Page 1

Željko Nastasic´ —

Gábor Deák Jahn

The Citroën

Technical Guide

Page 2

There are many car manufacturers, makes, models

and versions on the road today but—as we all

know—none of them compares to Citroën in its

engineering excellence, especially regarding

suspension comfort, roadholding, and stability.

In this book we tried to describe how the various

subsystems work. We never intended to replace

service manuals or similar technical instructions.

Illustrations are schematic, focusing on the

principles of operation rather than on minute

details of implementation.

This guide is not linked to any specific Citroën

model but describes all systems and solutions

used on a large number of cars from the glorious

line of DS, ID, CX, GS, GSA, BX, XM, Xantia, Xsara

and the C5.

Page 3

Table of Contents

Fuel Injection

Electronic Fuel Injection . . . . . . . . . . . . . . . 5

Diesel engines . . . . . . . . . . . . . . . . . . . 10

Electronic Diesel Control . . . . . . . . . . . . . . 15

Diesel Direct Injection . . . . . . . . . . . . . . . 17

Suspension

A Suspension Primer. . . . . . . . . . . . . . . . 19

Hydropneumatic Suspension . . . . . . . . . . . 20

Hydractive I . . . . . . . . . . . . . . . . . . . . 24

Hydractive II . . . . . . . . . . . . . . . . . . . . 29

Anti-sink system. . . . . . . . . . . . . . . . . . 32

Activa Suspension . . . . . . . . . . . . . . . . . 33

Hydractive 3. . . . . . . . . . . . . . . . . . . . 35

Steering

Power Assisted Steering . . . . . . . . . . . . . . 38

DIRAVI Steering . . . . . . . . . . . . . . . . . . 40

Self-steering Rear . . . . . . . . . . . . . . . . . 42

Brakes

Standard braking system. . . . . . . . . . . . . . 44

Anti-lock Braking System. . . . . . . . . . . . . . 45

Electrical Systems

Multiplex network . . . . . . . . . . . . . . . . . 47

Air Conditioning

Air conditioning . . . . . . . . . . . . . . . . . . 50

Appendix

ORGA number . . . . . . . . . . . . . . . . . . 53

Index

Page 4

Fuel Injection

Page 5

The Citroën Guide Fuel Injection: Electronic Fuel Injection 5

U

Electronic Fuel Injection

The Otto engine needs a mixture of fuel and air

for its operation. It would be the task of the fuel

supply—carburetor or injection—to provide the

engine with the ideal mixture. Unfortunately,

there is no such thing as an ideal mixture.

Perfect combustion, as chemistry calls it, would require air

and fuel in proportion of 14.7 parts to 1 (this is the

stochiometric ratio). While this might be satisfactory for the

scientists, the real-life conditions of a vehicle call for slightly

different characteristics.

We use the ratio of actual mixture to the stochiometric

mixture, called lambda (l), to describe the composition of

the mixture entering the engine: l=1 denotes the chemi

cally ideal mixture, l<1 means rich, l>1 is lean.

The best performance would require a slightly rich mix

ture, with the lambda around 0.9, while fuel economy

would need a slightly lean one, between 1.1 and 1.3. Some

harmful components in exhaust gas would reduce in quan

tity between lambda values of 1 to 1.2, others below 0.8 or

above 1.4. And if this is not yet enough, a cold engine re

quires a very rich mixture to keep running. After warming

Fuel injection

up, the mixture can return to normal, but the temperature

of the incoming air still plays a significant role: the cooler

the air, the denser it becomes, and this influences the

lambda ratio as well.

All these requirements are impossible to satisfy with sim

pler mechanical devices like carburetors. Electronic fuel in

jection provides a system that can measure the many cir

cumstances the engine is operating in and decide on the

amount of fuel (in other words, the lambda ratio) entering

the engine. By carefully adjusting the internal rules of this

device, manufacturers can adapt the characteristic of the

fuel injection to the actual requirements: a sporty GTi

would demand rather different settings than a city car; be

sides, catalytic converters have their own demands that, as

we will later see, upset the applecart quite vehemently.

Earlier, fuel injection systems only knew about fuel, the

ignition was supplied by traditional methods. Later on,

these systems (now called engine management systems)

took on the duty of generating the sparks as well. But even

with this second incarnation, the fuel injection part re

mained practically the same, thus the following section ap

plies to both kind of systems.

-

-

-

-

-

-

The two most important inputs describing the actual oper

ating condition of the engine, thus determining the fuel de

mand are the engine speed (revolution) and engine

load. The engine speed can be measured easily on systems

using traditional ignition: the ignition primary circuit gener

ates pulses with their frequency proportional to engine

speed (the tachometer uses this same signal to show the

rpm to the driver). When the injection system provides the

ignition as well, it cannot at the same time rely on it, so an

additional sensor is used instead.

The engine load is usually determined by measuring the

quantity of air the engine tries to suck in. There are various

methods of attaining this: earlier systems used a flap which

is deflected by the air flowing through the sensor—the an

gle of deflection is proportional to the amount of air pass

ing through (air flow sensor, AFS). Later systems used a

pressure sensor measuring the pressure inside the inlet man

ifold (manifold absolute pressure, MAP sensor). Yet an

other system (although not used on Citroëns) heats a plati

num wire and lets the incoming air passing around cool it;

by measuring the current needed to keep the wire tempera

ture at a constant value above the temperature of the in

coming air, the mass of air can be determined. Some sim

pler systems do not even measure the amount of air but use

a pre-stored table in their computer to approximate it

based upon the engine speed and the position of the throt

tle pedal—not that accurate but certainly much cheaper.

Under ideal conditions, these two inputs would already

be enough to control the engine. A large table can be set

-

-

-

Amount of fuel

injected

idle 33…3

850 rpm 45…5

900 rpm 56…7

… …………

Engine speed

6,000 rpm 98…10

Engine load

0% 5% … 100%

up, like the one il

lustrated here (of

course, this is an il

lustration only, the

actual values mean

nothing here), and

for any pair of in

coming engine speed and load values the necessary fuel

amount can be determined. By keeping the pressure of fuel

constant behind the injector valves, the amount of fuel in

jected depends solely on the time period the injectors are

opened for, hence, the table can contain injector opening

times.

-

An this is exactly how it is done in modern injection sys

-

tems: the controlling microcomputer keeps a lookup table

like this to determine the base pulse width. Earlier systems

-

were constructed from discrete, analog elements, not like a

-

small computer; a more or less equivalent circuit made of

-

various hybrid resistance arrays and semiconductors were

used for the same purpose.

-

Chip tuning, by the way, is the simple operation of replac

-

ing the said table with another one, yielding different char

-

acteristics (usually to gain power, allowing for worse fuel

economy). As the computer stores this table in a program

mable memory—similar in function to the BIOS in desktop

-

computers—, replacing it is possible. The earlier systems

with analog circuits cannot be modified that easily.

So, we obtained the base pulse width from the table but

as the operating conditions of automotive engines are

-

-

-

-

-

-

-

-

Page 6

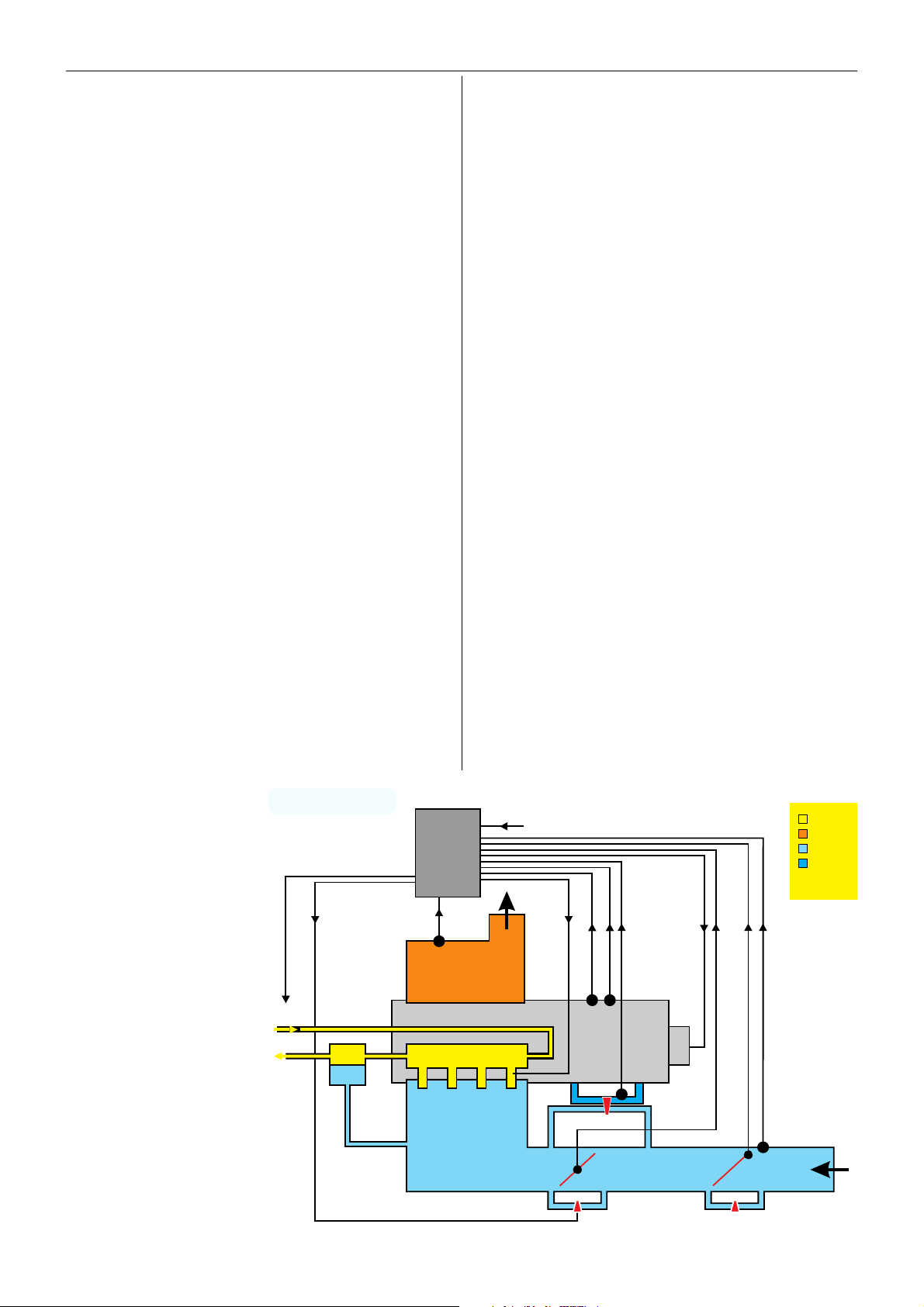

The Citroën Guide Fuel Injection: Electronic Fuel Injection 6

distributor

O

S*

engine

ECU

fuel

pump

CTS

MAPATS* TP

throttle

ISCM

fuel

i

njector &

pressure

regulator

ATS*

fuel

exhaust

air

coolant

not present

in all systems

*

EFI M ONOPOINT

distributor

fuel

exhaust

air

coolant

not present

in all systems

*

OS*

engine

pressure

regulator

ECU

fuel

pump

CTS

AFS ATSTS

AAV

throttle

idle speed idle mixture

fuel

injectors

fuel rail

CSV*

EFI M ULTIPOINT

U

hardly ideal for any reasonable amount of time, several cor

rections have to be applied. Our air flow meter measures

the volume of the air but we would need to know the mass

of the air to calculate the required lambda ratio—remem

ber, colder air is denser, thus the same volume contains

more gas, requiring more fuel to provide the same mixture.

To accomplish this, the injection system uses an air temper-

ature sensor (ATS)—although on some systems it mea

sures not the air but the fuel-air mixture—and lengthens

the injector pulse width according to this input (except for

the case of the airflow meter using a heated wire, this one

takes the air temperature into account automatically, conse

quently, there is no need for correction).

circumstances that require

special consideration. While

most of the time an engine

works under partial load, so it

makes sense to spare fuel by

basing on a relatively leaner

mixture across this range of

operation, cold start and

warm-up, modest decelera

tion and fully depressed throt

tle, idle speed all require dif

ferent treatment.

pedal is communicated to the

computer by a throttle posi

tion switch (TS) or throttle

potentiometer (TP). These

devices signal both fully open

and fully closed (idling) throt

tle positions. When the pedal

is fully depressed, the com

puter makes the mixture

richer to provide good acceler

ation performance.

It is not only the external

The position of the throttle

Idle speed is more compli

cated: the throttle is closed,

so there has to be a bypass to

let the engine receive fuel to

run. In simpler systems this by

pass is constant (but manu

ally adjustable to set the cor

rect idle speed) in a warm en

-

-

-

gine, providing a fixed

amount of air, although the

computer can decide on a

varying amount of fuel to be

injected. Later systems gener

ally use a controlling device

changing the cross section of

the bypass, regulating the

amount of air coming

through (these systems often

have no facility to adjust the

idle speed, the computer

knows the correct revolution

and maintains it without any

help from mechanical de

vices). The controlling device

can either be an idle speed control valve (ISCV) or an

-

idle control stepper motor (ICSM). The first one can

only open or close the idle bypass, so any regulation must

be done by rapidly opening and closing it by the computer,

the second one can gradually change the bypass, hence

fine tuning is easier and smoother.

Just like the choke on carburetors, there is a complete

subsystem dealing with cold start and warm up, as the re

-

quirements under such circumstances are so different from

the normal operation that they cannot be fulfilled by the

regular control. The ECU monitors the ignition key

-

switch to learn when the engine is started, then looks for

the input from the coolant temperature sensor (CTS) to

-

-

-

-

-

-

-

Page 7

The Citroën Guide Fuel Injection: Electronic Fuel Injection 7

distributor

O

S*

engine

ECU

CTS

MAPATS* TP

throttle

ISCM

CAS

fuel

exhaust

air

coolant

not present

in all systems

*

fuel

pump

fuel

i

njector &

pressure

regulator

ATS*

EMS MONOPOINT

U

see whether this is a cold start or a warm one. If the coolant

fluid is measured cold, a special warm-up sequence will be

started.

The engine needs significantly more fuel, a richer mix

ture during this period. This extra fuel is used for two pur

poses: first, part of the fuel injected is condensed on the

cold walls of the engine, second, to ensure better lubrication, the engine should run at an elevated revolution during

this period.

There are two ways to provide more fuel: through the

usual injectors, making the computer inject more gas than

normal, or by using an additional cold start injector

(CSV)—there is only one such injector even in multipoint

systems. This injector is fed through a temperature-timer

switch, protruding into the coolant just like the CTS, plus it

is heated by its own electric heater. The injector operates as

long as the ignition key is in the starting position but its be

havior later on is governed by the timer switch. The colder

the engine initially is, the longer it stays closed to let the

cold start injector do its job. In a warm engine (above 40 °C)

it does not close at all.

Without a cold start injector, the computer itself adds

about 50% extra fuel initially and drops this surplus to

about 25% until the end of a 30-second time period.

From that point, the surplus is dictated by the warming

of the engine, communicated by the CTS to the computer.

EFI systems without an idle speed control device often use

an electromechanical auxiliary air valve (AAV). This

valve, which is fully open when the engine is still cold but

will close gradually as it warms up, lets an additional

amount of air measured by the AFS pass through the sys

tem. Because it is measured, it tricks the computer into pro

viding more fuel. The valve is heated by its own heating ele

ment as well as the engine, thus it closes shortly.

The injectors are electrovalves. As with any electromag

net, there is a small time delay between the arrival of the

control signal and the actual opening of the valve due to

the build-up of electromagnetic fields. The length of this de

lay depends heavily on the

voltage the injectors are fed

with. The same pulse width

would result in shorter open

ing time, hence less fuel in

-

jected if the battery voltage

drops below nominal (which

is often the case on cold morn

ings). The injection computer

therefore has to sense the bat

tery voltage and to lengthen

the injector pulse width if nec

essary.

The final, total pulse width

(also called injector duty cy

cle) is calculated by summing

up all these values received:

the base pulse width from the

RPM/AFS table lookup, the

various correction factors

based on the temperature sen

sors, throttle position and the

like, plus finally, the voltage

correction.

As the computer has already calculated the exact

amount of fuel to be injected, there is only one task left: ac

tually injecting it. There are two possible ways: to inject the

fuel into the common part of the inlet, still before the throt

tle butterfly, or to inject them close to the inlet valves, indi

vidually to each cylinder. Depending on the solution cho

-

-

-

sen, the system will be called monopoint or multipoint.

Monopoint fuel injection requires a single common injec

tor; the smaller cost and simpler setup makes it more com

-

mon on smaller engines (in the case of Citroëns, the 1380

ccm ones). In all cases, the computer actually calculates the

half of the fuel amount required as it will be injected in two

installments, once for each revolution of the engine.

The injectors of the multipoint system can be operated si

multaneously or individually. Previous Citroëns on the road

today still use simultaneous operation. Individual cylinder in

-

jection, however, holds great potential—just to name one,

-

some of the cylinders of a larger engine can be temporarily

ing at partial load, saving a considerable amount of fuel—,

so we are sure to meet this sort of fuel injection systems in

the future.

All systems—regardless of the number of injectors—use

a similar fuel supply layout. The fuel is drawn from the tank

by a continuously operating fuel pump, transported via a fil

shut off by cutting off their fuel supply if the car is operat

ter to the injectors, then back to the tank. There is a pres

sure regulator in the circuit as well to keep the pressure of

the fuel at a constant pressure above that in the inlet mani

fold (this regulator is a separate unit on multipoint systems

while integrated into the injector on monopoint ones). As

-

the pressure difference between the two sides of the injec

-

tors are constant, the amount of fuel injected depends

-

solely on the opening time of the injectors. The pressure

used in contemporary EFI systems is 3 to 5 bars.

-

This is practically all there is to it, there are only a couple

of safety and economy features in addition. If the engine

revolution exceeds a certain limit (between 1,200 and

-

1,500 usually) and the throttle is closed—this is called decel

-

-

-

-

-

-

Page 8

The Citroën Guide Fuel Injection: Electronic Fuel Injection 8

distributor

OS*

engine

pressure

regulator

ECU

fuel

pump

injectors

CTS

AFS ATSTS

AAV

throttle

ISCV

idle mixture

fuel

CO p ot

CAS KS

fuel rail

fuel

exhaust

air

coolant

not present

in all systems

*

EMS MULTIPOINT

U

eration—, the momentum of the car is sufficient to rotate

the engine through the wheels. To save fuel, the injection is

cut off. As soon as the engine speed drops below the limit

or the throttle is opened, the injection is reintroduced—sup

posedly smoothly and gradually, however, many drivers

complain about some jerkiness.

To avoid prolonged operation at revolutions exceeding

the specification of the engine, the injection is cut off above

a maximum engine speed (6,000-7,000rpm, depending

on the engine). And finally, to avoid the hazard of fire in a

crash and the fuel squirting from the injection system with

the engine stopped or possibly destroyed, the relay of the in

jectors is controlled by the ECU, allowing fuel injection only

when the ignition (or the signal of the corresponding sen

sor) is present.

Who will light our fire?

Models with simpler fuel injection have traditional (elec

tronic) ignition systems which are practically equivalent to

the solution used on cars with carburetors.

The distributor has two purposes: generating the driv

ing signal for the ignition system and to distribute the high

voltage to the four cylinders in turn. This two parts inside

the distributor are electrically separate but mechanically

coupled—both are driven by the camshaft to keep them in

sync with the strokes of the engine.

The ignition signal thus starts from the distributor. A

magnetic induction sensor (consisting of a rotating foursided magnet and a pick-up coil) sends a pulse to the igni

tion module at each firing point. This pulse will be switched

to the ignition coil (an autotransformer; auto here does

not mean that it is manufactured for automotive use, auto

transformers have their primary and secondary coils con

nected) by a power transistor inside the module. The cur

rent change in the primary coil induces very high voltage

spikes in the secondary circuit. These spikes then go back to

the HT part of the distributor

which in turn sends them to

the spark plug of the actual

cylinder requiring the spark.

It takes some time for the

spark to ignite the fuel-air mix

ture inside the combustion

chamber: this means that the

spark has to arrive slightly be

fore the piston reaches its top

position (top dead center,

TDC), so that it will receive the

downward force of the deto

nation in the right moment.

However, as the engine speed

increases, so does the speed

of the piston or the distance it

travels during a given period

of time. Therefore, the exact

time of the spark has to be ad

vanced as the revolution in

creases. Traditional systems

do this by adding a vacuum

line connecting the inlet mani

fold to the distributor. As the

-

-

-

-

-

-

vacuum increases with the engine revolution, its sucking

force rotates the inner part of the distributor slightly away

from its original position, causing all its timing devices

switch earlier, as required by the value of the timing ad

-

-

vance.

Clever systems can get away without a distributor: some

CXs have such an ignition setup. This systems has two igni

tion coils, both serving two spark plugs at the same time.

These two spark plugs belong to cylinders whose pistons

move in unison: one is compressing, the other exhausting.

Although both plugs generate sparks at the same time, the

one in the exhausting cylinder will be wasted.

-

Two birds with one stone

-

We made the ignition seem too simple in the previous sec

tion. While it works as described, there are many factors to

be considered if we want to build a modern ignition sys

tem. For instance, the timing advance depends not only on

-

-

engine speed but on many other factors as well: engine

load, engine temperature and to some extent, the air tem

perature.

-

-

Just like the carburetor was not really good at deciding

the amount of fuel required by the engine, the traditional

ignition is similarly not perfect in estimating the timing ad

vance and other characteristics of the sparks needed. An

electronic system similar to the one used for fuel injection

shows clear advantages over any earlier system.

And as they use about the same sensors and rely on each

other, what could be more logical than to integrate them

-

into a common system, elegantly called an engine man-

agement system?

-

If we compare the schematics of the corresponding EFI

-

and EMS systems, they look almost the same. There are two

-

notable differences: the small arrow on the line connecting

the ECU to the distributor has changed its direction and a

new sensor, a crank angle sensor (CAS) has appeared.

Page 9

The Citroën Guide Fuel Injection: Electronic Fuel Injection 9

%

CH

n

m

CO

NO

x

0.9 1.11.00.99 V

%

CO

CH

nm

NO

x

0.8 1.21.0 1.3

V

U

Both changes have to do with the fact that the enhanced

system, whose new task is to generate the ignition signals

as well, cannot at the same time build on them as inputs.

This new sensor—practically a replacement for the induc

tion magnet in the distributor of earlier systems—informs

the computer of both engine speed and camshaft position.

The flywheel has steel pins set into its periphery. As it ro

tates, the inductive magnet of the CAS sends pulses to the

computer. Two of the pins are missing and this hole passes

before the sensor just as the first piston reaches its TDC posi

tion. The missing pins cause a variance in the sensor output

that can be read by the ECU easily.

The rest is the same: the base pulse width is calculated

based on the CAS and AFS/MAP sensors. The correction fac

tors—air temperature, idle or full load, starting, warming

up, battery voltage—sum up into an additional pulse

width. Besides, the same input signals (AFS, CAS, CTS and

TS/TP) are used for another lookup in a table, yielding the

correct dwell time and timing advance for the ignition. The

dwell period remains practically constant but the duty cycle

varies with the chaging engine speed. The ignition signal is

amplified and sent to a distributor containing only second

ary HT components: it does not create the ignition signal

only routes the HT current to each spark plug in firing order.

Some systems also have a knock sensor (KS), sensing

the engine vibration associated with pre-ignition (so-called

pinking). If this occurs, the ignition timing is retarded to

avoid engine damage.

Think green

As we saw, fuel injection and engine management systems

are capable of determining the ideal amount of fuel to be in

jected, depending on the conditions of operation and sev

eral other factors in the engine. It is capable of deciding on

lean mixture for general, partial load to save fuel, or on rich

mixture when performance considerations call for this.

Unfortunately, this is not what such systems are used for

today. With the proliferation of catalytic converters, the

only concern of our systems is the welfare of the converter.

Ideal combustion would not generate polluting materi

als in the exhaust gas. Fuel is a mixture of various hydrocar

bons (C

(O

) of the air, should transform to carbon-dioxide (CO2)

2

and water vapor (H

besides, fuel contains many additives: the exhaust gas, in

addition to the products mentioned, has various byprod

ucts as well, some of them toxic: carbon-monoxide (CO),

various unburned hydrocarbons (C

(NO

anti-knock additives found in the fuel.

), which when burned together with the oxygen

nHm

O). However, combustion is never ideal,

2

), nitrogen-oxides

) and lead (Pb) in various substances coming from the

x

nHm

The relative amount of these

byproducts depend on the

lambda ratio of the air-fuel mix

ture burned. As shown on the di

agram, a value between 1.2 and

1.3 would give a relatively low

percentage of toxic byproducts

while, as we can recall, being a

lean mixture would be in the

right direction towards fuel

economy.

By using platinum (Pt) or rhodium (Rh) as a catalyst—a

catalyst is a substance whose presence is required to enable

(or to boost) a chemical transformation while it does not

take part in the process itself, remaining intact—the follow

ing processes can be carried out:

2 CO + O

2 C

-

2H6

2 NO + 2 CO W N

W 2 CO2(oxidation)

2

+ 7 O2W 4 CO2+ 6 H2O (oxidation)

+ 2 CO2(reduction)

2

These precious metals are applied in a very thin layer to the

surface of a porous ceramic body with thousands of holes

to make the surface contacting the exhaust gases much

greater. Actually, a converter does not contain more than 2

or 3 gramms of these metals.

If you compare this diagram

with the previous one, you will

see that the real gain is the

supression of nitrogen-oxides.

CO and C

will be reduced as

mHn

well, although to a much lesser

extent. Nevertheless, the overall

reduction in polluting byprod

ucts is quite high, amounting

up to 90 percent. Lead sub

-

stances are not considered as

lead must not reach the converter anyway, it would clog the

fine pores of the converter in no time. The fuel used in cars

equipped with a catalytic converter has to be completely

free of lead.

But there is something of even greater consequence de

picted on the diagram: to keep the amount of pollutants

down, the lambda has to be kept inside a very small value

range, practically at l=1 all the time. If the lambda drops

-

just a fraction below 1, the CO emission rises sharply, while

-

a small step above 1 skyrockets the NO

emission. The main

x

task of the fuel injection is therefore to ensure that the airfuel mixture sticks to the stochiometric ratio all the time.

This means higher consumption than the one of a car with

fuel injection without a converter to start with.

There are situations where this lambda cannot be ob

served. A cold engine will simply stall without a much richer

-

mixture, thus the cold start mechanism does not obey the

-

lambda control. The catalytic converter does not work at all

below 250 °C, so this is not a significant compromise (its

normal operating temperature is 400 to 800 °C, above

800 °C is already harmful; unburned fuel getting into the ex

haust and detonating inside the converter could cause over

-

heating, thus ignition and similar problems has to be recti

fied as soon as possible in catalytic cars).

Dynamic acceleration (full throttle) is also something not

observing the welfare of the converter. Reducing pollution

might be a noble cause but to be able to end an overtaking

is even more important…

The system uses an oxygen sensor (OS, also called

-

lambda sensor) which measures the oxygen content of the

-

exhaust gas. It is located between the engine exhaust and

the catalytic converter. Similarly to the converter, it is not

functional below 300 °C, hence it has its own heating ele

ment to make it reach its operating temperature faster.

The computer uses the input from this sensor to keep the

mixture injected always as close to l=1 as possible. If the

sensor is still too cold to give accurate input, the computer

can ignore it safely.

-

-

-

-

-

-

-

Page 10

The Citroën Guide Fuel Injection: Diesel engines 10

U

Diesel engines

Diesel oil has been a contender to gasoline for

many decades. Earlier diesel engines were not re

fined enough to win the hearts of many drivers

but recent advances in technology made these en

gines not only a worthy competitor in all areas

but in some features—fuel economy or low end

torque, to name just two—even exceeding the

characteristics of their gasoline counterparts. And

in addition to the general technological advan

tages, Citroën’s diesel engines have a widely ac

cepted reputation—even among people blaming

the quirkiness of its suspension or other fea

tures—of being excellent and robust.

As it is widely known, diesel engines have no ignition to initi

ate their internal combustion, they rely on the self-combus

tion of the diesel oil entering into a cylinder filled with hot

air. Due to this principle of operation, the supply of the fuel

has to comply with much more demanding requirements

than it is necessary in the case of gasoline engines.

Unlike in the gasoline engine, not a mixture but air en

ters into the cylinders via the inlet valves. During the adia

batic compression all the energy absorbed is used to in

crease the temperature of the gas. The small droplets of

fuel will be injected at high velocity near the end of the com

pression stroke into this heated gas still in motion. As they

start to evaporate, they form a combustible mixture with

the air present which self-ignites at around 800 °C.

This self-ignition, however, is not instantaneous. The lon

ger the delay between the start of the injection and the ac

tual ignition (which depends on the chemical quality of the

-

-

-

-

-

diesel oil, indicated by the cetane number), the more fuel

will enter the cylinder, leading to harsher combustion, with

the characteristic knocking sound. Only with the careful har

monization of all aspects—beginning of injection, the distri

bution of the amount injected in time, the mixing of the

fuel and air—can the combustion be kept at optimal level.

Small diesel engines suitable for cars were made possible

by a modification to the basic principle, that allowed these

stringent parameters to be considerably relaxed. It includes

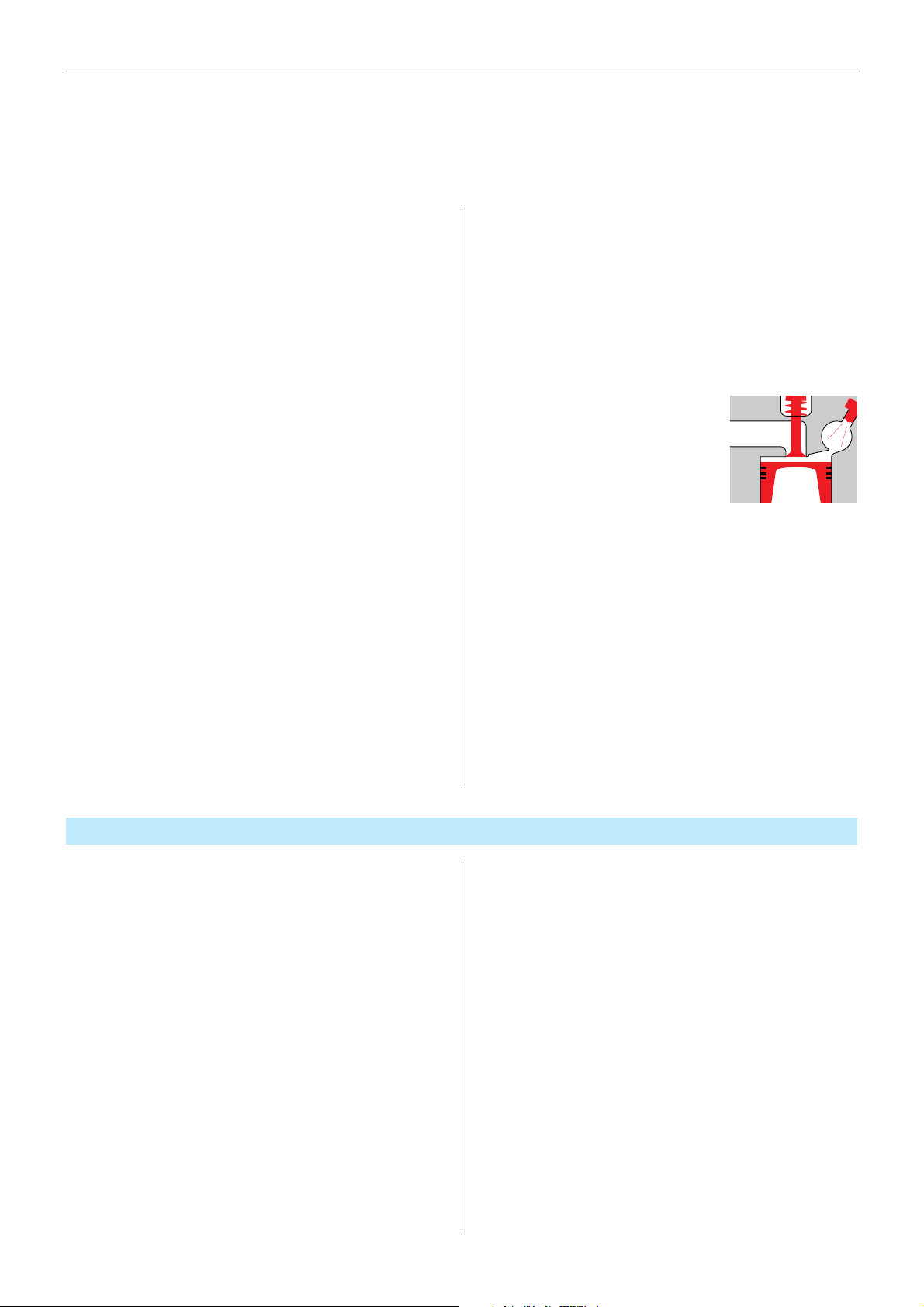

a separate swirl chamber connected

to the cylinder via a restrictor orifice.

The air compressed by the piston in

the cylinder enters this chamber

through the orifice, starting to swirl in

tensively. The fuel will then be injected

into this swirl, and the starting igni

tion propels the fuel-air mixture still incompletely burned

into the cylinder where it will mix with the air, continue and

finish the combustion process. Using a prechamber results

in smaller ignition delay, softer combustion, with less noise

and physical strain on the engine parts, but introduces

some loss of energy because of the current of air having to

-

-

pass between the chambers. Citroën engines of this type

use a tangentially connected spherical prechamber.

-

As diesel engine evolution continued, better simulation

and modeling techniques became available, which, to

gether with the improvements in fuel injection technology,

lessened or removed the problems initially solved by the in

-

troduction of the prechamber. The direct injection engines

-

of today have no prechamber, instead, the piston has a spe

cially formed swirl area embedded in its face.

-

-

-

-

-

-

-

Mechanical injection

Although the basic principles of fuel injection are similar to

what we have already discussed for gasoline engines, there

are some notable differences. First of all, diesel engines op

erate without restricting the amount of air entering the en

gine: there is no throttle, the only means of regulating the

engine is to vary the amount of fuel injected.

The fuel is injected into the engine, creating a combusti

ble mixture in the same place it is going to be burned. Be

cause the forming of this mixture results in its self-combus

tion, the diesel injection system is, in essence, an ignition

control system. Unlike on the gasoline engine, fuel injection

and ignition cannot be separated in a diesel engine.

The complete mechanical injection system is built into a

single unit which can be divided into five individual—al

though interconnected—subsystems:

a low pressure fuel pump to deliver the fuel for the

U

rest of the injection system;

a high pressure pump and distributor that routes

U

the fuel to the appropriate cylinders in firing order

(similar in purpose to the distributor on gasoline en

gines) and generates the high pressure needed for the

injection as well;

-

-

-

-

-

-

-

a regulator that determines the amount of fuel to be

U

injected in relation to the engine speed, modified by

additional factors like idle speed, cold starting, full

load, etc.;

an injection adjuster to compensate for the higher

U

engine speed by advancing the start time of the injec

tion;

a fuel stop valve to cut off the fuel supply when the

U

ignition has been switched off.

The diesel fuel is drawn—through a filter—from the tank by

the low pressure pump 1 operated by the engine. A pres

sure regulating valve 2 ensures that the fuel pressure will

not exceed a preset limit; when the pressure reaches this

value, the valve opens and lets the fuel flow back to the pri

mary side of the pump.

The piston 6 of the high pressure part is driven through

a coupling 4 consisting of a cam disc and four cam rollers.

The piston rotates together with the shaft coming from the

-

-

-

Page 11

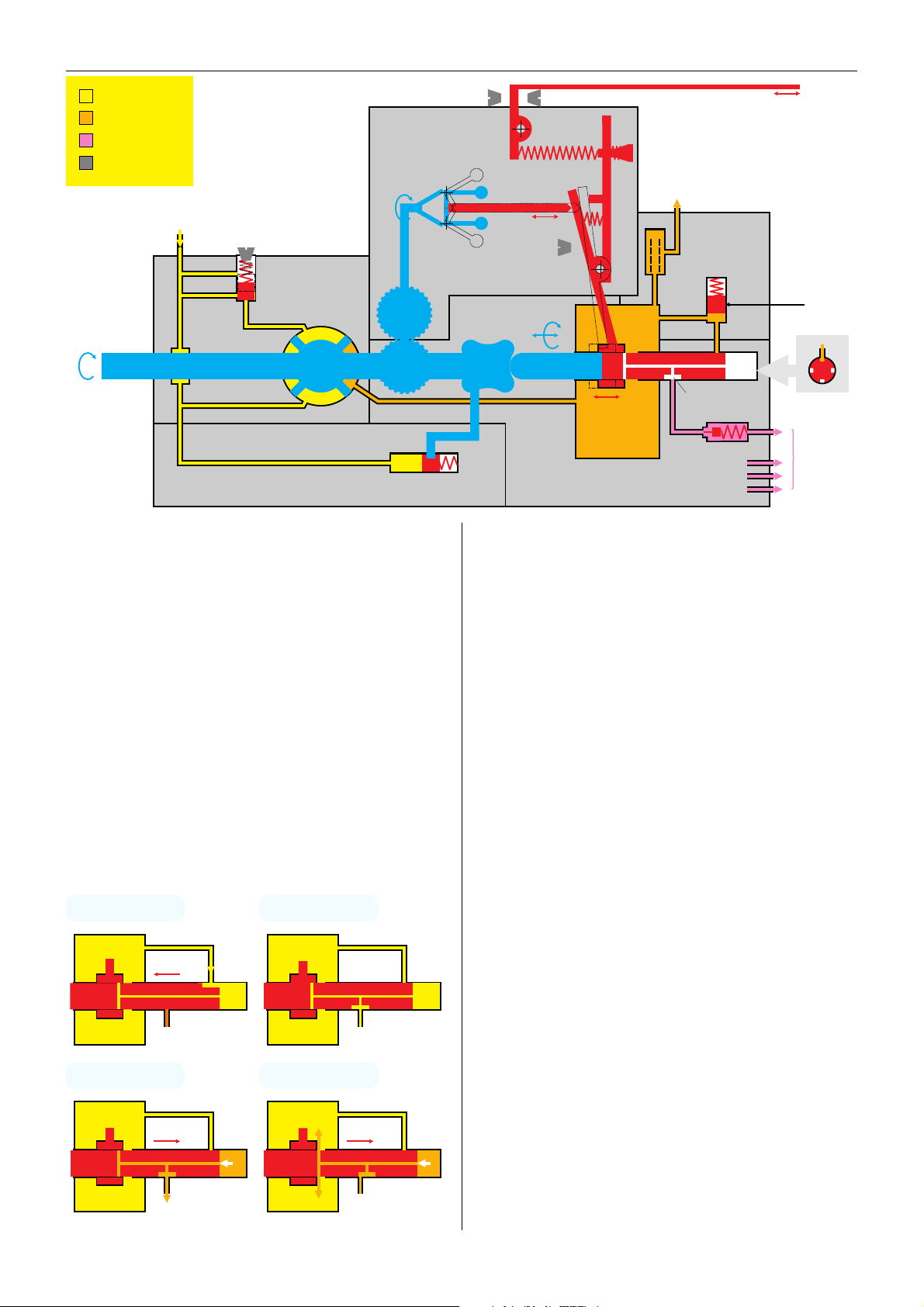

The Citroën Guide Fuel Injection: Diesel engines 11

engine

fuel from/to tank

low pressure

high pressure

adjusting screws

fuel pump

2

injection

adjuster

high pressure pump

and distributor

fuel stop

valve

regulator

fuel

1

3

4

5

6

f

uel

to tank

7

injectors

8

9

Û

Ü

Ý

accelelator

pedal

Þ

ß

à

á

â

ignition

switch

ã

ä

6

å

idlefull

æ

PHASE 2

PHASE 4PHASE 3

PHASE 1

55

55

66

66

injector

U

engine but the coupling adds a horizontal, alternating

movement as well: for each turn, the shaft and the piston 6

performs four push-pull cycles.

It is the pushing movement of this piston 6 that creates

the high pressure and sends the fuel to the injectors. The

fuel, provided by the pump 1 arrives through the fuel stop

electro-valve â, which is constantly open while the ignition

switch is on but cuts the fuel path when it is turned off.

First, the piston 6 is pulled back by the coupling 4,

letting the fuel enter the chamber and the longitudinal bore

inside the piston. As the side outlets are blocked by the regu

lator collar 5, the fuel stays inside the chamber (phase 1).

In the next phase, the piston rotates and closes the in

gress of fuel from the stop valve â. On the other side of the

piston, the high pressure outlet opens but as the fuel is not

yet under pressure, it will stay in the chamber.

In phase 3 the piston is energetically pushed by the cam

disc and rollers of the coupling 4, injecting the fuel stored

in the chamber into the output line with a significant force.

As the piston 6 moves to the right, at some point the

side outlets will emerge from under the regulator collar 5—the fuel injection into the real output will stop imme

diately, and the rest of the fuel stored in the chamber will

leave through this path of lesser resistance. This is phase 4,

the end of the injection cycle.

Actually, this operation is repeated four times for each

revolution of the incoming shaft. There are four high pres

sure outlets radially around the piston, each serving a given

cylinder. As the outlet slot ä of the piston turns around, it al

lows only one of the outlets to receive the fuel.

-

The pressure valves 7 serve to drop the pressure in the in

-

jector lines once the injection cycle is over. To reduce the cav

-

-

itation caused by the pressure waves generated by the rapid

closing of the injector valves, a ball valve minimizing the

back flow is also used.

The length of phase 3, thus the amount of fuel injected

depends on the position of the collar 5. If it is pushed to the

right, it will cover the side outlets for a longer time, result

ing in a longer injection phase, and vice versa. If it stays in

the leftmost position, no fuel will be injected at all.

And this is exactly what the regulator part does: it

-

moves this collar 5 to the left and to the right, as the actual

requirements dictate. The lever 9 attached to the collar is ro

tated around its pivot by several contributing forces. The

two main inputs are the position of the accelerator pedal

as communicated through a regulator spring Ý and the ac

tual engine speed, driving a centrifugal device 8 via a pair

of gears 3. The higher the engine speed, the more the

shaft å protrudes to the right, pushing on the lever Û.

When the engine is being started, the centrifugal device

8 and the shaft å are in their neutral position. The starting

lever Û—pushed into its starting position by a spring Ü—

sets the position of the collar 5 to supply the amount of

-

-

fuel needed for the starting.

As the engine starts to rotate, a relatively low speed will

already generate a large enough force in the centrifugal de

vice 8 to push the shaft å and overcome the force of the

Page 12

The Citroën Guide Fuel Injection: Diesel engines 12

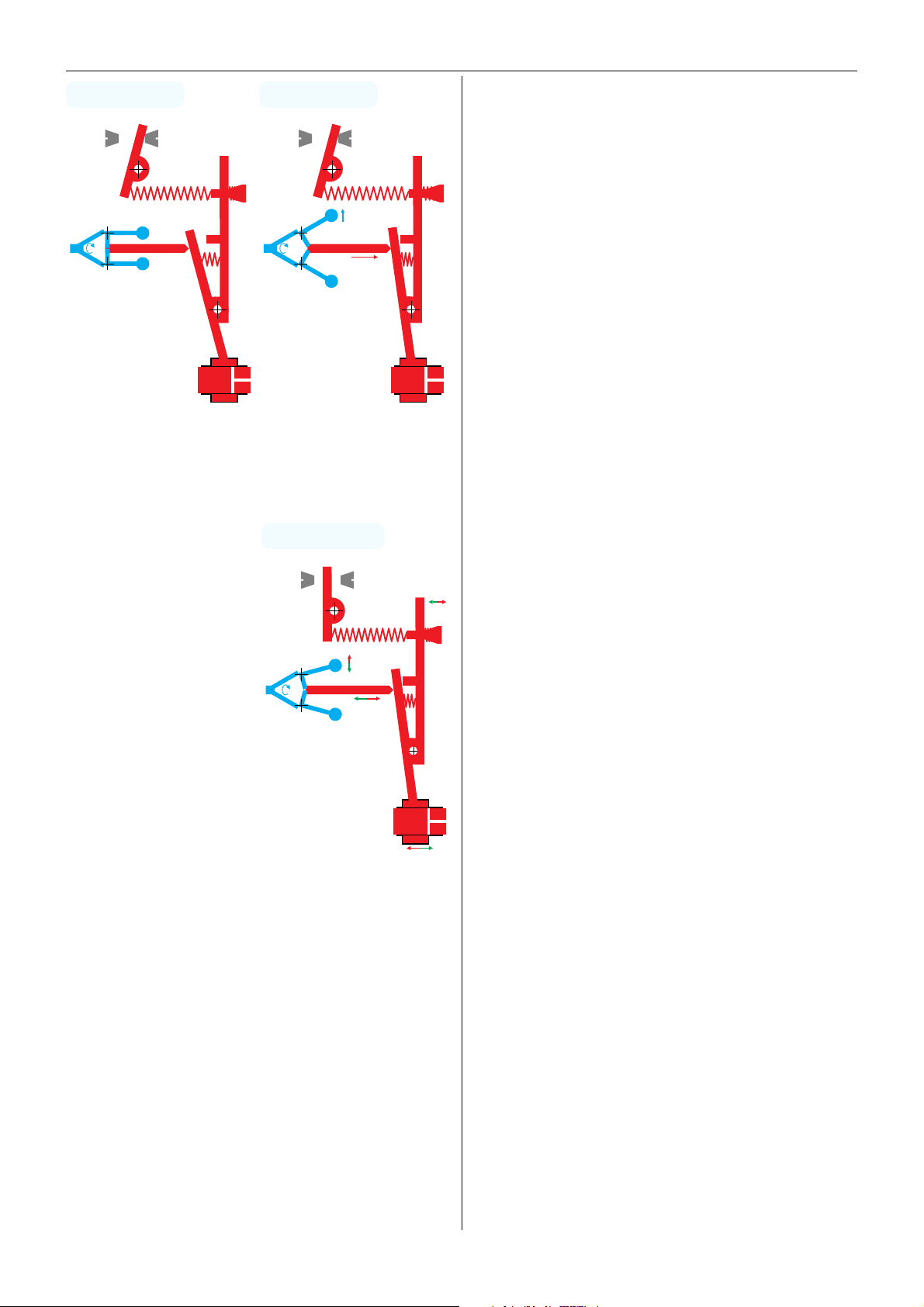

DECREASE/INCREASE

9

Ü

Ý

pedal

Þ

ß

6

å

Û

5

8

STARTING IDLE SPEED

99

ÛÛ

ÜÜ

ÝÝ

pedal

ÞÞ

ßß

66

5

åå

5

8

8

pedal

U

The excess fuel will finally leave the pump unit through

an overflow valve ã, flowing back to the fuel tank.

Something needs to be corrected…

rather weak spring Ü. This will rotate the lever Û, moving

the collar 5 to the left, setting the amount of fuel required

for idling. The accelerator pedal is in the idle position as

well, dictated by the adjustment screw ß. The idle spring Þ

keeps the regulator in equilibrium.

Normally, the amount of

fuel will be regulated by the

position of the pedal as both

springs Ü and Þ are fully

compressed and do not take

an active part in the process.

When the driver pushes on

the pedal, the regulating

spring Ý stretches, both le

-

vers 9 and Û rotate and

move the collar 5 to the

right, to allow the maximum

amount of fuel to be in

jected. As the actual engine

speed catches up, the centrif

ugal device 8 opens up,

pushing the shaft å to the

right, countering the previ

ous force, gradually return

-

ing the collar 5 towards the no fuel position, until the point

is reached where the amount of fuel injected maintains the

equilibrium. When the driver releases the pedal, the inverse

of this process takes place. During deceleration—pedal at

idle, engine rotated by the momentum of the car—the fuel

is cut off completely.

Without such regulation, if enough fuel is provided to

overcome the engine load, it would continue accelerating

until self-destruction (this is called engine runaway). Speed

regulation is a feedback mechanism comparing the actual

speed of the engine to the one dictated by the gas pedal

and modifies the amount of fuel as necessary. If either the

engine speed changes (because of varying load, going over

a hill, for instance) or the driver modifies the position of the

accelerator pedal, the regulation kicks in, adding more or

less fuel, until a new equilibrium is reached. If the engine is

powerful enough to cope with the load, keeping the pedal

in a constant position means constant cruising speed in a

diesel car; gasoline vehicles need speed regulated fly-bywire systems or cruise controls to achieve the same.

The chemistry involved in the combustion dictates some pa

rameters of fuel injection, the most important being the

smoke limit, the maximum amount of fuel injected into a

given amount of air, that results in combustion without re

sulting in soot particles. Although gasoline engines also

have this limit, they normally operate with a constant fuel

to air mixture that automatically places the amount of fuel

below this critical limit. Diesel engines, in contrast, operate

with a variable fuel to air mixture, using this very variation

for power regulation. With diesel fuel observing the smoke

limit is a much stricter task because once soot starts to de

velop, this changes the character of the combustion itself,

resulting in a sudden and huge increase in the amount of

particulates—a bit like a chain reaction.

Because the maximum amount of fuel injected depends

on how far the lever Û is allowed to rotate counter-clock

wise, the inability of the pump to inject too much fuel,

thereby crossing the smoke limit, is insured by an end stop

æ for this lever. This very basic means of smoke limit correc

tion, adjusted for worst case conditions, was developed fur

ther on turbocharged engines, and still further on electroni

cally controlled injection systems.

Timing is of enormous importance in a diesel engine.

During the stroke of combustion, several events take place

in close succession: the fuel injection system starts its deliv

ery, then the fuel is actually injected (the time elapsed between these two is the injection delay), slightly later the fuel

will self-ignite (this delay is the ignition delay), then the injec

tion will stop but the combustion is still raging, first reach

ing its maximum, then dying away slowly (on the scale of

milliseconds, that is).

Just like in a gasoline engine, the ignition delay remains

constant while the engine speed changes. The fuel has to ig

nite before the piston passes its TDC position, but with the

increasing engine speed, the distance the piston travels dur

ing a given period of time becomes longer. Therefore, the in

jection has to be advanced in time to catch the piston still in

time. The injection adjuster à feeds on the fuel pressure

provided by the pump 1, proportional to the engine speed.

This will move the piston, which in turn, through the le

vers, modifies the relative position of the cam rollers to the

cam disc inside the coupling 4, increasing or decreasing

the phase difference between the revolutions of the engine

and the rotating-alternating movement of the distributor

piston 6.

Some engines also have additional minor correction

mechanisms á that modify the idle speed and timing de

pending on engine temperature, to provide better cold

start performance. The engine temperature is measured in

directly, through the coolant acting on cylinder and pistonlike elements filled with paraffin. As the paraffin expands or

contracts as the coolant temperature dictates, the trans

formed mechanical movement, coupled through cables to

two movable end stops for both the lever 9 and the injec

tion adjuster à, modifies the idle speed and the injection

timing of the engine. Because correct timing depends on

temperature, the corrections, although relatively slight, in

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Page 13

The Citroën Guide Fuel Injection: Diesel engines 13

9

Ý

pedal

Þ

ß

turbo

pressure

æ

ç

HP fuel

return

2

1

3

air

exhaust

1

2

3

4

5

U

sure that the amount of fuel injected as well as the timing

provide better combustion and lower pollution when the

engine is started and operated at low temperatures. They

do not have any effect once the engine reaches the normal

operating temperature.

Now that the correct amount of fuel is care

fully determined and the necessary high pres

sure generated by the pump, it has to be in

jected into the swirl chamber. The pressurized

fuel entering the injector through a filter 1

tries to press the piston 2 upwards but a

spring 3 counters this force. As soon as the

pressure exceeds the force of the spring

(which can be adjusted by placing appropri

ately sized shims behind it), the piston jumps

up and the fuel rushes into the swirl chamber

through the small orifice now opened. After the injection

pump closes its pressure valve at the end of the injection pe

riod, the spring 3 pushes the piston 2 back, closing the ori

fice until the next injection cycle.

Each swirl chamber has its own glow plug whose only

purpose is to heat up the chamber in cold weather. They

start to glow when the ignition key is turned into the first

position and stay glowing for some time afterwards unless

the starting was unsuccessful.

Turbo

More power requires

more fuel. An efficient

way to boost the performance is to provide

both more air and fuel

to the engine. The ex

haust gases rushing out

from the engine waste

a great deal of energy; a

turbocharger 4 spun

by the exhaust flow taps into this source of energy to pro

vide added pressure in the air inlet. Diesel engines are partic

ularly well suited for turbocharging. Gasoline engines may

not have the inlet pressure raised too much because the air

and fuel mixture may subsequently self-ignite when it is not

supposed to, and instead of burning controllably, detonate.

In a diesel such a situation is not possible because the fuel is

injected only when combustion should actually happen in

the first place. As a result, relatively high inlet pressures can

be used, considerably improving the power output of a die

sel engine, and with proper attention to the subtleties of

the design, engine efficiency and fuel consumption.

On its own, once the amount and pressure in the ex

haust manifold reaches a level high enough to power it,

with the engine fully loaded, the turbine would spin propor

tionally to engine speed squared, because both the pres

sure and the volume of the air pumped into the engine are

increasing.

Because the engine is required to deliver as much torque

as possible at the widest possible range of engine revolu

tion, the requirements on the turbine are somewhat contra

dictory. If the turbo is made very small and light, it will spin

up very quickly due to its low mass and inertia, ensuring its

full benefit already at low rpms. However, with a moderate

-

increase in engine speed, the rotational speed of the tur

bine (note the quadratic relationship) would become exces

sively high. When the turbine blade speed approaches the

speed of sound, a supersonic wave effect occurs that can

abruptly leave it without any load, at which point runaway

would occur, resulting in severe damage to the turbine.

On the other hand, if the turbine was dimensioned so

-

that even at the highest engine speed it is still operating

-

within safe limits, it would not be useful at all in the middle

range where the engine is most often used. A compromise

can be achieved using an overpressure valve, the waste

gate valve 5. The turbo pressure is constantly monitored

by this valve opening above a set pressure limit, letting the

exhaust escape through a bypass. This avoids turbo run

-

away by making the turbo rotational speed proportional to

that of the engine, once the limit pressure is reached. This

way the quick spin-up resulting from the quadratic relation

ship can be preserved while the turbocharging effect is ex

-

tended over a significant percentage of the usable engine

-

speed range—typically the higher 70-80%. But it comes at

a price: because of the simplicity of such a regulation, the

limit pressure is dictated by the maximum turbine speed,

which is usually calculated for maximum engine speed plus

a safety margin. The maximum pressure is already reached

at lower engine and turbine speeds, where the turbine

could conceivably still provide more pressure because of a

lesser demand for air volume. Although with a simple

wastegate a certain amount of the turbocharging potential

is lost, the increase in power output is still substantial.

Citroën is a pioneer in implementing variable wastegate

limit pressure using a controllable wastegate valve, to tap

into this previously unused turbo potential.

Essentially, a turbocharged diesel engine runs in two dif

ferent modes: atmospheric pressure or turbo-charged. The

atmospheric pressure mode prevails while the exhaust gas

produced is not yet sufficient to power the turbine (below a

given engine speed and load). Once this limit is crossed and

the turbine starts generating higher than atmospheric pres

-

sure, the engine is running in turbocharged mode.

-

The injection pump regula

tor needs to know about the

changes in the inlet pressure,

because those changes mean

differences in the amount of

air entering the engine. And

this also means that the upper

limit of fuel injected needs to

-

be changed correspondingly.

These injection systems are

tuned for the turbo producing

-

the rated waste pressure (also

known as full boost). How

-

ever, the amount of fuel injected during the atmospheric

-

mode of the engine—before the turbo kicks in—has to be

reduced in order to avoid crossing the smoke limit. The

turbo pressure drives a limiter in the injection pump: with

the increasing pressure the piston æ moves down. Its vary

-

ing diameter forces the lever ç rotate around its pivot,

-

which then acts as a stop to limit the allowed range of oper

ation of the regulator lever 9, limiting the amount of fuel to

be injected.

Intercooler

-

-

-

-

-

-

-

-

-

-

-

-

Page 14

The Citroën Guide Fuel Injection: Diesel engines 14

U

Towards a cleaner world

Exhaust Gas Recycling (EGR) systems were used—depend

ing on the market—as add-on units. An electronic unit mea

suring the coolant temperature and the position of the gas

pedal control on the pump (with a potentiometer fitted to

the top of the control lever) controls a valve which lets part

of the exhaust gas get back into the inlet.

Post-glowing is also used as a pollution reducing mecha

nism. A definite post-glow phase, lasting for up to minutes

is usually controlled by a combination of a timer and the en

gine coolant temperature: either the timeout of 4 minutes

runs out or the engine reaches 50 °C. An additional mecha

nism prevents post-glowing if the engine was not actually

started.

-

-

-

-

-

Page 15

The Citroën Guide Fuel Injection: Diesel engines 15

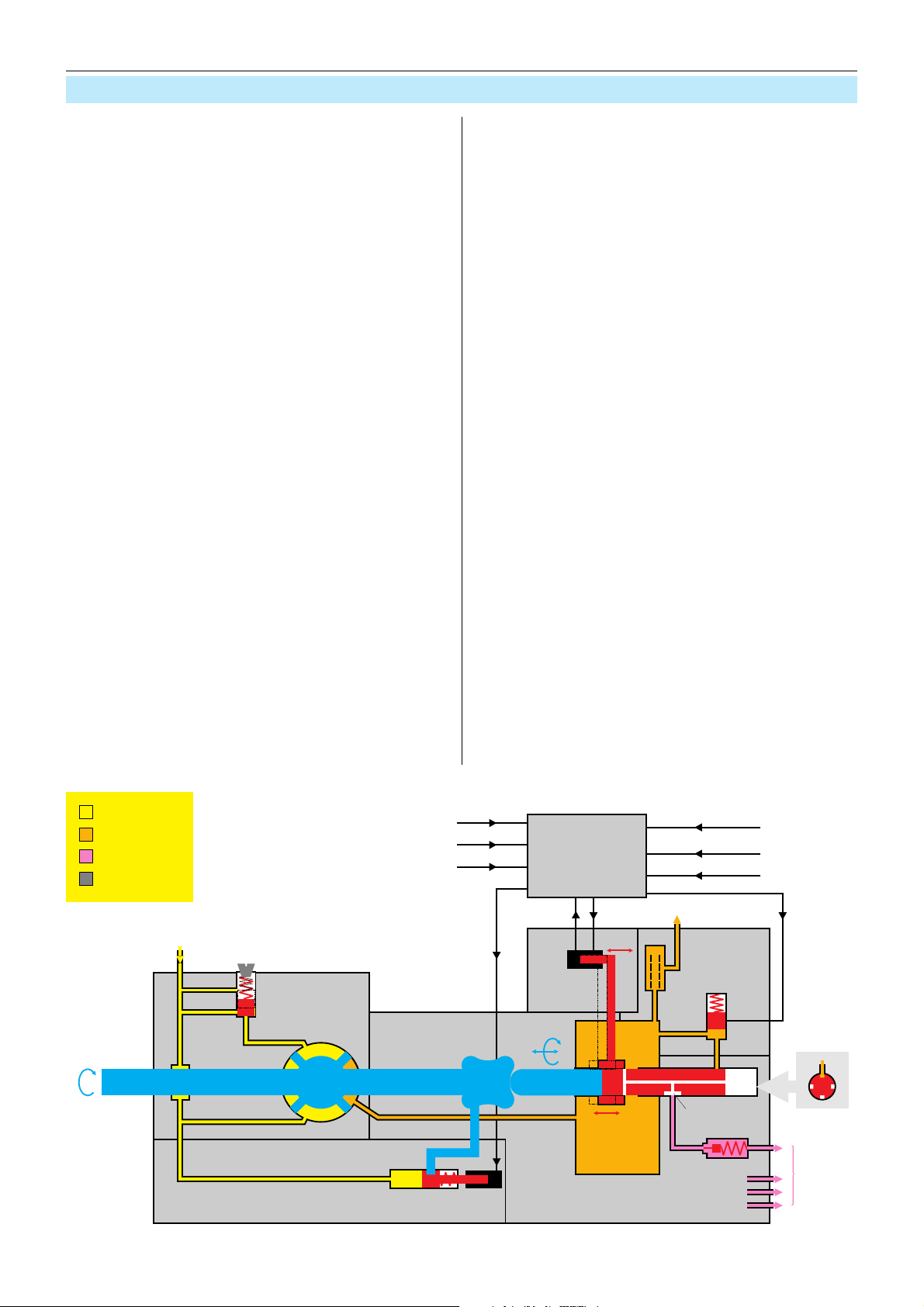

engine

fuel from/to tank

low pressure

high pressure

adjusting screws

fuel pump

2

injection

adjuster

high pressure pump

and distributor

fuel stop

valve

actuator

fuel

1

4

5

6

fuel

to tank

7

injectors

Û

accelelator

pedal

à

â

ã

ä

6

ECU

temperatures

(air, fuel, coolant)

regulator

position

vehicle speed

air quantity

engine speed

atmospheric

air pressure

ß

8

U

Electronic Diesel Control

Just like it is the case with gasoline engines and carburetors,

a mechanical device—even one as complicated as a diesel

injection pump—cannot match the versatility and sensibil

ity of a microcomputer coupled with various sensors, apply

ing sophisticated rules to regulate the whole process of fuel

injection.

The only input a mechanical pump can measure is the en

gine speed. The amount of air entering into the engine, un

fortunately, is far from being proportional to engine speed,

and the turbo or the intercooler disturbs this relationship

even further. As the injection always has to inject less fuel

than the amount which would already generate smoke, the

mechanical pump—capable only of a crude approximation

of what is actually going on in the engine—wastes a signifi

cant amount of air, just to be of the safe side.

The satisfactory combustion in diesel engines relies on

the exhaust as well—if this is plugged up, more of the ex

haust gases stay in the cylinder, allowing less fresh air to en

ter. A mechanically controlled injection pump has no feed

back from the engine (except for the engine speed)—it will

simply pump too much fuel into the engine, resulting in

black smoke. An electronically controlled injection pump,

on the other hand, can tell how much air has actually en

tered by using a sensor (although only the latest systems

use such a sensor).

There are also other factors never considered by a me

chanical system. The details of the combustion process de

pend heavily on the chemical characteristics of the fuel. The

ignition delay, as we have already seen, depends on the

cetane number of the diesel oil. In spite of the fact that cor

rect timing has a paramount influence on the performance

and the low pollutant level of a diesel engine, the mechani

cal system can have no information about this very impor

tant input factor. Less essential but still important is the tem

perature of the incoming air. With measuring all the circum

stances and conditions in and around the engine (air, en

gine and fuel temperatures), the injection system can

achieve better characteristics, lower fuel consumption and

less pollution.

-

All in all, the electronically controlled injection pump not

only adds precision to the injection process as its gasoline

counterpart does but introduces completely new methods

of regulation; therefore it represents a much larger leap for

wards than fuel injection in gasoline engines. In spite of

this, it is quite similar to its mechanical predecessor. From

the five subparts, four remain practically the same, only the

regulator is replaced with a simple electromagnetic actua

tor that changes the position of the same regulator collar 5

as in the mechanical pump, in order to regulate the amount

of fuel to be injected.

The real advantage over the former, mechanical pumps

is that an electronic device, a small microcomputer can han

dle any complex relationship between the input values and

the required output. With mechanical systems, only simple

correction rules are possible, and as the rules get more com

plicated, the mechanics quickly becomes unfeasible. In con

trast to this, the ECU just have to store a set of characteristic

curves digitized into lookup tables, describing the amount

of fuel to be injected using three parameters: engine

speed (measured by a flywheel inductive magnet), cool

ant temperature (measured by a sensor protruding into

the coolant liquid), air temperature (measured by a sen

sor in the air inlet).

The newer HDi engines use an air mass sensor using a

-

heated platinum wire (as that mentioned on page 5). Hav

ing the exact amount of air to enter the engine, these latest

-

EDC systems can deliver true closed loop regulation.

-

A potentiometer attached to the accelerator pedal

-

sends information about the pedal position to the com

-

puter. This signal is used as the main input, conveying the in

-

-

-

-

-

-

-

-

-

-

-

Page 16

The Citroën Guide Fuel Injection: Diesel engines 16

U

tentions of the driver. The ECU uses this sensor to learn

about special conditions like idle speed or full load as well.

Air temperature is measured by a sensor in the inlet mani

fold (but if the air mass is measured by a heated platinum

wire sensor, this already provides the necessary air tempera

ture correction, thus there is no need for an additional sen

sor).

The ECU stores the basic engine characteristics, the intrin

sic relationship between the air intake and the engine

speed (plus the manifold pressure if a turbo is fitted). The

values obtained from this table are corrected according to

the inputs of the various sensors, in order to arrive at a basic

timing and smoke limit value. The actual amount of fuel in

jected and the accurate timing are a function of these

results and the position of the accelerator pedal.

The final amount of fuel calculated will be used to con

trol the electric actuator 8 which—by moving a lever Û—

changes the position of the regulating collar 5. To ensure

the necessary precision, the factual position is reported

back to the computer using a potentiometer.

As we have already mentioned, the exact timing of the in

jection is of utmost importance in a diesel engine. The elec

tronic system uses a needle movement sensor built into

one of the injectors (the other are assumed to work com

pletely simultaneously) notifying the computer about the

precise time of the beginning of the injection. Should there

be any time difference between the factual and designated

opening times, the electro-valve ß of the injection ad

juster à will receive a correction signal until the difference

disappears. If the electro-valve is completely open, the injec

tion start will be delayed, if it is closed, the start time will be

advanced. To achieve the timing required, the valve is

driven with a modulated pulse signal, with the duty cycle

(on-off ratio) determined by the ECU.

The input from this sensor is also used for compensating

calculations on the amount of fuel injected, and to provide

the on-board computer with the exact amount of fuel used

up so that it can calculate the momentary and average con

sumption.

The computer has extensive self-diagnostic functionality.

Many sensors can be substituted with standard input val

ues in case of a failure (serious errors will light up the diag

nostic warning light on the dashboard). Some sensors can

even be simulated using other sensors—for instance, the

role of a failing engine speed sensor might be filled in by

the signal generated from the needle movement sensor.

As there is no standalone ignition in a diesel engine, the

only way to stop it is to cut off the fuel supply. The mechani

cal default position of the actuator 8 is the position where

no fuel enters the injectors at all; this is where it returns

when the computer receives no more voltage from the bat

tery, the ignition switch having turned off.

As it has already been mentioned, the inlet pressure is

one of the principal EDC parameters for a turbocharged en

gine. Later Citroën turbocharged diesels—starting with the

2.5 TD engine of the XM—pioneered variable turbo pres

sure technology. The wastegate on these turbines has sev

eral actuators, fed with the turbo pressure through electric

valves. The ECU, based on the relevant engine operation pa

rameters obtained from the sensors, controls these actua

tors in various combinations, providing a selection of two

or three different wastegate limit pressures. This lets the sys

tem ease the compromise between the turbo pressure and

turbine speed: the pressure is kept at the usual value for

higher engine speeds (limited by the maximum turbine

speed) but is allowed to go higher than that in the middle

rpm ranges, adding a significant amount of torque in the

range where it is most needed.

-

Green versus Black

-

Diesel oil, just like gasoline, is a mixture of various hydrocar

bons (C

the air, transforms to carbon-dioxide (CO

(H

O). However, as the combustion is never ideal, the ex

-

2

), and burned together with the oxygen (O2)of

nHm

) and water vapor

2

haust gas also contains various byproduct gases: carbonmonoxide (CO), various unburned hydrocarbons (C

trogen-oxides (NO

-

). The relatively high lambda value a die

x

sel engine is operating with reduces the hydrocarbon and

carbon-monoxide content to 10–15%, and the amount of

nitrogen-oxides to 30–35% of the corresponding figures

measured in gasoline engines without a catalytic converter.

The sulphur content of the fuel—drastically reduced during

the recent decades—is responsible for the emission of sul

phur-dioxide (SO

Conversely, these engines emit 10–20 times more par

-

) and sulphuric acid (H2SO4).

2

ticulates—or black soot—than gasoline engines. These are

unburned or incompletely burned hydrocarbons attached

to large particles of carbon. These substances are mainly al

dehydes and aromatic hydrocarbons; while the first only

-

smells bad, the second is highly carcinogenic.

The much higher amount of particulates is due to the dif

ferent combustion process. The various aspects of mixture

formation, ignition and burning occur simultaneously, they

are not independent but influence each other. The distribu

tion of fuel is not homogenous inside the cylinder, in zones

where the fuel is richer the combustion only takes place

near the outer perimeter of the tiny fuel droplets, produc

ing elemental carbon. If this carbon will not be burned later

-

because of insufficient mixing, local oxygen shortage (large

fuel droplets due to insufficient fuel atomization, caused by

worn injectors) or the combustion stopping in cooler zones

-

inside the cylinder, it will appear as soot in the exhaust. The

-

diameter of these small particles is between 0.01 and

10 mm, the majority being under 1 mm. Keeping the

amount of fuel injected below the smoke limit—the

lambda value where the particulate generation starts to rise

extremely—is essential.

Similarly to gasoline engines, the exhaust gas can be

-

post-processed to reduce the amount of pollutants even fur

ther. There are two different devices that can be used:

Soot burning filter: as the diesel engine always oper

U

-

ates with excess air (its lambda is above 1), there is

enough oxygen in the exhaust gas to simply burn the car

bon soot present. The burning filter is manufactured

-

from ceramic materials that can withstand the resulting

high temperatures (up to 1200 °C). As the diesel engine

-

is very sensitive to excessive back pressure, the filter has

-

to be able to self-regenerate. This is solved by the addi

tion of organic metal substances.

-

Catalytic converter, identical to the simpler ones used

U

-

on gasoline engines before the proliferation of threeway, controlled converters. It reduces the carbon-monox

-

ide and hydrocarbon content of the exhaust gas.

nHm

), ni

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Page 17

The Citroën Guide Fuel Injection: Diesel engines 17

U

Diesel Direct Injection

I think that at this point, soot burning filters will have to be

cut out of the PDF and put in at a similar ecological section

under DI/HDI—since that is the only system that actually

makes soot burning practical, and the only system that im

plements it.

Soot burning was experimented with a lot but was never

made practical before HDI due to a too low exhaust temper

ature. The particle filter would need heating to a very high

temperature and that was deemed to be too dangerous.

Even with cerine additives, essentially, there would have to

be a separate small burner to heat up the filter, which is

again another system that can go wrong. HDI essentially in

tegrates a burner by alowing post-injection, something

that is simply impossible for injection systems derived from

a classical pump due to teh timing required. I think that for

soot management it is enough to write that the smoke limit

control is vastly improved by the better regulation of the

EDC.

Other things like controlled swirl and multi-valve technol

ogy, also pioneered by Citroën (XM 2.1 TD!) should be men

tioned. The catalytic converter section remains unchanged.

And, of course, there should be an "In addition to the pol

lution management implemented on mechanical injection

systems" sentence somewhere in there, since proper cold

start corrections and EGR are implemented in EDC units by

default.

-

-

-

-

-

-

Page 18

Suspension

Page 19

The Citroën Guide Suspension: A Suspension Primer 19

U

A Suspension Primer

From the early days of the automobile—and even

before, in the time of horse-drawn carts—it was

already well known that the body of the car, hous

ing both the passengers and the load, has to be

decoupled from the unevenness of the road sur

face.

This isolation is much more than a question of comfort. The

vertical force of the jolts caused by the repeating bumps

and holes of the road surface are proportional to the square

of the vehicle speed. With the high speeds we drive at to

day, this would result in unbearable shock to both people

and the mechanical parts of the car. Jolts in the body also

make it more difficult to control the vehicle.

Consequently, there has to be an elastic medium be

tween the body and the wheels, however, the elasticity and

other features of this suspension medium are governed by

many, mostly contradicting factors.

The softer, more elastic the spring, the less the sus

pended body will be shaken by various jolts. For the sake of

comfort, we would thus need the softest spring possible.

Unfortunately, too soft a spring will collapse under a given

weight, losing all its elasticity. The elasticity of the spring

would need to be determined as a function of the weight

carried but the weight is never constant: there is a wide

range of possible load requirements for any car. On one

hand, a hard suspension will not be sensitive to load varia

tions but being hard, will not fulfill its designated purpose,

either. A soft suspension, on the other hand, is comfortable

but its behavior will change significantly on any load varia

tion. To cope with this contradicting requirements, an elas

tic medium of decreasing flexibility would be required: such

a spring will become harder as the weight to be carried in

creases.

When the spring is compressed under the weight of the

load, it’s not only its flexibility that changes. The spring de

flects, causing the clearance between the car and the road

surface decrease, although a constant clearance would be a

prerequisite of stable handling and roadholding. At first

sight, this pushes us towards harder springs: soft springs

would result in excessive variations of vertical position — un

less, of course, we can use some other mechanism to en

sure a constant ground clearance.

In addition to the static change caused by load varia

tions, the deflection of the spring is changing constantly

and dynamically when the wheels roll on the road surface.

The body of the vehicle dives, squats, rolls to left and right

as the car goes over slopes, holes and bumps in the road,

corners, accelerates or decelerates.

-

-

When a deflected spring is released again, the energy

stored in it will be released but as there is no actual load for

this energy, the elastic element, the mass of the suspension

and the vehicle form an oscillatory system, causing a series

of oscillations to occur instead of the spring simply return

ing to its neutral position.

Any vertical jolt would thus cause such oscillations: the

upward ones are transmitted to the car body while the

downward ones make the wheels bounce, losing contact

with and adhesion to the road surface. The first is only dis

comforting, but the second is plainly dangerous. In addi

tion, it’s not only the spring that oscillates; the tires contain

air which is a highly elastic spring medium. Oscillation in it

self causes unwanted motion but when the corrugation of

the road surface happens to coincide with the period of the

suspension oscillations, it might lead to synchronous reso

nance, a detrimental situation leading to serious damages

in the suspension elements.

Mass in motion can also be viewed as a source for kinetic

energy; because of this, moving parts of the suspension are

often reduced in weight to decrease this portion of the

stored energy, and this in turn eases the requirements on

the dampers as they have to dissipate less unwanted energy

as heat. This solution, however, often shifts the frequency

of the self-oscillation of the suspension upwards. Unfortu

nately, occupants are more sensitive to higher frequencies

-

reducing comfort (mostly adding noise), so this is an area

where compromise is needed.

Conventional suspension systems use a second element,

-

a shock absorber to dampen these oscillations. The ab

-

sorber uses friction to drain some of the energy stored in

the spring in order to decrease the oscillations. Being an ad

-

ditional element presents new challenges: the characteris

tics of both the spring and the absorber have to be

matched carefully to obtain any acceptable results. The ab

-

sorber ought to be both soft and hard at the same time: a

soft absorber suppresses the bumps of the road but does

not decrease the oscillations satisfactorily while a hard ab

sorber reduces the oscillations but lets the passengers feel

the unevenness of the road too much. Due to this contradic

-

tion, conventionally suspended cars have no alternative but

-

to find a compromise between the two, according to the in

tended purpose of the car: sport versions are harder but of

-

fer better roadholding, luxurious models sacrifice roadhold

ing for increased comfort. This contradiction clearly calls for

a unified component serving both as a spring and an

absorber, harmonizing the requirements.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Page 20

The Citroën Guide Suspension: Hydropneumatic Suspension 20

U

Hydropneumatic Suspension

As we saw, the ideal suspension would require

elasticity decreasing with the load, constant

ground clearance, shock absorbers integrated

into the suspension—all these beyond the obvi

ous independent suspension for all wheels. And

this is exactly what Citroën’s unique hydropneu

matic suspension offers.

According to the Boyle–Mariotte formula defined in the

17th century, the pressure and the volume of a mass of gas

are inversely proportional at a constant temperature. There

fore, by keeping the mass of the gas constant and changing

the volume of its container, its pressure can be controlled

(the usual pneumatic suspensions operate on the opposite

principle: air is admitted or withdrawn from the system by

compressors and exhaust valves, modifying its mass while

keeping the volume constant).

-

-

The First Embodiment

The Citroën DS, introduced at the 1955 Paris Motor Show,