Page 1

CHA PTER

3

Installing the Cisco VG224 Voice Gateway

This chapter contains the procedures for installing your Cisco VG224 voice gateway and consists of the

following sections:

• Safety Recommendations, page 3-2

• Site Log, page 3-3

• Keeping Track–Checklist, page 3-4

• Mounting Tools and Equipment, page 3-5

• Unpacking and Inspection, page 3-5

• Rack-Mounting the Chassis, page 3-6

• Wall-Mounting the Chassis, page 3-9

• Bench-Top Installation, page 3-11

• Installing the Ground Connection, page 3-11

• Connecting Cables, page 3-14

• Ports, Connectors, and Pinouts, page 3-20

OL-5006-04

• Remote Terminal Connections (If Applicable), page 3-20

• Connecting Backup Power, page 3-21

Tip While you do this installation, record your progress and site information. See the suggested format in

the “Keeping Track–Checklist” section on page 3-4.

Warning

Warning

Only trained and qualified personnel should be allowed to install, replace, or service this equipment.

Statement 1030

Read the installation instructions before connecting the system to the power source.

Cisco VG224 Voice Gateway Hardware Installation Guide

Statement 1004

3-1

Page 2

Safety Recommendations

Safety Recommendations

The following information is included to alert you to safety recommendations and best practices when

working with this equipment.

Maintaining Safety with Electricity

Follow these guidelines when working on equipment powered by electricity.

Chapter 3 Installing the Cisco VG224 Voice Gateway

Warning

Warning

Do not work on the system or connect or disconnect cables during periods of lightning activity.

Statement 1001

Blank faceplates and cover panels serve three important functions: they prevent exposure to

hazardous voltages and currents inside the chassis; they contain electromagnetic interference (EMI)

that might disrupt other equipment; and they direct the flow of cooling air through the chassis. Do not

operate the system unless all cards, faceplates, front covers, and rear covers are in place.

1029

General Safety Practices

Follow these guidelines to ensure personal safety and protect the equipment:

• Keep the chassis area clear and dust-free during and after installation.

• Put the removed chassis cover in a safe place.

• Keep tools away from walk areas where you and others could fall over them.

• Do not wear loose clothing that could get caught in the chassis.

• Wear safety glasses if you are working under any conditions that might be hazardous to your eyes.

Warning

This equipment must be installed and maintained by service personnel as defined by AS/NZS 3260.

Incorrectly connecting this equipment to a general-purpose outlet could be hazardous. The

telecommunications lines must be disconnected 1) before unplugging the main power connector or 2)

while the housing is open, or both.

Statement

Statement 1043

Safety Tips

Cisco VG224 Voice Gateway Hardware Installation Guide

3-2

Use these tips as safety guidelines when installing or working around this equipment.

• Locate the emergency power-off switch for the room in which you are working. Then, if an electrical

accident occurs, you can act quickly to turn off the power.

• Disconnect all power before installing or removing a chassis.

• Do not work alone if potentially hazardous conditions exist.

• Never assume that power is disconnected from a circuit. Always check.

OL-5006-04

Page 3

Chapter 3 Installing the Cisco VG224 Voice Gateway

• Look carefully for possible hazards in your work area, such as moist floors, ungrounded power

extension cables, and missing safety grounds.

• If an electrical accident occurs, proceed as follows:

–

Use caution; do not become a victim yourself.

–

Turn off power to the system.

–

If possible, send another person to get medical aid. Otherwise, assess the condition of the victim

and then call for help.

–

Determine if the person needs rescue breathing or external cardiac compressions; then take

appropriate action.

Preventing Electrostatic Discharge Damage

Electrostatic discharge (ESD) can damage equipment and impair electrical circuitry. ESD occurs when

electronic components are improperly handled; it can result in complete or intermittent failures.

Always follow ESD-prevention procedures when removing and replacing components.

• Ensure that the chassis is electrically connected to earth ground.

Site Log

Caution For safety, periodically check the resistance value of the antistatic strap, which should be between 1 and

Site Log

• Wear an ESD-preventive wrist strap, ensuring that it makes good skin contact.

• Connect the clip to the ESD-strap connection jack (to the left of the power switch on the rear of the

chassis) or to an unpainted chassis frame surface.

10 megohm (Mohm).

We recommend that you maintain a Site Log to record all actions relevant to the system. Site Log entries

might include the following:

• Installation—Print a copy of the Installation Checklist and insert it into the Site Log.

• Upgrades and maintenance—Use the Site Log to record ongoing maintenance and expansion

history. Update the Site Log to reflect the following:

–

Configuration changes

–

Maintenance schedules, requirements, and procedures performed

–

Comments, notes, and problems

–

Changes and updates to Cisco IOS software

OL-5006-04

Cisco VG224 Voice Gateway Hardware Installation Guide

3-3

Page 4

Chapter 3 Installing the Cisco VG224 Voice Gateway

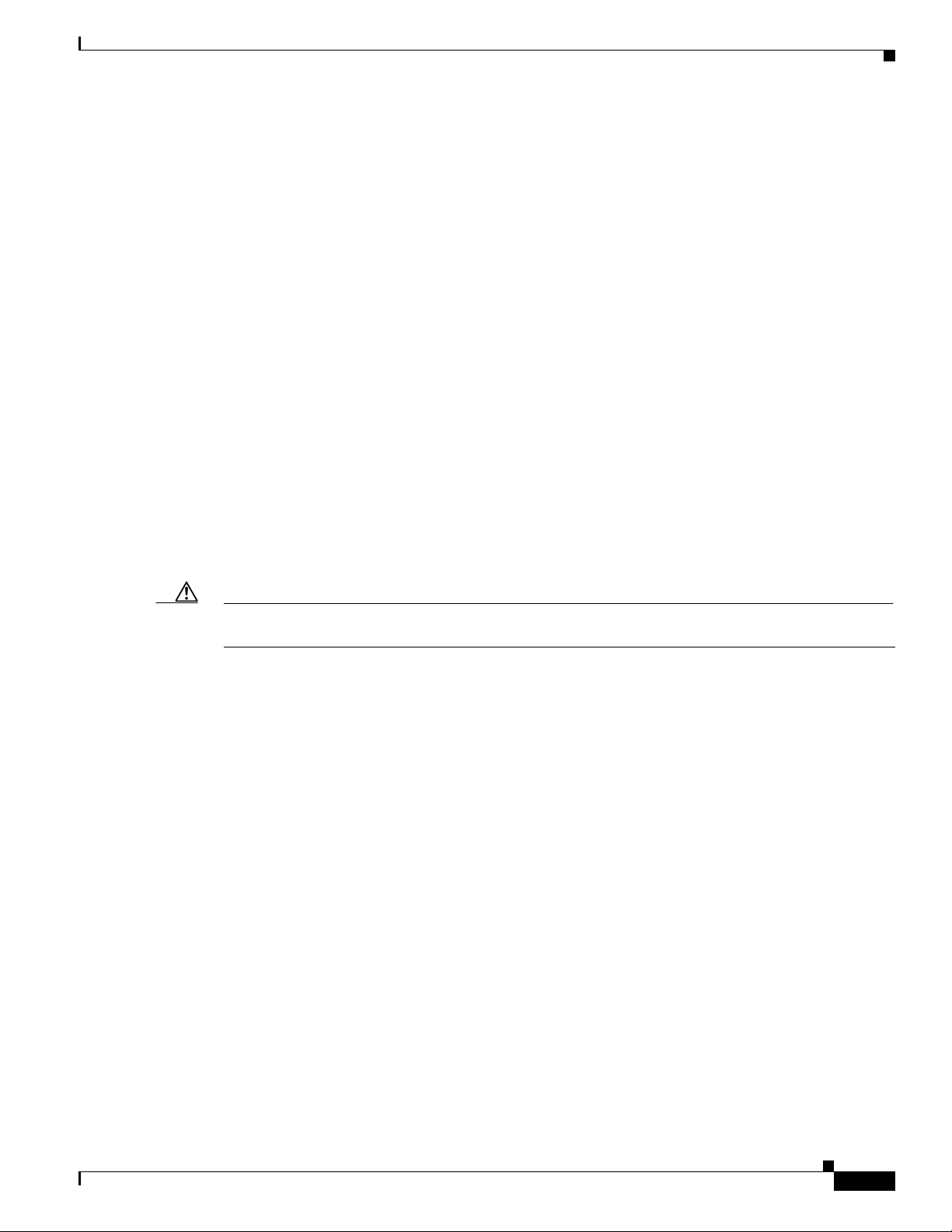

Keeping Track–Checklist

Keeping Track–Checklist

We recommend that you use an installation checklist and maintain a Site Log.

Installation Checklist

The Installation Checklist (see Figure 3-1) lists the tasks for installing a Cisco VG224 voice gateway.

Print a copy of this checklist and mark the entries as you complete each task. For each Cisco VG224

voice gateway, include a copy of the checklist in your Site Log.

Figure 3-1 Installation Checklist

Installation Checklist for site ______________________________________________

Cisco VG name/serial number _____________________________________________

Task Verified by Date

Background information placed in Site Log

Environmental specifications verified

Site power voltages verified

Installation site prepower check completed

Required tools available

Additional equipment available

Cisco VG received

Quick start guide received

Regulatory compliance and safety information received

Information packet, warranty card, and Cisco.com card received

Software version verified

Rack, desktop, or wall-mounting of chassis completed

Initial electrical connections established

ASCII terminal attached to console port

Modem attached to console port (for remote configuration)

Signal distance limits verified

Startup sequence steps completed

Initial operation verified

3-4

Cisco VG224 Voice Gateway Hardware Installation Guide

OL-5006-04

Page 5

Chapter 3 Installing the Cisco VG224 Voice Gateway

Mounting Tools and Equipment

Obtain the following tools and parts to install a Cisco VG224 voice gateway:

• Standard flat-blade screwdriver as required for attaching brackets to rack or wall

• Phillips screwdriver for attaching brackets to a Cisco VG224 voice gateway

• Mounting brackets and screws for 24-inch rack, if required

–

Four telco machine screws, for installing the chassis in a rack (use the screw size required by

the rack)

• Screws and anchors for wall-mounting, if required

–

Eight wood screws or other fasteners, for installing the chassis on a wall. An additional starter

screw can be used to facilitate wall-mounting.

• ESD-preventive wrist strap

In addition, you might need the following external equipment:

• Console terminal, or personal computer with terminal emulation software

• PC running terminal emulation software for administrative access

• Modem for remote access

Mounting Tools and Equipment

• Analog voice RJ-21 cable

• Ethernet switch

• Modem for remote configuration

Unpacking and Inspection

Do not unpack the Cisco VG224 until you are ready to install it. If the installation site is not ready, keep

the chassis in its shipping container to prevent accidental damage.

The Cisco VG224, cables, printed publications, and any optional equipment you ordered might be

shipped in more than one container. When you unpack each shipping container, check the packing list

to ensure that you received all the following items:

• Cisco VG224

• Power cord, 6-foot (1.8-meter)

• RJ-45-to-DB-25 adapter cable (labeled Console)

• RJ-45-to-DB-9 adapter cable (labeled Auxiliary)

• Rack-mounting brackets for 19-inch rack (one pair) with screws for attaching to chassis

• Chassis guard for wall-mounting applications

• Grounding lug and fasteners

• Cisco VG224 Voice Gateway Quick Start Guide

• Cisco VG224 Voice Gateway Regulatory Compliance and Safety Information

OL-5006-04

Inspect all items for shipping damage. If anything appears damaged, or if you encounter problems when

installing or configuring your system, contact a customer service representative. (See the “Obtaining

Technical Assistance” section on page xvi.)

Cisco VG224 Voice Gateway Hardware Installation Guide

3-5

Page 6

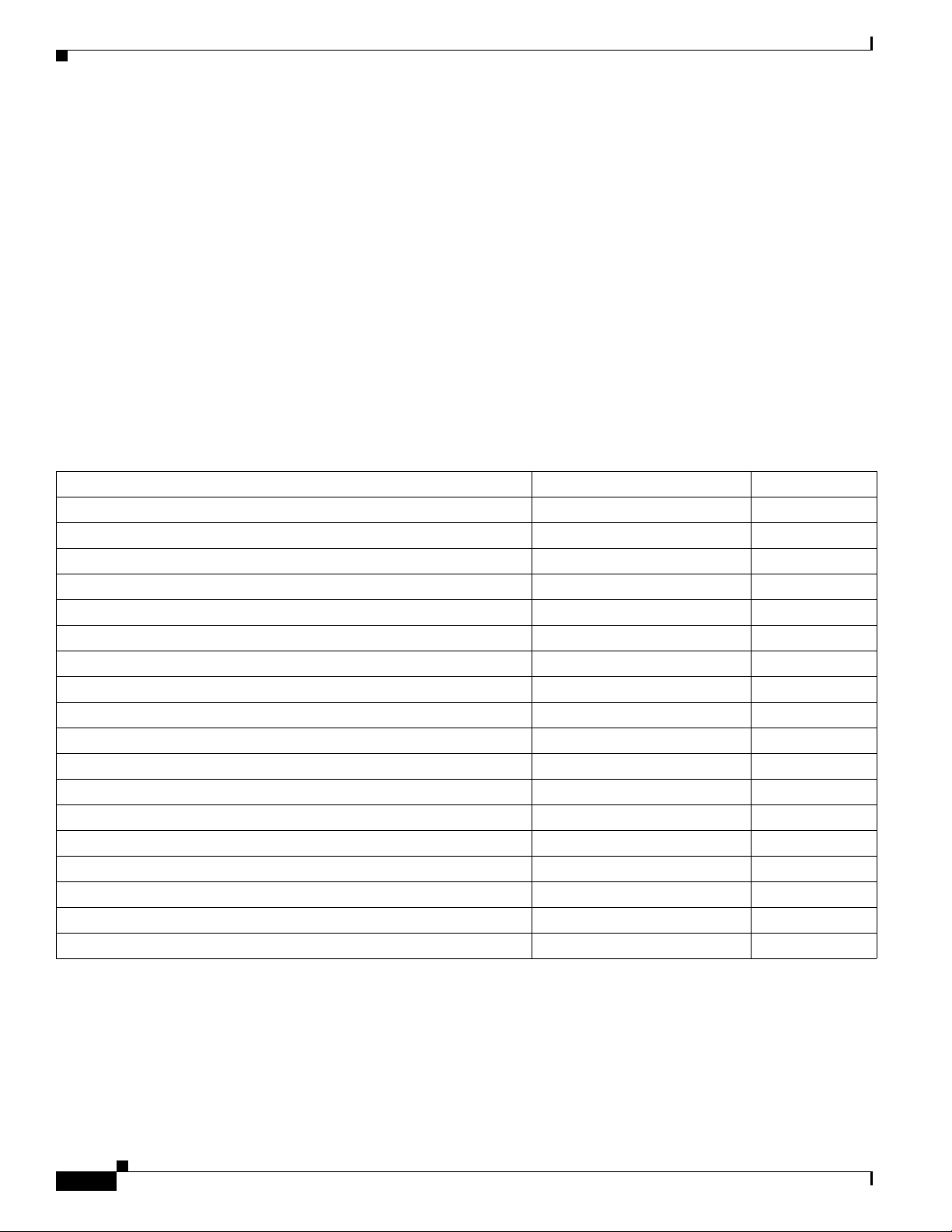

Rack-Mounting the Chassis

Rack-Mounting the Chassis

Your chassis ships with a pair of brackets for use with a 19-inch rack or mounting on the wall. The

bracket is shown in Figure 3-2.

Figure 3-2 Quick Mounting Bracket

Chapter 3 Installing the Cisco VG224 Voice Gateway

Mounting Screws

Two sets of mounting screws are provided, in separate packages. Take care to use each screw type, and

washers as needed, in the appropriate locations. Tab le 3-1 clarifies the differences between

rack-mounting and wall-mounting screws.

Table 3-1 Rack-Mounting Versus Wall-Mounting Screws

Rack-mounting Wall-mounting

• Eight countersunk Phillips head screws (four

• Washers are not required • Washers are required

per bracket)

88815

• Four 6–32 slotted hex screws (two per

bracket) and four plastic washers

3-6

Cisco VG224 Voice Gateway Hardware Installation Guide

OL-5006-04

Page 7

Chapter 3 Installing the Cisco VG224 Voice Gateway

Attaching the Brackets

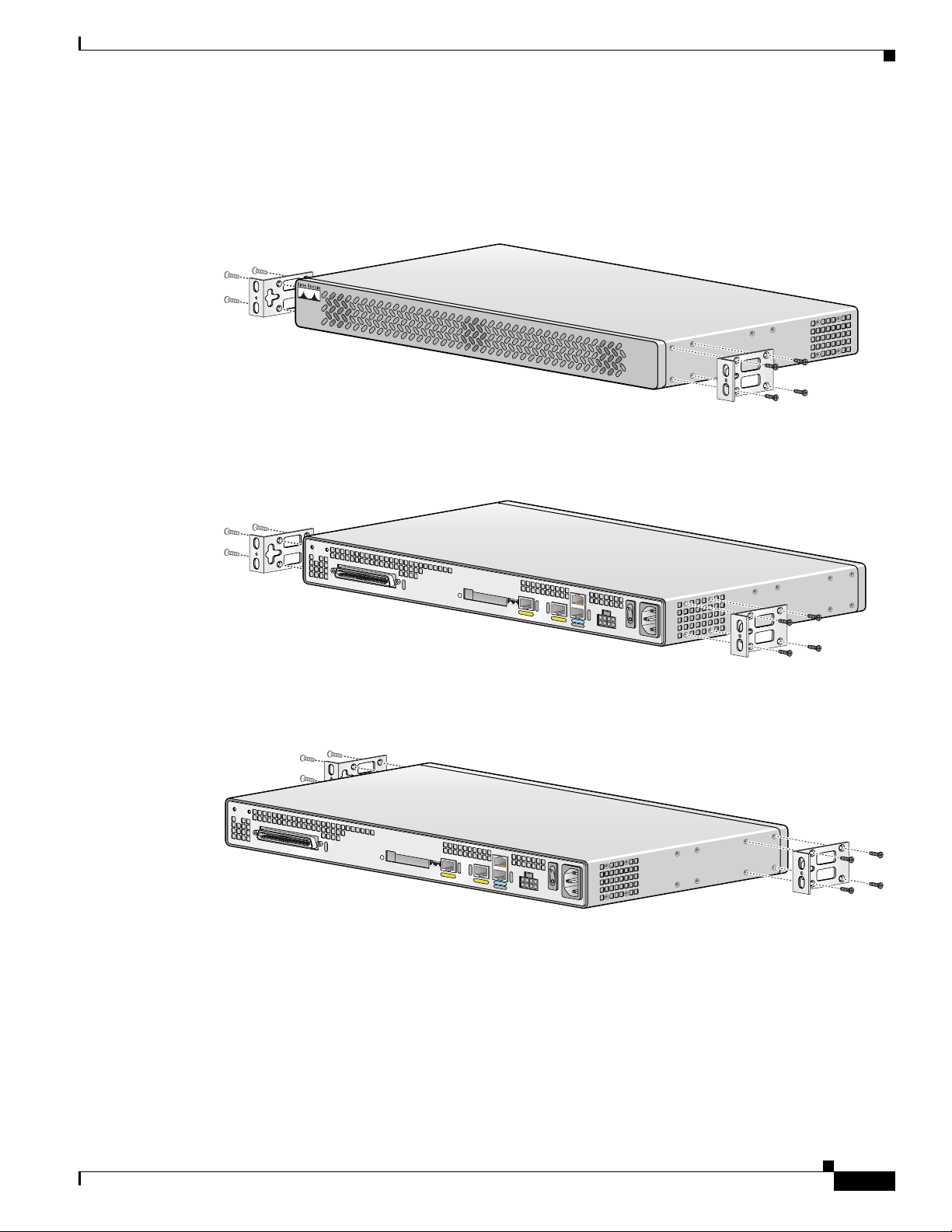

To install the chassis in a rack with the front panel forward, attach the brackets as shown in Figure 3-3.

Figure 3-3 19-Inch Rack Installation—Front Panel Forward

To install the chassis in a rack with the rear panel forward, attach the brackets as shown in Figure 3-4.

Figure 3-4 19-Inch Rack Installation—Rear Panel Forward

Rack-Mounting the Chassis

95915

CISCO

V

G224

V

G

224-24

FX

S

To install the chassis in a center-mount telco rack, attach the brackets as shown in Figure 3-5.

Figure 3-5 Telco 19-Inch Rack Installation—Rear Panel Forward

VG224-24FXS

95916

95917

OL-5006-04

Cisco VG224 Voice Gateway Hardware Installation Guide

3-7

Page 8

Chapter 3 Installing the Cisco VG224 Voice Gateway

Rack-Mounting the Chassis

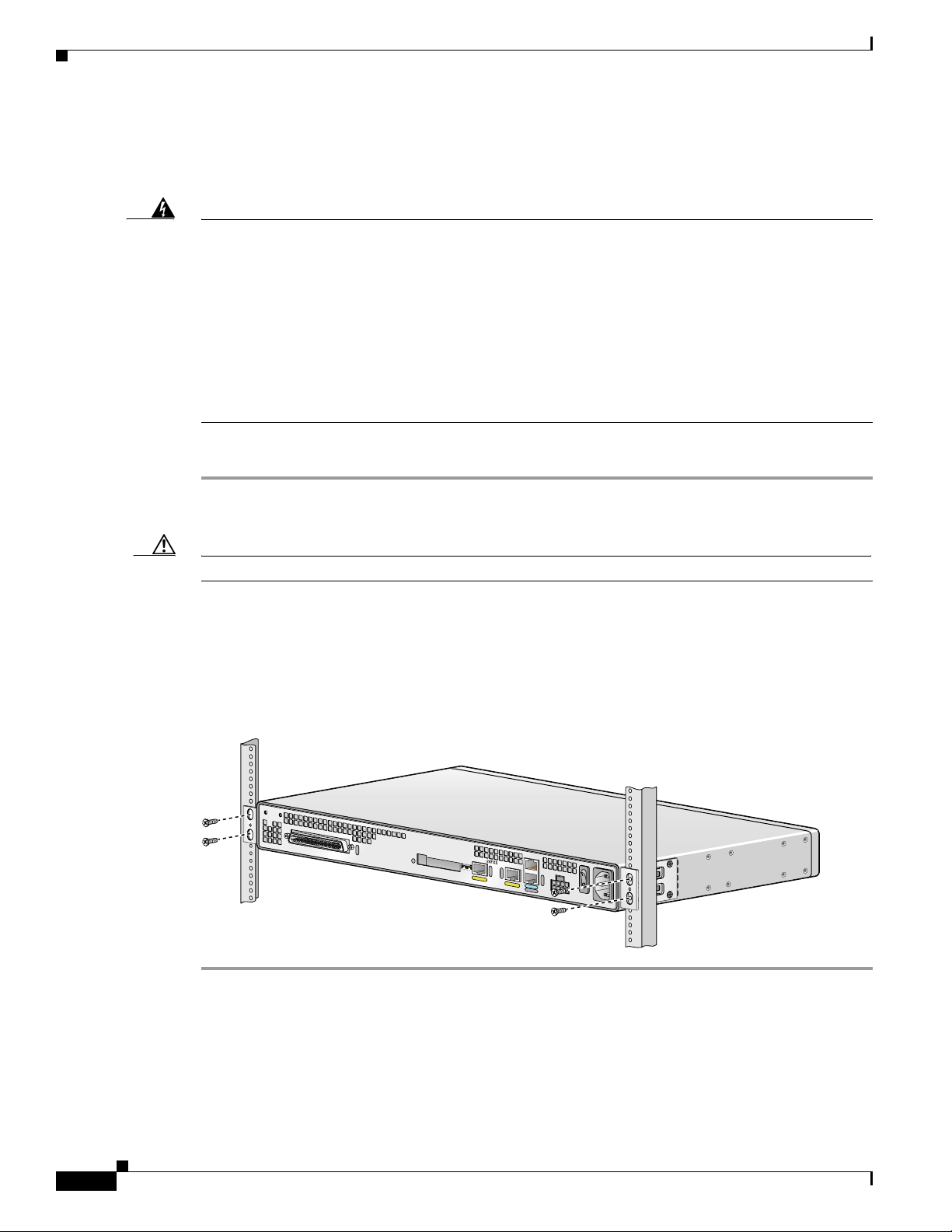

Installing the Cisco VG224 Voice Gateway in a Rack

The following warning applies only when the unit is rack-mounted:

Warning

To prevent bodily injury when mounting or servicing this unit in a rack, you must take special

precautions to ensure that the system remains stable. The following guidelines are provided to ensure

your safety:

This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

When mounting this unit in a partially filled rack, load the rack from the bottom to the top with the heaviest component

at the bottom of the rack.

If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing the unit in the rack.

Statement 1006

To rack-mount the chassis, follow this procedure:

Step 1 Choose one of the methods shown in Figure 3-3 on page 3-7, Figure 3-4 on page 3-7, or Figure 3-5 on

page 3-7, and attach the long leg of the mounting brackets to the chassis, as shown.

Caution Make sure to use the correct screws for this mounting option (see Table 3-1 on page 3-6).

Screws are included for attaching the brackets to the chassis, but not for installing the chassis in a rack

or on a wall. You need four additional machine screws to install the chassis in a rack. Use the screw size

required by your rack. After the brackets are secured to the chassis, you can rack-mount the chassis.

Step 2 Using screws that you provide, attach the chassis to the rack as shown in Figure 3-6 on page 3-8.

3-8

Figure 3-6 Attaching the Chassis to the 19-Inch Rack

VG224

103039

Cisco VG224 Voice Gateway Hardware Installation Guide

OL-5006-04

Page 9

Chapter 3 Installing the Cisco VG224 Voice Gateway

Wall-Mounting the Chassis

The following warning applies only when the unit is wall-mounted:

Wall-Mounting the Chassis

Warning

Caution You can wall-mount the unit with either the right or left side facing up; however, the front and rear panels

This unit is intended to be mounted on a wall. Please read the wall-mounting instructions carefully

before beginning installation. Failure to use the correct hardware or to follow the correct procedures

could result in a hazardous situation to people and damage to the system.

Statement 248

must be vertical.

Note For information about obtaining the chassis guard, refer to field notice number 28655, VG224 Chassis

Guard - Safety Regulation, at http://www-tac.cisco.com/Support_Library/field_alerts/fn28655.html.

To wall-mount the chassis, follow this procedure:

Step 1 Attach the short leg of one bracket to the chassis, as shown in Figure 3-7, using two 6-32 x 1/4 slotted

hex screws (provided). Be sure to use a plastic washer (provided) with each screw; the narrow end of the

washer must fit into the bracket slot, facing the chassis.

Caution Be sure to use the correct screws and plastic washers for this mounting option. (See Table 3 -1 o n

page 3-6.)

Figure 3-7 Attaching the Brackets for Wall-Mounting

88843

Step 2

Step 3 Attach the router to the wall using the brackets previously attached and attachment hardware that you

Attach the second bracket to the opposite side of the chassis.

provide as follows:

• You can install a starter screw in the wall, and hook the bracket keyhole over the screw. This holds

the unit in place for easy installation of the attachment screws.

• Attach both brackets to the wall.

OL-5006-04

Cisco VG224 Voice Gateway Hardware Installation Guide

3-9

Page 10

Wall-Mounting the Chassis

Note For attaching to a wall stud, each bracket requires two #10 wood screws (round- or pan-head) with #10

washers, or two #10 washer-head screws. The screws must be long enough to penetrate at least 3/4 inch

(20 mm) into supporting wood or metal wall stud.

Note For hollow-wall mounting, each bracket requires two wall anchors with washers. Wall anchors and

washers must be size #10.

• Figure 3-8 shows the orientation required for installation.

Figure 3-8 Wall-Mounting the Chassis

Chapter 3 Installing the Cisco VG224 Voice Gateway

1

3

2

4

SERIES

CISCO IAD2400

3-10

103517

Cisco VG224 Voice Gateway Hardware Installation Guide

OL-5006-04

Page 11

Chapter 3 Installing the Cisco VG224 Voice Gateway

1 Wall 3 Wall stud

2 Bracket 4 Keyhole for starter screw

Bench-Top Installation

Step 1 Verify that there is a suitable AC power outlet available.

Caution Do not plug this unit into an AC outlet that does not have a UL-certified receptacle that is properly tied

into building ground.

Step 2 Place the four rubber feet (from the accessory kit) in the four indentations on the underside of the

chassis.This helps provide proper airflow through and around the chassis.

Bench-Top Installation

Step 3 Place the Cisco VG224 voice gateway on a smooth, flat surface.

Caution Do not place anything on top of the chassis that weighs more than 10 lb (4.5 kg). Excessive weight on

top can damage the chassis.

Installing the Ground Connection

Warning

Warning

Warning

This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the

absence of a suitably installed ground conductor. Contact the appropriate electrical inspection

authority or an electrician if you are uncertain that suitable grounding is available.

AC connected units must have a permanent ground connection in addition to the power cable ground

wire. NEBS-compliant grounding satisfies this requirement.

Use copper conductors only.

Statement 1025

Statement 1024

Statement 284

OL-5006-04

You must connect the chassis to a reliable earth ground; the ground wire must be installed in accordance

with local electrical safety standards.

• For NEBS-compliant grounding, use size AWG 6 (13 mm

2

) wire and the ground lug provided in the

accessory kit.

• For NEC-compliant grounding, use size AWG 14 (2 mm

2

) or larger wire and an appropriate

user-supplied ring terminal.

Cisco VG224 Voice Gateway Hardware Installation Guide

3-11

Page 12

Installing the Ground Connection

Chapter 3 Installing the Cisco VG224 Voice Gateway

• For EN/IEC 60950-compliant grounding, use size AWG 18 (1 mm

2

) or larger wire and an

appropriate user-supplied ring terminal.

To ground the chassis, follow this procedure:

Step 1 Locate a suitable ground location.

Tip Use a multimeter to measure the resistance between various ground locations, such as the following:

• Between the ground of a junction box (outlet) and the ground of a power tap

• Between the ground of a junction box and a metal water pipe

• Between the Cisco VG224 voice gateway chassis and the ground of a power tap

• Between the Cisco VG224 voice gateway chassis and the ground of a junction box

A good ground connection should read between 0.0 and 0.5 ohms.

Step 2 Strip one end of the ground wire to the length required for the ground lug or terminal.

• For the NEBS ground lug—approximately 0.75 in. (20 mm)

• For user-provided ring terminal—as required

Step 3 Crimp the ground wire to the ground lug or ring terminal, using a crimp tool of the appropriate size. (See

Figure 3-9.)

Figure 3-9 Crimping a Ground Lug onto the Ground Wire

10360

Step 4

Attach the ground lug or ring terminal to the chassis as shown in Figure 3-10 or Figure 3-11. For the

ground lug, use the two screws with captive locking washers provided. For a ring terminal, use one of

the screws provided. Use a number 2 Phillips screwdriver, and tighten the screws to a torque of 8 to 10

in-lb (0.9 to 1.1 N-m).

Note You can orient the crimped end of the ground lug in either direction (right or left).

3-12

Step 5 Connect the other end of the ground wire to a grounding point at your site.

Cisco VG224 Voice Gateway Hardware Installation Guide

OL-5006-04

Page 13

Chapter 3 Installing the Cisco VG224 Voice Gateway

Figure 3-10 NEBS-Compliant Chassis Ground Connection Using Ground Lug

Installing the Ground Connection

Ground lug

VG224-24FXS

Figure 3-11 Chassis Ground Connection Using Ring Terminal

VG224-24FXS

Ring terminal

attachment

95919

103513

OL-5006-04

Cisco VG224 Voice Gateway Hardware Installation Guide

3-13

Page 14

Connecting Cables

Connecting Cables

For cables not included with your Cisco VG224 voice gateway, pinout information is in Appendix A,

“Cable Specifications and Information.” Cisco VG224 voice gateway ports are color-coded for

identification.

Chapter 3 Installing the Cisco VG224 Voice Gateway

Warning

Warning

Warning

Do not work on the system or connect or disconnect cables during periods of lightning activity.

Statement 1001

This product relies on the building’s installation for short-circuit (overcurrent) protection. Ensure that

the protective device is rated not greater than:

120 VAC, 15A (240 VAC, 10A international)

To prevent accidental discharge in the event of a power line cross, route on-premise wiring away

from power cables and off-premise wiring, or use a grounded shield to separate the on-premise

wiring from the power cables and off-premise wiring. A power line cross is an event, such as a

lightning strike, that causes a power surge. Off-premise wiring is designed to withstand power line

crosses. On-premise wiring is protected from power line crosses by a device that provides

overcurrent and overvoltage protection. Nevertheless, if the on-premise wiring is in close proximity

to, or not shielded from, the off-premise wiring or power cables during a lightning strike or power

surge, the on-premise wiring can carry a dangerous discharge to the attached interface, equipment,

and nearby personnel.

Statement 338

Statement 1005

Table 3-2 shows the results of the NEBS Type 1/3 power cross tests (tip/ring to ground) performed on

the Cisco VG224 voice gateway FXS ports.

Table 3-2 Results of the NEBS Power Cross Tests on FXS Ports

3-14

NEBS Tests Results

50 V/0.33 A; 15 minutes Pass

100 V/0.17 A; 15 minutes Pass

200 V/1.00 A; 1–second pulses, 60 repetitions Pass

Note The installation must comply with all applicable codes.

Cisco VG224 Voice Gateway Hardware Installation Guide

OL-5006-04

Page 15

Chapter 3 Installing the Cisco VG224 Voice Gateway

Connecting Cables

LAN and Power Cables

These cables and connections are described in Ta ble 3-3 and in Figure 3-12.

Table 3-3 LAN, Administrative Access, and Power Cable Selection

Port or Connection Color or Type Connected To Cable

Fast Ethernet Yellow Fast Ethernet switch Straight-through Fast Ethernet cable (not included)

Console Light blue PC or ASCII terminal

communication (COM) port

Auxiliary Black Modem for remote access RJ-45-to-DB25 auxiliary cable (included)

Power (not shown) Power 100–240 VAC, 50–60 Hz Grounding power cord (included)

1. Power cables vary to meet local requirements.

Figure 3-12 LAN and Administrative Access Connections

RJ-45-to-DB9 console cable (included)

1

3

2

Cisco VG224

Modem

4

Ethernet hub

1

VG224-24FXS

5

6

PC

1 Fast Ethernet port 4 Fast Ethernet (straight-through)

2 Console port 5 RJ-45-to-DB9 console cable

3 AUX port 6 RJ-45-to-DB25 auxiliary cable

95920

OL-5006-04

Cisco VG224 Voice Gateway Hardware Installation Guide

3-15

Page 16

Connecting Cables

Connecting the Input Power

Caution The Cisco VG224 voice gateway chassis provides inputs for both AC and DC power. Design your

installation to use only one type of power. Do not use AC and DC power at the same time. If you do, the

unit stops operating, and you need to reboot it with only a single power source.

Cable

Use the AC power cable.

Procedure

Step 1 Connect the AC power cable (supplied) to the recessed power plug on the rear of the concentrator.

Step 2 Plug the cable into a power source with a voltage of 100 to 240 VAC.

Chapter 3 Installing the Cisco VG224 Voice Gateway

Connecting the Console Port to a PC or an ASCII Terminal

Use the procedure in this section to connect the console port to a PC running terminal emulation

software.

Note The console port does not support hardware flow control.

Cable

Use an RJ-45-to-RJ-DB-9 console cable (see item 5 in Figure 3-12 on page 3-15)

For pinouts, see Table A-1 on page A-3 and Table A-2 on page A-4 in Appendix A, “Cable

Specifications and Information.”

Procedure

Step 1 Configure the terminal emulation software requirements:

9600 baud

8 data bits

1 stop bit

no parity

no flow control

3-16

Cisco VG224 Voice Gateway Hardware Installation Guide

OL-5006-04

Page 17

Chapter 3 Installing the Cisco VG224 Voice Gateway

Connecting the Auxiliary Port to a Modem

Use the procedure in this section to connect the auxiliary port to a modem.

Cable

Use an RJ-45-to-DB25 auxiliary cable (labeled Modem).

For pinouts, see Table A-3 on page A-5 and Table A-4 on page A-5 in Appendix A, “Cable

Specifications and Information.”

Procedure

Step 1 Connect the cable from the auxiliary port (black) to the DB-25 port on the modem. (See item 6 in

Figure 3-12 on page 3-15.)

Step 2 Configure the modem.

a. Match the transmission speed of the auxiliary port (default is 9600 baud).

b. Set the hardware flow control for Data Carrier Detect (DCD) and Data Terminal Ready (DTR)

operation.

Connecting Cables

Note The baud rate for the auxiliary (and console) port can be configured in software for 1200, 2400, 4800,

19200, 38400, 57600, and 115200.

Connecting the Fast Ethernet Port to the Fast Ethernet Switch

Use the procedure in this section to connect a Fast Ethernet port to the Fast Ethernet switch.

Cable

Use a straight-through Fast Ethernet cable (not included).

Procedure

Step 1 Connect the cable from a Fast Ethernet port to an available port on the Fast Ethernet switch. (See item

4 in Figure 3-12 on page 3-15.)

Step 2 Connect the second cable if it is required.

Note Not all models have two ports.

OL-5006-04

Cisco VG224 Voice Gateway Hardware Installation Guide

3-17

Page 18

Connecting Cables

Voice Cables

Chapter 3 Installing the Cisco VG224 Voice Gateway

Warning

Warning

For connections outside the building where the equipment is installed, the following ports must be

connected through an approved network termination unit with integral circuit protection.

FXS/T3/E3

Statement 1044

This equipment contains a ring signal generator (ringer), which is a source of hazardous voltage. Do

not touch the RJ-11 (phone) port wires (conductors), the conductors of a cable connected to the RJ-11

port, or the associated circuit-board when the ringer is active. The ringer is activated by an incoming

call.

Statement 1042

The analog FXS voice cables and connections are:

Color or Type Connected To Cable

RJ-21 Distribution panel RJ-21-to-RJ-21 straight-through cable (not included)

Figure 3-13 WAN and Voice Connections

Distribution panel

1

Cisco VG224

VG224-24FXS

2

Network

demarcation

1 RJ-21 cable 2 RJ-45 cable (through a patch panel) to central office

95921

3-18

Cisco VG224 Voice Gateway Hardware Installation Guide

OL-5006-04

Page 19

Chapter 3 Installing the Cisco VG224 Voice Gateway

Connecting the Analog Voice Interface to a Distribution Panel

To connect the multiport analog voice interface to a distribution panel, which connects to telephones,

faxes, or analog PBX equipment, use the following procedure. (See Figure 3-14.)

Cable

Use an RJ-21 cable with Amphenol 50-pin connectors (not included).

For RJ-21X/CA21A pinouts, see Table A-5 on page A-6 in Appendix A, “Cable Specifications and

Information.”

Connecting Cables

Warning

Procedure

This equipment contains a ring signal generator (ringer), which is a source of hazardous voltage. Do

not touch the RJ-11 (phone) port wires (conductors), the conductors of a cable connected to the RJ-11

port, or the associated circuit-board when the ringer is active. The ringer is activated by an incoming

call.

Statement 1042

Step 1 Connect the RJ-21 cable from the analog voice multiport to the distribution panel.

Step 2 Secure the cable in place using the strap.

Figure 3-14 Analog Voice Connection

VG224-24FXS

Distribution panel

103118

OL-5006-04

RJ-21 cable

Cisco VG224 Voice Gateway Hardware Installation Guide

3-19

Page 20

Chapter 3 Installing the Cisco VG224 Voice Gateway

Ports, Connectors, and Pinouts

Ports, Connectors, and Pinouts

Table 3-4 summarizes the cable connections between Cisco VG224 voice gateway and the network and

user interfaces. Find the port and the equipment or network type in the table; then look at the applicable

pinout table in Appendix A, “Cable Specifications and Information.”

Table 3-4 Cable Use Reference Table

Cisco VG224 Port Port Color Connector/Cable Interface To Pinout Information

Console Light blue RJ-45/Rollover PC Table A-1

ASCII terminal Table A-2

Auxiliary Black RJ-45/Rollover Modem Table A-3

Fast Ethernet Yellow RJ-45/Fast Ethernet LAN Table A-5

Analog voice multiport Gray RJ-21X/

50-conductor

Distribution panel for analog

telephone, fax, PBX, or

central office line

Table A-5

Remote Terminal Connections (If Applicable)

If you are configuring a Cisco VG224 voice gateway from a remote location, connect the modem and

the remote PC or terminal to the telephone network as described in this section.

Connecting to a Modem

To connect the local modem and the remote modem to live telephone outlets, use standard telephone

cables.

Connecting to a Remote PC

To link a Cisco VG224 voice gateway to a remote PC, use the following procedure:

Note The remote PC must be running terminal emulation software.

Step 1 Connect the remote PC and modem.

Step 2 Set the PC terminal emulation software requirements:

9600 baud

8 data bits

1 stop bit

no parity

no flow control.

Step 3 Key in and dial the telephone number of the Cisco VG224 voice gateway external modem.

3-20

Cisco VG224 Voice Gateway Hardware Installation Guide

OL-5006-04

Page 21

Chapter 3 Installing the Cisco VG224 Voice Gateway

Connecting to a Remote ASCII Terminal

To link a Cisco VG224 voice gateway to a remote ASCII terminal, such as a VT100, use the following

procedure:

Step 1 Connect the remote ASCII terminal and modem.

Step 2 Set the terminal requirements:

9600 baud

8 data bits

1 stop bit

no parity

no flow control.

Step 3 Key in the telephone number of the Cisco VG224 voice gateway external modem, or, if you are using a

Hayes-compatible modem, enter ATDT and the number to be dialed.

Connecting Backup Power

Connecting Backup Power

A Cisco VG224 voice gateway can be installed with optional backup power. Backup power to a

DC-powered chassis is provided by a 12-volt battery backup system; see the “Connecting a Backup

Battery to a DC-Powered Cisco VG224” section for connection instructions. Backup power to an

AC-powered chassis is provided by an uninterruptible power supply (UPS); see the “Connecting a UPS

to an AC-Powered Cisco VG224” section for connection instructions.

Caution The Cisco VG224 chassis provides inputs for both AC and DC power. Design your installation to use

only one type of power. Do not use AC and DC power at the same time. If you do, the unit stops

operating, and you must reboot it with only a single power source.

The maximum power requirement for the Cisco VG224 voice gateway is 70 W.

Connecting a Backup Battery to a DC-Powered Cisco VG224

Connect a 12-volt backup battery to the DC input connector on your Cisco VG224 voice gateway. Before

you install a backup battery, be sure to read the installation instructions for the backup battery

equipment.

Figure 3-15 shows a setup using an external backup battery.

OL-5006-04

Note Figure 3-15 shows one possible setup; please review your backup battery documents before setting up

your system.

Cisco VG224 Voice Gateway Hardware Installation Guide

3-21

Page 22

Connecting Backup Power

Figure 3-15 Connecting a Battery Backup to a DC-Powered Cisco VG224

Chapter 3 Installing the Cisco VG224 Voice Gateway

AC wall plug

Cisco VG224 voice gateway

Battery backup

VG224-24FXS

103120

DC plug

Caution Use a backup battery only if you are not using AC to power your Cisco VG224 voice gateway. Do not

use AC and DC power at the same time. If you do, the unit stops operating, and you need to reboot it

with only a single power source.

Note We recommend a 12-volt automotive battery if you require longer periods of battery backup (up to

8 hours).

Figure 3-16 shows the DC power connector. See Table 3-5 for pinout information for the DC power

connector on the Cisco VG224 voice gateway.

Table 3-5 Pinouts for DC Power Connector

Pin Number Descriptions Pin Number Descriptions

1 GND (input enable) 5 ON_BAT (battery is on)

2 +12V (power) 6 +12V (power)

3 REP_BAT (replace battery) 7 LOW_BAT (battery is low)

4 GND (power return) 8 GND (power return)

3-22

Figure 3-16 DC Power Connector

VG224-24FXS

103121

Pin 5

Pin 1

Cisco VG224 Voice Gateway Hardware Installation Guide

OL-5006-04

Page 23

Chapter 3 Installing the Cisco VG224 Voice Gateway

Connecting a UPS to an AC-Powered Cisco VG224

Connect an uninterruptible power supply to the AC input on your Cisco VG224 voice gateway. Before

you install a UPS, be sure to read the installation instructions for the UPS.

Figure 3-17 shows a setup using a UPS.

Note Figure 3-17 shows one possible setup; please review your UPS documents before setting up your system.

Figure 3-17 Connecting a UPS to an AC-Powered Cisco VG224

Cisco VG224 voice gateway

AC wall plug

UPS

V

G

2

2

4

-2

4

F

X

S

Connecting Backup Power

AC plug

103119

OL-5006-04

Cisco VG224 Voice Gateway Hardware Installation Guide

3-23

Page 24

Connecting Backup Power

Chapter 3 Installing the Cisco VG224 Voice Gateway

3-24

Cisco VG224 Voice Gateway Hardware Installation Guide

OL-5006-04

Loading...

Loading...