Page 1

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

January 2014

Cisco Systems, Inc.

www.cisco.com

Cisco has more than 200 offices worldwide.

Addresses, phone numbers, and fax numbers

are listed on the Cisco website at

www.cisco.com/go/offices.

Text Part Number: OL-6256-17

Page 2

THE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THIS MANUAL ARE SUBJECT TO CHANGE WITHOUT NOTICE. ALL

STATEMENTS, INFORMATION, AND RECOMMENDATIONS IN THIS MANUAL ARE BELIEVED TO BE ACCURATE BUT ARE PRESENTED WITHOUT

WARRANTY OF ANY KIND, EXPRESS OR IMPLIED. USERS MUST TAKE FULL RESPONSIBILITY FOR THEIR APPLICATION OF ANY PRODUCTS.

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION PACKET THAT

SHIPPED WITH THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNABLE TO LOCATE THE SOFTWARE LICENSE

OR LIMITED WARRANTY, CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

The following information is for FCC compliance of Class A devices: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio-frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference, in which case users will be required

to correct the interference at their own expense.

The following information is for FCC compliance of Class B devices: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If the equipment causes interference to radio or television reception, which can be

determined by turning the equipment off and on, users are encouraged to try to correct the interference by using one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Modifications to this product not authorized by Cisco could void the FCC approval and negate your authority to operate the product.

The Cisco implementation of TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB) as part of UCB’s public

domain version of the UNIX operating system. All rights reserved. Copyright © 1981, Regents of the University of California.

NOTWITHSTANDING ANY OTHER WARRANTY HEREIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE PROVIDED “AS IS” WITH

ALL FAULTS. CISCO AND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT

LIMITATION, THOSE OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT OR ARISING FROM A COURSE OF

DEALING, USAGE, OR TRADE PRACTICE.

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL DAMAGES, INCLUDING,

WITHOUT LIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE USE OR INABILITY TO USE THIS MANUAL, EVEN IF CISCO

OR ITS SUPPLIERS HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Cisco and the Cisco logo are trademarks or registered trademarks of Cisco and/or its affiliates in the U.S. and other countries. To view a list of Cisco trademarks, go to this

URL: www.cisco.com/go/trademarks. Third-party trademarks mentioned are the property of their respective owners. The use of the word partner does not imply a partnership

relationship between Cisco and any other company. (1110R)

Any Internet Protocol (IP) addresses and phone numbers used in this document are not intended to be actual addresses and phone numbers. Any examples, command display

output, network topology diagrams, and other figures included in the document are shown for illustrative purposes only. Any use of actual IP addresses or phone numbers in

illustrative content is unintentional and coincidental.

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

© 2014 Cisco Systems, Inc. All rights reserved.

Page 3

Preface xiii

Objective xiii

Audience xiii

Document Organization xiii

Document Conventions xiv

Related Documentation xv

Changes to This Document xv

CONTENTS

CHAPTER

CHAPTER

Obtaining Documentation and Submitting a Service Request xvii

1 Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Overview 1-1

Chassis Overview 1-1

Chassis Components 1-2

Chassis Slot Numbers 1-9

Chassis Cable Management 1-10

Chassis Cooling System 1-11

Chassis Power System 1-12

Safety Guidelines 1-12

Preventing Electrostatic Discharge 1-13

2 Installing and Removing Power Components 2-1

Power Systems Overview 2-1

Power Component Information Common to Two Types of Power System 2-2

Basic Chassis Power Details 2-2

Fixed Configuration Power System 2-3

Modular Configuration Power System 2-3

Precautions and Recommendations 2-3

Bonding and Grounding Guidelines 2-4

How to Install the Chassis Ground Cable 2-5

Prerequisites 2-5

Required Tools and Equipment 2-5

Steps 2-5

DC Power Systems 2-6

OL-6256-17

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

iii

Page 4

Contents

Fixed Configuration DC Power 2-6

Modular Configuration DC Power 2-9

AC Power Systems 2-11

Fixed Configuration AC Power 2-12

Modular Configuration AC Power 2-12

How to Install or Remove Fixed Configuration Power Components 2-13

Before Powering the Chassis Up or Down 2-14

Converting from One Fixed Configuration Power System to Another 2-14

Installing a PDU 2-15

Prerequisites 2-16

Required Tools and Equipment 2-16

Steps 2-16

What to Do Next 2-17

Removing a PDU 2-17

Prerequisites 2-17

Required Tools and Equipment 2-18

Steps 2-18

What to Do Next 2-18

Installing DC PDU Cables 2-19

Prerequisites 2-19

Required Tools and Equipment 2-20

Steps 2-20

Removing DC PDU Wiring 2-21

Prerequisites 2-21

Required Tools and Equipment 2-21

Steps 2-21

Installing a DC PEM or AC Rectifier 2-22

Prerequisites 2-22

Required Tools and Equipment 2-22

Steps 2-23

What to Do Next 2-23

Removing a DC PEM or AC rectifier 2-23

Prerequisites 2-24

Required Tools and Equipment 2-24

Steps 2-24

What to Do Next 2-25

iv

How to Install or Remove Modular Configuration Power Components 2-25

Installing a Modular Configuration Power Shelf 2-26

Required Tools and Equipment 2-29

Steps 2-29

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

OL-6256-17

Page 5

Contents

What to Do Next 2-34

Installing AC Power Cords or DC Power Shelf Wiring 2-35

Installing Modular Configuration DC Power Shelf Wiring 2-35

Prerequisites 2-36

Required Tools and Equipment 2-36

Steps 2-36

Installing DC Terminal Block Covers 2-37

Required Tools and Equipment 2-37

Steps 2-37

Installing Modular Configuration AC Power Shelf Wiring 2-38

Prerequisites 2-38

Required Tools and Equipment 2-39

Steps 2-39

What to Do Next 2-40

Installing AC or DC PMs 2-40

Required Tools and Equipment 2-40

Steps 2-40

What to Do Next 2-42

Removing AC or DC PMs 2-42

Required Tools and Equipment 2-42

Steps 2-43

What to Do Next 2-44

Removing AC Power Cords or DC Power Shelf Wiring 2-45

Removing Modular Configuration DC Power Shelf Wiring 2-45

Prerequisites 2-45

Required Tools and Equipment 2-45

Steps 2-46

Removing Modular Configuration AC Power Shelf Wiring 2-47

Prerequisites 2-47

Required Tools and Equipment 2-47

Steps 2-47

What to Do Next 2-48

Removing a Modular Configuration Power Shelf 2-48

Prerequisites 2-48

Required Tools and Equipment 2-49

Steps 2-49

What to Do Next 2-51

Power Up and Power Down a Chassis with a Modular Configuration AC or DC Power Shelf 2-51

Power Up a Chassis with a Modular Configuration AC or DC Power Shelf 2-52

Prerequisites 2-52

OL-6256-17

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

v

Page 6

Contents

Steps 2-52

Power Down a Chassis with a Modular Configuration AC or DC Power Shelf 2-52

Prerequisites 2-52

Steps 2-52

Converting from One Modular Configuration Power System to Another 2-53

Converting a Chassis from Fixed Configuration Power to Modular Configuration Power 2-54

CHAPTER

3 Installing and Removing Air Circulation Components 3-1

About Line Card Chassis Airflow 3-1

How to Install or Remove Air Circulation Components 3-2

Installing a Lower Fan Tray 3-2

Prerequisites 3-3

Required Tools and Equipment 3-3

Steps 3-3

What to Do Next 3-4

Installing a Rear Exhaust Screen 3-4

Prerequisites 3-4

Required Tools and Equipment 3-4

Steps 3-5

Removing a Lower Fan Tray 3-5

Prerequisites 3-6

Required Tools and Equipment 3-6

Steps 3-6

What to Do Next 3-7

Installing an Upper Fan Tray 3-7

Prerequisites 3-7

Required Tools and Equipment 3-7

Steps 3-7

What to Do Next 3-8

Removing an Upper Fan Tray 3-8

Prerequisites 3-8

Required Tools and Equipment 3-8

Steps 3-9

What to Do Next 3-9

Installing the Chassis Air Filter 3-9

Prerequisites 3-10

Required Tools and Equipment 3-10

Steps 3-10

What to Do Next 3-11

vi

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

OL-6256-17

Page 7

Removing the Chassis Air Filter 3-11

Prerequisites 3-11

Required Tools and Equipment 3-11

Steps 3-11

What to Do Next 3-11

Installing a Power Module Air Filter 3-12

Prerequisites 3-12

Required Tools and Equipment 3-12

Steps 3-13

What to Do Next 3-13

Removing a Power Module Air Filter 3-13

Prerequisites 3-13

Required Tools and Equipment 3-13

Steps 3-14

What to Do Next 3-14

Contents

CHAPTER

4 Installing and Removing Line Cards, PLIMs, and Associated Components 4-1

Information About Installing and Removing Cards and Associated Components 4-1

Guidelines and Warnings for Card Installation and Removal 4-2

Chassis Slot Numbers 4-4

Recommended Order of Card Installation 4-5

Cautions and Recommendations 4-5

Information About Impedance Carriers and Slot Covers 4-6

Information About Distributed Route Processors and Distributed Route Processor PLIMs 4-10

Information About Small Form-Factor Pluggable (SFP) Modules 4-12

Information About Hard Drives and PCMCIA Cards 4-12

Information About Cable Management Brackets 4-12

How to Install or Remove a Slot Cover 4-13

Installing a Slot Cover 4-13

Prerequisites 4-14

Required Tools and Equipment 4-14

Steps 4-14

What to Do Next 4-15

Removing a Slot Cover 4-15

Prerequisites 4-16

Required Tools and Equipment 4-16

Steps 4-16

What to Do Next 4-16

OL-6256-17

How to Install or Remove an Impedance Carrier 4-16

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

vii

Page 8

Contents

Installing an Impedance Carrier 4-16

Prerequisites 4-17

Required Tools and Equipment 4-18

Steps 4-18

What to Do Next 4-18

Removing an Impedance Carrier 4-18

Prerequisites 4-18

Required Tools and Equipment 4-18

Steps 4-19

What to Do Next 4-19

How to Install or Remove a Pillow Block 4-19

Installing a Pillow Block 4-19

Prerequisites 4-19

Required Tools and Equipment 4-20

Steps 4-20

What to Do Next 4-21

Removing a Pillow Block 4-21

Prerequisites 4-21

Required Tools and Equipment 4-21

Steps 4-21

What’s Next 4-22

How to Install or Remove a Switch Fabric Card 4-22

Installing a Switch Fabric Card 4-22

Prerequisites 4-23

Required Tools and Equipment 4-24

Steps 4-24

What to Do Next 4-26

Removing a Switch Fabric Card 4-26

Prerequisites 4-27

Required Tools and Equipment 4-27

Steps 4-27

What to Do Next 4-28

Verifying the Installation of a Switch Fabric Card 4-28

Understanding the Alphanumeric LEDs 4-28

Troubleshooting the Switch Fabric Card 4-28

How to Install or Remove an MSC, FP, or LSP 4-29

Installing an MSC, FP, or LSP 4-29

Prerequisites 4-31

Required Tools and Equipment 4-31

viii

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

OL-6256-17

Page 9

Steps 4-31

What to Do Next 4-33

Removing an MSC, FP, or LSP 4-33

Prerequisites 4-34

Required Tools and Equipment 4-34

Steps 4-34

What to Do Next 4-36

Verifying the Installation of an MSC, FP, or LSP 4-36

Understanding the Alphanumeric LEDs 4-37

Troubleshooting the MSC, FP, or LSP 4-37

How to Install or Remove an RP, PRP, or DRP PLIM 4-38

Installing an RP, PRP, or DRP Card 4-38

Prerequisites 4-38

Required Tools and Equipment 4-40

Steps 4-40

What to Do Next 4-41

Removing an RP, PRP, or DRP Card 4-41

Prerequisites 4-41

Required Tools and Equipment 4-42

Steps 4-42

What to Do Next 4-42

Verifying the Installation of an RP, PRP, or DRP Card 4-43

Understanding the Alphanumeric LEDs 4-44

Troubleshooting the RP, PRP, or DRP Card 4-44

Contents

OL-6256-17

How to Install or Remove a PCMCIA Card 4-45

Installing a PCMCIA Card 4-45

Prerequisites 4-46

Required Tools and Equipment 4-46

Steps 4-46

What to Do Next 4-46

Removing an RP PCMCIA Card 4-46

Prerequisites 4-47

Required Tools and Equipment 4-47

Steps 4-47

What to Do Next 4-47

How to Install or Remove a Physical Layer Interface Module 4-47

Installing a PLIM 4-47

Prerequisites 4-49

Required Tools and Equipment 4-49

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

ix

Page 10

Contents

Steps 4-49

What to Do Next 4-51

Removing a PLIM 4-51

Prerequisites 4-51

Required Tools and Equipment 4-52

Steps 4-52

What to Do Next 4-54

Verifying the Installation of a PLIM 4-54

Troubleshooting the PLIM 4-54

How to Install or Remove a Small Form-Factor Pluggable (SFP) Module 4-55

Installing a Bale-Clasp SFP Module 4-55

Prerequisites 4-55

Required Tools and Equipment 4-55

Steps 4-55

What to Do Next 4-56

Removing a Bale-Clasp SFP Module 4-56

Prerequisites 4-57

Required Tools and Equipment 4-57

Steps 4-57

What to Do Next 4-58

Replacing a SFP on a Line Card that Uses an Articulated Bracket 4-59

CHAPTER

5 Installing and Removing Exterior Components 5-1

Overview of the Exterior Components 5-1

Installing or Removing the Front Side Exterior Components 5-1

Removing the Cable Management Bracket 5-2

Prerequisites 5-2

Required Tools and Equipment 5-2

Steps 5-2

What to Do Next 5-3

Reinstalling the Cable Management Bracket 5-3

Prerequisites 5-4

Required Tools and Equipment 5-4

Steps 5-4

What to Do Next 5-4

Installing the Inlet Grille—Fixed Configuration Power Supply 5-5

Prerequisites 5-5

Required Tools and Equipment 5-5

Steps 5-6

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

x

OL-6256-17

Page 11

What to Do Next 5-6

Installing the Inlet Grille—Modular Configuration Power Supply 5-7

Prerequisites 5-7

Required Tools and Equipment 5-7

Steps 5-8

What to Do Next 5-8

Removing the Inlet Grille—Fixed and Modular Configuration Power Supply 5-8

Prerequisites 5-8

Required Tools and Equipment 5-8

Steps 5-8

What to Do Next 5-9

Installing the Front Cover 5-9

Prerequisites 5-9

Required Tools and Equipment 5-9

Steps 5-10

What to Do Next 5-11

Removing the Front Cover 5-11

Prerequisites 5-11

Required Tools and Equipment 5-11

Steps 5-11

What to Do Next 5-12

Contents

APPENDIX

APPENDIX

A Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Specifications A-1

B Product IDs for the Cisco CRS 8-Slot Line Card Chassis B-1

Cisco CRS 8-Slot Line Card Chassis Component Product IDs B-1

Optional Line Card, PLIM, SIP, and SPA Product IDs B-3

OL-6256-17

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

xi

Page 12

Contents

xii

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

OL-6256-17

Page 13

Preface

This preface explains the objectives, intended audience, and organization of the Cisco CRS Carrier

Routing System 8-Slot Line Card Chassis Installation Guide and describes the conventions that convey

instructions and other information.

The preface contains the following sections:

• Objective, page xiii

Objective

Audience

• Audience, page xiii

• Document Organization, page xiii

• Document Conventions, page xiv

• Related Documentation, page xv

• Changes to This Document, page xv

• Obtaining Documentation and Submitting a Service Request, page xvii

This installation guide describes how to install power, air circulation, line card, and external components

into and remove them from a Cisco CRS Carrier Routing System 8-Slot Line Card Chassis.

This guide is for customers who are responsible for installing the line card chassis components. The

reader is expected to have installed networking hardware in the past. No additional knowledge of routing

or the Cisco IOS-XR software is assumed.

Document Organization

This guide contains the following chapters and appendixes:

• Chapter 1, “Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Overview,” introduces the

various line card chassis systems and components.

• Chapter 2, “Installing and Removing Power Components,” details how to bring power to and install

power components in the line card chassis.

OL-6256-17

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

xiii

Page 14

• Chapter 3, “Installing and Removing Air Circulation Components,” describes how to install the fan

trays and air filters.

• Chapter 4, “Installing and Removing Line Cards, PLIMs, and Associated Components,” provides

instructions on how to install various cards, including modular services cards, switch fabric cards,

route processor cards, and the physical layer interface modules.

• Chapter 5, “Installing and Removing Exterior Components,” provides instructions on how to install

the chassis exterior components.

• Appendix A, “Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Specifications,” lists the

specifications for the line card chassis.

• Appendix B, “Product IDs for the Cisco CRS 8-Slot Line Card Chassis” lists the product IDs for

components of the Cisco CRS Carrier Routing System 8-Slot LCC.

Document Conventions

This guide uses the convention where the symbol ^ represents the key labeled Control. For example, the

key combination ^z means hold down the Control key while you press the z key.

Command descriptions use these conventions:

• Examples that contain system prompts denote interactive sessions, indicating the commands that

you should enter at the prompt. The system prompt indicates the current level of the EXEC

command interpreter. For example, the prompt

level, and the prompt

privileged level usually requires a password. Refer to the related software configuration and

reference documentation listed in Related Cisco CRS Series Documentation for additional

information.

router> indicates that you should be at the user

router# indicates that you should be at the privileged level. Access to the

• Commands and keywords are in boldface font.

• Arguments for which you supply values are in italic font.

• Elements in square brackets ([ ]) are optional.

• Alternative but required keywords are grouped in braces ({}) and separated by vertical bars (|).

Examples use these conventions:

• Terminal sessions and sample console screen displays are in screen font.

• Information you enter is in boldface screen font.

• Nonprinting characters, such as passwords, are in angle brackets (< >).

• Default responses to system prompts are in square brackets ([]).

• Exclamation points (!) at the beginning of a line indicate a comment line.

Note Means reader take note. Notes contain helpful suggestions or references to materials not contained in

this manual.

Timesaver Means the described action saves time. You can save time by performing the action described in the

paragraph.

xiv

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

OL-6256-17

Page 15

Caution Means reader be careful. You are capable of doing something that might result in equipment damage or

loss of data.

Warning

This warning symbol means danger. You are in a situation that could cause bodily injury. Before you

work on any equipment, be aware of the hazards involved with electrical circuitry and be familiar

with standard practices for preventing accidents. To see translations of the warnings that appear in

this publication, refer to the Regulatory Compliance and Safety Information document that

accompanied this device.

Related Documentation

For complete information on the CRS 8-Slot Line Card Chassis, see the following publications:

• Cisco CRS Carrier Routing System Hardware Documentation Guide

• Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Site Planning Guide

• Cisco CRS Carrier Routing System 8-Slot Line Card Chassis System Description

• Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Unpacking, Moving, and Securing

Guide

• Cisco CRS Carrier Routing System Regulatory Compliance and Safety Information

• Cisco CRS 3-Phase AC Power Distribution Unit Installation Guide

• Cisco CRS-1 Carrier Routing System to Cisco CRS-3 Carrier Routing System Migration Guide

• Cisco CRS Carrier Routing System Ethernet Physical Layer Interface Module Installation Note

• Cisco CRS Carrier Routing System Packet-over-SONET/SDH Physical Layer Interface Module

Installation Note

For a complete listing of available software documentation for the Cisco CRS Carrier Routing System,

see the About Cisco IOS XR Software Documentation, available online at:

Statement 1074

http://www.cisco.com/en/US/products/ps5845/index.html

Then check the links under “Technical Documentation & Tools.”

Changes to This Document

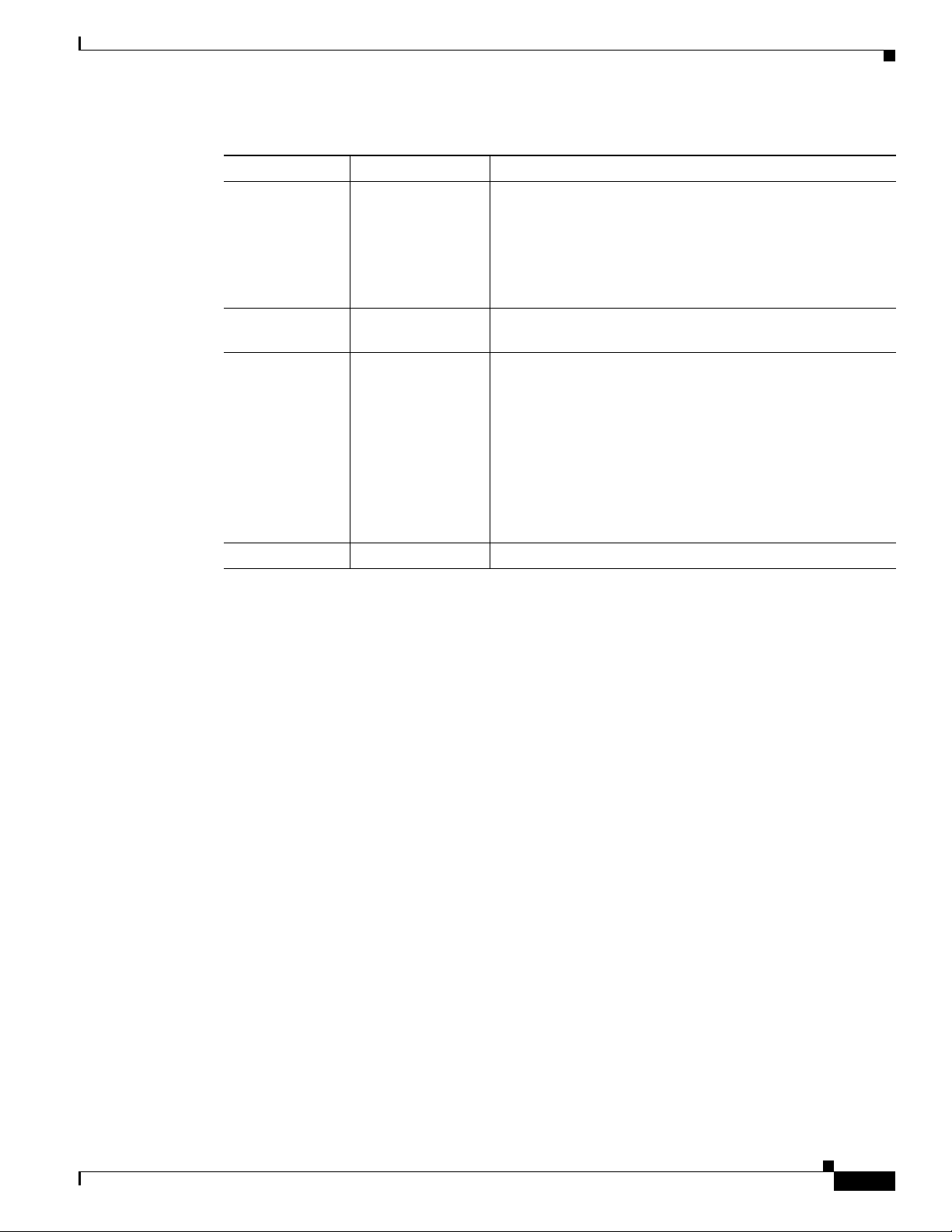

Table 1 lists the technical changes made to this document since it was first printed.

Table 1 Changes to This Document

Revision Date Change Summary

OL-6256-17 January 2014 Added updates to support the Cisco CRS-X, which includes

OL-6256-16 June 2013 Added information about how to replace a SFP on a line card

OL-6256-17

new line cards, switch fabric cards, and PLIMs.

that uses an articulated bracket.

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

xv

Page 16

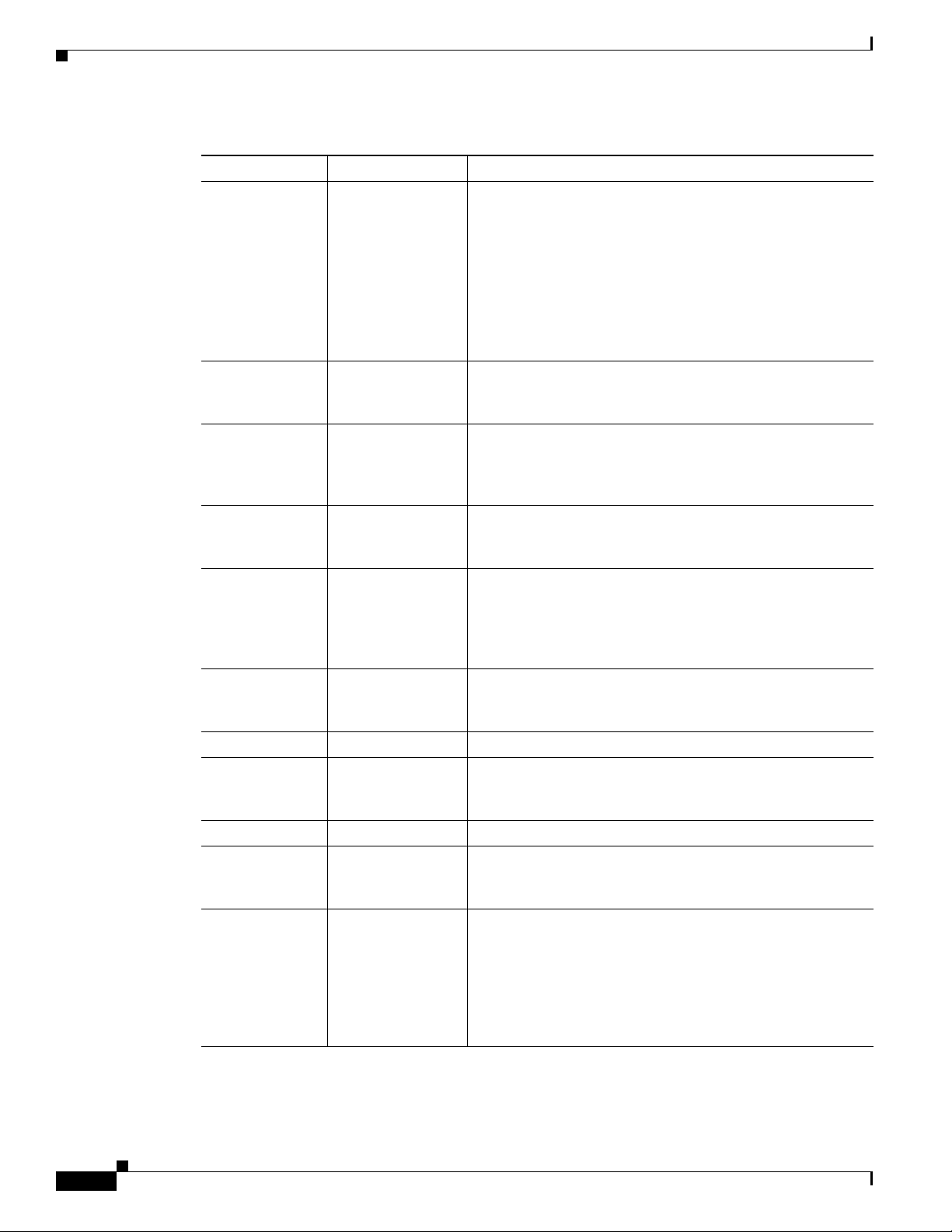

Table 1 Changes to This Document (continued)

Revision Date Change Summary

OL-6256-15 July 2011 Added information about new CRS-LSP Label Switch

Processor (LSP) card to the following sections:

• Chapter 1, “Cisco CRS Carrier Routing System 8-Slot

Line Card Chassis Overview”

• Chapter 4, “Installing and Removing Line Cards, PLIMs,

and Associated Components”

• Appendix A, “Cisco CRS Carrier Routing System 8-Slot

Line Card Chassis Specifications”

OL-6256-14 July 2011 Added new modular configuration AC cord clamp. Updated

Appendix A and added Appendix B. Minor editorial and

technical changes were also made.

OL-6256-13 April 2011 Added information about new CRS-8-PRP-6G and

CRS-8-PRP-12G Performance Route Processor (PRP) cards.

Technical updates and minor editorial changes were also

made.

OL-6256-12 November 2010 Updated grounding and modular configuration power

sections. Minor editorial and technical changes were also

made.

OL-6256-11 October 2010 Added information about the new MSC140 and FP140 line

cards; FQ123-140G switch fabric card; 20-port, 14-port,

8-port, and 4-port 10-GE XFP PLIMs; and the 1-port 100-GE

CFP PLIM. Minor editorial and technical changes were also

made.

OL-6256-10 September 2010 Added new procedures on installing and removing modular

configuration power components to Chapter 2, “Installing

and Removing Power Components.”

OL-6256-09 Jan 2010 Added installation of rear exhaust screen.

OL-6256-08 May 2008 Added new procedures on installing and removing a pillow

block to Chapter 4, “Installing and Removing Line Cards,

PLIMs, and Associated Components.”

OL-6256-07 February 2008 Minor technical changes.

OL-6256-06 August 2007 Updated the document with technical corrections. Also added

procedures in Chapter 5, “Installing and Removing Exterior

Components,” on installing the updated inlet grille.

OL-6256-05 October 2006 Updated the document with technical corrections. Also added

procedures in Chapter 5, “Installing and Removing Exterior

Components,” on installing and removing the front and rear

doors, installing and removing the inlet and exhaust grilles,

and added procedures for changing the location of the door

hinge and adjusting the width of the chassis doors if the doors

do not latch properly.

xvi

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

OL-6256-17

Page 17

Table 1 Changes to This Document (continued)

Revision Date Change Summary

OL-6256-04 April 2006

OL-6256-03 December 2005 Updated Chapter 2, “Unpacking and Mounting the Chassis”

OL-6256-02 March 2005

OL-6256-01 December 2004 Initial release of the document.

• Removed Chapter 2, “Unpacking and Mounting the

Chassis” from this guide to consolidate this information

in the Cisco CRS Carrier Routing System 8-Slot Line

Card Chassis Unpacking, Moving, and Securing Guide.

• Changed the book title to Cisco CRS Carrier Routing

System 8-Slot Line Card Chassis Installation Guide.

to reflect new packaging.

• Updated Chapter 2, “Unpacking and Mounting the

Chassis” to include information on mounting the chassis

in the rack from the rear.

• Updated Chapter 3, “Installing and Removing Power

Components” to include new wiring information.

• Updated Chapter 5, “Installing and Removing MSCs,

PLIMs, and Associated Components” to include

information on installing and removing slot covers and

impedance carriers.

Obtaining Documentation and Submitting a Service Request

For information on obtaining documentation, submitting a service request, and gathering additional

information, see the monthly What’s New in Cisco Product Documentation, which also lists all new and

revised Cisco technical documentation, at:

http://www.cisco.com/en/US/docs/general/whatsnew/whatsnew.html

OL-6256-17

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

xvii

Page 18

xviii

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

OL-6256-17

Page 19

CHA P T ER

1

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Overview

This installation guide describes how to install the power, air circulation, line card, and external

components into and remove them from a Cisco CRS Carrier Routing System 8-Slot Line Card Chassis.

This chapter introduces the Cisco CRS 8-slot line card chassis at the highest level. It contains

illustrations of the front and rear of the chassis, complete with callouts to each hardware component. For

details on each subsystem discussed in this chapter, see Cisco CRS Carrier Routing System 8-Slot Line

Card Chassis System Description.

This chapter presents the following topics:

• Chassis Overview, page 1-1

• Chassis Components, page 1-2

• Chassis Slot Numbers, page 1-9

• Chassis Cable Management, page 1-10

• Chassis Cooling System, page 1-11

• Chassis Power System, page 1-12

• Safety Guidelines, page 1-12

• Preventing Electrostatic Discharge, page 1-13

Chassis Overview

The Cisco CRS 8-slot line card chassis can be installed in locations where the 16-slot system may not

fit (for example, colocation facilities, data centers, and many Tier II and Tier III locations). The routing

system consists of a single rack-mount chassis that contains the following major system components:

• Up to eight modular services cards (MSCs), forwarding processor (FP) cards, and label switch

processor (LSP) cards, also called line cards (up to eight)

• Physical layer interface modules, or PLIMs (up to eight, one for each line card)

• Route processor (RP) cards (up to two) or performance route processor (PRP) cards (up to two)

• Switch fabric cards (four required)

• SPA Interface Processors (SIPs) and Shared Port Adapters (SPAs) which can be installed instead of

PLIMs

OL-6256-17

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

1-1

Page 20

Chassis Components

Chapter 1 Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Overview

–

SIP is a carrier card that is similar to a PLIM and inserts into a line card chassis slot and

interconnects to an MSC, FP, or LSP like a PLIM. Unlike PLIMs, SIPs provide no network

connectivity on their own.

–

SPA is a modular type of port adapter that inserts into a subslot of a compatible SIP carrier card

to provide network connectivity and increased interface port density. A SIP can hold one or

more SPAs, depending on the SIP type and the SPA size. POS/SDH and Gigabit Ethernet SPAs

are available.

• A chassis midplane that connects MSCs, FPs, or LSPs to their PLIMs and to switch fabric cards.

The LCC supports 40G, 140G, and 200G fabric cards, as follows:

• The Cisco CRS-1 Carrier Routing System uses fabric cards designed for 40 G operation

(CRS-8-FC/S or CRS-8-FC/M cards).

• The Cisco CRS-3 Carrier Routing System uses fabric cards designed for 140G operation

(CRS-8-FC140/S or CRS-8-FC140/M cards).

• The Cisco CRS-X Carrier Routing Sytsem uses fabric cards designed for 200G operation

(CRS-8-FC400/S cards in 200G mode).

A mixture of 40G, 140G, and 200G fabric cards is not supported except during migration.

Note Throughout this document, the generic term Cisco CRS Carrier Routing system refers to the Cisco

CRS-1, Cisco CRS-3, and Cisco CRS-X Carrier Routing Systems, unless otherwise specified.

Chassis Components

This section lists the main components of a Cisco CRS 8-slot line card chassis. It primarily identifies the

components that are considered field-replaceable units (FRUs), but where additional detail is useful

identifies subassemblies that are not field replaceable.

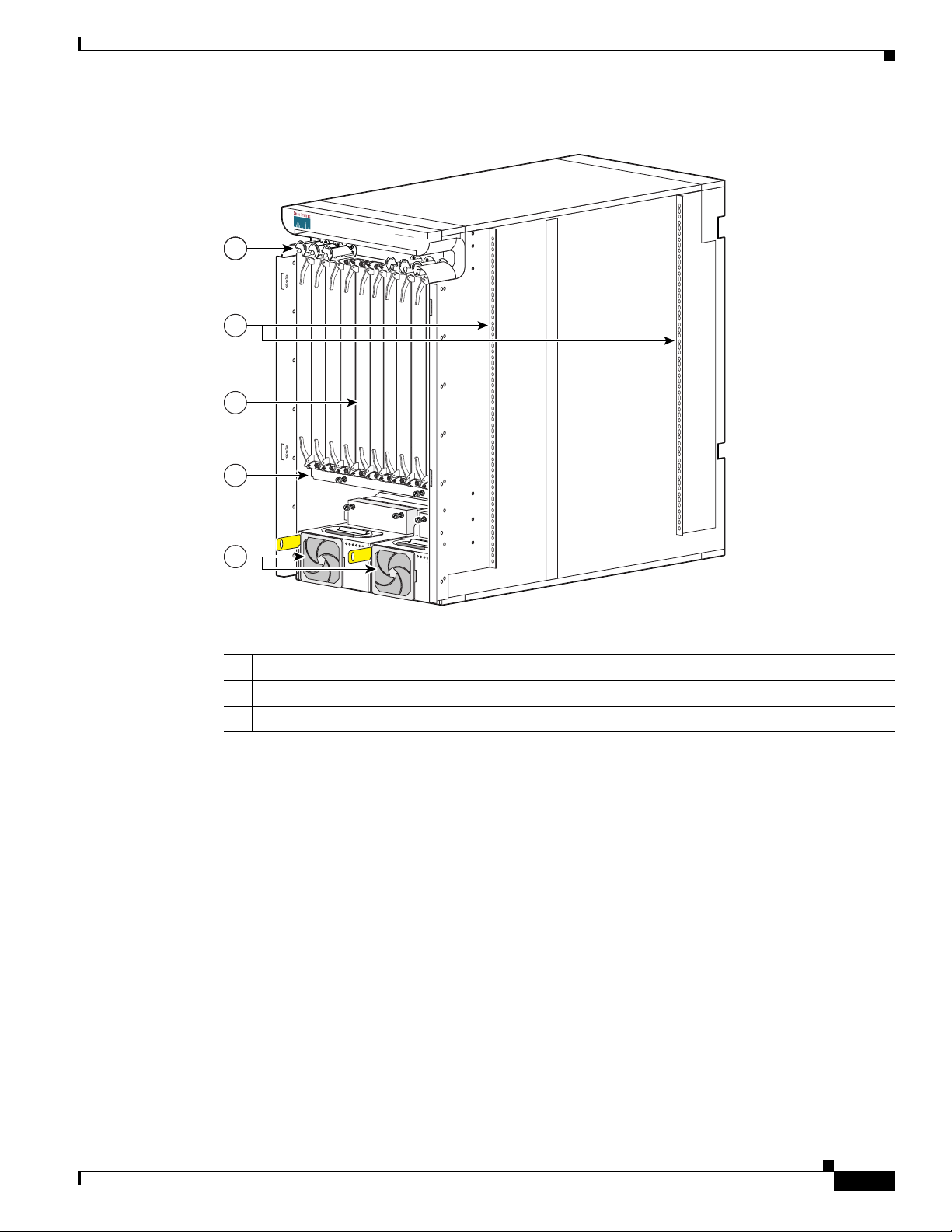

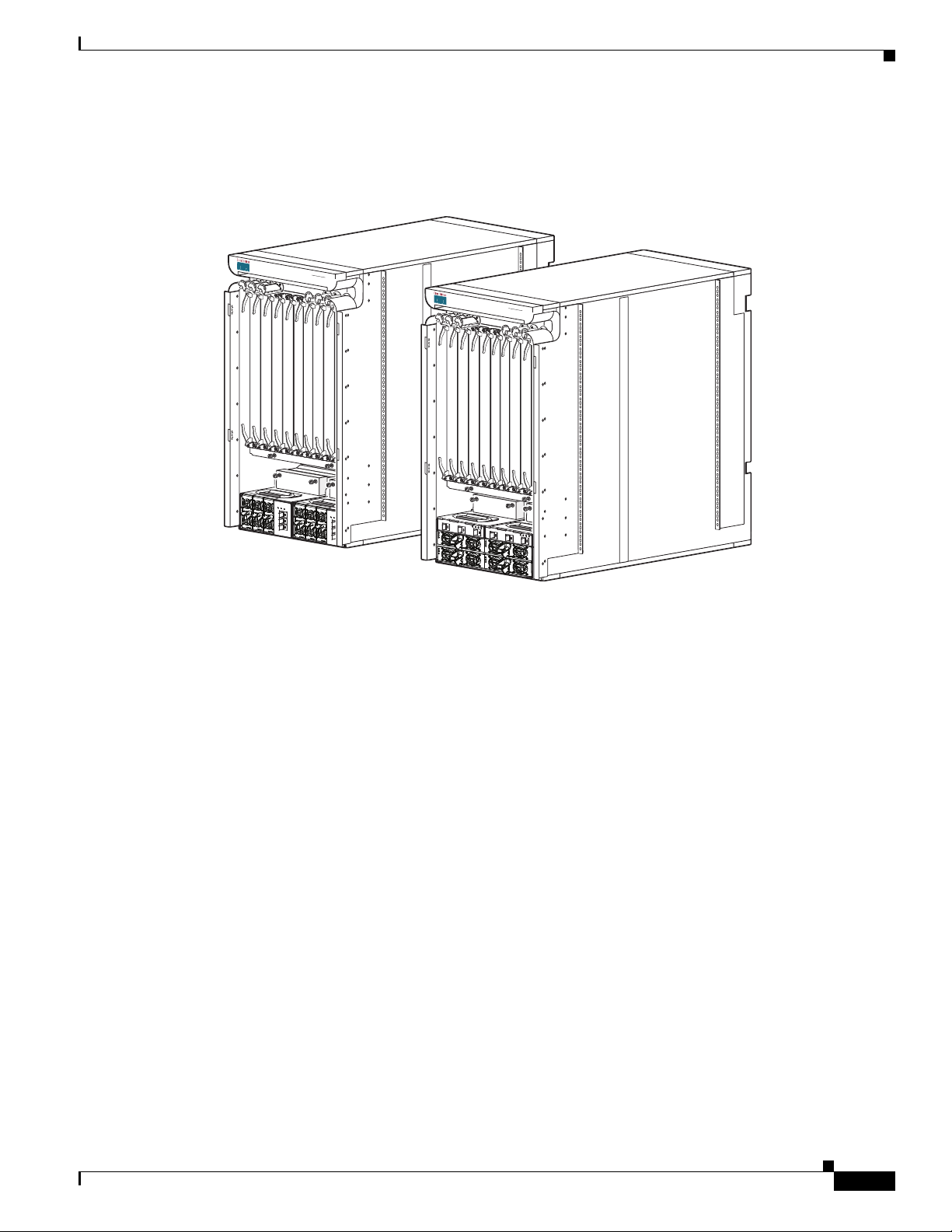

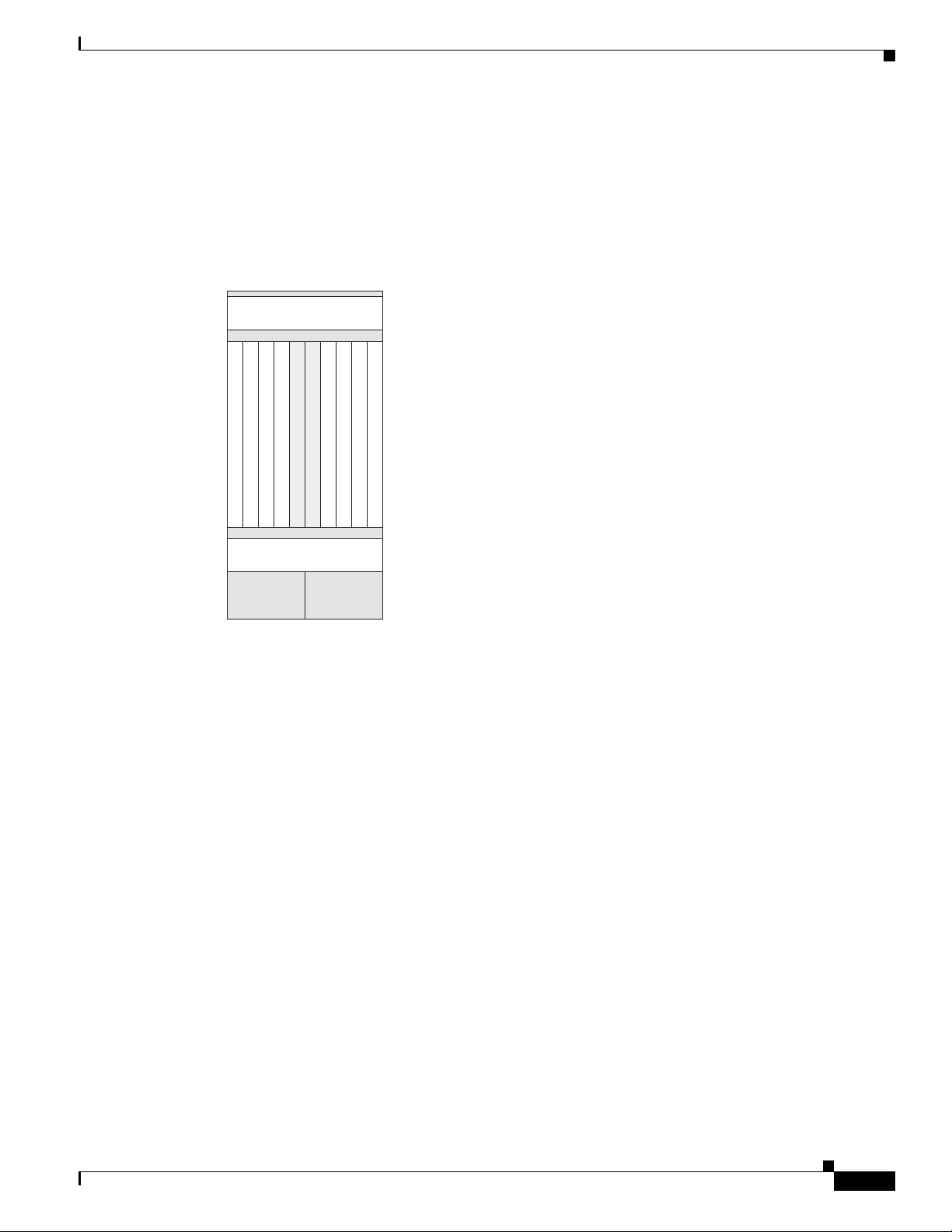

Figure 1-1 shows the front view of a Cisco CRS 8-slot line card chassis with a fixed configuration AC

power system installed. The front view of a Cisco CRS 8-slot line card chassis with a fixed configuration

DC power system installed is similar.

1-2

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

OL-6256-17

Page 21

Chapter 1 Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Overview

122775

P

O

W

E

R

O

K

F

L

T

A

C

F

A

I

L

C

B

T

M

P

L

L

M

O

T

P

O

W

E

R

O

K

F

L

TA

C

F

A

I

L

C

B

T

M

P

L

L

MO

T

1

3

4

2

5

CISCO CRS-1

S

E

R

I

E

S

LINECARD CHASSIS

Figure 1-1 Front (PLIM) View of Line Card Chassis—Fixed Configuration Power Shown

Chassis Components

1 Cable management bracket 4 Air filter

2 Chassis vertical mounting brackets 5 Power System

3 PLIM and RP slots (RPs in middle 2 slots)

OL-6256-17

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

1-3

Page 22

Chassis Components

281369

CRS 8-Slot DC Rear

CRS 8-Slot AC Rear

Chapter 1 Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Overview

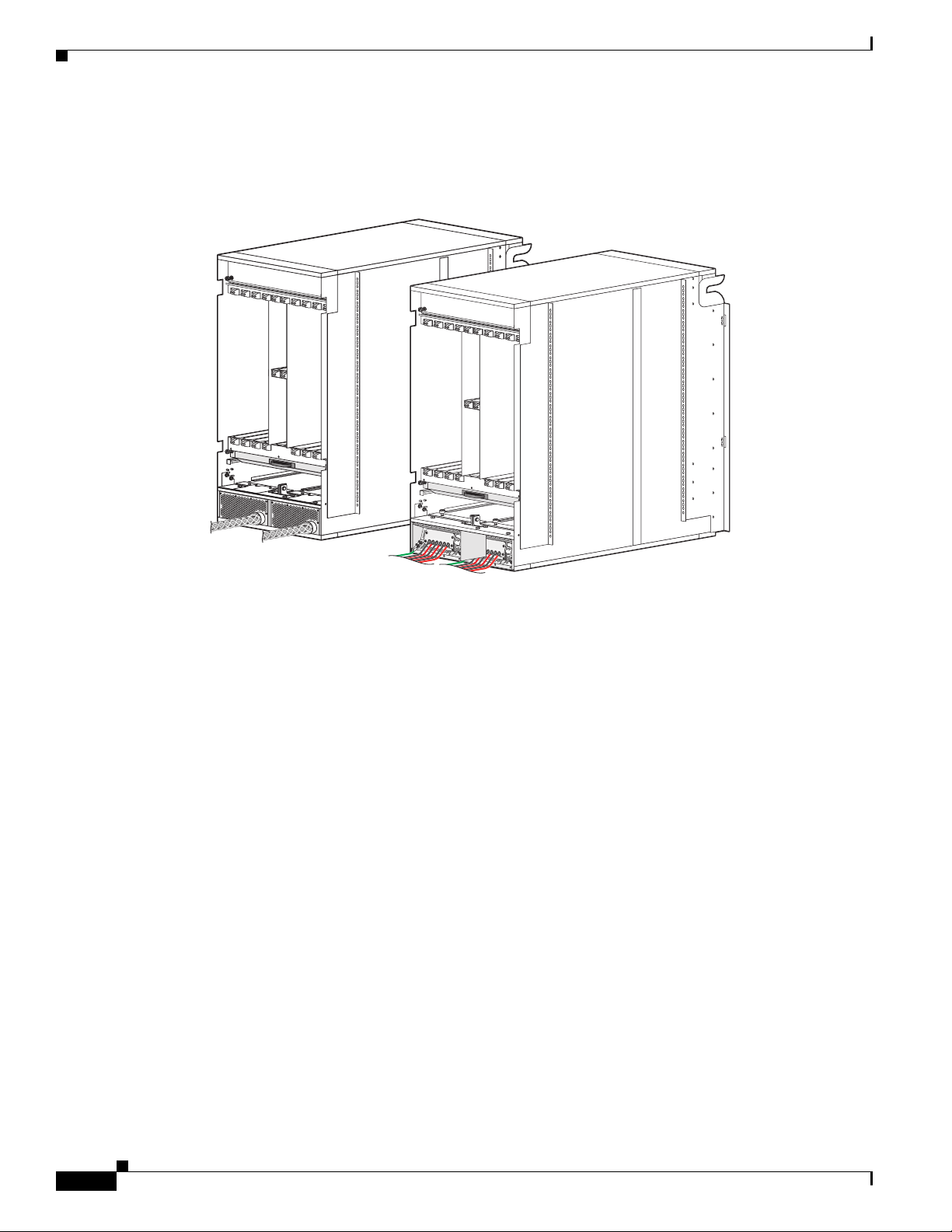

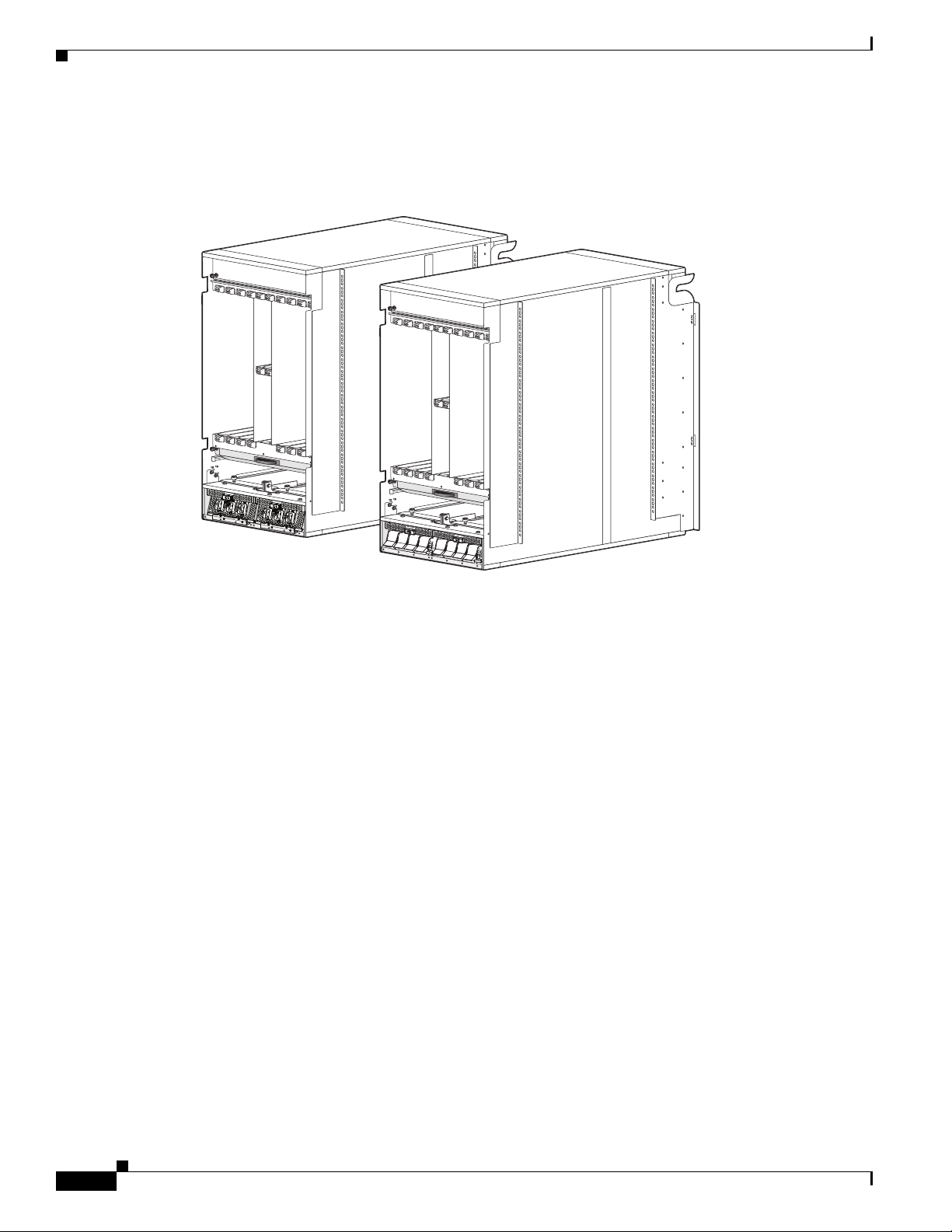

Figure 1-2 shows the rear view of a Cisco CRS 8-slot line card chassis with fixed configuration AC and

DC power systems installed.

Figure 1-2 Rear (MSC) View of Line Card Chassis—Fixed Configuration Power Shown

1-4

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

OL-6256-17

Page 23

Chapter 1 Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Overview

CRS 8-Slot DC Front

CRS 8-Slot AC Front

CISCO CRS-1

SER

I

E

S

LINECARD CHASSIS

281370

CISCO CRS-1

S

ERIES

LINECARD CHASSIS

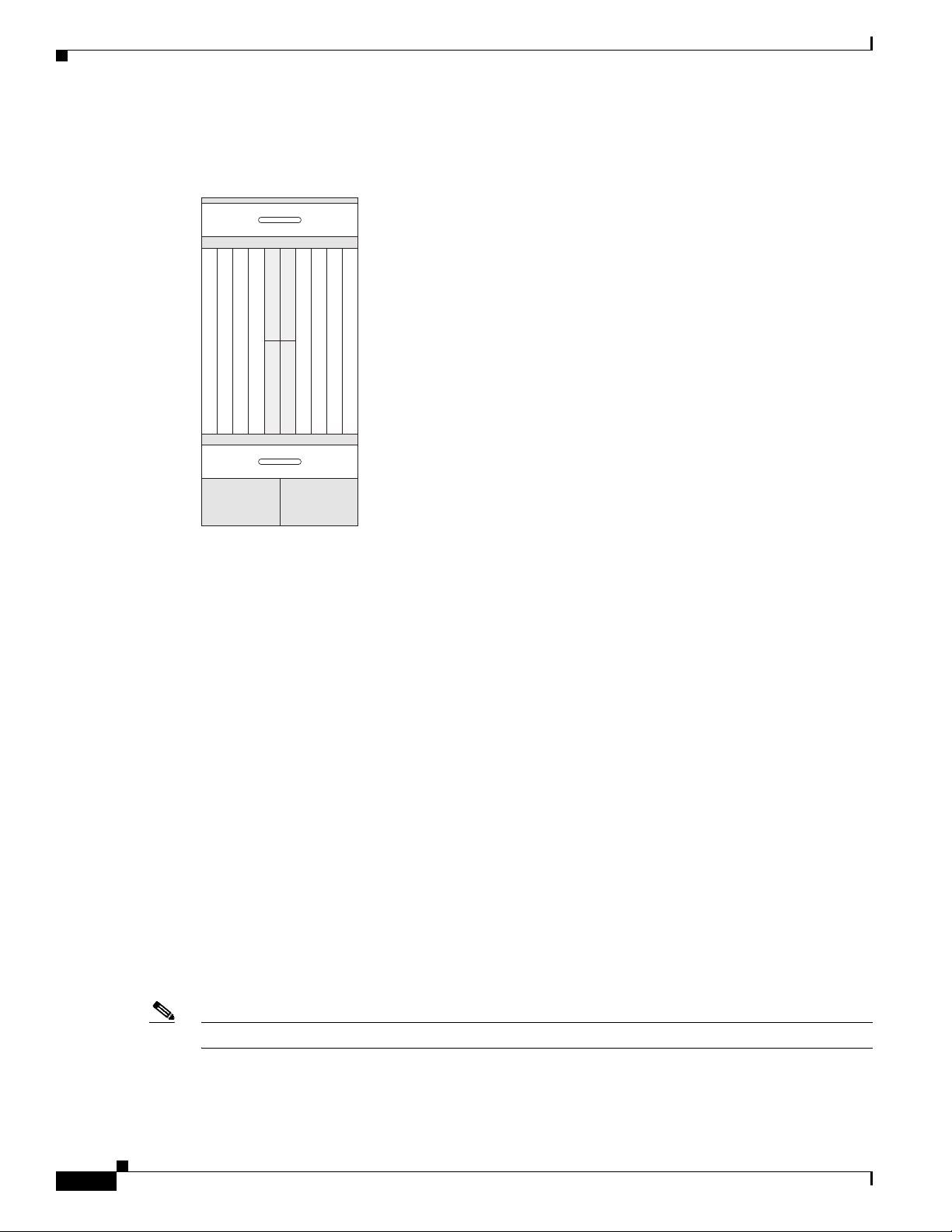

Figure 1-3 shows the front view of a Cisco CRS 8-slot line card chassis with modular configuration AC

and DC power systems installed.

Figure 1-3 Front (PLIM) View of Line Card Chassis—Modular Configuration Power Shown

Chassis Components

OL-6256-17

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

1-5

Page 24

Chassis Components

281371

CRS 8-Slot DC Rear

CRS 8-Slot AC Rear

Chapter 1 Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Overview

Figure 1-4 shows the rear view of a Cisco CRS 8-slot line card chassis with modular configuration AC

and DC power systems installed.

Figure 1-4 Rear (MSC) View of Line Card Chassis—Modular Configuration Shown

1-6

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

OL-6256-17

Page 25

Chapter 1 Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Overview

122776

1

4

3

2

5

6

7

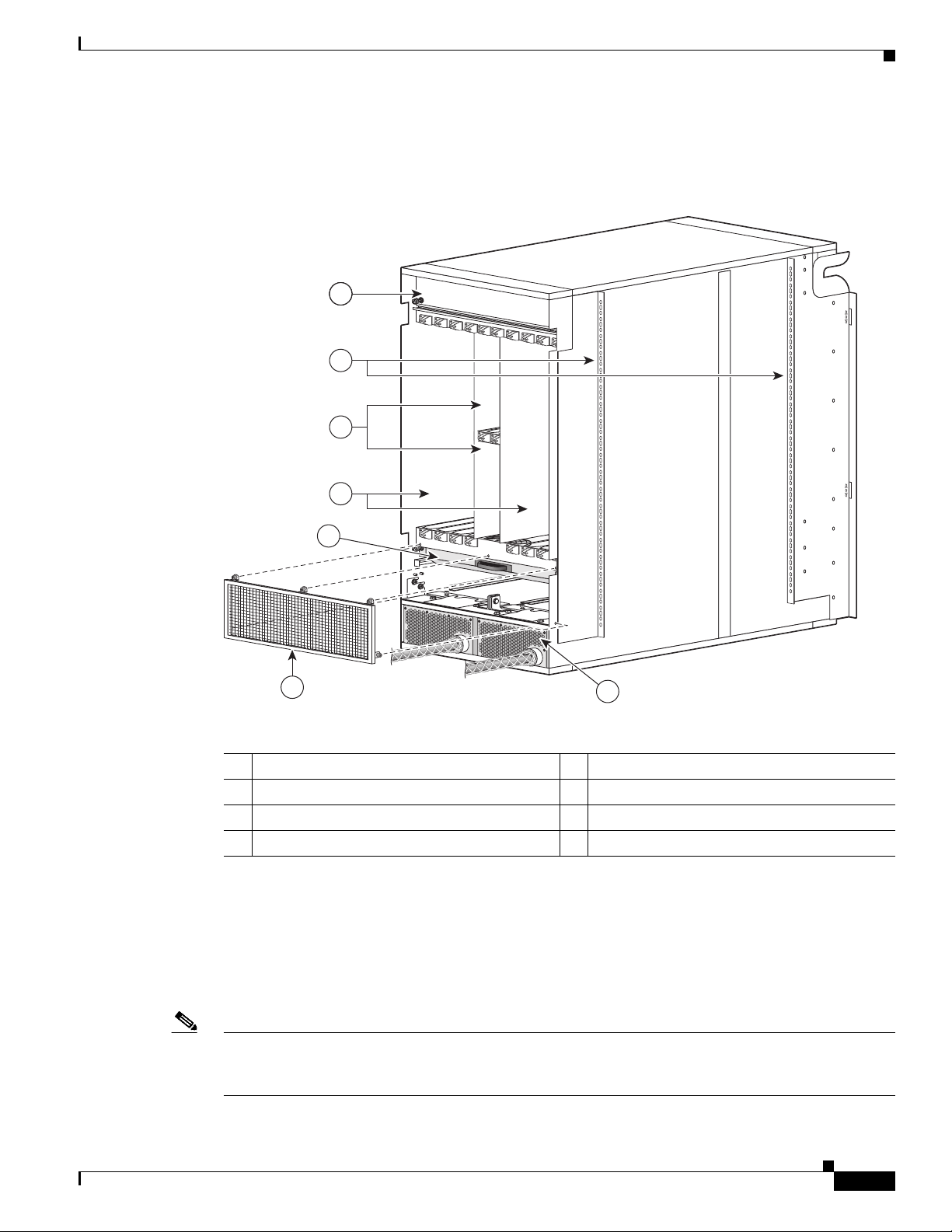

Figure 1-5 shows the rear view of a Cisco CRS 8-slot line card chassis with a fixed configuration AC

power system installed.

Figure 1-5 Rear (MSC) View of Line Card Chassis—Fixed Configuration Shown

Chassis Components

OL-6256-17

1 Upper fan tray (beneath cover) 5 Lower fan tray

2 Chassis vertical mounting brackets 6 Rear exhaust screen

3 Switch fabric card (half-height) slots 7 Power system

4 MSC slots

The Cisco CRS 8-slot line card chassis contains:

• As many as eightMSC, FP or LSP cards (all types are also called line cards), and eightPLIMs. The

line card and PLIM are an associated pair of cards that mate through the chassis midplane. The line

card provides the forwarding engine for Layer 3 routing of user data, and the PLIM provides the

physical interface and connectors for the user data. The line card can be associated with several

different PLIMs, which provide different interface speeds and technologies.

Note For a complete list of line cards, route processors, SPAs and SIPs, and interface modules supported in

the Cisco CRS 8-slot line card chassis, go to the Cisco Carrier Routing System Data Sheets at:

http://www.cisco.com/en/US/products/ps5763/products_data_sheets_list.html.

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

1-7

Page 26

Chassis Components

Chapter 1 Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Overview

• A chassis midplane that connects line cards to their associated PLIMs. The midplane design allows

a line card to be removed from the chassis without having to disconnect the cables that are attached

to the associated PLIM. The midplane distributes power, connects the line cards to the switch fabric

cards, and provides control plane interconnections. The midplane is not field replaceable by the

customer.

• One or two route processor cards (RPs). The RPs provide the intelligence of the system by

functioning as the Cisco CRS 8-slot line card chassis system controller (serving as part of the control

plane in multi-chassis systems) and providing route processing. Only one RP is required for system

operation. For redundant operation, you can order a second RP as an option (CRS-8-RP/R). When

two RPs are used, only one RP is active at a time. The second RP acts as a “standby” RP, serving as

a backup if the active RP fails.

The RP also monitors system alarms and controls the system fans. LEDS on the front panel indicate

active alarm conditions.

A Performance Route Processor (PRP) is also available for the Cisco CRS 8-slot line card chassis.

Two PRPs perform the same functions as two RPs, but provide enhanced performance for both route

processing and system controller functionality.

Note A chassis may not be populated with a mix of RP and PRP cards. Both route processor cards

should be of the same type (RP or PRP).

• Upper and lower fan trays. The fans pull cool air through the chassis. A removable air filter is located

below the PLIM card cage at the front of the chassis.

• Four half-height switch fabric cards (SFCs). These cards provide the three-stage Benes switch fabric

for the routing system. The switch fabric performs the cross-connect function of the routing system,

connecting every MSC (and its associated PLIM) with every other MSC (and its associated PLIM)

in the system.

The switch fabric receives user data from one line card and PLIM pair and performs the switching

necessary to route the data to the appropriate egress line card and PLIM pair. The switch fabric is

divided into eight planes that are used to evenly distribute the traffic across the switch fabric. Each

switch fabric card implements two planes of the switch fabric.

• A power system that provides redundant power to the chassis. Two types of power systems are

available: fixed configuration power and modular configuration power. Both power configurations

use either AC or DC power. The fixed configuration power solution contains two power distribution

units (PDUs), with either one AC rectifier or one DC power entry modules (PEM) per PDU. The

modular configuration power solution contains two power shelves with either up to four DC power

modules (PMs) or up to three AC PMs per power shelf.

The PLIM side of the chassis is considered the front of the chassis, where user data cables attach to the

PLIMs and cool air enters the chassis. The MSC side, which is where warm air is exhausted, is

considered the rear of the chassis.

1-8

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

OL-6256-17

Page 27

Chapter 1 Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Overview

Chassis Slot Numbers

This section identifies the location and slot numbers for major cards and modules (primarily the

field-replaceable units) that plug into the chassis.

Figure 1-6 shows the slot numbering on the front (PLIM) side of the Cisco CRS 8-slot line card chassis.

Figure 1-6 Line Card Chassis Slot Numbering—Front (PLIM) Side

012

3

RP 0

RP 1

456

7

Chassis Slot Numbers

Power A Power B

122778

As shown, the Cisco CRS 8-slot line card chassis numbers on the PLIM side of the chassis include the

card cage with:

• Eight PLIM slots: left to right, 0, 1, 2, 3, 4, 5, 6, 7

• Two route processor card slots, RP0 and RP1

• Power shelf A and power shelf B

OL-6256-17

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

1-9

Page 28

Chassis Cable Management

Figure 1-7 shows the slot numbers on the rear (MSC) side of the Cisco CRS 8-slot line card chassis.

Figure 1-7 Line Card Chassis Slot Numbers—Rear (MSC) Side

Chapter 1 Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Overview

FAN 0

7654SM 0 SM 2

Power B Power A

SM 1 SM 33210

FAN 1

122779

As shown, the slot numbers on the MSC side of the chassis include:

• Fan tray 0 and fan tray 1

• Card cage, including:

–

Eight line card slots (0, 1, 2, 3, 4, 5, 6, 7)

–

Four half-height switch fabric card slots (SM0, SM1, SM2, and SM3)

• Power shelf A and Power shelf B

The MSC slot numbers are reversed from the PLIM slot numbers on the other side of the chassis.

Because an MSC mates with its associated PLIM through the midplane, MSC slot 0 is on the far right

side of the chassis looking at it from the rear (MSC) side.

PLIM slot 0 is on the far left side of the chassis, looking at if from the front (PLIM) side. MSC slot 0

and PLIM slot 0 mate with each other through the midplane, and so do all other MSC and PLIM slots (0

through 7).

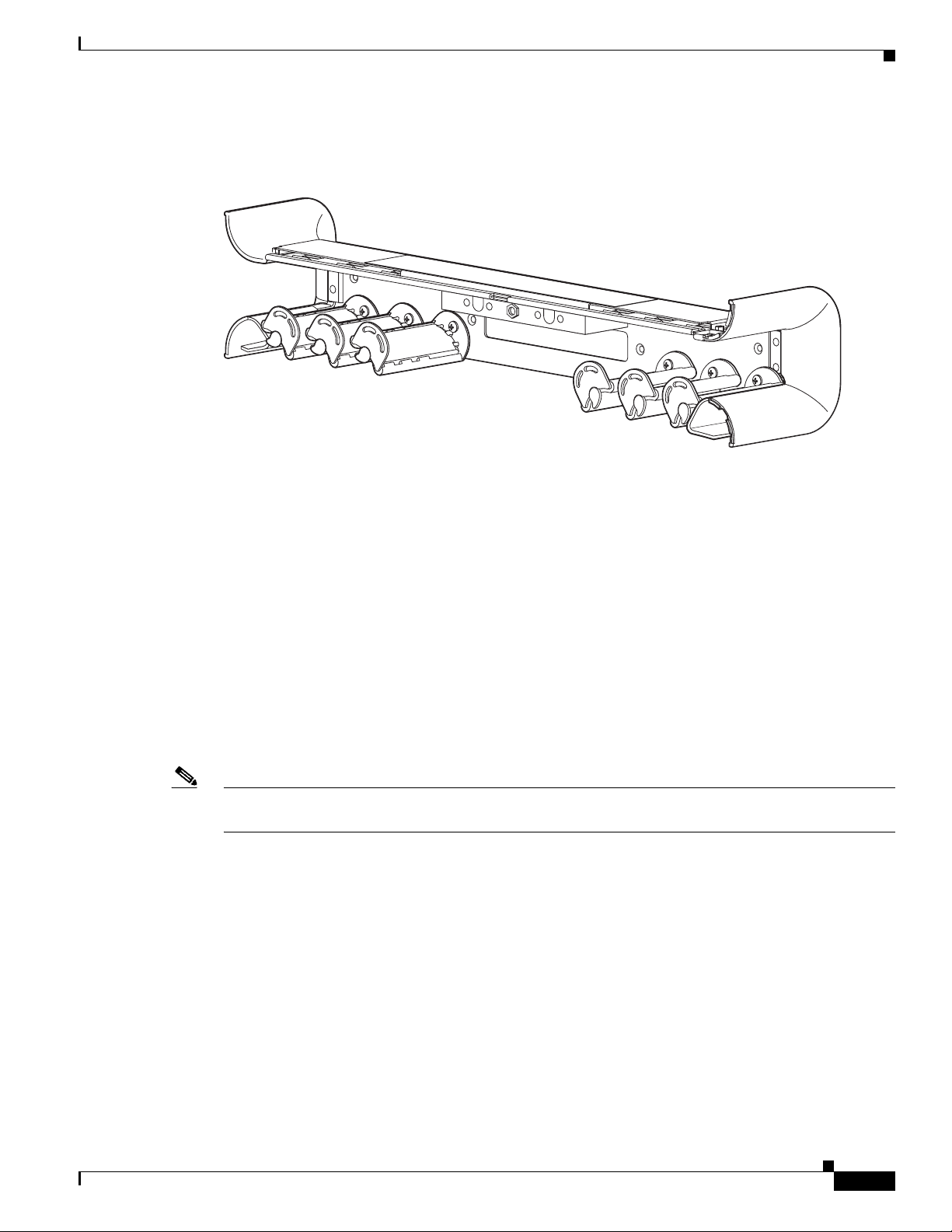

Chassis Cable Management

The Cisco CRS 8-slot line card chassis has cable management features for the front (PLIM) side of the

chassis, just above the card cage. The horizontal cable management trays have a special telescoping

feature that allows them to be extended when the chassis is upgraded with higher-density cards. This

extension also helps when installing the cables in the chassis.

Note Do not install the front cover on the chassis when the telescoping feature is in use.

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

1-10

OL-6256-17

Page 29

Chapter 1 Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Overview

122789

Figure 1-8 shows the cable management bracket.

Figure 1-8 Cable Management Bracket

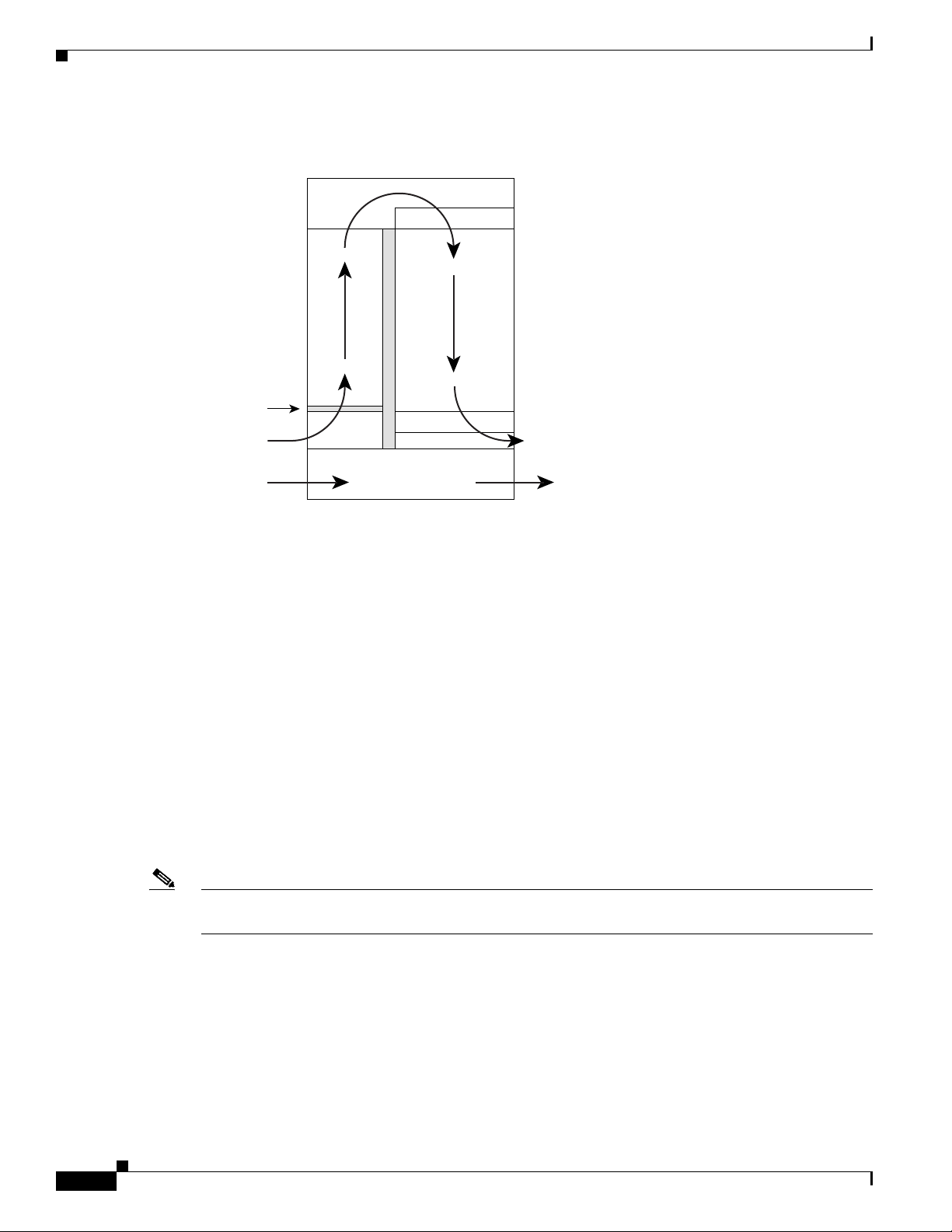

Chassis Cooling System

Chassis Cooling System

The chassis has two fan trays, each with four fans, that cool the chassis card cages. Cool air flows in at

the bottom front of the chassis and flows through the chassis card cages and through the fans in the fan

trays before being exhausted through the bottom rear of the chassis (see Figure 1-9). In addition, each

AC or DC power module at the bottom of the chassis has self-contained fans that pull in cool air from

the front of the chassis and exhaust warm air out the rear.

A replaceable air filter is located on the front of the chassis below the PLIM card cage. Each fixed

configuration power module also has a replaceable air filter that attaches to the module at the front

(PLIM) side of the chassis. How often the air filters should be replaced depends on the facility

environment. In a dirty environment, or when you start getting frequent temperature alarms, you should

always check the intake grills for debris, and then check the air filters to see if they need to be replaced.

Note We recommend that you check the air filters once a month. Replace a filter when you notice a significant

amount of dust.

OL-6256-17

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

1-11

Page 30

Chassis Power System

122784

Fan

Air enters

PLIM side

Power system

Fan

Air exits MSC and

fabric card side

Front Rear

Air filter

Chapter 1 Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Overview

Figure 1-9 Airflow Through 8-Slot Line Card Chassis

Chassis Power System

Two types of power systems are available for the Cisco CRS 8-slot line card chassis: fixed configuration

power and modular configuration power. Both power systems can be powered by either AC or DC power.

The chassis power system takes the facility power and converts it to the DC voltage necessary to power

chassis components.

For more information, refer to Chapter 2, “Installing and Removing Power Components.”

Safety Guidelines

Before you perform any procedure in this document, review the safety guidelines in this section to avoid

injuring yourself or damaging the equipment. The following guidelines are for your safety and to protect

equipment. The guidelines do not include all hazards. Be alert.

Note Review the safety warnings listed in Regulatory Compliance and Safety Information that are applicable

to your router before installing, configuring, or troubleshooting any installed card.

• Keep the work area clear and dust-free during and after installation. Do not allow dirt or debris to

enter into any laser-based components.

• Do not wear loose clothing, jewelry, or other items that could get caught in the router while working

with line cards, or their associated components.

• Cisco equipment operates safely when used in accordance with its specifications and product-usage

instructions.

• Be sure to power down a fixed configuration PDU or modular configuration power shelf before

removing it from the chassis.

1-12

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

OL-6256-17

Page 31

Chapter 1 Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Overview

Preventing Electrostatic Discharge

Electrostatic discharge (ESD) damage, which can occur when electronic cards or components are

improperly handled, results in complete or intermittent failures. We recommend to use an

ESD-preventive strap whenever you handle network equipment or one of its components.

Following are guidelines for preventing ESD damage:

• Always use an ESD-preventive wrist or ankle strap and ensure that it makes good skin contact.

Connect the equipment end of the connection cord to an ESD connection socket on the router or to

a bare metal surface on the chassis.

• Handle a card by its ejector levers, when applicable, or the card’s metal carrier only; avoid touching

the board or connector pins.

• Place a removed card board-side-up on an antistatic surface or in a static-shielding bag. If you plan

to return the component to the factory, immediately place it in a static-shielding bag.

• Avoid contact between the card and clothing. The wrist strap protects the board only from ESD

voltage on the body; ESD voltage on clothing can still cause damage.

Preventing Electrostatic Discharge

OL-6256-17

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

1-13

Page 32

Preventing Electrostatic Discharge

Chapter 1 Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Overview

1-14

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

OL-6256-17

Page 33

Installing and Removing Power Components

This chapter provides instructions on how to install and remove Cisco CRS Carrier Routing System

8-slot line card chassis power components.

Power Systems Overview

There are two options for power systems: the fixed configuration power system and the modular

configuration power system. Power components are not interchangeable between the fixed and modular

configuration power system.

• Fixed configuration power system consists of two power distribution units (PDUs) and either DC

power entry modules (PEMs) or AC rectifiers. The AC version requires 3-phase AC-Delta or

AC-Wye input power to the PDU. The PDU distributes facility power to the AC rectifier or DC PEM,

which in turn provides processed power to the chassis. A removable air filter is located on the front

of each DC PEM and AC rectifier. The fixed configuration power system includes SNMP MIBS and

XML support.

CHA P T ER

2

• Modular configuration power system consists of two power shelves and either AC or DC power

modules (PMs). However, unlike the fixed configuration power system, the AC version of the

modular configuration power system requires single-phase AC input power to power the shelves. If

you have 3-phase AC-Delta or AC-Wye at your equipment, a Cisco CRS PDU will be required to

convert 3-phase AC input power to single-phase AC input power for the power shelf. At the shelf

level, the power system provides 2N redundancy; the PMs themselves provide load-share

redundancy. The modular configuration power system also includes SNMP MIBs and XML support.

Note In a fixed configuration AC or DC power system, PDU refers to the power component that connects to

the AC rectifier or DC PEM.

Note In a modular configuration AC power system, PDU refers to the Cisco CRS PDU that converts 3-phase

AC-Wye or AC-Delta input power to single-phase AC input power for the modular configuration AC

power shelf. For further information, refer to Cisco CRS 3-Phase AC Power Distribution Unit

Installation Guide.

OL-6256-17

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

2-1

Page 34

Chapter 2 Installing and Removing Power Components

Power Component Information Common to Two Types of Power System

This chapter presents the following topics:

• Power Component Information Common to Two Types of Power System, page 2-2

• How to Install or Remove Fixed Configuration Power Components, page 2-13

• How to Install or Remove Modular Configuration Power Components, page 2-25

• Converting a Chassis from Fixed Configuration Power to Modular Configuration Power, page 2-54

Power Component Information Common to Two Types of Power

System

This section contains information shared by the fixed configuration power components and the modular

configuration power components in the following topics:

• Basic Chassis Power Details, page 2-2

• Bonding and Grounding Guidelines, page 2-4

• How to Install the Chassis Ground Cable, page 2-5

• DC Power Systems, page 2-6

• AC Power Systems, page 2-11

Basic Chassis Power Details

The Cisco CRS 8-slot line card chassis can be configured with either a DC-input power subsystem or an

AC-input power subsystem. The chassis power system provides the necessary power for chassis

components. Site power requirements differ, depending on the source voltage used.

A fixed configuration AC PDU connects to an AC rectifier, while a fixed configuration DC PDU

connects to a DC PEM. A modular configuration AC power shelf houses up to 3 AC PMs, while a

modular configuration DC power shelf houses up to 4 DC PMs. It is required that you use only one type

of power shelf in a chassis at a time.

Note In a modular configuration power system, both AC and DC power supplies are referred to as power

modules (PMs).

Warning

This unit might have more than one power supply connection. All connections must be removed to

de-energize the unit.

Statement 1028

2-2

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

OL-6256-17

Page 35

Chapter 2 Installing and Removing Power Components

Fixed Configuration Power System

Three types of PDUs exist for fixed configuration power system:

• AC Wye PDU

• AC Delta PDU

• DC PDU

The AC PDU connects to the AC rectifier, while the DC PDU connects to the DC PEM. Although there

are differences among the different PDU types (AC Wye, AC Delta, and DC), they are installed in the

same manner. For detailed information, see the “How to Install or Remove Fixed Configuration Power

Components” section on page 2-13.

Note The fixed configuration PDUs arrive preassembled in the chassis. AC power cords arrive preattached but

the DC power cables need to be installed.

Caution Use only one type of fixed configuration PDU—AC Wye, AC Delta, or DC—and its mating AC rectifier

or DC PEM in a chassis at one time.

Power Component Information Common to Two Types of Power System

Modular Configuration Power System

The modular configuration AC power shelves connect to AC PMs, while the modular configuration DC

power shelves connect to DC PMs. Although there are differences between the two different power shelf

types (AC and DC), they are installed in the same manner. Similarly, the modular configuration AC and

DC PMs are installed in the same manner. For detailed information, see the “How to Install or Remove

Modular Configuration Power Components” section on page 2-25.

Caution Use only one type of modular configuration power shelf—AC or DC—and its mating AC or DC PMs in

a chassis at one time.

Precautions and Recommendations

Follow these precautions and recommendations when planning power connections to the router:

• Check the power at your site before installation and periodically after installation to ensure that you

are receiving clean power. Install a power conditioner, if necessary.

• Properly ground your system to avoid damage from lightning and power surges.

Note For the fixed configuration power system, although PDUs may be installed or removed without powering

down the system, for safety purposes we recommend that you power down the system before you install

or remove a PDU.

OL-6256-17

For the modular configuration power system, although power shelves may be installed or removed

without powering down the system, for safety purposes we recommend that you power down the system

before you install or remove a power shelf.

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

2-3

Page 36

Power Component Information Common to Two Types of Power System

Bonding and Grounding Guidelines

The router chassis has safety earth ground connections in conjunction with the power cabling to the fixed

configuration PDUs. Modular configuration power supports chassis grounding only. The chassis allows

you to connect the central office ground system or interior equipment ground system to the bonding and

grounding receptacles on the router chassis, when either a fixed or modular configuration power system

is installed. Six chassis grounding points are provided at the rear (MSC) side of the chassis, as shown in

Figure 2-1. Each side of the chassis has one pair of threaded ground studs located on the inside of the

chassis and two sets of grounding receptacles located on the outside of the chassis. These ground points

are also called the network equipment building system (NEBS) bonding and grounding points.

Note These bonding and grounding receptacles satisfy the Telcordia NEBS requirements for bonding and

grounding connections.

Figure 2-1 NEBS Bonding and Grounding Points (Rear of Chassis) - Fixed Configuration AC

Power Shown

Chapter 2 Installing and Removing Power Components

1

2

1 NEBS bonding and grounding points (inside chassis)

2 NEBS bonding and grounding points (outside chassis)

Caution Do not remove the chassis ground cable unless the chassis is being replaced.

122792

2-4

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

OL-6256-17

Page 37

Chapter 2 Installing and Removing Power Components

How to Install the Chassis Ground Cable

This section describes how to install the ground cable on the Cisco CRS 8-slot line card chassis.

Prerequisites

To connect the routing system to a network equipment building system (NEBS)-compliant bonding and

grounding system at the site, you must have the following:

• Minimum of one grounding lug that has two M6 bolt holes with 0.63-inch (5/8 inch) (1.6 cm) of

spacing between them, center to center, and a 6-AWG multistrand copper cable. The lug is similar

to the type used for the DC-input power supply leads, as shown in Figure 2-4.

• Four M6 or equivalent hex-head nuts with integrated locking washers are shipped pre-installed on

the inside of the chassis.

• Eight M6 or equivalent hex-head bolts with integrated locking washers are shipped pre-installed on

the outside of the chassis.

• Ground cable routed upwards or downwards, per customer installation requirements. Although we

recommend at least 6-AWG multistrand copper cable, the actual cable diameter and length depend

on your router location and site environment. This cable is not available from Cisco Systems; it is

available from any commercial cable vendor. The ground cable should be sized according to local

and national installation requirements.

Power Component Information Common to Two Types of Power System

Caution The DC Return of the Cisco CRS 8-slot chassis should remain isolated from the system frame and

chassis (DC-I: Isolated DC Return).

Required Tools and Equipment

You need the following tools to perform this task:

• One ground lug for equipment-side ground connection. In a rack application, the rack-side of the

ground cable will also require a lug.

• Ground cable

• Crimping tool and lug specific die

• 10-mm 6 pt. combination wrench

• Torque wrench with 10-mm 6 pt. socket and rated accuracy at 30 in.-lb (3.39 N-m)

Steps

To attach the ground cable to the chassis, perform the following steps:

Step 1 Use the crimping tool mandated by the lug manufacturer to crimp the lug to the ground cable.

Step 2 Using the 10-mm wrench, attach the ground cable to one of the grounding points at the rear of the

chassis. Then use the torque wrench to tighten to a torque of 30 in.-lb (3.39 N-m). Figure 2-2 shows how

the ground cable is attached to the ground points on the outside of the chassis.

OL-6256-17

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

2-5

Page 38

Power Component Information Common to Two Types of Power System

254895

Figure 2-2 Ground Cables Attached to Chassis Grounding Points

Chapter 2 Installing and Removing Power Components

1 NEBS bonding and grounding points (inside chassis)

2 NEBS bonding and grounding points (outside chassis)

DC Power Systems

Each DC powered chassis contains two fixed configuration PDUs or two modular configuration power

shelves for 2N redundancy.

• In the fixed configuration power system, each PDU accepts one DC PEM for 2N redundancy. The

PDUs and PEMs are field replaceable. The PDUs contain the input power connectors.

• In the modular configuration power system, each power shelf accepts up to four DC PMs. The power

shelves and DC PMs are field replaceable. The power shelves contain the input power connectors.

Note Depending on the hardware deployed at your site, your system may not consume the maximum

power supplied by the power system.

Fixed Configuration DC Power

The Cisco CRS 8-slot line card chassis DC power system provides 7,500 watts to power the chassis. Each

DC PDU is connected to three pairs of DC power feeds and powers a single DC PEM. Input DC power

enters the PDU and is passed to the PEM, which provides power to the components in the chassis.

• Each DC PEM has its own circuit breaker.

• The fixed configuration power system distributes power in power zones.

2-6

• The DC PDUs and DC PEMs are field replaceable.

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

OL-6256-17

Page 39

Chapter 2 Installing and Removing Power Components

129533

1

Unlike the Cisco CRS 16-slot line card chassis, the Cisco CRS 8-slot line card chassis does not contain

an alarm module. A microprocessor in the DC PEM monitors the status of each DC PEM. The

microprocessor communicates with the system controller on the route processor (RP) card. LEDs on the

front panel of the RP card indicate active alarm conditions.

The DC PDU is shipped with a plastic safety cover over the input terminal block, as shown in Figure 2-3.

This safety cover has two parts, each part held on to the PDU with a Phillips screw. We recommend

removing the safety cover only when wiring and unwiring the chassis. The safety cover is slotted in such

a way that the cables can only come out on the bottom portion of the cover.

Figure 2-3 Fixed Configuration DC PDU with Plastic Safety Cover

Power Component Information Common to Two Types of Power System

1 Each set of cables (RTN and –48 V/–60 V) is a single VDC input.

Each PDU requires three DC inputs of –48/–60 VDC (nominal), 60 A service. The PDU has three sets

of double-stud terminals (-48/-60 VDC Lines and -48/-60 VDC Returns) for connecting to the VDC inputs.

Each DC PDU should be connected to a different central office DC power source:

• One PDU should be connected to three –48/–60 VDC “A” buses.

• Other PDU should be connected to three –48/–60 VDC “B” buses.

If DC power to a PDU fails, the other PDU provides enough power for the chassis. This 2N power

redundancy enables the routing system to operate in spite of single power failure.

For DC power cables, we recommend that you use commensurately rated, high-strand-count copper

cable. These cables are not available from Cisco Systems; they are available from any commercial

vendor. DC power cables must be terminated by cable lugs at the power shelf end.

Note All six -48/-60 VDC Return input cables for one chassis should have the same cable gauges and the

lengths should be matched within 10 percent of deviation.

The grounding lugs should be dual-hole and able to fit over M6 terminal studs at 0.63 in (1.6 cm) centers,

as shown in Figure 2-4 (for example, Panduit part number LCD2-14A-Q, or equivalent).

OL-6256-17

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

2-7

Page 40

Power Component Information Common to Two Types of Power System

Crimp area

310354

2.40

+/- .06

0.60

+/- .04

0.10

+/- .01

0.25

+/- .04

0.380.63

+/- .02

End View

Ø 0.27

+/- .02

2 holes

All measurements in inches

310355

2.11

REF

2.11

REF

0.60

+/- .04

0.25

+/- .04

0.38

REF

0.88

+/- .04

.10

+/- .01

1.18

REF

45° +/- 5°

0.63

+/- .02

Ø 0.27

+/- .02

2 holes

All measurements in inches

Figure 2-4 DC Power Grounding Cable Lug

The terminal lugs (in other words, all lugs not used for grounding) should be 45-degree angled,

industry-standard dual-hole compressions lugs, and able to fit over M6 terminal studs at 0.63 in (1.6 cm)

centers, as shown in Figure 2-5.

Note In the fixed configuration power system, power cables have a 20 in.-lb (2.26 N-m) torque value and

ground cables have a 30 in.-lb (3.39 N-m) torque value. The PDU mounting screws have a 9 in.-lb (1.04

N-m) torque value.

Chapter 2 Installing and Removing Power Components

Figure 2-5 DC Power Cable Lug

2-8

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

OL-6256-17

Page 41

Chapter 2 Installing and Removing Power Components

The color coding of the source DC power cable leads depends on the color coding of the site DC power

source. Typically, green or green and yellow indicates that the cable is a ground cable. Follow your local

practices for cable color code and markings. You must ensure that the power cables are connected to the

DC-input power shelf terminal studs in the proper positive (+) and negative (–) polarity.

In some cases, the source DC cable leads might have a positive (+) or negative (–) label, but you must

verify the polarity by measuring the voltage between the DC cable leads. When making the

measurement, the positive (+) lead and negative (–) lead must always match the (+) and (–) labels on the

PDU.

Caution When installing DC power cables, make sure that the polarity of the DC input wiring is correct.

For additional power details, see Appendix A, “Cisco CRS Carrier Routing System 8-Slot Line Card

Chassis Specifications” or Cisco CRS Carrier Routing System 8-Slot Line Card Chassis System

Description.

Modular Configuration DC Power

The Cisco CRS 8-slot line card chassis modular configuration DC power system can provide up to

8,400 W to power the line card chassis. The modular configuration DC power system uses A or B power

shelves to provide reliable, 2N redundant power to all chassis components.

Power Component Information Common to Two Types of Power System

Note Depending on the hardware deployed at your site, your system may not consume the maximum power

supplied by the power system.

The Cisco CRS 8-slot line card chassis does not contain an alarm module. The DC PM monitors PM

status and processes alarm functions. The PM distributes power and passes PM status signals to the

system. Alarms are processed through the route processor (RP). LEDs on the front panel of the RP card

indicate active alarm conditions.

If DC power to one modular configuration power shelf fails, the other power shelf provides enough

power for the chassis. This 2N power redundancy enables the routing system to operate in spite of single

power failure.

Each power shelf operates with up to four DC inputs of –48/–60 VDC (nominal), 60 A. The power shelf

accepts input DC power in the range –40 to –72 VDC.

OL-6256-17

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

2-9

Page 42

Power Component Information Common to Two Types of Power System

Figure 2-6 shows the wiring on the rear of a modular configuration DC power shelf.

Figure 2-6 Modular Configuration DC Power Shelf Wiring

Chapter 2 Installing and Removing Power Components

281336

We recommend that the terminal block covers, shown in Figure 2-6, should only be removed when

wiring and unwiring the power shelf. The terminal block cover is slotted in such a way that cables can

only come out the bottom portion of each cover.

The power supply terminal block lug opening width is 0.63 inch (1.6 cm). The terminal posts are

centered 0.63 inches (5/8 inch) (1.6 cm) apart and are M6-threaded. We recommend that you use an

appropriately sized 180-degree angle (straight) industry standard 2-hole, standard barrel compression

lug, as shown in Figure 2-7, or an appropriately sized 45-degree angle industry standard 2-hole, standard

barrel compression lug, as shown in Figure 2-8.

Figure 2-7 180-Degree (Straight) DC Power Cable Lug

All measurements in inches

310354

End View

0.60

+/- .04

0.10

+/- .01

Ø 0.27

+/- .02

2 holes

0.25

+/- .04

2.40

+/- .06

Crimp area

0.380.63

+/- .02

2-10

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

OL-6256-17

Page 43

Chapter 2 Installing and Removing Power Components

Figure 2-8 45-Degree DC Power Cable Lug

All measurements in inches

Power Component Information Common to Two Types of Power System

2.11

REF

0.60

+/- .04

.10

+/- .01

Ø 0.27

+/- .02

2 holes

0.25

+/- .04

0.63

+/- .02

+/- .04

2.11

REF

0.38

REF

0.88

1.18

REF

45° +/- 5°

310355

Note In the modular configuration power system, DC power cables have a torque value of 20 in.-lb (2.26 N-m)

and chassis ground cable connectors have a torque value of 30 in.-lb (3.39 N-m).

For additional power details, see Appendix A, “Cisco CRS Carrier Routing System 8-Slot Line Card

Chassis Specifications” or Cisco CRS Carrier Routing System 8-Slot Line Card Chassis System

Description.

AC Power Systems

Each AC powered chassis contains two fixed configuration AC PDUs or two modular configuration AC

power shelves for 2N redundancy.

• In the fixed configuration power system, each PDU accepts one AC power rectifier. The PDUs and

AC power rectifiers are field replaceable.

• In the modular configuration power system, each power shelf can contain up to three AC PMs. The

power shelves and the AC PMs are field replaceable.

Note Depending on the hardware deployed at your site, your system may not consume the maximum power

supplied by the power system.

OL-6256-17

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

2-11

Page 44

Power Component Information Common to Two Types of Power System

Fixed Configuration AC Power

An AC-powered Cisco CRS 8-slot line card chassis contains two AC power distribution units (PDUs)

and two AC rectifier modules. Each AC PDU is connected to a 3-phase (200 to 240) input VAC power

source and connects to a single 7500-watt AC rectifier module that is field replaceable. Each AC rectifier

module converts input AC power to the 54.5 VDC used by the Cisco CRS 8-slot line card chassis. Each

rectifier has its own circuit breaker.

To provide 2N power redundancy for the Cisco CRS 8-slot line card chassis, each PDU and AC rectifier

pair is connected to a different AC power source. During normal operation when both power sources are

operational, both PDUs and rectifiers function together to power the chassis. However, if a power source

fails, the other power source provides the other PDU and rectifier pair with enough input power to power

the chassis. This 2N power redundancy enables the routing system to operate despite the power failure.

Two versions of the AC PDU are available to accommodate AC input power in either the Delta or Wye

configuration. Each PDU has a different Cisco part number. The PDUs are shipped with AC power cords

that are 14 feet (4.3 m) long.

Unlike the Cisco CRS 16-slot line card chassis, the Cisco CRS 8-slot line card chassis does not contain

an alarm module. A microprocessor in the AC rectifier monitors the status of each AC rectifier. The

microprocessor communicates with the system controller on the RP card. LEDs on the front panel of the

RP card indicate active alarm conditions.

Chapter 2 Installing and Removing Power Components

The AC PDUs have the following input VAC power requirements:

• AC Wye input: 3-phase, 200 to 240 VAC nominal (phase-to-neutral), 50 to 60 Hz,

16 A (International) or 20 A (North America). The PDU is rated for 14-amp service, and accepts AC

input of 16 or 20 A.

The Wye power cord has a 5-pin IEC 60309 plug that is rated for 400 VAC, 16 or 20 A, (3W + N +

PE). The power cord plugs into a similarly rated IEC 60309 receptacle.

• AC Delta input: 3-phase, 200 to 240 VAC nominal (phase-to-phase), 50 to 60 Hz, 30 A. The PDU is

rated for 24-amp service, and accepts AC input of 30 A.

The Delta power cord has a 4-pin NEMA L15-30P plug that is rated for 250 VAC, 30 A (3W + PE).

The power cord plugs into a similarly rated NEMA L15-30R locking-type receptacle.

For additional power details, see Appendix A, “Cisco CRS Carrier Routing System 8-Slot Line Card

Chassis Specifications” or Cisco CRS Carrier Routing System 8-Slot Line Card Chassis System

Description.

Modular Configuration AC Power

The Cisco CRS 8-slot line card chassis modular configuration AC power system can provide up to

9,000 W to power the line card chassis.

Note Depending on the hardware deployed at your site, your system may not consume the maximum power

supplied by the power system.

2-12

The modular configuration power system provides the following features:

• AC power shelf redundancy

• PM load-share redundancy

• Elimination of power zone distribution, while maintaining zone protection

• Capacity for future growth

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

OL-6256-17

Page 45

Chapter 2 Installing and Removing Power Components

The modular configuration AC power systems use A or B power shelves to provide reliable, 2N

redundant power to all chassis components.

The Cisco CRS 8-slot line card chassis does not contain an alarm module. The AC PM monitors PM

status and processes alarm functions. The AC PM distributes power and passes PM status signals to the

system. Each PM has its own integrated fuse to protect the system, and each PM is plugged into its own

power outlet. Alarms are processed through the RP. LEDs on the front panel of the RP indicate active

alarm conditions.

Unlike the fixed configuration AC power system, which requires 3-phase AC Delta or AC Wye input

power, the modular configuration AC power system requires single-phase AC input power. If you have

3-phase AC Delta or AC Wye at your equipment, a Cisco CRS PDU will be required to convert 3-phase

AC input power to single-phase AC input power for the power shelf. For further information, refer to

Cisco CRS 3-Phase AC Power Distribution Unit Installation Guide.

The modular configuration AC power shelf has the following input VAC power requirements:

• Single-phase, 200 to 240 VAC nominal, 50 to 60 Hz, 16 A.

Each power shelf contains three IEC-320-C22 receptacles which can accept up to three

IEC-320-C21 connector female cords.

How to Install or Remove Fixed Configuration Power Components

Note In order to maintain a balanced 3-phase power load, three AC PMs are required to be installed in a Cisco

CRS 8-slot line card chassis AC modular configuration power shelf.

Note If single-phase AC power is available at your site, we recommend that you use appropriate short-circuit

protection in compliance with national and local electrical codes.

For additional power details, see Appendix A, “Cisco CRS Carrier Routing System 8-Slot Line Card

Chassis Specifications” or Cisco CRS Carrier Routing System 8-Slot Line Card Chassis System

Description.

How to Install or Remove Fixed Configuration Power

Components

This section contains the following procedures:

• Before Powering the Chassis Up or Down, page 2-14

• Converting from One Fixed Configuration Power System to Another, page 2-14

• Installing a PDU

• Removing a PDU

OL-6256-17

• Installing DC PDU Cables, page 2-19

• Removing DC PDU Wiring, page 2-21

• Installing a DC PEM or AC Rectifier

• Removing a DC PEM or AC rectifier

Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

2-13

Page 46

How to Install or Remove Fixed Configuration Power Components

Note Although there are differences among the different fixed configuration PDU types (AC Wye, AC Delta,

and DC), they are installed in the same manner.

Note Although there are differences between the AC rectifier and DC PEM (AC Wye, AC Delta, and DC), they

are installed in the same manner.

Before Powering the Chassis Up or Down

While the line card chassis does not have a single power switch that powers the entire chassis and all its