Page 1

MANUAL FOR

BURNERS

BRULEURS

BRENNER

QUEMADORES

BRUCIATORI

- INSTALLATION

- OPERATION

- MAINTENANCE

LIGHT OIL BURNERS

G18 G-.SP

PG25 G-.SP

PG30 G-.TN

M03978CA Rev. 00 10/99

FOREWORD Page 2

PARTE I: INSTALLATION Page 4

PARTE II: OPERATION Page 11

PARTE III: MAINTENANCE Page 12

APPENDIX Page 18

Complying with

EMC 89/336/CEE

LV 73/23/CEE

Technical Documentation CIB Unigas S.p.a. - Campodarsego (PD)

Page 2

PREFACE

THIS MANUAL IS SUPPLIED AS AN INTEGRAL AND ESSENTIAL PART OF THE PRODUCT AND MUST BE DELIVERED

TO THE USER.

INFORMATION INCLUDED IN THIS SECTION ARE DEDICATED BOTH TO THE USER AND TO PERSONNEL FOLLOWING

PRODUCT INSTALLATION AND MAINTENANCE.

THE USER WILL FIND FURTHER INFORMATIONS ABOUT OPERATING AND USE RESTRICTIONS, IN THE SECOND

SECTION OF THIS MANUAL. WE HIGHLY COMMEND TO READ IT.

CAREFULLY KEEP THIS MANUAL FOR FUTURE REFERENCE.

1) GENERAL INTRODUCTION

The equipment must be installed in compliance with the

regulations in force, following the manufacturer’s instructions,

by qualified personnel.

Qualified personnel means those having technical knowledge

in the field of components for civil or industrial heating

systems, sanitary hot water generation and particularly

service centres authorised by the manufacturer.

Improper installation may cause injury to people and animals,

or damage to property, for which the manufacturer cannot be

held liable.

* Remove all packaging material and inspect the equipment

for integrity.

In case of any doubt, do not use the unit - contact the supplier.

The packaging materials (wooden crate, nails, fastening

devices, plastic bags, foamed polystyrene, etc), should not be

left within the reach of children, as they may prove harmful.

* Before any cleaning or servicing operation, disconnect the

unit from the mains by turning the master switch OFF, and/or

through the cut-out devices that are provided.

* Make sure that inlet or exhaust grilles are unobstructed.

* In case of breakdown and/or defective unit operation,

disconnect the unit. Make no attempt to repair the unit or take

any direct action.

Contact qualified personnel only.

Units shall be repaired exclusively by a servicing centre, duly

authorised by the manufacturer, with original spare parts.

Failure to comply with the above instructions is likely to impair

the unit’s safety.

To ensure equipment efficiency and proper operation, it is

essential that maintenance operations are performed by

qualified personnel at regular intervals, following the

manufacturer’s instructions.

* When a decision is made to discontinue the use of the

equipment, those parts likely to constitute sources of danger

shall be made harmless.

* In case the equipment is to be sold or transferred to another

user, or in case the original user should move and leave the

unit behind, make sure that these instructions accompany the

equipment at all times so that they can be consulted by the

new owner and/or the installer.

* For all the units that have been modified or have options

fitted then original accessory equipment only shall be used.

* This unit shall be employed exclusively for the use for which

it is meant. Any other use shall be considered as improper

and, therefore, dangerous.

The manufacturer shall not be held liable, by agreement or

otherwise, for damages resulting from improper installation,

use and failure to comply with the instructions supplied by the

manufacturer.

2) SPECIAL INSTRUCTIONS FOR BURNERS

*The burner should be installed in a suitable room, with

ventilation openings complying with the requirements of the

regulations in force, and sufficient for good combustion.

* Only burners designed according to the regulations in force

should be used.

* This burner should be employed exclusively for the use for

which it was designed.

* Before connecting the burner, make sure that the unit rating

is the same as delivery mains (electricity, gas oil, or other fuel).

*Observe caution with hot burner components. These are,

usually, near to the flame and the fuel pre-heating system,

they become hot during the unit operation and will remain hot

for some time after the burner has stopped.

* When the decision is made to discontinue the use of the

burner, the user shall have qualified personnel carry out the

following operations:

a) Remove the power supply by disconnecting the power cord

from the mains.

b) Disconnect the fuel supply by means of the hand-operated

shut-off valve and remove the control handwheels from their

spindles.

Special warnings

* Make sure that the burner has, on installation, been firmly

secured to the appliance, so that the flame is generated inside

the appliance firebox.

* Before the burner is started and, thereafter, at least once a

year, have qualified personnel perform the following

operations:

a) set the burner fuel flow rate depending on the heat input of

the appliance;

b) set the flow rate of the combustion-supporting air to obtain a

combustion efficiency level at least equal to the lower level

required by the regulations in force;

c) check the unit operation for proper combustion, to avoid any

harmful or polluting unburnt gases in excess of the limits

permitted by the regulations in force;

d) make sure that control and safety devices are operating

properly;

e) make sure that exhaust ducts intended to discharge the

products of combustion are operating properly;

f) on completion of setting and adjustment operations, make

sure that all mechanical locking devices of controls have been

duly tightened;

g) make sure that a copy of the burner use and maintenance

instructions is available in the boiler room.

* In case of repeated burner shut-downs, do not continue resetting the unit manually. Contact qualified personnel to take

care of such defects.

* The unit shall be operated and serviced by qualified

personnel only, in compliance with the regulations in force.

2

FOREWORD

Page 3

3) GENERAL INSTRUCTIONS DEPENDING ON FUEL USED

3B) FIRING WITH GAS, GASOIL OR OTHER FUELS

3A) ELECTRICAL CONNECTION

* For safety reasons the unit must be efficiently earthed and

installed as required by current safety regulations.

* It is vital that all saftey requirements are met. In case of any

doubt, ask for an accurate inspection of electrics by qualified

personnel, since the manufacturer cannot be held liable for

damages that may be caused by failure to correctly earth the

equipment.

* Qualified personnel must inspect the system to make sure

that it is adequate to take the maximum power used by the

equipment shown on the equipment rating plate. In particular,

make sure that the system cable cross section is adequate for

the power absorbed by the unit.

* No adaptors, multiple outlet sockets and/or extension cables

are permitted to connect the unit to the electric mains.

An omnipolar switch shall be provided for connection to mains,

as required by the current safety regulations.

The use of any power-operated component implies

observance of a few basic rules, for example:

- do not touch the unit with wet or damp parts of the body and/

or with bare feet;

- do not pull electric cables;

- do not leave the equipment exposed to weather (rain, sun,

etc.) unless expressly required to do so;

- do not allow children or inexperienced persons to use

equipment;

* The unit input cable shall not be replaced by the user.

In case of damage to the cable, switch off the unit and contact

qualified personnel to replace.

* When the unit is out of use for some time the electric switch

supplying all the power-driven components in the system (i.e.

pumps, burner, etc.) should be switched off.

GENERAL

* The burner shall be installed by qualified personnel and in

compliance with regulations and provisions in force; wrong

installation can cause injuries to people and animals, or

damage to property, for which the manufacturer cannot be

held liable.

* Before installation, it is recommended that all the fuel supply

system pipes be carefully cleaned inside, to remove foreign

matter that might impair the burner operation.

* Before the burner is commissioned, qualified personnel

should inspect the following:

a) the fuel supply system, for proper sealing;

b) the fuel flow rate, to make sure that it has been set based on

the firing rate required of the burner;

c) the burner firing system, to make sure that it is supplied for

the designed fuel type;

d) the fuel supply pressure, to make sure that it is included in

the range shown on the rating plate;

e) the fuel supply system, to make sure that the system

dimensions are adequate to the burner firing rate, and that the

system is equipped with all the safety and control devices

required by the regulations in force.

* When the burner is to remain idle for some time, the fuel

supply tap or taps should be closed.

SPECIAL INSTRUCTIONS FOR USING GAS

* Have qualified personnel inspect the installation to ensure

that:

a) the gas delivery line and train are in compliance with the

regulations and provisions in force;

b) all gas connections are tight;

c) the boiler room ventilation openings are such that they

ensure the air supply flow required by the current regulations,

and in any case are sufficient for proper combustion.

* Do not use gas pipes to earth electrical equipment.

* Never leave the burner connected when not in use. Always

shut the gas valve off.

* In case of prolonged absence of the user, the main gas

delivery valve to the burner should be shut off.

Precautions if you can smell gas

a) do not operate electric switches, the telephone, or any other

item likely to generate sparks;

b) immediately open doors and windows to create an air flow

to purge the room;

c) close the gas valves;

d) contact qualified personnel.

* Do not obstruct the ventilation openings of the room where

gas appliances are installed, to avoid dangerous conditions

such as the development of toxic or explosive mixtures.

3FOREWORD

Page 4

PART I: INSTALLATION MANUAL

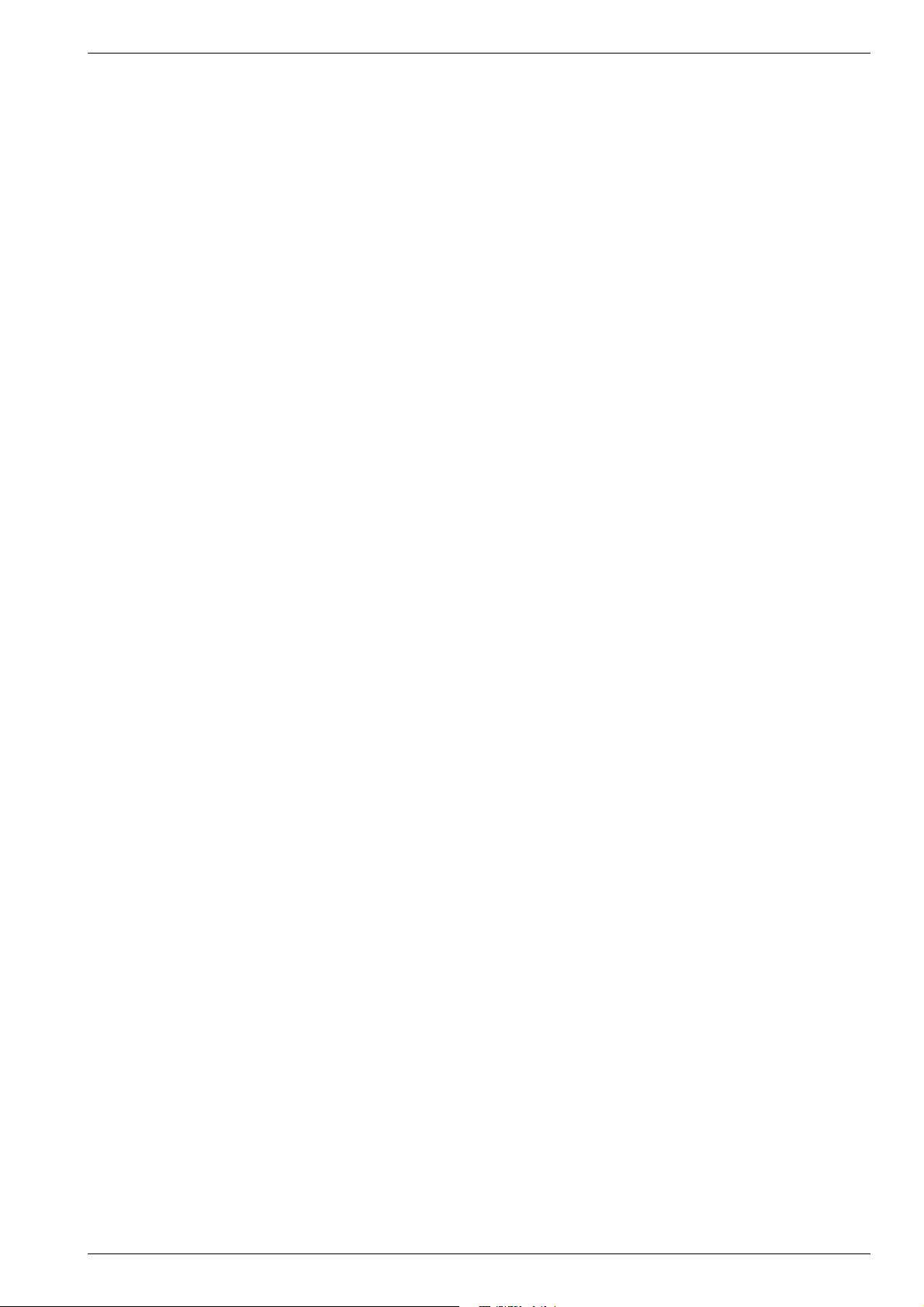

TECHNICAL DATA

BURNER TYPE G18 SP PG25 SP PG30 TN

Input min kcal/h 90.300 140.200 140.200

max kcal/h 180.000 250.200 300.000

min kW 105 163 163

max kW 209 291 349

Oil firin g rate kg/h m in. 9 14 14

kg/h max. 18 25 30

Fuel light oil light oil light oil

Electrical supply 230V 230V 230V

Frequency 50 Hz 50 Hz 50 Hz

Motor 2800 g/1' kW 0.25 0.37 0.37

A absorbed A 1.5 2.2 2.2

Total power absorption kW 0.55 0.87 0.87

Operation Soft start Soft start

Single

stage

BURNER MODEL IDENTIFICATION

Burners are identified by burner type and model. Burner type identification is described as follow:

Type: G18 Model: G-. SP. S. *. A.

(1) (2) (3) (4) (5) (6)

(1) BURNER TYPE G18 SP - PG25 SP - PG30 TN

(2) FUEL G = Light oil (Viscosity at 20°C 5 cSt)

(3) ADJUSTMENT SP = Soft Start

TN = Single Stage

(4) BLAST TUBE LENGHT (See overall dimensions)

S = Standard

L = Long

(5) DESTINATION COUNTRY * see data plate

(6) SPECIAL VERSIONS A = Standard

OVERALL DIMENSIONS

ABBLCCLDEGKH P M

G1 8 SP

275 90 200 365 475 340 255 115 230 125 121÷134 M8

Fig. 1

4

INSTALLATION

Page 5

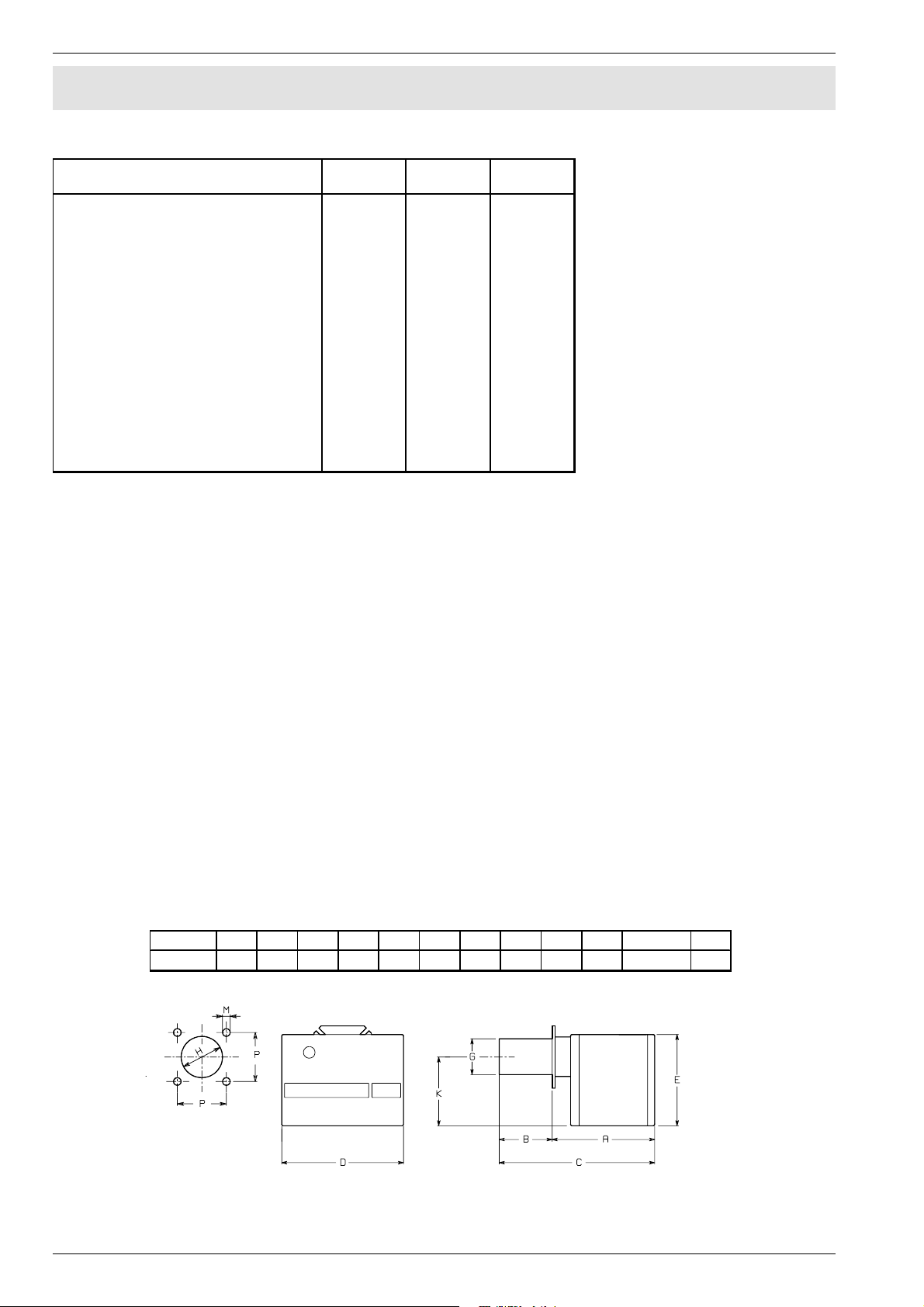

OVERALL DIMENSIONS

ABBLCCLD EFGKHPM

PG25SP

PG30SP

515 155 345 660 850 267 260 520 133 290 125 155 M10

PERFORMANCE CURVES

1.8

1.6

1.4

1.2

1

0.8

0.6

0.4

Back pressure in

0.2

0

combustion chamber mbar

6 8 10 12 14 16 18 20

Fig. 1a

Fig. 2

4

3

2

1

0

Back pressure in

-1

combustion chamber mbar

Back pressure in

10 12 14 16 18 20 22 24 26 28 30

3

2.5

2

1.5

1

0.5

0

-0.5

-1

combustion chamber mbar

10 12 14 16 18 20 22 24 26 28 30 32 34

Oil rate Kg/h

Fig. 3

Oil rate Kg/h

Fig. 3a

INSTALLATION

Oil rate Kg/h

5

Page 6

MOUNTINGS AND CONNECTIONS

The burners are despatched in cardboard packages.

The packaging contains the following items:

1 burner;

2 flexible light oil tubes;

1 light oil filter;

1 gasket to be inserted between the burner and the boiler;

1 this manual, the Guarantee Certificate and the test certificate.

To get rid of the burner’s packing and in the event of scrapping of the latter, follow the procedures

laid down by current laws on disposal of materials.

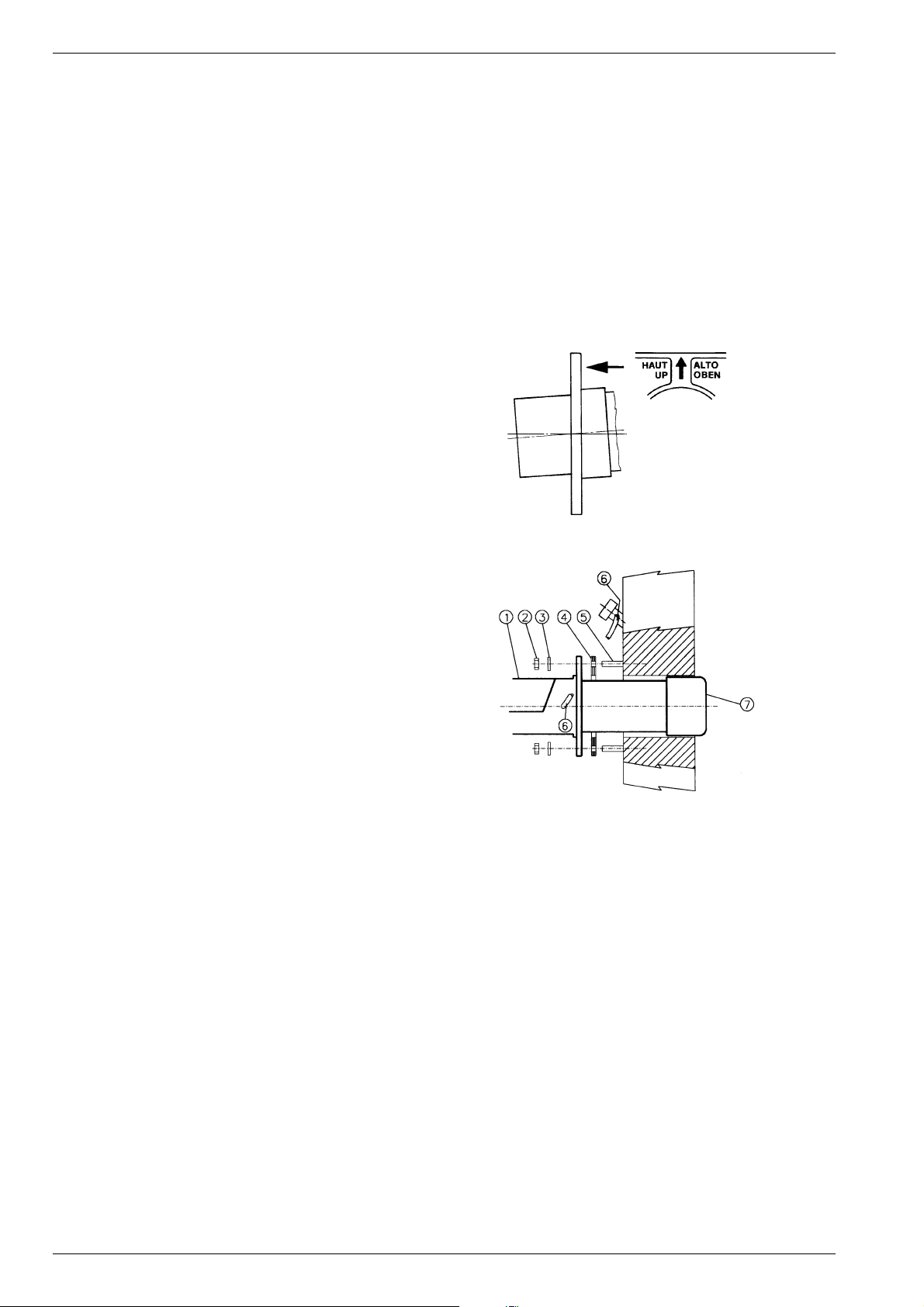

FITTING BURNER TO BOILER

G18SP

Attach the flange of the burner to the boiler with the

reference as shown in picture. This allows a correct

inclination towards the combustion chamber

Fig. 4

PG25SP - PG30TN

After fitting the burner to the boiler see that the

space between the blast tube and the refractory

lining is sealed with appropriate insulating material

(ceramic fibre cord or refractory cement).

Key

1) Burner

2) Fixing nut

3) Washer

4) Seal

5) Stud bolt

6) Sightglass cleaning tube

7) Blast tube

Fig. 4a

6

INSTALLATION

Page 7

G18SP PG25SP PG30TN

Fig. 5 Fig. 5bFig. 5a

Fig. 6

7

Page 8

SETTINGS

Burners G18SP - PG25SP

These burners are fitted with a double-regulation pump. The flame control device, a twin-stage one, after the pre-purgue stage,

energized the valve EV1 and the burner starts up.

After few seconds, the intervention of the second stage caused the energizing of the valve EV2, so the burner is feeded with a

maximum pressure of about 18 bar.

Burner PG30TN

Before carry out the settings, start-up the light oil pump proceeding as follows:

- start up the burner, light the photoresistor after the solenoid valve opening and leak the air from the manometer gauge.

Before starting up the burner, be sure that the return pipe to the tank is not obstructed; any obstruction would cause the pump

seal to break.

Light oil flow rate setting

The light oil rate is adjusted by chosing a nozzle with appropriate dimensions and setting the inlet pump pressure; to chose the

nozzle, refer to the tables below.

LIGHT OIL PUMP SETTINGS

Burners G18SP - PG25SP

Adjust the pump for the ingnition, to a pressure value of about 8-10 bar (see fig. 7).

After 10”, the safety device drives the second stage; set the pump to a pressure value of 18 bar, by means of the regulation screw.

Burner PG30TN

Set the pump to a pressure value from 10 to 14 bar, depending by the nozzle fitted (see table 2).

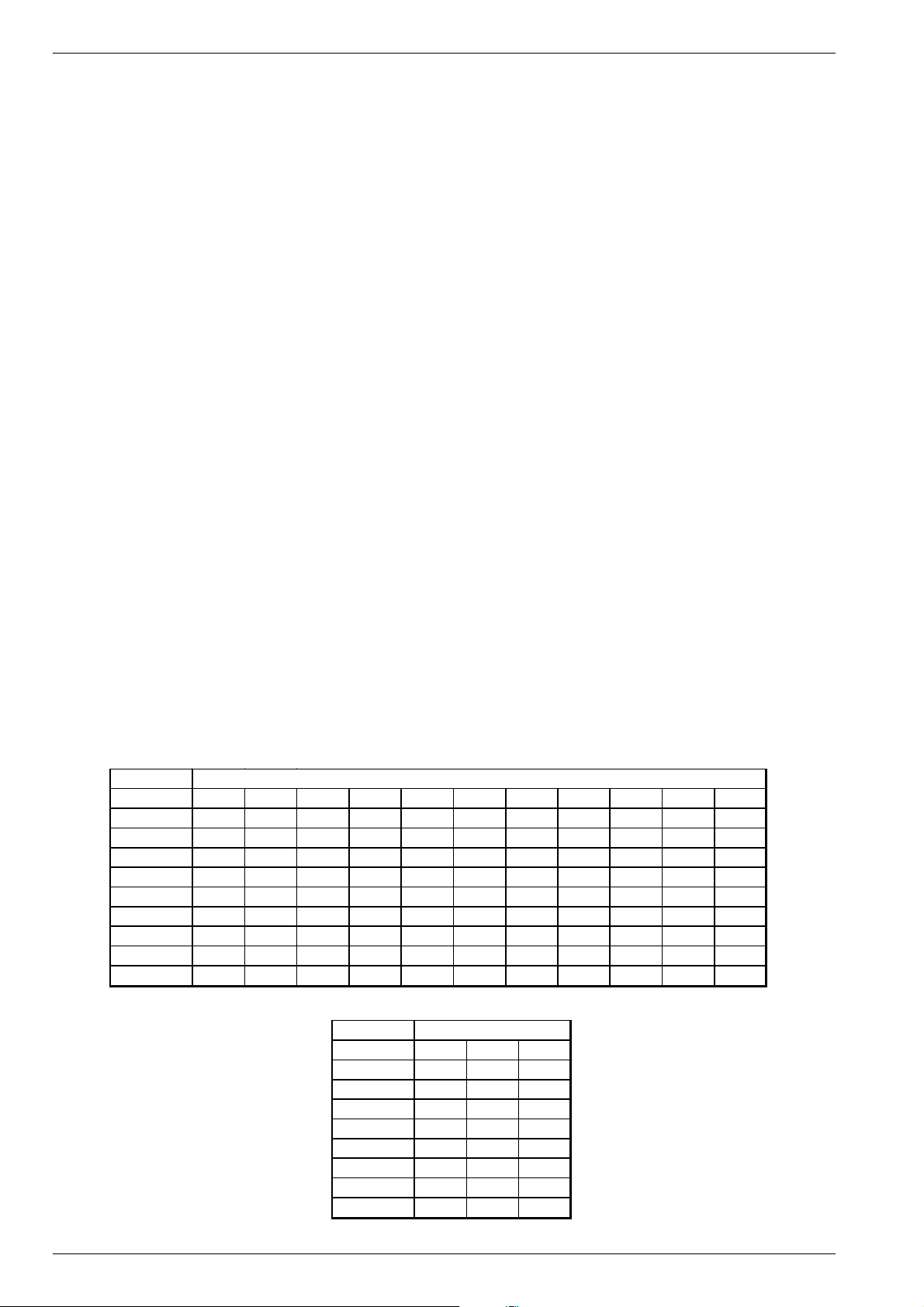

SELECTING THE OIL NOZZLE

Table 1 - Burners G18SP - PG25SP

BAR

GPH 8 9 101112131415161718

1.75 6.02 6.38 6.73 7.05 7.37 7.67 7.96 8.24 8.51 8.77 9.02

2.00 6.88 7.29 7.69 8.06 8.42 8.77 9.10 9.42 9.72 10.02 10.31

2.25 7.74 8.20 8.65 9.07 9.47 9.86 10.23 10.59 10.94 11.28 11.60

2.50 8.59 9.12 9.61 10.08 10.53 10.96 11.37 11.77 12.16 12.53 12.89

3.00 10.31 10.94 11.53 12.09 12.63 13.15 13.64 14.12 14.59 15.03 15.47

3.50 12.03 12.76 13.45 14.11 14.74 15.34 15.92 16.48 17.02 17.54 18.05

4.00 13.75 14.59 15.37 16.13 16.84 17.53 18.19 18.83 19.45 20.05 20.63

4.50 15.47 16.41 17.30 18.14 18.95 19.72 20.47 21.18 21.88 22.55 23.21

5.00 17.19 18.23 19.22 20.16 21.05 21.91 22.74 23.54 24.31 25.06 25.78

Table 2 - Burner PG30TN

8

BAR

GP H 1 0 1 2 1 4

3.50 13.45 14.74 15.92

4.00 15.37 16.84 18.19

4.50 17.30 18.95 20.47

5.00 19.22 21.05 22.74

5.50 21.14 23.16 25.01

6.00 23.06 25.26 27.29

6.50 24.98 27.37 29.56

7.00 26.91 29.47 31.84

INSTALLATION

Page 9

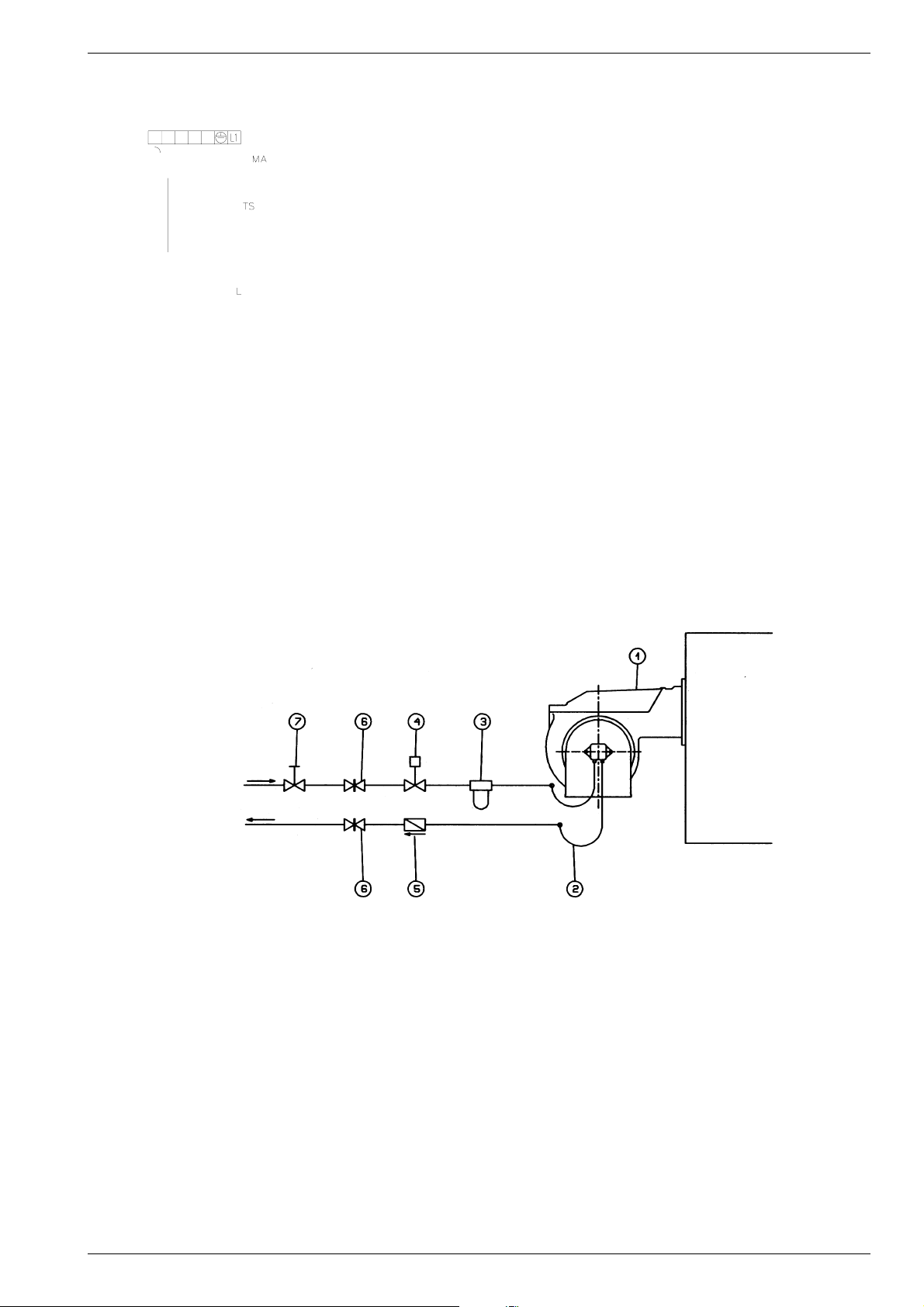

LIGHT OIL PUMPS

SUNTEC AS57C

Suction height: 0.5 bar

Advised value to prevent

air separation from oil: 0.35 bar

Rated speed: max. 2850 rpm

Operation viscosity: from 2 to 12 cSt

Inlet pressure: max. 2 bar

DELTA VM2RL2

Suction height: 0.5 bar

Advised value to prevent

air separation from oil: 0.35 bar

Rated speed: max. 3500 rpm

Operation viscosity: from 1.5 to 50 cSt

Inlet pressure: 0.7 - 1.5 bar

Fig. 7

Key

1 Pressure regulator

2 Manometer

3 Vacuum gauge

4 Solenoid valve

5 Nozzle

6 Supply to nozzle

7 Suction

8 Return

SUNTEC AT2 45C

Suction height: 0.45 bar

Advised value to prevent

air separation from oil: 0.35 bar

Rated speed: max. 3600 rpm

Operation viscosity: from 2 to 12 cSt

Inlet pressure: max. 2 bar

1 Low pressure regulation (first stage)

2 Manometer

3 Vacuum gauge

4 Lockoout solenoid valve

4a High-low pressure solenoid valve

5 To nozzle

6 High pressure regulation (second stage)

7 Suction

8 Return (with internal by-pass plug)

Fig. 8

Fig. 9

INSTALLATION

9

Page 10

AIR FLOW ADJUSTMENT

+

VBS

-

Burner G18SP

VBS

Fig. 10

Fig. 10

Fig. 11

Fig. 11

Loose the screw VBS and rotate the air damper in the desired

position, to set the air flow.

At the end of settings, tight the screw VBS.

Burners PG25SP - PG30TN

Loose the screw VBS and set the air flow, working directly on the

air damper.

At the end of settings, tight the screw VBS.

COMBUSTION HEAD ADJUSTMENT

The burner is factory-adjusted with the combustion head in the “max” position (maximum output).

Move back the combustion head towards the “MIN” position, turning the screw VRT clockwise.

G18SP

Fig. 12

Fig. 12

PG25SP - PG 30TN

10

Fig. 12a

Fig. 12a

INSTALLATION

Page 11

PART II: OPERATION MANUAL

LIMITATIONS OF USE

THE BURNER IS AN APPLIANCE DESIGNED AND CONSTRUCTED TO OPERATE ONLY AFTER BEING CORRECTLY

CONNECTED TO A HEAT GENERATOR (E.G. BOILER, HOT AIR GENERATOR, FURNACE, ETC.), ANY OTHER USE IS

TO BE CONSIDERED IMPROPER AND THEREFORE DANGEROUS.

THE USER MUST GUARANTEE THE CORRECT FITTING OF THE APPLIANCE, ENTRUSTING THE INSTALLATION OF IT

TO QUALIFIED PERSONNEL AND HAVING THE FIRST COMMISSIONING OF IT CARRIED OUT BY A SERVICE CENTRE

AUTHORISED BY THE COMPANY MANUFACTURING THE BURNER. A FUNDAMENTAL FACTOR IN THIS RESPECT IS

THE ELECTRICAL CONNECTION TO THE GENERATOR’S CONTROL AND SAFETY UNITS (CONTROL THERMOSTAT,

SAFETY, ETC.) WHICH GUARANTEES CORRECT AND SAFE FUNCTIONING OF THE BURNER.

THEREFORE ANY OPERATION OF THE APPLIANCE MUST BE PREVENTED WHICH DEPARTS FROM THE

INSTALLATION OPERATIONS OR WHICH HAPPENS AFTER TOTAL OR PARTIAL TAMPERING WITH THESE (E.G.

DISCONNECTION, EVEN PARTIAL, OF THE ELECTRICAL LEADS, OPENING THE GENERATOR DOOR, DISMANTLING

OF PART OF THE BURNER).

DO NOT EVER OPEN OR DISMANTLE ANY COMPONENT OF THE MACHINE.

OPERATE ONLY THE MAIN SWITCH, WHICH THROUGH ITS EASY ACCESSIBILITY AND RAPIDITY OF OPERATION

ALSO FUNCTIONS AS AN EMERGENCY SWITCH, AND ON THE RE-SET BUTTON.

IN THE EVENT OF REPEATED LOCKOUTS, DO NOT PERSIST WITH THE RE-SET BUTTON AND CONTACT QUALIFIED

PERSONNEL WHO WILL PROCEED TO ELIMINATE THE MALFUNCTION.

WARNING: DURING NORMAL OPERATION THE PARTS OF THE BURNER NEAREST TO THE GENERATOR (COUPLING

FLANGE) CAN BECOME VERY HOT, AVOID TOUCHING THEM SO AS NOT TO GET BURNT.

OPERATION

11

Page 12

PART III: MAINTENANCE

At least once a year carry out the following maintenance procedures.

If servicing is on a seasonal basis, it is recommended at the end of the season; routine sevice should be carried out every

months.

Note: Any operation on the burner must be carried out with the main electricity switched off.

PERIODICAL SERVICING

- Clean and examine the oil filter cartridge and replace it if necessary;

- Examine the condition of the oil flexìble pipeworks and check for possible leaks;

- Clean and examine the filter inside the oil pump;

- Dismantle, examine and clean the combustion head. When reassembling respect the measures reported in table 3.

- Examine the ignition electrodes and their ceramic insulators, adjust and replace if necessary (fig. 13);

- Dismantle and clean the oil nozzle (important: use solvents for cleaning and not metal utensils).

At the end of the maintenence procedures replace the burner, light it and check the shape of the flame:if in doubt replace the

nozzle(s);

where the burner is used intensively it is recommended to replace the nozzles at the beginning of the operating season;

- Examine and carefully clean the flame detector photoelectric cell and replace if necessary. If in doubt light the burner and

then check the detector circuit as shown in Fig. 14.

Correct position of electrodes and combustion

head (G18SP)

Prepare a stable surface where lying the burner

during maintenance.

To gain access to the combustion head and to the

nozzles, loose the screw which lock the blast tube

and remove it from the part that remains fixed to

the boiler.

To guarantee a good ignition, respect the

measures indicated in table 3.

Be sure to lock the screw that fix the electrodes

group, before reassembly the burner.

Removal of the combustion head

(PG25SP - PG30TN)

- Remove the cap C;

- Take out the photoresistance from its housing;

- Unscrew the floating pipe-fitting E from the oil

pipe, using 2 spanners, to avoid to loose the pipefirrings from the distribution block;

- Remove the screws V and unscrew the screw

VRT until the threaded rod AR is free;

Remove the complete assembly as shown in

figure 13a.

Note: To re-assemble reverse the order of

procedures descibed above.

AR

VRT

R

Table 3

Fig. 13

G1 8 SP

PG28SP

PG30TN

ABCD

60°6446

45°10546

60°8446

45°12546

60°8446

45°12546

C

Fig. 13a

C

12

V

MAINTENANCE

Page 13

CHECK OF THE IONIZATION CURRENT

To check the detector signal follow the

prcedure shown in fig. 14.

If the signal is not within the prescribed

range, check the electrical contacts; check

also that the combustion head is clean and

the photoelectric sensor is correctly

positioned. Replace it if necessary.

TERMINAL BLOCK MC

Scale µA DC

Minimum current .7067 ( witt )Tj/TT3 1 Tf52.9337 (-0.0101 Tc-0.0061 Tw[flame:)-6187.8(65e µT)]TJ -10 -1523 TD-0.0002 Tc-0.0516 TwMaxnimum current 467067 ( witoutt )Tj/TT3 1 Tf33.5337 (03 Tc0.001 Tw[flame:)-4346.7(5e µT)]TJ -1.084 -1533-3 TD-0.0002 Tc-0.0376 TwMaxnimum(posibale current )Tj/TT2 1 Tf-1.93337 (00.0547067 ( witt )Tj/TT3 1 Tf52.9337 (-0.0006 Tc[flame:)-19606.6200e µT)]TJ/TT5 1 Tf8 0 0 8279.626 24.88 Tm0.0071 TcMAINTENANCE

Fig. 14

F

AULA

S FINDING T

ABLET

13

Page 14

ELECTRICAL DIAGRAM code 01-369 BURNER G18SP

1 - Electric supply 230V 50Hz 2N a.c.

2 - Don't reverse Phase and Neutral

3 - Make sure that the burner is properly hearted

CO Time counter

EVG1 Light oil solenoid valve Ist stage

EVG2 Light oil solenoid valve II

F Fuse

FR Photoresistor

IL Main switch

L1 Phase

LF Burner operation light

LB Burner lockout light

LOA24/BOA64 Flame monitor device

MA Power supply terminal block

MV Fan motor

N Neutral

ST Thermostats or pressure switches

TA Ignition transformer

TS Boiler thermostat or pressure switch

nd

stage

ELECTRICAL DIAGRAM code 04-575 BURNER PG25SP

1 - Electric supply 230V 50Hz 2N a.c.

2 - Don't reverse Phase and Neutral

3 - Make sure that the burner is properly hearted

14

MAINTENANCE

EVG1 Light oil solenoid valve

F Fuse

FR Photoresistor

IL Main switch

L Phase

LFA Burner operation light

LB Burner lockout light

LEVG1 Opening of EVG1 signalization light

LOA24/BOA64 Flame monitor device

LTA Ignition transformer signalization light

MA Power supply terminal block

MC Terminal block for burner components connection

MV Fan motor

N Neutral

ST Thermostats or pressure switches

TA Ignition transformer

Page 15

ELECTRICAL DIAGRAM code 04-574 BURNER PG30TN

1 - Electric supply 230V 50Hz 2N a.c.

2 - Don't reverse Phase and Neutral

3 - Make sure that the burner is properly hearted

EVG1 Light oil solenoid valve Ist stage

EVG2 Light oil solenoid valve II

F Fuses

FR Photoresistor

IL Main switch

L Phase

LF Burner operation light

LB Burner lockout light

LEVG1 EVG1 opening signalization light

LEVG2 EVG2 opening signalization light

LOA24/BOA64 Flame monitor device

MA Power supply terminal block

MC Terminal block for burner components connection

LTA Ignition transformer light

MV Fan motor

N Neutral

ST Thermostats or pressure switches

TA Ignition transformer

nd

stage

MAINTENANCE

15

Page 16

SPARE PARTS BURNER G18SP

POS. DESCRIPTION CODE POS. DESCRIPTION CODE

1

HOUSING 3010019 19 BLAST TUBE 3090055

2

CONDENSER 6030004 20 COMBUSTION HEAD 3060115

3

MOTOR 2180009 21 ELECTRODE SUPPORT 2280016

4

FLAME CONTROL DEVICE LOA24 2020445 22 GASKET 2110031

5

SOCKET FOR LOA24 2030409 23 FLANGE 2100011

6

SUPPORT BRACKET 2430004 24 DISTRIBUTION MOVING BLOCK 2320012

7

TRANSFORMER 2170106 25 LIGHT OIL PIPE 2220125

8

BURNER CASING 2050228 27 CONNECTOR 6200008

9

FAN 2150004 28 SUNTEC AT2 45C PUMP 2590147

10

COMPLETE JOINT 254… 29 FILTER 2090016

13

ATOMIZER 3020020 30 FLEXIBLE HOSE 2340001

14

NOZZLE 261.. 31 SOLENOID VALVE COIL 2580402

15

ATOMIZER SUPPORT 2280006 32 AIR DAMPER 1010702

16

BOTTOM 2010102 33 PHOTORESISTOR QRB1B 2510008

17

IGNITION CABLES 6050122 34 ADJUSTING SCREW 2320011

18 IGNITION ELECTRODE 2080203

16

MAINTENANCE

Page 17

SPARE PARTS BURNERS PG25SP - PG30TN

POS. DESCRIPTION PG25SP PG30TN

1 ELECTRIC BOARD 6100086 6100086

2 THERMAL RELAY --- --3 SOCKET FOR FLAME CONTROL DEVICE 2030415 2030415

4 FLAME CONTROL DEVICE 2020445 2020445

5CONTACTOR --- --6 IGNITION TRANSFORMER 2170107 2170107

7 TOP COVER 2210103 2210103

8 LANDIS PHOTORESISTOR 2510003 2510003

9 GASKET 2110004 2110004

10 IGNITION CABLES 6050109 6050109

11 LONG ELECTRODE --- --12 SHORT ELECTRODE 2080208 2080208

13 STANDARD BLAST TUBE 3090033 3090033

13 LONG BLAST TUBE 3090035 3090035

14 DIFFUSER 3060179 3060179

15 NOZZLE 261… 261…

16 STANDARD NOZZLE SUPPORT 3020009 3020009

16 LONG NOZZLE SUPPORT 3020017 3020017

17 STANDARD LIGHT OIL PIPE 3071003 3071003

17 LONG LIGHT OIL PIPE 3071021 3071021

22 COIL FOR SUNTEC PUMP 2580402 2580402

22 COIL FOR DELTA PUMP --- 2580406

23 SUNTEC PUMP 2590147 2590144

23 DELTA PUMP --- 2590009

24 LIGHT OIL FILTER 2090016 2090016

25 FLEXIBLE HOSES 2340001 2340001

26 AIR DAMPER 2140005 2140005

30 COMPLETE JOINT FOR SUNTEC PUMP 2540109 2540109

30 COMPLETE JOINT FOR DELTA PUMP --- 2540103

33 FAN 2150006 2150006

34 BURNER CASING 2050117 2050117

35 HEAD ADJUSTING SCREW 2320503 2320503

36 ELECTRIC MOTOR 2180704 2180704

MAINTENANCE

17

Page 18

APPENDIX: COMPONENTS CHARACTERISTICS

FLAME CONTROL DEVICE LANDIS LOA24 Page 18

LIGHT OIL PUMPS Page 19

LANDIS AUTOMATIC CONTROLLER LOA24

FOR LIGHT OIL BURNERS

Use

LOA... safety devices are intended for use in conjunction with

QRB... photoresistors, for lighting and controlling low capacity

forced air diesel burners with max. capacity 30 kg/h in accordance

with standard DIN 4787.

The One or two flames are lit, depending on electrical connections,

with or without post-ignition.

Performance

The controllers just need plugging in, so they can be mounted in

almost any position: on the burner, on the electrical panel or on

the control panel. The casing is made of robust heat-resistant

plastic and contains:

- the thermic programmer operating a multiple switch control

system with ambient temperature compensator

- flame signal amplifier with flame relay

- warning light indicating lockout and associated sealed reset

button.

The plug-in socket, also made of robust heat-resistant plastic,

contains the 12 terminals and also:

- 3 neutral terminals, ready wired up to terminal 2

- 4 earth terminals for earthing the burner

- 2 supplementary terminals numbered “31” and “32”.

The socket has two openings at the bottom for the leads; 5 others

with threaded connection for cable holders PG11 or

3/4UNP for non-metallic sleeves are located on a mobile stuffing

box, one on either side and 3 on the front.

There are two flexible metal tongues on the sides of the socket

for mounting.

To dismantle it only requires gentle pressure with a screw driver

in the slot of the mounting guide.

The base dimensions of the socket are exaclty the same as for

types LAB/LAI and there is no difference in the diameter of the

reset button, the two mounting screws and the flange of the

burner earth.

Safety at low voltage levels

Safety devices against any reduction in the mains voltage

operate on a special electronic circuit which, in the event of the

power supply falling below 165V~, stops the burner switching on

without releasing the fuel and locks out the apparatus.

Wiring diagram of the programme

To ensure correct wiring it is essential to observe local standards

and follow the instructions of the burner manufacturer with

regard to assembly and start-up.

t2 Safety time

t3n Post-ignition time

t4 Interval between the flame lighting and energising of

solenoid 2a at terminal 5

Internal layout

AL Optical alarm

BV. Fuel valve

EK Reset button

FR Flame relay

fr Flame relay contacts

FS Flame alight signal

G Burner motor

K Flame relay anchor to delay the tzl command in the

event of a premature flame signal or endorse it where

the signal is correct.

OH diesel pre-heater

OW Operational all-clear contact

QRB Photo-resistant cell (flame detector)

R Thermostat or pressure switch

TZ Thermo-electric programmer (bimetal system)

tz.. TZ contacts

V Flame signal amplifier

W Safety thermostat or pressure switch

Z Ignition transformer

These are safety devices

To tamper with them in any way may have unforeseeable

consequences !

Do not open them!

Program's key:

Controller output signals

Required input signals

A’ Burner start up with diesel pre-heater OH

A Burner start-up without diesel pre-heater

B Flame lit

C Normal operation

D Normal stop through R

tw Oil pre-heating time until operational all clear given

through contact OW

tl Pre-purge time

t3 Pre-ignition time

18

APPENDIX

Page 19

Technical characteristics

Voltage 220V-15%..240V+10% or 100V

-15%...110V+10%

Frequency 50...60Hz +/- 6%

External fuse max.10A slow action

Contact flow:

- terminal 1 5A

- terminal 3 5A (incl.capacity absorbed by motor and pre-

heater)

Terminal flow:

- terminals 4, 5 &10 1A

- terminals 6&7 2A

- terminal 8 5A

Absorbed cap 3VA

Protection IP40

Premitted temp:

operational -20...+60°C

transport & storage -50...+60°C

Emplacement any

Mass (weight) controller 180 g

socket 50 g

AGK accessories 12 g

DELTA “VM” PUMPS

In the VM series of DELTA pumps the pressurised flow of oil P

is shut off by a built in solenoid and may therefore be switched

on for startup of the motor pre-purge) or off before the motor

itself switches off (flame goes out instantly when the spray from

the nozzle stops).

Oil pressure is regulated and kept constant by the piston valve

which is activated when the light comes on to signify that the oil

discharged exceeds nozzle capacity and is being returned to

the tank (twin-pipe system) or being returned to the suction

pipe through a bypass in the pipe (single-pipe system).

In this model both the single-pipe and twin-pipe versions have

automatic priming. It is recommended that in eiether case a

standard external filter be installed.

All twin-pipe models can be used as single-pipe systems with

the simple removal of a nylon plug and by closing the return

pipe.

Technical data

Oil viscosity 1,5÷50 cSt

Oil temperature 50°C

Pressure range 2÷10 bars

4÷15 bars

8÷20 bars

10÷125 bars

Suction vacuum max.0,5 bars

Suction pressure max.0,7 bars

Return pressure max.1,5 bars

Rotational speed max.3500 rpm

Filter stainless steel mesh 110 micron, 20 cm

Mounting Hub 32, shaft 8 (DIN 24220)

On request: flange, hub 54, shaft 7/16"

2

Commands in the event of operational interference

- Stray light/premature ignition

During pre-purge and/or pre-ignition there should be no flame

signal. If there is a flame signal, eg from premature ignition due

to a faulty solenoid, external light, short circuit in the photoresistor

or wiring, malfunction in the flame signal amplifier, etc., at the

end of pre-purge and safety time the controller locks out the

burner and stops the fuel flow even during safety time.

- Absence of flame

If there is no flame at the end of safety time the controller locks

out immediately.

- Absence of flame during operation

If there is no flame during operation the controller cuts off the

supply of fuel and automatically initiates a fresh start-up

programme: at the end of t4 the start-up programme ends.

Whenever there is a safety stop, terminals 3-8 and 11 are deenergised in less than 1 second; at the same time a remote

lockout signal is transmitted through terminal 10. The controller

can be reset after c. 50 seconds.

Hydraulic connections

Return suction 1/8"G 1/4"G (1/8"G only Vl,V2)

Delivery 1/8"G vacuum gauge 1/8"G

Rate VMl, VM2: max.0,1 Nm; VM3: 0,18 Nm

APPENDIX

19

Page 20

SUNTEC AS oil pumps

- Oil

- Flow up to 75 1/h (c.600,000 kcal/h - 700 kW)

- Twin-pipe system

- Single-pipe system

Technical data

Mounting On flange or hub in acccordance with

standards DIN 24220 and ISO/TC 109 SC

3 DP 5062F

Threads round-headed in accordance with ISO R

228-NFE 03005(DIN2S9)

Supply and return R 1/4"

Delivery R 1/8"

Pressure R 1/8"

On cover R 1/8"

Valve function Pressure control and cut out

2

120 micron

Filter area 34 cm

,

Shaft 8 mm in acc. with DIN 24220

Plug Inserted

By-pass Insert for twin-pipe, remove for single-

pipe system

Weight 1,8 kg - hub-mounted

1,9 kg - flange-mounted

Rotation and delivery position (view from shaft side)

A - clockwise rotation/RH delivery

C - anticlockwise rotation/LH delivery

Hydraulic data

Operational pressure range

7-14 bars adjustable

9-15 bars adjustable (for AS67)

Calibration 9 bars at factory

Viscosity at 20°C 2-12mm2/s (cSt)

Supply pressure max.2 bars

Return pressure max.2 bars

Suction max. vacuum 0,5 bars;

recommended 0,35 bars to

avoid separation of oil and gas

Rotational speed 2850 rpm

Max. oil temperature 70°C

Torque 1,0cm - daN

Absorbed capacity see motor curves

Electrical data

Solenoid voltage 20V +10%-15%; 50/60Hz

Absorbed capacity 9VA

Length of coil cable 600mm

Length of plug cable 600mm

Cable Ø6 mm with cross section of

0,75 mm

2

A Closed solenoid valve

B Open solenoid valve (NO)

C Closed return

1 Solenoid valve

2 Pressure regulating valve

3 Pressure adjustment

4 To nozzle

5 Pressure gauge port

Oil under suction

Oil under pressure

By-passed oil returned to

tank or to suction

6 Escape valve

7 Shaft seal

8 Vacuum gauge port

9 By-pass plug “P”

10 Gear set

11 Inlet

12 Return

13 Back to suction

20

Twin pipe installation Single pipe installation (remove the by-pass plug “P”)

APPENDIX

Page 21

Operation

The gear-set draws oil from the tank through the built-in filter and transfers it to the valve that regulates the oil pressure or tne nozzle

line. All oil which does not go through the nozzle line will be dumped through the valve back to the return line or, if it is a one-pipe

installation, back to the suction port in the gear-set.

The hydraulic valve has a cut-off function besides regulating the nozzle pressure. Contrary to the AN pump, the valve has no bleed

slot. The function of the bleed slot is taken over by the solenoid valve. When the solenoid valve is non-activated, the by-pass channel

between the pressure and return sides of the valve is open. No pressure will then be built up to open the valve. It does not matter

which speed the gear set has. When the solenoid is activated, this by-pass channel will be closed and because of the full speed

of the gear set, the pressure necessary to open the valve will be built up very rapidly which gives a very sharp cut-on function.

When the burner stops, the solenoid opens the by-pass at the same moment which drains all the oil down to the return and the

nozzle valve closes immediately. This gives a very sharp cut-off function.

The cut-on and off can be regulated regardless of motor speed and has an extremely fast response. The torque requirement is low

up to full motor speed.

SUNTEC AT oil pumps

- Oil

- Twin-pipe system

- Single-pipe system

- Twin feed

Technical data

Mounting On hub Ø 32mm, in acccordance with

standards DIN 24220

Threads round-headed in accordance with ISO R

228-NFE 03005 (DIN259)

Supply and return R 1/4"

Delivery R 1/8"

Pressure R 1/8"

On cover R 1/8"

Valve function Pressure regulation

2,

Filter Area 34 cm

mesh 120 micron

Shaft Ø 8 mm in acc. with DIN 24220

By-pass Insert for twin-pipe, remove for single-

pipe system

Weight 1,3 kg

Rotation and delivery position (viewed from shaft side)

D - counterclockwise rotation/right delivery

C - counterclockwise rotation/left delivery

Hydraulic data

Operational pressure range to the nozzle

4 - 25 bar

Calibration 22 bars at factory

Viscosity at 20°C 2-12mm

2

/s (cSt)

Supply pressure max.2 bars

Return pressure max.2 bars

Suction max. vacuum 0,35 bars,

recommended to

avoid separation of oil and gas

Rotational speed 3600 rpm

Max. oil temperature 70°C

Torque 1,0 cm - daN

Electrical data

Solenoid voltage 220V +10%-15%; 50/60Hz

Absorbed capacity 9VA

Protection IP50

Max. pressure 25 bar

Approved by TUV n.1 x 23985S

PUMP OPERATING PRINCIPLE

The gear set draws oil from the tank through the built-in filter and transfers it to the nozzle line via the cut off solenoid valve.

Pressure regulation is assured by two spool valves, one for each pressure mode.

In one pipe operation, oil which is not required at the nozzle is returned directly to the gear inlet via the pressure regulating

valves and the suction line flow is equal to the nozzle flow.

In two pipe operation, the by-pass plug must be fitted in the return port, which ensures that the oil dumped by the regulating

valves is returned to the tank and the suction line flow is equal to the gear set capacity.

Purging on 2 pipe installations is assured by a bleed flat on the pistons. On 1 pipe installations, a high pressure connection

must be loosened until the air is evacuated from the system.

Switching between low and high pressure is assured by a normally open by-pass solenoid valve. When this solenoid is non

activated, a by-pass channel is open, allowing the normal operation of the low pressure valve which sets the nozzle pressure.

When this solenoid is activated, the by-pass channel is closed, thus pressure will build up on both sides of the low pressure

valve eliminating its effect and the high pressure valve now determines the nozzle pressure.

The blocking solenoid valve is of the normally closed type and is situated in the nozzle line.

This design ensures extremely fast response and the switching can be selected according to the burner operating sequence

independently from the motor speed.

When the solenoid is non-activated, the valve is closed and all oil pressurised by the gear set passes through the regulators

to suction or the return line, depending upon the pipe arrangement.

As soon as the solenoid is activated, oil passes to the nozzle line at the pressure set by the pressure regulating valve.

APPENDIX

21

Page 22

A Closed by-pass solenoid valve

B Opened by-pass solenoid valve

C Opened cut-off solenoid valve

D Closed cut-off solenoid valve

1 Manometer plug

2 To nozzle

3 Shaft seal

Oil under suction

Oil under pressure

By-passed oil returned to

tank or to suction

4 Return to suction

5 By-pass plug

6 Return (twin pipe installation)

7 Suction (twin pipe installation)

8 Vacuum gauge plug

9 Gear

10 Hi-pressure regulator with control screw

11 Lo-pressure regulator with control screw

Twin pipe installation Single pipe installation (remove the

by-pass plug “P”)

22

APPENDIX

Page 23

23

Page 24

Via C. Colombo, 9 - 35011 Campodarsego (PD) Italy

Tel. +39-049-9200944 - Fax +39-049-9200945-9201269

Internet: www.cibunigas.it - E mail: cibunigas@cibunigas.it

Loading...

Loading...