Page 1

Doc. No.

78-1064-02

Cisco 7000 and Cisco 7507

Chassis Replacement Instructions

Product Numbers: CHAS-7K, MAS-7K, CHAS-7507, MAS-7507

Customer Order Number: DOC-781064=

This document contains instructions for replacing a Cisco 7000 and Cisco 7507 chassis as a spare

part.

Note With a few exceptions, the chassis replacement procedures are identical for both chassis;

therefore, throughout this document, both chassis are referred to as the chassis; the exceptions are

clearly noted.

You will remove the processor modules and power supplies from your existing chassis and install

them in the replacement chassis. The term processor modules refers to the RP, SP (or SSP), and

interface processors in the Cisco 7000, and the RSP2 and interface processors in the Cisco 7507.

These instructionsare applicableonly tosystems thatare alreadyoperational andfor whichfirst-time

installation and startupverification has been performed.If you have notalready installed the system

and verified that it operates properly, or if you are moving the chassis to anew location, refer to the

Cisco 7000 Hardware Installation and Maintenance or Cisco 7507 Hardware Installation and

Maintenance publications for installation information.

The sections in this document include the following:

• Product Overview, page 2

• Prerequisites, page 6

• Unpacking the Chassis, page 11

• Replacing a Rack-Mounted Chassis, page 11

• Moving System Components, page 18

• Verifying the Installation, page 24

Copyright © 1995

Cisco Systems, Inc.

All rights reserved.

• Cisco Information Online, page 48

1

Page 2

Product Overview

Product Overview

The Cisco7000 andCisco 7507 replacementchassis comprisethe sheet metalhousing, frontchassis

panels, and all internal components (MAS-7K and MAS-7507, respectively). An optional

replacement chassis is shipped with a spare power supply (CHAS-7K and CHAS-7507,

respectively).

The rear of the chassis contains the seven processor slots and the two power supply bays. The

processor slots in the replacement chassis contain blank board carriers, which you will remove

individually as you install the interface processors from the old system. You will complete the

system by installing the processormodules and power supplies that you remove from your existing

system.

All of the components you will move to the new chassis are accessible from the rear ofthe chassis.

The descriptions that follow assume that you are viewing the chassis from the rear, or

interface-processor end, which is the orientation of the Cisco 7000 shown in Figure 1 or the

Cisco 7507 shown in Figure 2.

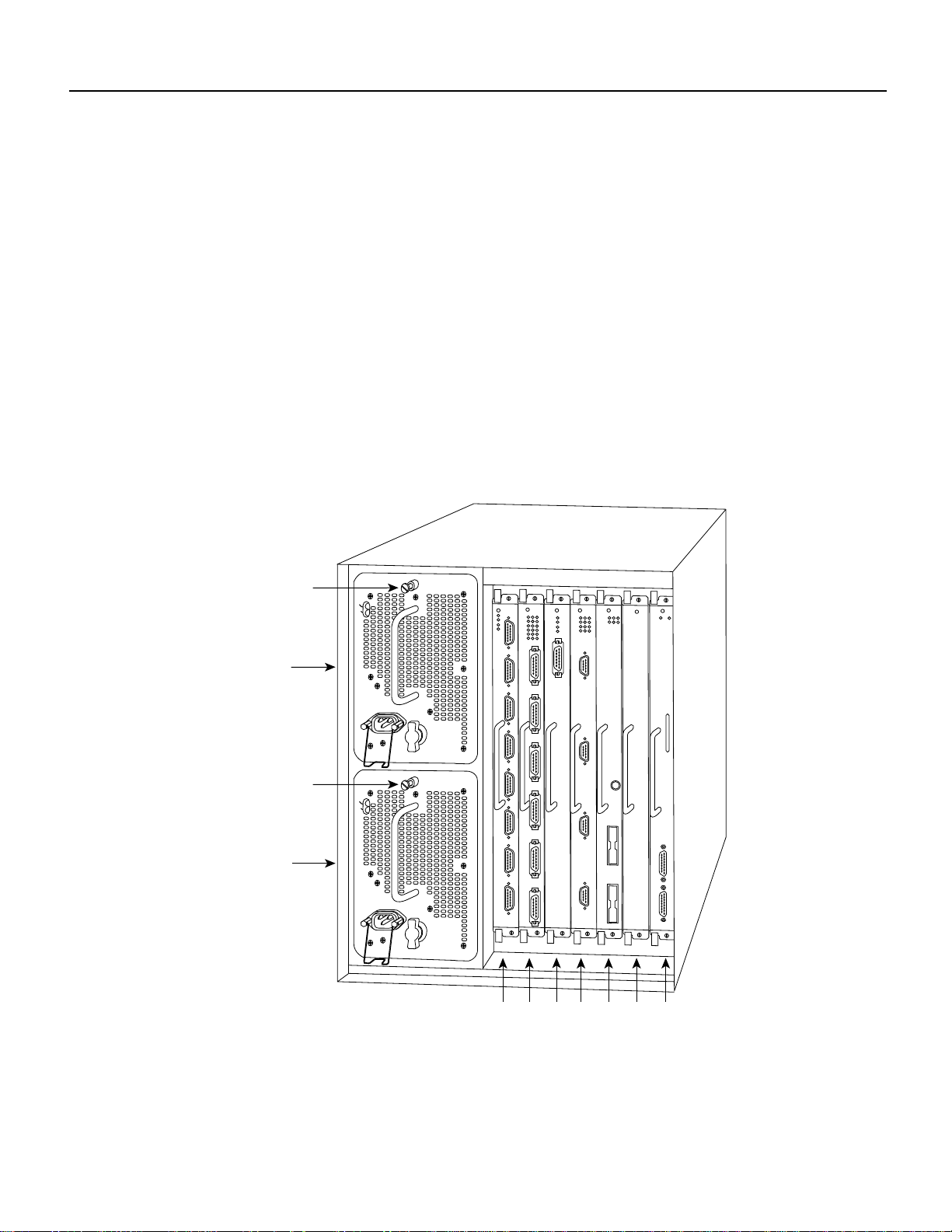

Figure 1 Cisco 7000 Chassis Rear View

Captive

installation screw

Upper

power supply

Captive

installation screw

Lower

power supply

DC FAIL

AC POWER

DC FAIL

AC POWER

I

O

H2358

I

O

Slot 0

2

1

3 4 SP

or

RP

slot

SSP

slot

2 Cisco 7000 and Cisco 7507 Chassis Replacement Instructions

Page 3

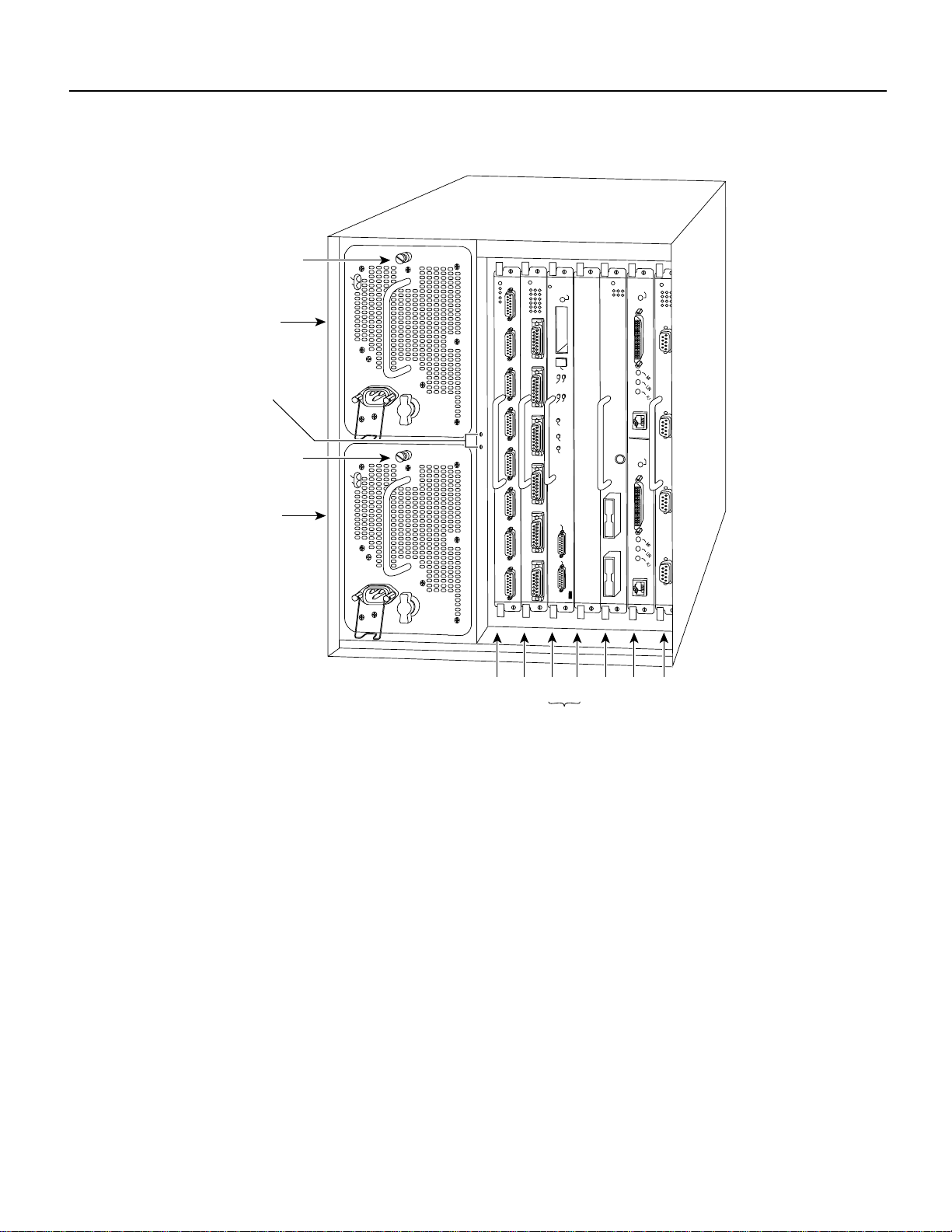

Figure 2 Cisco 7507 Chassis Rear View

aptive

stallation screw

pper

ower supply

DC FAIL

AC POWER

NORMAL

Product Overview

ENABLE

hassis

rounding

ceptacles

aptive

stallation screw

ower

ower supply

DC FAIL

AC POWER

I

O

I

O

Slot 0

EJECT

SLOT 1

SLOT 0

MASTER

SLAVE

SLAVE/MASTER

CPU HALT

RESET

AUX.

ROUTE SWITCH PROCESSOR 2

CONSOLE

2

1

34 5 6

ENABLE

H3888

RSP slots

The lower power supply bay is the default bay for systems with a single supply. The upper bay

houses thesecond power supplyin systemswith redundantpower.Power suppliesslide intothe bays

and must be fully inserted before the power switch can be turned on. On each power supply, the

on/off switch prevents the power supply from being removed from the chassis when the power

supply switch (labeled O forthe off position, and | forthe on position) is in the on (|)position. (See

Figure 3.) When the switch is on, a metal tab extends into a slot in the chassis. When the switch is

turned off (O), the tab is raised and clears the slot. A captive installation screw at the top of each

supply secures the supply in the bay and provides grounding for the system.

Cisco 7000 and Cisco 7507 Chassis Replacement Instructions 3

Page 4

Product Overview

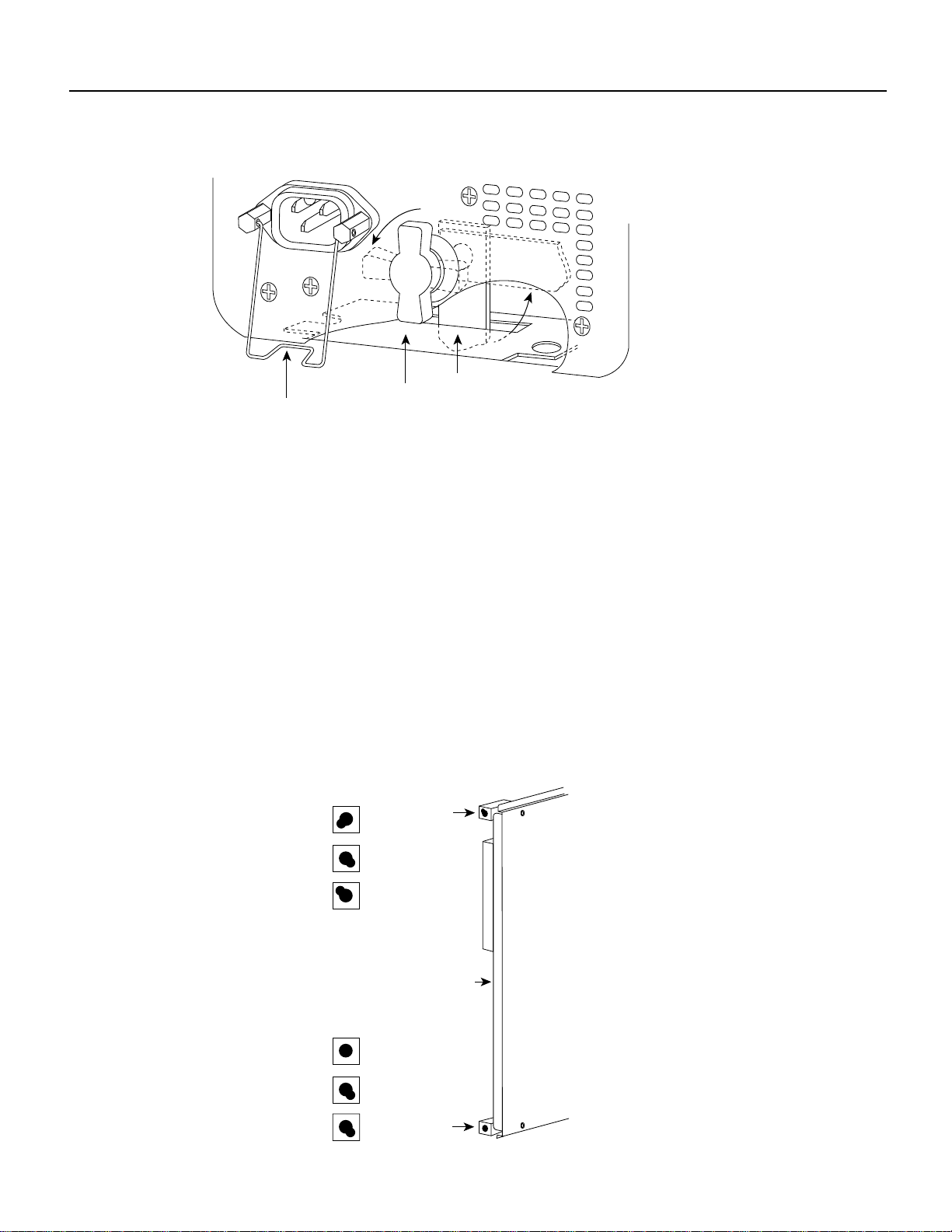

Figure 3 Power Supply Safety Interlocks

I

O

H1315a

Locking device

in ON and

locked positions

Cable-retention clip

Safety interlock

switch

To the rightof the powersupply bays, the processorslots house the processormodules. In the Cisco

7000, theRP isalwayslocated inthe farright slot(the RPslot), andthe SP(or SSP)is alwayslocated

in the adjacent slot. The remaining five interface processor slots, numbered 0–4 from left to right,

support anycombination of network interfacetypes: serial, FDDI,Ethernet, and Token Ring, andso

forth.

In the Cisco 7507, the RSP2 is always located in slot 2 or 3. The remaining six interface processor

slots, numbered 0 and 1 and 4 through 6, from left to right, support any combination of network

interface type.

The processormodules slideinto theslots andconnect directlyto thebackplane. Thebackplane slots

are keyed to guides on each type of board. (See Figure 4 for the Cisco 7000 and Figure 5 for the

Cisco 7507.) The keys ensure that the processor modules can be installed only in their designated

slots.

Figure 4 Cisco 7000 System Backplane Slot Key Guides

Key guides on interface

processors, RP and SP (or SSP)

Top

Interface processor

slots 0–5

Top

key guide

SSP (or SSP)

RP

Rear of

processor card

Bottom

Interface processor

slots 0–5

SSP (or SSP)

RP

Bottom

key guide

4 Cisco 7000 and Cisco 7507 Chassis Replacement Instructions

H3144

Page 5

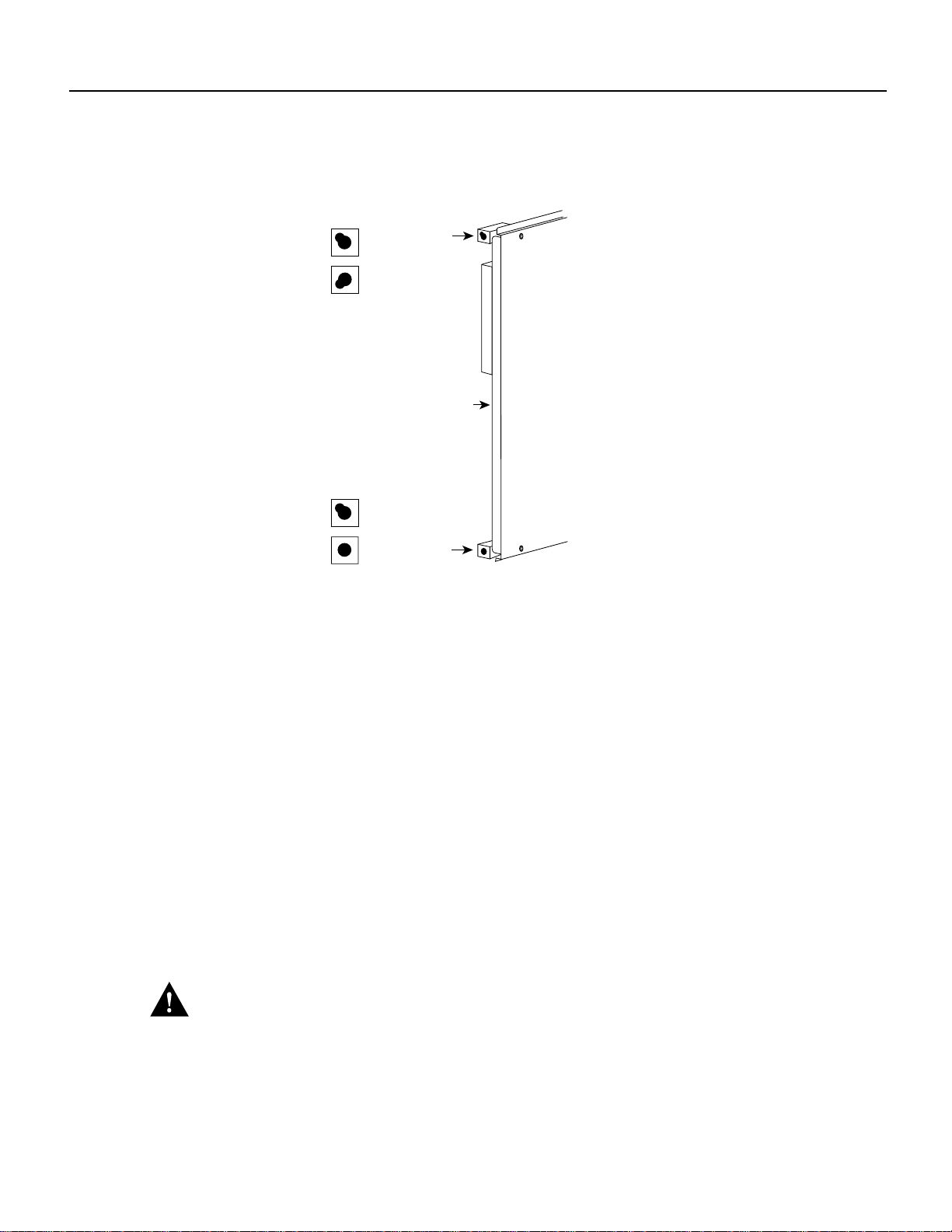

Figure 5 Cisco 7507 System Backplane Slot Key Guides

Key guides on interface

processors and RSP2

Top

RSP2

Top

key guide

Product Overview

Interface processor

Interface processor

slots

RSP2

slots

Bottom

Rear of

processor card

Bottom

key guide

H3126

Spring-loaded ejectorlevers helpto ensure thatthe processormodules are eitherfully inserted inthe

backplane or fully dislodged from it. It is particularly important to use the ejector levers when

removing or installing processor modules because the bus connectors on the boards must be either

fully inserted in the backplane or fully dislodged from it when the system is operating. Any

processor module that is only partially connected to the backplane can hang the bus.

Captive installation screws at the top and bottom of each processor module faceplate, when

tightened, provide EMI shielding and also help ensure proper seating in the backplane. (See

Figure 8.) After using the ejector levers to install a processor module, tighten the top and bottom

captive installation screws to prevent the module from becoming partially dislodged from the

backplane. These screws must be tightened to meet EMI specifications.

For complete descriptionsof all system components, refer tothe Cisco 7000 Hardware Installation

and Maintenance or Cisco 7507 Hardware Installation and Maintenance publications.

Figure 8 on page 19 shows a detail ofthe bottom ejector lever function. Whenyou push the bottom

ejector leverupward, andpush thecorresponding topejector leverdownward,the ejector levers push

the board connectors into the backplane at the rear of the slot inside the chassis. Push the bottom

ejector lever a full 90 degrees upward, and push the upper ejector lever 90 degrees downward, to

ensure that the board connectors are fully seated in the backplane.

Caution The ejector levers ensure that the backplaneconnectors on the card are fully seatedin, or

fully ejectedfrom, the backplane. Failureto use theejector levers couldresult in a partialbackplane

connection, which can hang the system.

Cisco 7000 and Cisco 7507 Chassis Replacement Instructions 5

Page 6

Prerequisites

Prerequisites

Before you move a chassis or any of the system components, review the safety guidelines and

requirements in this section and ensure that you have the necessary parts and tools you will need.

Warning Thiswarning symbol meansdanger. You arein a situationthat could causebodily injury.

Before you work on any equipment, be aware of the hazards involved with electrical circuitry and

be familiar with standard practices for preventing accidents.

Waarschuwing Dit waarschuwingssymbool betekent gevaar. U verkeert in een situatie die

lichamelijk letselkan veroorzaken.Voordat uaan enige apparatuurgaat werken, dientu zichbewust

te zijn van de bij elektrische schakelingen betrokken risico's en dient u op de hoogte te zijn van

standaard maatregelen om ongelukken te voorkomen.

Varoitus Tämävaroitusmerkkimerkitsee vaaraa. Olettilanteessa,joka voijohtaaruumiinvammaan.

Ennen kuin työskentelet minkään laitteiston parissa, ota selvää sähkökytkentöihin liittyvistä

vaaroista ja tavanomaisista onnettomuuksien ehkäisykeinoista.

Attention Ce symbole d'avertissement indique un danger. Vous vous trouvez dans une situation

pouvant causer des blessures ou des dommages corporels. Avant de travailler sur un équipement,

soyez conscient des dangers posés par les circuits électriques et familiarisez-vous avec les

procédures couramment utilisées pour éviter les accidents.

Warnung Dieses Warnsymbol bedeutet Gefahr. Sie befinden sich in einer Situation, die zu einer

Körperverletzungführen könnte. Bevor Siemit derArbeit anirgendeinem Gerätbeginnen, seien Sie

sich der mit elektrischen Stromkreisen verbundenen Gefahren und der Standardpraktiken zur

Vermeidung von Unfällen bewußt.

Avvertenza Questo simbolo di avvertenza indica un pericolo. La situazione potrebbe causare

infortuni alle persone. Prima di lavorare su qualsiasi apparecchiatura, occorre conoscere i pericoli

relativiai circuitielettrici edessere alcorrentedelle pratichestandard perla prevenzione di incidenti.

Advarsel Dette varselsymbolet betyr fare. Du befinner deg i en situasjon som kan føre til

personskade. Før du utfører arbeid på utstyr, må du vare oppmerksom på de faremomentene som

elektriskekretser innebærer,samt gjøredeg kjentmed vanlig praksisnår detgjelder åunngå ulykker.

Aviso Este símbolo de aviso indicaperigo. Encontra-se numasituação que lhepoderá causar danos

físicos. Antes de começar a trabalhar com qualquer equipamento, familiarize-se com os perigos

relacionados com circuitos eléctricos, e com quaisquer práticas comuns que possam prevenir

possíveis acidentes.

¡Advertencia! Este símbolo de aviso significa peligro. Existe riesgo para su integridad física.

Antes de manipular cualquier equipo, considerar los riesgos que entraña la corriente eléctrica y

familiarizarse con los procedimientos estándar de prevención de accidentes.

Varning! Denna varningssymbol signalerar fara. Du befinner dig i en situation som kan leda till

personskada. Innan du utför arbete på någon utrustning måste du vara medveten om farorna med

elkretsar och känna till vanligt förfarande för att förebygga skador.

6 Cisco 7000 and Cisco 7507 Chassis Replacement Instructions

Page 7

Safety Guidelines

Prerequisites

The following guidelines will help to ensure your safety and protect the equipment. This list is not

inclusive of all potentially hazardous situations, so be alert.

Warning Before working on a system that has an on/off switch, turn OFF the power and unplug

the power cord. (For translations of this safety warning, refer to the section “Power Disconnection

Warning” on page 36.)

Warning Do not touch the power supply when the power cord is connected. For systems with a

power switch, line voltages are present within the power supply even when the power switch is off

and the power cord is connected. For systems without a power switch, line voltages are present

within the power supply whenthe power cord isconnected. (For translations ofthis safety warning,

refer to the section “Power Supply Warning” on page 36.)

Warning Before working on a chassis or working near power supplies, unplug the power cord on

AC units; disconnect the power at the circuit breaker on DC units. (For translations of this safety

warning, refer to the section “Power Supply Disconnection Warning” on page 37.)

Warning This unit might have more than one power cord. To reduce the risk of electric shock,

disconnect the two power supply cords before servicing the unit. (For translations of this safety

warning, refer to the section “Electric Shock Warning” on page 38.)

• Never try to lift the chassis by yourself; two people are required to lift the chassis.

• Use a hand truck or pallet jack to move the chassis between locations.

• Always disconnect all power cords and interface cables before moving the chassis.

• Keep tools and chassis components away from walk areas.

• Do not work alone when potentially hazardous conditions exist.

• Do not perform any action that creates a potential hazard to people or makes the equipment

unsafe.

• Carefully examine your work areafor possible hazards such as moist floors, ungrounded power

extension cables, and missing safety grounds.

Cisco 7000 and Cisco 7507 Chassis Replacement Instructions 7

Page 8

Prerequisites

Lifting the Chassis Safely

The chassis weighs 76pounds when empty (no processor modules or power supplies installed) and

145 pounds when fully configured with two power supplies and all interface slots populated.

Whenever you lift the chassis or any heavy object, follow these guidelines:

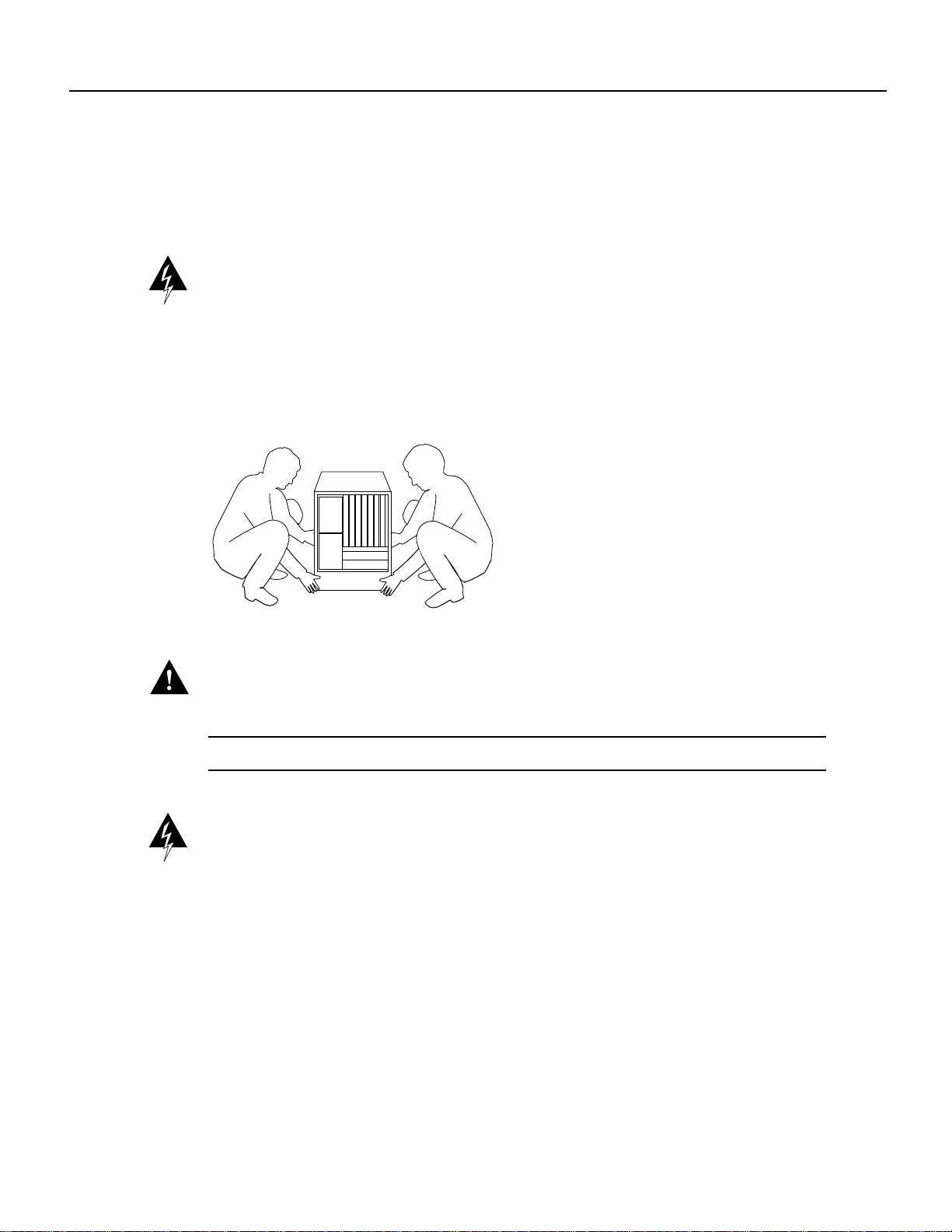

Warning Two people are required tolift the chassis. Grasp the chassis underneath the lower edge

and lift with both hands.To prevent injury, keep your back straightand lift with your legs, not your

back. To prevent damage to the chassis and components, never attempt to lift the chassis with the

handles on thepower supplies or on theinterface processors, or by theplastic panels on the front of

the chassis. These handles were not designed to supportthe weight of the chassis. (For translations

of this safety warning, refer to the section “Chassis Lifting Warning” on page 39.)

Figure 6 Lifting Safely

H2336

Caution To prevent damage,neverattempt tolift thechassis withthe handleson thepower supplies

or the interface processors. These handles are not designed to support the weight of the chassis.

Note The following warning is for units equipped with DC-input power supplies.

Warning Before performing any of the following procedures, ensure that power is removed from

the DC circuit. To ensure that all power is OFF, locate the circuit breaker on the panel board that

services theDC circuit, switch thecircuit breaker tothe OFF position,and tape the switchhandle of

the circuit breaker in the OFF position. (For translations of this safety warning, refer to the section

“DC Power Disconnection Warning” on page 40.)

• Remove all power supplies before lifting the chassis. Each supply weighs 20 pounds.

• Always disconnect all external cables before lifting or moving the chassis.

8 Cisco 7000 and Cisco 7507 Chassis Replacement Instructions

Page 9

Safety with Electricity

Prerequisites

Follow these basic guidelines when working with any electrical equipment:

• Before beginning any procedures, locate the emergency power-off switch forthe room in which

you are working.

• Never assume that power has been disconnected from a circuit; always check.

• Always disconnectall cables (including network interface andtelephone wiring) andremove all

power supplies before moving or lifting the chassis.

Warning Always disconnect all cables before moving or working on the chassis. Even when the

chassis is disconnected from all power sources, telephone wiring can still deliver potentially lethal

electrical surges.

• Never install telephone wiring during a lightning storm.

Warning Do not work on the system or connect or disconnect cables during periods of lightning

activity. (For translations of this safety warning, refer to the section “Lightning Activity Warning”

on page 41.)

• Never install telephone jacks in wet locations unless the jack is specifically designed for wet

• Never touch uninsulated telephone wires or terminals unless the telephone line has been

• Use caution when installing or modifying telephone lines.

Cable Strain Relief

If possible,position thenew replacementchassis close enoughto the existing systemso thatyou can

avoidhaving todisconnect powerand interface cables.Be sure to disengage anystrain reliefdevices

before attempting to pull the cables from the port. Following are descriptions of the different

methodsof strainrelief thatare usedon thepowersupplies andthe varioustypes ofnetworkinterface

ports:

• On the AC-input power supplies, a cable retention clip snaps up around the connector on the

• On the DC-input power supplies, two nylon cable ties provide strain relief for the DC-input

• Serial interface cables (alltypes) use thumbscrews on the cableconnectors that secure the cable

locations.

disconnected at the network interface.

power cord to prevent it from being inadvertently pulled out of the power supply port. Before

attempting to disconnect the power cord, be sure topush the retention clip down away from the

cable connector.

cables.

to the FSIP port.

• Ethernet interface cables use either slide-type locks or thumbscrews. The Ethernet Interface

Processor (EIP) ports are shipped from the factory with slide-type locks on each port; however,

a conversion kit is also shipped for replacing the slide-type locks with jackscrews to

accommodate Ethernet interface cables with thumbscrews.

Cisco 7000 and Cisco 7507 Chassis Replacement Instructions 9

Page 10

Prerequisites

• Multimode Fiber Distributed Data Interface (FDDI) connectors use small plastic arms on two

sides ofthe connectorthat actlike springsand areconstrained by theinside ofthe connectorport.

To remove a multimode cable from a FIP port, pinch the two plastic arms inward while pulling

the connector out of the port.

When removing any cable, pull the cable out at the connector; never pull or tug on the cable itself.

For detailed descriptions of the interface connectors and ports, refer to the Cisco 7000 Hardware

Installation and Maintenance or Cisco 7507 Hardware Installation and Maintenance publications.

List of Parts and Tools

You need someor all of thefollowing toolsand parts to performthis replacement procedure.Before

you begin, read through the procedure to determine which tools you need for this replacement

procedure.

• Number 2 Phillips or3/16-inch flat-blade screwdriver forthe captive installationscrews on each

processor module. (Most systems use Phillips screws, but some of the earlier systemsproduced

use slotted screws.)

• A 1/4-inchflat-blade or Number 2Phillips screwdriver toinstall the power supply. Earlier power

supplies (the first few hundred shipped) have a slotted-head captive installation screw.

• ESD-preventionequipment orthe disposable groundingwrist strapincluded withall upgrade kits

• Antistatic mat, foam pad, or bag for removed processor modules in case you are not able to

immediately insert them into the new chassis.

If your chassis is mounted in a rack, you will need the following tools to remove and replace the

mounting hardware:

• Number 2 Phillips screwdriver

• 3/16-inch flat-blade screwdrivers

• Tape measure

• Level

• One 7/16-inch open-end (or adjustable) wrench if you will remove the chassis feet

Preventing Electrostatic Discharge Damage

Electrostatic discharge (ESD) damage, which occurs when electronic boards or components are

improperly handled, can result in complete or intermittent failures. The processor modules each

comprise a printed circuit board thatis fixed in a metal carrier. Electromagnetic interference (EMI)

shielding, connectors,and ahandle are integral componentsof the carrier. TheLED board,however,

isnot intendedto behandled andhas noframe orshielding.Handle theLED boardby theedges only;

never touch the board components, traces, or connector pins.

Caution Always handle an LED board by the edges only; avoid touching the board components,

traces, or connector pins.

10 Cisco 7000 and Cisco 7507 Chassis Replacement Instructions

Page 11

Unpacking the Chassis

Following are guidelines for preventing ESD damage:

• Always use an ESD strap and ensure that it makes good skin contact.

• When removingor installing anLED board, connectthe equipment endof the groundstrap to an

unpainted surface of the chassis, suchas the vertical metal frame that is exposed when thefront

chassis panels are removed.

• Handle boards by the edges only; avoid touching the board components, traces, or connector

pins.

• Place a removed board component-side-up on an antistatic surfaceor in a staticshielding bag. If

you are returning the board tothe factory, immediately placeit in a static shielding bag to avoid

ESD damage.

• Avoid contactbetween the boardand clothing. Thewrist strap only protectsthe board fromESD

voltages on the body; ESD voltages on clothing can still cause damage.

Caution Forsafety,periodically checkthe resistancevalue ofthe antistaticstrap. Themeasurement

should be within the range of 1 and 10 megohms.

Preparing the Work Area

Althoughsome networkdowntime isunavoidablewhile youremove theRP andSP andreplacethem

in the new chassis, you can minimize network downtime by placing the old and new chassis close

together.If your existingchassis is mounted ina rack, and thereis space in thesame rack or another

rack close by, install the new chassis in the rack before shutting down the existing chassis. Leave

network interface cables connected to the interface ports only if the following conditions are true:

• You are able to place the new chassis next to the existing chassis, and moving the processor

modules to the new chassis will not strain the interface cables.

• You will not have to lift the new chassis after the processor modules and power supplies are

installed.

• The new chassis is already located in its permanent location, or you will need to move it only a

few feet into the space vacated by the old chassis when it is removed.

• Before removing anexisting chassis that israck mounted, you are ableto install the new chassis

in the same rack or an adjacent rack, and moving theprocessor modules to the new chassis will

not strain the interface cables.

If these conditionsare not true, for instance,if you must remove a rack-mountedchassis before you

can install the new chassis, you must disconnect all power and network interface cables.

Unpacking the Chassis

To unpack the new chassis, follow the directions in the document Cisco 7000 and Cisco 7507

Unpacking Instructions (DocumentNumber 78-1067-xx), which ships with every newchassis; this

document is also available on UniverCD.

Replacing a Rack-Mounted Chassis

This section describes how to replacethe chassis in a system that is installed in an equipment rack.

The order in which you remove the existing system, install the new chassis, and replace the

components will vary depending upon the space available in the rack and in the work area. Assess

your rack and lab configuration and choose the appropriate replacement plan from the following:

Cisco 7000 and Cisco 7507 Chassis Replacement Instructions 11

Page 12

Replacing a Rack-Mounted Chassis

• If there is sufficient space available in the same rack (or an adjacent rack) to install the

replacement(empty) chassisbefore youremovethe existingsystem, youcanminimize downtime

and avoidhaving to disconnectnetwork interfacecables byleaving theexisting systemoperating

whileyou installthe replacementchassis inthe rack.Justensure thatboth chassis,when installed,

will beclose enoughto avoidstraining cablesconnected tothe interfaceprocessors. If thisoption

is possible, proceed to the section “Adding a New Chassis to the Rack.”

• If sufficient rack space is not available to install both chassis (if you must remove the existing

system from therack to make room for thereplacement chassis), you will have to disconnect all

network interface cables and remove the power supplies before removing the existing system

from the rack. Be sure to label the interface cables to avoid crossing them when you reconnect

them tothe interface ports.As you disconnectcables from theinterface processors, completethe

configuration worksheetprovided atthe end ofthis document tohelp you reconnectthe cables to

the correct ports. (For the Cisco 7000, refer to Figure 17, and for the Cisco 7507, refer to

Figure 18.)

• If the existing system is installed in an enclosed rack, or if a power strip or other rack fixture

blocks access to the power supply bays, you may have to remove the existing system with the

power supplies intact and then install them in the replacement chassis before you install that

chassis in the rack.If you must choose this method,ensure that you have sufficient assistance to

lift and support the chassis and the rack. The chassis weights over 100 pounds with two power

supplies installed, and the rear of the chassis is heaviest.

Note Be sure that you have sufficient help (assistants) to lift and support the chassis and the rack

when performing these procedures. The empty replacement chassis weights 75 pounds. A fully

configured chassis weighs 145 pounds. Whenever possible, remove all power supplies before

moving or lifting the chassis.

Warning Two people are required tolift the chassis. Grasp the chassis underneath the lower edge

and lift with both hands.To prevent injury, keep your back straightand lift with your legs, not your

back. To prevent damage to the chassis and components, never attempt to lift the chassis with the

handles on thepower supplies or on theinterface processors, or by theplastic panels on the front of

the chassis. These handles were not designed to supportthe weight of the chassis. (For translations

of this safety warning, refer to the section “Chassis Lifting Warning” on page 39.)

12 Cisco 7000 and Cisco 7507 Chassis Replacement Instructions

Page 13

Adding a New Chassis to the Rack

If there is sufficient rack space to install the replacement chassis before you remove the existing

system, proceed as follows.

Step 1 Follow the instructions in the section “Unpacking the Chassis” on page 11 to unpack the

rack mounting hardware and, after the mounting hardware is installed, to unpack the

chassis.

Step 2 Ensurethat there are atleast 20 inches of verticalspace free in therack above or below the

existing system, or in a nearby rack, in which to install the replacement chassis.

Warning To prevent bodily injury when mounting or servicing this unit in a rack, you must take

special precautions to ensurethat the system remains stable. The followingguidelines are provided

to ensure your safety:

— This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

— When mounting this unit in a partially filled rack, load the rack from the bottom to the top

with the heaviest component at the bottom of the rack.

— If the rack is provided with stabilizing devices, install the stabilizers before mounting or

servicing the unit in the rack. (For translations of this safety warning, refer to the section

“Chassis Warning—Rack-Mounting and Servicing” on page 42.)

Replacing a Rack-Mounted Chassis

Warning Do not use a ramp inclined at more than 10 degrees. (For translations of this safety

warning, refer to the section “Ramp Warning” on page 44.)

Step 3 Follow the instructions in the Cisco 7000 and Cisco 7507 Rack-Mount Kit Installation

Instructions (Document Number 78-1058-xx), which is included with the rack- mounting

hardware, to install the mounting hardware and replacement chassis in the rack.

Step 4 When the replacement chassis is secured in the rack, turn off all power supplies in the

existing system.

Step 5 Proceed to the section “Moving System Components” on page 18 to move the power

supplies and processor modules to the new chassis.

Caution When removing and replacing interface processors, be careful not to strain or bend

network interface cables.

Step 6 When all of the components are moved to the new chassis, ensure that all of the captive

installation screws on the power supplies and all interface processors are tightened.

Step 7 Proceedto the section“Verifying the Installation”on page 24to verify thatall components

are installed correctly.

Step 8 To remove the old chassis (which should now be empty), use a 1/4-inch flat-blade

screwdriver to loosen the four binder-head screws that secure the left and right ears to the

front mounting strips on the equipment rack. (See Figure 7).

Cisco 7000 and Cisco 7507 Chassis Replacement Instructions 13

Page 14

Replacing a Rack-Mounted Chassis

Caution To prevent damage,never attemptto lift orsupport the frontof the chassiswith the plastic

front panels. The panels can break away and allow the chassis to drop.

Step 9 To remove the empty chassis from the rack, position one person in the back of the rack to

push the chassis out the front, and position two people in front of the rack to support the

chassis as it is pushed forward out of the rack.

Caution The following step might shift the chassis’ center of gravity to the front of the rack and

may cause the rack or the chassis to tip or fall. Before proceeding, ensure that you have sufficient

assistance to prevent the rack from toppling and the chassis from falling out of the rack.

Step 10 Slowly push the chassis out of the front of the rack while the two assistants in the front of

the rackgrasp the chassis alongthe metal undersidesbehind the plastic frontpanels. When

the chassis is clear of the rack, lower it to the floor.

Step 11 Follow the safety guidelines in the section “Lifting the Chassis Safely” on page 8, and

remove the empty chassis from the area.

Replacing the Existing Rack-Mounted Chassis

If sufficient rackspace isnot available toinstall bothchassis (ifyou mustremove theexisting system

from the rack to make room for the replacement chassis), you will have to disconnect all network

interface cables and remove the powersupplies before removing the existing system from therack.

Be sureto labelthe interface cables to avoid crossingthem whenyou reconnect themto theinterface

ports. Asyou disconnectcables fromthe interfaceprocessors, complete theconfiguration worksheet

to help you reconnect the cables to the correct ports.

Step 1 Usethe configuration worksheetprovided at the endof this document oryour own method

to label the interface cables and record the port connection for each cable. (For the Cisco

7000, refer to Figure 17, and for the Cisco 7507, refer to Figure 18.)

Step 2 Turn all power supplies OFF.

Note The following warning is for units equipped with DC-input power supplies.

Warning Before performing any of the following procedures, ensure that power is removed from

the DC circuit. To ensure that all power is OFF, locate the circuit breaker on the panel board that

services theDC circuit, switch thecircuit breaker tothe OFF position,and tape the switchhandle of

the circuit breaker in the OFF position. (For translations of this safety warning, refer to the section

“DC Power Disconnection Warning” on page 40.)

Step 3 Afterreviewing thedescriptions in the section“Cable Strain Relief” on page9, disconnect

all power and network interface cables from the rear of the existing system.

14 Cisco 7000 and Cisco 7507 Chassis Replacement Instructions

Page 15

Replacing a Rack-Mounted Chassis

Caution If the existing chassis is installed in an enclosed rack, or if a power strip or other rack

fixture blocks access to the power supply bays, you might have to remove the existing system with

the power supplies intact, and then install them in the replacement chassis before you install that

chassis in the rack. Ensure that you have sufficient assistance to support the chassis and to prevent

the rack from tippingwhile you move the chassisinto or out of the rack.A fully-configured chassis

weighs 145 pounds, and the rear of the chassis is heaviest.

Step 4 Remove all power supplies from the existing system and place them aside (leave the

processor modules installedin the chassis.) Referto the section “Moving Power Supplies”

on page 21

Cisco 7000 and Cisco 7507 Chassis Replacement Instructions 15

Page 16

Replacing a Rack-Mounted Chassis

Step 5 Onthe frontof therack, use a1/4-inch flat-bladescrewdriver toloosen andremove thefour

binder-head screws that secure the left and right ears to the front mounting strips on the

equipment rack. (See Figure 7.) Keep the removedscrews together; you will need them to

secure the replacement chassis in the rack.

Figure 7 Rack Mounting Hardware

Bracket

Chassis ear with

captive sliding

H2292

grommets

Warning

M4 x 10-mm long Phillips

flat-head screws (to attach

ears to chassis)

The following step might shift the chassis’ center of gravity to the front of the rack and

10-32 x 5/8-inch long Phillips

pan-head screws with integral

square cone washers

(for mounting brackets and

chassis ears to rack posts)

may cause the rack or the chassis to tip or fall. Before proceeding, ensure that you have sufficient

assistance to prevent the rack from toppling and the chassis from falling out of the rack. Never

attempt to lift or support the front of the chassis with the plastic front panels.The panels can break

away and allow the chassis to drop.

16 Cisco 7000 and Cisco 7507 Chassis Replacement Instructions

Page 17

Replacing a Rack-Mounted Chassis

Step 6 Position one person in the back of the rack to push the chassis out the front, and position

two peoplein front of therack to supportthe chassis and lower it to thefloor as it is pushed

forward out of the rack. Slowly push the chassis out of the front of the rack while the two

assistants in the front of the rack grasp the chassis along the metal undersides behind the

plastic front panels. When the chassis is clear of the rack, lower it to the floor.

Step 7 Positionthe removedchassis sothat you willhave roomat the rearof the chassisto remove

the processor modules, and ensure that it will not be in the way when you install the

replacement chassis in the rack.

Step 8 Usea Number 2 Phillips screwdriver to remove the chassis ears from theremoved chassis

and install them on the replacement chassis in the same position. Figure 7 shows the ears

mounted on the front of the chassis; if you are installing the system with the rear of the

chassis facing out of the front of the rack, use the mounting holes nearest the edge of the

ears (farthest from the bend) to mount them to the chassis.

Warning If you must lift the new chassis with the power supplies installed, ensure that you have

sufficient assistance to lift the chassis and support the rack. A fully configured chassis weighs

145 pounds, and the rear of the chassis is heaviest.

Step 9 With one person positioned on each sideof the replacementchassis, grasp the undersideof

the chassisbehind thefront plastic panelsand liftthe replacement chassisup untilit is level

with the rails in the rack.

Step 10 Insert the rear of the chassisinto the rack and lower it until the bottom of the chassis rests

on the rails.

Step 11 Slide the chassis back into the rack until the ears on the chassis are flush against the front

mounting strip on the rack.

Step 12 Use the four binder-head screws you removed in Step 5 to secure the ears to the front

mounting strip on the rack. (See Figure 7).

Step 13 Proceed to the section “Moving System Components” on page 18 to move the power

supplies and processor modules to the new chassis.

Caution When removing and replacing interface processors, be careful not to strain or bend

network interface cables.

Step 14 Whenall of the componentsare moved tothe newchassis, reconnect all interfacecables to

the interface ports. Ifyou filled out the configuration worksheet, use it asa guideline. (For

the Cisco 7000, refer to Figure 17, and for the Cisco 7507, refer to Figure 18.)

Step 15 Proceedto the section “Verifyingthe Installation” onpage 24 to verify thatall components

are installed correctly.

Cisco 7000 and Cisco 7507 Chassis Replacement Instructions 17

Page 18

Moving System Components

Moving System Components

The following sections describe the procedures for removing each processor module and power

supply from the old chassis and installing it in the new chassis. Move and install all processor

modules before you move the power supplies. If you removed your existing chassis from an

equipment rack, the powersupplies should already be removed; however,do not install them in the

replacement chassis until all processor modules are installed. Each interface processor slot in the

replacement chassis contains a blank board carrier. Remove the blank carriers individually as you

prepare to move each interface processor from the corresponding slot in the existing chassis.

If you are able to place both chassis close enough to avoid straining the connected interface cables

when you move the interface processors to the new chassis, you can leave the interface cables

connected. If you must disconnect the cables, label each cable with its slot and port number before

you disconnect it. You can alsouse the optional configuration worksheet provided at the endof this

document to record the cable positions. (For the Cisco 7000, refer to Figure 17, and for the Cisco

7507, refer to Figure 18.)

Caution Be sure to wear an ESD-prevention device while performing these steps. Review the

guidelines in the section “Preventing Electrostatic Discharge Damage” on page 10 if necessary.

Step 1 Place the existing and replacement chassis side by side, if possible, and ensure that your

path between the two chassis is unobstructed.

Step 2 Slipon agrounding strap orother ESD-preventiondevice andattach it toone ofthe captive

installation screwson a power supply inthe rear of the chassis. (SeeFigure 1 or Figure 2.)

If you already removed the power supplies, clip the ESD-preventive strap to the captive

screw on any unfinished chassis surface.

Step 3 On the existing system, turn all power supply switches OFF (O) if you have not already

done so.

Step 4 On each interface cable connected to an interface processor, check the available slack to

determine whether removing the interface processor will strain the cable. Do not risk

straining the cables; if you are not sure if there is enough slack in the cable, disconnect it

before removing the interface processor.

Step 5 Checkthe slack on cables thatare connected to the RP(in the Cisco 7000) orRSP2 (in the

Cisco 7507) console or auxiliary ports and also disconnect those cables if necessary.

Step 6 If you must disconnect the cables, label each one and use the configuration worksheet at

theend ofthis documentto recordthe portconnections ofeach cableto avoid crossingthem

when you reconnect them to the new chassis. (For the Cisco 7000, refer to Figure 17, and

for the Cisco 7507, refer to Figure 18.) The section “Cable Strain Relief” on page 9

describes the different methods of strain relief used on the various interface types.

Moving the Processor Modules

Before removing any of the processor modules from the existing chassis, ensure that all system

power is off. Do not turn on the power for the replacement chassis until you have verified that all

components are installed properly.

After looseningthe captiveinstallation screws,use the ejectorlevers toremove andinstall processor

modules. The ejectorlevers help toensure that backplane connectorson the card are fully seated in,

or fully ejected from, the backplane. (Refer to the ejector lever description on page 5.)

18 Cisco 7000 and Cisco 7507 Chassis Replacement Instructions

Page 19

Moving System Components

Failureto use theejector leverscould result ina partialbackplane connectionand subsequentsystem

crash. Also,be sure totighten both the topand bottom captive installationscrews oneach module to

ensure that it will remain seated properly. When replacing components, work from right to left.

When you remove a processor module, immediatelyinstall it in the newchassis and secure it in the

identical slotbefore removing thenext processor module.Before removing processormodules, first

remove theblank board carrier from thecorresponding slot in thenew chassis so thatyou can move

the processor module directly into the same slot in the new chassis.

Follow these steps to move the processor modules to the new chassis:

Step 1 Use a screwdriver (Number 2 Phillips or 1/4-inch flat-blade) to loosen the captive

installation screws at the top and bottom of the faceplate. (See Figure 8a).

Figure 8 Bottom Ejector Lever and Captive Installation Screw

a

Processor

module

carrier guide

Captive

installation

screw

b

Bottom ejector lever

Processor module

slot

c

Stop

immediately

on contact

Cisco 7000 and Cisco 7507 Chassis Replacement Instructions 19

H1482a

Page 20

Moving System Components

Step 2 Place your thumbs on the upper and lower ejector levers and simultaneously push the top

Step 3 Grasp the carrier handle with one hand and place your other hand under the carrier to

Figure 9 Handling a Processor Module During Installation

leverup andthe bottom lever down to releasethe boardconnector from thebackplane. (See

Figure 8c.)

support and guide it out of the slot. (See Figure 9.) Avoid touching the board or any

connector pins.

H1355a

Step 4

Carefully pull the carrierstraight out of the slot, keepingyour other hand under the carrier

to guide it. (See Figure 9.) Keep the carrier at a 90-degree orientation to the backplane.

Immediately proceed to thefollowing step to install theremoved board in thereplacement

chassis.

Caution In the Cisco 7000, you must install the RP in the slot labeled RP, and the SP (or SSP) in

the slot labeled SP. The RP slot is the far right slot when viewing the chassis from the rear, and the

SP slot is immediately to the left of the RP. The interface processors can be installed in any of the

interface processor slots, labeled0-4. The slots are keyed forcorrect installation. Forcing the RP or

SP into the wrong slot can damage the backplane and board connectors.

In theCisco 7507, you mustinstall the RSP2 inslot 2 or 3.The interface processors can be installed

in any of the interface processor slots, labeled 0 and 1, and 4 through 6. The slots are keyed for

correct installation. Forcing a processor module into the wrong slot can damage the backplane and

board connectors.

Step 5 Place the back of the carrier in the appropriate slot in the new chassis and align the notch

on the top and bottom of the carrier with the groove in the top and bottom of the chassis

slot. (See Figure 8a and Figure 8b).

20 Cisco 7000 and Cisco 7507 Chassis Replacement Instructions

Page 21

Moving System Components

Step 6 While keeping the carrier at a 90-degree orientation to the backplane, carefully slide the

carrierinto theslot untilthe backof thefaceplatemakes contactwith theejector levers.(See

Figure 8b.)

Step 7 Usingthe thumb and forefinger of each hand, simultaneouslypush the top lever down and

the bottom lever up 90 degrees to fully seat the board connectors in the backplane. (See

Figure 8c.)

Caution Do notuse unnecessaryforce when installingprocessor modules. Always guidethe board

carrier into the slot only until the carrier faceplate is flush against the ejector lever, then use the

ejector levers to pushthe interface processor fully intothe slot and seat itin the backplane properly.

Step 8 Use a screwdriver (Number 2 Phillips or 1/4-inch flat-blade) to tighten the captive

installation screws on the top and bottom of the faceplate. (See Figure 8).

Step 9 RepeatSteps 1 through 8for each remaining processormodule, working from rightto left.

Before removing a processor module from the existing chassis, remove the blank board

carrier from the corresponding slot in the replacement chassis. Try to replace interface

processors in the same slot number you removed them from to avoid confusion when

reconnecting cables and checking the installation.

Step 10 Proceed to the next section to move the power supplies.

Note Leave the blank board carriers installed in all unfilled interface processor slots.

Moving Power Supplies

You can insert the power supplies and connect the power cables, but do not turn on system power

until you are ready to restart the system and check the installation. Always install the first power

supply in thelower power supply bayand the second, if any, in the upper bay. Remember to tighten

the captive installation screw on the top of each power supply. The screw prevents the supply from

becoming dislodged from the power connections inside the chassis and also provides proper

grounding for the system.

Follow these steps to move a power supply:

Step 1 If you have already removed all power supplies, proceed to Step 7.

Step 2 Ensure that the switch on each power supply is turned fully to OFF (O), then disconnect

Step 3 Disconnect the power cable from each power source.

Step 4 Disconnect the power cable from each power supply.

Step 5 Usea screwdriverto loosen the captive installationscrew on the power supply in the lower

all power cords from the power sources.

bay.

Step 6 Grasp the power supply handle and pull the supply out of the bay. Place one hand

underneath tosupport thebottom ofthe supplyas youpull itout ofthe bay. (SeeFigure 10.)

Immediately proceed to the following step to install the removed power supply in the

replacement chassis.

Cisco 7000 and Cisco 7507 Chassis Replacement Instructions 21

Page 22

Moving System Components

Note Use bothhands to handlepower supplies.Each weighs20 pounds. Ifthe powersupply resists

when you attempt to pull it out of the bay, the switch is probably not fully in the OFF (O) position,

or the captive installation screwat the top ofthe supply is notfully loosened. Turnthe power switch

fully counterclockwise to OFF (O), and check the captive installation screw, then try removing the

supply again.

Figure 10 Handling a Power Supply (AC-Input Power Supply Shown)

Captive

installation

screw

Step 7

DC FAIL

AC POWER

H1356a

I

0

Fill the lower power supply bay first. Insert the rear of the power supply into the bay and

align it so that it will go straight into the bay.

Step 8 Pushthe power supply all the wayinto the bay. Do notuse unnecessary force; firmly push

the supply back into the bay until the power supply front panel is flush against the chassis

rear panel.

Caution When inserting a power supply into the bay, do not useunnecessary force; slamming the

powersupply into thebay candamage the connectorson therear of the supply andinside thechassis.

Step 9 Use a screwdriver to tighten the captive installation screw on the top of the power supply.

Caution Alwaystighten the captive installationscrew atthe topof the powersupply beforeturning

on the power switch. This screw prevents the power supply from shifting away from the internal

connector and provides proper grounding for the supply.

Step 10 If you are removing or installing a second power supply, use a screwdriver to remove the

cover plate from the upper power supply bay. Store the removedcover plate and replace it

whenever the system is operating with one power supply.

Step 11 Repeat Steps 2 through 9 for the second power supply, if any.

Step 12 On each power supply in the new chassis, push the cable retention clip down, away from

the power cord port, and plug in the power cord.

22 Cisco 7000 and Cisco 7507 Chassis Replacement Instructions

Page 23

Moving System Components

Step 13 To secure the AC-input cable in the power supply AC receptacle, push up the cable

retention clip up until it snaps into place around the connector.

To secure the DC-input cable to the power supply, attach the three leads to the terminal

block, and thenattach two nyloncable ties around theDC-input cable and thebracket near

the terminal block. (See Figure 11.) Color code depends on your DC source.

Warning Whenstranded wiring isrequired, useapproved wiring terminations,such asclosed-loop

or spade-type with upturned lugs. These terminations should be the appropriate size for the wires

and shouldclamp both theinsulation and conductor. (For translationsof this safetywarning, referto

the section “DC Power Supply Warning” on page 44.)

Warning The illustration shows the DC power supply terminal block. Wire the DC power supply

using the appropriate lugsat the wiring end, as illustrated. Theproper wiring sequence is ground to

ground, positiveto positive (line toL), and negativeto negative (neutralto N). Note that the ground

wire shouldalways beconnected first anddisconnected last. (For translationsof this safetywarning,

refer to the section “DC Power Supply Wiring Warning” on page 45.)

Step 14 Place the terminal block cover over the terminal block and secure it with the two captive

installation screws. (See Figure 11.)

Figure 11 DC-Input Power Supply Cable Connections

DO NOT SHIP WITH POWER SUPPLY

INSTALLED

FASTENER TO BE FULLY ENGAGED

BEFORE OPERATING POWER SUPPLY

Captive installation

OUT FAIL

INPUT POWER

screw

Power leads attached

to terminal block

( ) negative

( ) positive

( ) ground

Nylon ties on cable

and metal bracket

INPUT VOLTAGE : 40-72 V=

Step 15

INPUT CURRENT : 24-13A

Connect the opposite end of each power cable to an appropriate power source.

H2530

Caution Do not turn on any power supplies until you are ready to power up the system. The

interlock switch that locks the power supply in the slot also turns on the system power.

Step 16 Proceedto the section“Verifying the Installation”on page 24to applypower andcheck the

installation.

Cisco 7000 and Cisco 7507 Chassis Replacement Instructions 23

Page 24

Verifying the Installation

Verifying the Installation

This section provides instructions for first ensuring that all connections are secure and then for

restarting the system and verifying that it operates correctly. If the system does not start up and

operate asexpected, the troubleshootingprocedures in this sectionwill help you isolate the cause of

the problem.

Checking Connections

Perform a final installation check of all components and cable connections as follows:

Step 1 Checkthe processor modules to makesure that eachis inserted allthe way intoits slot, and

that both the top and bottom captive installation screws are tightened.

Step 2 Checkthe interfacecable connections tothe interfaceprocessors, and ensurethat all cables

are fully seated in the ports and all strain relief systems are engaged.

Step 3 Ensure that the console cable is secured to the console port on the RP (in the Cisco 7000)

or the RSP2 (in the Cisco 7507), and that the console terminal is turned ON.

Step 4 Check the power supplies for the following:

• Each powersupply is insertedall the wayinto its bay, andthe captiveinstallation screw

on each one is tightened.

Restarting the System

When you have checked all of the connection points, you will restart the system by turning on the

power supplies, andthen verify that the system is operating properly by observing the LEDs on the

rear of the system.

Note The following warning is for units equipped with DC-input power supplies.

Warning Afterwiring theDC powersupply,removethe tapefrom thecircuit breakerswitch handle

and reinstatepower by moving the handleof the circuitbreaker to theON position. (Fortranslations

of this safety warning, refer to the section “DC Power Connection Warning” on page 46.)

Step 1 Turn ONthe lowerpowersupply byturning thepower supplyswitch clockwiseone-quarter

Note Ifthe powersupply switchresists, thepower supplyis probablynot fullyinserted intothe bay.

Turnthe power switch off (fully counterclockwiseto O), pull the power supply outof the bay about

two inches, then push the power supply firmly back into the slot. Do not slam the supply into the

slot; doing so can damage the connectors on the supply and the backplane. Tighten the captive

installation screw before proceeding.

• All power supply cables are inserted into the power supply and secured with the cable

retention clip.

turn. The lower power LED on the front of the chassis will go on.

24 Cisco 7000 and Cisco 7507 Chassis Replacement Instructions

Page 25

Verifying the Installation

Step 2 Afterturning onthe lower power supply, turnON theupper powersupply (ifone ispresent)

for redundant power. The upper power LED on the front of the chassis will go on.

Step 3 While the system initializes, the boot error LED on the RP (or the CPU halt LED on the

RSP2 and RP) goes on for about five seconds or less, then goes out when the boot is

complete. The interface processor LEDs also go on in irregular sequence as the RP (or

RSP2) initializes each one.

Step 4 Afterthe system boots thesoftware and initializes the interface processors (approximately

30 seconds), verify that the RP (or RSP2) LEDs are in the following states:

• Normal LED is on

• CPU halt LED is off (on the RSP2 and RP)

• Boot error LED is off (on the RP)

Step 5 Verify thatall of the enabledLEDs on all interfaceprocessors (and on theSP or SSP in the

Cisco 7000) are on.

Step 6 Verify that the console terminal displays a script and system banner.

When you have verified all of the conditions in Steps 1 through 6, the replacement procedure is

complete, and you can now resume normal operation.

An errorcondition exists ifno indicators go onat power upor after initialization, orif the booterror

or CPUhalt LEDs goon andremain on. Ifthis happens, proceedto thesection “Troubleshootingthe

Installation” to isolate the problem.

Cisco 7000 and Cisco 7507 Chassis Replacement Instructions 25

Page 26

Verifying the Installation

Troubleshooting the Installation

Followthe procedures inthis section ifthe system doesnot restart andboot as expected. Mostoften,

problems you encounter while replacing the components in a new chassis are caused by power

supplies or processor modules that are not properly installed and therefore are not connected

properly inside thechassis. Use the followingdescriptions of the normal startupsequence to isolate

the problem, then use the troubleshooting procedures whenever the system fails to operate as

expected. If you are unable to successfully restart the system, contact a service representative.

LED Descriptions

Following are descriptions ofthe functions of the LEDs on the power supplies, chassis front panel,

and the RP. These are the states you should observe when you restart the system.

Power Supply LEDs

Each AC-input powersupply contains ACpower and DCfail LEDs anda power switchas shown in

Figure 12. The green AC power LED indicates that the power supply is turned on and is receiving

inputAC power.The yellow DCfailLED isnormally off,butgoes onif thepower supplyshuts down

for any of the following reasons:

• Power supply DCsection failure, which could be causedby loss of AC power (input line failure

or operator turned off system power), or an actual failure in the power supply

• Power supply shutdown initiated by the power supply because it detected an out-of-tolerance

temperature or voltage condition in the power supply

Figure 12 Power Supply LEDs

Captive

installation

DC FAIL

AC POWER

screw

Power supply

front panel

I

O

DC FAIL

AC POWER

LEDs

AC power

receptacle

On/off switch

26 Cisco 7000 and Cisco 7507 Chassis Replacement Instructions

H1314a

Locking device

Page 27

Verifying the Installation

In systems with a single DC-input power supply, and in systems with redundant power when both

powersupplies are shuttingdown, the outfail LED goeson momentarily asthe system rampsdown,

but goes out when the power supply has completely shut down. In systems with redundant power

and one power supply still active, the out fail LED on the failed power supply will remain on

(powered by the active supply).

The DC-input power supply LEDs include the input power LED and the out fail LED.

(See Figure 13.) The green inputpower LED is onwhen the input power isapplied. The yellow out

fail LED is normally off, but flashes at power on for a lamp test.

The out fail LED goes on if the power supply shuts down for either of the following reasons:

• Power supply DC-output failure, which could be caused by loss of DC-input power (input line

failure or operator turned off system power) or an actual failure in the DC-input power supply

• Power supply shutdown, initiated by the power supply because it detected an out-of-tolerance

temperature or voltage condition in the power supply

Figure 13 DC-Input Power Supply LEDs (Similar Location to the AC-Input Power Supply)

OUT FAIL

INPUT POWER

H2498

Caution

installation screw is tightened before restarting the system. The captive installation screw provides

proper groundingand preventsthe powersupply from slidingout ofthe bay anddislodging from the

backplane power connectors.

When youturn the power supplyon to powerup the system,the green ACpower LED onthe power

supply should go on and remain on, and the DC fail LED should remain off. The AC power LED

will not go on if the power supply switch is not fullyin the on (|) position, or if the power supplyis

not properly seated in the bay, and the connectors are not making proper contact,or if the supply is

not receiving AC input power.

The yellow DC fail LED is normally off, but goes on if the power supply shuts down for either of

the following reasons:

Always ensure that each power supply is fully seated in the bay and that the captive

• Power supply DCsection failure, which could be causedby loss of AC power (input line failure

or operator turned off system power), or an actual failure in the power supply

• Power supply shutdown, which is initiated by the power supply because it detected an

out-of-tolerance temperature or voltage condition in the power supply

Cisco 7000 and Cisco 7507 Chassis Replacement Instructions 27

Page 28

Verifying the Installation

In systems with a single power supply, and in systems with redundant power when both power

supplies are being shut down, the DC fail (or output fail) LED goes on momentarily as the system

ramps down, but goes out when the power supply has completely shut down. In systems with

redundant power and one power supply still active, the DC fail (or output fail) LED on the failed

power supply will remain on (powered by the active supply).

It is unlikely that the power supply will shut down during startup because of an overtemperature

condition; it can, however, shut down if it detects an overvoltage or undervoltage condition during

startup. Refer to the Cisco 7000 Hardware Installation and Maintenance or Cisco 7507 Hardware

Installation and Maintenance publications for descriptions of environmental monitoring functions.

System Front Panel LEDs

Three system status LEDs on the front of thechassis, shown in Figure 14, indicate the status of the

system and the power supplies. The normal LED (which is controlled by the RP or RSP2) goes on

to indicate that the system is in a normal operating state. The upper power and lower power LEDs

go on toindicate that a powersupply is installed in theindicated power supply bayand is providing

power tothe system. The chassis front panelupper or lower power LED shouldgo on whenever the

power supply in the corresponding bay is turned on, and thepower LED on the power supply is on.

Figure 14 Front Panel LEDs (Cisco 7000 Shown—Identical to Cisco 7507)

UPPER

POWER

LOWER

POWER

NORMAL

UPPER

LOWER

POWER

NORMAL

POWER

Cisco 7000

H1407a

28 Cisco 7000 and Cisco 7507 Chassis Replacement Instructions

Page 29

Verifying the Installation

Route Processor LEDs (Cisco 7000)

Figure 15 showsthe LEDs on an RP installedin the chassis. The three LEDson the RP indicate the

system andRP status. Whenthe system isturned on orrestarted, the booterror LED goeson for one

or two seconds, then goes out. The CPU halt LED, which goes on only if the system detects a

processor hardwarefailure, should nevergo on. If the booterror LED remains onfor more than five

seconds, the system is unable to boot and should be restarted. A successful boot is indicated when

the boot error LED goes out; however, this does not necessarily mean that the system has reached

normal operation. During normal operation, the CPU halt and boot error LEDs should be off, and

the normal LED should be on.

Figure 15 RP LEDs

NORMAL

CPU HALT

BOOT ERROR

H1363a

Cisco 7000 and Cisco 7507 Chassis Replacement Instructions 29

Page 30

Verifying the Installation

Route Switch Processor LEDs (Cisco 7507)

Figure 16 showsthe two LEDson the RSP2.They indicate thesystem and RSP2 status.The normal

LED goeson to indicate thatthe system is operational.During normal operation,the CPU halt LED

on the RSP2 should be off and stay off unless the system detects a processor hardware failure. A

successful boot is indicated when the normal LED comes on and stays on; however, this does not

necessarily mean thatthe system has reached normaloperation. The slot 0and slot 1 LEDs indicate

which PCMCIA slot is in use and blinkwhen either slot is being accessed by the system, if a Flash

memory card is installed.

Figure 16 RSP2 LEDs

NORMAL

SLOT 1

SLOT 0

MASTER

SLAVE

EJECT

SLAVE/MASTER

CPU HALT

RESET

H3071

30 Cisco 7000 and Cisco 7507 Chassis Replacement Instructions

Page 31

Interface Processor, SP, and SSP LEDs

The SP or SSP (onthe Cisco 7000) and all interface processors contain anenabled LED. When on,

this LED indicatesthat the SP orinterface processor is operational andthat it is powered up. Itdoes

not necessarily mean that the interface ports on the interface processors are functional or enabled.

When the bootsequence iscomplete, allof theenabled LEDs(on theSP andall interfaceprocessors)

should go on. If any do not go on, one of the following errors is indicated:

• The interface processor or SP is not installed correctly (it is not fully seated in the backplane

connector).

• The SP or interface processor has failed.

System Startup Sequence

By checking the state of the LEDs, you can determine when and where the system failed in the

startup sequence. Thefunctions of the chassisfront panel LEDs areduplicated on the RP(or RSP2)

and the power supplies.Because you turn on thesystem power withthe power supplyswitches, it is

easiest to observe the startup behavior from the rear of the chassis.

Most often,problems youencounter while replacingthe componentsin a new chassis willbe caused

by power supplies or processor modules that are not properly installed and, therefore, are not

connected properlyinside thechassis. Usethe followingdescriptions ofthe normal startupsequence

to isolate theproblem, then use the troubleshootingprocedures wherever thesystem fails to operate

as expected.

Verifying the Installation

When you start up the system by turning on the power supply switches (lower power supply first,

upper power supply second) you should observe the following:

Step 1 When you turn the lower power supply ON, the power LED on the lower power supply

should go on, and the DC fail (or output fail) LED should remain off.

• If the power supply switch resists, the power supply is probably not fully inserted into

the bay. Turn the power switch OFF (fully counterclockwise to O), pull the power

supply outof the bay abouttwo inches, thenpush the power supplyfirmly back into the

slot. Do not slam the supply into the slot; doing so can damage the connectors on the

supply and the backplane. Tighten the captive installation screw before proceeding.

• If thepowerLED goes on,the power sourceis good,and thepower supplyis functional.

• If theDC fail (oroutput fail) LED goeson, or ifthe power LEDdoes not goon, suspect

the power supplyor the power source.Try topower up thesystem withthe upper power

supply if one is present.

Step 2 When you turn the upper power supply ON, the power LED on the upper power supply

should go on, and the DC fail (or output fail) LED should remain off.

• If thepowerLED goes on,the power sourceis good,and thepower supplyis functional.

• If theDC fail (oroutput fail) LED goeson, or ifthe power LEDdoes not goon, suspect

the power supplyor thepower source.If thelowerpower supplyis functioningproperly,

continue monitoring the startup sequence.

• If the LEDs on one or both power supplies fail to go on as expected, suspect a power

supply or input power failure. Before contacting a service representative, refer to the

Cisco 7000 Hardware Installation and Maintenance or Cisco 7507 Hardware

Installation and Maintenance publications for power subsystem troubleshooting

procedures.

Cisco 7000 and Cisco 7507 Chassis Replacement Instructions 31

Page 32

Verifying the Installation

Step 3 Listen for the system blower. It generates about 60 dB, so you should immediately hear it

Step 4 Whenyou have verified thatthe power suppliesare functioningproperly,observe theLEDs

start operating. If youdetermine that the power suppliesare functioning normally and that

the blower isfaulty,contact a servicerepresentative.If the systemblower doesnot function

properly at initial startup, there are no installation adjustments that you should make.

on the RP (or RSP2). While the system initializes, the boot error LED on the RP goes on

for about five seconds or less, then goes out when the boot is complete.

• If the boot error goes on then goes off as expected, proceed to Step 5.

• If noneof the RP (orRSP2) LEDs goon, suspect thatit is notproperly connected to the

backplane connector. Turnall power supplyswitches OFF, then usethe ejector levers at

the top and bottom of the RP (or RSP2) faceplate to ensure that it is seated properly.

Push the top lever down while pushing the bottom lever up until both levers are at a

90-degree orientation to the rear of the chassis.(Refer to page 19 for a description and

illustration of the ejector levers.) Tighten both the top and bottom captive installation

screws, then restart the system.

• If all RP(or RSP2) LEDs stillfail to go on,suspect that an improperlyconnected SP or

interface processor hashung the bus. Turn all power supplyswitches OFF,then use the

ejector levers to ensure that each board is seated properly. On each ejector lever pair,

push the top lever down while pushing the bottom lever up until both levers are at a

90-degree orientation to the rear of the chassis.(Refer to page 19 for a description and

illustration of theejector levers.)Tighten all captive installation screws, thenrestart the

system.

• Proceed with the startup verification to determine whether or not the RP (or RSP2)

initializes the remaining processor modules. If it does continue, and the enabled LED

goeson andthe remainingprocessor modulesdo notgo on,allow thesystem tocontinue

operation and contact a service representative.

• If the boot errorLED (on the RP) stays on longerthan 10 seconds, or if itgoes on after

system initialization, a boot error has occurred. Restart the system. If this does not

correct the problem, suspect a system software error.

Step 5 The CPU halt LED on the RP (or RSP2) should always remain OFF. If it goes on during

the startup sequence, the system has encountered a processor hardware error.

• Turnall powerOFF,then removethe RP (orRSP2) and checkthe configuration register

settings.Refer tothe Cisco7000 Hardware Installationand Maintenanceor Cisco7507

Hardware Installation and Maintenance publications for a description of the settings.

• If the LEDgoes on duringa second startupattempt, suspect aprocessor hardware error.

Step 6 During the boot process, the LEDs on most of the interfaces go on in irregular sequence;

this does not indicate correct system startup or failure.

32 Cisco 7000 and Cisco 7507 Chassis Replacement Instructions

Page 33

Verifying the Installation

Step 7 When the system boot is complete, the RP (or RSP2) begins to initialize the interface

processors. During this initialization, the LEDs on each interface processor behave

differently (most flash on and off). The enabled LED on each interface processor goes on

when initialization has been completed.

• If theenabled LED on theSP (in theCisco 7000) andall interface processorsgo on, the

system has booted successfully, and the system is now functional.

• If the RP (or RSP2) LEDs previously indicated a successful system boot, but none of

the enabled LEDs goes on, on the SP (in the Cisco 7000) or the interface processors,

suspect that one of them has shifted out of its backplane connector and hung the bus.

Turn all system power OFF, then use the ejector levers to ensure that the SP and each

interface processor is fully seated in the backplane. Push the top lever down while

pushing the bottom lever up until both levers are at a 90-degree orientation to the rear

of the chassis. (Referto page 19 for a description and illustrationof the ejector levers.)

Tightenthe captive installationscrewsat thetop andbottom ofthe SPand eachinterface

processor, then restart the system by turning ON all power supply switches.

• If the enabled LED on a single interface processor is not on, suspect that the interface

processor has shifted out of its slot. You do not have to turn off the system power to

remove and replace an interface processor. Use the ejector levers to ensure that the

interface processor is seated in the backplane. Push the top lever down while pushing

the bottom lever up until both levers are at a 90-degree orientation to the rear of the

chassis.(Refer topage 19 fora descriptionand illustrationofthe ejectorlevers.)Tighten

the captiveinstallation screwsat the topand bottomof theinterface processorfaceplate.

After thesystem reinitializes theinterfaces, the enabledLED on theinterface processor

should go on.

• If the enabled LEDs still fail to go on after performing these steps, suspect that the SP

(on the Cisco 7000) or an interface processor has failed.

Step 8 When the system boot is complete, and the SP (on the Cisco 7000) and all interface

processors have been initialized, the console screen displays a script and system banner.

• If all ofthe previous conditionsare met and this banneris displayed, the systemstartup

was successful, and your installation is complete.

• If an error message is displayed on the terminal, refer to the Router Products

Configuration Guide publication for error message definitions.

• If theconsole screen is blank,check the terminaland ensure that itis turned on and that

the console cable is correctly connected between the terminal and the console port on

the RP (or RSP2).

• Check theterminal settingsand ensurethat the terminalis setfor 9600 baud,8 data bits,

no parity, and 2 stop bits.

• If theterminal isset correctlyand still fails tooperate, suspectthat theterminal is faulty.

Connect adifferent terminaland thenrestart the systemby turningON all power supply

switches.

If thesystem stillfails to startup oroperate properly afteryou have performedthese troubleshooting

procedures, or if you isolate the cause of the problem to a failed component, contact a service

representative for further assistance.

Thiscompletes thechassis replacementprocedure.For completesystem hardwaredescriptions, refer

to theCisco 7000HardwareInstallation andMaintenance orCisco 7507 Hardware Installationand

Maintenance publication. For software command descriptions and examples, refer to the Router

Products Command Reference publication.

Cisco 7000 and Cisco 7507 Chassis Replacement Instructions 33

Page 34

Verifying the Installation

Figure 17 Cisco 7000 Port Configuration Worksheet

O

01234SPRP

I

Chassis

serial number

Slot 0

Circle one:

AIP/CIP/EIP/FIP/

FSIP/HIP/TRIP

0/0

0/1

0/2

0/3

0/4

0/5

0/6

0/7

Router name

Location

Slot 1

Circle one:

AIP/CIP/EIP/FIP/

FSIP/HIP/TRIP

1/0

1/1

1/2

1/3

1/4

1/5

1/6

1/7

Slot 2

Circle one:

AIP/CIP/EIP/FIP/

FSIP/HIP/TRIP

2/0

2/1

2/2

2/3

2/4

2/5

2/6

2/7

Prepared by

Date

Slot 3

Circle one:

AIP/CIP/EIP/FIP/

FSIP/HIP/TRIP

3/0

3/1

3/2

3/3

3/4

3/5

3/6

3/7

Slot 4

Circle one:

AIP/CIP/EIP/FIP/

FSIP/HIP/TRIP

4/0

4/1

4/2

4/3

4/4

4/5

4/6

4/7

H1324a

34 Cisco 7000 and Cisco 7507 Chassis Replacement Instructions

Page 35

Figure 18 Cisco 7507 Port Configuration Worksheet

0123456

I

O

Verifying the Installation

Chassis

serial number

Slot 0

Circle one:

AIP/CIP/EIP/FEIP/FIP/

FSIP/HIP/TRIP/MIP

0/0

0/1

0/2

0/3

0/4

0/5

0/6

0/7

Router name

Location

Slot 1

Circle one:

AIP/CIP/EIP/FEIP/FIP/

FSIP/HIP/TRIP/MIP

1/0

1/1

1/2

1/3

1/4

1/5

1/6

1/7

Slot 2

RSP2

Slot 3

RSP2

Slot 4

Circle one:

AIP/CIP/EIP/FEIP/FIP/

FSIP/HIP/TRIP/MIP

4/0

4/1

4/2

4/3

4/4

4/5

4/6

4/7

Prepared by

Date

Slot 5

Circle one:

AIP/CIP/EIP/FEIP/FIP/

FSIP/HIP/TRIP/MIP

5/0

5/1

5/2

5/3

5/4

5/5

5/6

5/7

Slot 6

Circle one:

AIP/CIP/EIP/FEIP/FIP/

FSIP/HIP/TRIP/MIP

6/0

6/1

6/2