Page 1

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

First Published: 2013-08-31

Last Modified: 2014-06-10

Americas Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

http://www.cisco.com

Tel: 408 526-4000

800 553-NETS (6387)

Fax: 408 527-0883

Text Part Number: OL-30453-01

Page 2

THE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THIS MANUAL ARE SUBJECT TO CHANGE WITHOUT NOTICE. ALL STATEMENTS,

INFORMATION, AND RECOMMENDATIONS IN THIS MANUAL ARE BELIEVED TO BE ACCURATE BUT ARE PRESENTED WITHOUT WARRANTY OF ANY KIND,

EXPRESS OR IMPLIED. USERS MUST TAKE FULL RESPONSIBILITY FOR THEIR APPLICATION OF ANY PRODUCTS.

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION PACKET THAT SHIPPED WITH

THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNABLE TO LOCATE THE SOFTWARE LICENSE OR LIMITED WARRANTY,

CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

The following information is for FCC compliance of Class A devices: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15

of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio-frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which case users will be required to correct the interference at their own expense.

The following information is for FCC compliance of Class B devices: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15

of the FCC rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If the equipment causes interference to radio or television reception, which can be determined by turning the equipment off and on, users are

encouraged to try to correct the interference by using one or more of the following measures:

Reorient or relocate the receiving antenna.

•

Increase the separation between the equipment and receiver.

•

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

•

Consult the dealer or an experienced radio/TV technician for help.

•

Modifications to this product not authorized by Cisco could void the FCC approval and negate your authority to operate the product

The Cisco implementation of TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB) as part of UCB’s public domain version

of the UNIX operating system. All rights reserved. Copyright©1981, Regents of the University of California.

NOTWITHSTANDING ANY OTHER WARRANTY HEREIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE PROVIDED "AS IS" WITH ALL FAULTS.

CISCO AND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, THOSE OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT OR ARISING FROM A COURSE OF DEALING, USAGE, OR TRADE PRACTICE.

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL DAMAGES, INCLUDING, WITHOUT

LIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE USE OR INABILITY TO USE THIS MANUAL, EVEN IF CISCO OR ITS SUPPLIERS

HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Any Internet Protocol (IP) addresses and phone numbers used in this document are not intended to be actual addresses and phone numbers. Any examples, command display output, network

topology diagrams, and other figures included in the document are shown for illustrative purposes only. Any use of actual IP addresses or phone numbers in illustrative content is unintentional

and coincidental.

Cisco and the Cisco logo are trademarks or registered trademarks of Cisco and/or its affiliates in the U.S. and other countries. To view a list of Cisco trademarks, go to this URL: http://

www.cisco.com/go/trademarks. Third-party trademarks mentioned are the property of their respective owners. The use of the word partner does not imply a partnership

relationship between Cisco and any other company. (1110R)

©

2017 Cisco Systems, Inc. All rights reserved.

Page 3

CONTENTS

Preface

CHAPTER 1

CHAPTER 2

Preface vii

Audience vii

Document Conventions vii

Documentation Feedback ix

Obtaining Documentation and Submitting a Service Request ix

Overview 1

Overview of the Cisco Nexus 7718 Switch Installation Features 1

Preparing the Site 9

Humidity Requirements 9

Altitude Requirements 9

Dust and Particulate Requirements 10

Minimizing Electromagnetic and Radio Frequency Interference 10

Shock and Vibration Requirements 11

Grounding Requirements 11

Planning for Power Requirements 11

Rack and Cabinet Requirements 14

Clearance Requirements 17

CHAPTER 3

Installing the Chassis 19

Installing a Rack or Cabinet 19

Unpacking and Inspecting a New Switch 20

Installing the Bottom-Support Rails 21

Installing a Chassis in a Rack or Cabinet 24

Grounding a Switch Chassis 32

Grounding the Front ID Doors 35

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

OL-30453-01 iii

Page 4

Contents

Installing Cable Management Frames 40

Installing the Front Doors 46

Installing the Air Filters 48

CHAPTER 4

CHAPTER 5

Connecting to the Network 53

Guidelines for Connecting Ports 53

Connecting a Console to the Switch 54

Connecting the Management Interface 55

Creating the Initial Switch Configuration 56

Connecting Interface Ports to the Network 57

Connecting a Fiber-Optic Cable to a Transceiver 58

Disconnecting Optical Ports from the Network 58

Maintaining Transceivers and Optical Cables 59

Managing the Switch 61

Displaying Information About Installed Hardware Modules 61

Displaying the Hardware Inventory for a Switch 63

Displaying the Backplane and Serial Number Information 65

Displaying Environmental Information for a Switch 67

Displaying Temperatures for Modules 70

Connecting to a Module 72

Saving the Module Configuration 73

Displaying Power Usage Information 73

Reloading a Module 73

Rebooting the Switch 74

Overview of Supervisor Modules 75

Shutting Down a Supervisor Module 76

Overview of I/O Module Support 76

Accessing an I/O Module through a Console 77

Displaying Information for the Installed Modules 78

Purging the Module Configuration 80

Shut Down or Power Up an I/O Module 81

Overview of Fabric Module Support 82

Change the Amount of Power Reserved for Fabric Modules 82

Shutting Down or Powering Up a Fabric Module 83

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

iv OL-30453-01

Page 5

Contents

Power Modes Overview 83

Guidelines for Configuring Power Redundancy Modes 84

Configuring the Power Mode 88

Maximum Power Available for 3-kW Power Supplies 89

Maximum Power Available for 3-kW DC Power Supplies 91

Maximum Power Available for 3.5-kW Inputs (AC) 92

Maximum Power Available for 3.5-kW Inputs (DC) 96

Overview of Fan Trays 99

Displaying the Status for the Fan Trays 102

CHAPTER 6

APPENDIX A

Installing or Replacing Modules, Fan Trays, and Power Supplies 103

Using an ESD Wrist Strap to Prevent ESD Damage 103

Installing or Replacing a Supervisor Module 105

Installing or Replacing an I/O Module 108

Replacing a Fan Tray 110

Migrating from Gen 1 Fan Trays (N77-C7718-FAN) to Gen 2 Fan Trays

(N77-C7718-FAN-2) 117

Installing or Replacing a Fabric Module 118

Installing or Replacing a Power Supply in a Switch Chassis 124

Connecting a 3-kW AC Power Supply to AC Power Sources 126

Connecting a 3.5-kW HVAC/HVDC Power Supply to AC Power Sources 127

Connecting DC Power Supplies with Power Sources 129

Connecting a 3.5-kW HVAC/HVDC Power Supply to DC Power Sources 131

Switch Specifications 133

Environmental Specifications 133

Switch Dimensions 134

Power Requirements 134

Maximum Power Available for 3-kW Power Supplies 135

Maximum Power Available for 3-kW DC Power Supplies 137

Maximum Power Available for 3.5-kW Inputs (AC) 138

Maximum Power Available for 3.5-kW Inputs (DC) 142

Weights and Quantities for the Chassis, Modules, Fan Trays, and Power Supplies 145

Transceivers, Connectors, and Cables Used with Each I/O Module 147

100-Gb CPAK Transceiver Specifications 154

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

OL-30453-01 v

Page 6

Contents

100-Gb QSFP+ Transceiver Specifications 155

40-Gb QSFP+ Transceiver Specifications 157

10-Gb SFP+ Optical Transceivers and Fabric Extender Transceivers 159

10BASE-DWDM SFP+ Transceiver Specifications 163

1-Gb SFP Transceivers 167

1000BASE-CWDM SFP Transceiver Cables 167

1000BASE-DWDM SFP Transceiver Specifications 169

1000BASE-T and 1000BASE-X SFP Transceiver Specifications 171

RJ-45 Module Connectors 173

Power Supply Cable Specifications 174

3-kW AC Power Cord Specifications 174

3.5-kW HVAC/HVDC Power Supply AC Power Cord Specifications 176

3-kW DC Power Cord Specifications 187

APPENDIX B

APPENDIX C

APPENDIX D

3.5-kW HVAC/HVDC Power Supply DC Power Cord Specifications 187

LEDs 191

Chassis LEDs 191

Supervisor Module LEDs 192

I/O Module LEDs 194

Fabric Module LEDs 195

Fan Tray LEDs 196

Power Supply LEDs 196

Accessory Kits 199

Accessory Kit Contents 199

Site Preparation and Maintenance Records 203

Site Preparation Checklist 203

Contact and Site Information 205

Chassis and Module Information 205

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

vi OL-30453-01

Page 7

Preface

This preface describes the audience, organization and conventions of the Cisco Nexus 7000 Series NX-OS

Fundamentals Configuration Guide. It also provides information on how to obtain related documentation.

Audience, page vii

•

Document Conventions, page vii

•

Documentation Feedback, page ix

•

Obtaining Documentation and Submitting a Service Request, page ix

•

Audience

This publication is for network administrators who configure and maintain Cisco Nexus devices.

Document Conventions

Note

OL-30453-01 vii

As part of our constant endeavor to remodel our documents to meet our customers' requirements, we have

modified the manner in which we document configuration tasks. As a result of this, you may find a

deviation in the style used to describe these tasks, with the newly included sections of the document

following the new format.

Command descriptions use the following conventions:

DescriptionConvention

bold

Italic

Bold text indicates the commands and keywords that you enter literally

as shown.

Italic text indicates arguments for which the user supplies the values.

Square brackets enclose an optional element (keyword or argument).[x]

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

Page 8

Document Conventions

Preface

DescriptionConvention

[x | y]

Square brackets enclosing keywords or arguments separated by a vertical

bar indicate an optional choice.

{x | y}

Braces enclosing keywords or arguments separated by a vertical bar

indicate a required choice.

[x {y | z}]

Nested set of square brackets or braces indicate optional or required

choices within optional or required elements. Braces and a vertical bar

within square brackets indicate a required choice within an optional

element.

variable

Indicates a variable for which you supply values, in context where italics

cannot be used.

string

A nonquoted set of characters. Do not use quotation marks around the

string or the string will include the quotation marks.

Examples use the following conventions:

DescriptionConvention

Terminal sessions and information the switch displays are in screen font.screen font

Information you must enter is in boldface screen font.boldface screen font

Note

Caution

italic screen font

Arguments for which you supply values are in italic screen font.

Nonprinting characters, such as passwords, are in angle brackets.< >

Default responses to system prompts are in square brackets.[ ]

!, #

An exclamation point (!) or a pound sign (#) at the beginning of a line

of code indicates a comment line.

This document uses the following conventions:

Means reader take note. Notes contain helpful suggestions or references to material not covered in the

manual.

Means reader be careful. In this situation, you might do something that could result in equipment damage

or loss of data.

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

viii OL-30453-01

Page 9

Preface

Documentation Feedback

Documentation Feedback

To provide technical feedback on this document, or to report an error or omission, please send your comments

to: .

We appreciate your feedback.

Obtaining Documentation and Submitting a Service Request

For information on obtaining documentation, using the Cisco Bug Search Tool (BST), submitting a service

request, and gathering additional information, see What's New in Cisco Product Documentation.

To receive new and revised Cisco technical content directly to your desktop, you can subscribe to the What's

New in Cisco Product Documentation RSS feed. RSS feeds are a free service.

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

OL-30453-01 ix

Page 10

Obtaining Documentation and Submitting a Service Request

Preface

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

x OL-30453-01

Page 11

CHAPTER 1

Overview

This chapter includes the following sections:

Overview of the Cisco Nexus 7718 Switch Installation Features, page 1

•

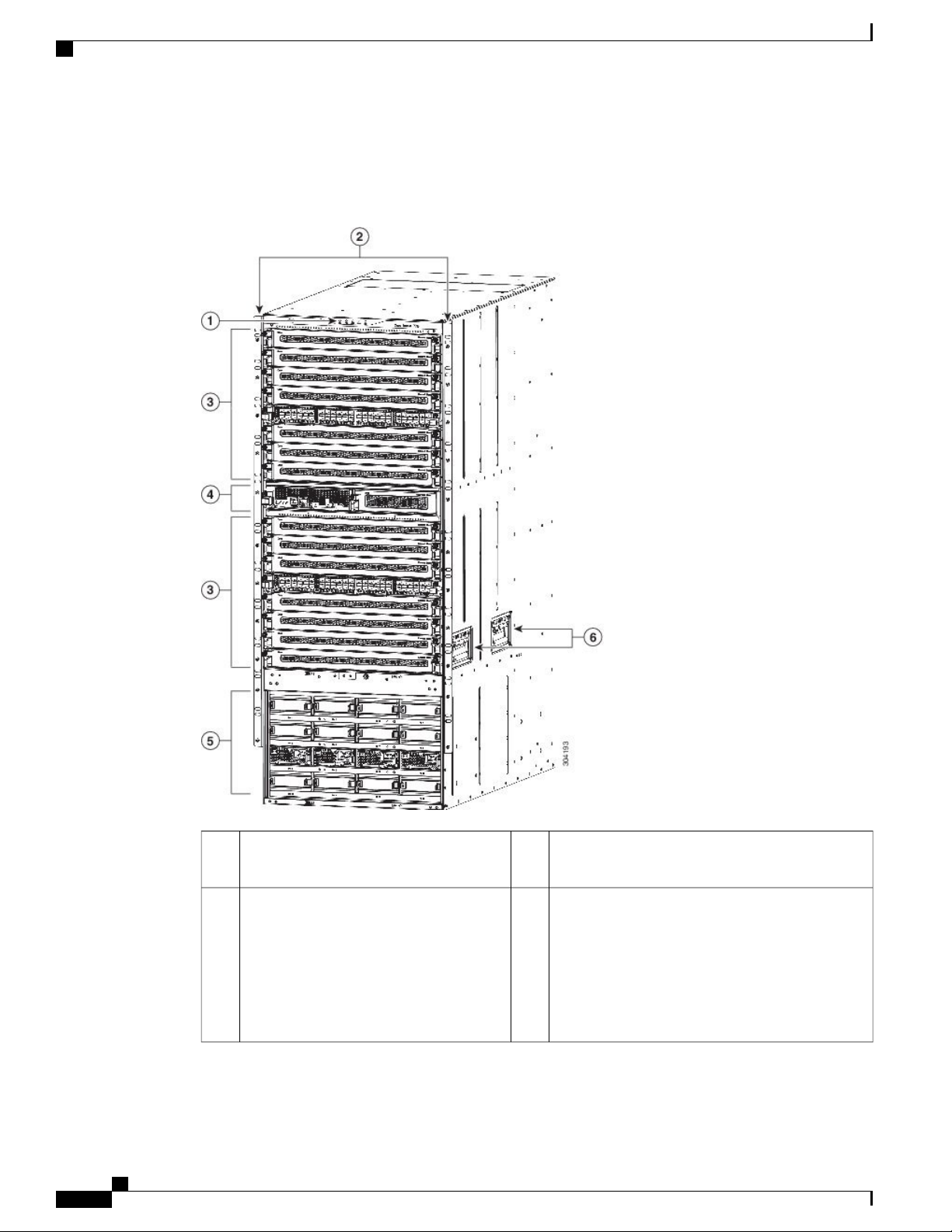

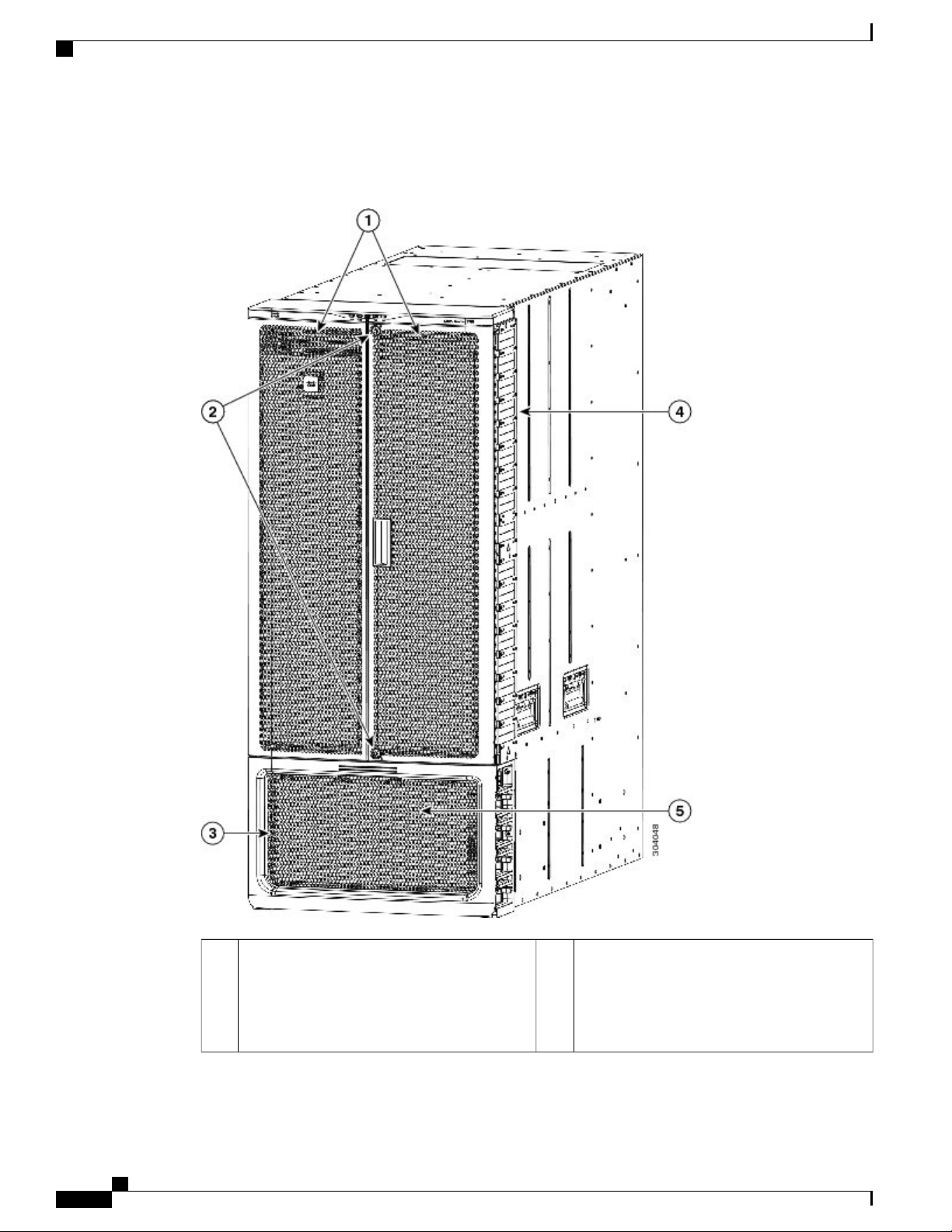

Overview of the Cisco Nexus 7718 Switch Installation Features

The Cisco Nexus 7718 chassis has 18 slots for one or two supervisor modules and up to 16 I/O modules. The

chassis also holds up to six fabric modules, up to 16 AC or DC 3-kW and 3.5-kW HVAC/HVDC power

supplies, and three fan trays. To group the many networking cables for each I/O module on this chassis, you

can install cable management frames on the chassis. You can install optional locking front doors and you can

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

OL-30453-01 1

Page 12

Overview of the Cisco Nexus 7718 Switch Installation Features

install an optional set of air filters on the front door and cable management frames. The following figure shows

the standard hardware features seen from the front of the chassis.

Figure 1: Standard Hardware Features on the Front of the Cisco Nexus 7718 Chassis

Overview

Supervisor modules (one or two) (N77-SUP2E) in

4Chassis LEDs1

Slots 9,10

Power supplies (up to 16)

2

side of the chassis)

5Chassis mounting brackets (one on each

3-kW AC power supply (N77-AC-3KW)

•

3-kW DC power supply (N77-DC-3KW)

•

3.5-kW HVAC/HVDC power supply

•

(N77-HV-3.5KW)

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

2 OL-30453-01

Page 13

Overview

3

I/O modules (1–16) in Slots 1-8, 11-18

48-port 1- and 10-Gigabit Ethernet

•

I/O module (N77-F248XP-23E)

48-port 1- and 10-Gigabit Ethernet

•

I/O module (N77-F348XP-23)

48-port 1- and 10-Gigabit Ethernet

•

I/O module (N77-M348XP-23L)

24-port 40-Gigabit Ethernet I/O

•

module (N77-F324FQ-25)

24-port 40-Gigabit Ethernet I/O

•

module (N77-M324FQ-25L)

12-port 100-Gigabit Ethernet I/O

•

module (N77-F312CK-26)

12-port 100-Gigabit Ethernet I/O

•

module (N77-M312CQ-26L)

Overview of the Cisco Nexus 7718 Switch Installation Features

Chassis handles (used only for small movements

6

on the rack)

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

OL-30453-01 3

Page 14

Overview of the Cisco Nexus 7718 Switch Installation Features

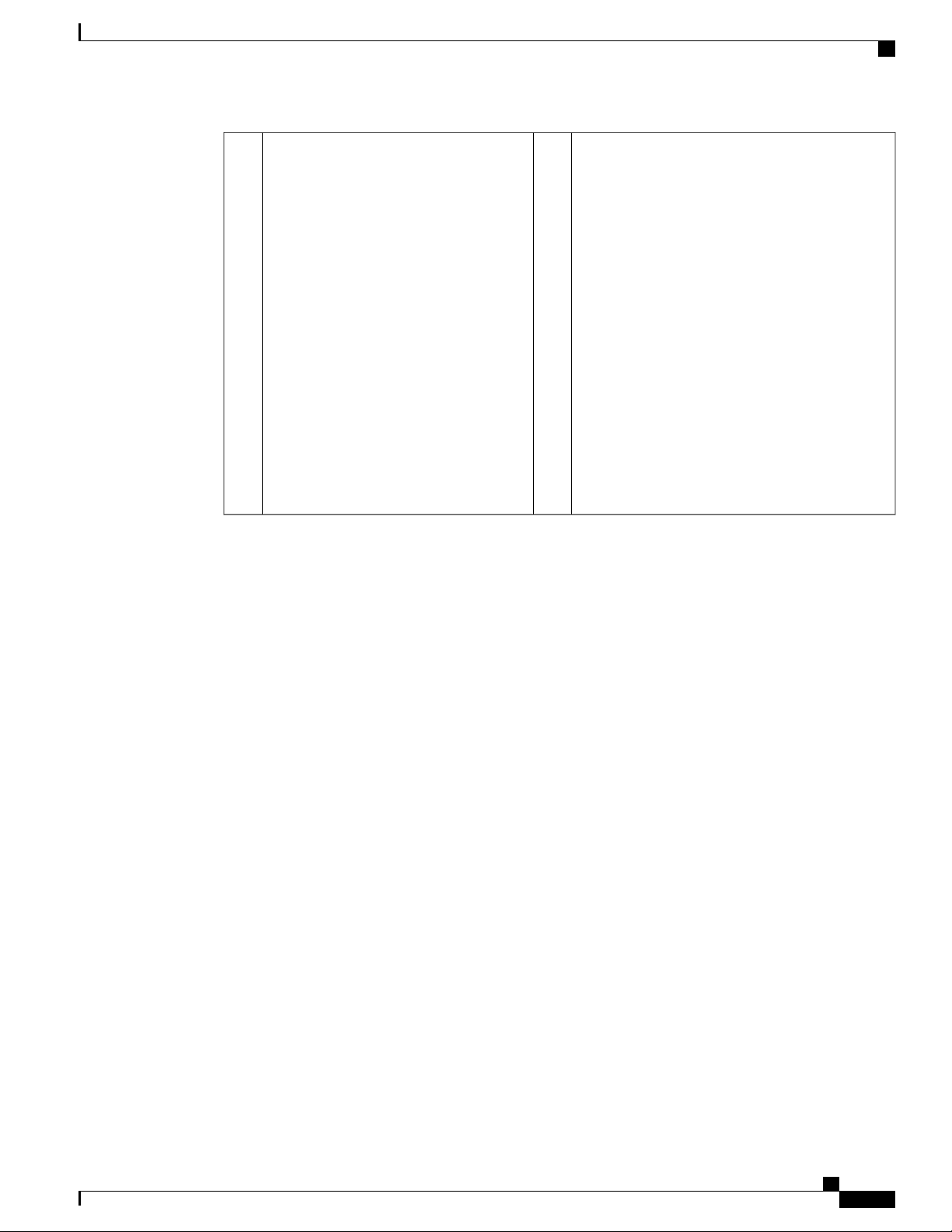

The following figure shows the standard hardware features seen from the rear of the chassis.

Figure 2: Standard Hardware Features on the Rear of the Cisco Nexus 7718 Chassis

Overview

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

4 OL-30453-01

Page 15

Overview

Overview of the Cisco Nexus 7718 Switch Installation Features

1

Three fan trays — only 1 fan tray,

N77-C7718-FAN, is shown in this figure to

show fabric modules in back. There are 2 types

of fan trays: 38 mm Gen 1 fan trays

(N77-C7718-FAN) and 76 mm Gen 2 fan trays

(N77-C7718-FAN-2). Use the Gen 2 fan trays

for Network Equipment Building System

(NEBS) compliance when the Cisco Nexus

7700 M3-Series 12-port 100-Gigabit Ethernet

I/O module (N77-M312CQ-26L) is installed

on the switch.

2

fan tray) (N77-C7718-FAB-2)

Blank module in place of missing fabric module3

Fabric and fan tray LEDs4Fabric modules (up to six with two behind each

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

OL-30453-01 5

Page 16

Overview of the Cisco Nexus 7718 Switch Installation Features

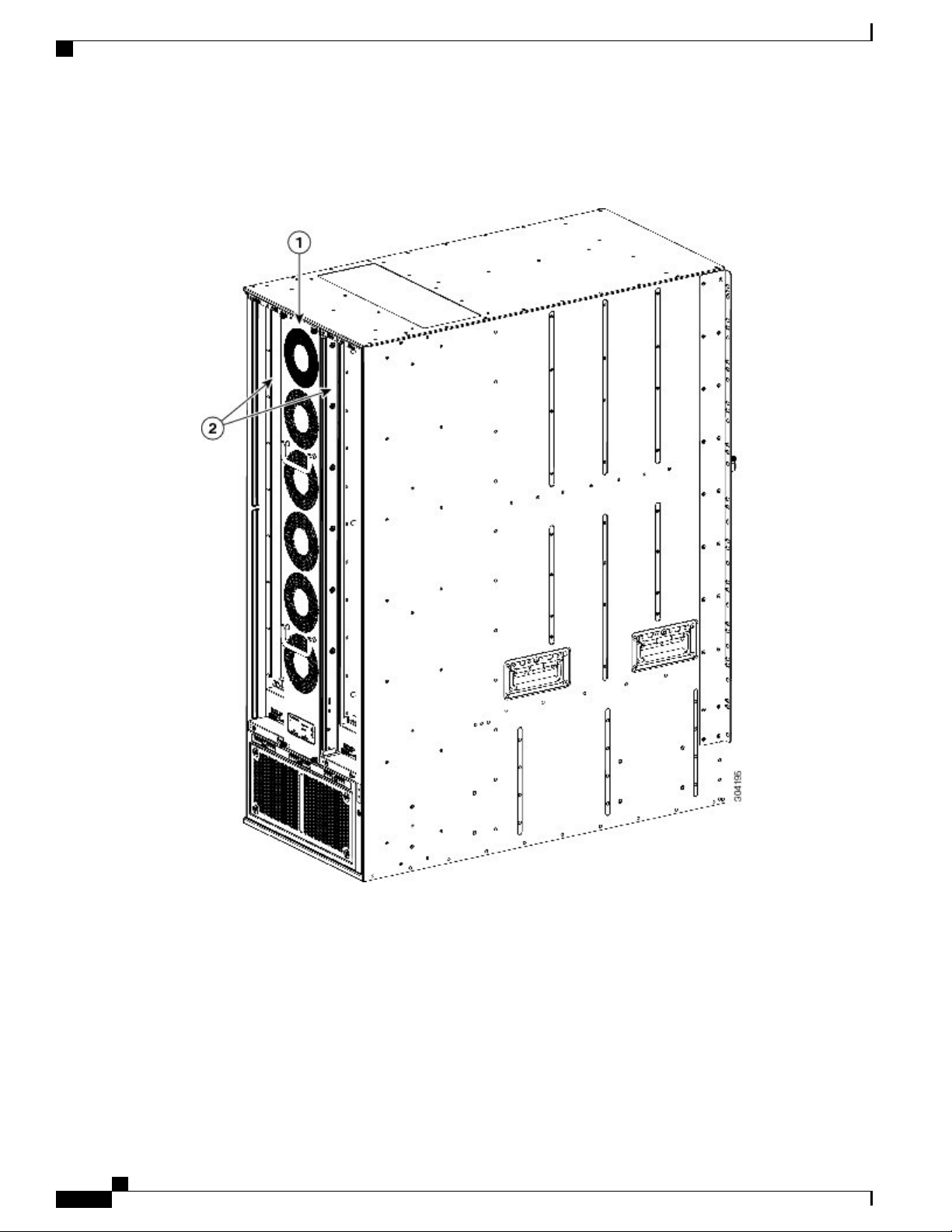

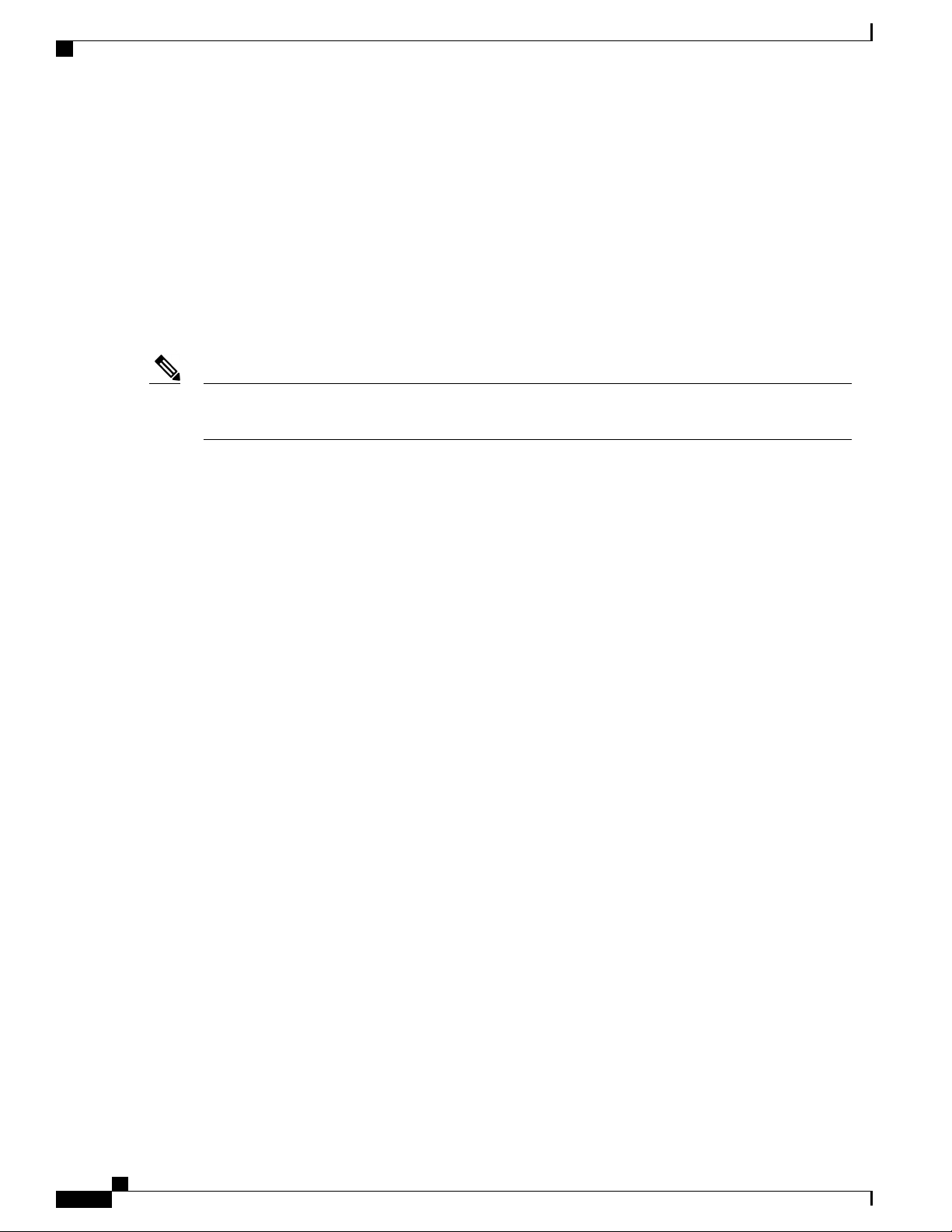

The following figure shows the optional features seen on the front of the Cisco Nexus 7718 chassis.

Figure 3: Optional Hardware Features on the Front of the Cisco Nexus 7718 Chassis

Overview

Air filter (N77-C7718-AFLT) inside each of

4Front doors with locks (N77-C7718-FDK)1

the top two front doors (filters not shown),

between each door and the cable management

frame (not shown), and over the cable

management frames (shown).

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

6 OL-30453-01

Page 17

Overview

2

management area

Power supply door (N77-C7718-FDK)3

Overview of the Cisco Nexus 7718 Switch Installation Features

Power supply cable management frames (not

5Locks to prevent access to the cable

seen behind the power supply door).

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

OL-30453-01 7

Page 18

Overview of the Cisco Nexus 7718 Switch Installation Features

Overview

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

8 OL-30453-01

Page 19

CHAPTER 2

Preparing the Site

This chapter includes the following sections:

Humidity Requirements, page 9

•

Altitude Requirements, page 9

•

Dust and Particulate Requirements, page 10

•

Minimizing Electromagnetic and Radio Frequency Interference, page 10

•

Shock and Vibration Requirements, page 11

•

Grounding Requirements, page 11

•

Planning for Power Requirements, page 11

•

Rack and Cabinet Requirements, page 14

•

Clearance Requirements, page 17

•

Humidity Requirements

High humidity can cause moisture to seep into the switch. Moisture can cause corrosion of internal components

and degradation of properties such as electrical resistance, thermal conductivity, physical strength, and size.

The switch is rated to operate at 8 to 80 percent relative humidity, with a humidity gradation of 10 percent

per hour.

The switch can withstand from 5 to 90 percent relative humidity. Buildings in which the climate is controlled

by air-conditioning in the warmer months and by heat during the colder months usually maintain an acceptable

level of humidity for the switch equipment. However, if the switch is located in an unusually humid location,

you should use a dehumidifier to maintain the humidity within an acceptable range.

Altitude Requirements

If you operate a switch at a high altitude (low pressure), the efficiency of forced and convection cooling is

reduced and can result in electrical problems that are related to arcing and corona effects. This condition can

also cause sealed components with internal pressure, such as electrolytic capacitors, to fail or to perform at a

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

OL-30453-01 9

Page 20

Dust and Particulate Requirements

reduced efficiency. This switch is rated to operate at altitudes from –500 to 13,123 feet (–152 to 4,000 meters).

You can store the switch at altitudes of –1,000 to 30,000 feet (–305 to 9,144 meters).

Dust and Particulate Requirements

Exhaust fans cool power supplies and system fan trays cool switches by drawing in air and exhausting air out

through various openings in the chassis. However, fans also ingest dust and other particles, causing contaminant

buildup in the switch and increased internal chassis temperature. A clean operating environment can greatly

reduce the negative effects of dust and other particles, which act as insulators and interfere with the mechanical

components in the switch.

Preparing the Site

Note

If you are using this switch in a nonclean environment, you can order and install optional air fliters. These

air filters require that you also order the optional front door for the chassis.

In addition to regular cleaning, follow these precautions to avoid contamination of your switch:

Do not permit smoking near the switch.

•

Do not permit food or drink near the switch.

•

Minimizing Electromagnetic and Radio Frequency Interference

Electromagnetic interference (EMI) and radio frequency interference (RFI) from the switch can adversely

affect other devices such as radio and television (TV) receivers operating near the switch. Radio frequencies

that emanate from the switch can also interfere with cordless and low-power telephones. Conversely, RFI

from high-power telephones can cause spurious characters to appear on the switch monitor.

RFI is defined as any EMI with a frequency above 10 kHz. This type of interference can travel from the switch

to other devices through the power cable and power source or through the air like transmitted radio waves.

The Federal Communications Commission (FCC) publishes specific regulations to limit the amount of EMI

and RFI that can be emitted by computing equipment. Each switch meets these FCC regulations.

To reduce the possibility of EMI and RFI, follow these guidelines:

Cover all open expansion slots with a metal filler.

•

Always use shielded cables with metal connector shells for attaching peripherals to the switch.

•

When wires are run for any significant distance in an electromagnetic field, interference can occur between

the field and the signals on the wires and cause the following implications:

Bad wiring can result in radio interference emanating from the plant wiring.

•

Strong EMI, especially when it is caused by lightning or radio transmitters, can destroy the signal drivers

•

and receivers in the chassis and even create an electrical hazard by conducting power surges through

lines into equipment.

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

10 OL-30453-01

Page 21

Preparing the Site

Shock and Vibration Requirements

Note

To predict and prevent strong EMI, you might need to consult experts in radio frequency interference

(RFI).

The wiring is unlikely to emit radio interference if you use twisted-pair cable with a good distribution of

grounding conductors. If you exceed the recommended distances, use a high-quality twisted-pair cable with

one ground conductor for each data signal when applicable.

If the wires exceed the recommended distances, or if wires pass between buildings, give special consideration

to the effect of a lightning strike in your vicinity. The electromagnetic pulse caused by lightning or other

high-energy phenomena can easily couple enough energy into unshielded conductors to destroy electronic

switches. You may want to consult experts in electrical surge suppression and shielding if you had similar

problems in the past.

Shock and Vibration Requirements

The switch is being shock- and vibration-tested for operating ranges, handling, and earthquake standards to

Network Equipment Building Standards (NEBS) Zone 4 per GR-63-Core.

Grounding Requirements

The switch is sensitive to variations in voltage supplied by the power sources. Overvoltage, undervoltage,

and transients (or spikes) can erase data from the memory or cause components to fail. To protect against

these types of problems, ensure that there is an earth-ground connection for the switch. You can connect the

grounding pad on the switch either directly to the earth-ground connection or to a fully bonded and grounded

rack.

You must provide the grounding cable to make this connection but you can connect the grounding wire to the

switch using a grounding lug that ships with the switch. Size the grounding wire to meet local and national

installation requirements. Depending on the power supply and system, a 12 AWG to 6 AWG copper conductor

is required for U.S. installations (for those installations, we recommend that you use commercially available

6 AWG wire). The length of the grounding wire depends on the proximity of the switch to proper grounding

facilities.

Note

You automatically ground the AC power supplies when you connect them to a power source, but you

cannot ground a 3-kW DC power supply. You must connect the chassis to the facility earth ground.

Planning for Power Requirements

To plan for the power requirements of a switch, you must determine each of the following:

Power requirements of the switch

•

Minimum number of power supplies required to power the switch and its components

•

Power mode to use and the number of additional power supplies required for that mode

•

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

OL-30453-01 11

Page 22

Planning for Power Requirements

You must also ensure that the circuit used for the switch is dedicated to the switch to minimize the possibility

of circuit failure.

When you know the amount of power that is required for operations (available power) and redundancy (reserve

power), you can plan for the required number of input power receptacles with reach of the switch location.

Procedure

Preparing the Site

Step 1

Determine the power requirement for the switch by summing the maximum wattage for each installed module

(see the following table).

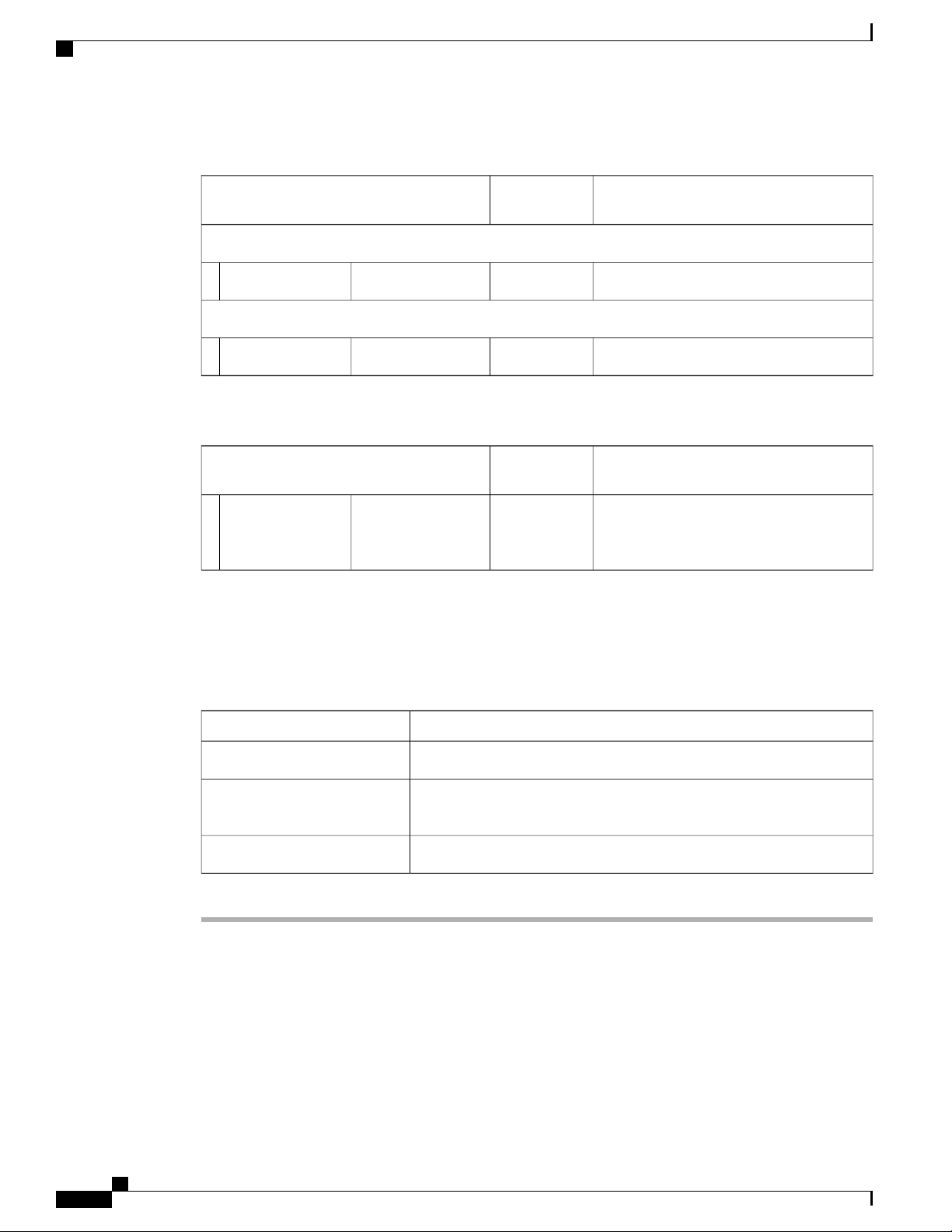

Table 1: Power Requirements for the Cisco Nexus 7718 Switch Modules

TypicalMaximumQuantityComponent

Supervisor Modules

1 or 2

——

(same

type if

137 W265 WSupervisor 2 Enhanced (N77-SUP2E)

using 2)

F2 I/O Modules

1 to 16

——

(can

mix

451 W500 W48-port 1- and 10-Gigabit Ethernet I/O module (N77-F248XP-23E)

types)

F3 I/O Modules

——

450 W480 W48-port 1- and 10-Gigabit Ethernet I/O module (N77-F348XP-23)

650 W740 W24-port 40-Gigabit Ethernet I/O module (N77-F324FQ-25)

640 W730 W12-port 100-Gigabit Ethernet I/O module (N77-F312CK-26)

M3 I/O Modules

——

500 W560 W48-port 1- and 10-Gigabit Ethernet I/O module (N77-M348XP-23L)

700 W750 W24-port 40-Gigabit Ethernet I/O module (N77-M324FQ-25L)

800 W1095 W12-port 100-Gigabit Ethernet I/O module (N77-M312CQ-26L)

102 W300 W3 to 6Fabric Modules (N77-C7718-FAB-2)

Fan Trays

———

51 W900 W338 mm Gen 1 Fan Tray (N77-C7718-FAN)

51 W900 W376 mm Gen 2 Fan Tray (N77-C7718-FAN-2)

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

12 OL-30453-01

Page 23

Preparing the Site

Step 2

Planning for Power Requirements

For example, if you are installing a switch with two Supervisor 2 modules (2 x 265 W), 16 48-port 10-Gigabit

Ethernet I/O modules (PID: N77-F248XP-23E) (16 x 500 W), six fabric modules (6 x 300 W) and three fan

trays (3 x 900 W), the power requirements for this switch would be 13,030 W.

Note

Maximum power values are used for calculating the power

requirements.

Determine the number of power supplies needed for the available power requirement by dividing the power

requirement amount (see Step 1) by the output wattage of the power supplies installed in the switch.

For 3-kW power supplies, round up a fractional result to the nearest ones digit to determine the number of

power supplies needed.

For example, if you are installing a switch with 3-kW power supplies and have a consumption of 13,030 W,

you need five power supplies (13,030 W / 3000 W = 4.34 or 5 power supplies) to operate the switch and all

of its modules.

Step 3

Select one of the following power modes to determine the number of additional power supplies required for

reserve power:

• Combined power—Do not add any power supplies to the number of power supplies calculated for the

available power in Step 2. This power mode does not provide power redundancy, so no extra power

supplies are needed.

• Power supply redundancy (n+1 redundancy)—Add one power supply (reserve power supply). This form

of power redundancy provides a reserve power supply that can replace any active power supply that

goes offline.

• Input source redundancy (grid redundancy)—Add enough power supplies (reserve power supplies) to

at least equal the total output of the active power supplies (number of power supplies calculated in Step

2). Typically, you would double the number of power supplies. You must plan for a second power source

for the reserve power supplies. For example, if you calculate that you need two 3-kW power supplies

for 6 kW of available power, you need another two 3-kW power supplies for 6 kW of reserve power

(for a total of four 3-kW power supplies used for available and reserve power).

• Full redundancy (n+1 and grid redundancy)—Add enough power supplies (reserve power supplies) to

at least equal the output of the active power supplies (number of power supplies calculated in Step 2).

For power supply (n+1) redundancy, ensure that you have at least one extra power supply. For input-source

(grid) redundancy, you will probably double the number of power supplies. You must plan for a second

power source with at least the same amount of input power for the reserve power supplies. For example,

if you calculate that you need two 3-kW power supplies for 6 kW of active power, then you need another

two 3-kW power supplies for 6 kW of reserve power (for a total of four 3-kW power supplies used for

active and reserve power). Either one of the reserve power supplies can replace any of the active power

supplies.

Step 4

Be sure that the power source circuits are dedicated to the switch and not to other electrical equipment.

For combined power mode (no power redundancy) or power supply (n+1) redundancy, you need only one

dedicated circuit. For input-source (grid) or full redundancy, you must have two dedicated power circuits,

each circuit powering half of the 3-kWor 3.5-kW power supplies. The requirements for each circuit are listed

in the following table.

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

OL-30453-01 13

Page 24

Rack and Cabinet Requirements

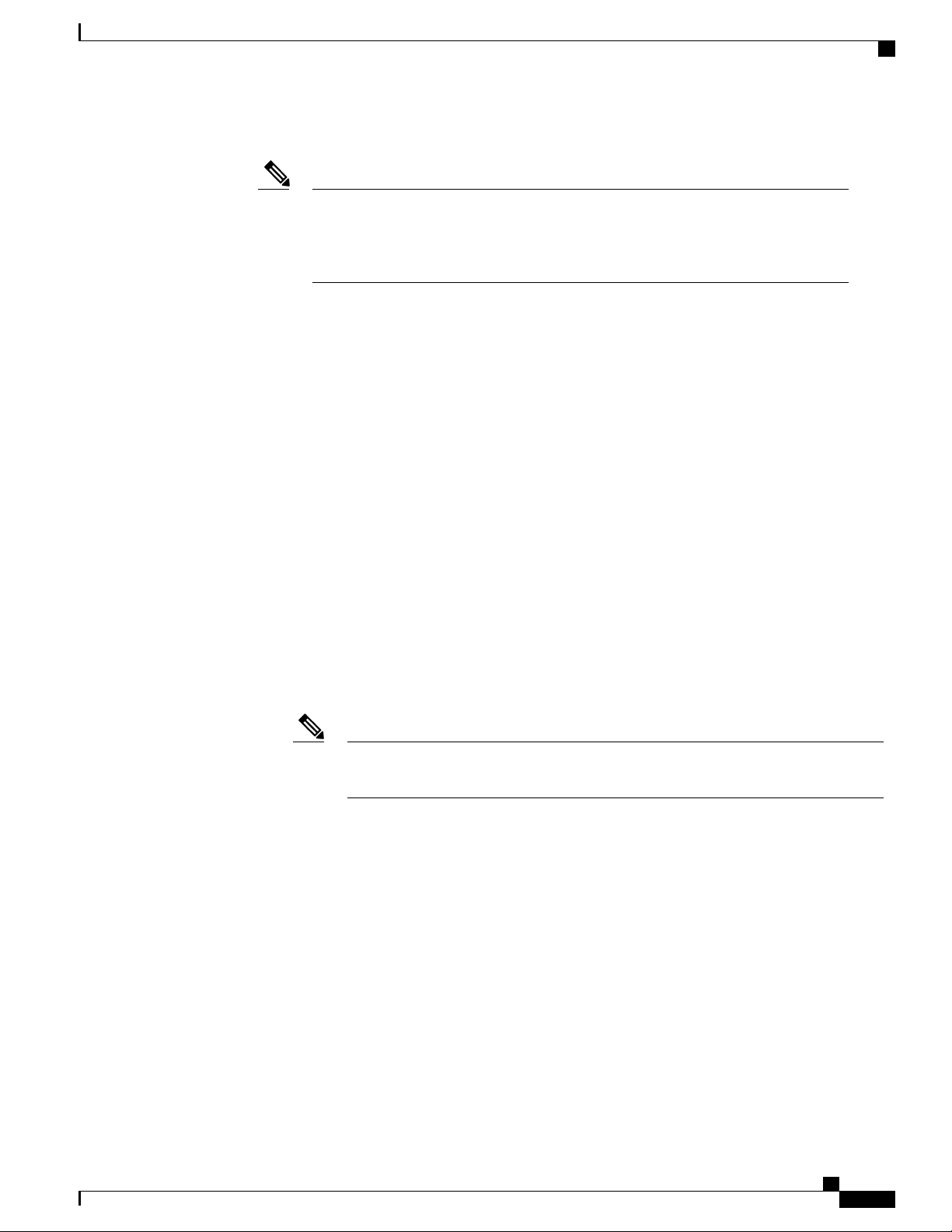

Table 2: Circuit Requirements for 3-kW Power Supplies

Preparing the Site

Step 5

Power Supply

Circuits

AC Power Supplies

DC Power Supplies

Table 3: Circuit Requirements for 3.5-kW HVAC/HVDC Power Supplies

Power Supply

Circuits

1(N77-HV-3.5KW)3.5-kW

HVAC/HVDC

power supply

Plan the placement of the input power receptacles within reach of the power cables used for each power supply

(see the following table for the maximum distances).

Typically, power receptacles are placed on the rack with the switch. If the DC power source is further than

allowed by the DC power cables, you can install a power interface unit (PIU) in the rack with the switch and

connect that to the power source with other cabling.

Requirement for Each CircuitNumber of

20 A at 110 VAC or 220 VAC1(N77-AC-3.0KW)3-kW power supply

20A1(N77-DC-3.0KW)3-kW power supply

Requirement for Each CircuitNumber of

20 A at 110 VAC, 210 VAC, 220/230 VAC

and 277 VAC or 20 A at 210 VDC, 220/240

VDC and 380 VDC

Maximum Distance Between Receptacle and Power SupplyPower Supply

12 feet (3.6 m)All AC power supplies

14 feet (4.26 m)HVAC/HVDC 3.5-kW power

supplies

Determined by the length of the power cord that you supply.DC 3-kW power supplies

Rack and Cabinet Requirements

You can install the following types of racks or cabinets for your switch:

Standard perforated cabinets

•

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

14 OL-30453-01

Page 25

Preparing the Site

Solid-walled cabinets with a roof fan tray (bottom to top cooling)

•

Rack and Cabinet Requirements

Note

Installation clearance requirements for solid-wall cabinets are not in the scope of this

guide. Such installations have to be custom-engineered by a cooling professional. The

customised configuration should satisfy the requirements mentioned in the Preparing

the Site and the Switch Specifications sections.

Standard open four-post Telco racks

•

To correctly install the switch in a cabinet that is located in a hot-aisle/cold-aisle environment, you should fit

the cabinet with baffles to prevent exhaust air from recirculating into the chassis air intake.

Work with your cabinet vendors to determine which of their cabinets meet the following requirements or see

the Cisco Technical Assistance Center (TAC) for recommendations:

Use a standard 19-inch, four-post Electronic Industries Alliance (EIA) cabinet or rack with mounting

•

rails that conform to English universal hole spacing per section 1 of the ANSI/EIA-310-D-1992 standard.

The height of the rack or cabinet must accommodate the 26-RU (45.25 inches or 114.9 cm) height of

•

the switch and its bottom support bracket.

The depth of a four-post rack must be 24 to 32 inches (61.0 to 81.3 cm) between the front and rear

•

mounting brackets.

Required clearances between the chassis and the edges of its rack or the interior of its cabinet are as

•

follows:

7.5 inches (19.1 cm) is required between the chassis and the front of the rack or interior of the

◦

cabinet (required for cabling).

3.0 inches (7.6 cm) is required between the rear of the chassis and the perforated rear door of the

◦

cabinet (required for airflow inside the cabinet if used).

Note

This requirement does not apply to enclosures which have a solid rear door or wall with

other exhaust configurations.

No clearance is required between the chassis and the sides of the rack or cabinet (no side airflow).

◦

Additionally, you must consider the following site requirements for the rack:

Power receptacles must be located within reach of the power cords used with the switch.

•

AC power supplies

◦

Power cords for 3-kW AC power supplies are 8 to 12 feet (2.5 to 3.6 m) long.

◦

DC power supplies

◦

Power cords for 3.0-kW DC power supplies are supplied and dimensioned by the customer.

◦

HVAC/HVDC power supplies

◦

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

OL-30453-01 15

Page 26

Rack and Cabinet Requirements

Clearance required for cables that connect to as many as 1600 ports (in addition to the cabling required

•

for other devices in the same rack). These cables must not block access to any removable chassis modules

or block airflow into or out of the chassis. Route the cables through the cable management frames on

the left and right sides of the chassis.

Where necessary, have a seismic rating of Network Equipment Building Standards (NEBS) Zone 3 or

•

Zone 4, per GR-63-CORE if required.

Minimum gross load rating of 2000 lb (907.2 kg) (static load rating) if supporting two switches.

•

Preparing the Site

Power cords for 3.5-kW HVAC/HVDC power supplies are 14 feet (4.26 m) long.

◦

1

1

Currently undergoing NEBS testing.

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

16 OL-30453-01

Page 27

Preparing the Site

Clearance Requirements

You must provide the chassis with adequate clearance between the chassis and any other rack, device, or

structure so that you can properly install the chassis, route cables, provide airflow, and maintain the switch.

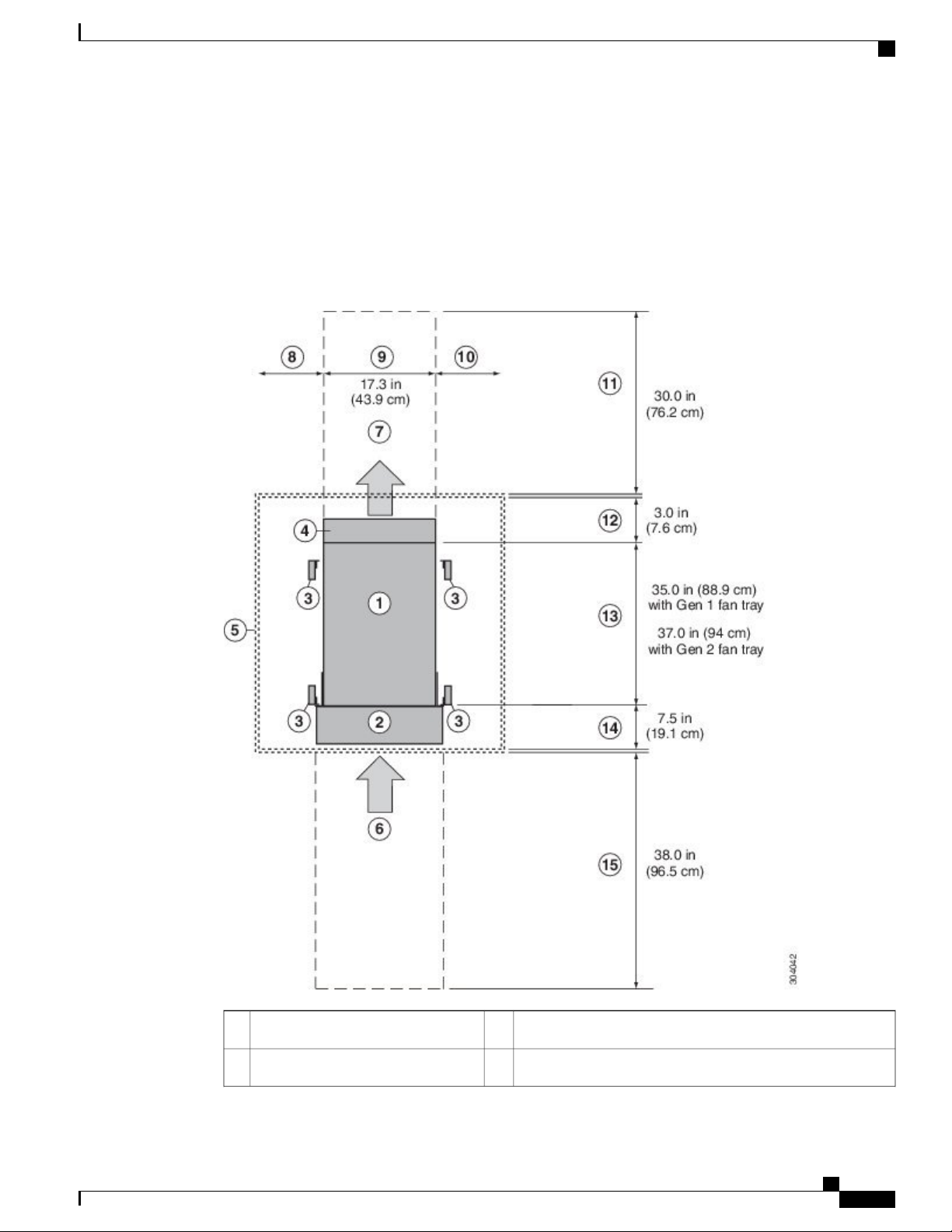

For the clearances required for an installation of this chassis, see the following figure.

Figure 4: Clearances Required for the Chassis

Clearance Requirements

Chassis width9Chassis1

No right side clearance required (no airflow on right side)10Cable management frames2

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

OL-30453-01 17

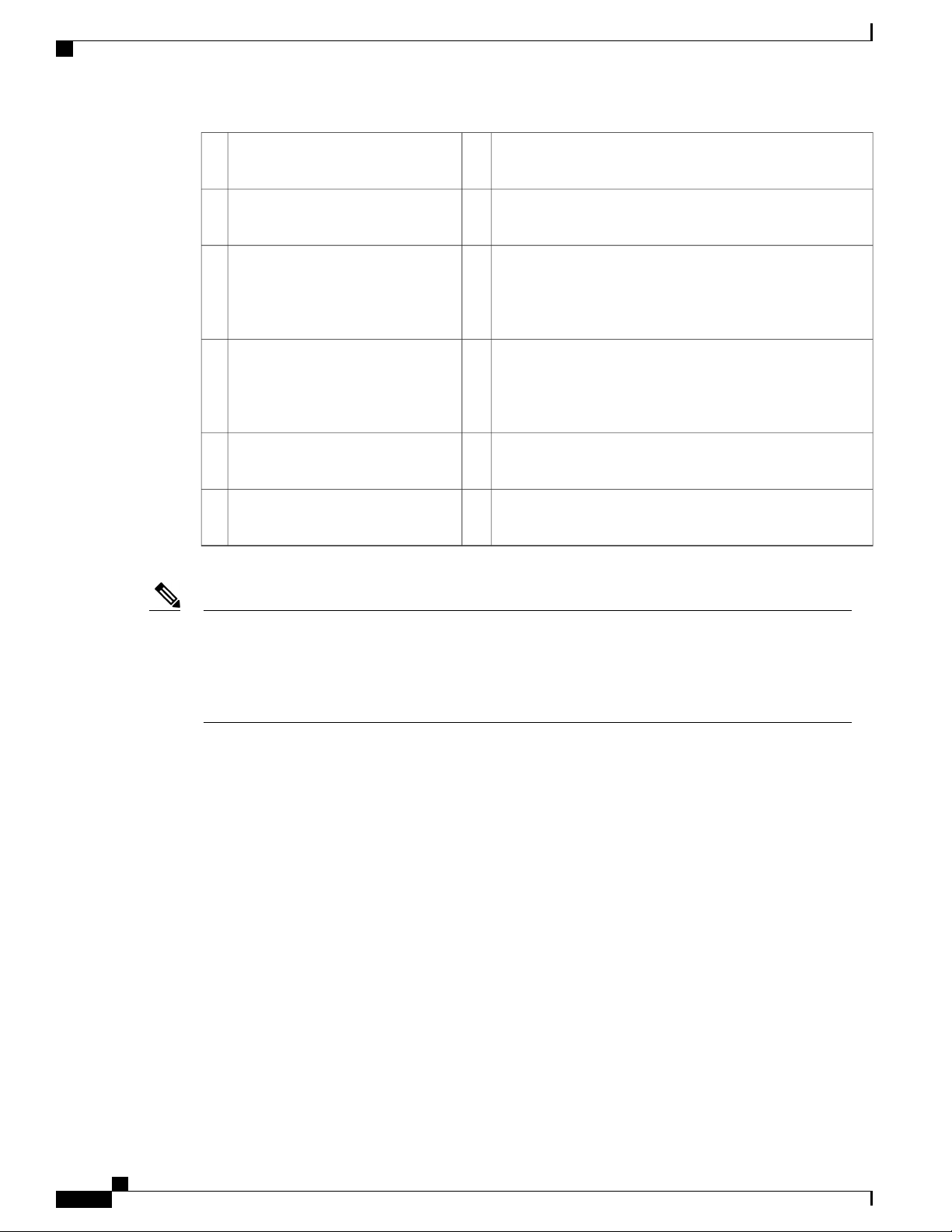

Page 28

Clearance Requirements

4

5

6

7

(allow 2 inches [5 cm])

(no side clearance required)

modules and power supplies

modules and power supplies

Preparing the Site

Rear service clearance required to replace fan trays and fabric

11Vertical rack-mount posts and rails3

modules

Airflow clearance required between the chassis and inside

12Area required for fan tray handles

of cabinet (if used)

Chassis depth

13Nearest object or inside of cabinet

Note

The chassis depth will increase by 2 inches when

the 76mm Gen 2 fan tray (N77-C7718-FAN-2) is

used.

Clearance required between the front of the chassis and the

14Air intake from cold aisle for all

inside of the cabinet (if used) or edge of cold aisle (if no

cabinet) for the cable management frames and the optional

front doors

Front service clearance required for installing the chassis and

15Air exhaust to hot aisle for all

replacing the modules

Note

No left side clearance required (no

8

airflow on left side)

Figure 4: Clearances Required for the Chassis , on page 17 shows the clearance requirements for

conventional cold-aisle to hot-aisle systems which include rack enclosures with perforated front and rear

doors. The information given above does not apply to enclosures which have a solid rear or front door or

wall with other inlet or exhaust configurations. We recommend consulting a cooling professional if a solid

rear or front door is used.

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

18 OL-30453-01

Page 29

Installing the Chassis

This chapter includes the following topics:

Installing a Rack or Cabinet, page 19

•

Unpacking and Inspecting a New Switch, page 20

•

Installing the Bottom-Support Rails , page 21

•

Installing a Chassis in a Rack or Cabinet, page 24

•

Grounding a Switch Chassis, page 32

•

Installing Cable Management Frames, page 40

•

Installing the Front Doors, page 46

•

Installing the Air Filters, page 48

•

CHAPTER 3

Installing a Rack or Cabinet

Before you install the switch, you must install a standard four-post, 19-inch EIA data center rack (or a cabinet

that contains such a rack) that meets the requirements listed in Rack and Cabinet Requirements.

Procedure

Step 1

Step 2

Step 3

OL-30453-01 19

Bolt the rack to the concrete subfloor before moving the chassis onto it.

Warning

Statement 1048

If the rack has bonded construction, connect it to the earth ground. This action enables you to easily ground

the switch and its components and to ground your electrostatic discharge (ESD) wrist strap to prevent damaging

discharges when you handle ungrounded components before installing them.

If you need access to the source power at the rack, include either AC power receptacles or a DC power interface

unit (PIU) with the amperage required by the switch that you are installing. .

Stability hazard. The rack stabilizing mechanism must be in place, or the rack must be bolted to

the floor before you slide the unit out for servicing. Failure to stabilize the rack can cause the rack

to tip over.

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

Page 30

Unpacking and Inspecting a New Switch

If you are using DC power, be sure that the DC power supply is grounded and that there is direct access to

the facility DC power or indirect access though a power interface unit (PIU). You must connect the DC power

supply to the earth ground before you connect it to the facility DC power.

Take care when connecting units to the supply circuit so that wiring is not overloaded.Warning

Statement 1018

Note

If you are using the combined power mode or power-supply redundancy, you need only one power

source. If you are using input-source redundancy or full redundancy, you need two power sources.

Unpacking and Inspecting a New Switch

Before you install a new chassis, you need to unpack and inspect it to be sure that you have all the items that

you ordered and verify that the switch was not damaged during shipment. If anything is damaged or missing,

contact your customer representative immediately.

Installing the Chassis

Caution

Tip

Step 1

When you handle the chassis or its components, you must follow ESD protocol at all times to prevent

ESD damage. This protocol includes but is not limited to wearing an ESD wrist strap that you connect to

the earth ground.

Do not discard the shipping container when you unpack the switch. Flatten the shipping cartons and store

them with the pallet used for the system. If you need to move or ship the system in the future, you will

need these containers.

Procedure

Compare the shipment to the equipment list that is provided by your customer service representative and

verify that you have received all of the ordered items.

The shipment should include boxes for the following:

System chassis, which includes the following installed components:

•

1 or 2 supervisor modules

◦

1 to 16 I/O modules

◦

Up to 6 fabric modules

◦

3 fan trays

◦

1 to 16 power supply units

◦

Switch accessory kit

•

To see a list of what is included in this kit, see Accessory Kit Contents, on page 199.

Cable management frames

•

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

20 OL-30453-01

Page 31

Installing the Chassis

Left and right side frames

◦

Top frame

◦

M4 x 12 mm flat-head Phillips screws (12)

◦

• Front door kit — Optional (N77-C7718-FDK)

Front door (1) (69-2532-01)

◦

M3 x 8 mm pan-head screws (2) (48-0393-01)

◦

• Air filter kit — Optional (N77-C7718-AFLT)

Air filter (1) for the front door

◦

Door-side brush filters (2)

◦

Cable-management frame brush filters (2)

◦

M4 x 12 mm flat-head Phillips screws (12)

◦

Installing the Bottom-Support Rails

Step 2

Step 3

Check the contents of each box for damage.

If you notice any discrepancies or damage, send the following information to your customer service

representative by email:

Invoice number of the shipper (see the packing slip)

•

Model and serial number of the missing or damaged unit

•

Description of the problem and how it affects the installation

•

Installing the Bottom-Support Rails

The bottom-support rails support the chassis in the rack or cabinet. To maximize the stability of the rack, you

must attach these rails at the lowest possible rack unit (RU). If anything lighter than the switch is already

installed in the rack, you should make sure that it is positioned above where you will be installing the switch.

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

OL-30453-01 21

Page 32

Installing the Bottom-Support Rails

Installing the Chassis

Warning

Step 1

To prevent bodily injury when mounting or servicing this unit in a rack, you must take special precautions

to ensure that the system remains stable. The following guidelines are provided to ensure your safety:

This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

•

When mounting this unit in a partially filled rack, load the rack from the bottom to the top with the

•

heaviest component at the bottom of the rack.

If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing

•

the unit in the rack.

Statement 1006

To attach the bottom-support rails to a four-post EIA rack, follow these steps:

Before You Begin

Before you can install the bottom support rails, make sure that you have done each of the following:

Installed a four-post rack or cabinet (see Installing a Rack or Cabinet).

•

Unpacked and inspected the chassis shipment.

•

Procedure

Position one of the two adjustable bottom-support rails at the lowest possible RU in the rack or cabinet. Adjust

the length of the rail so that it stretches from the outer edges of the front and rear vertical mounting rails. You

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

22 OL-30453-01

Page 33

Installing the Chassis

Installing the Bottom-Support Rails

can expand the rail so that its mounting brackets are spaced between 24 to 32 inches (61.0 to 81.3 cm). See

the following figure.

Figure 5: Positioning Bottom-Support Rails for a Cisco Nexus 7718 Chassis

1

2Position two bottom-support rails at the

lowest RU on the rack.

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

OL-30453-01 23

Allow at least 45.5 inches (115.6 cm) (26 RU)

for each Cisco Nexus 7718 chassis.

Page 34

Installing a Chassis in a Rack or Cabinet

Installing the Chassis

Step 2

Attach the bottom-support rail to the rack or cabinet. Use a Phillips screwdriver to screw in four M6 x 19 mm

or 12-24 x 3/4 inch Phillips screws on each end of the rail (using a total of 8 screws for the rail) as shown in

the following figure. Tighten each screw to 40 in. lbs (4.5 N.m) of torque.

Figure 6: Attaching Bottom-Support Rails to a Rack

1

(8 per rail)

Step 3

Repeat the first two steps to attach the other bottom-support rail to the other side of the rack.

Note

Make sure that the two bottom-support rails are level with one another. If they are not level, adjust

the higher rail down to the level of the lower rail.

What to Do Next

When the bottom-support rails are installed at the lowest possible RU and are level, you are ready to install

the chassis in the rack or cabinet.

Installing a Chassis in a Rack or Cabinet

To move a chassis to a rack, it is necessary to slide the chassis onto a mechanical lift, use that mechanical lift

to position the chassis in front of its place on the rack, slide the chassis from the lift to the rack, and then bolt

the chassis to the rack. You can make the chassis easier to move if you remove the power supplies, fan trays,

and fabric modules. These modules are sealed to minimize the chance of being damaged by electrostatic

discharge (ESD), so you can remove them from the chassis to make the chassis easier to move.

Adjustable bottom-support rails (2)2M6 x 19 mm (or 12-24 x 3/4 in.) Phillips screws

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

24 OL-30453-01

Page 35

Installing the Chassis

Before You Begin

You have fully installed a rack or cabinet (see Installing a Rack or Cabinet).

•

Installing a Chassis in a Rack or Cabinet

Note

Stability hazard. The rack stabilizing mechanism must be in place, or the rack must be

bolted to the floor before you slide the unit out for servicing. Failure to stabilize the

rack can cause the rack to tip over. Statement 1048

You have installed the bottom-support rails to the lowest possible RU in the rack and there is at least 25

•

RU (43.75 inches [111 cm]) of space above the rails to install the chassis.

Data center ground is accessible where you are installing the chassis.

•

If there are other devices in the rack, you have arranged the heavier devices below lighter devices, and

•

all devices are installed as low as possible with spacing left for the switch chassis.

You have unpacked and inspected the chassis shipment for completeness and damage.

•

You have the following tools and equipment:

•

Mechanical lift capable of lifting the weight of the chassis and the modules, fan trays, and power

◦

supplies installed in it. Fully loaded, the switch weighs up to 923 lb (419 kg). If you remove the

units protected from ESD damage (power supplies, fan trays, and fabric modules), the maximum

weight of the chassis is 586 lb (266 kg). To determine the full weight of your chassis with its

modules installed (or the weight if you remove the protected modules), see Weights and Quantities

for the Chassis, Modules, Fan Trays, and Power Supplies, on page 145.

You must use a mechanical lift to lift anything weighing over 120 pounds (55 kg).Caution

Note

Number 1 Phillips-head torque screwdriver

◦

18 12-24 x 3/4-inch or M6 x 19 mm Phillips screws from the bottom-support rails kit

◦

You should also have at least three persons to move the chassis, which can weigh up to 923 pounds (449

kg), onto and off the mechanical lift and rack.

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

OL-30453-01 25

Page 36

Installing a Chassis in a Rack or Cabinet

Installing the Chassis

Warning

Step 1

To prevent bodily injury when mounting or servicing this unit in a rack, you must take special precautions

to ensure that the system remains stable. The following guidelines are provided to ensure your safety:

This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

•

When mounting this unit in a partially filled rack, load the rack from the bottom to the top with the

•

heaviest component at the bottom of the rack.

If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing

•

the unit in the rack.

Statement 1006

Procedure

If you need to make the chassis as light as possible for moving, remove the following modules and place them

where their connectors will not be damaged:

• Power supplies—For each power supply, press and hold the eject lever, and use the handle on the front

of the power supply to pull the power supply out of the chassis.

• Fan trays—Unscrew the four captive screws, and use the two handles on the fan tray to pull the fan tray

out of the chassis.

• Fabric modules—For each fabric module, keep your face at least 12 inches (30 cm) away from the

modules, press both eject buttons on the front, rotate both levers away from the front of the module, use

the levers to pull the module out of the chassis.

Step 2

Load the chassis onto a mechanical lift as follows:

a) Position the mechanical lift next to the shipping pallet that holds the chassis.

b) Elevate the lift platform to the level of the bottom of the chassis (or no more than 1/4 inch [0.635 cm]

below the bottom of the chassis).

c) Use at least four persons to slide the chassis fully onto the lift so that the side of the chassis touches or is

close to the vertical rails on the lift. Make sure that the front and rear of the chassis are unobstructed so

you can easily push the chassis into the rack.

Warning

To prevent personal injury or damage to the chassis, never attempt to lift or tilt the chassis using

the handles on modules (such as power supplies, fans, or cards); these types of handles are not

designed to support the weight of the unit. Statement 1032

Caution

To lift the chassis, use a mechanical lift, not the handles on the side of the chassis (the handles are

not rated for lifting over 200 pounds [91 kg]). Use the side handles for only repositioning the

chassis after it is already on the mechanical lift or in the rack or cabinet.

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

26 OL-30453-01

Page 37

Installing the Chassis

Installing a Chassis in a Rack or Cabinet

Step 3

Step 4

Step 5

Use the mechanical lift to position the chassis in front of the four-post rack or cabinet and elevate the chassis

to the level of the bottom-support rails or no more than 1/4 inch (0.6 cm) above the bracket.

Make sure that the chassis is positioned with the rear (the side with the open power supply slots) ready to go

into the rack or cabinet first. If necessary, you can use the two handles on either side of the chassis to move

the chassis on the lift.

Use two persons to push the chassis halfway onto the rack or cabinet and use one person to guide the chassis

down the bottom-support brackets while making sure that the chassis does not get caught on any edges of the

bottom support brackets.

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

OL-30453-01 27

Page 38

Installing a Chassis in a Rack or Cabinet

Push only the lower front sides of the chassis—do not push on any modules and do not use any module handles

to move the chassis.

Figure 7: Moving the Chassis onto a Rack or Cabinet

Installing the Chassis

1

3Push the sides of the lower half of the front side of the chassis

(do not push on any of the modules or module handles).

Rack vertical mounting

rails.

Chassis mounting brackets.2

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

28 OL-30453-01

Page 39

Installing the Chassis

Installing a Chassis in a Rack or Cabinet

Step 6

Step 7

Step 8

If the mechanical lift is raised above the bottom-support brackets, gently lower the lift to the level of the

brackets or no more than 1/4 inch (0.6 cm) below the brackets.

This keeps the chassis level on the brackets and helps prevent the chassis from getting caught on the inside

edges of the bottom-support brackets.

Use two persons to fully push the chassis all the way onto the rack or cabinet.

You have pushed the chassis all the way when its two vertical mounting brackets come in contact with the

vertical rails on the rack or cabinet.

Align the mounting bracket on the chassis to the vertical mounting rails on the rack, and attach the chassis to

the rack.

Align the screw holes in the chassis mounting brackets to the screw holes in the vertical mounting rails on

the rack or cabinet. Use a Phillips screwdriver to screw in nine M6 x 19-mm or 12-24 x 3/4-inch screws in

each of the two chassis mounting brackets (use a total of 18 screws for two mounting brackets). See the

following figure.

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

OL-30453-01 29

Page 40

Installing a Chassis in a Rack or Cabinet

To adjust the placement of the chassis on the bottom-support rails, use the chassis handles shown in

Tip

the following figure.

Figure 8: Attaching the Chassis to the Rack

Installing the Chassis

1

2Handles used to adjust the chassis

placement

Nine M6 x 19 mm or 10-24 x 3/4 in. Phillips screws used

to attach each side bracket to a front mounting rail (use a

total of 18 screws)

Step 9

If you removed any fabric modules before moving the chassis, replace each one in the chassis as follows:

a) Holding the front of the fabric module (the side with the LEDs), turn the module so that the front side is

vertical.

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

30 OL-30453-01

Page 41

Installing the Chassis

Installing a Chassis in a Rack or Cabinet

Step 10

Step 11

Note

The top of the module has an alignment bracket running from the rear to the front. The electrical

connectors will be at the bottom.

b) Align the rear of the fabric module to an open fabric slot and insert the bracket on top of the module in

the track at the top of the slot.

Note

If there are only three fabric modules to install, install them in fabric slots 1, 3, and

5.

c) Slide the module part way into the slot.

d) Unscrew the captive screw on each of two ejector levers on the front of the module and rotate the two

levers away from the module.

e) Holding the levers, slide the module all the way into the slot until it stops.

f) Simultaneously rotate both levers to the front of the module and secure them to the module by screwing

their captive screws to the module. Tighten each screw to 8 in-lb (0.9 N·m).

If you removed any fan trays before moving the chassis, reinstall each one in the chassis as follows:

a) Holding each of the two handles on the fan tray with your two hands, align the fan tray to an open fan tray

slot.

Note

The two alignment brackets on top of the fan tray should align to two tracks at the top of the

slot.

b) Slide the fan tray into the slot until the front of the fan tray comes in contact with the rear of the chassis.

Note

The two alignment pins on the fan tray (on the top and one on the bottom) should go into holes

in the chassis and the four captive screws on the fan tray should align to screw holes in the chassis.

c) Screw in the four captive screws to the chassis and tighten each screw to 8 in-lb (0.9 N·m).

If you removed any power supplies before moving the chassis, reinstall each one as follows:

a) Determine which power supply slots to fill and ensure that each of those slots is open.

If you are using the combined or power supply redundancy mode, you can use any slot for the power

supply that you are installing. If you are using input-source or full redundancy mode, you must group the

power supplies that are to be connected to the same grid on either the left or right power supply slots in

the chassis (that is, place the power supplies for grid A in slots 1, 2, 5, or 6 and place the power supplies

for grid B in slots 3, 4, 7, or 8).

Step 12

b) Place one hand on the front of the power supply and place your other hand under it to support its weight.

c) Align the power supply to an open power supply slot.

Note

The alignment bracket on top of the power supply should align to a track at the top of the slot

and a bar at the bottom of the power supply should be guided by a track at the bottom of the slot.

d) Slide the power supply all the way into the slot until it stops.

e) Slide the handle in the middle of the ejector lever toward the end of the lever and rotate the lever to the

front of the power supply. Release the middle handle.

Note

The lever should grab the inside of the slot and push the power supply onto its mid plane

connectors.

f) Screw in the two captive screws on the front of the power supply to the chassis. Tighten each screw to 8

in-lb (0.9 N·m).

Connect each installed power supply with an AC power circuit as follows:

Note

If you are using combined power mode (no power redundancy) or power supply (n+1) power mode,

connect all of the power supplies to the same power circuit (grid). If you are using input source (n+n)

or full power mode, connect half of the power supplies (located in slots 1, 2, 5, 6, 9, 10, 13, and 14)

to one AC power circuit and the other half of the power supplies (located in slots 3, 4, 7, 8, 11, 12,

15, and 16) to another AC power circuit. When you connect each power supply to an AC power

circuit, the LEDs on the power supply turn on. The switch can operate when each of the required

power supplies have a green OUTPUT LED lit.

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

OL-30453-01 31

Page 42

Grounding a Switch Chassis

a) Ensure that the power supply is turned off by making sure that the power switch is set to 0.

b) Connect the power cable that shipped with the power supply to the AC power source.

c) Connect the other end of the power cable to the power supply outlet.

What to Do Next

After the chassis is secured to the rack, you can ground the switch (see Grounding a Switch Chassis, on page

32).

Grounding a Switch Chassis

The switch is fully grounded as soon as you connect the chassis and the power supplies to the earth ground

in the following ways:

You connect the chassis to either a fully-bonded, grounded rack or to the data center ground.

•

Installing the Chassis

Note

You connect the AC and HVAC/HVDC power supplies to the earth ground automatically when you

•

connect an AC or HVAC/HVDC power supply to an AC or HVAC/HVDC power source.

The system ground, also referred to as the network equipment building system (NEBS)

ground, provides additional grounding for EMI shielding requirements and for the

low-voltage supplies (DC-DC converters) on the modules. This grounding system is

active even when the AC and HVAC/HVDC power cables are not connected to the

system.

Before You Begin

Before you can ground the chassis, you must have a connection to the earth ground for the data center building.

If you installed the switch chassis into a bonded rack (see the rack manufacturer's instructions for more

information) that now has a connection to the data center earth ground, you can ground the chassis by connecting

its grounding pad to the rack. Otherwise, you must connect the chassis grounding pad directly to the data

center ground.

To connect the switch chassis to the data center ground, you need the following tools and materials:

• Grounding lug—A two-holed standard barrel lug that supports up to 6 AWG wire. This lug is supplied

with the accessory kit.

• Grounding screws—Two M4 x 8 mm (metric) pan-head screws. These screws are shipped with the

accessory kit.

• Grounding wire—Not supplied with the accessory kit. This wire should be sized to meet local and

national installation requirements. Depending on the power supply and system, a 12 AWG to 6 AWG

copper conductor is required for U.S. installations. We recommend that you use commercially available

6 AWG wire. The length of the grounding wire depends on the proximity of the switch to proper grounding

facilities.

Number 1 manual Phillips-head torque screwdriver.

•

Crimping tool to crimp the grounding wire to the grounding lug.

•

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

32 OL-30453-01

Page 43

Installing the Chassis

Wire-stripping tool to remove the insulation from the grounding wire.

•

Procedure

Grounding a Switch Chassis

Step 1

Step 2

Step 3

Step 4

Use a wire-stripping tool to remove approximately 0.75 inch (19 mm) of the covering from the end of the

grounding wire.

Insert the stripped end of the grounding wire into the open end of the grounding lug as shown in the following

figure.

Figure 9: Inserting a Grounding Wire in a Grounding Lug

1

2NRTL listed 45-degree grounding

lug

Grounding cable with 0.75 in. (19 mm) of insulation

stripped from one end

Use the crimping tool to crimp the lug to the grounding wire. Verify that the ground wire is securely attached

to the grounding lug by attempting to pull the wire out of the crimped lug.

Secure the grounding wire lug to the grounding pad with two M4 screws, and tighten the screws to 11.5 to

15 in-lb (1.3 to 1.7 N·m) of torque.

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

OL-30453-01 33

Page 44

Grounding a Switch Chassis

The following figure shows the location of the grounding pad on the front of the chassis. There is another

grounding pad on the other side of the chassis.

Figure 10: Grounding Pad Location on the Front of the Cisco Nexus 7718 Chassis

Installing the Chassis

Grounding pad1

Step 5

Prepare the other end of the grounding wire and connect it to an appropriate grounding point in your site to

ensure an adequate earth ground for the switch. If the rack is fully bonded and grounded, connect the grounding

wire as explained in the documentation provided by the vendor for the rack.

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

34 OL-30453-01

Page 45

Installing the Chassis

Grounding the Front ID Doors

Grounding the Front ID Doors

Note

To comply with GR-1089, you have to bond the front industrial design (ID) doors to the ground port on

the chassis using the ground braid.

Figure 7 shows the two sections of the Cisco Nexus 7718 front ID doors. The upper two doors are used for

the I/O modules and the bottom door is used for the power supplies.

Figure 11: Front ID Door Sections

Door for power supplies2Doors for I/O modules1

Procedure

Step 1

OL-30453-01 35

Remove 7 screws from the front industrial design (ID) doors.

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

Page 46

Grounding the Front ID Doors

Figure 8 shows the 7 screws (circled) that have to be removed.

Figure 12: Front ID Door

Installing the Chassis

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

36 OL-30453-01

Page 47

Installing the Chassis

Grounding the Front ID Doors

Step 2

Install grounding cables to the left side of the power supply door, as shown in Figure 9, to connect the middle

plate with the top and bottom hinges.

Figure 13: Grounding Cable Locations on the Door for the Power Supplies

Flat washer2M4 screw1

Grounding cable4M4 screw3

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

OL-30453-01 37

Page 48

Grounding the Front ID Doors

Installing the Chassis

Step 3

Step 4

Tighten the screw to 7 in-lb (0.79 N-m) of torque to provide proper bonding.

Connect the grounding cable from the door for the power supplies to the switch chassis, as shown in Figure

10.

Figure 14: Grounding Cable Location between the door for the Power Supplies and the Cisco Nexus 7718 switch chassis

M4 screw2M4 screw1

Grounding cable4Flat washer3

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

38 OL-30453-01

Page 49

Installing the Chassis

Grounding the Front ID Doors

Step 5

Install a grounding cable between the left hand side door for the I/O modules and the switch chassis, as shown

in Figure 11. Repeat the procedure for installing a grounding cable between the right hand side door for the

I/O modules and the switch chassis.

Figure 15: Grounding Cable Location between the Left Hand Side Door for the I/O Modules and the Cisco Nexus 7718

Switch Chassis

Note

The grounding cable location for installing the grounding cable between the right hand side door for

the I/O modules and the Cisco Nexus 7718 switch chassis will be mirrored on the right hand side of

the switch.

M4 screw2Grounding cable1

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

OL-30453-01 39

Page 50

Installing Cable Management Frames

Installing the Chassis

Step 6

Step 7

Apply the star ring terminal end of the grounding cables to the front ID doors.

Connect the other round terminal of the grounding cable to the ground port on the chassis, as shown in Figure

11. Tighten the M4 screw to 9 to 12 in-lb (1.01 to 1.35 N-m) of torque.

Installing Cable Management Frames

You install the middle cable management frame and then install the lower and upper frames on the middle

frame. After installing the cable management frames on the left and right sides of the front of the chassis, you

install the top hood, and then tighten the screws holding all the frames to the chassis.

If you are installing the optional front doors on the chassis, you must have the cable management frames

already installed because they hold the front doors to the chassis.

Before You Begin

The chassis is installed and secured to the rack or cabinet.

•

You have the following tools and equipment:

•

Phillips torque screwdriver (customer supplied).

◦

Following frames and screws (shipped with the switch):

◦

Two cable management upper side frames

◦

Two cable management middle side frames

◦

Step 1

Two cable management lower side frames

◦

One cable management top hood frame

◦

36 M4 x 13-mm, flat-head, Phillips screws

◦

Procedure

Attach the middle cable management frames as follows:

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

40 OL-30453-01

Page 51

Installing the Chassis

Installing Cable Management Frames

a) Align the four screw holes in a middle cable management frame to four screw hole standoffs on one of

two brackets attached to the front of the chassis (see the following figure).

Figure 16: Attaching the Middle Cable Management Frame to the Chassis

Middle cable management frame with four

3Chassis mounting bracket1

screw holes

Four M4 x 13 mm screws that secure the middle

2

mounting bracket

4Four screw-hole standoffs on the chassis

cable management frame to the chassis

mounting bracket

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

OL-30453-01 41

Page 52

Installing Cable Management Frames

b) Use four M4 x 13 mm screws to attach the frame to the bracket. Do not tighten the screws.

c) Repeat steps 1a and 1b to attach the other middle cable management frame to the other side of the chassis.

Installing the Chassis

Step 2

Attach the lower cable management frames as follows:

a) Position a lower cable management frame below the installed middle cable management frame and slide

the lower frame onto the flange at the bottom of the middle frame.

Verify that the two angle brackets on the frame are touching the front of the chassis and that the screw

holes in the brackets align with screw holes in the chassis. If not, remove this frame and replace it with

the other lower frame.

Figure 17: Attaching a Lower Cable Management Frame to the Chassis

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

42 OL-30453-01

Page 53

Installing the Chassis

Installing Cable Management Frames

Two M4 x 13 mm screws to secure an angle bracket

4Chassis mounting bracket1

to the chassis

Two M4 x 13 mm screws to secure the frame to the

2

management frame

Middle cable management frame with

3

5Alignment flange on the middle cable

chassis mounting bracket

alignment groove on top, two screw

holes, and two angle brackets with two

screw holes each

b) Use two M4 x 13 mm screws to attach the frame to the vertical chassis mounting bracket. Do not tighten

the screws.

c) Use two M4 x 13 mm screws to attach each of the two angle brackets to the chassis (total of four screws).

Do not tighten the screws.

d) Repeat steps 2a, 2b, and 2c to attach the other lower cable management frame to the other side of the

chassis.

Step 3

Attach the upper cable management frames as follows:

a) Position the upper cable management frame above the installed middle cable management frame and slide

the upper frame onto the flange on the top of the middle frame (see the following figure).

Verify that the five screw holes on the frame align with five screw-hole standoffs on the chassis mounting

bracket.

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

OL-30453-01 43

Page 54

Installing Cable Management Frames

Figure 18: Attaching an Upper Cable Management Frame to the Chassis

Installing the Chassis

Screw hole standoff (5)4Chassis mounting bracket1

Five M4 x 13 mm screws to secure the frame to the

2

management frame

Upper cable management frame with five

3

5Alignment flange on the middle cable

chassis mounting bracket

screw holes and an alignment groove on

the bottom

Cisco Nexus 7718 Switch Site Preparation and Hardware Installation Guide

44 OL-30453-01

Page 55

Installing the Chassis

Installing Cable Management Frames

b) Use five M4 x 13 mm screws to attach the frame to the bracket. Do not tighten the screws.

c) Repeat steps 3a and 3b to attach the other upper cable management frame to the other side of the chassis.

Step 4

Attach the top hood to the cable management frames and chassis as follows:

a) Set the top hood, with its angle brackets pointing downward, on top of the two upper cable management

frames. Verify that the two alignment pins on the back side of the hood are aligned with two holes on the

top of the chassis (see Callouts 2 and 3 in the following figure).

Figure 19: Attaching the Top Hood Cable Management Frame to the Chassis

M4 x 13 mm screw (2) to secure the top hood to the

4Top hood cable management frame1

chassis

Step 5

Four M4 x 13 mm screws (two per side) to secure top

2

top hood frame

5Alignment pins on the back side of the

hood to each upper cable management frame

Align holes in the chassis3

b) Slide the hood toward the chassis so that the alignment pins enter the two holes. Verify that two holes on

each side of the angle bracket align to two screw holes on the cable management frames and a screw hole

on each side of the back angle bracket aligns with a screw hole on the chassis.

c) Use two M4 x 13 mm screws to attach the top hood to the chassis (see Callout 4 in the previous figure).

d) Use two M4 x 13 mm screws to attach each side of the top hood to the two side cable management frames