Cissell CBSC Installation Manual

Cabinet Unit

Sleever

CUS/CCBSC

Installation/Operation

CAB70N

CAB70N

WARNING

Read and understand these instructions

before operating or servicing these machines.

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

An LSG Company

831 South First Street, P.O. Box 32270

Louisville, KY 40232-2270

Phone: (502) 587-1292

Sales Fax: (502) 585-3625

Service/Parts Fax: (502) 681-1275

www.cissellmfg.com

Part No. AJ0851

June 2002

Table of

Contents

Safety.................................................................................................... 3

Installation........................................................................................... 5

Front View – CUS Sleever ................................................................... 5

Rear View – CUS Sleever .................................................................... 6

Dimensions and Specifications............................................................. 7

Electrical Data.................................................................................. 8

Motor Data ....................................................................................... 8

General Specifications ..................................................................... 8

Required Materials................................................................................ 9

Receiving Inspection ............................................................................ 9

Location Requirements......................................................................... 10

Foundation Requirements..................................................................... 10

Uncrating .............................................................................................. 10

Installing Anchor Bolts and Leveling Press ......................................... 11

Connecting Steam Supply and Return.................................................. 11

Connecting Air Service......................................................................... 11

Connecting Electrical Service............................................................... 12

Final Preparation for Use...................................................................... 12

Final Check-Out Procedure .................................................................. 12

Operation............................................................................................. 13

Operating Controls and Indicators ................................................... 13

Prepare to Dress Garmet on Buck.................................................... 15

Thread Sleeves on Buck Forms ....................................................... 15

Position Cuffs in Cuff Clamps......................................................... 16

Actuate Air Bags.............................................................................. 16

Align Seam Indicator Beam............................................................. 17

Free Cuffs from Cuff Clamps .......................................................... 17

Remove the Garment ....................................................................... 18

Prepare for Next Operation.............................................................. 18

Maintenance ........................................................................................ 19

Periodic Inspections.............................................................................. 19

Lubrication............................................................................................ 21

Adjusting Air Line Lubricator Flow Rate........................................ 22

Filling Air Line Lubricator .............................................................. 22

Cleaning Air Filter ........................................................................... 23

Cleaning Steam Strainer .................................................................. 23

Cleaning Customer-Furnished Steam Traps .................................... 23

Quality Troubleshooting....................................................................... 24

© Copyright 2002, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

AJ0851

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Notes

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

AJ0851

Safety

Danger indicates the presence of a hazard

that WILL cause SEVERE personal injury,

death, or substantial property damage if the

danger is ignored.

DANGER

Warning indicates the presence of a hazard

that CAN cause SEVERE personal injury,

death, or substantial property damage if the

warning is ignored.

WARNING

Caution indicates the presence of a hazard

that WILL or CAN cause MINOR personal

injury or property damage if the caution is

ignored.

CAUTION

Safe operating and maintenance practices presented in

this manual are emphasized with special safety

messages. These messages are categorized as

DANGER, WARNING and CAUTION. Explanations

of these categories are listed below.

These safety messages are used throughout this

manual to identify safe practices. Signal words are

placed with descriptions or steps where the need to

maintain safe conditions is critical.

Safety signs and labels are also placed on the press.

Those signs and labels are limited messages. Where

needed, further explanations are provided in the

manual. These signs are to be inspected for readability

and replaced when missing, damaged or unreadable.

Refer to Maintenance section of this manual for

inspections process. Refer to Parts Manual for

ordering information.

DANGER

To avoid possible serious injury, ensure

that air and steam supply systems have

adequate RELIEF VALVE PROTECTION or

have the pressures sufficiently limited at

the sources for safe operating pressures

as specified for this equipment.

W333

WARNING

To AVOID possible serious injury, BEFORE

performing maintenance or repair tasks:

• Shut off and lock out ALL electric power

to the unit.

• Shut off and lock out ALL air service to

the unit.

• Shut off and lock out ALL steam service

to the unit.

• Allow heated surfaces to cool.

W399

• Failure to install, maintain, and/or operate this machine according to the manufacturer’s

instructions may result in conditions which can produce serious injury, death, and/or

property damage.

• Do not repair or replace any part of the machine or attempt any servicing unless specifically

recommended or published in the service manual and that you understand and have the

skills to carry out.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the machine is properly grounded and to reduce the risk of fire,

electric shock, serious injury, or death.

AJ0851

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

WARNING

W335

3

Notes

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT AJ0851

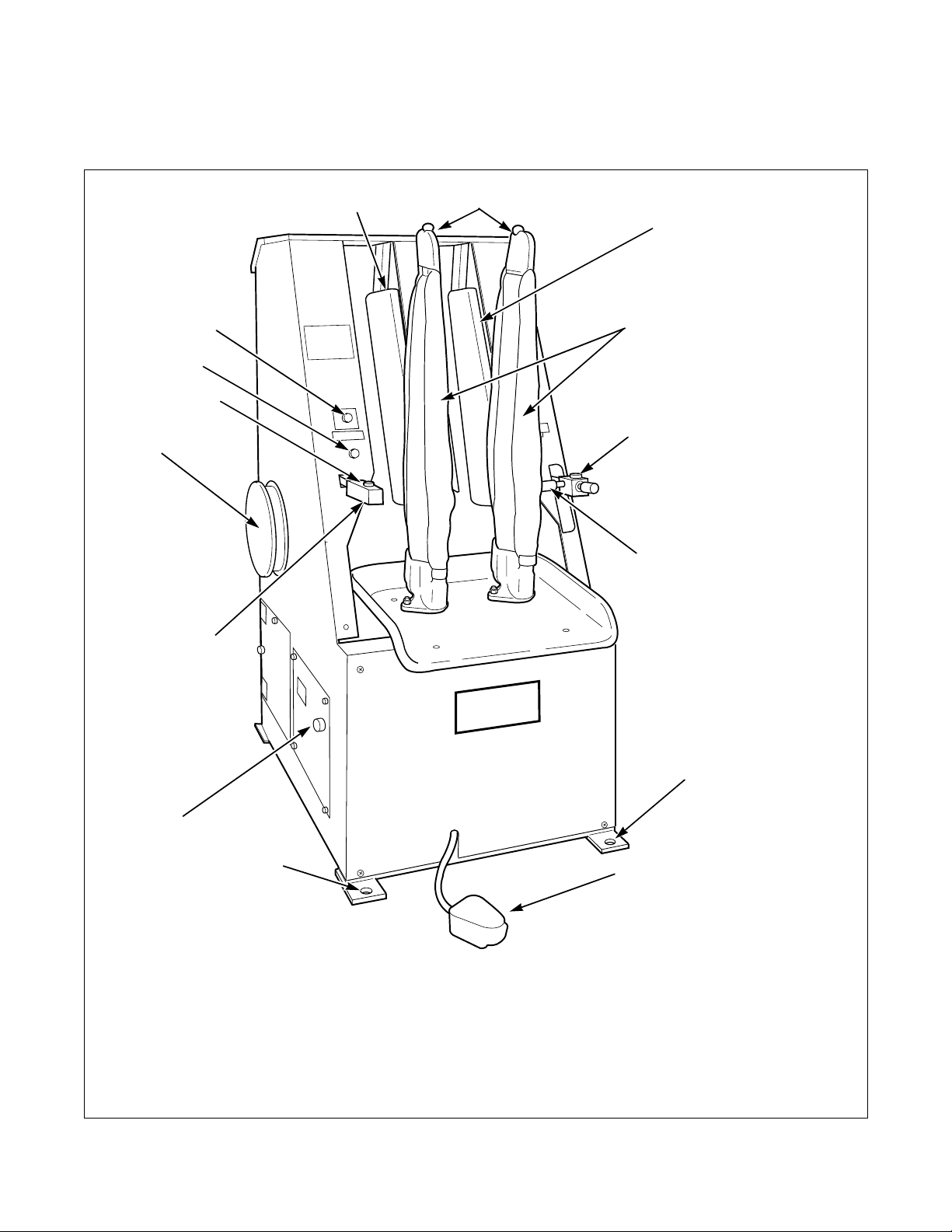

Front View – CUS Sleever

Installation

10

12

13

11

9

1

2

1

3

4

5

8

6

1 Heads 8 Electrical Enclosure

2 Cuff Clamps 9 Safety Handle Assembly

3 Bucks 10 Air Cleaner

4 Right START Pushbutton (Black) 11 Left START Pushbutton (Black)

5 Measuring Lamp 12 STOP Pushbutton (Red)

6 Anchor Bolt Holes 13 Timer Selection

7 Foot Pedal

7

Figure 1

AJ0851

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

6

CAB70N

5

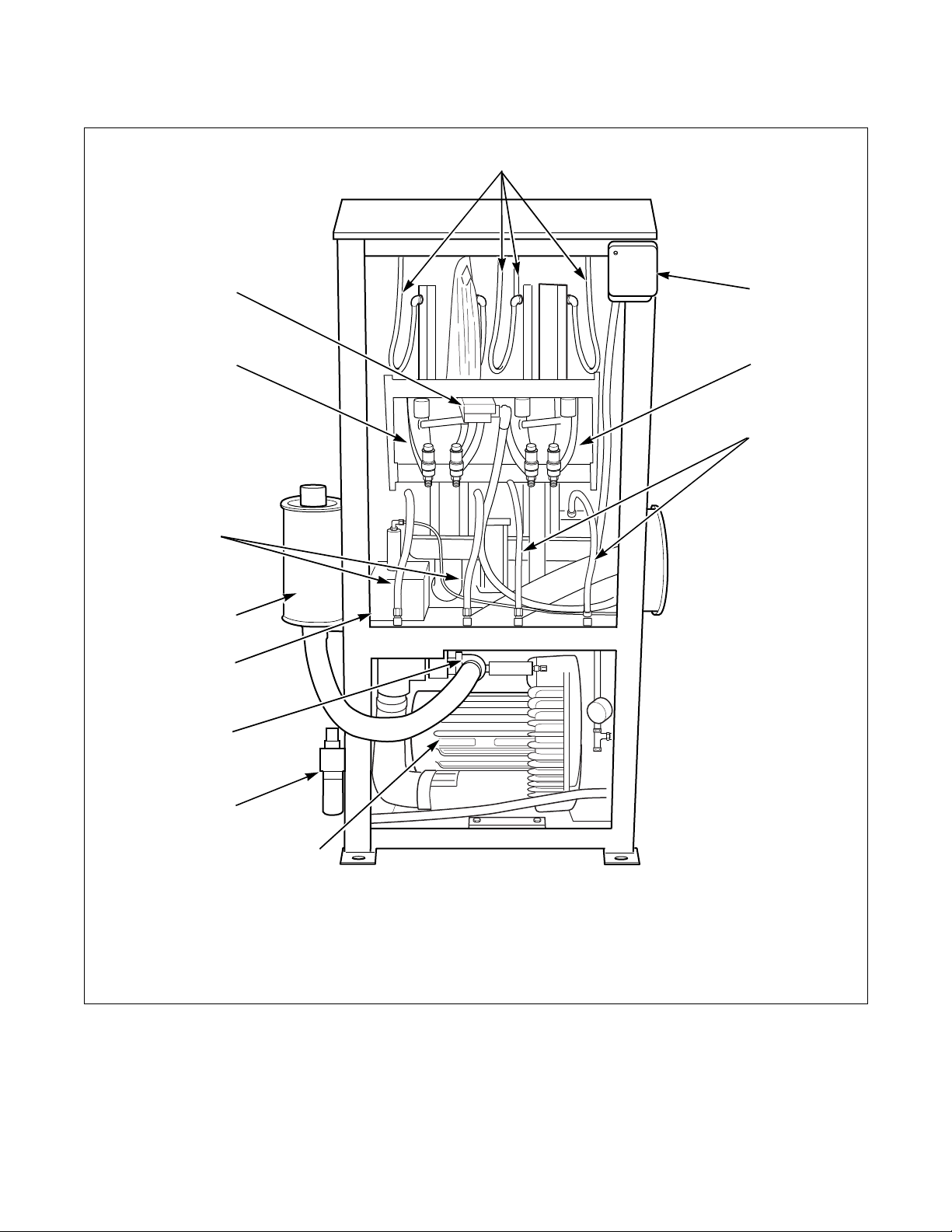

Installation

Rear View – CUS Sleever

1

10

3

4

9

8

7

2

3

4

6

5

1 Head Steam Inlet Hoses 6 Air Filter/Regulator/Lubricator Assembly

2 Electrical Connection 7 Low Pressure Valve Assembly

3 Pressure Arms 8 Damper Box

4 Head Steam Return Hoses 9 Exhaust Muffler

5 Blower 10 Heads Closed Microswitch

Figure 2

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

CAB71N

AJ0851

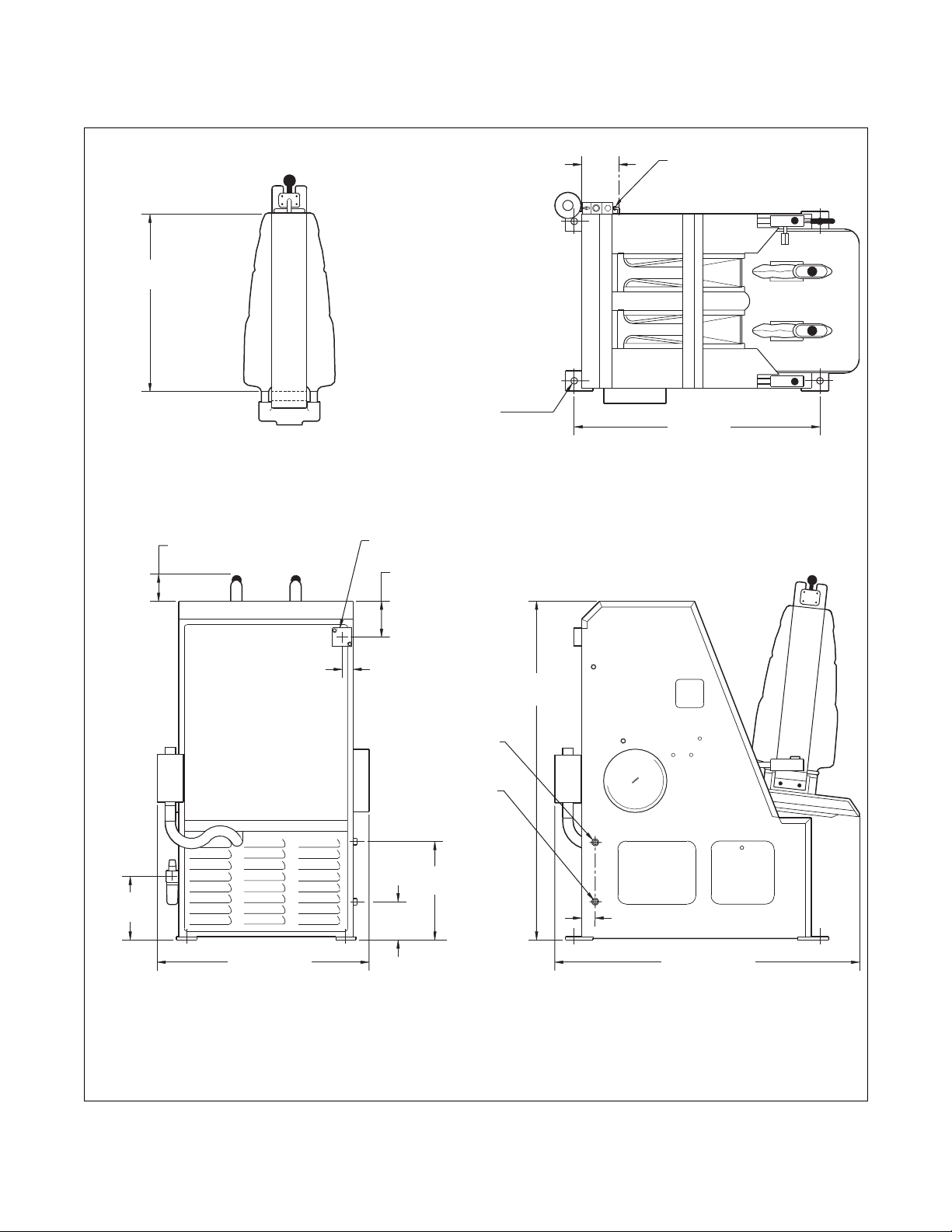

Dimensions and Specifications

Installation

24.56 in.

(624 mm)

This dimension

indicates the

pad length.

BUCK DIMENSIONS

2 in.

(51 mm)

MAX

3

(159 mm)

6.25 in.

2

6.5 in.

(165 mm)

1

40 in.

(1016 mm)

PLAN VIEW

2 in.

(51 mm)

58.5 in.

(1486 mm)

4

5

16.5 in.

11 in.

(279 mm)

33.75 in.

(858 mm)

MAX

(419 mm)

5.5 in.

(139 mm)

2 in.

(51 mm)

REAR ELEVATION SIDE ELEVATION

1 Air Inlet 1/4 FPT 4 Steam Supply 1/2 FPT

2 .88 in. (22 mm) Diameter Anchoring Holes 5 Steam Return 1/2 FPT

3 Electrical Junction Box 4 x 4 x 2.12, .5 in. K.O.

49.5 in.

(1257 mm)

CAB72N

AJ0851

Figure 3

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Loading...

Loading...