

Page 4

Hydraulic System UNIWRAP TIC

4 UNI-h 11/04

Page 5

TIC UNIWRAP Hydraulic System

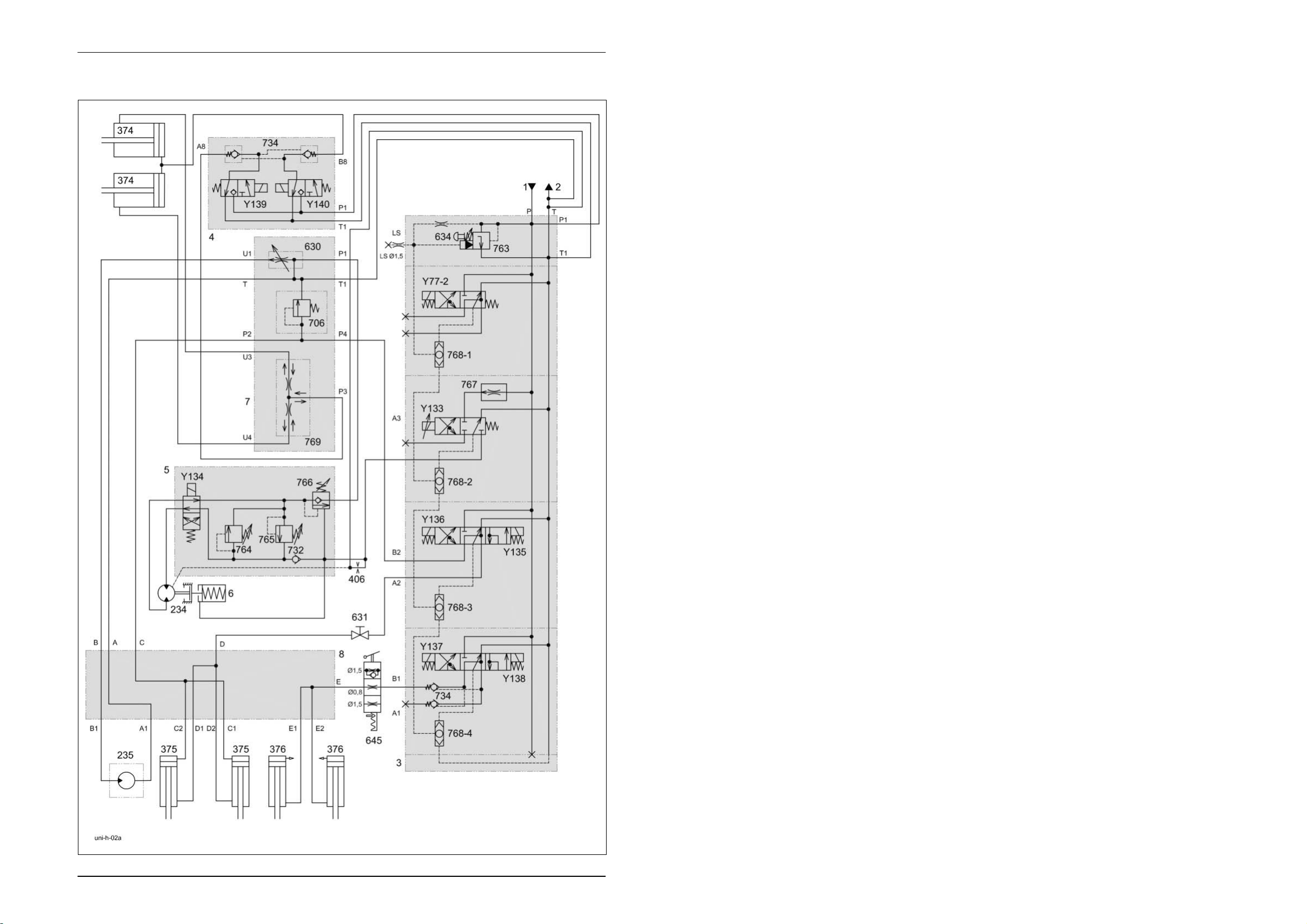

1

Hydraulic circuit diagram

1.1 Hydraulic circuit diagram up to serial no.: 72600130 ........................8

1.2 Hydraulic circuit diagram from machine no.: 72600131,

with tipping cradle service shut-off valve (631) ...............................12

1.3 Hydraulic circuit diagram from machine no.: 72600531,

with film clamping cutters flow divider (769)....................................16

1.4 Hydraulic circuit diagram from serial no.: 72601047,

with valve combination (630, 706, 769),

without 3-stage restrictor (645) .......................................................20

1.5 Hydraulic circuit diagram from serial no.: 72601047,

with valve combination (630, 706, 769),

with 3-stage restrictor (645) ............................................................24

11/04 UNI-h-Kap1 5

Page 6

Hydraulic System UNIWRAP TIC

6 UNI-h-Kap1 11/04

Page 7

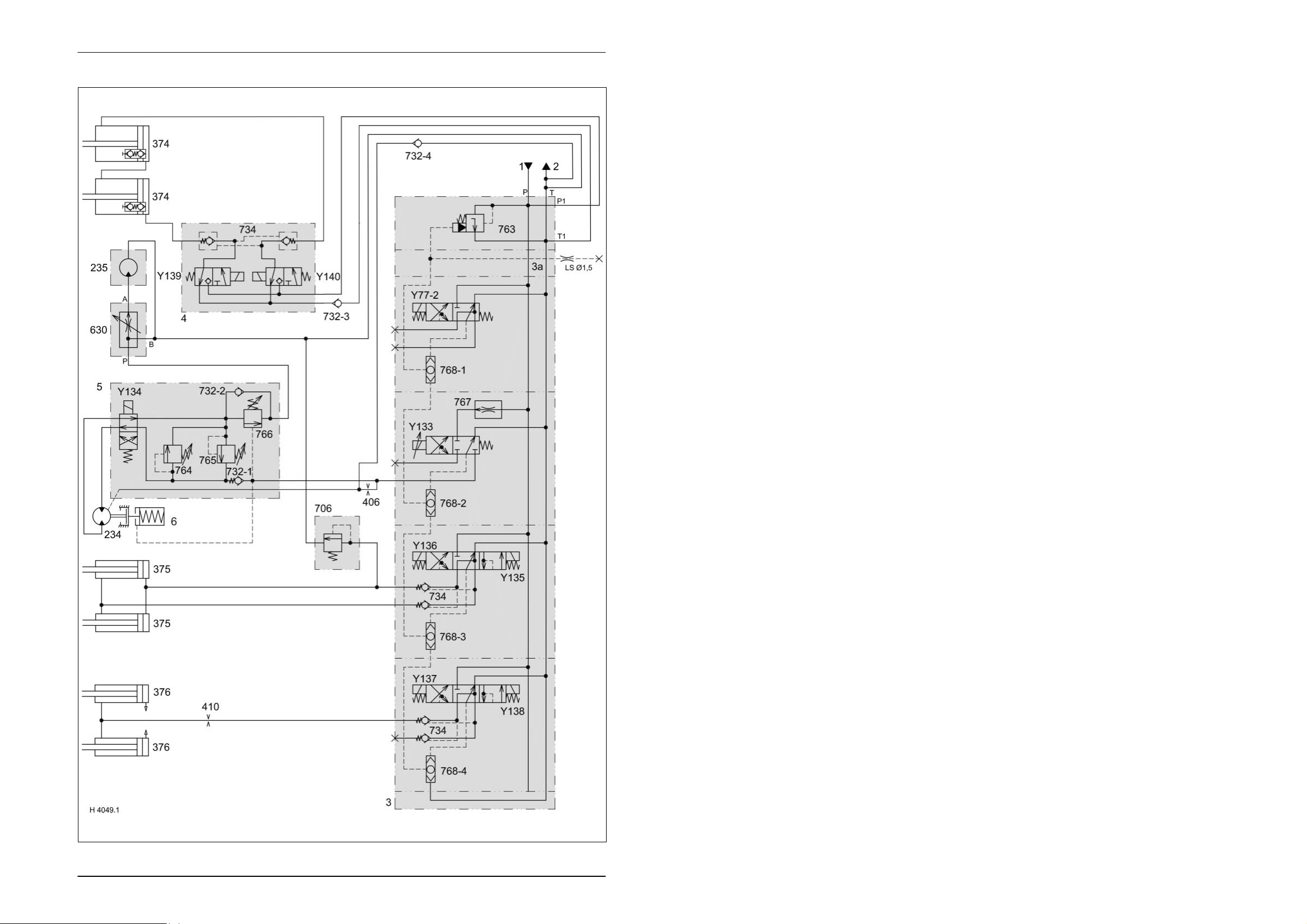

- up to serial no.: 72600130

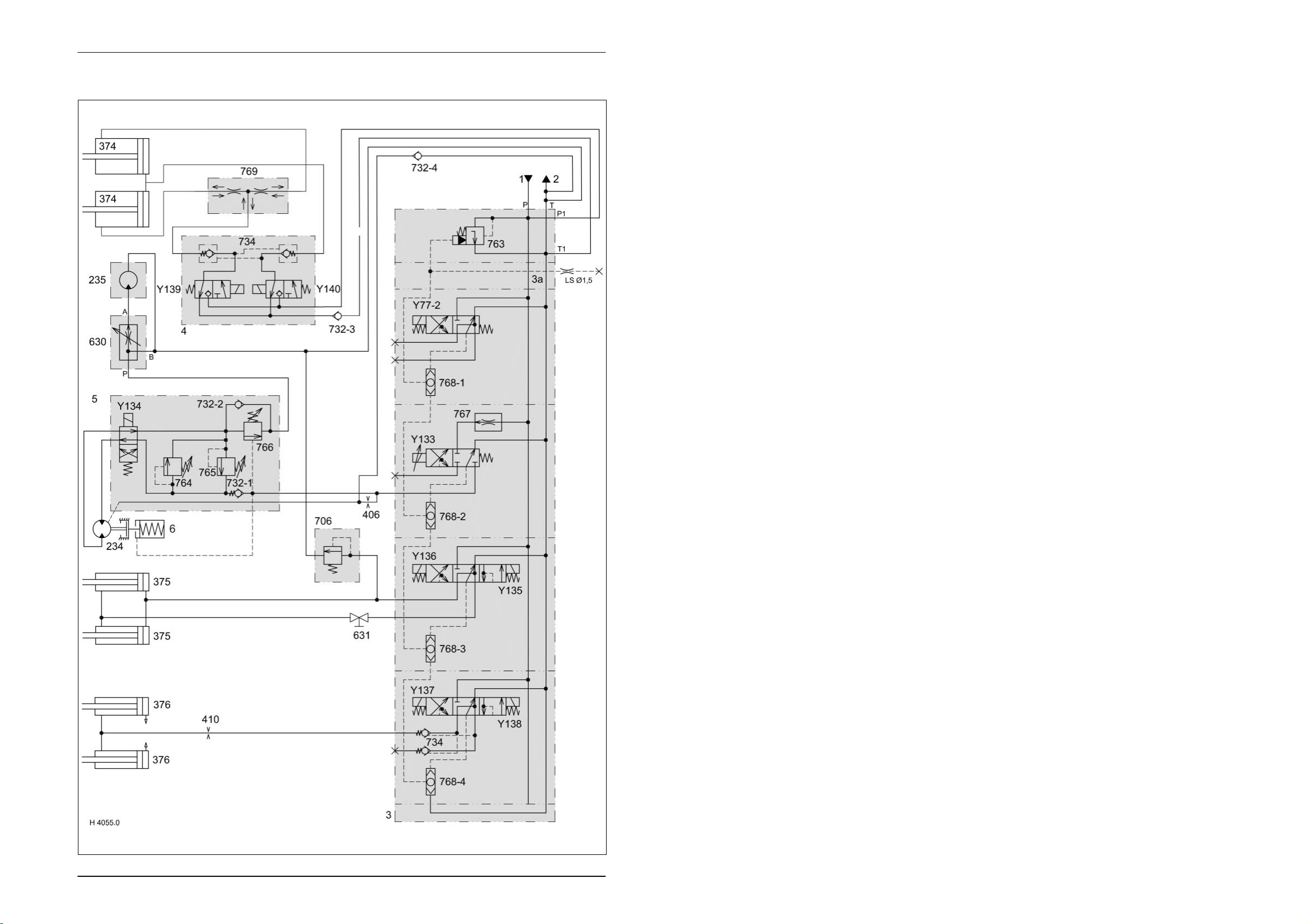

1.1

Hydraulic circuit diagram

Page 8

Hydraulic System UNIWRAP TIC

1.1 Hydraulic circuit diagram up to serial no.: 72600130

Key to diagram:

1 Feed line

2 Return line

3 Valve block

3a Plate

4 Valve block

5 Valve block

6 Disc brake

234 Wrapping arm motor

235 Wrapping table motor

374 Film clamping cutters hydraulic cylinder

375 Tipping cradle hydraulic cylinder

376 Wrapping table hydraulic cylinder

406 Orifice plate Ø 0.8 mm

410 Orifice plate Ø 1.5 mm

630 Wrapping table flow control valve

706 Pressure relief valve

732-1 Non-return valve

732-2 Non-return valve

732-3 Non-return valve

732-4 Non-return valve

734 Lock-up valve unit

763 Input pressure balance

764 Pressure relief valve (left) 115

765 Pressure relief valve (right) 115

766 Lower brake valve

767 Wrapping arm motor flow controller

768 LS signal shuttle valves

Y77 Master valve solenoid valve

Y133 Wrapping arm motor forward solenoid valve

Y134 Wrapping arm motor reverse solenoid valve

Y135 Lower tipping cradle solenoid valve

Y136 Raise tipping cradle solenoid valve

Y137 Lower wrapping table solenoid valve

Y138 Raise wrapping table solenoid valve

Y139 Open film cutters solenoid valve

Y140 Close film cutters solenoid valve

+10

+10

bar

bar

8 UNI-h-Kap1 11/04

Page 9

TIC UNIWRAP Hydraulic System

Description of function:

Orifice plate (406)

Ø 0.8 mm

The orifice plate (406) Ø 0.8 mm avoids pressure build-up and

consequently uncontrolled movements of the wrapping arm motor (234).

Wrapping table flow control

valve (630)

The wrapping table flow control valve supplies the hydraulic motor (235)

via output (A).

This volume flow can be adjusted and changes the wrapping table motor /

wrapping arm motor speed ratio and consequently the film layer overlaps.

Pressure relief valve (706) The pressure relief valve limits the pressure to 70 bar when lowering the

tipping cradle hydraulic cylinders.

Non-return valve (732-3) The non-return valve avoids faulty functions of the film clamping cutters

by building up pressure in the T line.

Input pressure balance

(763)

The input pressure balance keeps the connection from P to T open when

no control unit is actuated in valve block 3.

It is closed by LS pressure. The LS pressure is built up when the master

valve (Y77-2) or a control unit in valve block 3 is actuated.

Pressure relief valve (764) The pressure relief valve limits the oil pressure to the wrapping arm motor

(234) and the wrapping table motor (drive) connected in series to

+10

115

bar.

Pressure relief valve (765) The pressure relief valve limits the oil pressure of the wrapping arm motor

(234) to 115

+10

bar when decelerating.

Lower brake valve (766) The non-return valves 732-1/ 732-2 and the lower brake valve (766)

decelerate the wrapping arm motor (234) hydraulically on both sides if the

wrapping arm forward solenoid valve (Y133) is not energized.

Wrapping arm motor flow

controller (767)

The flow controller keeps the volume flow to the wrapping arm motor

(234) constant.

Maximum wrapping speed (approx. 20 l/min.) with SAM wrapping arm

motor.

Maximum wrapping speed (approx. 31 l/min.) with Danfoss wrapping arm

motor.

LS signal shuttle valves

(768)

When operating the control valves in parallel mode, the shuttle valves

allow sending the highest load pressure to the input pressure balance

(763) in each case.

Master valve solenoid valve

(Y77)

The master valve solenoid valve is actuated automatically when a

hydraulic function is to be carried out on the baler.

Now the pump flow is directed into the LS line so that the pressure that

builds up closes the pressure balance (763).

11/04 UNI-h-Kap1 9

Page 10

Hydraulic System UNIWRAP TIC

Description of function:

Wrapping arm forward

solenoid valve (Y133)

The solenoid valve controls the wrapping arm hydraulic motor.

A wrapping arm motor flow controller 767 is provided in the volume flow

input and keeps the volume flow constant.

When the control unit is activated, this volume flow is pumped to the

hydraulic motor (234) which drives the wrapping arm with 28 ... 30 rpm

max. The flow controller may be accessed via the screw plug at the

bottom of the control unit.

The rotational speed of the wrapping arm of 27 rpm ensures that the

wrapping process is shorter than the time required for producing the bale.

Wrapping arm reverse

solenoid valve (Y134)

The solenoid valve changes the direction of oil flow to the wrapping arm

motor (234) and consequently its sense of rotation.

Lower tipping cradle

The solenoid valve lowers the tipping cradle.

solenoid valve (Y135)

Raise tipping cradle

solenoid valve (Y136)

The solenoid valve raises the tipping cradle. The lock-up valve unit 734

avoids lowering of the raised tipping cradle.

Lower wrapping table

solenoid valve (Y137)

The solenoid valve lowers the wrapping table. The lock-up valve unit 734

in the cylinder line avoids lowering of the loaded wrapping table.

Raise wrapping table

The solenoid valve raises the wrapping table.

solenoid valve (Y138)

Open film cutters solenoid

valve (Y139)

The solenoid valve opens both film cutters.

The wrapping table raise solenoid coil (Y138) is actuated simultaneously

with solenoid coils (Y139). This is necessary in order to build up pressure

in the LS line to make the input pressure balance (763) close.

Close film cutters solenoid

valve (Y140)

The solenoid valve closes both film cutters.

The wrapping table raise solenoid coil (Y138) is actuated simultaneously

with solenoid coils (Y139). This is necessary in order to build up pressure

in the LS line to make the input pressure balance (763) close.

10 UNI-h-Kap1 11/04

Page 11

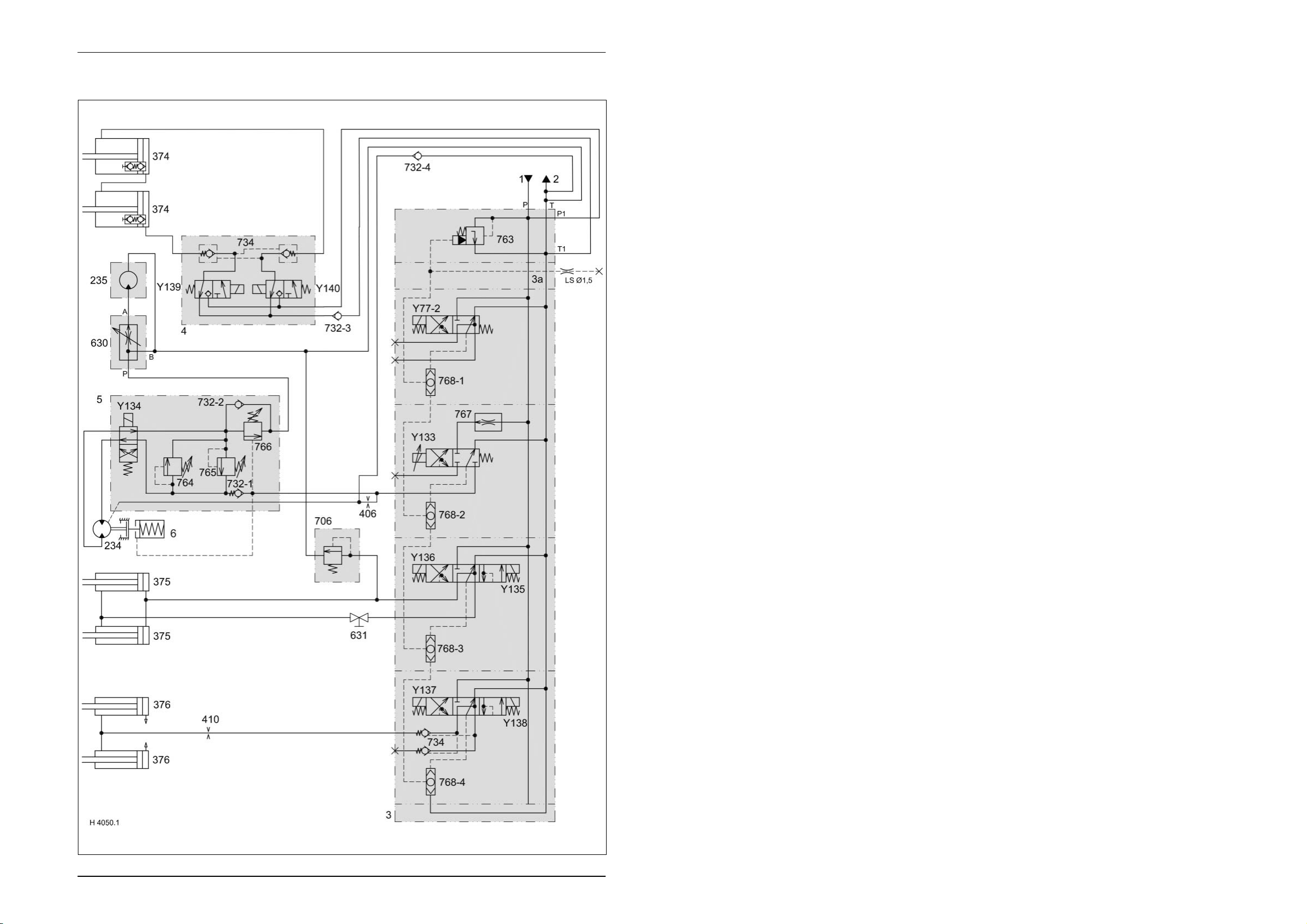

1.2

Hydraulic circuit diagram

- from machine no.: 72600131

- with tipping cradle service shut-off valve (631)

Page 12

Hydraulic System UNIWRAP TIC

1.2 Hydraulic circuit diagram from machine no.: 72600131,

with tipping cradle service shut-off valve (631)

Key to diagram::

1 Feed line

2 Return line

3 Valve block

3a Plate

4 Clamping cutters valve block

5 Wrapping arm motor valve block

6 Disc brake

234 Wrapping arm motor

235 Wrapping table motor

374 Film clamping cutters hydraulic cylinder

375 Tipping cradle hydraulic cylinder

376 Wrapping table hydraulic cylinder

406 Orifice plate Ø 0.8 mm

410 Orifice plate Ø 1.5 mm

630 Wrapping table flow control valve

631 Tipping cradle shut-off valve

706 Pressure relief valve

732-1 Non-return valve

732-2 Non-return valve

732-3 Non-return valve

732-4 Non-return valve

734 Lock-up valve unit

763 Input pressure balance

764 Pressure relief valve (left) 115

765 Pressure relief valve (right) 115

766 Lower brake valve

767 Wrapping arm motor flow controller

768 LS signal shuttle valves

Y77 Master valve solenoid valve

Y133 Wrapping arm motor forward solenoid valve

Y134 Wrapping arm motor reverse solenoid valve

Y135 Lower tipping cradle solenoid valve

Y136 Raise tipping cradle solenoid valve

Y137 Lower wrapping table solenoid valve

Y138 Raise wrapping table solenoid valve

Y139 Open film cutters solenoid valve

Y140 Close film cutters solenoid valve

+10

+10

bar

bar

12 UNI-h-Kap1 11/04

Page 13

TIC UNIWRAP Hydraulic System

Description of function:

Orifice plate (406)

Ø 0.8 mm

The orifice plate (406) Ø 0.8 mm avoids pressure build-up and

consequently uncontrolled movements of the wrapping arm motor (234).

Wrapping table flow control

valve (630)

The wrapping table flow control valve supplies the hydraulic motor (235)

via output (A).

This volume flow can be adjusted and changes the wrapping table motor /

wrapping arm motor speed ratio and consequently the film layer overlaps.

Tipping cradle shut-off valve

(631)

During service work, the tipping cradle shut-off valve shuts off the oil flow

from the hydraulic cylinders 375.

Pressure relief valve (706) The pressure relief valve limits the pressure to 70 bar when lowering the

tipping cradle hydraulic cylinders.

Non-return valve (732-3) The non-return valve avoids faulty functions of the film clamping cutters

by building up pressure in the T line.

Input pressure balance

(763)

The input pressure balance keeps the connection from P to T open when

no control unit is actuated in valve block 3.

It is closed by LS pressure. The LS pressure is built up when the master

valve (Y77-2) or a control unit in valve block 3 is actuated.

Pressure relief valve (764) The pressure relief valve limits the oil pressure to the wrapping arm motor

(234) and the wrapping table motor (drive) connected in series to

+10

115

bar.

Pressure relief valve (765) The pressure relief valve limits the oil pressure of the wrapping arm motor

(234) to 115

+10

bar when decelerating.

Lower brake valve (766) The non-return valves 732-1/ 732-2 and the lower brake valve (766)

decelerate the wrapping arm motor (234) hydraulically on both sides if the

wrapping arm forward solenoid valve (Y133) is not energized.

Wrapping arm motor flow

controller (767)

The flow controller keeps the volume flow to the wrapping arm motor

(234) constant.

Maximum wrapping speed (approx. 20 l/min.) with SAM wrapping arm

motor.

Maximum wrapping speed (approx. 31 l/min.) with Danfoss wrapping arm

motor.

LS signal shuttle valves

(768)

When operating the control valves in parallel mode, the shuttle valves

allow sending the highest load pressure to the input pressure balance

(763) in each case.

Master valve solenoid valve

(Y77)

The master valve solenoid valve is actuated automatically when a

hydraulic function is to be carried out on the baler.

Now the pump flow is directed into the LS line so that the pressure that

builds up closes the pressure balance (763).

11/04 UNI-h-Kap1 13

Page 14

Hydraulic System UNIWRAP TIC

Description of function:

Wrapping arm forward

solenoid valve (Y133)

The solenoid valve controls the wrapping arm hydraulic motor.

A wrapping arm motor flow controller 767 is provided in the volume flow

input and keeps the volume flow constant.

When the control unit is activated, this volume flow is pumped to the

hydraulic motor (234) which drives the wrapping arm with 28 ... 30 rpm

max. The flow controller may be accessed via the screw plug at the

bottom of the control unit.

The rotational speed of the wrapping arm of 27 rpm ensures that the

wrapping process is shorter than the time required for producing the bale.

Wrapping arm reverse

solenoid valve (Y134)

The solenoid valve changes the direction of oil flow to the wrapping arm

motor (234) and consequently its sense of rotation.

Lower tipping cradle

The solenoid valve lowers the tipping cradle.

solenoid valve (Y135)

Raise tipping cradle

solenoid valve (Y136)

The solenoid valve raises the tipping cradle. The lock-up valve unit 734

avoids lowering of the raised tipping cradle.

Lower wrapping table

solenoid valve (Y137)

The solenoid valve lowers the wrapping table. The lock-up valve unit 734

in the cylinder line avoids lowering of the loaded wrapping table.

Raise wrapping table

The solenoid valve raises the wrapping table.

solenoid valve (Y138)

Open film cutters solenoid

valve (Y139)

The solenoid valve opens both film cutters.

The wrapping table raise solenoid coil (Y138) is actuated simultaneously

with solenoid coils (Y139). This is necessary in order to build up pressure

in the LS line to make the input pressure balance (763) close.

Close film cutters solenoid

valve (Y140)

The solenoid valve closes both film cutters.

The wrapping table raise solenoid coil (Y138) is actuated simultaneously

with solenoid coils (Y139). This is necessary in order to build up pressure

in the LS line to make the input pressure balance (763) close.

14 UNI-h-Kap1 11/04

Page 15

1.3

Hydraulic circuit diagram

- from machine no.: 72600531

- with film clamping cutters flow divider (769)

Page 16

Hydraulic System UNIWRAP TIC

1.3 Hydraulic circuit diagram from machine no.: 72600531,

with film clamping cutters flow divider (769)

Key to diagram:

1 Feed line

2 Return line

3 Valve block

3a Plate

4 Clamping cutters valve block

5 Wrapping arm motor valve block

6 Disc brake

234 Wrapping arm motor

235 Wrapping table motor

374 Film clamping cutters hydraulic cylinder

375 Tipping cradle hydraulic cylinder

376 Wrapping table hydraulic cylinder

406 Orifice plate Ø 0.8 mm

410 Orifice plate Ø 1.5 mm

630 Wrapping table flow control valve

631 Tipping cradle shut-off valve

706 Pressure relief valve

732-1 Non-return valve

732-2 Non-return valve

732-3 Non-return valve

732-4 Non-return valve

734 Lock-up valve unit

763 Input pressure balance

764 Pressure relief valve (left) 115

765 Pressure relief valve (right)

766 Lower brake valve

767 Wrapping arm motor flow controller

768 LS signal shuttle valves

769 Film clamping cutters flow divider

Y77 Master valve solenoid valve

Y133 Wrapping arm motor forward solenoid valve

Y134 Wrapping arm motor reverse solenoid valve

Y135 Lower tipping cradle solenoid valve

Y136 Raise tipping cradle solenoid valve

Y137 Lower wrapping table solenoid valve

Y138 Raise wrapping table solenoid valve

Y139 Open film cutters solenoid valve

Y140 Close film cutters solenoid valve

+10

bar

16 UNI-h-Kap1 11/04

Page 17

TIC UNIWRAP Hydraulic System

Description of function:

Orifice plate (406)

Ø 0.8 mm

The orifice plate (406) Ø 0.8 mm avoids pressure build-up and

consequently uncontrolled movements of the wrapping arm motor (234).

Wrapping table flow control

valve (630)

The wrapping table flow control valve supplies the hydraulic motor (235)

via output (A).

This volume flow can be adjusted and changes the wrapping table motor /

wrapping arm motor speed ratio and consequently the film layer overlaps.

Tipping cradle shut-off valve

(631)

During service work, the tipping cradle shut-off valve shuts off the oil flow

from the hydraulic cylinders 375.

Pressure relief valve (706) The pressure relief valve limits the pressure to 70 bar when lowering the

tipping cradle hydraulic cylinders.

Non-return valve (732-3) The non-return valve avoids faulty functions of the film clamping cutters

by building up pressure in the T line.

Input pressure balance

(763)

The input pressure balance keeps the connection from P to T open when

no control unit is actuated in valve block 3.

It is closed by LS pressure. The LS pressure is built up when the master

valve (Y77-2) or a control unit in valve block 3 is actuated.

Pressure relief valve (764) The pressure relief valve limits the oil pressure to the wrapping arm motor

(234) and the wrapping table motor (drive) connected in series to

+10

115

bar.

Pressure relief valve (765) The pressure relief valve limits the oil pressure of the wrapping arm motor

(234) to 115

+10

bar when decelerating.

Lower brake valve (766) The non-return valves 732-1/ 732-2 and the lower brake valve (766)

decelerate the wrapping arm motor (234) hydraulically on both sides if the

wrapping arm forward solenoid valve (Y133) is not energized.

Wrapping arm motor flow

controller (767)

The flow controller keeps the volume flow to the wrapping arm motor

(234) constant.

Maximum wrapping speed (approx. 20 l/min.) with SAM wrapping arm

motor.

Maximum wrapping speed (approx. 31 l/min.) with Danfoss wrapping arm

motor.

LS signal shuttle valves

(768)

When operating the control valves in parallel mode, the shuttle valves

allow sending the highest load pressure to the input pressure balance

(763) in each case.

Film clamping cutters flow

divider (769)

The flow divider divides the oil flows for opening and closing the film

clamping cutters.

Master valve solenoid valve

(Y77)

The master valve solenoid valve is actuated automatically when a

hydraulic function is to be carried out on the baler.

Now the pump flow is directed into the LS line so that the pressure that

builds up closes the pressure balance (763).

11/04 UNI-h-Kap1 17

Page 18

Hydraulic System UNIWRAP TIC

Description of function:

Wrapping arm forward

solenoid valve (Y133)

The solenoid valve controls the wrapping arm hydraulic motor.

A wrapping arm motor flow controller 767 is provided in the volume flow

input and keeps the volume flow constant.

When the control unit is activated, this volume flow is pumped to the

hydraulic motor (234) which drives the wrapping arm with 28 … 30 rpm

max. The flow controller may be accessed via the screw plug at the

bottom of the control unit.

The rotational speed of the wrapping arm of 27 rpm ensures that the

wrapping process is shorter than the time required for producing the bale.

Wrapping arm reverse

solenoid valve (Y134)

The solenoid valve changes the direction of oil flow to the wrapping arm

motor (234) and consequently its sense of rotation.

Lower tipping cradle

The solenoid valve lowers the tipping cradle.

solenoid valve (Y135)

Raise tipping cradle

solenoid valve (Y136)

The solenoid valve raises the tipping cradle. The lock-up valve unit 734

avoids lowering of the raised tipping cradle.

Lower wrapping table

solenoid valve (Y137)

The solenoid valve lowers the wrapping table. The lock-up valve unit 734

in the cylinder line avoids lowering of the loaded wrapping table.

Raise wrapping table

The solenoid valve raises the wrapping table.

solenoid valve (Y138)

Open film cutters solenoid

valve (Y139)

The solenoid valve opens both film cutters.

The wrapping table raise solenoid coil (Y138) is actuated simultaneously

with solenoid coils (Y139). This is necessary in order to build up pressure

in the LS line to make the input pressure balance (763) close.

Close film cutters solenoid

valve (Y140)

The solenoid valve closes both film cutters.

The wrapping table raise solenoid coil (Y138) is actuated simultaneously

with solenoid coils (Y139). This is necessary in order to build up pressure

in the LS line to make the input pressure balance (763) close.

18 UNI-h-Kap1 11/04

Page 19

1.4

Hydraulic circuit diagram

- from serial no.: 72601047

- with valve combination (630, 706, 769)

- without 3-stage restrictor (645)

Page 20

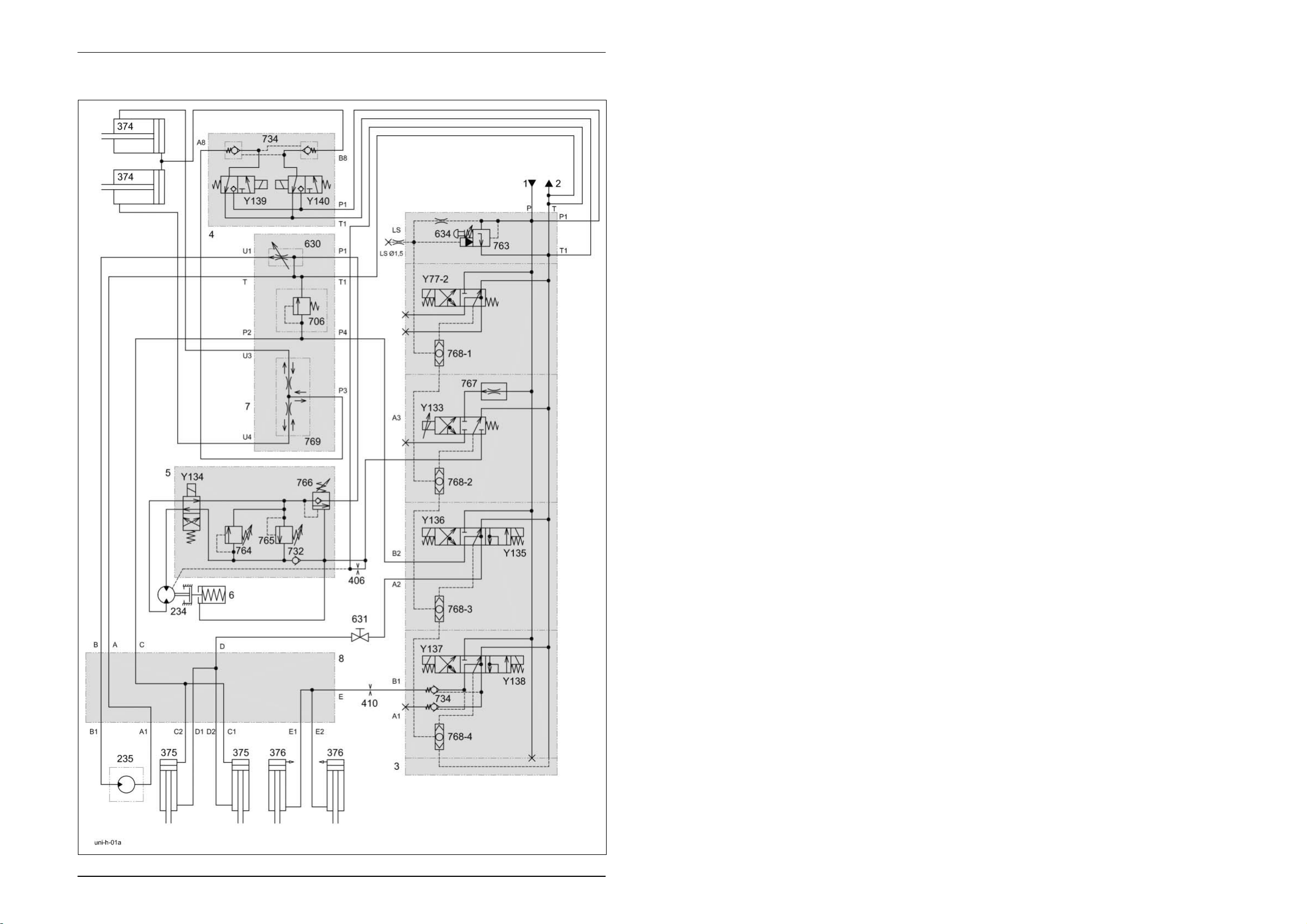

Hydraulic System UNIWRAP TIC

1.4 Hydraulic circuit diagram from serial no.: 72601047, with valve combination (630, 706, 769),

without 3-stage restrictor (645)

Key to diagram:

1 Feed line

2 Return line

3 Valve block

4 Valve block

5 Valve block

6 Disc brake

7 Valve combination

8 Manifold

234 Wrapping arm motor

235 Wrapping table motor

374 Film clamping cutters hydraulic cylinder

375 Tipping cradle hydraulic cylinder

376 Wrapping table hydraulic cylinder

406 Orifice plate Ø 0.8 mm

410 Orifice plate Ø 1.5 mm

630 Wrapping table flow control valve

631 Tipping cradle shut-off valve

634 System screw

706 Pressure relief valve

732 Non-return valve

734 Lock-up valve unit

763 Input pressure balance

764 Pressure relief valve (left) 115

765 Pressure relief valve (right)

766 Lower brake valve

767 Wrapping arm motor flow controller

768 LS signal shuttle valves

769 Film clamping cutters flow divider

Y77 Master valve solenoid valve

Y133 Wrapping arm motor forward solenoid valve

Y134 Wrapping arm motor reverse solenoid valve

Y135 Lower tipping cradle solenoid valve

Y136 Raise tipping cradle solenoid valve

Y137 Lower wrapping table solenoid valve

Y138 Raise wrapping table solenoid valve

Y139 Open film cutters solenoid valve

Y140 Close film cutters solenoid valve

+10

bar

20 UNI-h-Kap1 11/04

Page 21

TIC UNIWRAP Hydraulic System

Description of function:

Orifice plate (406)

Ø 0.8 mm

The orifice plate (406) Ø 0.8 mm avoids pressure build-up and

consequently uncontrolled movements of the wrapping arm motor (234).

Wrapping table flow control

valve (630)

The wrapping table flow control valve supplies the hydraulic motor (235)

via output (A).

This volume flow can be adjusted and changes the wrapping table motor /

wrapping arm motor speed ratio and consequently the film layer overlaps.

Tipping cradle shut-off valve

(631)

During service work, the tipping cradle shut-off valve shuts off the oil flow

from the hydraulic cylinders 375.

Pressure relief valve (706) The pressure relief valve limits the pressure to 70 bar when lowering the

tipping cradle hydraulic cylinders.

Non-return valve (732-3) The non-return valve avoids faulty functions of the film clamping cutters

by building up pressure in the T line.

Input pressure balance

(763)

The input pressure balance keeps the connection from P to T open when

no control unit is actuated in valve block 3.

It is closed by LS pressure. The LS pressure is built up when the master

valve (Y77-2) or a control unit in valve block 3 is actuated.

Pressure relief valve (764) The pressure relief valve limits the oil pressure to the wrapping arm motor

(234) and the wrapping table motor (drive) connected in series to

+10

115

bar.

Pressure relief valve (765) The pressure relief valve limits the oil pressure of the wrapping arm motor

(234) when decelerating.

Lower brake valve (766) The non-return valves 732-1/ 732-2 and the lower brake valve (766)

decelerate the wrapping arm motor (234) hydraulically on both sides if the

wrapping arm forward solenoid valve (Y133) is not energized.

Wrapping arm motor flow

controller (767)

The flow controller keeps the volume flow to the wrapping arm motor

(234) constant.

Maximum wrapping speed (approx. 20 l/min.) with SAM wrapping arm

motor.

Maximum wrapping speed (approx. 31 l/min.) with Danfoss wrapping arm

motor.

LS signal shuttle valves

(768)

When operating the control valves in parallel mode, the shuttle valves

allow sending the highest load pressure to the input pressure balance

(763) in each case.

Film clamping cutters flow

divider (769)

The flow divider divides the oil flows for opening and closing the film

clamping cutters.

Master valve solenoid valve

Y77

The master valve solenoid valve is actuated automatically when a

hydraulic function is to be carried out on the baler. Now the pump flow is

directed into the LS line so that the pressure that builds up closes the

pressure balance (763).

11/04 UNI-h-Kap1 21

Page 22

Hydraulic System UNIWRAP TIC

Description of function:

Wrapping arm forward

solenoid valve (Y133)

The solenoid valve controls the wrapping arm hydraulic motor.

A wrapping arm motor flow controller (767) is provided in the volume flow

input and keeps the volume flow constant.

When the control unit is activated, this volume flow is pumped to the

hydraulic motor (234) which drives the wrapping arm with 28 … 30 rpm

max. The flow controller may be accessed via the screw plug at the

bottom of the control unit.

The rotational speed of the wrapping arm of 27 rpm ensures that the

wrapping process is shorter than the time required for producing the bale.

Wrapping arm reverse

solenoid valve (Y134)

The solenoid valve changes the direction of oil flow to the wrapping arm

motor (234) and consequently its sense of rotation.

Lower tipping cradle

The solenoid valve lowers the tipping cradle.

solenoid valve (Y135)

Raise tipping cradle

solenoid valve (Y136)

The solenoid valve raises the tipping cradle. The lock-up valve unit (734)

avoids lowering of the raised tipping cradle.

Lower wrapping table

solenoid valve (Y137)

The solenoid valve lowers the wrapping table. The lock-up valve unit

(734) in the cylinder line avoids lowering of the loaded wrapping table.

Raise wrapping table

The solenoid valve raises the wrapping table.

solenoid valve (Y138)

Open film cutters solenoid

valve (Y139)

The solenoid valve opens both film cutters.

The wrapping table raise solenoid coil (Y138) is actuated simultaneously

with solenoid coils (Y139). This is necessary in order to build up pressure

in the LS line to make the input pressure balance (763) close.

Close film cutters solenoid

valve (Y140)

The solenoid valve closes both film cutters.

The wrapping table raise solenoid coil (Y138) is actuated simultaneously

with solenoid coils (Y139). This is necessary in order to build up pressure

in the LS line to make the input pressure balance (763) close.

22 UNI-h-Kap1 11/04

Page 23

1.5

Hydraulic circuit diagram

- from serial no.: 72601047

- with valve combination (630, 706, 769)

- with 3-stage restrictor (645)

Page 24

Hydraulic System UNIWRAP TIC

1.5 Hydraulic circuit diagram from serial no.: 72601047, with valve combination (630, 706, 769),

with 3-stage restrictor (645)

Key to diagram:

1 Feed line

2 Return line

3 Valve block

4 Valve block

5 Valve block

6 Disc brake

7 Valve combination

8 Manifold

234 Wrapping arm motor

235 Wrapping table motor

374 Film clamping cutters hydraulic cylinder

375 Tipping cradle hydraulic cylinder

376 Wrapping table hydraulic cylinder

406 Orifice plate Ø 0.8 mm

410 Orifice plate Ø 1.5 mm

630 Wrapping table flow control valve

631 Tipping cradle shut-off valve

634 System screw

645 3-stage restrictor

706 Pressure relief valve

732 Non-return valve

734 Lock-up valve unit

763 Input pressure balance

764 Pressure relief valve (left) 115

+10

bar

765 Pressure relief valve (right)

766 Lower brake valve

767 Wrapping arm motor flow controller

768 LS signal shuttle valves

769 Film clamping cutters flow divider

Y77 Master valve solenoid valve

Y133 Wrapping arm motor forward solenoid valve

Y134 Wrapping arm motor reverse solenoid valve

Y135 Lower tipping cradle solenoid valve

Y136 Raise tipping cradle solenoid valve

Y137 Lower wrapping table solenoid valve

Y138 Raise wrapping table solenoid valve

Y139 Open film cutters solenoid valve

Y140 Close film cutters solenoid valve

24 UNI-h-Kap1 11/04

Page 25

TIC UNIWRAP Hydraulic System

Description of function:

Orifice plate (406)

Ø 0.8 mm

The orifice plate (406) Ø 0.8 mm avoids pressure build-up and

consequently uncontrolled movements of the wrapping arm motor (234).

Wrapping table flow control

valve (630)

The wrapping table flow control valve supplies the hydraulic motor (235)

via output (A).

This volume flow can be adjusted and changes the wrapping table motor /

wrapping arm motor speed ratio and consequently the film layer overlaps.

Tipping cradle shut-off valve

(631)

During service work, the tipping cradle shut-off valve shuts off the oil flow

from the hydraulic cylinders 375.

Pressure relief valve (706) The pressure relief valve limits the pressure to 70 bar when lowering the

tipping cradle hydraulic cylinders.

Non-return valve (732-3) The non-return valve avoids faulty functions of the film clamping cutters

by building up pressure in the T line.

Input pressure balance

(763)

The input pressure balance keeps the connection from P to T open when

no control unit is actuated in valve block 3.

It is closed by LS pressure. The LS pressure is built up when the master

valve (Y77-2) or a control unit in valve block 3 is actuated.

Pressure relief valve (764) The pressure relief valve limits the oil pressure to the wrapping arm motor

(234) and the wrapping table motor (drive) connected in series to

+10

115

bar.

Pressure relief valve (765) The pressure relief valve limits the oil pressure of the wrapping arm motor

(234) when decelerating.

Lower brake valve (766) The non-return valves 732-1/ 732-2 and the lower brake valve (766)

decelerate the wrapping arm motor (234) hydraulically on both sides if the

wrapping arm forward solenoid valve (Y133) is not energized.

Wrapping arm motor flow

controller (767)

The flow controller keeps the volume flow to the wrapping arm motor

(234) constant.

Maximum wrapping speed (approx. 20 l/min.) with SAM wrapping arm

motor.

Maximum wrapping speed (approx. 31 l/min.) with Danfoss wrapping arm

motor.

LS signal shuttle valves

(768)

When operating the control valves in parallel mode, the shuttle valves

allow sending the highest load pressure to the input pressure balance

(763) in each case.

Film clamping cutters flow

divider (769)

The flow divider divides the oil flows for opening and closing the film

clamping cutters.

Master valve solenoid valve

(Y77)

The master valve solenoid valve is actuated automatically when a

hydraulic function is to be carried out on the baler. Now the pump flow is

directed into the LS line so that the pressure that builds up closes the

pressure balance (763).

11/04 UNI-h-Kap1 25

Page 26

Hydraulic System UNIWRAP TIC

Description of function:

Wrapping arm forward

solenoid valve (Y133)

The solenoid valve controls the wrapping arm hydraulic motor.

A wrapping arm motor flow controller (767) is provided in the volume flow

input and keeps the volume flow constant.

When the control unit is activated, this volume flow is pumped to the

hydraulic motor (234) which drives the wrapping arm with 28 … 30 rpm

max. The flow controller may be accessed via the screw plug at the

bottom of the control unit.

The rotational speed of the wrapping arm of 27 rpm ensures that the

wrapping process is shorter than the time required for producing the bale.

Wrapping arm reverse

solenoid valve (Y134)

The solenoid valve changes the direction of oil flow to the wrapping arm

motor (234) and consequently its sense of rotation.

Lower tipping cradle

The solenoid valve lowers the tipping cradle.

solenoid valve (Y135)

Raise tipping cradle

solenoid valve (Y136)

The solenoid valve raises the tipping cradle. The lock-up valve unit (734)

avoids lowering of the raised tipping cradle.

Lower wrapping table

solenoid valve (Y137)

The solenoid valve lowers the wrapping table. The lock-up valve unit

(734) in the cylinder line avoids lowering of the loaded wrapping table.

Raise wrapping table

The solenoid valve raises the wrapping table.

solenoid valve (Y138)

Open film cutters solenoid

valve (Y139)

The solenoid valve opens both film cutters.

The wrapping table raise solenoid coil (Y138) is actuated simultaneously

with solenoid coils (Y139). This is necessary in order to build up pressure

in the LS line to make the input pressure balance (763) close.

Close film cutters solenoid

valve (Y140)

The solenoid valve closes both film cutters.

The wrapping table raise solenoid coil (Y138) is actuated simultaneously

with solenoid coils (Y139). This is necessary in order to build up pressure

in the LS line to make the input pressure balance (763) close.

3-stage restrictor (645) To enable raising and lowering the wrapping table at different speeds, the

respective speed may be preselected using the 3-stage restrictor, see

chapter 4-15.

26 UNI-h-Kap1 11/04

Page 27

TIC UNIWRAP Hydraulic System

2

Pre-conditions for use

2.1 Blocking the master valve (Y77) .....................................................28

2.2 Connection to tractor hydraulic system...........................................29

11/04 UNI-h-Kap2 27

Page 28

Hydraulic System UNIWRAP TIC

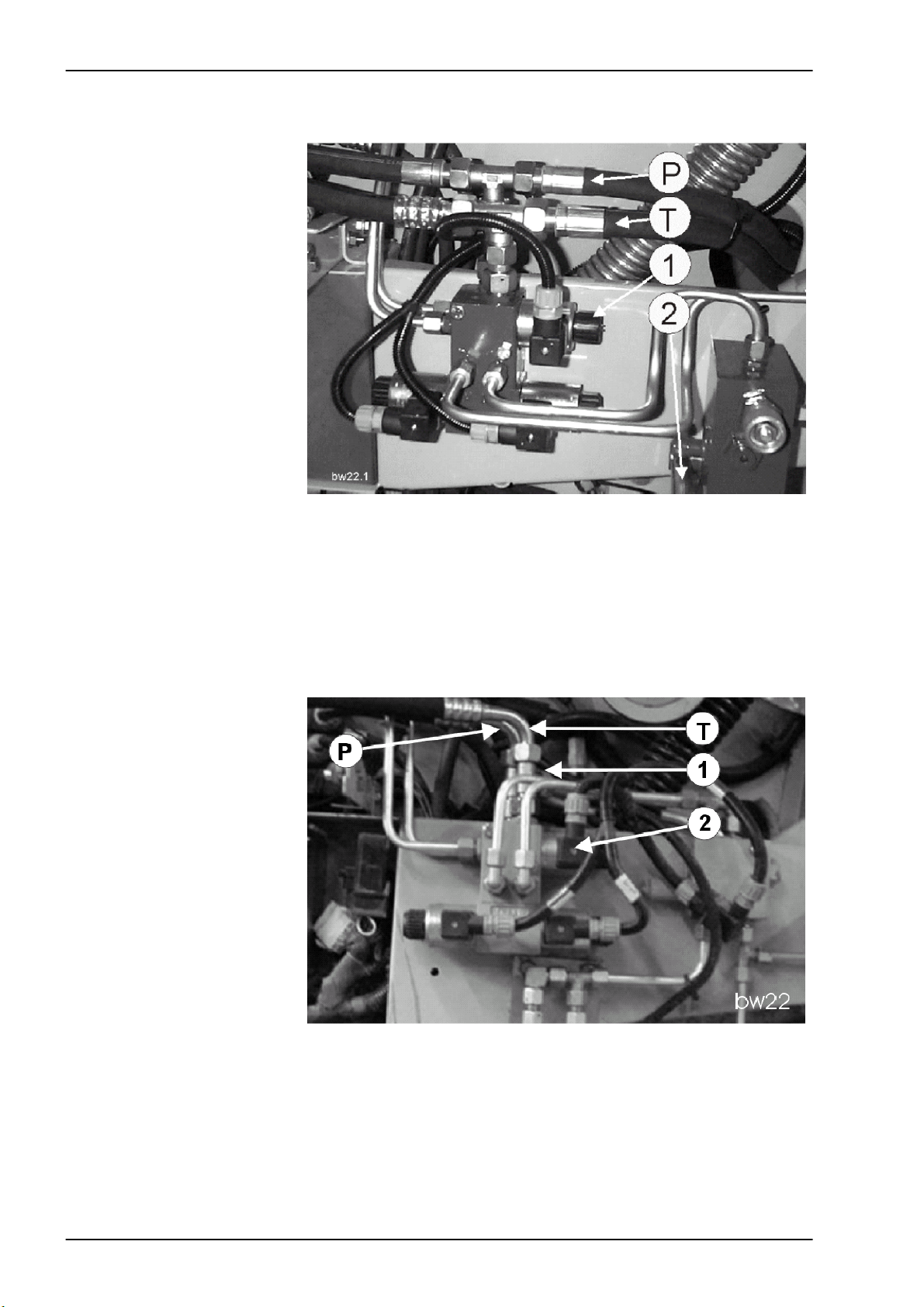

2.1

Blocking the master

valve (Y77)

From serial no.

Up to machine no.

1 Circulation shut-off valve solenoid coil (Y77-1)

Caution: The screw must be turned in.

The circulation shut-off valve is now permanently shut off.

2 Hand lever.

Horizontally (to the outside) = Working position

Vertically (to the bottom) = The tailgate is safeguarded in

open position (for service work)

P Feed line to UNIWRAP.

T Return line from UNIWRAP.

28 UNI-h-Kap1 11/04

1 Tee

2 Circulation shut-off valve solenoid coil (Y77-1)

P Feed line to UNIWRAP.

T Return line from UNIWRAP.

Page 29

TIC UNIWRAP Hydraulic System

2.2 Connection to tractor hydraulic system

Description of function: 1/2

The attachment can be connected to any tractor hydraulic system

available on the market.

Connection to tractors with

constant-flow hydraulic

system

The quick release coupling 1 is connected to a control unit port of the

tractor with adjustable oil flow.

This control unit provides oil supply for the attachment and is adjusted to

a constant volume flow of Q

The system screw 634 is turned out up to the stop so that the input

pressure balance 763 is operative.

The quick release coupling 2 is in general connected to the pressureless

return line T of the tractor.

If a pressureless return line is not allowed in continuous operation (e.g.

because lubrication of the tractor gearbox is not guaranteed), a doubleacting control unit can be used for supplying oil to the attachment.

In this case, the quick release coupling 1 is connected to port A (feed) and

quick release coupling 2 to port B (return) of the corresponding tractor

control valve.

Adjust the volume flow to Q

tractor's Operating Manual (e.g. "Continuous operation of hydraulic

motors").

The LS connection (LS, working hydraulics signal) is not used here.

If the tractor is not provided with a flow-adjustable control unit, the volume

flow must not exceed 35 to 50 l/min.

Connection to tractors with

constant-pressure hydraulic

system

The quick release coupling 1 is connected to a control unit port of the

tractor with adjustable oil flow.

This control unit provides oil supply for the attachment and is adjusted to

an oil flow of Q

= 35 to 50 l/min.

max

The system screw 634 is turned in up to the stop so that the input

pressure balance 763 is blocked.

The tractor's hydraulic pump is shut down when the system pressure has

been reached.

The quick release coupling 2 is connected to port T (pressureless return

line) of the tractor.

The LS connection (LS, working hydraulics signal) is not used here.

= 35 to 50 l/min.

max

= 35 to 50 l/min; please refer also to the

max

11/04 UNI-h-Kap2 29

Page 30

Hydraulic System UNIWRAP TIC

Description of function: 2/2

Connection to tractors with

load-sensing system and a

Power Beyond port

Test points/characteristics When no function is active on the attachment, the attachment must not

Connection to tractors with

load-sensing system without

a Power Beyond port

The quick release coupling 1 is connected directly to the pump via the

Power Beyond port P.

The quick release coupling 2 is connected to port T (pressureless return

line) of the tractor.

Here the LS connection (LS, working hydraulics signal) is connected with

the LS signal port of the tractor (the kit is available from the spare parts

department).

The system screw 634 is turned in up to the stop so that the input

pressure balance 763 is blocked.

The tractor's hydraulic pump regulates as a function of the attachment's

load signal.

load the tractor hydraulically.

(The tractor engine speed must not be reduced).

The allowed temperature of the tractor's hydraulic system must not be

exceeded; see also the Operator's Manual of the tractor.

The quick release coupling 1 is connected to a control unit port of the

tractor with adjustable oil flow.

This control unit provides oil supply for the attachment and is adjusted to

a constant volume flow of Q

= 35 to 50 l/min.

max

The system screw 634 is turned out up to the stop so that the input

pressure balance 763 is operative.

The quick release coupling 2 is in general connected to the pressureless

return line T of the tractor.

If a pressureless return line is not allowed in continuous operation (e.g.

because lubrication of the tractor gearbox is not guaranteed), a doubleacting control unit can be used for supplying oil to the attachment.

In this case, the quick release coupling 1 is connected to port A (feed) and

quick release coupling 2 to port B (return) of the corresponding tractor

control valve.

Adjust the volume flow to Q

= 35 to 50 l/min; please refer also to the

max

tractor's Operating Manual (e.g. "Continuous operation of hydraulic

motors").

The LS connection (LS, working hydraulics signal) is not used here.

If the tractor is not provided with a flow-adjustable control unit, the volume

flow must not exceed 35 to 50 l/min.

30 UNI-h-Kap1 11/04

Page 31

TIC UNIWRAP Hydraulic System

3

Valve block

3.1 Valve block, up to machine no. 130 ................................................34

3.2 Valve block - from machine no. 131,

with tipping cradle service shut-off valve (631) ...............................38

11/04 UNI-h-Kap3 31

Page 32

Hydraulic System UNIWRAP TIC

32 UNI-h-Kap3 11/04

Page 33

3.1

Valve block

- up to machine no. 130

Page 34

Hydraulic System UNIWRAP TIC

3.1 Valve block, up to machine no. 130

34 UNI-h-Kap3 11/04

Page 35

TIC UNIWRAP Hydraulic System

Key to diagram:

F Screw plug

Access to flow controller.

Note: Screw plug F must not protrude.

P Pump (supply line)

T Return line (tank)

3a Intermediate plate

763 Input pressure balance

767 Wrapping arm motor flow controller

768 LS signal shuttle valves

Y77 Master valve solenoid valve

Y133 Wrapping arm motor forward solenoid valve

Y135 Lower tipping cradle solenoid valve

Y136 Raise tipping cradle solenoid valve

Y137 Lower wrapping table solenoid valve

Y138 Raise wrapping table solenoid valve

11/04 UNI-h-Kap3 35

Page 36

Hydraulic System UNIWRAP TIC

Description of function:

Intermediate plate (3a) A connection from P to T is open in the intermediate plate.

The LS connection is closed.

Input pressure balance

(763)

The input pressure balance keeps the connection from P to T open when

no control unit is actuated in valve block 3.

It is closed by LS pressure. The LS pressure is built up when the master

valve (Y77-2) or a control unit in valve block 3 is actuated.

Wrapping arm motor flow

controller (767)

The flow controller keeps the volume flow to the wrapping arm motor

(234) constant.

Maximum wrapping speed (approx. 20 l/min.) with SAM wrapping arm

motor.

Maximum wrapping speed (approx. 31 l/min.) with Danfoss wrapping arm

motor.

LS signal shuttle valves

(768)

When operating the control valves in parallel mode, the shuttle valves

allow sending the highest load pressure to the input pressure balance

(763) in each case.

Master valve solenoid valve

(Y77)

The master valve solenoid valve is actuated automatically when a

hydraulic function is to be carried out on the baler.

Now the pump flow is directed into the LS line so that the pressure that

builds up closes the pressure balance (763). Now the entire volume flow

of the baler is available for performing hydraulic functions.

Wrapping arm forward

solenoid valve (Y133)

Controls the wrapping arm hydraulic motor.

A flow control valve is provided in the volume flow input which limits the

volume flow to approx. 20l/min on the SAM wrapping arm motor or

approx. 31l/min on the Danfoss wrapping arm motor. When the control

unit is activated, this volume flow is pumped to the wrapping arm motor

(234) which drives the wrapping arm with 28 ... 30 rpm max.

The flow controller may be accessed via the screw plug (F) at the bottom

of the control unit.

If required, adjust the maximum rotational speed of the wrapping arm

between 28 ... 30 rpm by carefully turning in or our the screw.

Screw plug (F) must not protrude. The rotational speed of 28 ... 30 rpm

ensures that the wrapping process is shorter than the time required for

producing the bale.

Lower tipping cradle

The solenoid valve lowers the tipping cradle.

solenoid valve (Y135)

Raise tipping cradle

solenoid valve (Y136)

The solenoid valve raises the tipping cradle. The lock-up valve unit 734

avoids lowering of the raised tipping cradle.

Lower wrapping table

solenoid valve (Y137)

The solenoid valve lowers the wrapping table. The lock-up valve unit 734

in the cylinder line avoids lowering of the loaded wrapping table.

Raise wrapping table

The solenoid valve raises the wrapping table.

solenoid valve (Y138)

36 UNI-h-Kap3 11/04

Page 37

3.2

Valve block

- from machine no. 131

- with tipping cradle service shut-off valve (631)

Page 38

Hydraulic System UNIWRAP TIC

3.2 Valve block - from machine no. 131, with tipping cradle service shut-off valve (631)

38 UNI-h-Kap3 11/04

Page 39

TIC UNIWRAP Hydraulic System

Key to diagram:

F Screw plug

Access to flow controller.

Note: Screw plug F must not protrude.

P Pump (supply line)

T Return line (tank)

3a Intermediate plate

763 Input pressure balance

767 Wrapping arm motor flow controller

768 LS signal shuttle valves

Y77 Master valve solenoid valve

Y133 Wrapping arm motor forward solenoid valve

Y135 Lower tipping cradle solenoid valve

Y136 Raise tipping cradle solenoid valve

Y137 Lower wrapping table solenoid valve

Y138 Raise wrapping table solenoid valve

11/04 UNI-h-Kap3 39

Page 40

Hydraulic System UNIWRAP TIC

Description of function:

Intermediate plate (3a) A connection from P to T is open in the intermediate plate.

The LS connection is closed.

Input pressure balance

(763)

The input pressure balance keeps the connection from P to T open when

no control unit is actuated in valve block 3.

It is closed by LS pressure. The LS pressure is built up when the master

valve (Y77-2) or a control unit in valve block 3 is actuated.

Wrapping arm motor flow

controller (767)

The flow controller keeps the volume flow to the wrapping arm motor

(234) constant.

Maximum wrapping speed (approx. 20 l/min.) with SAM wrapping arm

motor.

Maximum wrapping speed (approx. 31 l/min.) with Danfoss wrapping arm

motor.

LS signal shuttle valves

(768)

When operating the control valves in parallel mode, the shuttle valves

allow sending the highest load pressure to the input pressure balance

(763) in each case.

Master valve solenoid valve

(Y77)

The master valve solenoid valve is actuated automatically when a

hydraulic function is to be carried out on the baler.

Now the pump flow is directed into the LS line so that the pressure that

builds up closes the pressure balance (763). Now the entire volume flow

of the baler is available for performing hydraulic functions.

Wrapping arm forward

solenoid valve (Y133)

Controls the wrapping arm hydraulic motor.

A flow control valve is provided in the volume flow input which limits the

volume flow to approx. 20 l/min on the SAM wrapping arm motor or

approx. 31l/min on the Danfoss wrapping arm motor. When the control

unit is activated, this volume flow is pumped to the wrapping arm motor

(234) which drives the wrapping arm with 28 ... 30 rpm max.

The flow controller may be accessed via the screw plug (F) at the bottom

of the control unit.

If required, adjust the maximum rotational speed of the wrapping arm

between 28 ... 30 rpm by carefully turning in or our the screw.

Screw plug (F) must not protrude. The rotational speed of 28 ... 30 rpm

ensures that the wrapping process is shorter than the time required for

producing the bale.

Lower tipping cradle

The solenoid valve lowers the tipping cradle.

solenoid valve (Y135)

Raise tipping cradle

solenoid valve (Y136)

The solenoid valve raises the tipping cradle. The lock-up valve unit 734

avoids lowering of the raised tipping cradle.

Lower wrapping table

solenoid valve (Y137)

The solenoid valve lowers the wrapping table. The lock-up valve unit 734

in the cylinder line avoids lowering of the loaded wrapping table.

Raise wrapping table

The solenoid valve raises the wrapping table.

solenoid valve (Y138)

40 UNI-h-Kap3 11/04

Page 41

TIC UNIWRAP Hydraulic System

4

Individual components

4.1 Input pressure balance (763) ..........................................................42

4.2 Circulation shut-off valve (Y77-2)....................................................46

4.3 Wrapping arm control unit (Y133) ...................................................50

4.4 Tipping cradle control unit (Y135 / Y136)........................................54

4.4.1 Up to serial no.: with lock-up valve unit...............................54

4.4.2 From serial no.: without lock-up valve unit ..........................58

4.5 Wrapping table control unit (Y137 / Y138) ......................................62

4.6. Clamping cutters control unit (Y139 / Y140) ...................................66

4.7 Flow controller (630)........................................................................70

4.8 Pressure relief valve (706) ..............................................................74

4.9 Wrapping arm motor (234) ..............................................................76

4.10 Wrapping table motor (235).............................................................78

4.11 Tipping cradle service shut-off valve (631) .....................................80

4.12 Film clamping cutters hydraulic cylinder (374) ................................82

4.13 Film clamping cutters flow divider (769)..........................................84

4.14 Wrapping arm motor valve block (4) ...............................................90

4.15 3-stage restrictor .............................................................................92

4.16 Valve combination (7)......................................................................94

4.17 Manifold (8) .....................................................................................96

11/04 UNI-h-Kap4 41

Page 42

Hydraulic System UNIWRAP TIC

4.1 Input pressure balance (763)

42 UNI-h-Kap4 11/04

Page 43

TIC UNIWRAP Hydraulic System

Key to diagram:

P Channel pump

Volume flow input from the baler. Channel P continues through

each downstream control unit and is connected with the spool

in each case.

P1 Port. Supply of film cutter control unit

LS The LS channel is connected to each of the downstream

control units. Here the load pressure is applied when a control

unit is actuated.

T Return line (tank).

The channel T continues through each of the downstream

control units and is connected with the spool in each case.

T1 Port.

Return line input from the film cutter control unit.

1 Control ram

The compression spring pushes it to the left-hand stop when no

volume flow is flowing.

3 Bore

It connects the LS channel (load pressure) with the spring

space of the control ram.

634 System screw (option)

763 Input pressure balance

11/04 UNI-h-Kap4 43

Page 44

Hydraulic System UNIWRAP TIC

44 UNI-h-Kap4 11/04

Page 45

TIC UNIWRAP Hydraulic System

Description of function:

No volume flow flowing

The pressure spring pushes the control piston (1) to the left-hand stop.

The connection from P to T is closed.

Volume flow flowing – but

no control unit is actuated

The compression spring pushes the control ram (1) to its left-hand stop.

The connection from P to T is closed.

Volume flow enters the pressure balance via channel P (from the tractor

via the baler) and flows to each of the downstream control units. Since no

control unit is actuated, each spool shuts off the volume flow.

This builds up pressure which acts on the left-hand face end of the

control piston (1) and moves it to the right against the pressure spring.

Now the connection from P to T is opened so that the volume flow flows

back to the baler.

At the same time, a partial volume flow flows via the orifice plate (inside

the control piston) into the spring space of the control piston. The spring

space is pressureless because it is connected with the channel (LS) via

bore (3). This channel is pressureless, too, because no control unit is

actuated.

A pressure difference (∆p) of 9 bar results at the control piston because:

pressure ahead of the control piston = 9 bar

pressure in the spring space = 0 bar

A control unit is actuated,

e.g. the tipping cradle is

raised.

When the corresponding control unit is actuated, volume flow flows via

channel P and the spool into the tipping cradle cylinders. The load

pressure now generated is directed into the control piston spring space

through the LS channel and via bore (3).

This pressure build-up moves the control piston (1) to the left, partly

closing the connection from P to T. This closing is necessary to make

volume flow available for raising the tipping cradle.

However, the control piston is pushed to the left only until the pressure

difference (∆p) of 9 bar is re-established. A part of the volume flow will

continue to flow back to the baler via channel T.

When the tipping cradle cylinders have moved up to their stop, the

pressure rises and is applied in the control piston spring space via the LS

channel and pushes the control piston to the left-hand stop. The pressure

inside channel P actuates the pressure relief valve on the tractor (the

baler and the UNIWRAP are supplied with volume flow from here).

11/04 UNI-h-Kap4 45

Page 46

Hydraulic System UNIWRAP TIC

4.2 Circulation shut-off valve (Y77-2)

46 UNI-h-Kap4 11/04

Page 47

TIC UNIWRAP Hydraulic System

Key to diagram:

P Channel pump

Volume flow input from the baler. Channel P continues through

each downstream control unit and is connected with the spool

in each case.

T Return line (tank).

The channel T continues through each of the downstream

control units and is connected with the spool in each case.

A Port.

The connection is closed.

B Port.

The connection is closed.

LS The LS channel is connected to each of the downstream

control units. Here the load pressure is applied when a control

unit is actuated.

1 Spool.

Actuated by solenoid valve (3).

2 Bore

in the spool. It is connected with the LS channel that ends at

the upstream input pressure balance.

Y77-2 Master valve solenoid valve

It actuates the spool (1).

768-1 LS signal shuttle valves

11/04 UNI-h-Kap4 47

Page 48

Hydraulic System UNIWRAP TIC

Description of function:

The circulation shut-off valve solenoid coil (Y77-2) is actuated whenever a

hydraulic function is to be carried out on the baler (e.g. open tailgate, raise

pick-up ...).

No volume flow flowing

Due to the two pressure springs located at the face end, spool (2) is

positioned so that (see figure):

- channel P is shut off at the spool

- ports A and B are connected with the tank

- bore (2) is connected with the tank.

Hydraulic requirement from

the baler

The UNIWRAP electronics module actuates circulation shut-off valve

solenoid coil (Y77-2). Solenoid coil (Y77-2) moves spool (1) to the lefthand stop, thus opening the connection from P to A. Since port A is

closed, pressure is built up which then is applied in the LS channel via

bore (2) and LS signal shuttle valve (768-1). This pressure signal is

directed to the upstream input pressure balance (763) via the LS

channel.The pressure balance (763) switches over and shuts off the

connection from P to T which had been open so far. The volume flow is

now available to the baler.

48 UNI-h-Kap4 11/04

Page 49

TIC UNIWRAP Hydraulic System

11/04 UNI-h-Kap4 49

Page 50

Hydraulic System UNIWRAP TIC

4.3 Wrapping arm control unit (Y133)

50 UNI-h-Kap4 11/04

Page 51

TIC UNIWRAP Hydraulic System

Key to diagram:

P Channel pump

Volume flow input from the baler. Channel P continues through

each downstream control unit and is connected with the spool

in each case.

T Return line (tank)

The channel T continues through each of the downstream

control units and is connected with the spool in each case.

LS The LS channel is connected to each of the downstream

control units.

When the wrapping arm rotates, the load pressure acts here.

This pressure signal ends in the input pressure balance.

A Port

The wrapping arm hydraulic motor is connected here.

B Port

The connection is closed.

1 Spool

Actuated by solenoid valve (6).

2 Bore

In the spool, senses the load pressure in port A. Is connected

with the LS channel which ends in the input pressure balance.

3 2-way flow controller

It limits the max. volume flow to the wrapping arm motor to

20 l/min, resulting in a wrapping arm speed of 28 ... 30 l/min.

3a Orifice plate

3b Connection

Is a spiral groove which directs the load pressure from

port A (wrapping arm hydraulic motor) into the spring

space.

4 Spring support

This allows changing the spring force.

767 Wrapping arm motor flow controller

768-2 LS signal shuttle valve

Y133 Solenoid valve

- Is a proportional solenoid valve and actuates spool (1).

- Is actuated by the UNIWRAP electronics module.

11/04 UNI-h-Kap4 51

Page 52

Hydraulic System UNIWRAP TIC

Description of function:

No volume flow flowing Due to the two pressure springs located at the face end, spool (2) is

positioned so (see figure) that ports P and A are shut off.

Oil supply is available, but

control unit is not yet

actuated

The volume flow enters the control unit via channel P and flows through

orifice plate (3a) to spool (1).

Since the spool stops the flow, pressure is built up which acts on the

right-hand face end of the 2-way flow controller (3) and via connection

(3b) also in the spring space.

This compensates the pressure at the 2-way flow controller (3) which is

pushed to the right-hand stop by the pressure spring.

Control unit is actuated The speed of the hydraulic motor which drives the wrapping arm depends

on the amount of volume flow.

The higher the volume flow, the higher the motor speed. When the input

volume flow is constant, the hydraulic motor speed will be constant as

well.

When the wrapping arm starts, its speed is to be continuously increased

from 0 to 28 ... 30 rpm. To realise this start-up behaviour, the volume flow

to the hydraulic motor must be continuously increased.

The UNIWRAP electronics module actuates the solenoid coil (Y133) and

continuously increases its force which moves the spool (1) against the

pressure spring to the left.

This opens the connection from P to A continuously, thus constantly

increasing the volume flow and consequently the hydraulic motor speed.

When the solenoid coil (Y133) has moved the spool (1) fully to the left

against the pressure spring, the spool gap has reached its maximum

opening position.

In this position, the 2-way flow controller (767) regulates the volume flow

to approx. 20 l/min on the SAM wrapping arm motor or approx. 31 l/min

on the Danfoss wrapping arm motor, independently from the load.

This keeps the hydraulic motor speed constant.

52 UNI-h-Kap4 11/04

Page 53

TIC UNIWRAP Hydraulic System

Control behaviour When volume flow flows through the 2-way flow controller (767), different

pressure levels are generated:

- The pump pressure is applied ahead of the orifice plate (3a)

- The load pressure is applied behind the orifice plate (3a) via

connection (3b).

The pressure behind the orifice plate (3a) is lower than the pressure

ahead of the orifice plate. This pressure difference is referred to as ∆p.

The flow controller keeps this ∆p constant even when the load pressure

(in the spring space) changes. When ∆p is constant, the volume flow is

also constant.

Load pressure The load pressure generated is directed through the hollow-drilled spool

via bore (2), actuates the LS signal shuttle valve (768-2) and is then

transmitted into the LS channel which ends at the upstream input

pressure balance (763).

11/04 UNI-h-Kap4 53

Page 54

Hydraulic System UNIWRAP TIC

4.4 Tipping cradle control unit (Y135 / Y136)

4.4.1 Up to serial no.: with lock-up valve unit

54 UNI-h-Kap4 11/04

Page 55

TIC UNIWRAP Hydraulic System

Key to diagram:

P Channel pump

Volume flow input.

T Return line (tank)

LS LS channel.

When the tipping cradle is actuated, the load pressure acts

here. This pressure signal ends in the input pressure balance.

A Port

To the rod spaces of the hydraulic cylinders. The tipping cradle

is raised when pressure is built up.

B Port

To the piston spaces of the hydraulic cylinders. The tipping

cradle is lowered when pressure is built up.

1 Spool

Actuated by solenoid valve (6).

4 Ram

Opens the non-return valve (734-1) or (734-2)

734-1 Lock-up valve unit non-return valve

This seals off port A and is opened by ram (4).

734-2 Lock-up valve unit non-return valve

This seals off port B and is opened by ram (4).

768-3 LS signal shuttle valve

Y136 Raise tipping cradle solenoid valve

The solenoid valve moves the spool (1) to the left.

Y135 Lower tipping cradle solenoid valve

The solenoid valve moves the spool (1) to the right.

11/04 UNI-h-Kap4 55

Page 56

Hydraulic System UNIWRAP TIC

Description of function:

No volume flow flowing,

the solenoid valves are not

actuated.

Due to the two pressure springs located at the face end, spool (1) is

positioned so (see figure) that port P is shut off.

Ports A and B are sealed by the non-return valves.

Raise tipping cradle Solenoid coil (Y136) is actuated by the UNIWRAP electronics module and

moves spool (1) to the left.

Volume flow flows from channel P via the spool gap in front of the lock-up

valve unit non-return valve (734-1). Pressure is built up which:

- opens the lock-up valve unit non-return valve (734-1) and

- moves the piston (4) to the right.

The volume flow flows from port A via the open lock-up valve unit nonreturn valve (734-1) into the rod spaces of the hydraulic cylinders - the

tipping cradle is raised.

At the same time, the piston (4) is moved to the right and opens the lockup valve unit non-return valve (734-2). Port B (piston spaces of hydraulic

cylinders) is connected with the tank (T1) via the open lock-up valve unit

non-return valve (734-2) and spool (1).

Lower tipping cradle Solenoid coil (Y135) is actuated by the UNIWRAP electronics module and

moves spool (1) to the right.

Volume flow flows from channel P via the spool gap in front of the lock-up

valve unit non-return valve (734-2). Pressure is built up which:

- opens the lock-up valve unit non-return valve (734-2) and

- moves the piston (4) to the left.

The volume flow from port B flows via the open lock-up valve unit nonreturn valve (734-2) into the piston spaces of the hydraulic cylinders - the

tipping cradle is lowered.

At the same time, the piston (4) is moved to the left and opens the lockup valve unit non-return valve (734-1). Port A (rod spaces of the hydraulic

cylinders) is connected with the tank (T) via the open lock-up valve unit

non-return valve (734-1) and spool (1).

56 UNI-h-Kap4 11/04

Page 57

TIC UNIWRAP Hydraulic System

Notes:

11/04 UNI-h-Kap4 57

Page 58

Hydraulic System UNIWRAP TIC

4.4 Tipping cradle control unit (Y135 / Y136)

4.4.2 From serial no.: without lock-up valve unit

58 UNI-h-Kap4 11/04

Page 59

TIC UNIWRAP Hydraulic System

Key to diagram:

P Channel pump

Volume flow input.

T, T1 Return line (tank)

LS LS channel

When the tipping cradle is actuated, the load pressure acts

here. This pressure signal ends in the input pressure balance.

A Port

To the rod spaces of the hydraulic cylinders. The tipping cradle

is raised when pressure is built up.

B Port

To the piston spaces of the hydraulic cylinders. The tipping

cradle is lowered when pressure is built up.

1 Spool

Actuated by solenoid valve (6).

768-3 LS signal shuttle valve

Y136 Raise tipping cradle solenoid valve

The solenoid valve moves the spool (1) to the left.

Y135 Lower tipping cradle solenoid valve

The solenoid valve moves the spool (1) to the right.

11/04 UNI-h-Kap4 59

Page 60

Hydraulic System UNIWRAP TIC

Description of function:

No volume flow flowing,

the solenoid valves are not

Due to the two pressure springs located at the face end, spool (1) is

positioned so (see figure) that port P is shut off.

actuated.

Raise tipping cradle Solenoid coil (Y136) is actuated by the UNIWRAP electronics module and

moves spool (1) to the left.

Volume flow flows from channel P via the spool gap to port A and

continues into the rod spaces of the hydraulic cylinders – the tipping

cradle is raised.

At the same time, volume flow from the piston spaces of the hydraulic

cylinders flows via port B into the tank (T1).

Lower tipping cradle Solenoid coil (Y135) is actuated by the UNIWRAP electronics module and

moves spool (1) to the right.

Volume flow flows from channel P via the spool gap to port B and

continues into the piston spaces of the hydraulic cylinders – the tipping

cradle is lowered.

At the same time, the volume flow from the rod spaces of the hydraulic

cylinders flows via port A into the tank (T).

60 UNI-h-Kap4 11/04

Page 61

TIC UNIWRAP Hydraulic System

Notes:

11/04 UNI-h-Kap4 61

Page 62

Hydraulic System UNIWRAP TIC

4.5 Wrapping table control unit (Y137 / Y138)

62 UNI-h-Kap4 11/04

Page 63

TIC UNIWRAP Hydraulic System

Key to diagram:

P Channel pump

Volume flow input.

T, T1 Return line (tank)

LS LS channel

When the wrapping table is raised, the load pressure acts here.

This pressure signal ends in the input pressure balance.

A Port

Is closed.

B Port

To the rod spaces of the hydraulic cylinders. The wrapping

table is raised when pressure is built up.

1 Spool

Actuated by solenoid valve (6).

734-1 Lock-up valve unit non-return valve

This seals off port A and is opened by ram (4).

734-2 Lock-up valve unit non-return valve

This seals off port B and is opened by ram (4).

4 Ram

Opens the non-return valve (734-1) or (734-2)

768-4 LS signal shuttle valve

Y137 Lower wrapping table solenoid valve

The solenoid valve moves the spool (1) to the left.

Y138 Raise wrapping table solenoid valve

The solenoid valve moves the spool (1) to the right.

11/04 UNI-h-Kap4 63

Page 64

Hydraulic System UNIWRAP TIC

Description of function:

No volume flow flowing,

the solenoid valves are not

actuated.

Due to the two pressure springs located at the face end, spool (1) is

positioned so (see figure) that port P is shut off.

Port B is sealed by non-return valve (2).

Raise wrapping table Solenoid coil (Y138) is actuated by the UNIWRAP electronics module and

moves spool (1) to the right.

Volume flow flows from channel P via the spool gap in front of the lock-up

valve unit non-return valve (734-2). Pressure is built up which:

- opens the lock-up valve unit non-return valve (734-2) and

- moves the piston (4) to the left.

The volume flow flows via port B and via the open lock-up valve unit nonreturn valve (734-2) into the rod spaces of the hydraulic cylinders – the

wrapping table is raised.

Lower wrapping table Solenoid coil (Y137) is actuated by the UNIWRAP electronics module and

moves spool (1) to the left.

Volume flow flows from channel P via the spool gap in front of the lock-up

valve unit non-return valve (734-1). Pressure is built up which:

- opens the lock-up valve unit non-return valve (734-1)

(without importance here since port A is closed) and

- moves the piston (4) to the right.

The movement of the piston (4) to the right opens the lock-up valve unit

non-return valve (734-2). Port B (rod spaces of hydraulic cylinders) is

connected with the tank (T1) via the open lock-up valve unit non-return

valve (734-2) and the spool (1).

64 UNI-h-Kap4 11/04

Page 65

TIC UNIWRAP Hydraulic System

Notes:

11/04 UNI-h-Kap4 65

Page 66

Hydraulic System UNIWRAP TIC

4.6. Clamping cutters control unit (Y139 / Y140)

66 UNI-h-Kap4 11/04

Page 67

TIC UNIWRAP Hydraulic System

Key to diagram:

P Channel pump

Volume flow input.

T Return line (tank)

A Port

to the rod space of the right hydraulic cylinder.

B Port

to the ram space of the left hydraulic cylinder.

1 Ball

It is opened by the magnetic tappet (2).

When not energized, it closes port P.

2 Magnetic tappet

It is pushed down by the solenoid valve (Y139, Y140) and

opens ball (1).

7 Ram

Opens the non-return valve (734-1) or (734-2)

734-1 Lock-up valve unit non-return valve

This seals off port A and is opened by ram (4).

734-2 Lock-up valve unit non-return valve

This seals off port B and is opened by ram (4).

Y139 Open film cutters solenoid valve

is controlled by the UNIWRAP electronic module, actuates the

magnetic tappet (2) and thus opens the ball (1) = connection

from P to A.

Y140 Close film cutters solenoid valve

is controlled by the UNIWRAP electronic module, actuates the

magnetic tappet (2) and thus opens the ball (1) = connection

from P to B.

11/04 UNI-h-Kap4 67

Page 68

Hydraulic System UNIWRAP TIC

Description of function:

When de-energised, the balls (1) keep the pressure port P closed.

The load ports A and B are connected with tank T.

When a solenoid valve (Y139, Y140) is energized, the magnetic tappet

opens the ball (1) against the spring and the applied hydraulic pressure.

The connection from P to A or to B is released. At the same time, the ram

cone closes the feed line to the tank.

In this condition, a consumer connected to port “A” or “B” can perform

work.

After de-energizing solenoid valve (Y139, Y140), port A or B is relieved

again towards the tank.

68 UNI-h-Kap4 11/04

Page 69

TIC UNIWRAP Hydraulic System

Notes:

11/04 UNI-h-Kap4 69

Page 70

Hydraulic System UNIWRAP TIC

4.7 Flow controller (630)

Up to serial no.: 72601047

70 UNI-h-Kap4 11/04

Page 71

TIC UNIWRAP Hydraulic System

Key to diagram:

P Input for total volume flow = Return oil from wrapping arm

hydraulic motor (approx. 17 l/min)

A Port

Constant flow output to wrapping table hydraulic motor.

B Port

Residual flow output to tank.

E Adjusting screw

Adjusts the pre-stress of the pressure spring

1 Orifice plate

In the control piston (3), produces the pressure difference ∆p

which determines the constant flow at port A.

2 Control edge

Controls the passage to port B

3 Control piston

- is pushed to the left-hand stop by the pressure spring when

no volume flow is flowing

- is moved by the pressure difference Dp at the orifice plate (1)

when volume flow flows.

4 Bore

The constant flow to port A flows via this bore.

6 Connecting bore

Directs the pressure behind the orifice plate into the spring

space

630 Flow controller

Divides the total volume flow (port P) into:

- a constant flow (port A) which drives the wrapping table

hydraulic motor and

- a residual flow (port B) which is directed into the tank.

11/04 UNI-h-Kap4 71

Page 72

Hydraulic System UNIWRAP TIC

Description of function:

The total volume flow enters the flow controller via port P and flows

through the orifice plate (1).

Here the pressure difference ∆p appears. The pressure downstream of

the orifice plate (1) is lower than the pressure upstream of it.

The flow controller keeps this ∆p constant, even when the pressure in

port A changes. With a constant ∆p at the orifice plate (1), the volume

flow leaving via port A and driving the wrapping table hydraulic motor is

constant.

The constant flow at output A can be adjusted to up to 6 l/min. with

adjusting screw (E). This allows continuous adjustment of the speed of

wrapping table rollers between 19 to 25 rpm.

- Low speed = large film overlap;

- High speed = small film overlap.

72 UNI-h-Kap4 11/04

Page 73

TIC UNIWRAP Hydraulic System

11/04 UNI-h-Kap4 73

Page 74

Hydraulic System UNIWRAP TIC

4.8 Pressure relief valve (706)

74 UNI-h-Kap4 11/04

Page 75

TIC UNIWRAP Hydraulic System

Key to diagram:

Description of function:

The pressure relief valve limits the pressure when lowering the tipping

630 Flow controller

706 Pressure relief valve

cradle to 70 bar.

It is installed below the valve block.

11/04 UNI-h-Kap4 75

Page 76

Hydraulic System UNIWRAP TIC

4.9 Wrapping arm motor (234)

76 UNI-h-Kap4 11/04

Page 77

TIC UNIWRAP Hydraulic System

Key to diagram:

Description of function:

When the wrapping arm rotates, the brake is opened by compressed oil.

W Wrapping arm drive shaft

234 Wrapping arm hydraulic motor

B Brake

P Feed line

T Return line

Y134 Wrapping arm backward solenoid coil

V Valve block

L Leakage oil line

When the wrapping arm is at standstill, the brake is mechanically closed,

preventing wrapping arm rotation by hand.

11/04 UNI-h-Kap4 77

Page 78

Hydraulic System UNIWRAP TIC

4.10 Wrapping table motor (235)

78 UNI-h-Kap4 11/04

Page 79

TIC UNIWRAP Hydraulic System

Key to diagram:

235 Wrapping table motor

11/04 UNI-h-Kap4 79

Page 80

Hydraulic System UNIWRAP TIC

4.11 Tipping cradle service shut-off valve (631)

80 UNI-h-Kap4 11/04

Page 81

TIC UNIWRAP Hydraulic System

Key to diagram:

Description of function:

The Tipping cradle service shut-off valve 631 is mounted directly on the

631 Tipping cradle service shut-off valve

control unit port.

For service work, the raised tipping cradle can be secured with the shutoff valve.

11/04 UNI-h-Kap4 81

Page 82

Hydraulic System UNIWRAP TIC

4.12 Film clamping cutters hydraulic cylinder (374)

82 UNI-h-Kap4 11/04

Page 83

TIC UNIWRAP Hydraulic System

Key to diagram:

Description of function:

The hydraulic cylinders are connected in series.

Non-return valves (628) The non-return valves 628 at the bottom of the rams are not opened

Bleeding the hydraulic

cylinders

When the cylinders are extended, the rings R open the non-return valves

374 Film clamping cutters hydraulic cylinder

628 Non-return valve

A Ram space port

B Rod space port

K Ram

R Ring

The film cutter cylinders extend when hydraulic pressure is applied at

port A.

The film cutter cylinders retract when hydraulic pressure is applied at

port B.

mechanically when the hydraulic cylinders are retracted.

628 at the top of the rams.