Combination

Sleever, Bosom,

Body and Yoke Press

CSBBYMV

Operation/Maintenance

WARNING

Read and understand these instructions

before operating or servicing these machines.

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

An LSG Company

831 South First Street, P.O. Box 32270

Louisville, KY 40232-2270

Phone: (502) 587-1292

Sales Fax: (502) 585-3625

Service/Parts Fax: (502) 681-1275

www.cissellmfg.com

CAB438C

CAB438C

Part No. AJ0975

March 2004

Table of

Contents

Safety Information.............................................................................. 3

Explanation of Safety Messages........................................................... 3

Important Safety Instructions ............................................................... 3

Operation............................................................................................. 5

Front View of CSBBYMV ................................................................... 5

Rear View of CSBBYMV .................................................................... 6

Operating Controls and Indicators........................................................ 7

Operating Controls and Indicators................................................... 8

Resetting Air Circuit............................................................................. 10

Pressing Short Sleeve Shirts ................................................................. 10

Operating Instructions .......................................................................... 11

Pre-Operating Services .................................................................... 11

Post-Operating Services................................................................... 12

Cleaning Press Heads....................................................................... 12

CSBBYMV Operation Sequence..................................................... 13

Buck Dressing Instructions.............................................................. 14

Operating Tips ...................................................................................... 18

Shirt Quality..................................................................................... 18

Padding ............................................................................................ 19

Quality Troubleshooting....................................................................... 20

Maintenance ........................................................................................ 23

General.................................................................................................. 23

Periodic Inspections.............................................................................. 23

Periodic Inspections......................................................................... 24

Cleaning Air Filter ........................................................................... 25

Cleaning Steam Strainer .................................................................. 25

Cleaning Customer-Furnished Steam Traps .................................... 25

Lubrication....................................................................................... 26

Monthly Lubrication............................................................................. 28

Adjusting Air Line Lubricator Flow Rate........................................ 28

Filling Air Line Lubricator .............................................................. 29

© Copyright 2004, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

AJ0975

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Notes

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

AJ0975

Safety Information

Explanation of Safety Messages

Precautionary statements (“DANGER,” “WARNING,”

and “CAUTION”), followed by specific instructions,

are found in this manual and on machine decals. These

precautions are intended for the personal safety of the

operator, user, servicer, and those maintaining the

machine.

DANGER

Indicates an imminently hazardous

situation that, if not avoided, will cause

severe personal injury or death.

WARNING

Indicates a hazardous situation that, if not

avoided, could cause severe personal

injury or death.

Important Safety Instructions

Save These Instructions

WARNING

Failure to install, maintain, and/or operate

this machine according to manufacturer’s

instructions may result in conditions

which can produce serious injury, death

and/or property damage.

NOTE: The WARNING and IMPORTANT

instructions appearing in this manual are not

meant to cover all possible conditions and

situations that may occur. It must be understood

that common sense, caution, and carefulness are

factors which CANNOT be built into this press.

These factors MUST BE supplied by the person(s)

installing, maintaining or operating the ironer.

Always contact your dealer, distributor, service agent,

or the manufacturer on any problems or conditions you

do not understand.

CAUTION

Indicates a hazardous situation that, if not

avoided, may cause minor or moderate

personal injury or property damage.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

Always contact your dealer, distributor, service agent,

or the manufacturer on any problems or conditions you

do not understand.

1. Read all instructions before using the press.

2. Refer to the GROUNDING INSTRUCTIONS in

the INSTALLATION manual for the proper

grounding of the press.

3. Do not allow children to play on or in the press.

4. Do not reach into the press while the press is in

operation.

5. Do not install or store the press where it will be

exposed to water and/or weather.

6. Do not tamper with the controls.

7. Do not repair or replace any part of the press, or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that the user understands and has the

skills to carry out.

8. To reduce the risk of an electric shock or fire, DO

NOT use an extension cord or an adapter to

connect the press to the electrical power source.

AJ0975

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Safety Information

9. Use press only for its intended purpose, finishing

garments.

10. ALWAYS disconnect the press from electrical

supply before attempting any service. Disconnect

the power cord by grasping the plug, not the cord.

11. Install the press according to the

INSTALLATION INSTRUCTIONS. All

connections for steam, electrical power and

grounding must comply with local codes and be

made by licensed personnel when required.

12. Replace worn power cords and/or loose plugs.

13. Never operate the press with any guards

and/or panels removed.

14. DO NOT operate the press with missing or

broken parts.

15. DO NOT bypass any safety devices.

16. Failure to install, maintain, and/or operate this

press according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

NOTE: The WARNINGS and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining, or operating the press.

Any problems or conditions not understood should be

reported to the dealer, distributor, service agent or the

manufacturer.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

AJ0975

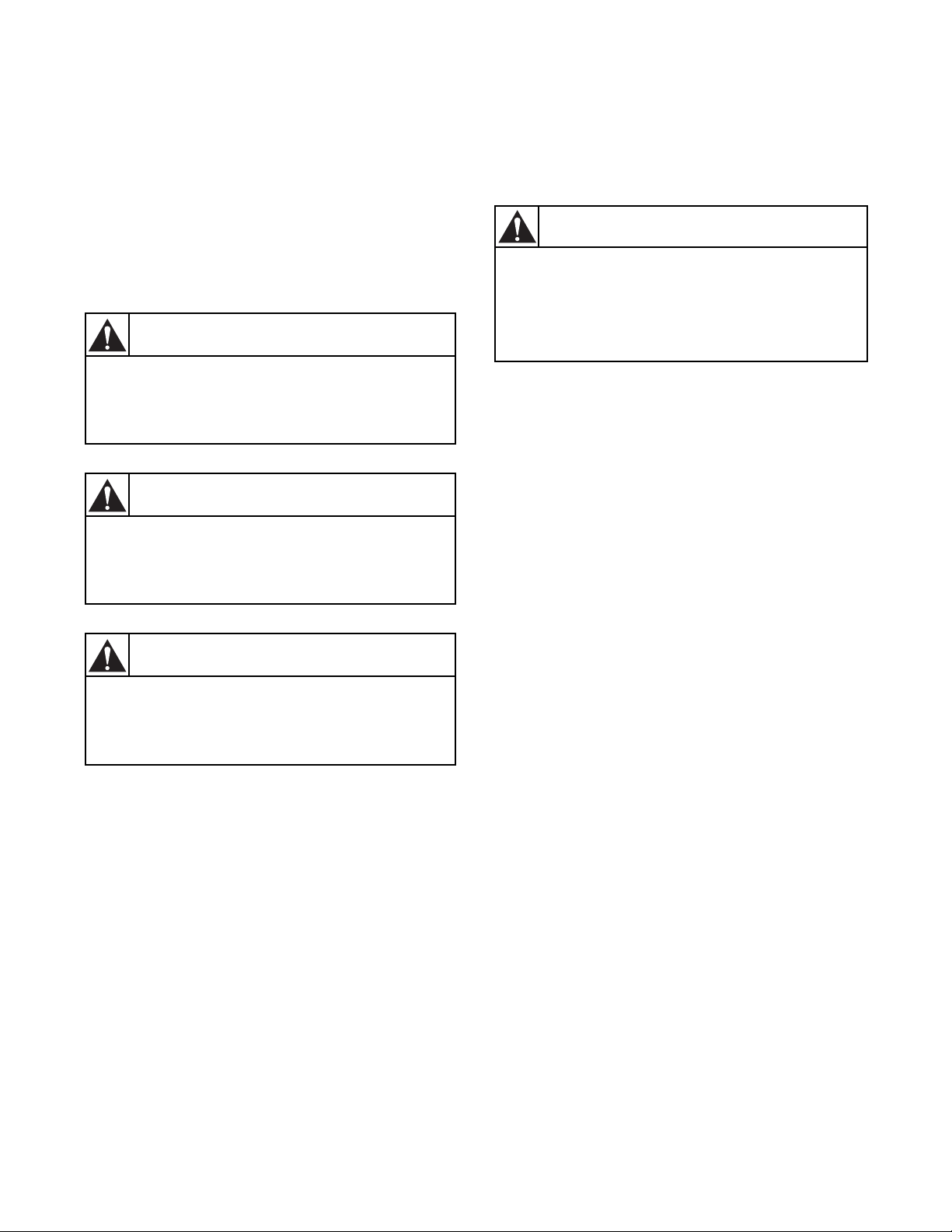

Front View of CSBBYMV

Operation

2

1

3

4

5

6

7

8

9

10

CAB697N

12

14

1 Left End Guard 8 Sleeve Blower

2 Sleeve Extender Arms 9 Heat Exchanger, Buck Air Bags

3 Buck 10 Heat Exchanger, Sleeves

4 Mirror 11 Electrical Control Panel

5 Safety Bars 12 Front Head

6 Water Spray Gun 13 Operator Control Buttons

7 Electrical Box 14 Adjustable Air Valves

13

11

Figure 1

CAB697N

AJ0975

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

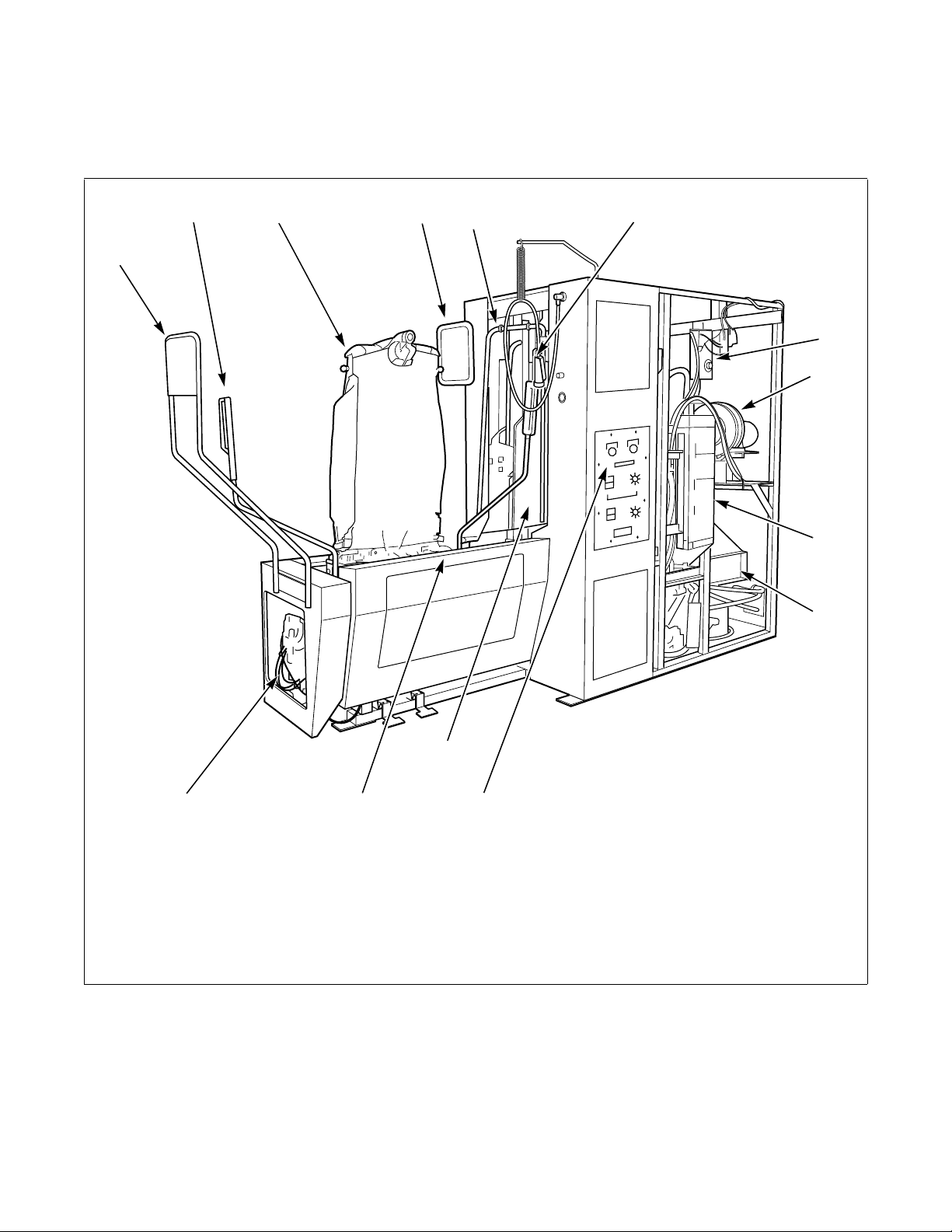

Operation

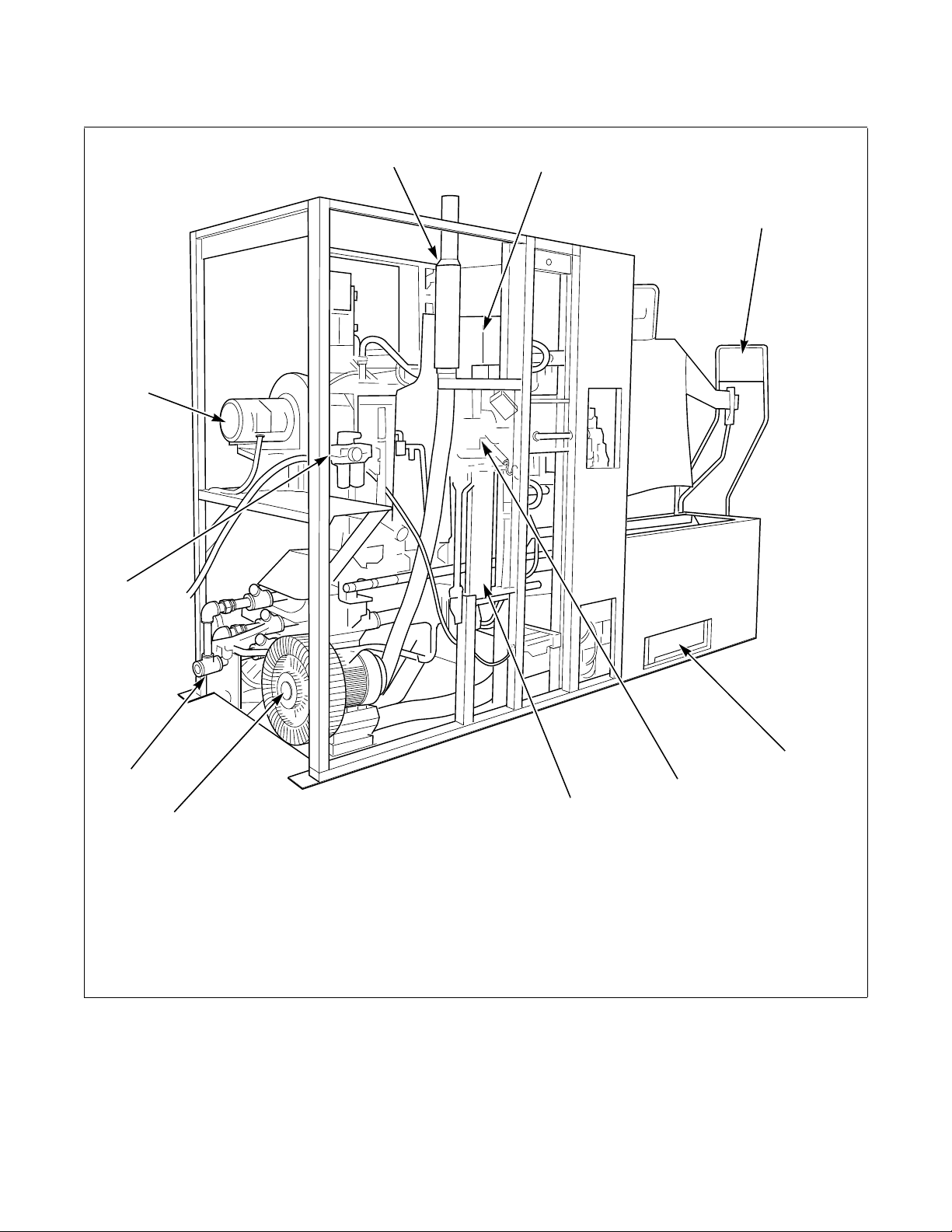

Rear View of CSBBYMV

11

9, 10

1

2

3

8

7

6

CAB83N

5

1 Exhaust Muffler 7 Blower, Buck Air Bags

2 Rear Head 8 Steam Inlet

3 Left End Guard 9 OSHA Approved Shut-Off Valve at Air Inlet

4 Air Intake Filters 10 Air Inlet, Filter, Regulator and Lubricator

5 Steam Solenoid Valve, Sleeves 11 Sleeve Blower

6 Steam Condensate Tank, Sleeves

Figure 2

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

4

CAB83N

AJ0975

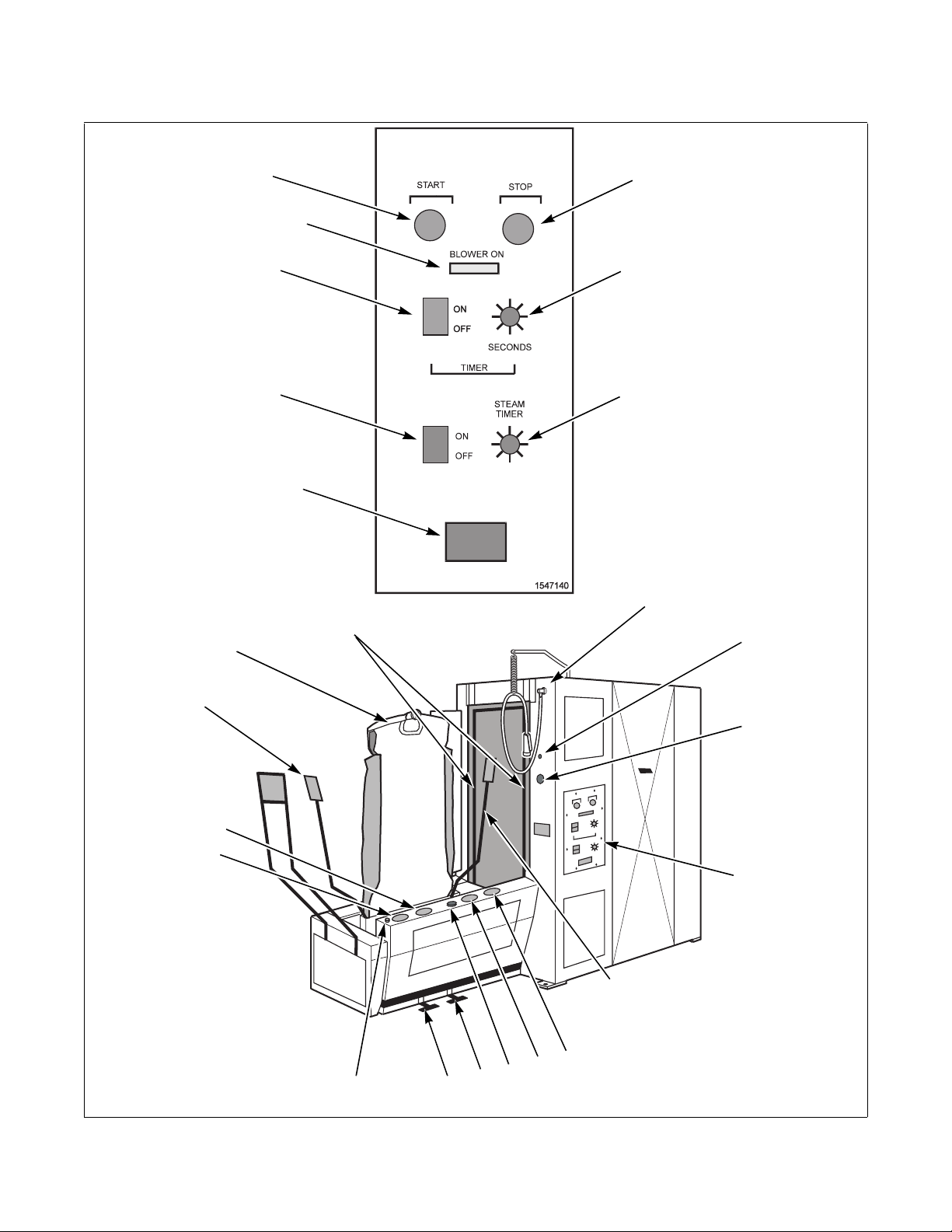

Operating Controls and Indicators

Operation

16

22

20

19

21

18

17

CAB89N

CAB89N

1

2

3

4

5

15

13

14

12

10

11

Figure 3

6

SEE DETAIL

ABOVE

15

CAB698N

CAB698N

7

8

9

AJ0975

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Operation

Operating Controls and Indicators

Refer to Figure 3.

Controls or

Indicators

Function Position or Indication

1. Red stop button Stops electrical service to blowers, timers, and heat exchanger. Press to actuate.

2. Cycle timer control

knob

3. Steam timer control

knob

4. Water gun needle

valve

Determines pressing cyle time. Rotate knob to desired

setting.

Determines the length of sleeve steaming time. Normally set at

5 seconds.

Rotate knob to desired

setting.

Turns water on and off to water spray gun. Turn clockwise to turn

water off. Turn

counterclockwise to turn

water on.

5. Reset button Energizes the air power control circuit. Press must be reset if press gauge

(item 6) registers 0 psi.

With buck in the out

position, press reset

button.

6. Gauge, reset system Indicates that air power is on or off to press. When gauge shows line

pressure, air is reset to

press. When gauge shows

zero pressure, air must be

reset for press to operate.

7. Right gray buck in

button

When pressed simultaneously with the left gray buck in button

(item

13), moves buck from dressing position to pressing position inside

cabinet.

Press simultaneously

with left gray buck in

button (item 13) to

actuate.

8. Black vacuum

Turns vacuum off to buck. Press to actuate.

release button

9. Emergency Stop

button

Exhausts entire air system except for air to collar clamp air cylinder.

Stops buck travel and opens press heads or keeps press heads from

closing. Press will not operate until air circuit is reset. (Applies to

machines produced after 1997.)

Press to actuate. Turn in

direction of arrow on

button to reset. Button

will pop up after

approximately 1/8 turn.

10. Collar clamp foot

pedal

Opens clamping arm on collar clamp (item 16). Depress foot pedal to

open collar clamp.

Release foot pedal to

close collar clamp.

11. Sleeve extender/

vacuum foot pedal

12. Sleeve extender

release button

13. Left gray buck in

button

14. Red head release

button

Moves the sleeve extenders out and turns vacuum on to buck. Depress foot pedal to

actuate.

Retracts sleeve extenders, which brings them in toward the buck. Should

Press to actuate.

be actuated before dressing shirt on buck.

When pressed simultaneously with the right gray buck in button

(item

7), moves buck from dressing position to pressing position inside

cabinet.

Opens the press heads. Buck will automatically return to the dressing

Press simultaneously

with right gray buck in

button (item 7) to actuate.

Press to actuate.

position when heads open.

Table 1 (Continued)

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

AJ0975

Table 1 (Continued)

Operation

Controls or

Indicators

15. Sleeve extender

rods

Clamp cuffs and extend sleeves outward for high quality finish. Extend shirt sleeves via

Function Position or Indication

foot pedal (item 11).

Retract sleeve extender

arms via sleeve extender

button (item 12).

16. Collar clamp Holds shirt collar in place on buck (refer to item 10). Open and close clamp

with foot pedal (item 10).

17. Safety bars Exhausts entire air system except air to collar clamp air cylinder. Stops

Press to actuate.

buck travel, and opens press heads or keeps press heads from closing.

Press will not operate until air circuit is reset.

18. Counter Registers number of garments pressed. Works only when timer is

on.

19. Steam timer

Turns steam timer on and off. Push to on or off position.

selector switch

20. Cycle timer selector

Turns cycle timer on and off. Push to on or off position.

switch

21. Indicator lamp Indicates electrical service is on or off to blowers, timers, and heat

exchanger.

Illuminates to indicate

electrical power is

present.

22. Black start button If air is reset to press, applies electrical service to blower and timers. If

Press to actuate.

air is not reset to press, start button will not operate.

AJ0975

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Operation

Resetting Air Circuit

The air circuit must be reset before press can be used.

Resetting is required if:

● Press has been shut down.

● Any safety bar or red emergency stop button has

been activated.

● Gauge indicates 0 air pressure.

To reset air to press:

Move buck to dressing position by hand.

Turn red emergency stop button in direction of arrows

until it pops up.

Press reset button. Air should reset and line pressure

(approximately 65 psi [4.48 bar]) should register on

gauge.

NOTE: If press does not reset, call a qualified

service technician.

Pressing Short Sleeve Shirts

Sleeve extender arms are not used when a short sleeve

shirt is dressed on the buck. The operator should turn

the steam timer selector switch to the off position to

stop live steam and sleeve blower air through sleeve

armhole.

CAUTION

To avoid possible injury:

• ALWAYS turn STEAM Timer Selector

switch OFF when pressing short sleeve

shirts.

• ALWAYS stand clear of live steam when

sending buck into pressing cabinet.

W441

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

AJ0975

Operating Instructions

These instructions will provide the best shirt pressing

quality and prolong padding life.

Pre-Operating Services

Perform the following services daily before using the

press:

1. Check condition of buck padding and air bags.

Replace if:

● Cover is scorched or torn.

Operation

WARNING

To avoid possible serious injury NEVER

use press unless BOTH safety bars are

working properly.

W375

8. Reset air to press. Send buck into cabinet. Allow

buck to travel into cabinet and heads to close.

Press emergency stop button. Press heads should

open; buck should remain stationary. Pressure

GAUGE should read 0.

● Air bags have holes.

● Flannel is hard or brittle (not springy).

2. While steam and air are off and heads are cool,

remove debris that may have fallen inside press.

Remove all lint.

3. Open shut-off valves in steam supply and return

lines. Allow 15 to 20 minutes for press to heat.

NOTE: Open shut-off valves slowly to prevent

water hammer.

4. Open valve(s) in air supply line and reset press.

CAUTION

To avoid possibly serious injury, ALWAYS

turn STEAM Timer Selector switch to OFF

position during pre-operating services.

W442

5. Turn off steam to buck steam sleeve openings by

pressing the steam timer selector switch to the off

position.

6. Simultaneously press and release both gray buck

in buttons. As buck travels into cabinet, press

safety bar located near the operator. Buck should

stop; press heads should remain open; and air

should exhaust from system. Pressure gauge

should read 0.

NOTE: It is necessary to pull buck back to dressing

position before resetting the press.

9. Reset air to press.

NOTE: Emergency stop button must be reset after

it is actuated. Turn in the direction as indicated by

the button. Continue turning until button pops up.

10. Preheat buck prior to starting production.

IMPORTANT: Preheating the buck will prevent

water build-up in sleeve blower system, as well as

provide the best shirt production. Without

preheating, water can discharge from buck on

nearby garments.

11. Mist air bags with water and send unloaded buck

into pressing cabinet. Repeat 3 or 4 times to

preheat bucks and prolong life of air bags.

NOTE: Repeat step 10 if buck has not been in

operation for more than 30 minutes.

12. Close customer-furnished electrical disconnect

switch or set circuit breaker(s).

13. Start blower by pressing black start button. Allow

blower to run for 5 minutes.

NOTE: It is necessary to pull buck back to dressing

position before resetting the press.

7. Reset air to press. Simultaneously press and

release both gray buck in buttons. Allow buck to

travel into cabinet and heads to close. Press other

safety bar. Press heads should open; buck should

remain stationary gauge should read 0.

NOTE: It is necessary to pull buck back to dressing

position before resetting the press.

AJ0975

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Operation

Post-Operating Services

Perform the following services after the final operation

of the day or anytime press will be idle for an extended

period of time:

1. Turn off steam to buck sleeve openings by

pressing the steam Timer Selector switch to the

off position.

2. Mist air bags with water and send unloaded buck

into pressing cabinet (this will prolong the life of

the air bag and eliminate formation of wrinkles in

air bags). Repeat 4 times.

3. Press one safety bar to relieve air pressure and

stop blower.

4. Open customer-furnished electrical disconnect

switch or trip the circuit breaker.

5. Close steam shut-off valve.

6. Close shut-off valve at air inlet.

7. Clean buck padding with a damp cloth. Check

condition of buck padding and air bags. Replace

padding if:

● Cover is scorched or torn.

● Bags have holes.

● Flannel is hard or brittle (not springy).

8. Clean press heads if required.

Cleaning Press Heads

Press heads require cleaning if:

● Discoloration transfers from head to shirts.

● Shirts stick to heads as the heads open.

Once precautions listed in these WARNINGS have

been met, follow directions provided with surface

cleaner to clean press heads.

WARNING

To avoid possible serious injury, heads

should be cleaned ONLY by properly

trained personnel.

W376

WARNING

To avoid possible serious injury, ALWAYS

shut off services to press BEFORE

removing guards and covers to clean

press heads.

• Shut off AND lock out ALL electrical

power to press.

• Shut off AND lock out ALL air pressure

to press using the relieving shut-off

valve at air supply inlet.

• Reduce steam pressure to 0 AND lock

out steam supply to press.

• Let heated surfaces cool.

W377

12

WARNING

If using a surface cleaner which requires

heat to the press, use an industry

approved heat protective mitt or other

heat protective device as press heads are

cooling down.

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

W378

AJ0975

Operation

CSBBYMV Operation Sequence

Single Operator. Refer to Figure 4.

A typical single operator shirt station consists of:

● One CSBBYMV sleeve, bosom, body and yoke

press

● One collar and cuff press (CUCC)

● One collar post

● One damp box

To increase operator productivity (with less fatigue)

position the items listed above as shown in

Set timers as follows:

● Steam timer – 5 seconds

● Cycle timer – 35 seconds (100% cotton)

● Cycle timer – 25 seconds (Blends)

NOTE: Pressing and steam times may vary based

on:

● Steam pressure at the press. Ideally, steam

pressure at press should be 105-115 psi

(7.24-7.93 bar).

● Shirt fabric (100% cotton, blends, etc.).

● Fabric thickness and weight.

● Moisture retention in shirts should be 40% to

50%.

The sequence begins by removing a shirt from the

damp box and dressing it on the collar and cuff press.

As this shirt progresses COUNTERCLOCKWISE

through the station, other shirts will also be introduced

until there is a shirt at the collar post, the CSBBYMV

and the CUCC. The operator will then move in a

CLOCKWISE direction to keep shirts in all three

operations simultaneously.

Figure 4.

5. Unload CUCC. Hang shirt 2 on garment hook.

6. Load shirt 3 from damp box onto CUCC.

7. Remove shirt 1 from buck. Place on collar post.

Form collar and button. Leave shirt on collar post

to cure.

8. Load shirt 2 from garment hook onto buck.

9. Unload CUCC. Hang shirt 3 on garment hook.

10. Load shirt 4 from damp box onto CUCC.

11. Hang shirt 1 from collar post on finished rack.

12. Unload shirt 2 from buck. Place on collar post.

Repeat steps 7 through 12.

2

1

3

5

4

CAB416N

TYPICAL CSBBYMV LAYOUT

CAB416N

1 Collar Post

2 CSBBYMV

3 CUCC

4 Damp Box

5 Operator

Figure 4

The operation sequence for the CSBBYMV is:

1. Load shirt 1 from damp box onto CUCC.

2. Unload CUCC. Hang shirt 1 on garment hook.

3. Load shirt 2 from damp box onto CUCC.

4. Load shirt 1 from garment hook onto buck.

AJ0975

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Operation

Buck Dressing Instructions

The steps listed below outline the procedure for

dressing a shirt on the buck.

1. Grasp shirt by neck band with label side facing

you. Turn to buck and swing the right arm of shirt

over the buck (at the same time you are guiding

the left side so the buck fills shirt armhole). Refer

Figure 5.

to

NOTE: This action should be as natural as putting

on your own shirt. Never lift the shirt over the buck

(this would result in unnecessary fatigue).

4. Depress collar clamp foot pedal to open collar

clamp. Slide index finger of each hand along

neck band from the top down to the points of the

collar. Guide left collar point under right point.

Butt neck band ends together. Do NOT overlap

band ends except for large size shirts. Refer to

Figure 7.

5. Hold neck band ends up in place with two fingers

placed just below button and buttonhole of neck

band. Release collar clamp foot pedal to close

clamp against shirt collar. Buttonhole must be

under clamp so that button strip will not distort it

when pulled. Refer to

Figure 8.

CAB417N

Figure 5

2. Using your right hand, bring the shirt around the

buck and let it rest in position. Grasp extreme

ends of shirt yoke with both hands. Stretch yoke

and center shirt on the buck. Refer to

Figure 6.

3. Front seam of yoke should form a straight line

across the buck when properly dressed.

CAB419N

Figure 7

CAB420N

14

CAB418N

Figure 6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 8

AJ0975

Operation

6. Grasp one sleeve with gusset facing you. Overlap

gusset of cuff as if you are going to button cuff so

that air does not escape gusset. The sleeve end is

now closed (do not button). Refer to

Figure 9.

CAB421N

NOTE: Dress sleeve into clamp at CUFF SEAM.

Do NOT place cuff in clamp. Loading cuff into

clamp will pinch or crease the cuff. A guide on each

clamp will cause you to meet resistance if cuff is

accidentally loaded. Refer to

Figure 11

Figure 11.

CAB478N

Figure 9

7. Turn cuff so gusset is facing away from you.

Slide closed sleeve upward in the sleeve extender

just above cuff seam. Sleeve should not be

twisted between shoulder and cuff. Pleat closest

to gusset should ride top edge of sleeve. Repeat

with other sleeve. Refer to

NOTE:.

CAB422N

NOTE: Do NOT leave gap between cuff and clamp

when loading sleeve. The area of the sleeve below

clamp will NOT finish properly. Refer to

1

1 Cuff

2 Sleeve

1

2

Figure 12

Figure 12.

2

CAB479N

NOTE: Do NOT clamp short sleeve shirts. Instead,

turn STEAM Timer Selector switch to the OFF

position when pressing short sleeve shirts. Return

STEAM Timer Selector switch to the ON position

for long sleeves.

AJ0975

Figure 10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Operation

8. Press the left foot pedal to extend the sleeves and

turn the buck vacuum on.

9. Notice a natural “A” at shirt’s placket. The gap at

the bottom is related to shirt size. The larger

shirts will have a smaller gap. Refer to

CORRECT

Figure 13.

CAB423N

Figure 14

11. With thumb and first finger of both hands, grasp

the bottom of the placket and side seam at the left

side of the shirt. Gently pull downward. Pull the

placket downward in the direction of the natural

“A.” This action has straightened the front and

back of the shirt.

WRONG

WRONG

CAB254N

Figure 13

10. Using the thumb and first finger of both hands,

grasp bottom of placket and side seam on right

side of shirt. Gently pull downward. Pull placket

downward in the direction of the “A.” Refer to

Figure 13.

IMPORTANT: Do NOT attempt to fit the shirt to

the buck or placket bowing will occur. The side

seams of the shirt should roll toward back of buck.

Remember, dress the shirt LOOSELY. The air bags

will expand to fit the shirt.

12. Look in mirror to check shirt back for horizontal

or angled wrinkles from the middle of yoke

outward toward the sides. If necessary, gently

pull shirt downward in center to remove these

wrinkles. Air bags will remove vertical wrinkles

when forming shirt.

NOTE: The front and back of shirt should now be

straight.

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

AJ0975

13. Spray with water gun if necessary. Refer to

Figure 15.

Figure 15

14. If necessary, move your hand in an upward

direction over the pocket to remove any air

trapped inside. Refer to

Figure 16.

Operation

CAB424N

CAB425N

Figure 16

NOTE: Only excessive wrinkles must be removed

by operator.

15. Press both BUCK IN buttons at the same time to

start pressing cycle.

NOTE: Stay clear as buck enters cabinet.

CAB426N

Figure 17

17. Press right foot pedal to release collar clamp. Lift

right side of shirt. Move right shoulder clear of

buck with a slight upward then backward motion

of your hand. Do not swing your right arm over

the buck (that would be unnecessary motion).

Refer to

Figure 18.

16. When press cycle is finished and buck has

traveled out of cabinet, unclamp sleeves by

pulling both of them down at the same time.

Refer to

AJ0975

Figure 17.

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

CAB427N

Figure 18

17

Operation

18. Using your left hand, grasp the left sleeve just

next to the yoke. Pull the shirt to your left and off

the buck. As the right side of shirt clears the

buck, position the fingers of your right hand so

they catch the left side of shirt and slide to the

right of the yoke. This opens the shirt and

supports it so it can easily drape over collar form.

Refer to

Figure 19.

Operating Tips

Shirt Quality

The CSBBYMV gives a high volume professional

finish to sleeves, bosom, body, sides and yoke of

shirts. To achieve best shirt quality and volume:

● Extract shirts to obtain 40% to 50% moisture

retention.

● Keep press padding in good condition.

Too much moisture in shirts will increase pressing

cycle time, reduce shirt production and padding life.

Too little moisture will cause poor shirt finish.

Checking Moisture Retention in Shirts

Moisture retention is the percentage increase in weight

of a load of shirts after they are washed and extracted.

To check moisture retention:

● Weigh a load of dry shirts.

● Wash and extract shirts and then weigh them

again.

CAB428N

Figure 19

19. Grasp center of collar with thumb and finger of

both hands just above neck band. Run hands

along collar slightly turning the collar back.

When fingers reach the end of neck band, hold

neck band straight out and completely fold collar

over. Continue holding folded collar and polish

inside of neck band on collar form. Run the collar

from right to left while applying light tension.

20. Pull collar toward you. Place collar against collar

former and press collar firmly down against

heated collar post. Allow collar to cure on post.

21. Push sleeve extender release button to bring

sleeve rods toward buck for loading next shirt.

The percentage increase in weight is the moisture

retention for that load.

Example: A load of shirts weighs 50 pounds

kg) dry. After being washed and extracted, that

(22.68

same load weighs 70 to 75 pounds (31.75 to 34.02 kg).

The difference in weight is 20 to 25 pounds (9.07 to

kg). The percentage of added weight is the

11.34

difference over the dry weight or 20/50 and 25/50

which is 40%/50%.

Extract times required for optimum moisture retention

will vary by washer. Always test several loads of shirts

when determining extract and conditioning times.

Shirt fabric also affects moisture retention. One

hundred percent (100%) cotton shirts will hold more

moisture than cotton/poly blended shirts.

NOTE: Do NOT judge moisture by touch. Warm

shirts feel dryer than cold shirts.

Shirt Quality Troubleshooting

Most quality related problems are due to:

● Worn base pads, padding, and air bags.

● Incorrect dressing techniques (refer to Operating

Instructions).

18

● Incorrect moisture retention.

● Improper steam pressure.

Refer to Table 2 for problems and recommended

solutions.

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

AJ0975

Operation

Padding

Padding is very important to garment quality. Air bags

which are worn or made from improper material

cannot give good results. Bag and cover assemblies

purchased from different suppliers can affect shirt

quality.

Thirty ounce (30 oz.) flannel padding (manufactured

from reprocessed nylon) is originally provided with

the press. It is considered to be the best, most

economical padding available. In most cases, this

material will give quality performance for a period of

3 to 5 weeks, depending on production, type of

garment pressed, moisture retention, and chemical

residue in shirts.

NOTE: Replace worn flannel with thirty ounce

(30 oz.) flannel. Fifty ounce (50 oz.) flannel is NOT

recommended for vacuum units.

To increase the life cycle, build up padding that has

developed low areas and is producing pin wrinkles or

rough dry spots on finished shirts by:

● Cutting pieces of cotton flannel to exact size of

depression in padding.

The life cycle of nylon air bags can be extended if

sprayed with water and pressed between heads

(without a shirt on the buck) three times at every

break.

Dressing techniques used by the operator can also

produce rapid local wear or permanent distortion of air

bags.

NOTE: An operator that “saws” the collar in

dressing a buck will often wear out the yoke bag on

each side of collar clamp. If wear of this kind

occurs, spraying these local areas with silicone

spray is recommended. Silicone spray is available

in aerosol cans from most hardware stores.

● Feathering edges of the flannel.

● Fitting those pieces under padding in the

depressions.

AJ0975

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

19

Operation

Quality Troubleshooting

4

1

3

2

1

3

SHIRT QUALITY

5

7

4

Figure 20

Refer to Figure 20.

Trouble Probable Cause Solution

Damp patches

on sleeve

(item 1)

1. Cycle time too short. Increase Timer.

2. Boiler pressure too low. Adjust pressure.

3. Faulty trap or check valve in steam return

Clean, repair or replace faulty trap or check valve.

line from condensate tank.

5

7

6

CAB263N

Placket bowing

at the button

strips (item 2)

4. Steam supply coming from bottom of

Correct inlet piping. Refer to Installation Manual.

header, no riser.

1. Operator pulling shirt too tightly on buck. Dress shirt so it hangs in natural “A.” Refer to Buck

Dressing Instructions.

2. Shirt not held in place by vacuum. Fan or draft in plant blows shirt during transfer.

Redirect fan. Close window or door which causes draft.

Check for hole or collapsed hoses. Flannel padding is

too thick. Install thirty ounce (30 oz.) flannel padding.

3. Air remains in side air bags at end of

pressing cycle and distorts shirts.

4. Air to side air bags distorts shirt before

Damper to heat exchanger is not closing off or is not

closing off soon enough. Adjust as necessary.

Adjust high pressure air to buck air bags.

heads begin to press.

Table 2 (Continued)

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

AJ0975

Table 2 (Continued)

Trouble Probable Cause Solution

Operation

Rough dry damp

patches on sides

(item 3)

Damp patches

on front or back

of garment, OR

pin wrinkles or

rough dry spots

around front

button strip

(items 2 and 4)

1. Pressing cycle too short. Increase pressing time.

2. Shirt moisture retention is over 50%. Reduce moisture retention by increasing extract time or

speed or by increasing water temperature of final rinse.

3. Shirt moisture retention is under 40%. Increase moisture retention by decreasing extract time

or speed or by decreasing water temperature.

4. Improper air bags installed on buck. Check air pressure gauge on discharge tube when buck

is in pressing position and blower is on. If air pressure

gauge does not read between .7 and 1 psi, replace air

bag using the recommended vendor list in your

Preventative Maintenance Guide.

5. Operator is over-spraying garment. Instruct operator to use less water spray.

6. Insufficient temperature at heat exchanger. Either heat exchanger trap or check valve is faulty and

needs repair or replacement; or steam pressure to press

is lower than 115 psi (7.92 bar).

7. Collapsed hoses in blower air system. Check ALL hoses in blower air system. Check for

collapsed inner wall by removing hose from machine.

Straighten hose and look through hose from one end to

the other.

8. Air leak at discharge tube. Align discharge tube to meet up with receiving tube.

9. Holes in side air bags. Replace air bags.

1. Pressing cycle too short. Increase pressing time.

2. Shirt moisture retention is over 50%. Reduce moisture retention by increasing extract time or

speed or by increasing water temperature of final rinse.

3. Shirt moisture retention is under 40%. Increase moisture retention by decreasing extract time

or speed or by decreasing water temperature.

4. Operator is over-spraying garment. Instruct operator to lessen water spray.

5. Insufficient temperature at either front or

rear press head.

Check traps and check valves in steam return for

proper operation. Clean, repair or replace as required.

Steam pressure to press should be 115 psi (7.92 bar).

Rough, dry in

yoke area

(item 5)

AJ0975

6 . Air pressure is low. Provide 65 psi (4.48 bar) air inlet pressure.

7. Padding has sunken areas or is worn and

Replace flannel and/or steel padding.

must be replaced.

1. Same as Probable Causes 1 through 6 on

item 3.

2. Electric thermostat is set below 350°F

Take corrective action.

Set thermostat at 350°F (178°C).

(178°C).

3. Electric heater element or thermostat is

malfunctioning.

Refer to Service Manual or contact a qualified service

technician.

Table 2 (Continued)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Operation

Table 2 (Continued)

Trouble Probable Cause Solution

Middle pleat is

too long

(extends down

entire back of

shirt) (item 6)

Shirt side pleat

is distorted or

crease is pressed

into shirt

(item 7)

1. Holes in air bag do not allow air bags to fill

Replace bag and cover assembly on buck.

out shirt.

2. Collapsed hoses in blower system restrict

airflow to air bags.

Check ALL hoses in blower air system. Check for

collapsed inner wall by removing hose from machine.

Straighten hose and look through hose from one end to

another.

3. Improper air bags installed on buck. Check air pressure gauge on discharge tube when buck

is in pressing position and blower is on. If air pressure

gauge does not read between .7 and 1 psi, replace air

bag using the recommended vendor list in your

Preventative Maintenance Guide.

1. Yoke bag is not providing proper lift. Check where yoke bag is sewn into cover. It should

extend 1/2 in. (12.7 mm) beyond cover on either side.

2. Operator is pulling a twist into back of shirt. Have operator use mirror and make one slight tug in

middle of shirt toward the bottom area.

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

AJ0975

General

Maintenance

This section contains information and instructions

required to perform periodic inspections and lubricate

the press.

Shutdowns due to unscheduled maintenance can be

avoided or minimized by:

● performing periodic inspections as described

and

● performing lubrication services at the time

intervals specified in these instructions.

The following are recommended precautions that

service personnel must understand and apply when

performing general periodic maintenance tasks.

WARNING

To avoid possible serious injury:

• ALWAYS shut off services to press

BEFORE removing guards and covers

to do ANY maintenance, service,

set-up, adjustments or repair tasks.

• Shut off AND lock out ALL electric

power to press.

• Shut off AND lock out ALL air service to

press.

• Shut off AND lock out ALL steam

service to press.

• Let heated surfaces cool.

• Be sure moving parts are at a standstill.

• ALWAYS be careful to AVOID spring

loaded components when working

inside press.

• NEVER adjust, clean or dress buck

while indexing press.

• ALL maintenance, services, etc., MUST

be performed ONLY by qualified service

personnel.

W379

WARNING

To avoid possible serious injury ALWAYS

close air supply line shut-off valve AND

lock out air service BEFORE:

• opening filter drain cock

• removing filter bowl

• filling oil bowl

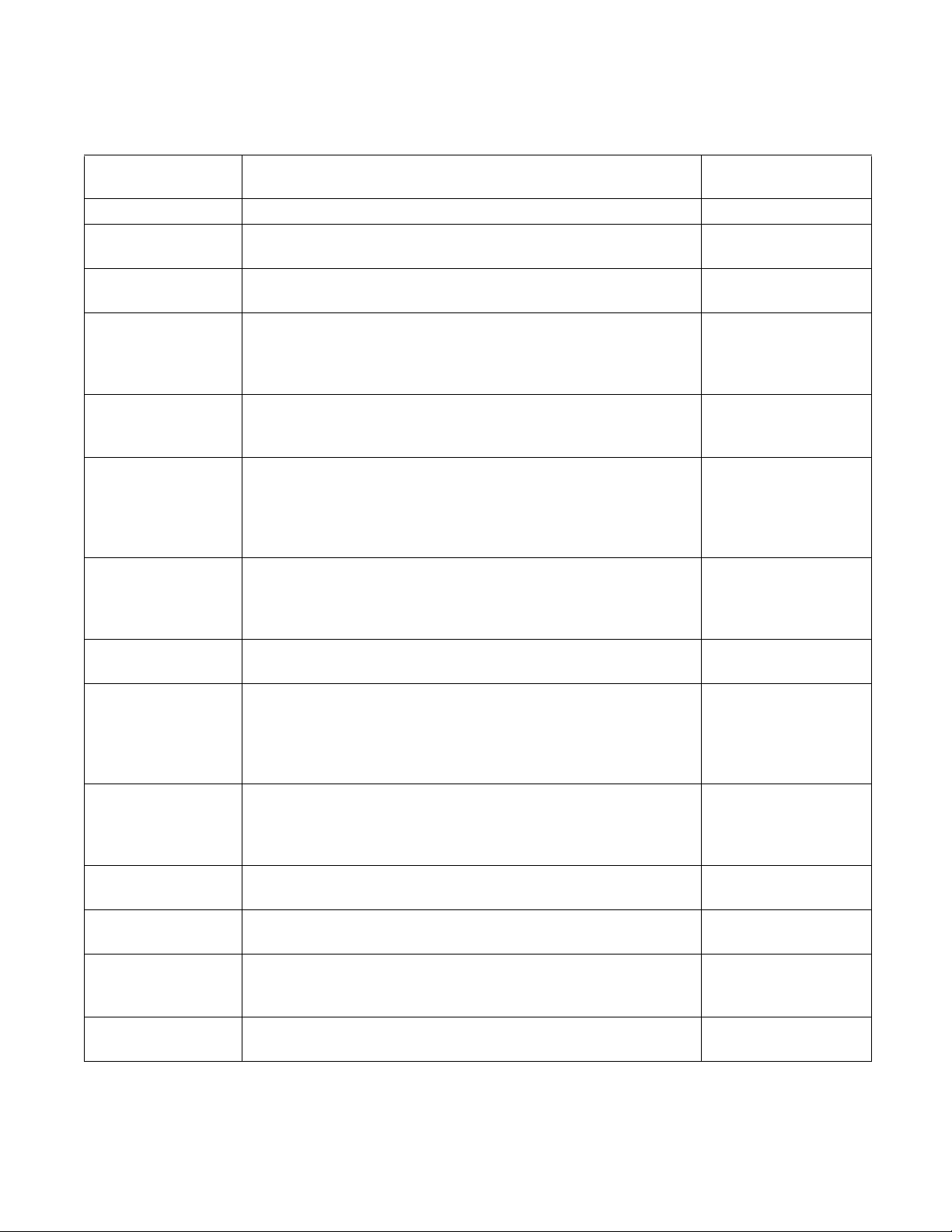

Periodic Inspections

The frequency at which inspections should be

performed, the inspection procedures to be followed,

and the corrective actions to take are listed in

If complete details for the inspections and/or

corrective actions are not listed in

referenced paragraphs for detailed instructions.

Table 3, refer to the

W380

Table 3.

AJ0975

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

23

Maintenance

Periodic Inspections

Timer Intervals Operation or Inspection Corrective Action

Daily or as required Visually inspect the air intake filters. Replace when dirty. They are

throwaway-type filters but can be

cleaned once before discarding.

Visually inspect intake air screen. Remove lint from screen.

NOTE: Do not operate blowers unless air filters are installed.

Visually inspect the sight glass in the air

line filter at the inlet.

Visually check the discharge tube gasket. Replace worn or missing gasket.

NOTE: DO NOT operate press if discharge tube gasket is missing.

Weekly Inspect air line filter for sediment. Clean as necessary.

Inspect all safety labels. See Parts

Manual for location and description of

labels.

Inspect buck stop adjustments. Shock

absorber should not bottom out.

Every 2 weeks Inspect steam strainers in steam inlet and

outlet lines and in traps.

Inspect each blower motor intake for lint

build-up.

Inspect customer-furnished steam traps

per instructions provided with traps.

Monthly Check all steam and air connections for

visual signs of leakage.

Check condition of the flexible steam

hoses.

Attempt to rock buck at operator station

back and forth; check rollers against

rails.

Every 6 months Remove all covers and check cap

screws, fittings and cylinders for security

of attachments.

Table 3

If moisture and oil are collecting in the

bowl, the auto-drain is not working.

Clean, repair or replace air filter.

Replace labels which are damaged,

missing or unreadable.

Adjust shock or bumper as required.

Clean strainers and traps.

Remove lint from motor.

Clean as necessary.

Tighten any loose connections. Replace

lines where necessary.

Steam hoses with broken braids must be

replaced.

If buck carriage rollers are loose against

rails, tighten as required. Rollers should

be snug, but not too tight.

Tighten as required.

24

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

AJ0975

Maintenance

Cleaning Air Filter

Air filters remove foreign matter and condensate from

supply air as it passes through filter. The frequency at

which the filter baffle plate and filter element should

be cleaned depends upon the amount of condensate

and foreign matter in the supply air. The condensate

level should not raise above the baffle. That is a sign of

a faulty auto-drain which would need to be cleaned,

replaced or repaired.

Erratic regulator operations or loss of regulation is

almost always due to dirt.

The following steps outline the procedure for cleaning

the air filter.

WARNING

To avoid possible serious injury ALWAYS

close air supply line shut-off valve AND

lock out air service BEFORE:

• opening filter drain cock

• removing filter bowl

• filling oil bowl

W380

1. Close and lock air service shut-off valve.

2. Remove filter bowl. Use a strap wrench if

required. Disassemble regulator, making notes as

a guide for reassembly.

Cleaning Steam Strainer

Strainer removes foreign matter from steam. The

frequency at which the strainer must be cleaned is

dependent upon the amount of foreign matter

suspended in the steam. It is recommended that the

strainer screen be removed and checked for cleanliness

after 2 weeks or 80 hours of operation. If little or no

foreign matter has collected on the screen, time

between inspections can be increased accordingly.

WARNING

To avoid possible serious injury when

cleaning or repairing traps or strainers:

• Shut off AND lock out ALL steam

service to press.

• Let heated surfaces cool.

W381

Cleaning Customer-Furnished Steam

Traps

Some steam traps are provided with internal steam

strainers. These strainers should be cleaned.

All repairable traps should be opened at least once a

year to visually check operating mechanisms.

Remove sediment and dirt from trap body. The

mechanism may require cleaning by immersing in

appropriate cleaning fluid.

3. Clean parts with household soap and blow out

body with compressed air.

IMPORTANT: DO NOT use cleansing agents such

as acetone, benzene, carbon tetrachloride, gasoline,

toluene, etc., which are damaging to the plastic

sight glass.

4. Reassemble per your notes. Make sure o-ring is

in position on the filter bowl. Tighten bowl to

filter body. Tighten slightly more than hand tight.

5. Open air service shut-off valve.

Maintenance kits available. Refer to parts manual for

numbers.

NOTE: Check instructions provided with trap or

with trap manufacturer for appropriate cleaning

fluids.

AJ0975

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

25

Maintenance

Lubrication

WARNING

To avoid possible serious injury:

• ALWAYS close air supply line shut-off

valve AND lock-out air service BEFORE

performing lubrication services.

W437

Monthly Lubrication

Refer to Figure 21, Figure 22 and Ta b l e 4 for lubrication points.

B

B

A

A

E

E

D

D

CAB542N

CAB542N

F

APPLICATION OF SYMBOL

APPLICATION OF SYMBOL

HI-TEMP

HI-TEMP

LUBRICANT

LUBRICANT

ISO VG 32

ISO VG 32

GRADE OIL

GRADE OIL

C

C

Figure 21

26

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

AJ0975

G

H

Maintenance

90

120

40

160

APPLICATION OF SYMBOL

HI-TEMP

LUBRICANT

ISO VG 32

GRADE OIL

Figure 22

CAB94N

AJ0975

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

27

Maintenance

Monthly Lubrication

Refer to Figure 21 and Figure 22.

Lubrication

Point

(A) Sleeve expander

rod cylinders

Type of Lubricant

ISO VG 32 grade oil Disconnect air line from cylinder. Dispense 4 drops of oil into air

Lubrication

Service

line. Reconnect air line and actuate cylinder to get oil inside

cylinder.

(B) Collar block Ajax hi-temp lubricant Disconnect air line from collar block at base of buck. Dispense 4

drops of oil into air line. Reconnect air line and actuate collar

block to get oil inside cylinder.

C) Buck indexing

cylinder

ISO VG 32 grade oil With buck in dressing position, remove air line from shaft end of

cylinder and dispense 6 to 8 drops of oil into air line. Reconnect

air line and push buck into pressing position. With buck in

pressing position, remove air line from tail end of cylinder and

dispense 6 to 8 drops of oil into air line. Reconnect air line and

pull buck back to dressing position.

(D) Front head closing

cylinder

ISO VG 32 grade oil With blower and timer turned off, and heads open, remove line

from bottom (end opposite shaft) of cylinder. Dispense 4 to 6

drops of oil into air line and reconnect air line. Index buck into

cabinet and allow heads to close. With heads closed, repeat

procedure for air line at shaft end of cylinder. After air line is

reconnected, press button to allow heads to open.

(E) Sleeve extender

ISO VG 32 grade oil Dispense 4 drops to ensure proper working order.

pivot point

(F) Foot Pedals ISO VG 32 grade oil Oil foot pedal at pivot point.

(G) Buck indexing

Va l ve

(H) front head closing

valve

ISO VG 32 grade oil Disconnect air line at the valve. Dispense 6-8 drops of oil into air

line. Reconnect air lines.

ISO VG 32 grade oil Disconnect air line at the valve.Dispense several drops of oil into

air line. Reconnect air line.

NOTE: Buna-N seals are used extensively throughout the valves and cylinders in the air circuit

downstream from the inline oiler. Oils containing graphite fillers, detergent, etc., and fire-resistant and

synthetic oils are not compatible with Buna-N seals. Seal swelling and valve malfunctioning will result with

use of improper oils.

Table 4

Adjusting Air Line Lubricator Flow Rate

The air system oil lubricator should be adjusted so

approximately one drop of oil every ten machine

cycles is metered into the air system. The following

steps outline the procedure for adjusting the air system

2. To increase flow rate, use a screwdriver to turn

the adjusting screw no more than a 1/8 turn in the

counterclockwise direction. Likewise, turn

clockwise to decrease oil flow. Refer to item 1,

Figure 23.

oil lubricator:

1. To initially adjust flow rate, turn on air and cycle

press. Set knob to obtain desired flow rate. After

system reaches normal operating temperature,

check drip rate again and adjust as required.

28

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

AJ0975

Filling Air Line Lubricator

IMPORTANT: To avoid o-ring leaks at the top of

the bowl, do not remove bowl. Fill through the oil

fill hole. Refer to item 2,

When oil level falls below 1/4 full, refill the bowl to

3/4 full (oil level approximately 1/2 inch [12.7 mm]

from top) with SAE 10 weight non detergent oil (refer

).

to

Figure 23.

Maintenance

WARNING

To avoid possible serious injury, ALWAYS

close air supply line shut-off valve AND

lock out air service BEFORE filling oil

bowl.

W383

IMPORTANT: Do not overfill bowl. Damage to

filter, regulator, valves and cylinders will result and

void warranty.

1

2

TOP VIEW

SIDE VIEW

1 Oil Flow Rate Adjusting Screw 3 Air Line Lubricator

2 Oil Fill Hole

Figure 23

3

1631605B

SCR103N

AJ0975

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

29

Maintenance

Notes

30

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

AJ0975

Loading...

Loading...