Page 1

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

First Published: 2019-06-26

Americas Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

http://www.cisco.com

Tel: 408 526-4000

800 553-NETS (6387)

Fax: 408 527-0883

Page 2

THE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THIS MANUAL ARE SUBJECT TO CHANGE WITHOUT NOTICE. ALL STATEMENTS,

INFORMATION, AND RECOMMENDATIONS IN THIS MANUAL ARE BELIEVED TO BE ACCURATE BUT ARE PRESENTED WITHOUT WARRANTY OF ANY KIND,

EXPRESS OR IMPLIED. USERS MUST TAKE FULL RESPONSIBILITY FOR THEIR APPLICATION OF ANY PRODUCTS.

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION PACKET THAT SHIPPED WITH

THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNABLE TO LOCATE THE SOFTWARE LICENSE OR LIMITED WARRANTY,

CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

The Cisco implementation of TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB) as part of UCB's public domain version of

the UNIX operating system. All rights reserved. Copyright©1981, Regents of the University of California.

NOTWITHSTANDING ANY OTHER WARRANTY HEREIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE PROVIDED “AS IS" WITH ALL FAULTS.

CISCO AND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, THOSE OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT OR ARISING FROM A COURSE OF DEALING, USAGE, OR TRADE PRACTICE.

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL DAMAGES, INCLUDING, WITHOUT

LIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE USE OR INABILITY TO USE THIS MANUAL, EVEN IF CISCO OR ITS SUPPLIERS

HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Any Internet Protocol (IP) addresses and phone numbers used in this document are not intended to be actual addresses and phone numbers. Any examples, command display output, network

topology diagrams, and other figures included in the document are shown for illustrative purposes only. Any use of actual IP addresses or phone numbers in illustrative content is unintentional

and coincidental.

All printed copies and duplicate soft copies of this document are considered uncontrolled. See the current online version for the latest version.

Cisco has more than 200 offices worldwide. Addresses and phone numbers are listed on the Cisco website at www.cisco.com/go/offices.

Cisco and the Cisco logo are trademarks or registered trademarks of Cisco and/or its affiliates in the U.S. and other countries. To view a list of Cisco trademarks, go to this URL: www.cisco.com

go trademarks. Third-party trademarks mentioned are the property of their respective owners. The use of the word partner does not imply a partnership relationship between Cisco and any

other company. (1721R)

©

2019 Cisco Systems, Inc. All rights reserved.

Page 3

CONTENTS

CHAPTER 1

CHAPTER 2

Overview 1

Features 1

Package Contents 3

Serial Number Locations 4

Front Panel 5

Front Panel LEDs 7

Rear Panel 10

Rear Panel LEDs 11

Power Supply 12

Hardware Specifications 13

Product ID Numbers 14

Power Cord Specifications 14

Installation Preparation 23

Installation Warnings 23

Safety Recommendations 25

CHAPTER 3

Maintain Safety with Electricity 25

Prevent ESD Damage 26

Site Environment 26

Power Supply Considerations 26

Rack Configuration Considerations 27

Mount and Connect 29

Unpack and Inspect the Chassis 29

Rack-Mount the Chassis 29

Connect Cables, Turn on Power, and Verify Connectivity 32

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

iii

Page 4

Contents

CHAPTER 4

Maintenance and Upgrade 35

Power Button Shutdown 35

Remove and Replace a Drive 36

Remove and Replace a Power Supply 38

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

iv

Page 5

Features

CHAPTER 1

Overview

• Features, on page 1

• Package Contents, on page 3

• Serial Number Locations, on page 4

• Front Panel, on page 5

• Front Panel LEDs, on page 7

• Rear Panel, on page 10

• Rear Panel LEDs, on page 11

• Power Supply, on page 12

• Hardware Specifications, on page 13

• Product ID Numbers, on page 14

• Power Cord Specifications, on page 14

The Cisco Firepower Management Center (FMC) 1600, 2600, and 4600 management appliances run software

that provides extensive intelligence about the users, applications, devices, threats, and vulnerabilities that exist

in your network. It also uses this information to analyze your network’s vulnerabilities. It then provides tailored

recommendations on what security policies to put in place and what security events you should investigate.

See Product ID Numbers, on page 14 for a list of the field-replaceable product IDs (PIDs) associated with

the FMC 1600, 2600, and 4600. You can remove and replace drives and power supplies. For all other internal

component failures, you must send your chassis for RMA.

The FMC management appliances support Cisco Firepower Threat Defense software. See the Cisco Firepower

Compatibility Guide, which provides Cisco Firepower software and hardware compatibility, including operating

system and hosting environment requirements, for each supported Firepower version.

Note

The FMC 1600, 2600, and 4600 are certified for Federal Information Processing Standards (FIPS) 140-2

beginning in Cisco Firepower version 6.4.1. See the "Security Certifications Compliance" topic in the

"Appliance Platform Settings" chapter in the Firepower Management Center Configuration Guide for the

instructions on how to enable security certifications compliance.

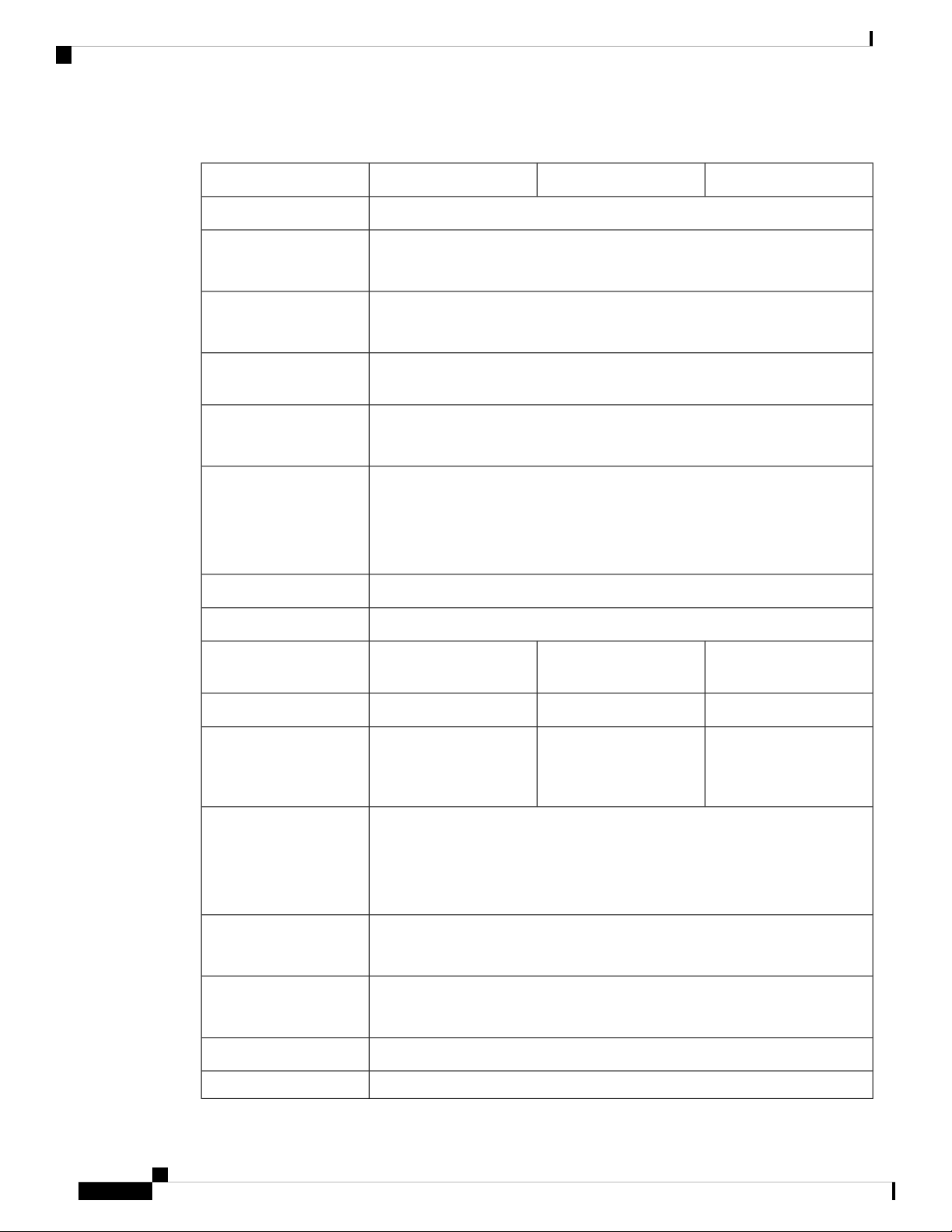

The following table lists the features of the FMC 1600, 2600, and 4600.

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

1

Page 6

Features

Overview

Table 1: FMC 1600, 2600, and 4600 Features

460026001600Feature

1 RUForm factor

Rack mount

Airflow

Pullout asset card

Flex flash card

Grounding hole

Processor

Yes

Standard 19-in. (48.3 cm) 4-post EIA rack

Front to rear

Cold aisle to hot aisle

Displays the serial number and the MAC address for the two built-in management

ports.

32 GB (for vMedia)

Internal component only; not field-replaceable

Yes

Two threaded holes for dual-hole grounding lug

Use is optional; the supported AC power supplies have internal grounding, so

no additional chassis grounding is required.

YesLocator beacon

YesPower switch

One Intel Xeon 4110

processor

Two Intel Xeon 4110

processors

Two Intel Xeon 4116

processors

RDIMMs

Internal component only;

not field-replaceable

Management ports

USB ports

VGA port

128-GB RAM64-GB RAM32-GB RAMMemory

Two 16-GB

DDR4-2400-MHz

DIMMs

Four 16-GB

DDR4-2400-MHz

DIMMs

Eight 16-GB

DDR4-2400-MHz

DIMMs

Two built-in RJ-45 SFP+ ports

Support for 1000 Mbps, 1 Gbps, and 10 Gbps

The primary management port is eth0. You can use eth1, eth2, and eth3 as

secondary management or event ports.

Two

USB 3.0 Type A

One 3-row 15-pin DB-15 connector

Enabled by default

Two fixed SFP+ portsSFP ports

SFP-10G-SR (10 GB)Supported SFP+

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

2

Page 7

Overview

Package Contents

460026001600Feature

Serial console port

System power

Fans

Storage

RAID controller

Package Contents

One

RJ-45 serial port running RS-232 (RS-232D TIA-561)

Two 770-W AC power supplies

Hot-swappable and redundant as 1+1

2626 BTU/hrPower consumption

Six fans for front-to-rear cooling

Internal component only; not field-replaceable

Two 1.2-TB 10-K SAS

HDDs

RAID 1, hot-swappable

One

The chassis has a dedicated internal riser for a PCIe-style Cisco modular RAID

controller card.

Internal component only; not field-replaceable

Four 600-GB 10-K SAS

HDDs

RAID 5, hot-swappable

Ten 1.2-TB SAS SSDs

RAID 6, hot-swappable

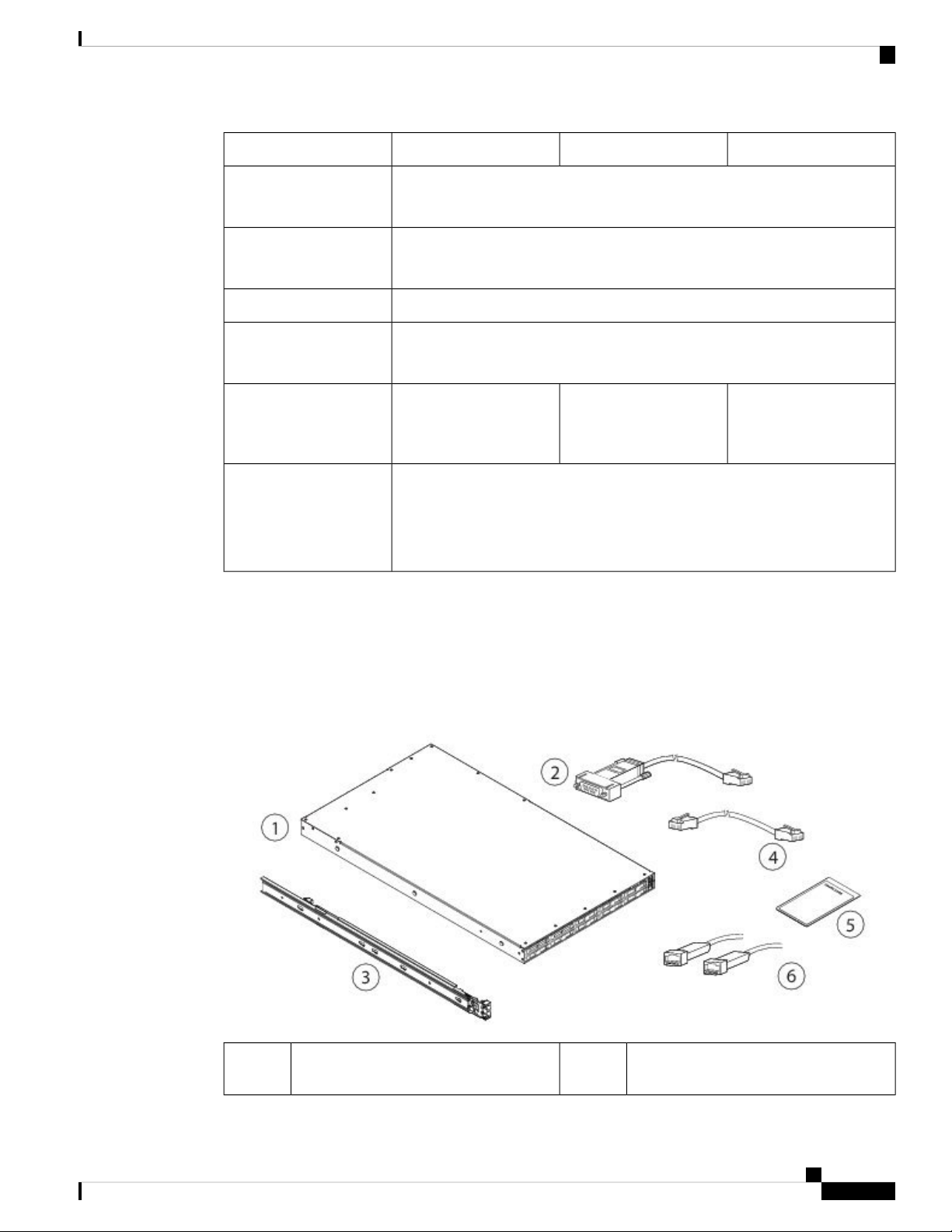

The following figure shows the package contents for the FMC 1600, 2600, and 4600. Note that the contents

are subject to change and your exact contents might contain additional or fewer items.

Figure 1: Package Contents

2Chassis1

RJ-45 to DP9-RS232 console cable (Cisco

part number 72-3383-XX)

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

3

Page 8

Serial Number Locations

Overview

3

800-43376-02)

5

Useful Links Cisco Firepower Management

Center 1600, 2600, and 4600

The steps in the Useful Links document

send you to the documentation you need

to install, set up, and configure your FMC.

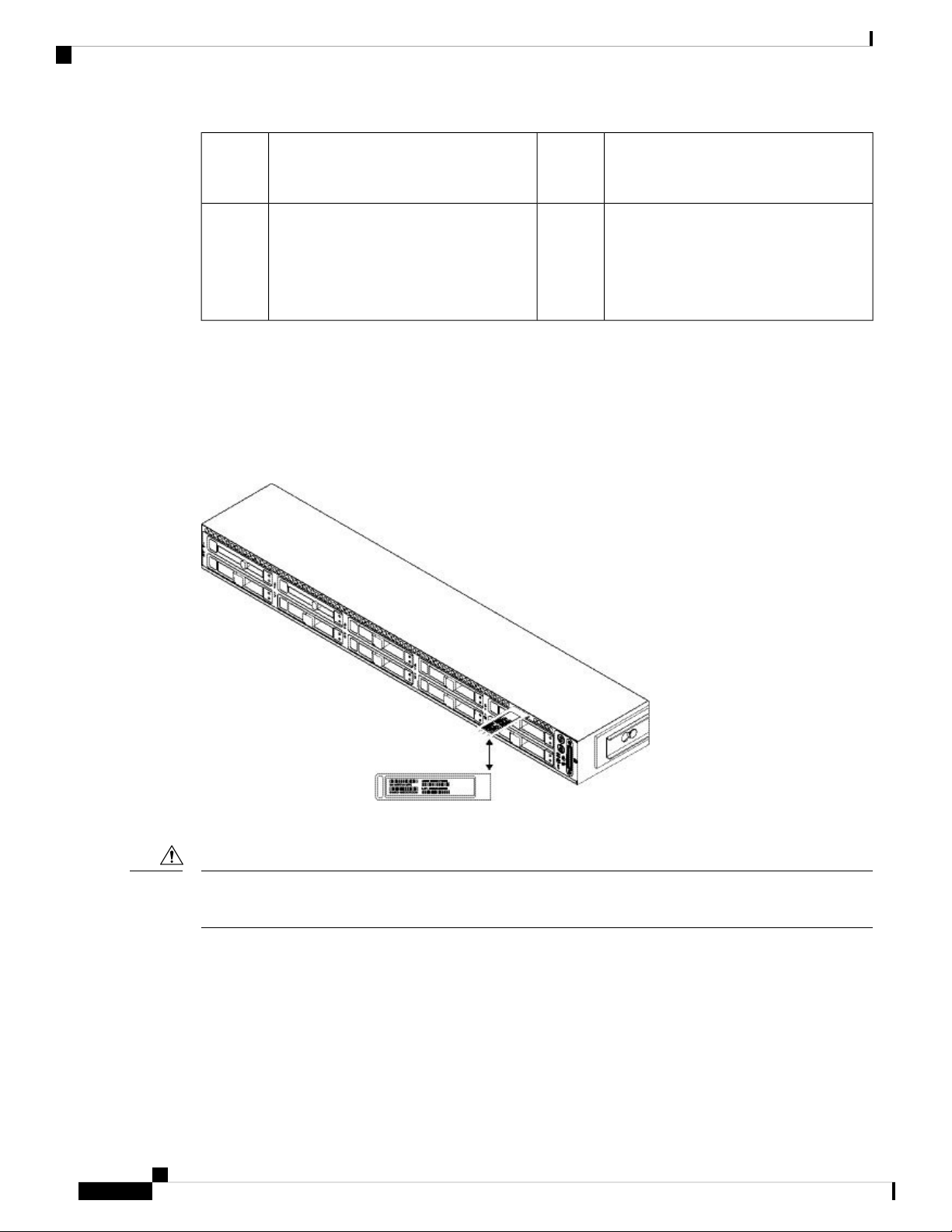

Serial Number Locations

The serial number (SN) for the FMC 1600, 2600, and 4600 is printed on the pullout asset card located on the

front panel as shown in the following figure of the FMC 1600.

Figure 2: Serial Number on Pullout Asset Card

4Cisco rail kit (Cisco part number

6

RJ-45 to RJ-45 Cat 5 Ethernet cable,

yellow six feet long (Cisco part number

72-1482-XX)

Two 10-Gb SFP transceivers with cables

Optional; in package if ordered.

4

The serial number is also on the label on the cover of the chassis as shown in the following figure.

Caution

The cover latch on the top of the chassis cover is not supported. There are no internal field-replaceable parts

in the FMC 1600, 2600, and 4600.

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

Page 9

Overview

Front Panel

Figure 3: Serial Number Location on Cover

Front Panel

2Serial number label1

Cover latch

Not supported

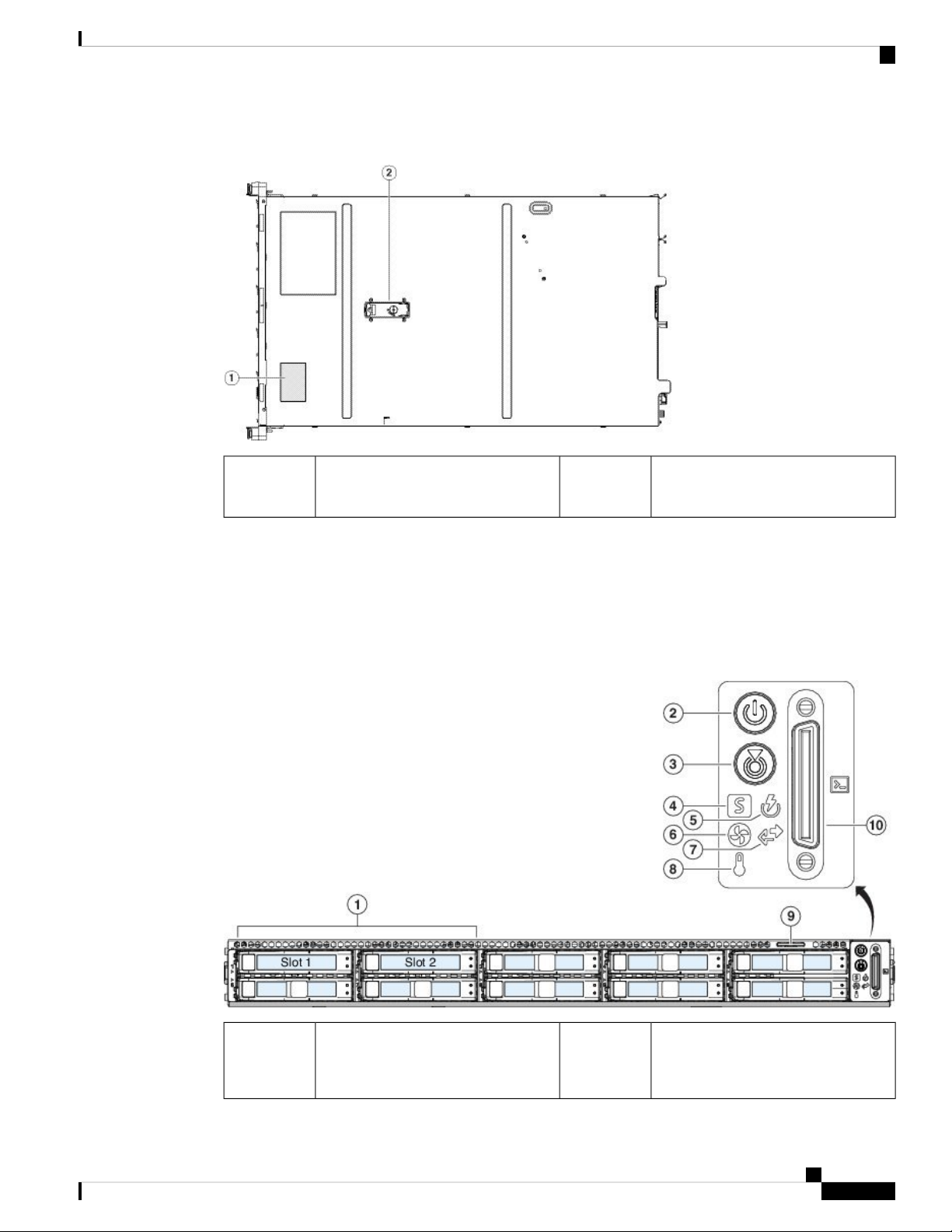

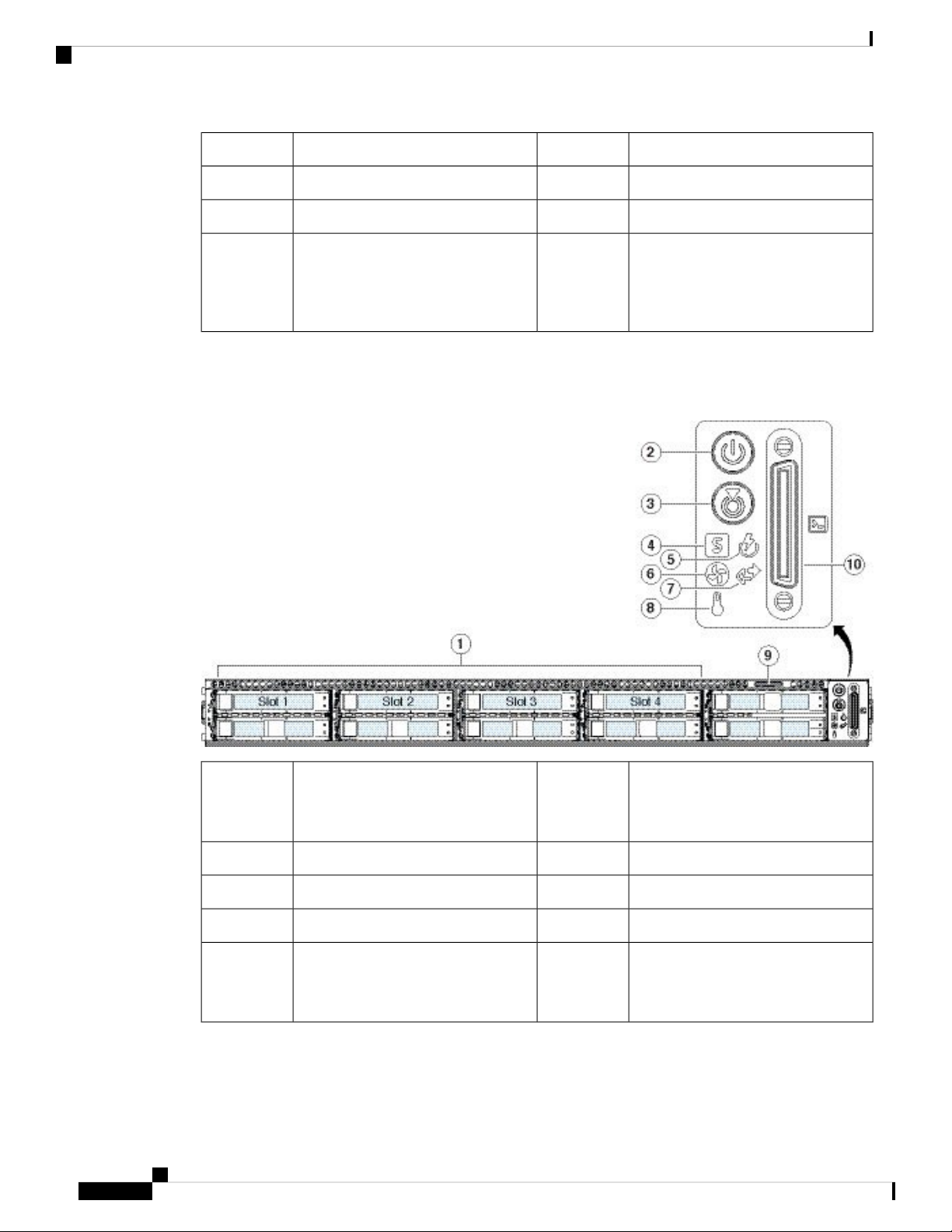

The following figure shows the front panel features and disk-drive configuration for the FMC 1600. See Front

Panel LEDs, on page 7 for a description of the LEDs.

Figure 4: FMC 1600 Front Panel

1

Power button/power status LED2Drive bays

Supports two SAS HDDs in slots 1 and

2

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

5

Page 10

Front Panel

Overview

System status LED4Unit identification button/LED3

Fan status LED6Power supply status LED5

Temperature status LED8Network link activity LED7

10Pullout asset card9

Keyboard, video, and mouse (KVM)

port

Not supported; use the VGA and USB

keyboard ports instead.

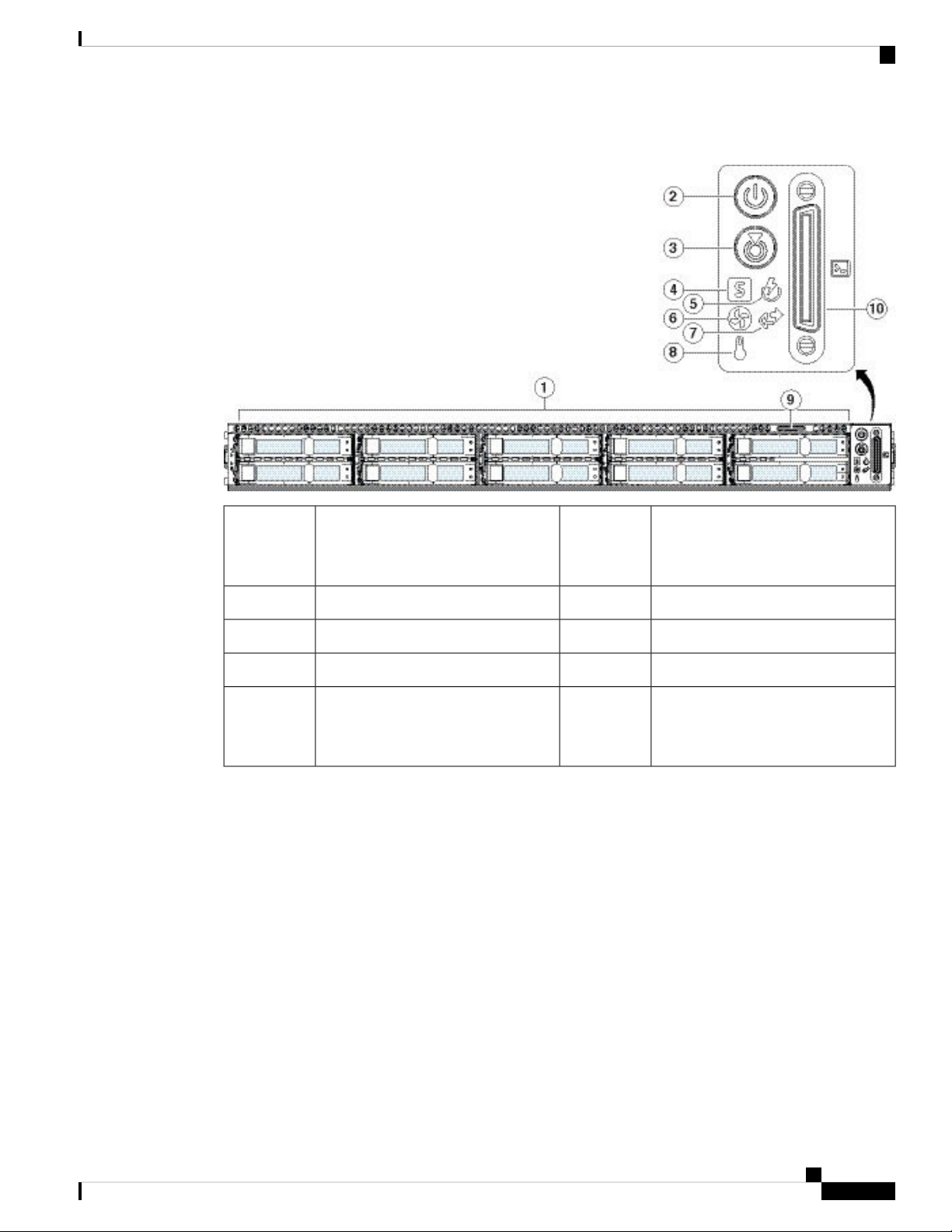

The following figure shows the front panel features and disk-drive configuration for the FMC 2600. See Front

Panel LEDs, on page 7 for a description of the LEDs.

Figure 5: FMC 2600 Front Panel

1

Power button/power status LED2Drive bays

Supports four SAS HDDs in slots 1

through 4

System status LED4Unit identification button/LED3

Fan status LED6Power supply status LED5

Temperature status LED8Network link activity LED7

10Pullout asset card9

KVM port

Not supported; use the VGA and USB

keyboard ports instead.

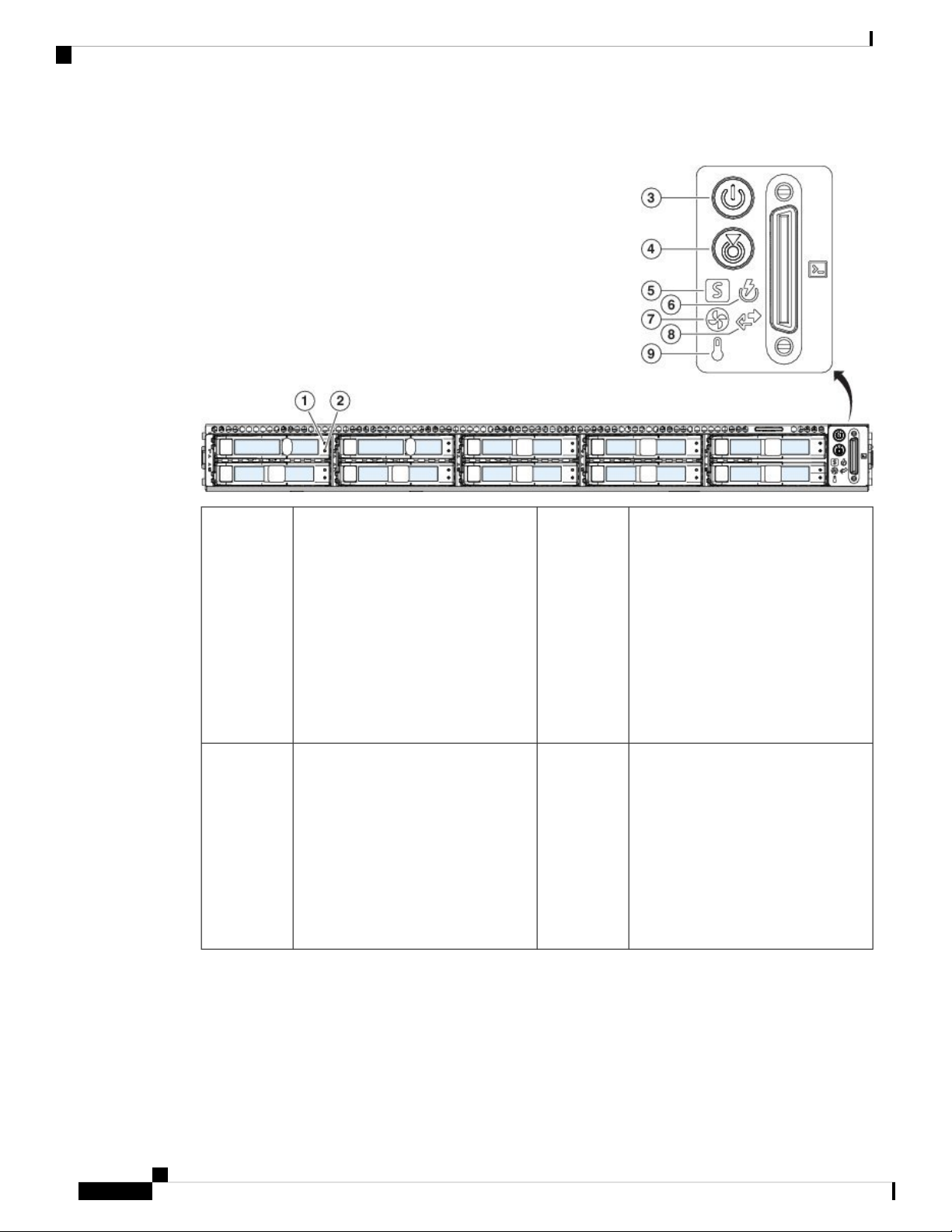

The following figure shows the front panel features and disk-drive configuration for the FMC 4600. See Front

Panel LEDs, on page 7 for a description of the LEDs.

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

6

Page 11

Overview

Front Panel LEDs

Figure 6: FMC 4600 Front Panel

1

Front Panel LEDs

The following figure shows the front panel LEDs and describes their states.

Supports ten SAS SSDs in slots 1

through 6

Power button/power status LED2Drive bays

System status LED4Unit identification button/LED3

Fan status LED6Power supply status LED5

Temperature status LED8Network link activity LED7

10Pullout asset card9

KVM port

Not supported; use the VGA and USB

keyboard ports instead.

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

7

Page 12

Front Panel LEDs

Overview

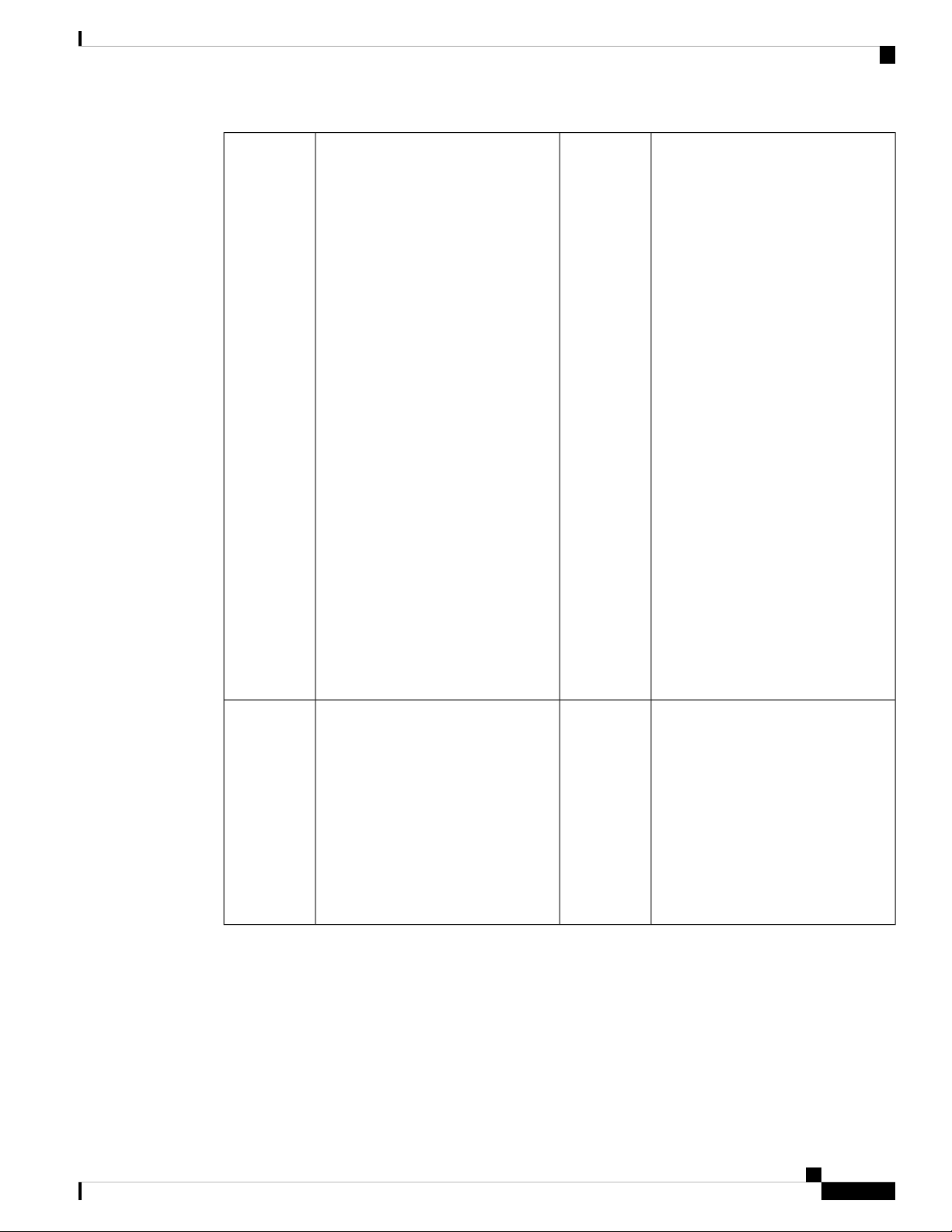

Figure 7: Front Panel LEDs and Their States

1

2Drive fault LED:

• Off—The drive is operating

properly.

• Amber—Drive fault detected.

• Amber, flashing—The drive is

rebuilding.

Drive activity LED:

• Off—There is no drive in the

drive tray (no access, no fault).

• Green—The drive is ready.

• Green, flashing—The drive is

reading or writing data.

• Amber, flashing with 1-second

interval—Drive locate function

activated in the software.

3

4Power LED:

• Off—There is no AC power to

the chassis.

• Amber—The chassis is in standby

mode.

• Green—The chassis is in main

Unit identification LED:

• Off—The unit identification

function is not in use.

• Blue, flashing—The unit

identification function is

activated.

power mode. Power is supplied

to all components.

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

8

Page 13

Overview

Front Panel LEDs

5

6System status LED:

• Green—The chassis is running in

normal operating condition.

• Green, flashing—The chassis is

performing system initialization

and memory check.

• Amber—The chassis is in a

degraded operational state (minor

fault).

Power supply status LED:

• Green—All power supplies are

operating normally.

• Amber—One or more power

supplies are in a degraded

operational state.

• Amber, flashing—One or more

power supplies are in a critical

fault state.

• Power supply redundancy is

lost.

• CPUs are mismatched.

• At least one CPU is faulty.

• At least one DIMM is faulty.

• At least one drive in a RAID

configuration failed.

• Amber, two flashes—There is a

major fault with the system board.

• Amber, three flashes—There is a

major fault with the DIMMs.

• Amber, four flashes—There is a

major fault with the CPUs.

7

8Fan status LED:

• Green—All fans are operating

properly.

• Amber, flashing—One or more

fans breached the unrecoverable

threshold.

Network link activity LED:

• Off—The Ethernet port link is

idle.

• Green—One or more Ethernet

ports are link-active, but there is

no activity.

• Green, flashing—One or more

Ethernet ports are link-active with

activity.

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

9

Page 14

Rear Panel

Overview

Rear Panel

Note

9

Although the Cisco Integrated Management Controller (CIMC) is not supported on the FMC, you can use

Lights-Out-Management (LOM) on the default management interface (eth0) on a Serial Over LAN (SOL)

connection to remotely monitor or manage the FMC system. For information about using LOM and SOL, see

the Cisco Firepower Management Center Getting Started Guide for Models 1600, 2600, and 4600 for more

information.

Temperature status LED:

• Green—The chassis is operating

at normal temperature.

• Amber—One or more

temperature sensors breached the

critical threshold.

• Amber, flashing—One or more

temperature sensors breached the

unrecoverable threshold.

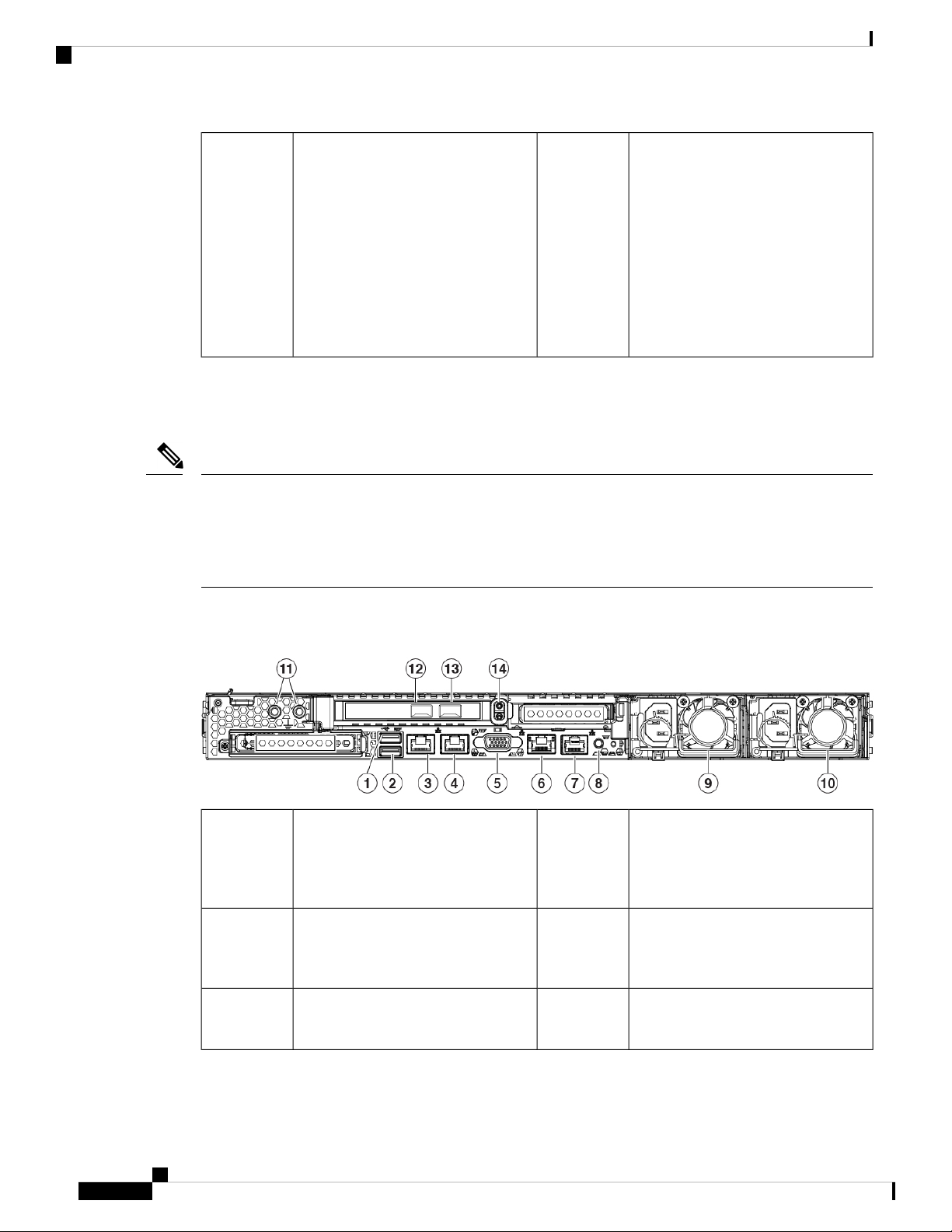

The following figure shows the rear panel of the FMC 1600, 2600, and 4600.

Figure 8: Rear Panel

1

You can connect a keyboard, and along

with a monitor on the VGA port, you

can access the console.

3

Supports 100/1000/10000 Mbps

depending on link partner capability.

2USB 3.0 Type A (USB 1)

4eth0 management interface (labeled 1)

6VGA video port (DB-15 connector)5

USB 3.0 Type A (USB 2)

You can connect a keyboard, and along

with a monitor on the VGA port, you

can access the console.

eth1 management interface (labeled 2)

Gigabit Ethernet 100/1000/10000

Mbps interface, RJ-45, LAN2

CIMC interface (labeled M)

Not supported

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

10

Page 15

Overview

Rear Panel LEDs

7

11

13

Rear Panel LEDs

Disabled by default; use the VGA port

and keyboard USB port instead. See

the "Set up Serial Access" topic in the

Cisco Firepower Management Center

Getting Started Guide for Models

1600, 2600, and 4600.

grounding lug

10-Gigabit Ethernet SFP+ support

Use only Cisco-supported SFP+

transceivers.

Unit identification button8Serial console port (RJ-45 connector)

770-W AC power supply (PSU 2)10770-W AC power supply (PSU 1)9

12Threaded holes for dual-hole

14eth3 management interface

eth2 management interface

10-Gigabit Ethernet SFP+ support

Use only Cisco-supported SFP+

transceivers.

Riser handle

Not in use

The following figure shows the rear panel LEDs and describes their states.

Figure 9: Rear Panel LEDs and Their States

1

link (speed on both LAN1 and LAN2):

• Off—Link speed is 100 Mbps.

• Amber—Link speed is 1 Gbps.

• Green—Link speed is 10 Gbps.

2100-Mbps/1-Gbps/10-Gbps Ethernet

100-Mbps/1-Gbps/10-Gbps Ethernet

link status (speed on both LAN1 and

LAN2):

• Off—No link is present.

• Green—Link is active.

• Green, flashing—Traffic is

present on the active link.

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

11

Page 16

Power Supply

Overview

3

management link:

• Off—Link speed is 10 Mbps.

• Amber—Link speed is 100 Gbps.

• Green—Link speed is 1 Gbps.

5

• Off—The unit identification

function is not in use.

• Blue, flashing—The unit

identification function is

activated.

41-Gbps Ethernet dedicated

6Rear unit identification:

1-Gbps Ethernet dedicated

management link:

• Off—No link is present.

• Amber—Link is active.

• Green, flashing—Traffic is

present on the active link.

Power supply (one LED for each

power supply):

• Off—No AC input (12-V main

power off; 12-V standby power

off)

• Green, flashing—12-V main

power off; 12-V standby power

on.

• Green—12-V main power on;

12-V standby power on.

• Amber, flashing—Warning

threshold detected but 12-V main

power on.

Power Supply

The following table lists the specifications for each 770-W AC power supply used in the FMC 1600, 2600,

and 4600.

Table 2: Power Supply Specifications

AC input voltage range

AC input frequency

• Amber—Critical error detected;

12-V main power off ( for

example, overcurrent,

overvoltage, or overtemperature

failure).

SpecificationDescription

1313 BTU/hrPower consumption

Nominal range: 100 to 120 V AC, 200 to 240 V AC

Range: 90–132 V AC, 180–264 V AC

Nominal range: 50–60 Hz

Range: 47–63 Hz

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

12

Page 17

Overview

Hardware Specifications

SpecificationDescription

Maximum AC input current

Efficiency rating

Hardware Specifications

9.5 A peak at 100-V AC

4.5 A peak at 208 V AC

950 VA at 100 V ACMaximum input volt amperes

770 WMaximum output power for each power supply

15 A (subcycle duration)Maximum inrush current

12 ms at 770 WMaximum hold-up time

12 V DCPower supply output voltage

12 V DCPower supply standby voltage

Climate Savers Platinum Efficiency (80 Plus Platinum

certified)

RSP2Form factor

IEC320 C13/C15Input connector

The following table lists the hardware specifications for the FMC 1600, 2600, and 4600.

Table 3: FMC 1600, 2600, and 4600 Hardware Specifications

460026001600Specification

1.7 x 16.89 x 29.8 in. (4.32 x 43.0 x 75.6 cm)Dimensions (H x W x D)

36.0 lb (17.0 kg)34.1 lb (16.8 kg)

loaded chassis)

Temperature

Relative humidity

Altitude

32.2 lb (16.6 kg)Maximum weight (fully

Operating: 50 to 95°F (10 to 35°C)

Maximum temperature is derated by 1°F/547 ft (1°C/300 m) of altitude above

3117 ft (950 m).

Nonoperating: –40 to 149°F (–40 to 65°C)

When the appliance is stored or transported.

Operating: 8 to 90% noncondensing

Nonoperating: 5 to 95% noncondensing

Operating: 0 to 10,000 ft

Nonoperating: 0 to 40,000 ft when the appliance is stored or transported

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

13

Page 18

Product ID Numbers

Overview

460026001600Specification

Sound power level

Sound pressure level

Product ID Numbers

The following table lists the field-replaceable PIDs associated with the FMC 1600, 2600, and 4600. The spare

components are ones that you can order and replace yourself. If any internal components fail, you must RMA

the entire chassis including the SFPs and SFP cables. Remove the drives and power supplies before you send

the chassis for RMA.

Table 4: FMC 1600, 2600, and 4600 PIDs

5.8 Bels (measure A-weighted per ISO7779 LWAd)

Operation at 73°F (23°C)

43 dBa (measure A-weighted per ISO7779 LpAM)

Operation at 73°F (23°C)

DescriptionPID

AC power supplyFMC-M5-PS-AC-770W

AC power supply (spare)FMC-M5-PS-AC-770W=

FMC 1600 and 4600 1.2-TB hard disk driveFMC-M5-HDD-1.2TB

Power Cord Specifications

Each power supply has a separate power cord. Standard power cords or jumper power cords are available for

connection to the FMC 1600, 2600, and 4600. The jumper power cords for use in racks are available as an

optional alternative to the standard power cords.

If you do not order the optional power cord with the system, you are responsible for selecting the appropriate

power cord for the product. Using a incompatible power cord with this product may result in electrical safety

hazard. Orders delivered to Argentina, Brazil, and Japan must have the appropriate power cord ordered with

the system.

Note

Only the approved power cords and jumper cords provided with the FMC 1600, 2600, and 4600 are supported.

The following power cords and jumper cords are supported.

FMC 1600 and 4600 1.2-TB hard disk drive (spare)FMC-M5-HDD-1.2TB=

FMC 2600 600-GB hard disk driveFMC-M5-HDD-600G

FMC 2600 600-GB hard disk drive (spare)FMC-M5-HDD-600G=

Rail kitUCSC-RAILB-M4

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

14

Page 19

Overview

Power Cord Specifications

Figure 10: Argentina CAB-250V-10A-AR

Cord set rating: 10 A, 250 V2Plug: IRAM 20731

Connector: IEC 60320/C133

Figure 11: Australia CAB-9K10A-AU

Connector: IEC 60320/C153

Figure 12: Brazil PWR-250V-10A-BZ

Connector: IEC 60320/C133

Cord set rating: 10 A, 250 V2Plug: A.S. 3112-20001

Cord set rating: 10 A, 250 V2Plug: NBR 141361

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

15

Page 20

Power Cord Specifications

Figure 13: Cabinet Jumper CAB-C13-C14-2M

Figure 14: Cabinet Jumper CAB-C13-C14-AC

Overview

Cord set rating: 10A, 250V2Plug: SS10A1

Connector: HS10S, C-13 to C-143

3

Connector: HS10S, C-13 to C-14 (recessed

receptacle)

Figure 15: Cabinet Jumper CAB-C13-CBN

Connector: HS10S, C-13 to C-143

Cord set rating: 10 A, 250 V2Plug: SS10A1

Cord set rating: 10 A, 250 V2Plug: SS10A1

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

16

Page 21

Overview

Power Cord Specifications

Figure 16: China CAB-250V-10A-CH

Cord set rating: 10 A, 250 V2Plug: GB2099.1/20081

Connector: IEC 60320/C133

Figure 17: Europe CAB-9K10A-EU

Connector: IEC 60320/C15 (VSCC 15)3

Figure 18: India CAB-250V-10A-ID

Connector: IEC 60320-C133

Cord set rating: 10 A/16 A, 250 V2Plug: CEE 7/7 (M2511)1

Cord set rating: 16 A, 250 V2Plug: IS 6538-19711

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

17

Page 22

Power Cord Specifications

Figure 19: Israel CAB-250V-10A-IS

Figure 20: Italy CAB-9K10A-IT

Overview

Cord set rating: 10 A, 250 V2Plug: SI-321

Connector: IEC 60320-C133

3

Connector: IEC 60320/C15

(EN 60320/C15M)

Figure 21: Japan CAB-JPN-3PIN

Connector: IEC 60320/C133

Cord set rating: 10 A, 250 V2Plug: CEI 23-16/VII (I/3G)1

Cord set rating: 12 A, 125 V2Plug: JIS 83031

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

18

Page 23

Overview

Power Cord Specifications

Figure 22: Japan CAB-C13-C14-2M-JP

Cord set rating: 10 A, 250 V2Plug: EN 60320-2-2/E1

Connector: EN 60320/C13 to C143

Figure 23: Korea CAB-9K10S-KOR

Connector: IEC 60320/C153

Figure 24: North America CAB-9K12A-NA

Connector: IEC 60320/C153

Cord set rating: 10 A, 250 V2Plug: EL211 (KSC 8305)1

Cord set rating: 13 A, 125 V2Plug: NEMA5-15P1

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

19

Page 24

Power Cord Specifications

Figure 25: North America CAB-N5K6A-NA

Figure 26: North America CAB-AC-L620-C13

Overview

Cord set rating: 10 A, 125 V2Plug: NEMA6-15P1

Connector: IEC 60320/C133

Connector: IEC 60320/C133

Figure 27: Switzerland CAB-9K10A-SW

Connector: IEC 60320/C153

Cord set rating: 13 A, 250 V2Plug: NEMA L6-20 (molded twist lock)1

Cord set rating: 10 A, 250 V2Plug: SEV 1011 (MP232-R)1

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

20

Page 25

Overview

Power Cord Specifications

Figure 28: Taiwan CAB-ACTW

Cord set rating: 10 A, 125 V2Plug: EL 302 (CNS10917)1

Connector: IEC 60320/C133

Figure 29: United Kingdom CAB-9K10A-UK

Cord set rating: 10 A, 250 V2Plug: BS1363A/SS1451

Connector: IEC 60320/C153

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

21

Page 26

Power Cord Specifications

Overview

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

22

Page 27

Installation Preparation

• Installation Warnings, on page 23

• Safety Recommendations, on page 25

• Maintain Safety with Electricity, on page 25

• Prevent ESD Damage, on page 26

• Site Environment, on page 26

• Power Supply Considerations, on page 26

• Rack Configuration Considerations, on page 27

Installation Warnings

Be sure to read the REGULATORY & COMPLIANCE SAFETY INFORMATION document before installing

the Firepower Management Center management appliance.

CHAPTER 2

Caution

Warning

Warning

Do NOT open the appliance except under direction from TAC.

Take note of the following warnings:

Statement 1071—Warning Definition

IMPORTANT SAFETY INSTRUCTIONS

This warning symbol means danger. You are in a situation that could cause bodily injury. Before you work

on any equipment, be aware of the hazards involved with electrical circuitry and be familiar with standard

practices for preventing accidents. Use the statement number provided at the end of each warning to locate

its translation in the translated safety warnings that accompanied this device.

SAVE THESE INSTRUCTIONS

Statement 1005—Circuit Breaker

This product relies on the building’s installation for short-circuit (overcurrent) protection. Ensure that the

protective device is rated not greater than: USA: 120 V, 15 A (EU: 250 V, 16 A)

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

23

Page 28

Installation Warnings

Installation Preparation

Warning

Warning

Warning

Warning

Statement 1004—Installation Instructions

Read the installation instructions before using, installing or connecting the system to the power source.

Statement 12—Power Supply Disconnection Warning

Before working on a chassis or working near power supplies, unplug the power cord on AC units; disconnect

the power at the circuit breaker on DC units.

Statement 43—Jewelry Removal Warning

Before working on equipment that is connected to power lines, remove jewelry (including rings, necklaces,

and watches). Metal objects will heat up when connected to power and ground and can cause serious burns

or weld the metal object to the terminals.

Statement 94—Wrist Strap Warning

During this procedure, wear grounding wrist straps to avoid ESD damage to the card. Do not directly touch

the backplane with your hand or any metal tool, or you could shock yourself.

Warning

Warning

Warning

Statement 1045—Short-Circuit Protection

This product requires short-circuit (overcurrent) protection to be provided as part of the building installation.

Install only in accordance with national and local wiring regulations.

Statement 1021—SELV Circuit

To avoid electric shock, do not connect safety extra-low voltage (SELV) circuits to telephone-network voltage

(TNV) circuits. LAN ports contain SELV circuits, and WAN ports contain TNV circuits. Some LAN and

WAN ports both use RJ-45 connectors. Use caution when connecting cables.

Statement 1024—Ground Conductor

This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the absence

of a suitably installed ground conductor. Contact the appropriate electrical inspection authority or an electrician

if you are uncertain that suitable grounding is available.

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

24

Page 29

Installation Preparation

Safety Recommendations

Warning

Warning

Warning

Statement 1040—Product Disposal

Ultimate disposal of this product should be handled according to all national laws and regulations.

Statement 1074—Comply with Local and National Electrical Codes

To reduce risk of electric shock or fire, installation of the equipment must comply with local and national

electrical codes.

Statement 19—TN Power Warning

The device is designed to work with TN power systems.

Safety Recommendations

Observe these safety guidelines:

• Keep the area clear and dust free before, during, and after installation.

• Keep tools away from walkways, where you and others might trip over them.

• Do not wear loose clothing or jewelry, such as earrings, bracelets, or chains that could get caught in the

chassis.

• Wear safety glasses if you are working under any conditions that might be hazardous to your eyes.

• Do not perform any action that creates a potential hazard to people or makes the equipment unsafe.

• Never attempt to lift an object that is too heavy for one person.

Maintain Safety with Electricity

Warning

Before working on a chassis, be sure the power cord is unplugged.

Be sure to read the REGULATORY & COMPLIANCE SAFETY INFORMATION document before installing

the chassis.

Follow these guidelines when working on equipment powered by electricity:

• Before beginning procedures that require access to the interior of the chassis, locate the emergency

power-off switch for the room in which you are working. Then, if an electrical accident occurs, you can

act quickly to turn off the power.

• Do not work alone if potentially hazardous conditions exist anywhere in your work space.

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

25

Page 30

Prevent ESD Damage

Installation Preparation

• Never assume that power is disconnected; always check.

• Look carefully for possible hazards in your work area, such as moist floors, ungrounded power extension

cables, frayed power cords, and missing safety grounds.

• If an electrical accident occurs:

• Use caution; do not become a victim yourself.

• Disconnect power from the system.

• If possible, send another person to get medical aid. Otherwise, assess the condition of the victim,

and then call for help.

• Determine whether the person needs rescue breathing or external cardiac compressions; then take

appropriate action.

• Use the chassis within its marked electrical ratings and product usage instructions.

• The chassis is equipped with an AC-input power supply, which is shipped with a three-wire electrical

cord with a grounding-type plug that fits into a grounding-type power outlet only. Do not circumvent

this safety feature. Equipment grounding should comply with local and national electrical codes.

Prevent ESD Damage

ESD occurs when electronic components are improperly handled, and it can damage equipment and impair

electrical circuitry, which can result in intermittent or complete failure of your equipment.

Always follow ESD-prevention procedures when removing and replacing components. Ensure that the chassis

is electrically connected to an earth ground. Wear an ESD-preventive wrist strap, ensuring that it makes good

skin contact. Connect the grounding clip to an unpainted surface of the chassis frame to safely ground ESD

voltages. To properly guard against ESD damage and shocks, the wrist strap and cord must operate effectively.

If no wrist strap is available, ground yourself by touching the metal part of the chassis.

For safety, periodically check the resistance value of the antistatic strap, which should be between one and

10 megohms.

Site Environment

See Hardware Specifications, on page 13 for information about physical specifications.

To avoid equipment failures and reduce the possibility of environmentally caused shutdowns, plan the site

layout and equipment locations carefully. If you are currently experiencing shutdowns or unusually high error

rates with your existing equipment, these considerations may help you isolate the cause of failures and prevent

future problems.

Power Supply Considerations

See Power Supply, on page 12 for more detailed information about the power supply in the chassis.

When installing the chassis, consider the following:

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

26

Page 31

Installation Preparation

• Check the power at the site before installing the chassis to ensure that it is free of spikes and noise. Install

a power conditioner, if necessary, to ensure proper voltages and power levels in the appliance-input

voltage.

• Install proper grounding for the site to avoid damage from lightning and power surges.

• The chassis does not have a user-selectable operating range. Refer to the label on the chassis for the

correct appliance input-power requirement.

• Several styles of AC-input power supply cords are available for the chassis; make sure that you have the

correct style for your site.

• If you are using dual redundant (1+1) power supplies, we recommend that you use independent electrical

circuits for each power supply.

• Install an uninterruptible power source for your site, if possible.

Rack Configuration Considerations

Rack Configuration Considerations

See Rack-Mount the Chassis, on page 29 for the procedure for rack-mounting the chassis.

Consider the following when planning a rack configuration:

• If you are mounting a chassis in an open rack, make sure that the rack frame does not block the intake

or exhaust ports.

• Be sure enclosed racks have adequate ventilation. Make sure that the rack is not overly congested as each

chassis generates heat. An enclosed rack should have louvered sides and a fan to provide cooling air.

• In an enclosed rack with a ventilation fan in the top, heat generated by equipment near the bottom of the

rack can be drawn upward and into the intake ports of the equipment above it in the rack. Ensure that

you provide adequate ventilation for equipment at the bottom of the rack.

• Baffles can help to isolate exhaust air from intake air, which also helps to draw cooling air through the

chassis. The best placement of the baffles depends on the airflow patterns in the rack. Experiment with

different arrangements to position the baffles effectively.

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

27

Page 32

Rack Configuration Considerations

Installation Preparation

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

28

Page 33

CHAPTER 3

Mount and Connect

• Unpack and Inspect the Chassis, on page 29

• Rack-Mount the Chassis, on page 29

• Connect Cables, Turn on Power, and Verify Connectivity, on page 32

Unpack and Inspect the Chassis

Note

The chassis is thoroughly inspected before shipment. If any damage occurred during transportation or any

items are missing, contact your customer service representative immediately. Keep the shipping container in

case you need to send the chassis back due to damage.

See Package Contents, on page 3 for a list of what shipped with the chassis.

Step 1 Remove the chassis from its cardboard container and save all packaging material.

Step 2 Compare the shipment to the equipment list provided by your customer service representative. Verify that you have all

items.

Step 3 Check for damage and report any discrepancies or damage to your customer service representative. Have the following

information ready:

• Invoice number of shipper (see the packing slip)

• Model and serial number of the damaged unit

• Description of damage

• Effect of damage on the installation

Rack-Mount the Chassis

You can install the chassis in a rack using the Cisco rack kit.

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

29

Page 34

Rack-Mount the Chassis

Note

Mount and Connect

The rack must be of the following type:

• A standard 19-in. (48.3-cm) wide, 4-post EIA rack with mounting posts that conform to English universal

hole spacing per section 1 of ANSI/EIA-310-D-1992.

• The rack post holes can be square 0.38-in. (9.6 mm), round 0.28-in. (7.1 mm), #12-24 UNC, or #10-32

UNC when you use the supplied slide rails.

• The minimum vertical rack space per chassis must be 1 RU, equal to 1.75 in. (44.45 mm).

• The slide rails for the chassis have an adjustment range of 24 to 36 in. (610 to 914 mm).

The slide rails supplied by Cisco Systems for the chassis do not require tools for installation if you install

them in a rack that has square 0.38-in. (9.6 mm), round 0.28-in. (7.1 mm), or #12-24 UNC threaded holes.

Before you begin

Take note of the following warning:

Warning

Statement 1006—Chassis Warning for Rack-Mounting and Servicing

To prevent bodily injury when mounting or servicing this unit in a rack, you must take special precautions to

ensure that the system remains stable. The following guidelines are provided to ensure your safety:

• This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

• When mounting this unit in a partially filled rack, load the rack from the bottom to the top with the

heaviest component at the bottom of the rack.

• If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing the

unit in the rack.

Step 1 Attach the inner rails to the sides of the chassis:

a) Align an inner rail with one side of the chassis so that the three keyed slots in the rail align with the three pegs on the

side of the chassis.

b) Set the keyed slots over the pegs, and then slide the rail toward the front to lock it in place on the pegs. The front slot

has a metal clip that locks over the front peg.

c) Install the second inner rail to the opposite side of the chassis.

Figure 30: Attach the Inner Rail to Side of Chassis

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

30

Page 35

Mount and Connect

Rack-Mount the Chassis

Locking clip on inner rail2Front of chassis1

Step 2 Open the front securing plate on both slide-rail assemblies. The front end of the slide-rail assembly has a spring-loaded

securing plate that must be open before you can insert the mounting pegs into the rack-post holes.

On the outside of the assembly, push the green arrow button toward the rear to open the securing plate.

Figure 31: Front Securing Mechanism, Inside of Front End

3

Securing plate shown pulled back to open

position

Step 3 Install the slide rails into the rack:

a) Align one slide-rail assembly front end with the front rack-post holes that you want to use.

The slide rail front end wraps around the outside of the rack post and the mounting pegs enter the rack-post holes

from the outside-front.

Note

The rack post must be between the mounting pegs and the open securing plate.

b) Push the mounting pegs into the rack-post holes from the outside-front.

c) Press the securing plate release button, marked “PUSH.” The spring-loaded securing plate closes to lock the pegs in

place.

d) Attach the second slide-rail assembly to the opposite side of the rack. Make sure that the two slide-rail assemblies

are at the same height with each other and are level front-to-back.

e) Pull the inner slide rails on each assembly out toward the rack front until they hit the internal stops and lock in place.

Step 4 Insert the chassis into the slide rails:

a) Align the rear of the inner rails that are attached to the chassis sides with the front ends of the empty slide rails on

the rack.

b) Push the inner rails into the slide rails on the rack until they stop at the internal stops.

c) Slide the release clip toward the rear on both inner rails, and then continue pushing the chassis into the rack until its

front slam latches engage with the rack posts

Rack post2Front mounting pegs1

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

31

Page 36

Connect Cables, Turn on Power, and Verify Connectivity

Figure 32: Inner Rail Release Clip

Mount and Connect

2Inner rail release clip1

Inner rail attached to the chassis and inserted

into outer rail

3

Outer rail attached to rack post4Button to unlock rail

Press this button to unlock the rail so you can

pull out the chassis from the rack when

uninstalling or performing maintenance.

Step 5 (Optional) Secure the chassis in the rack more permanently by using the two screws that are provided with the slide rails.

Perform this step if you plan to move the rack with chassis installed. With the chassis fully pushed into the slide rails,

open a hinged slam latch lever on the front of the chassis and insert the screw through the hole that is under the lever.

The screw threads into the static part of the rail on the rack post and prevents the chassis from being pulled out. Repeat

for the opposite slam latch.

What to do next

Continue with Connect Cables, Turn on Power, and Verify Connectivity, on page 32.

Connect Cables, Turn on Power, and Verify Connectivity

This procedure references the rear panel ports of the FMC 2600 and 4600. The FMC 1600 is the same except

that it does not have the two 10-G SFP+ ports above the Ethernet ports.

After rack mounting the chassis, follow these steps to connect cables, turn on power, and verify connectivity.

Note

AC power supplies have internal grounding and so no additional chassis grounding is required when the

supported AC power cords are used. For more information about supported power cords, see Power Cord

Specifications, on page 14.

Note

Although the CIMC is not supported on the FMC, you can use LOM on the default management interface

(eth0) on a SOL connection to remotely monitor or manage the FMC system. For information about using

LOM and SOL, see the Cisco Firepower Management Center Getting Started Guide for Models 1600, 2600,

and 4600 for your model.

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

32

Page 37

Mount and Connect

Connect Cables, Turn on Power, and Verify Connectivity

Before you begin

Take note of the following warnings.

Warning

Statement 1009—Laser Radiation

Laser radiation is present when the system is open.

Warning

Statement 1014—Laser Radiation

Laser radiation is present when the system is open and interlocks bypassed.

Warning

Statement 1051—Laser Radiation

Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or

view directly with optical instruments.

Warning

Statement 1053—Class 1M Laser Radiation

Class 1M laser radiation when open. Do not view directly with optical instruments.

Step 1 (Optional) VGA port and USB port—Connect a monitor to the VGA port and a keyboard to the USB port to complete

initial setup at the CLI. You can alternatively complete initial setup using HTTPS on eth0 (see Step 2).

Note

Figure 33: Cable Connections

The serial console port is not enabled for initial setup.

1

10 Gigabit Ethernet SFP+ support

Use only Cisco supported SFP+s

transceivers.

2eth2 management interface

eth3 management interface

10 Gigabit Ethernet SFP+ support

Use only Cisco supported SFP+s

transceivers.

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

33

Page 38

Connect Cables, Turn on Power, and Verify Connectivity

Mount and Connect

3

4Two USB 3.0 Type A ports

You can connect a keyboard, and along

with a monitor on the VGA port, you can

access the console.

5

6eth1 management interface (named 2)

Gigabit Ethernet 100/1000/10000 Mbps

interface, RJ-45

7

Serial console port

eth0 management interface (named 1)

Gigabit Ethernet 100/1000/10000 Mbps

interface, RJ-45

eth0 is the default management interface.

VGA video port (DB-15 connector)

This port is disabled by default; use the

VGA port and keyboard USB port instead.

Use the console cable (RJ-45 to DB-9) to

connect a computer to the FMC.

Step 2 eth0 management interface (named 1)—Use this interface to perform initial setup using HTTPS, to perform routine

management, and to manage devices from the FMC chassis. Using an Ethernet cable, connect the eth0 interface to your

default management network reachable from your management PC. This interface is the default management interface

and is enabled by default.

Note

You must perform initial setup to change the eth0 IP address to match your network. You can use the

VGA/keyboard CLI for initial setup to set the eth0 IP address, or you can connect your computer directly to

eth0, change the address using the HTTPS initial setup, and then connect eth0 to your network.

Step 3 (Optional) eth1 management interface (named 6)—Connect this management interface to the same or different network

from your other management interfaces depending on your network needs. For information about management interfaces

and network topology, see the Firepower Management Center Configuration Guide for your version.

Step 4 eth2 and eth3 management interfaces—If your model includes 10-Gigabit Ethernet SFP+ interfaces, install any

Cisco-supported SFP+ transceivers and cables as needed. You can connect these interfaces to the same or different network

from your other management interfaces depending on your network needs. For more information about management

interfaces and network topology, see the Firepower Management Center Configuration Guide for your version.

Each Cisco-certified SFP+ transceiver (SFP-10G-SR) has an internal serial EEPROM that is encoded with security

information. This encoding allows us to identify and validate that the SFP transceiver meets the requirements for the

FMC chassis.

Note

Only Cisco certified SFP+ transceivers are compatible with the 10-G interfaces. Cisco TAC may refuse support

for any interoperability problems that result from using an untested third-party SFP transceiver.

Step 5 Power—Use one of the supported power cords to connect the power supplies of the chassis to your power source. For

more information about supported power cords, see Power Cord Specifications, on page 14.

Step 6 Verify—Press the Power button on the front of the chassis, and verify that the power status LED is on.

Step 7 Setup and configuration—See the Cisco Firepower Management Center Getting Started Guide for Models 1600, 2600,

and 4600 to continue setup and configuration.

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

34

Page 39

Maintenance and Upgrade

• Power Button Shutdown, on page 35

• Remove and Replace a Drive, on page 36

• Remove and Replace a Power Supply, on page 38

Power Button Shutdown

The FMC runs in two modes:

• Main power mode—Power is supplied to all FMC components and all operating systems can run.

• Standby power mode—Power is supplied only to the service processor and certain components. You can

safely remove power cords from the FMC in this mode.

CHAPTER 4

Caution

Step 1 Check the Power LED:

• Amber—The FMC is already in standby mode and you can safely remove power.

• Green—The FMC is in main power mode and you must shut it down before you can safely remove power.

Step 2 Perform a graceful shutdown or a hard shutdown:

Caution

• Graceful shutdown—Press and release the Power button. The operating system performs a graceful shutdown and

After you shut down the FMC to standby power, electric current is still present in the chassis. To completely

remove power as directed in some maintenance procedures, you must disconnect all power cords from all

power supplies on the FMC.

You can shut down the FMC using the front panel Power button or software management. See the system

shutdown procedure in the Firepower Management Center Configuration Guide for your version for the

software procedures.

To avoid data loss or damage to your operating system, perform a graceful shutdown of the operating system.

the FMC goes into standby mode. The power LED is amber.

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

35

Page 40

Remove and Replace a Drive

• Emergency shutdown—Press and hold the Power button for four seconds to force the main power off and immediately

enter standby mode.

Remove and Replace a Drive

Note

The drives are hot-swappable. You do not have to shut down the FMC to remove or replace drives.

Note

You cannot add more drives to your FMC. You can only replace the drives in the slots that are supported for

your model.

Maintenance and Upgrade

Warning

Warning

Warning

Warning

Before you begin

Statement 1018—Supply Circuit

To reduce risk of electric shock and fire, take care when connecting units to the supply circuit so that wiring

is not overloaded.

Statement 1019—Main Disconnecting Device

The plug-socket combination must be accessible at all times, because it serves as the main disconnecting

device.

Statement 1024—Ground Conductor

This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the absence

of a suitably installed ground conductor. Contact the appropriate electrical inspection authority or an electrician

if you are uncertain that suitable grounding is available.

Statement 1030—Equipment Installation

36

Only trained and qualified personnel should be allowed to install, replace, or service this equipment.

Warning

Statement 1073—No User-Serviceable Parts

No serviceable parts inside. To avoid risk of electric shock, do not open.

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

Page 41

Maintenance and Upgrade

Remove and Replace a Drive

Warning

Statement 1074—Comply with Local and National Electrical Codes

To reduce risk of electric shock or fire, installation of the equipment must comply with local and national

electrical codes.

Step 1 Remove the drive that you are replacing:

a) Press the release button on the face of the drive tray.

b) Grasp and open the ejector lever and then pull the drive tray out of the slot.

Figure 34: Remove the Drive

Release button2Ejector handle1

Step 2 Remove the four drive-tray screws that secure the drive to the tray and then lift the drive out of the tray.

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

37

Page 42

Remove and Replace a Power Supply

Figure 35: Remove the Drive Tray

Maintenance and Upgrade

Step 3 Install a new drive:

a) Place a new drive in the empty drive tray and install the four drive-tray screws.

b) With the ejector lever on the drive tray open, insert the drive tray into the empty drive bay.

c) Push the tray into the slot until it touches the backplane, and then close the ejector lever to lock the drive in place.

Remove and Replace a Power Supply

The FMC ships with two power supplies, which are redundant and hot-swappable. One is the active power

supply and the other is the standby power supply (1+1).

This FMC also supports cold redundancy. Depending on the power being drawn by the FMC, one power

supply might actively provide all power to the system while the remaining power supply is put into a standby

state. For example, if the power consumption can be satisfied by power supply 1, then power supply 2 is put

into a standby state.

Caution

When you replace power supplies, do not mix power supply types in the FMC. Both power supplies must be

the same wattage and Cisco PID.

Drive removed from drive tray2Drive tray screws ( two on each side)1

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

38

Page 43

Maintenance and Upgrade

Remove and Replace a Power Supply

Trouble

Warning

Warning

Warning

Power supply health monitoring notifies you if the power supply loses power or malfunctions so that redundancy

is lost. Check the power supply cables to make sure they are functioning. If they are and errors are still

occurring, replace the power supply.

Before you begin

Take note of the following warnings:

Statement 1018—Supply Circuit

To reduce risk of electric shock and fire, take care when connecting units to the supply circuit so that wiring

is not overloaded.

Statement 1019—Main Disconnecting Device

The plug-socket combination must be accessible at all times, because it serves as the main disconnecting

device.

Statement 1024—Ground Conductor

This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the absence

of a suitably installed ground conductor. Contact the appropriate electrical inspection authority or an electrician

if you are uncertain that suitable grounding is available.

Warning

Statement 1030—Equipment Installation

Only trained and qualified personnel should be allowed to install, replace, or service this equipment.

Warning

Statement 1073—No User-Serviceable Parts

No serviceable parts inside. To avoid risk of electric shock, do not open.

Warning

Statement 1074—Comply with Local and National Electrical Codes

To reduce risk of electric shock or fire, installation of the equipment must comply with local and national

electrical codes.

Step 1 Remove the power supply:

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

39

Page 44

Remove and Replace a Power Supply

a) Grasp the power supply handle while pinching the release lever toward the handle.

b) Pull the power supply out of the bay.

Figure 36: Remove and Replace the AC Power Supply

Maintenance and Upgrade

Step 2 Install a new power supply:

a) Grasp the power supply handle and insert the new power supply into the empty bay.

b) Push the power supply into the bay until the release lever locks.

c) Connect the power cord to the new power supply.

d) If you shut down the FMC, press the Power button to return it to main power mode.

Handle2Release lever1

Cisco Firepower Management Center 1600, 2600, and 4600 Hardware Installation Guide

40

Loading...

Loading...